Artificial short-seam structure of rolled concrete arch dam

A roller compacted concrete, artificial technology, applied in the direction of arch dams, dams, etc., can solve the problems of penetrating cracks, damage to the integrity of arch dams, etc., and achieve the effect of speeding up the pouring progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

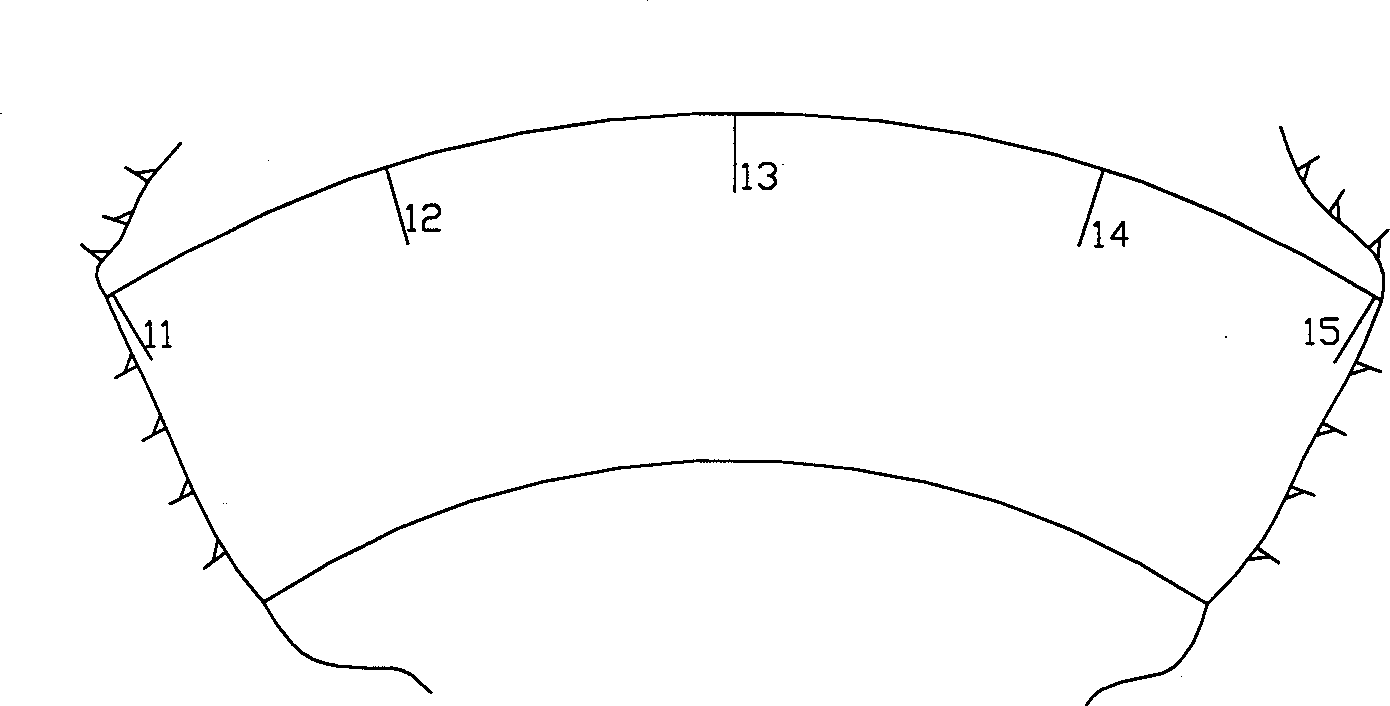

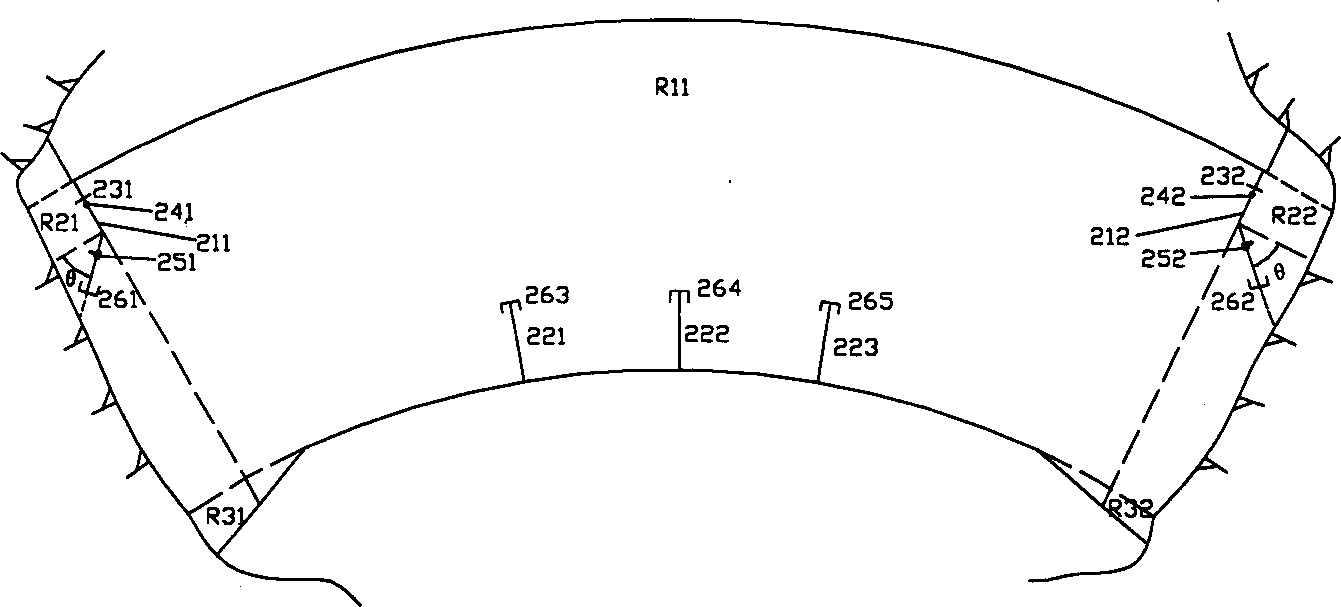

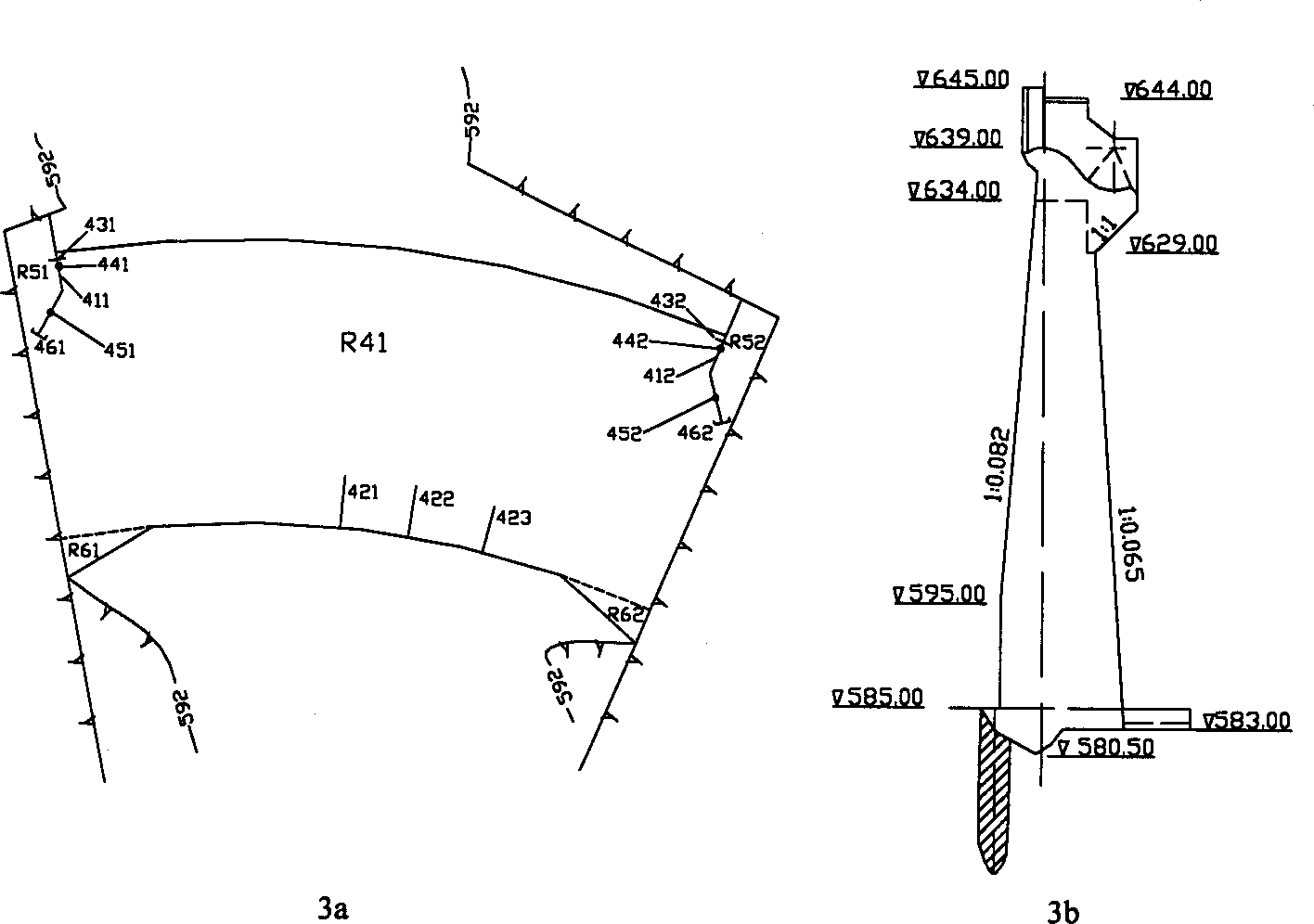

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0022] The artificial short joint structure of the roller compacted concrete arch dam proposed by the present invention is as follows: figure 2 As shown in the figure, artificial creases 211 and 212 are set at the left and right abutments of the arch dam, with a radial length of 1.0 m to 1.5 m, generally not exceeding 1 / 4 of the dam thickness, so as not to increase the shear stress of the abutment. The crease angle θ is about 30-60°, and the crease length is similar to the radial direction. Set water stops 231 and 232 on the upstream surface of the artificial crease, set drain pipes 241 and 242 in the seam, and arrange grouting pipes and grouting boxes 251 and 252 at the edge of the seam, so that grouting can be performed after the concrete on the upstream dam surface cools down. connected into a whole. Crack stop materials 261 and 262 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com