Patents

Literature

39results about How to "Guaranteed heating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

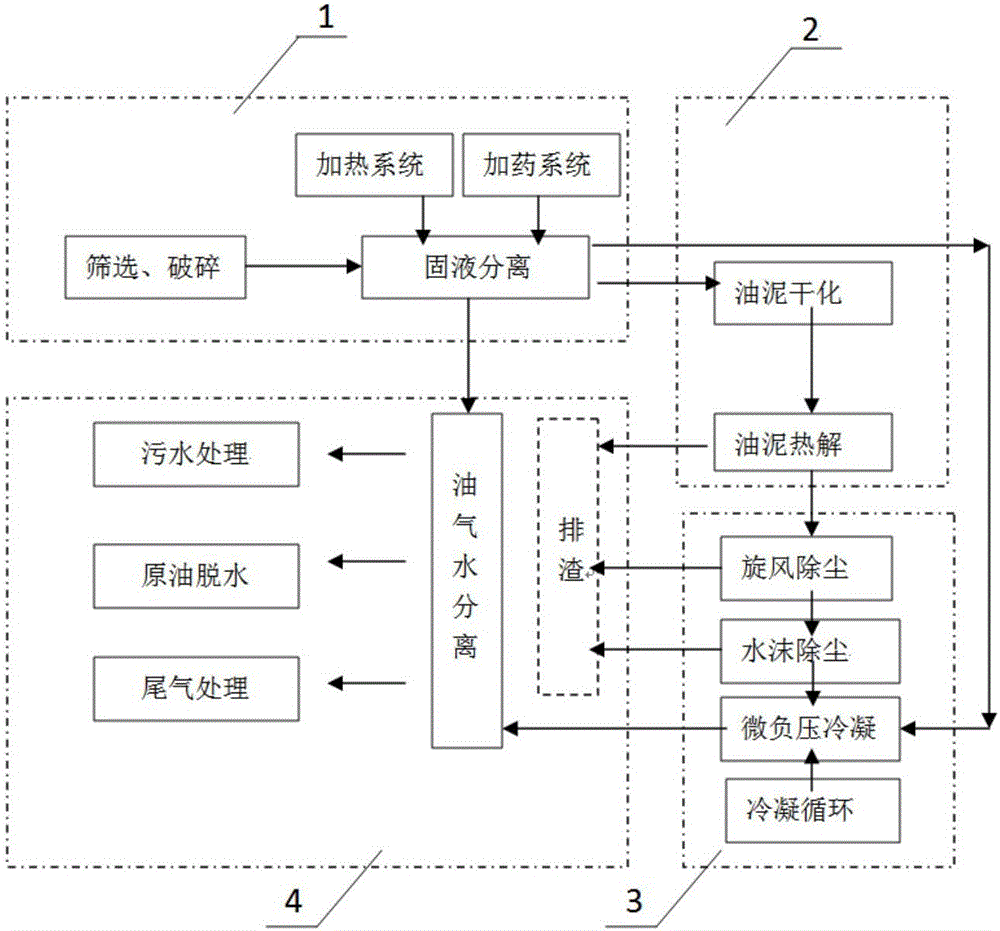

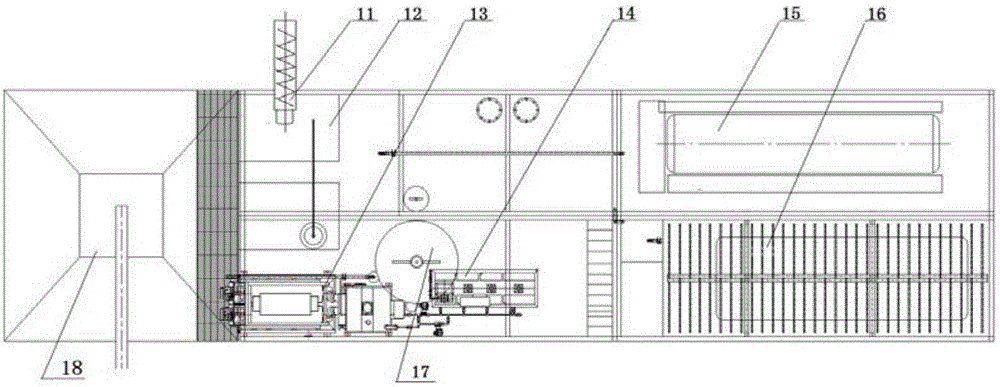

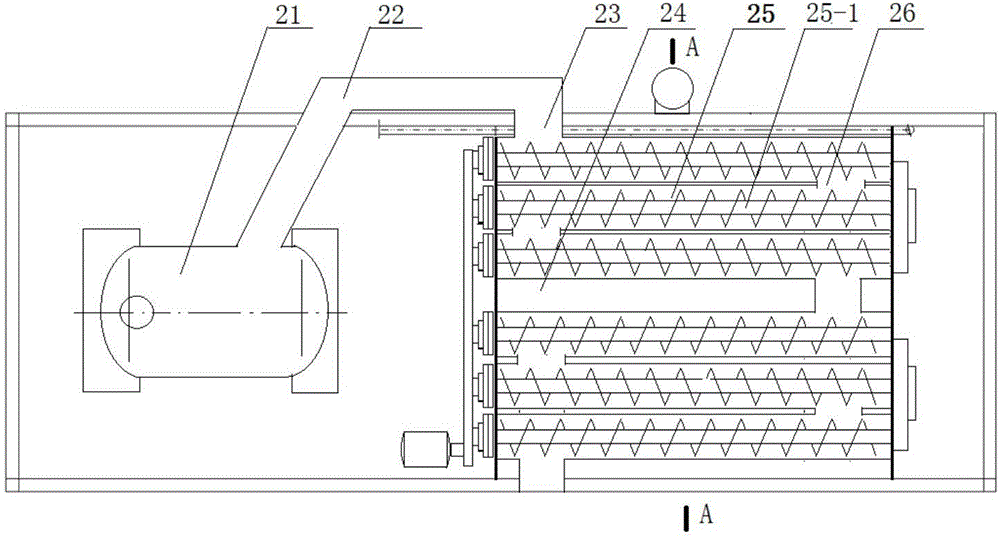

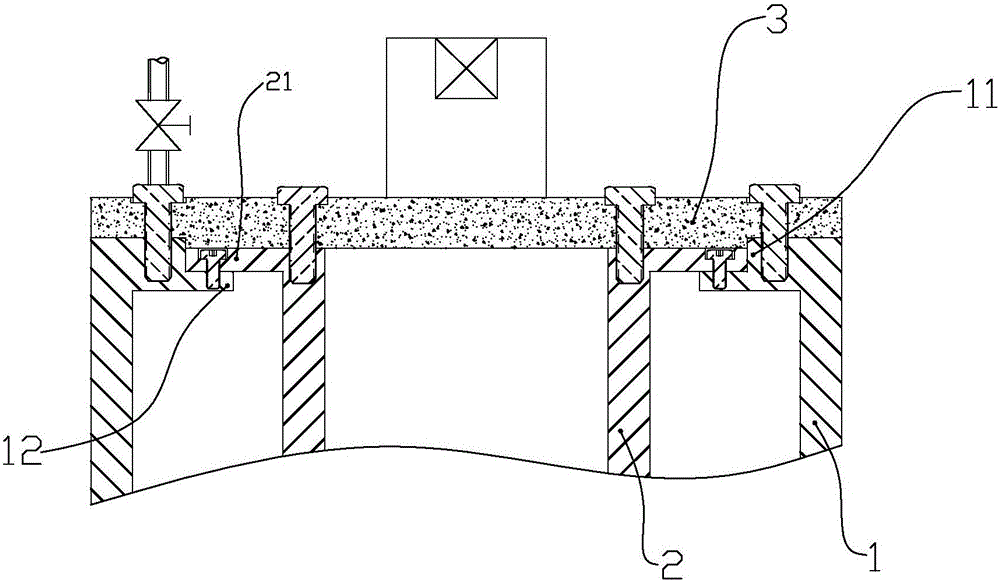

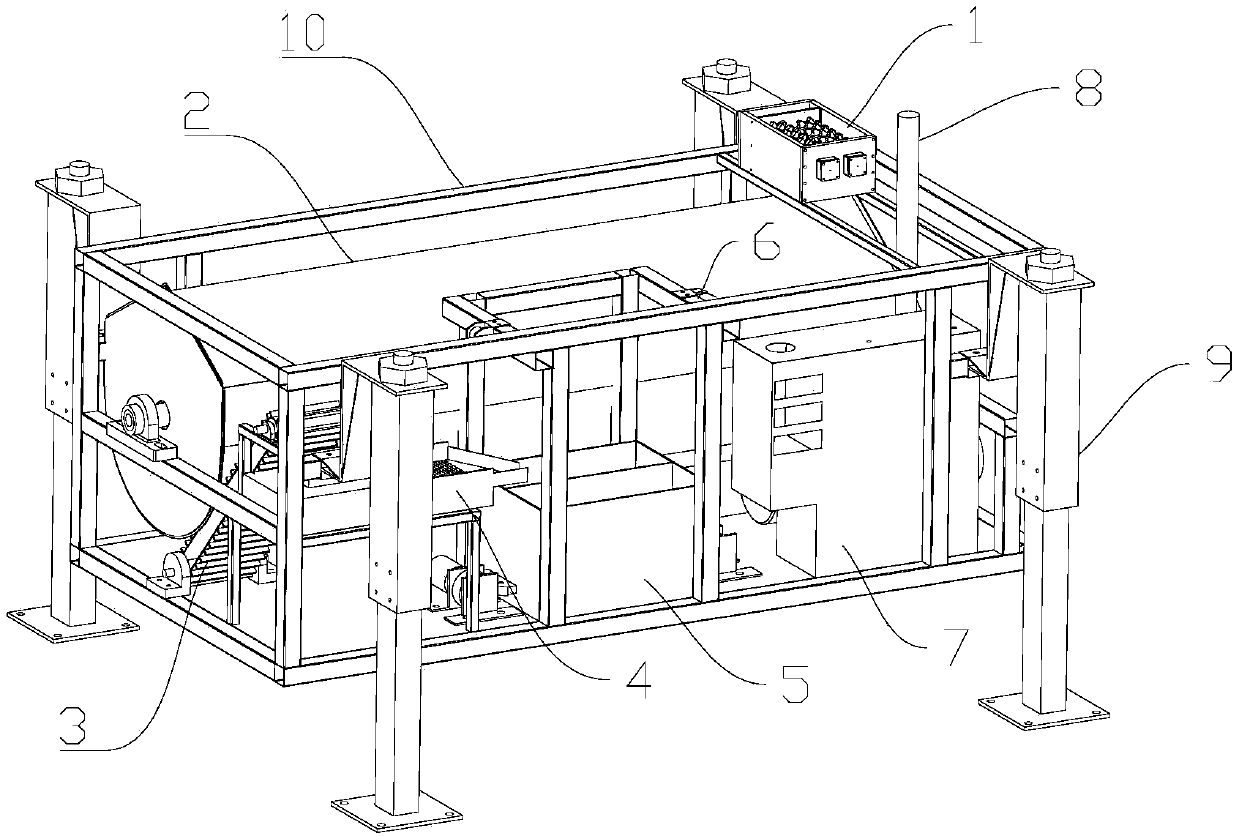

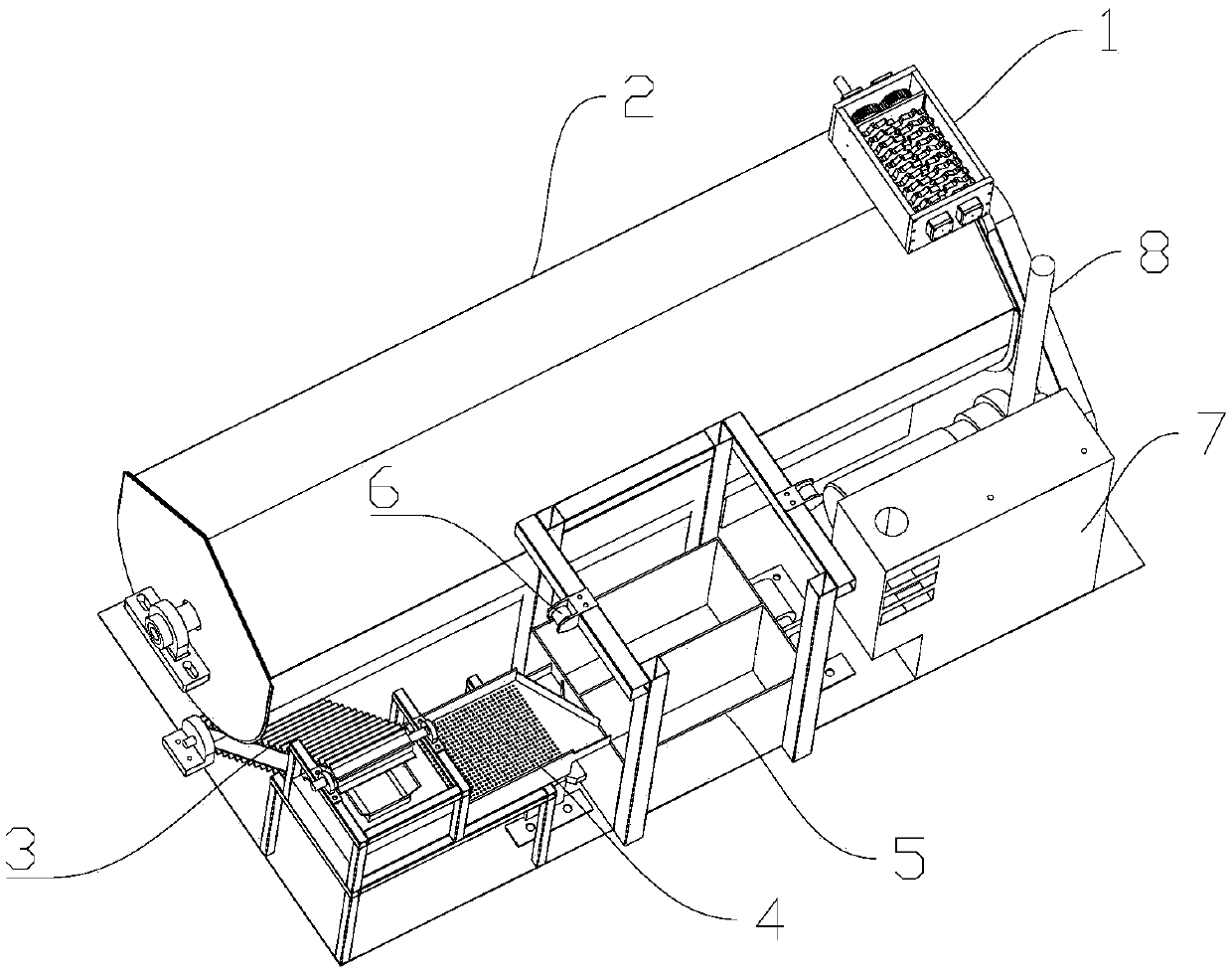

Industrialization scale pyrolysis treatment system and method for oily sludge

InactiveCN106746419ALarge amount of processingEasy to operateCombination devicesSludge treatment by de-watering/drying/thickeningPetroleumPyrolysis

The invention belongs to the field of waste disposal in petroleum industry, and relates to an industrialization scale pyrolysis treatment system for oily sludge. The industrialization scale pyrolysis treatment system comprises a feeding pre-separation unit for performing secondary screening and solid-liquid separation on the oily sludge, a drying pyrolysis unit