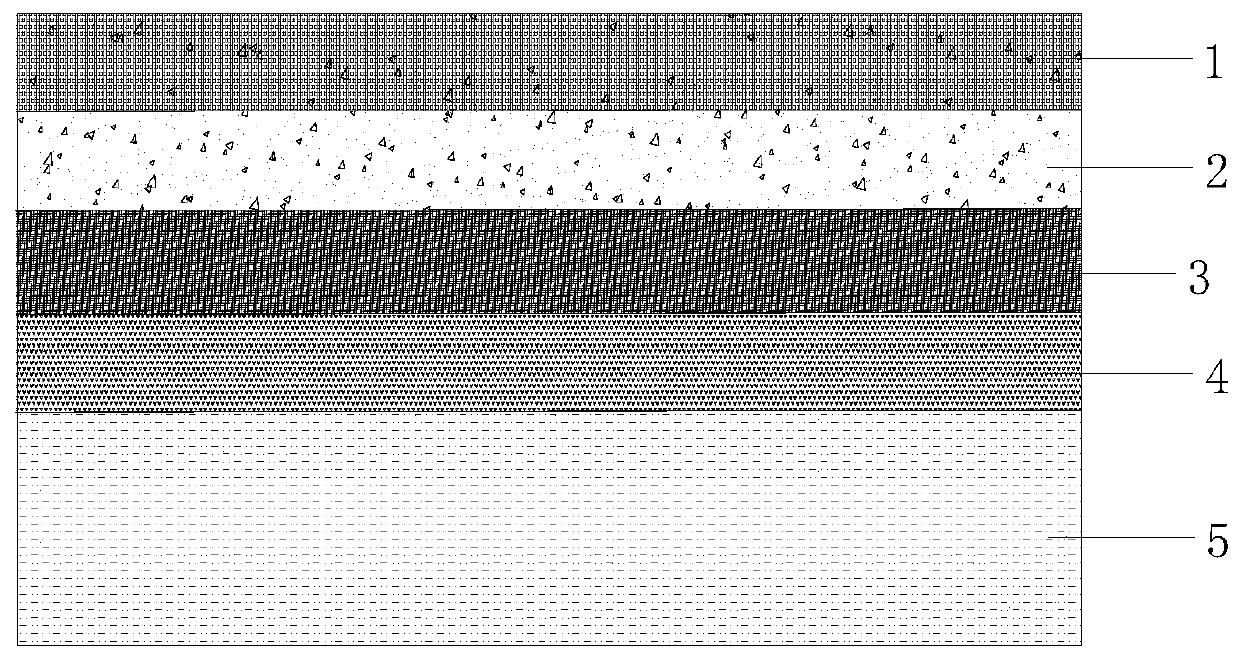

Steel slag semi-flexible composite pavement structure

A composite pavement, semi-flexible technology, applied in the direction of on-site coagulation pavement, roads, roads, etc., can solve the problems of fatigue cracking of semi-flexible pavement, so as to reduce fatigue cracking, prolong anti-fatigue life, and prolong long-term effectiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

