Warm mix recycled asphalt mixture with high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and preparation method of warm mix recycled asphalt mixture

A technology of asphalt mixture and recycled asphalt, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of lower mixing temperature and energy consumption, high mixing temperature, and high energy consumption, and achieve Reduce the heating temperature and construction temperature, reduce aging and energy consumption, and the effect of good construction workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

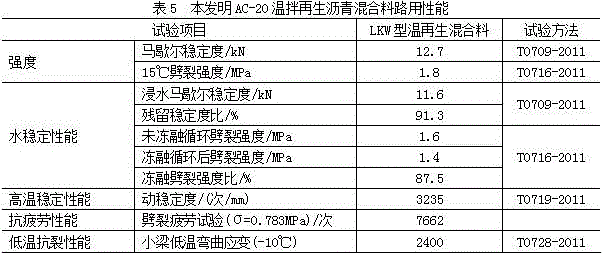

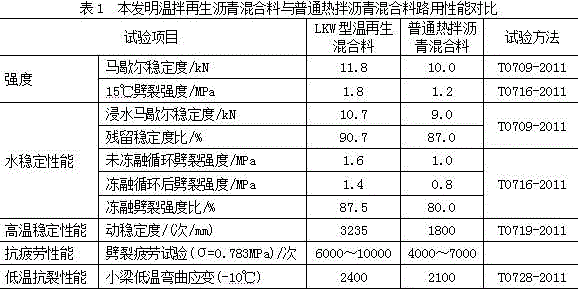

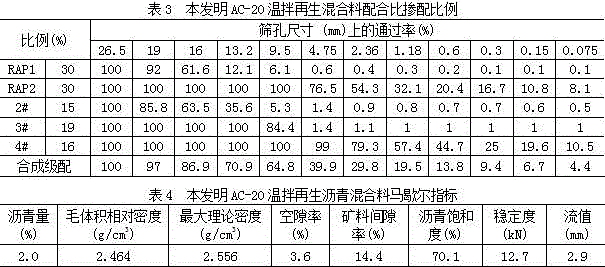

[0034] Example 1: The high-performance warm-mix recycled asphalt mixture with high RAP content of the present invention is used in the construction of the lower layer of AC-20, replacing the lower layer of conventional AC-20 hot-mix asphalt concrete, while ensuring the road performance of the concrete, it can achieve sufficient Utilize the recycling of asphalt pavement materials, reduce the amount of new aggregates, reduce the mixing temperature, and achieve the effects of energy saving and emission reduction.

[0035] This high RAP content high-performance warm mix recycled asphalt mixture includes the following mass percentage components: recycled asphalt pavement material (RAP material) recycled asphalt pavement material 60%, aggregate 38%, fresh asphalt and warm mix regenerated agent 2.0% , in which the content of warm mix rejuvenator is 0.3% of the mass of newly mixed asphalt.

[0036] The preparation method of the high RAP content high-performance warm-mix recycled aspha...

Embodiment 2

[0058] Example 2: The high-performance warm-mix recycled asphalt mixture with high RAP content of the present invention is used in the construction of the upper layer of AC-16 to replace the upper layer of conventional AC-16 hot-mix asphalt concrete.

[0059] The high-performance warm-mix recycled asphalt mixture with high RAP content (AC-16 upper layer asphalt mixture) includes the following mass percentage components: recycled asphalt pavement material (RAP material), recycled asphalt pavement material 50%, aggregate 47.2%, The newly mixed asphalt and the warm mix rejuvenator are 2.8%, and the content of the warm mix regenerant is 0.4% of the mass of the newly mixed asphalt.

[0060] The preparation method of the high RAP content high-performance warm-mix recycled asphalt mixture comprises the following steps:

[0061] (1) RAP material recycling and stacking

[0062] Carry out sampling inspection on the old asphalt pavement that needs to be milled to ensure that the quality...

Embodiment 3

[0079] Example 3: The high RAP content high-performance warm-mix recycled asphalt mixture of the present invention is used in AC-25 coarse-grained construction to replace conventional AC-25 coarse-grained hot-mix asphalt concrete. The high-performance warm-mix recycled asphalt mixture with high RAP content (AC-25 lower layer asphalt mixture) includes the following mass percentage components: recycled asphalt pavement material (RAP material) 70%, aggregate 28.2%, new asphalt and Warm mix regenerant 1.8%, the content of warm mix regenerant is 0.5% of the newly mixed asphalt mass.

[0080] The preparation method and equipment used for this high-RAP content high-performance warm-mix recycled asphalt mixture are the same as those in Example 1. In the crushing and screening of recycled materials, the same batch of recycled materials obtained in step (1) is fully mixed by machinery, crushed to a particle size of ≤ 31.5mm, and then screened to a particle size of 0-31.5 mm. Two grades...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com