for performing drying and pyrolysis reaction on the oily sludge, a dust removal and condensation unit for performing dust removal and condensation on a pyrolysis gas mixture generated by the drying pyrolysis unit, and a discharge treatment unit which receives and treats separated substances of the other units respectively. Solid or solid-liquid mixed waste such as the oily sludge can be finally treated to achieve reduction, stabilization, harmlessness and recycling.

Owner:PANJIN NINGTAI ENERGY TECH

Amorphous composite materials, and preparation method and applications thereof

The invention belongs to the field of metal amorphous composite materials, and discloses amorphous composite materials, and a preparation method and applications thereof. The amorphous composite materials comprise nickel, zirconium, titanium, niobium, aluminum and copper with a nickel-based amorphous phase as a matrix phase and beta-Ti and (Cu,Ni) Ti2 as reinforcing phases, and comprise the specific components according to the atomic percentage: 30-59 at.% of Ni, 10-24 at.% of Zr, 10-35 at.% of Ti, 7-10 at.% of Nb, 3-7 at.% of Al, 1-3 at.% of Cu, and the balance being inevitable trace impurities. The amorphous composite materials are prepared by rapidly sintering a nickel-based amorphous powder and a titanium-based amorphous powder. With control of the addition amount of the nickel-based amorphous powder, the amorphous composite materials with different amorphous phase content can be obtained. The amorphous composite materials are nearly fully dense, and can be applied in the fields of aeronautics and astronautics, military industry and the like.

Owner:SOUTH CHINA UNIV OF TECH

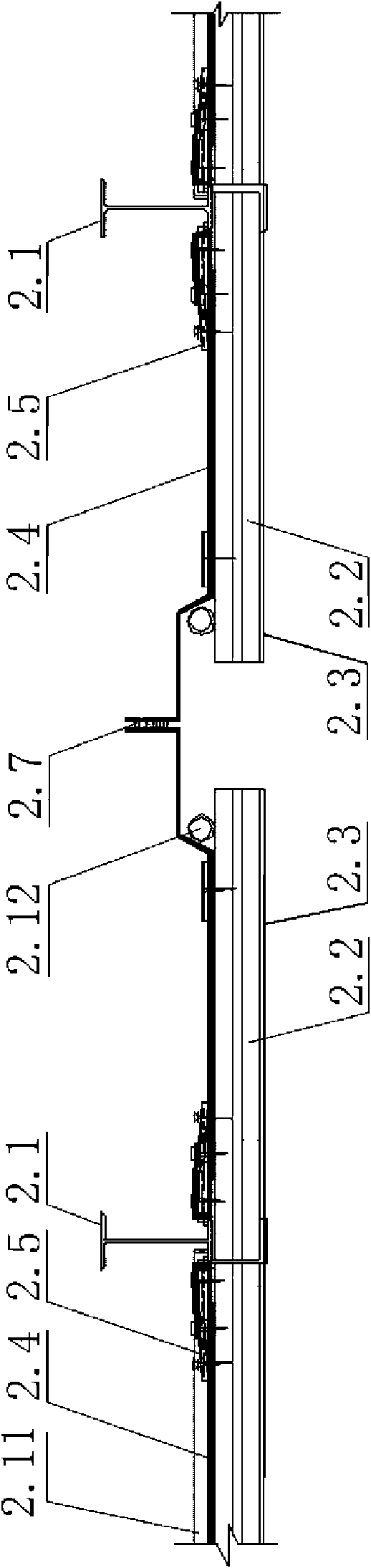

Electrothermal heating maintenance device inside concrete

InactiveCN101579888AImprove maintenance qualityGuarantee the construction qualityCeramic shaping apparatusCross connectionSafety net