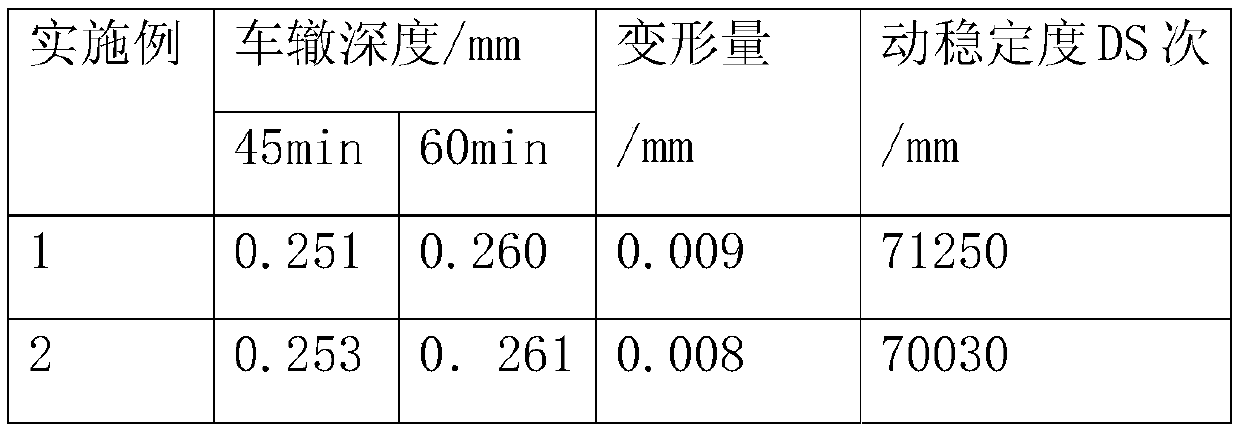

Embodiment 1

[0022] The steel slag semi-flexible composite pavement structure of this embodiment, raw materials include the following components by weight: 80 parts of asphalt, 300 parts of steel slag, 110 parts of ordinary portland cement, 100 parts of fly ash, hydroxyethyl methyl cellulose ether 5 parts, 20 parts of rubber particles, 3 parts of octene polymer, 3 parts of maleic anhydride, 2 parts of allyl ether, 1 part of hydroxyethyl acrylate, 2 parts of styrene-butadiene-styrene block copolymer , 1 part of plasticizer, 1 part of polyester fiber;

[0023] In this embodiment, the steel slag is a mixture of coarse steel slag with a particle size of 10 mm and fine steel slag with a particle size of 5 mm, and the steel slag has been passivated; the weight ratio of the coarse steel slag to the fine steel slag is 3:1

[0024] In this embodiment, the rubber particles are a mixture of coarse rubber particles with a particle diameter of 0.5 mm and fine rubber particles with a particle diameter o...

Embodiment 2

[0026] The steel slag semi-flexible composite pavement structure of this embodiment, raw materials include the following components by weight: 120 parts of asphalt, 480 parts of steel slag, 130 parts of ordinary Portland cement, 160 parts of fly ash, hydroxyethyl methyl cellulose ether 10 parts, 30 parts of rubber particles, 8 parts of octene polymer, 8 parts of maleic anhydride, 6 parts of allyl ether, 3 parts of hydroxyethyl acrylate, 4 parts of styrene-butadiene-styrene block copolymer , 3 parts of plasticizer, 3 parts of polyester fiber;

[0027] In this embodiment, the steel slag is a mixture of coarse steel slag with a particle size of 20mm and fine steel slag with a particle size of 10mm, and the steel slag has been passivated; the weight ratio of the coarse steel slag to the fine steel slag is 3:1

[0028]In this embodiment, the rubber particles are a mixture of coarse rubber particles with a diameter of 1 mm and fine rubber particles with a particle diameter of 0.2 mm...

Embodiment 3

[0030] The steel slag semi-flexible composite pavement structure of this embodiment, raw materials include the following components by weight: 80 parts of asphalt, 500 parts of steel slag, 110 parts of ordinary Portland cement, 160 parts of fly ash, hydroxyethyl methyl cellulose ether 5 parts, 30 parts of rubber particles, 3 parts of octene polymer, 8 parts of maleic anhydride, 2 parts of allyl ether, 3 parts of hydroxyethyl acrylate, 2 parts of styrene-butadiene-styrene block copolymer , 3 parts of plasticizer, 1 part of polyester fiber;

[0031] In this embodiment, the steel slag is a mixture of coarse steel slag with a particle size of 10mm and fine steel slag with a particle size of 10mm, and the steel slag has been passivated; the weight ratio of the coarse steel slag to the fine steel slag is 3:1

[0032] In this embodiment, the rubber particles are a mixture of coarse rubber particles with a diameter of 0.5 mm and fine rubber particles with a particle diameter of 0.2 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com