A kind of heating method of cold-packed electrical steel

A heating method and technology of electrical steel, applied in the field of metallurgy, can solve problems such as failure to work for 24 hours, equipment damage, delay time, etc., and achieve the effects of improving production pass rate, reducing waste judgment, and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In Xichang Steel Vanadium Hot Rolling Plant, an engineering test was carried out according to the composition design and process design of the invention, and the production grade was 50PRW1300 non-oriented electrical steel. The composition is as shown in Table 1:

[0039] Table 1 Chemical composition of 50PRW1300 non-oriented electrical steel (wt%)

[0040] Production grade

C

Si

mn

als

50PRW1300

0.0030

0.20

0.22

0.18

[0041] 1. Incoming steelmaking materials are stacked and slowly cooled. The specific method is: put 2 to 3 hot billets at the bottom, 2 to 3 hot billets at the top, and stack hot billets on both sides (the higher the temperature, the better).

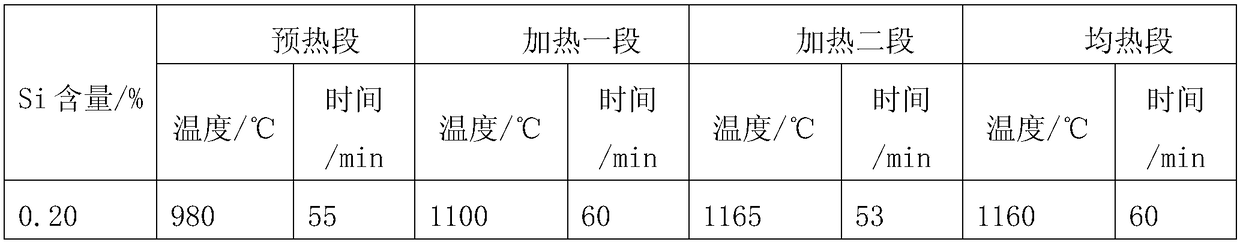

[0042] 2. The heating process carried out according to the silicon content is shown in Table 2:

[0043] Table 2 Heating process of 50PRW1300 non-oriented electrical steel

[0044]

[0045] 3. In order to ensure the time of each section in the furnace and ensure ...

Embodiment 2

[0049] In Xichang Steel Vanadium Hot Rolling Plant, an engineering test was carried out according to the composition design and process design of the invention, and the production grade was 50PRW800 non-oriented electrical steel. The composition is as shown in Table 3:

[0050] Table 3 Chemical composition of 50PRW800 non-oriented electrical steel (wt%)

[0051] Production grade

C

Si

mn

als

50PRW800

0.0035

0.98

0.27

0.28

[0052] 1. Incoming steelmaking materials are stacked and slowly cooled. The specific method is: put 2 to 3 hot billets at the bottom, 2 to 3 hot billets at the top, and stack hot billets on both sides (the higher the temperature, the better).

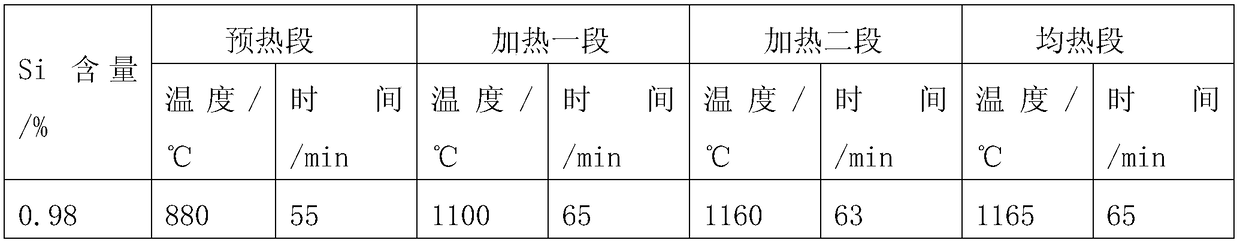

[0053] 2. The heating process carried out according to the silicon content is shown in Table 4:

[0054] Table 4 Heating process of 50PRW800 non-oriented electrical steel

[0055]

[0056] 3. In order to ensure the time of each section in the furnace and to ensure s...

Embodiment 3

[0060] In Xichang Steel Vanadium Hot Rolling Plant, engineering tests were carried out according to the composition design and process design of the invention, and the production grade was 50PRW600 non-oriented electrical steel. The composition is as shown in Table 3:

[0061] Table 5 Chemical composition of 50PRW600 non-oriented electrical steel (wt%)

[0062] Production grade

C

Si

mn

als

50PRW600

0.0020

1.51

0.27

0.23

[0063] 1. The incoming steelmaking materials are stacked and slowly cooled. The specific method is: put 2 to 3 hot billets at the bottom, 2 to 3 hot billets at the top, and stack hot billets on both sides (the higher the temperature, the better);

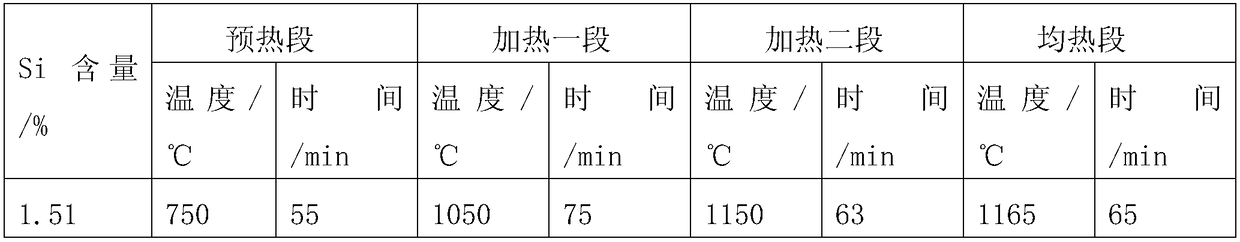

[0064] 2. The heating process carried out according to the silicon content is shown in Table 6:

[0065] Table 6 Heating process of 50PRW600 non-oriented electrical steel

[0066]

[0067] 3. In order to ensure the time of each section in the furnace and to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com