The invention provides an electrothermal heating maintenance device inside concrete, wherein a heating resistance wire is bundled on the structural reinforcing steel bar inside concrete of buildings in construction, the heating resistance wire is connected with a power supply via a low-voltage power supply cable outside the concrete, a lifting protective frame comprises a frame body and a safety net attached to the frame body, the frame body is formed by cross connection of a vertical main keel with transverse sub-keels, the left side and the right side of the frame body are connected with vertical edge steel tubes, the vertical main keel is connected with the floor of building via a wall-attached hanging part, the frame body is a steel-wood structure, the top of the vertical main keel is provided with H-shaped steel provided with lifting holes, and the vertical main keel is also used as vertical guide rail. By using the manner of internal heating, the device has high heat efficiency and low thermal loss, and can save a great deal of energy; the heating speed of concrete can be reliably guaranteed, and the temperature is easily controlled; the maintenance conditions of concrete are good, and the construction quality can be guaranteed; the early strength of concrete is high, thereby creating favorable conditions for continuous upper construction and shortening the construction period.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

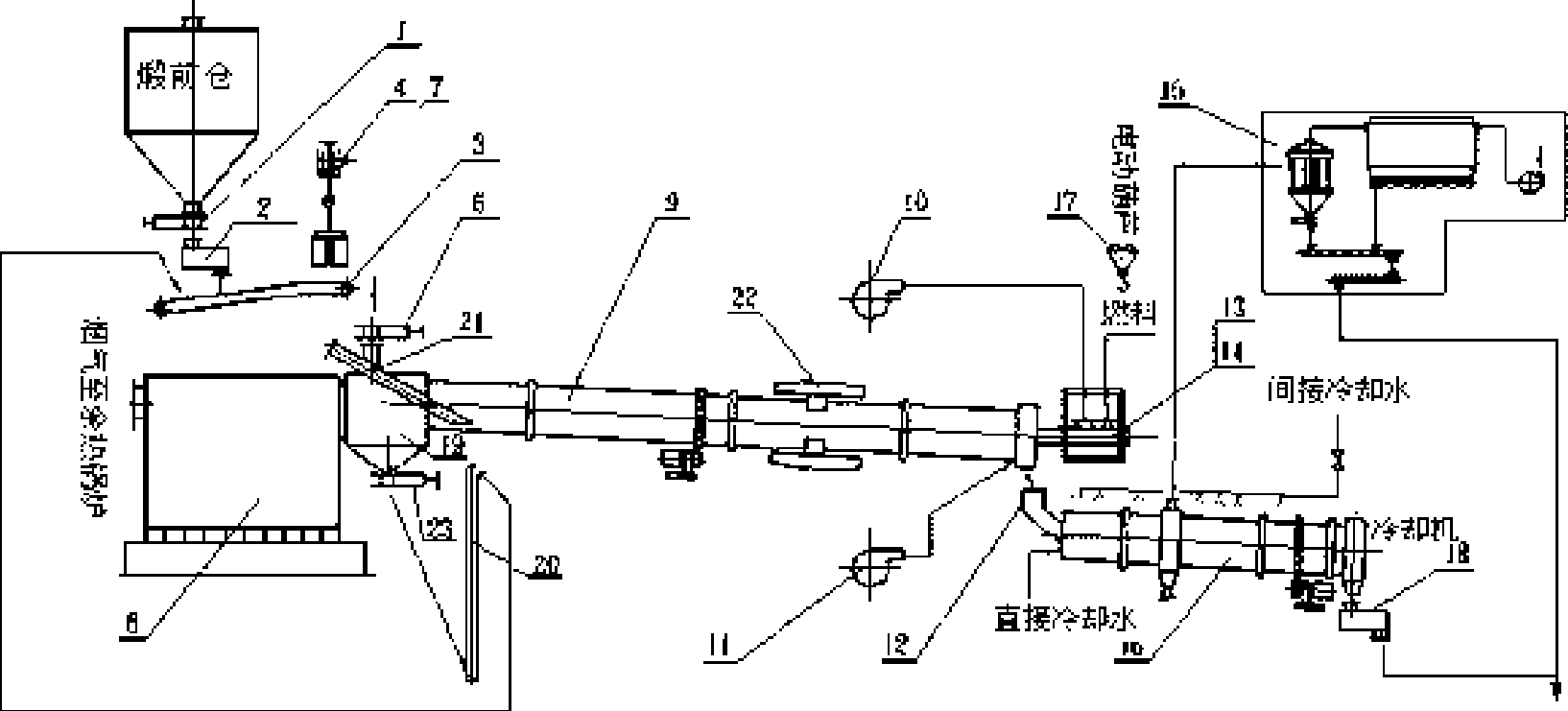

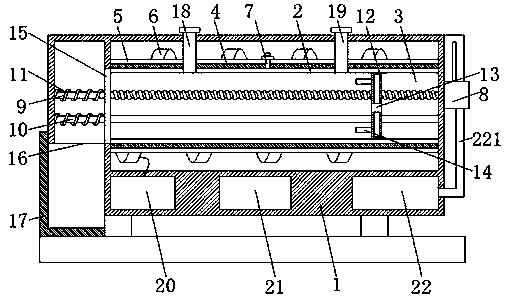

