Bio-filler for absorbing and degrading hydrophobic organic waste gases, and preparation method of bio-filler

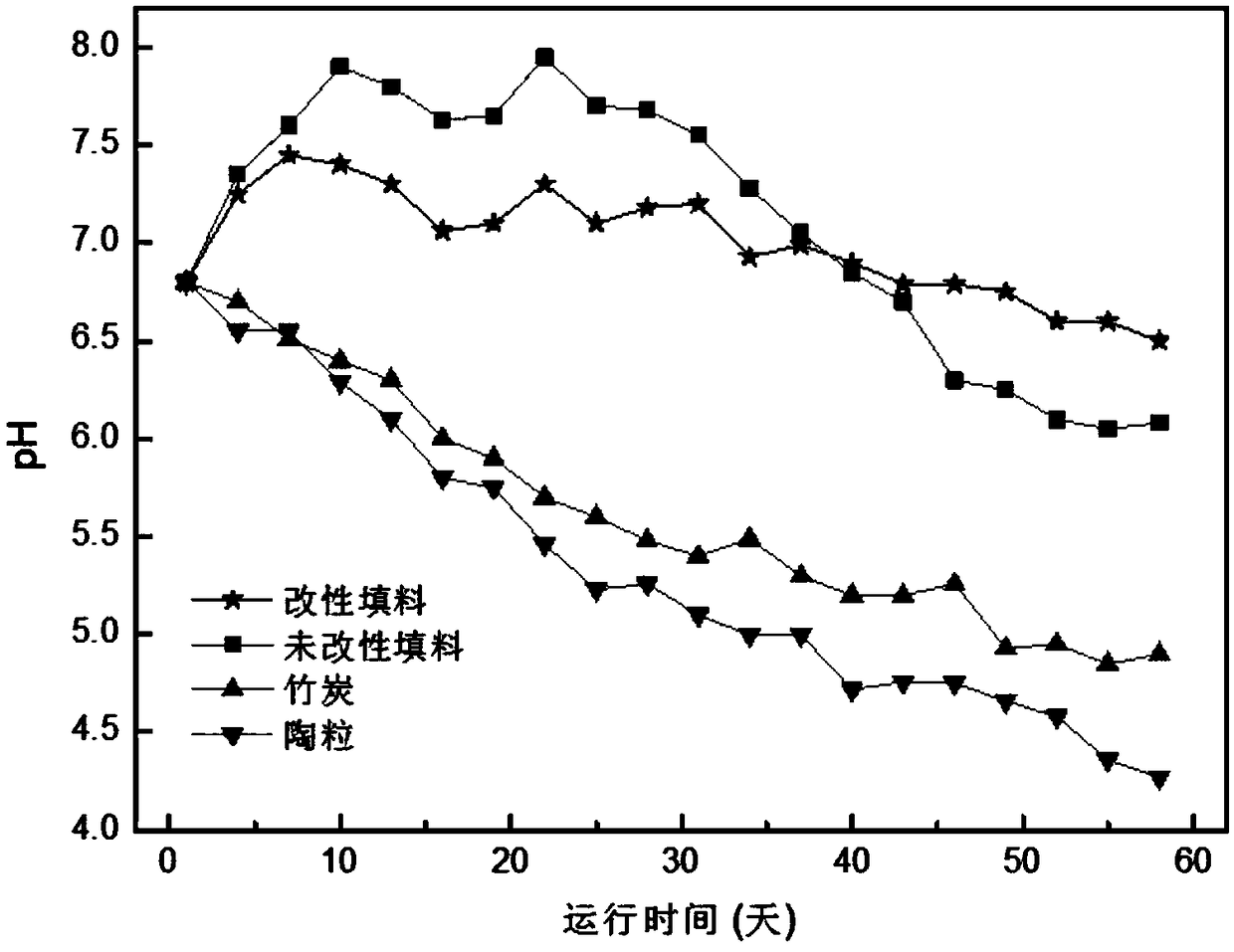

A technology of organic waste gas and biological fillers, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of reducing treatment efficiency, dry shrinkage, and no VOCs, so as to promote oxidation-reduction reactions, improve adhesion and Humidity, promotes the effect of absorbing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

