Maintenance for foam in inner-layer well wall concrete of freezing shaft

A technology of concrete foam and freezing well, which is applied to shaft equipment, wellbore lining, earth-moving drilling, etc., can solve the problems of continuous supply of warm water, large consumption of spray water, and difficulty of water temperature control, and can reduce maintenance water and avoid temperature. Cracks, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

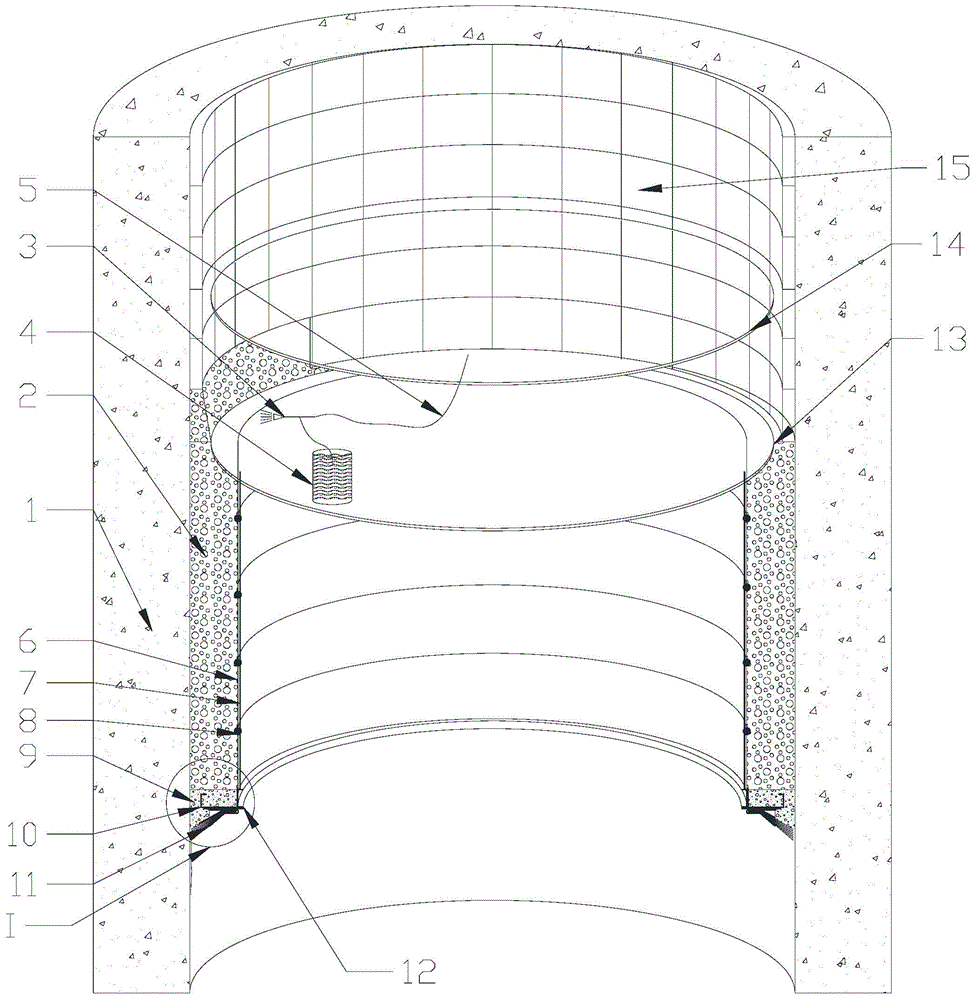

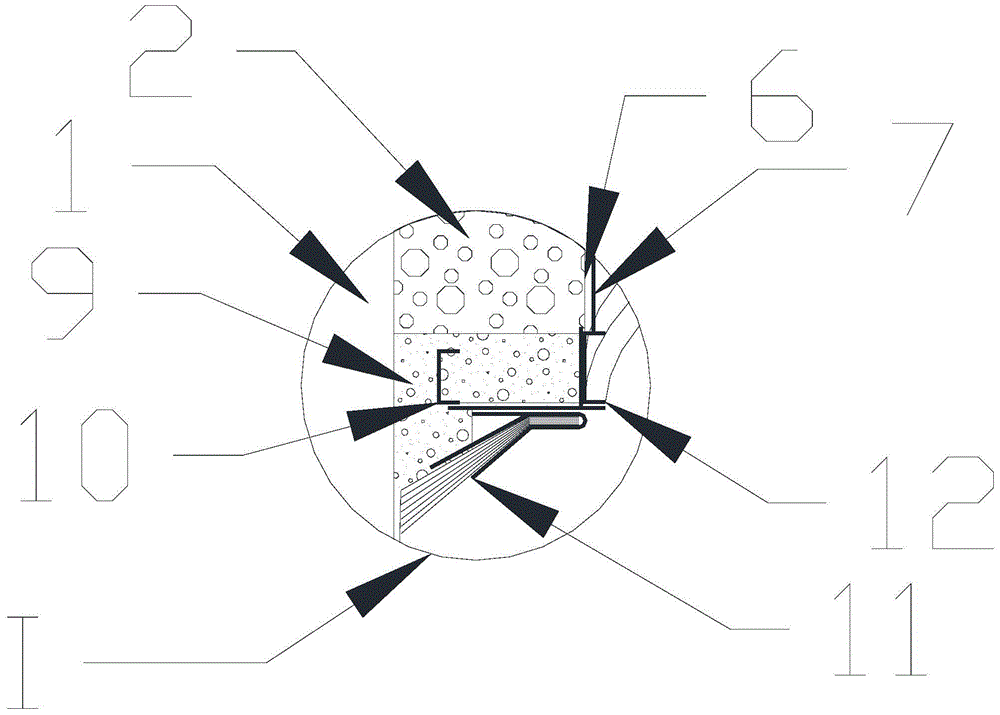

[0025] Such as figure 1 and figure 2 As shown, in the present invention, the concrete foam curing device for freezing the inner layer of the wellbore includes a liquid foam layer 2, a foam curing cylinder, a foam stock solution storage container 4, a foam generator 3 and a warm water pipe 5, and the foam curing cylinder includes a cylinder wall and a bottom 12, the bottom 12 is arranged on the outside of the wall and fixedly connected with the wall; the liquid foam layer 2 is arranged between the concrete inner well wall 1 and the wall, The foam curing cylinder is arranged on the inner side of the concrete inner layer well wall 1, and is hung on the bottom of the demoulding tray 13; the liquid inlet of the foam generator 3 is connected with the liquid outlet of the foam stock s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com