Mass concrete cooling water circulation and construction method

A technology of mass concrete and cooling water circulation, applied in water supply installations, water supply installations, infrastructure engineering, etc., can solve problems such as cracks, achieve low cost, ecological protection, solve the difficulty of water intake, and prevent concrete temperature cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

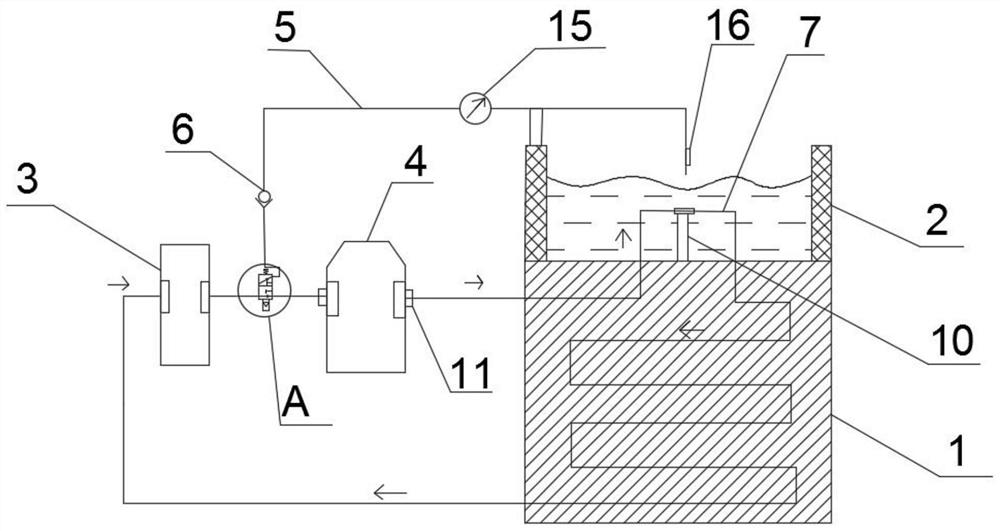

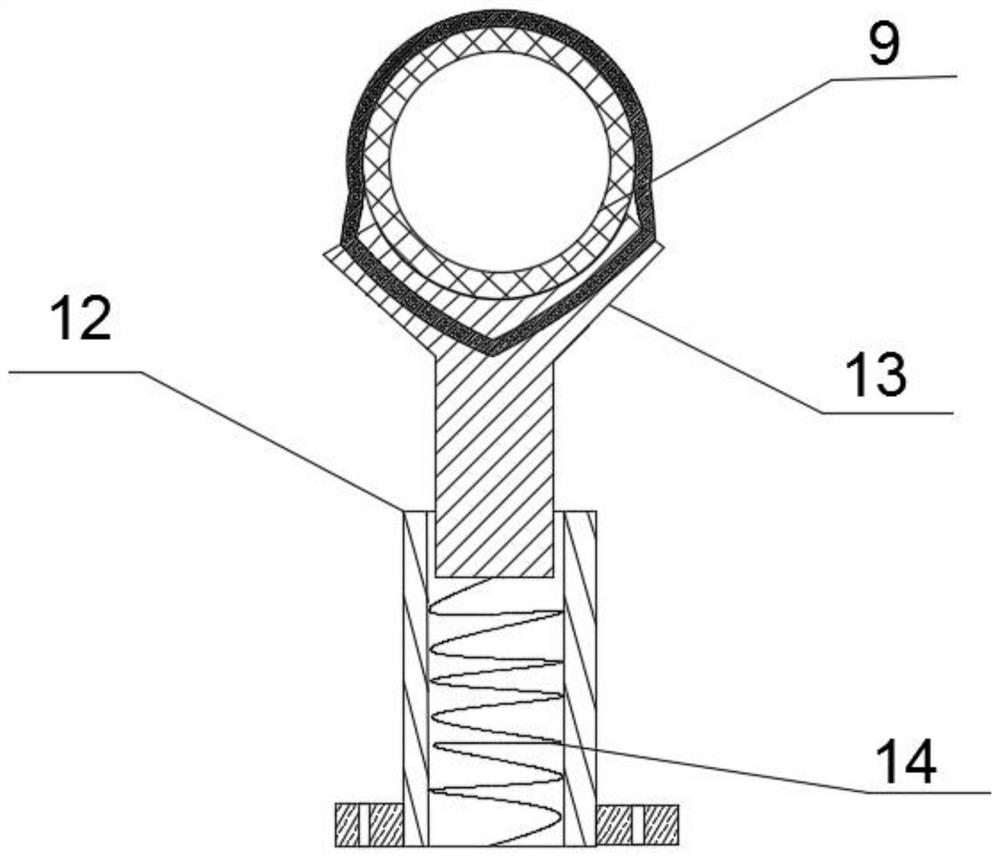

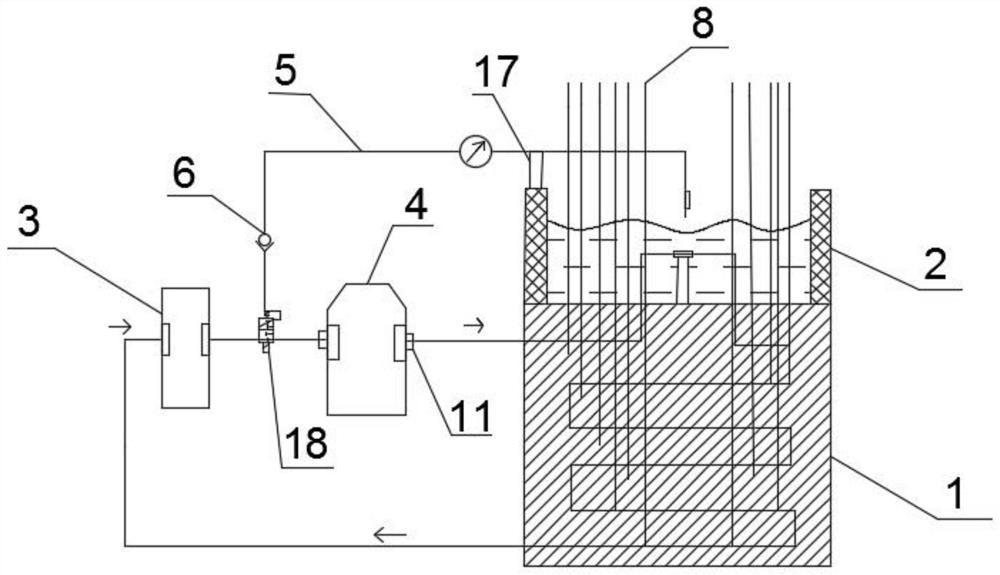

[0053] Such as Figure 1 to Figure 4 Shown: a large-volume concrete cooling water circulation, including the pouring pit 1 and power supply after pouring concrete, and also includes a water circulation module and a water storage module. The water circulation module includes a delivery pipeline, a water storage tank 3 and a cooling tower 4. In the pit 1, a water partition wall 2 is arranged on the upper surface of the pouring pit 1, and the water partition wall 2 is suitable for water storage and curing of concrete;

[0054] The water storage tank 3 is provided with an output end and an input end. The output end transports water into the cooling tower 4. The cooling tower 4 cools the water at the output end of the water storage tank 3, and outputs the cooling water into the delivery pipeline of the pouring pit 1. The water storage tank 3 The input end of the input port transports the water after pouring the concrete inside the pit 1 back to the water storage tank 3;

[0055] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com