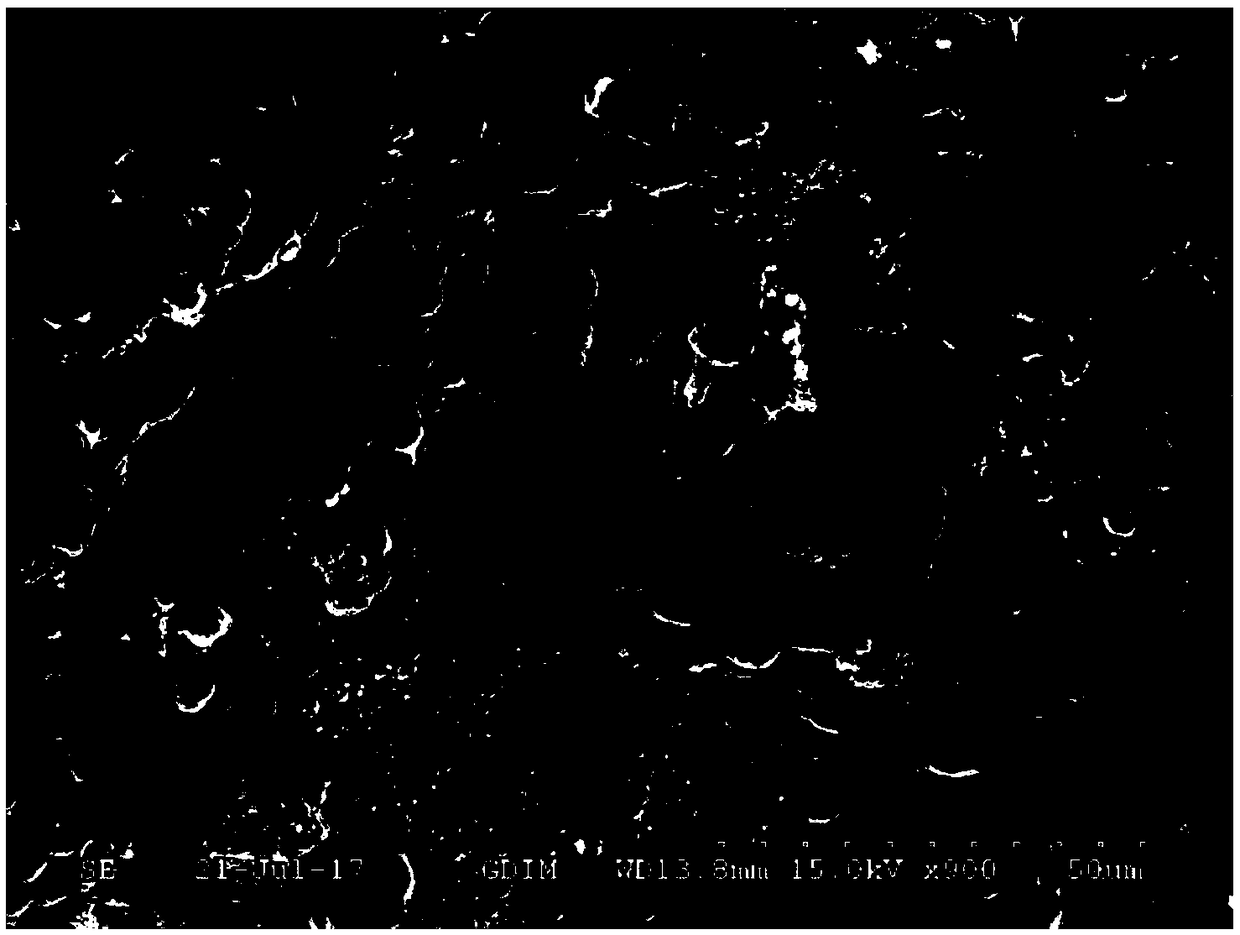

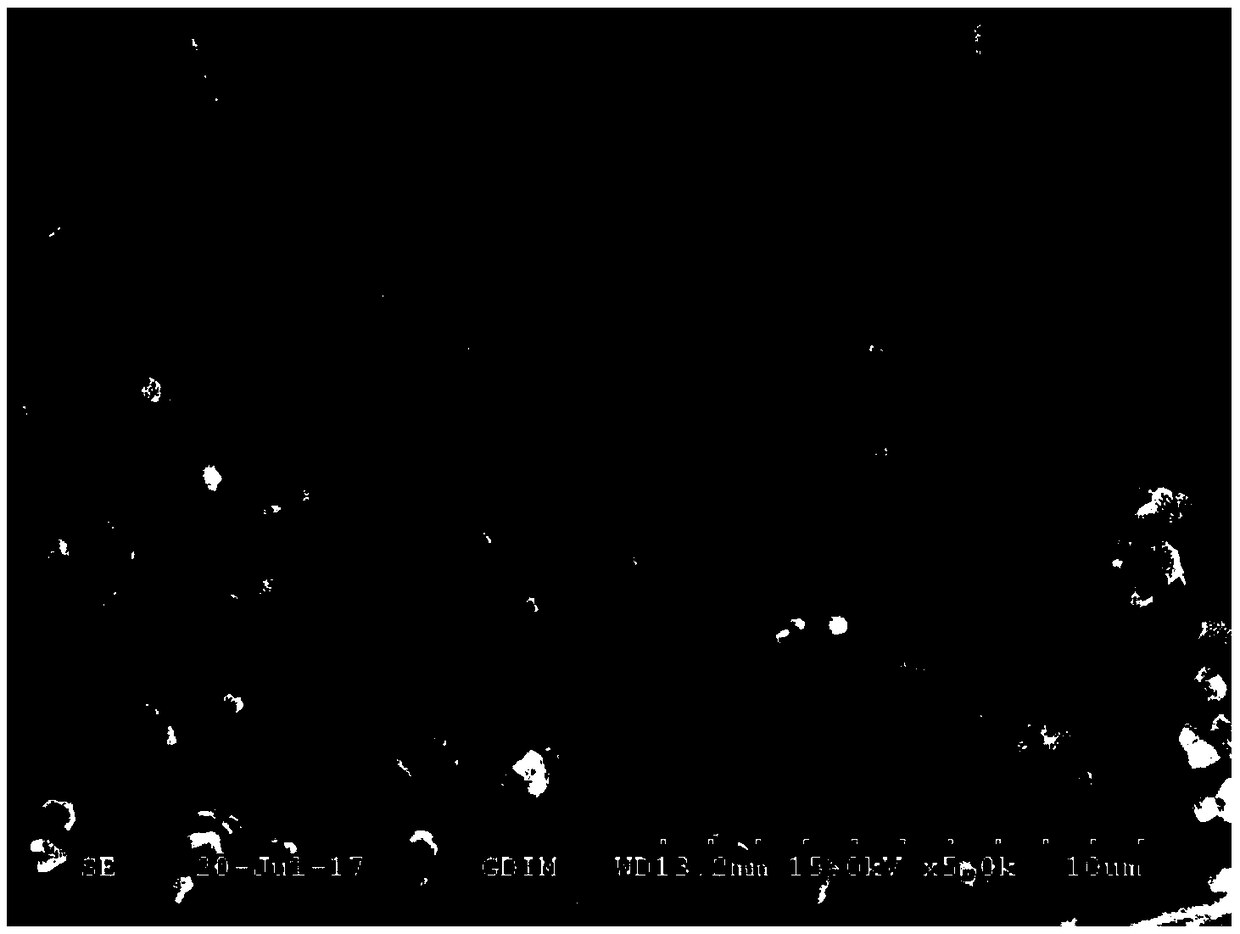

[0034] 1. Preparation of biofiller for adsorption and degradation of hydrophobic organic waste gas

[0035] The biological filler for adsorbing and degrading hydrophobic organic waste gas includes the following raw materials in percentage by weight: 5% of modified iron-based β-cyclodextrin, 5% of diatomaceous earth, 15% of biochar (powder), 35% of ceramsite, oxidation Calcium 5%, silicate inorganic gel (P.Ⅱ42.5R Portland cement) 20% and water 15%.

[0036] Preparation:

[0037] (1) Add the modified iron-based β-cyclodextrin into water, stir until completely dissolved, then add calcium oxide, and continue stirring until completely dissolved to obtain Sol A;

[0038] (2) Mix diatomite, biochar and silicate inorganic gel evenly to obtain powder B;

[0039](3) Soak the ceramsite in sol A for 5 minutes and place it in the granulator, keep rotating at a constant speed, control the speed at 25r / min, and control the angle of the turntable at 45°; then divide the powder B into 8 time...

Embodiment 2

[0049] 1. Preparation of biofiller for adsorption and degradation of hydrophobic organic waste gas

[0050] The biological filler for adsorbing and degrading hydrophobic organic waste gas includes the following raw materials in percentage by weight: 10% of modified iron-based β-cyclodextrin, 5% of diatomaceous earth, 20% of biochar (powder), 25% of ceramsite, oxidation Calcium 5%, silicate inorganic gel (P.Ⅱ42.5R Portland cement) 20% and water 15%.

[0051] Preparation:

[0052] (1) Add the modified iron-based β-cyclodextrin into water, stir until completely dissolved, then add calcium oxide, and continue stirring until completely dissolved to obtain Sol A;

[0053] (2) Mix diatomite, biochar and silicate inorganic gel evenly to obtain powder B;

[0054] (3) Soak the ceramsite in sol A for 5 minutes and place it in the granulator, keep rotating at a constant speed, the speed is controlled at 20r / min, and the angle of the turntable is controlled at 45°; then the powder B is d...

Embodiment 3

[0060] 1. Preparation of biofiller for adsorption and degradation of hydrophobic organic waste gas

[0061] The biological filler for adsorbing and degrading hydrophobic organic waste gas includes the following raw materials in percentage by weight: 17% of modified iron-based β-cyclodextrin, 5% of diatomaceous earth, 15% of biochar (powder), 20% of ceramsite, oxidation Calcium 3%, silicate inorganic gel (P.Ⅱ42.5R Portland cement) 20% and water 20%.

[0062] Preparation:

[0063] (1) Add the modified iron-based β-cyclodextrin into water, stir until completely dissolved, then add calcium oxide, and continue stirring until completely dissolved to obtain Sol A;

[0064] (2) Mix diatomite, biochar and silicate inorganic gel evenly to obtain powder B;

[0065] (3) Soak the ceramsite in sol A for 5 minutes and place it in the granulator, keep rotating at a constant speed, the speed is controlled at 20r / min, and the angle of the turntable is controlled at 45°; then the powder B is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com