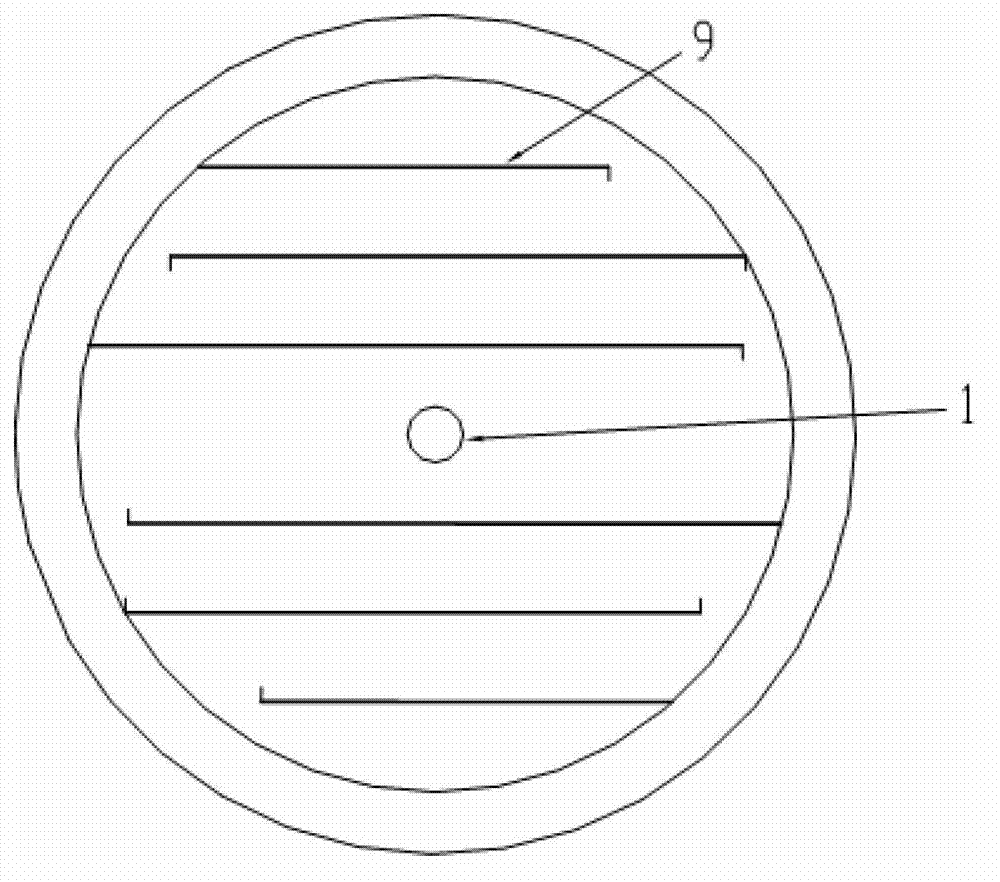

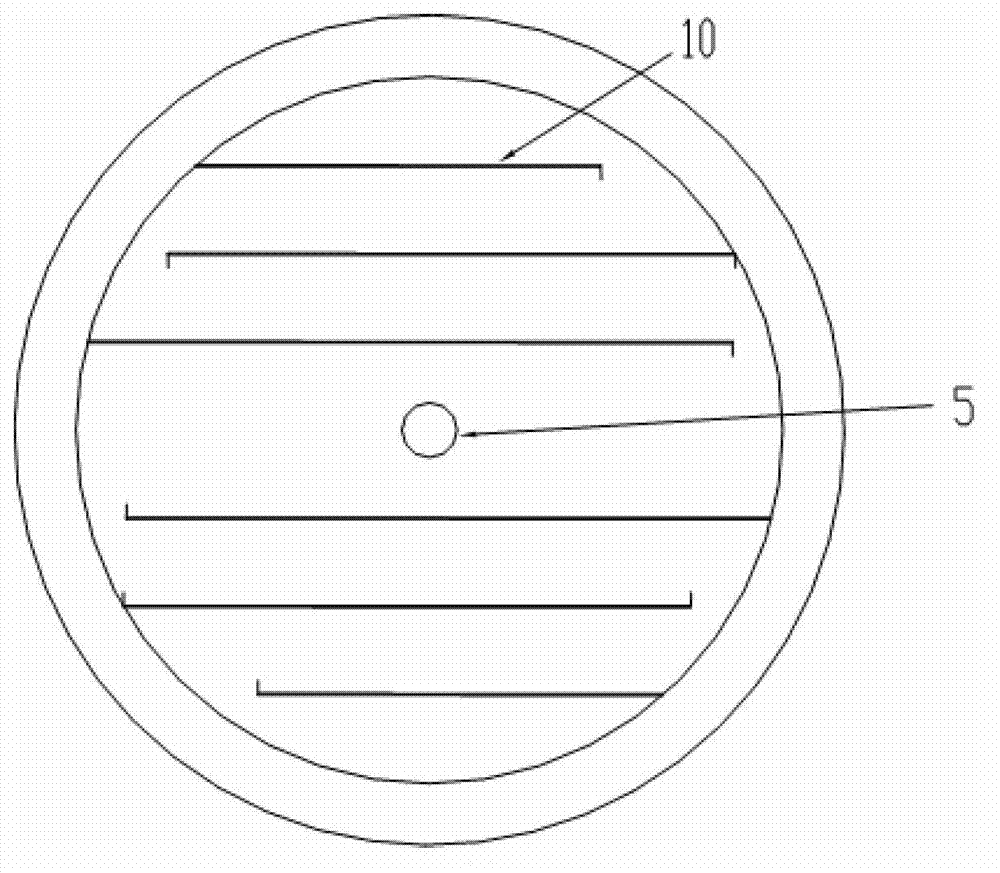

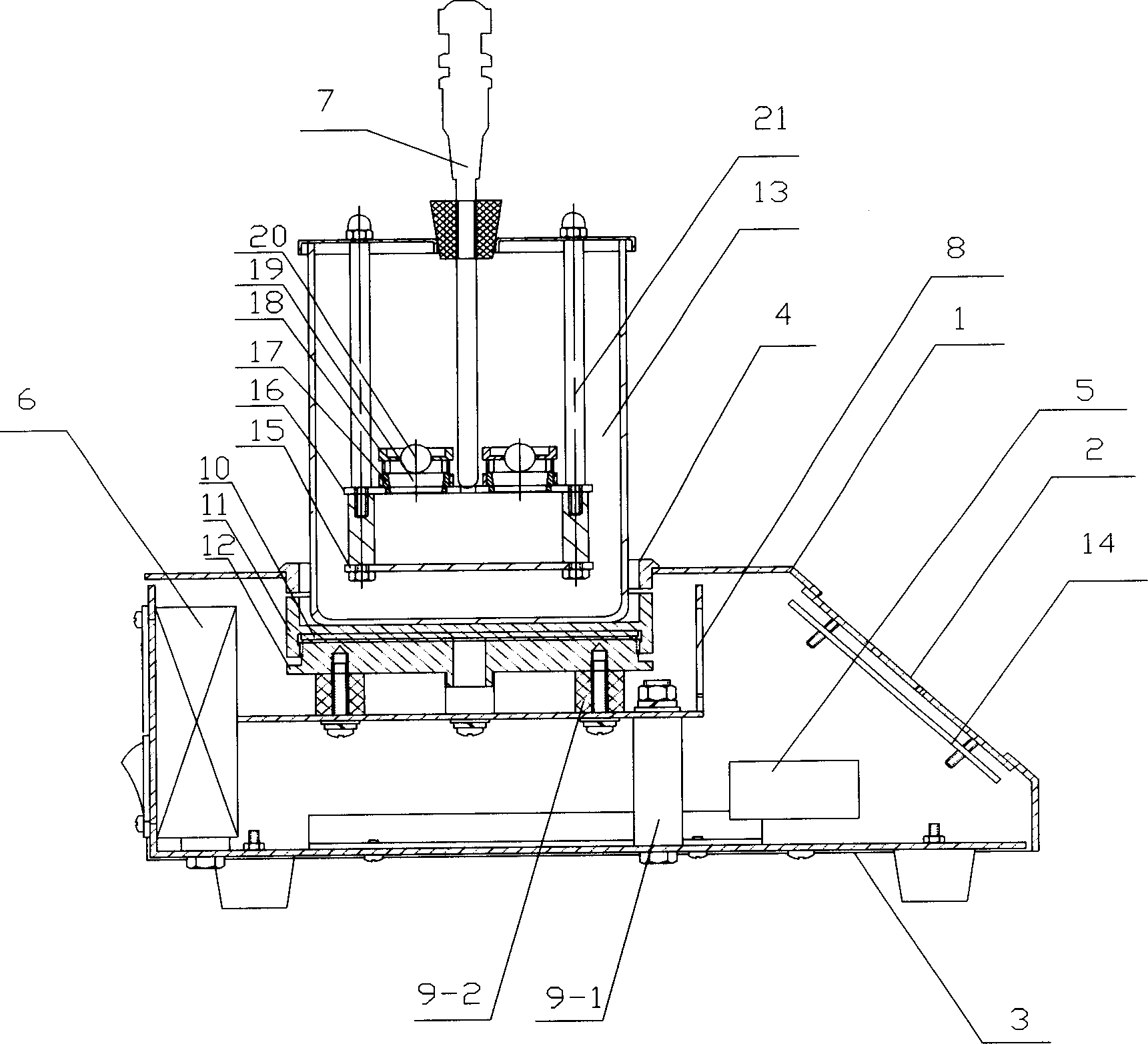

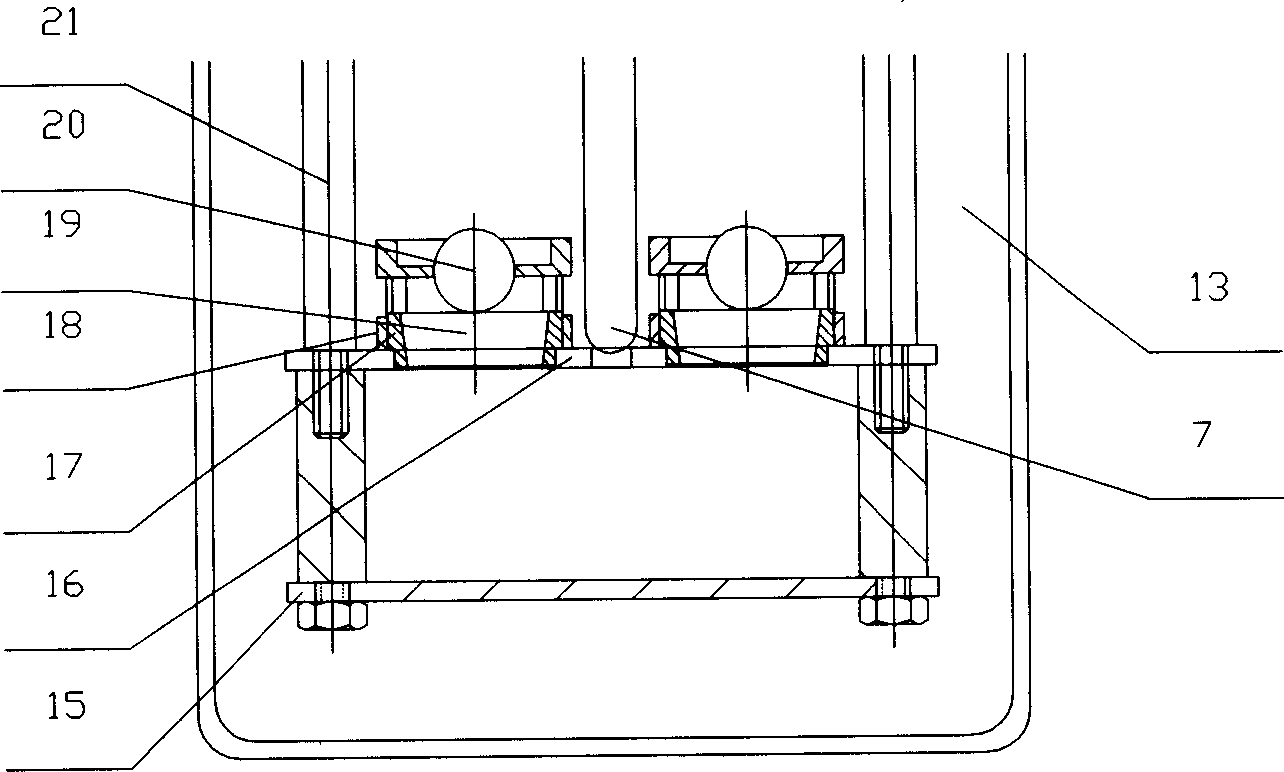

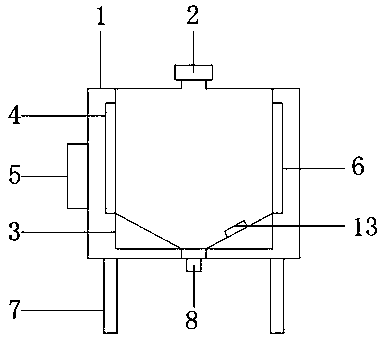

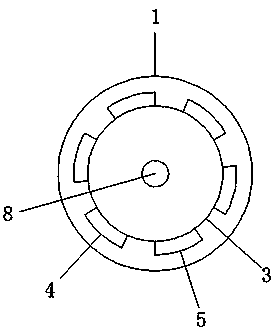

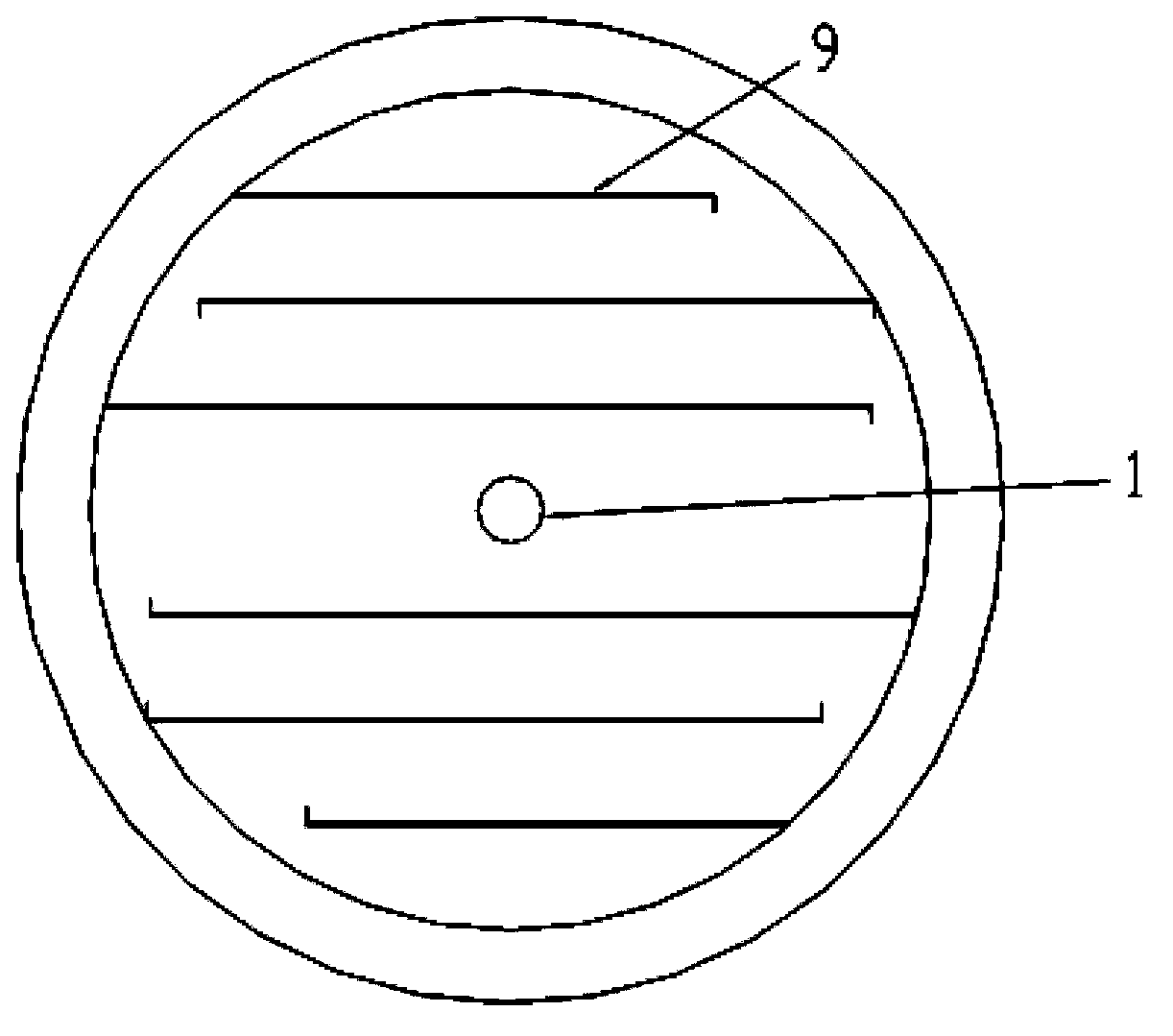

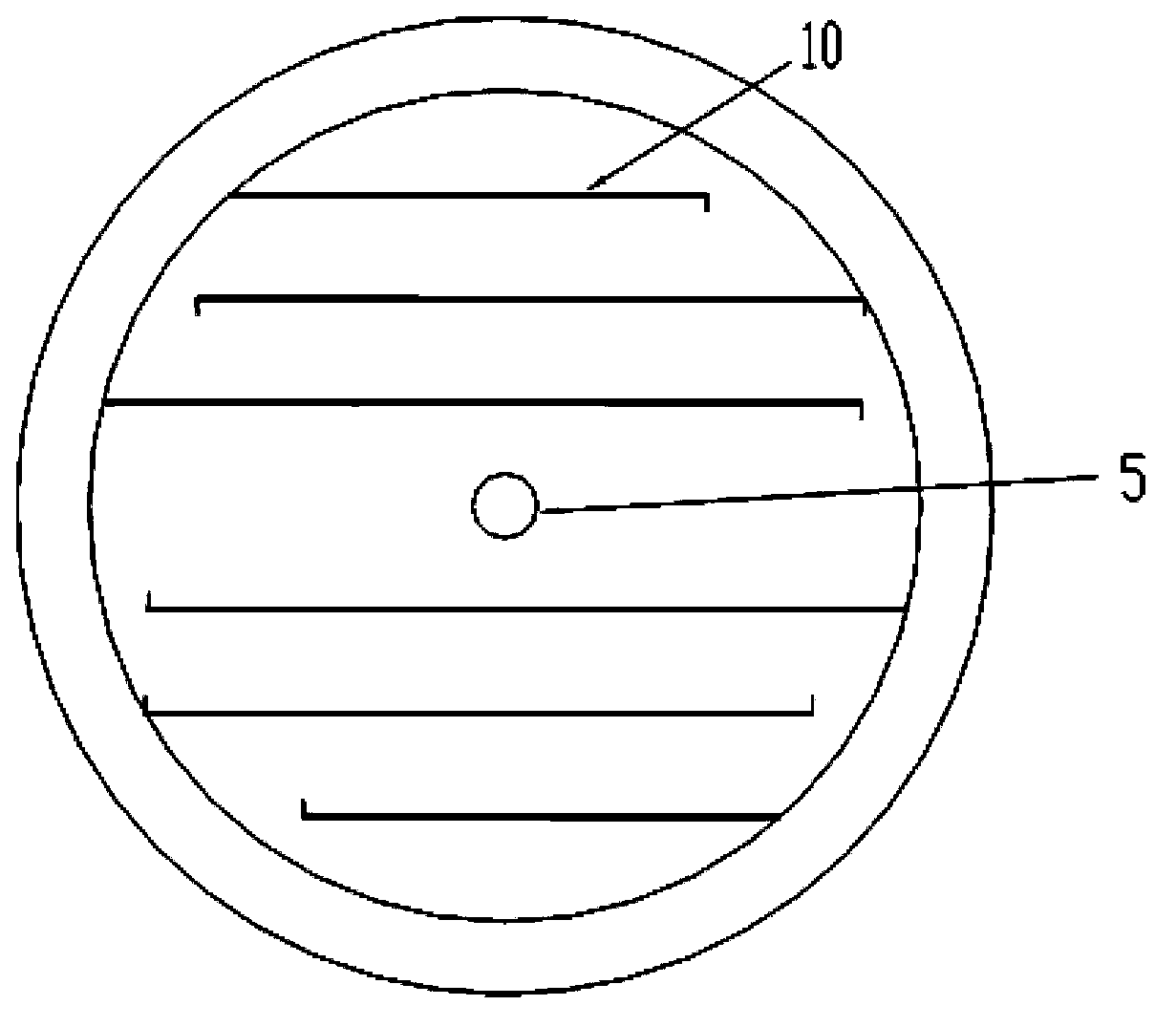

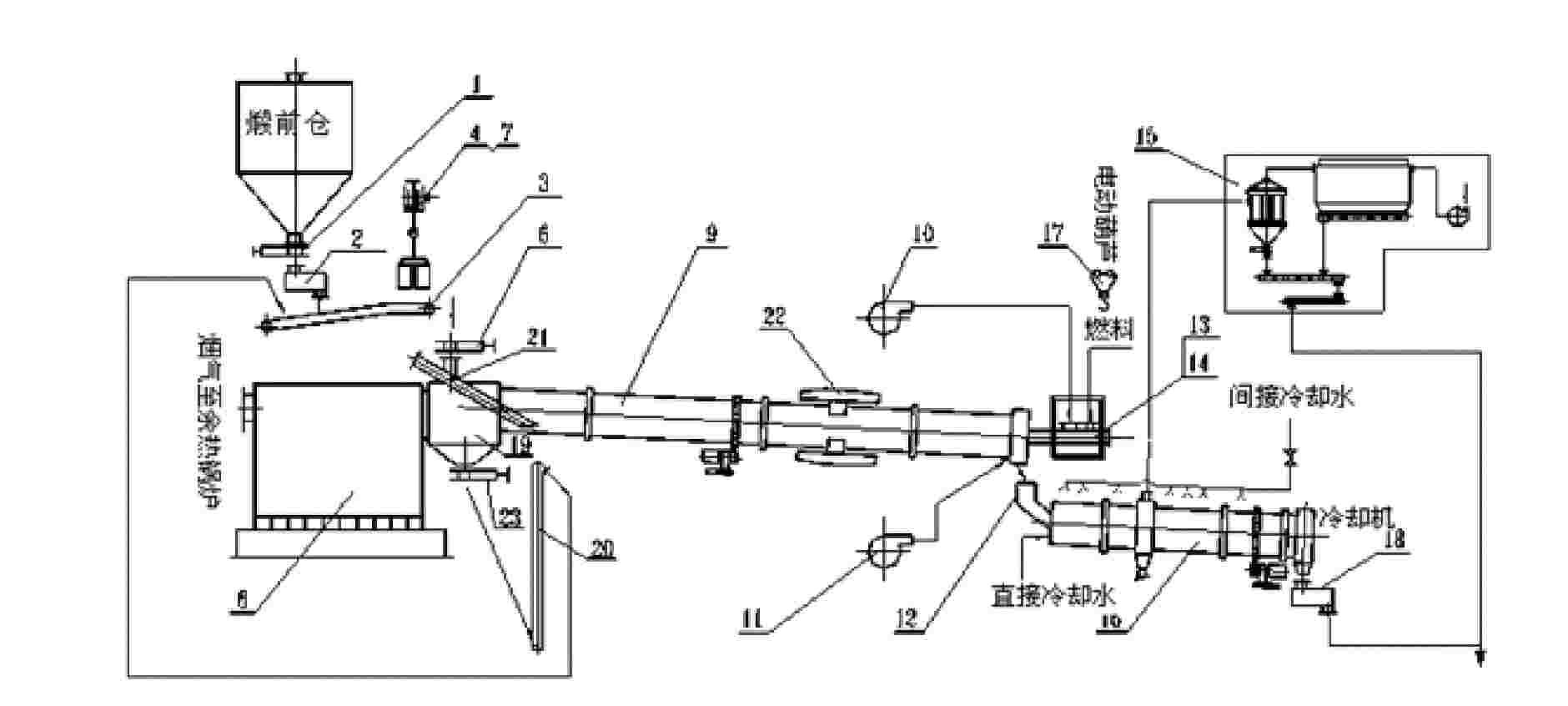

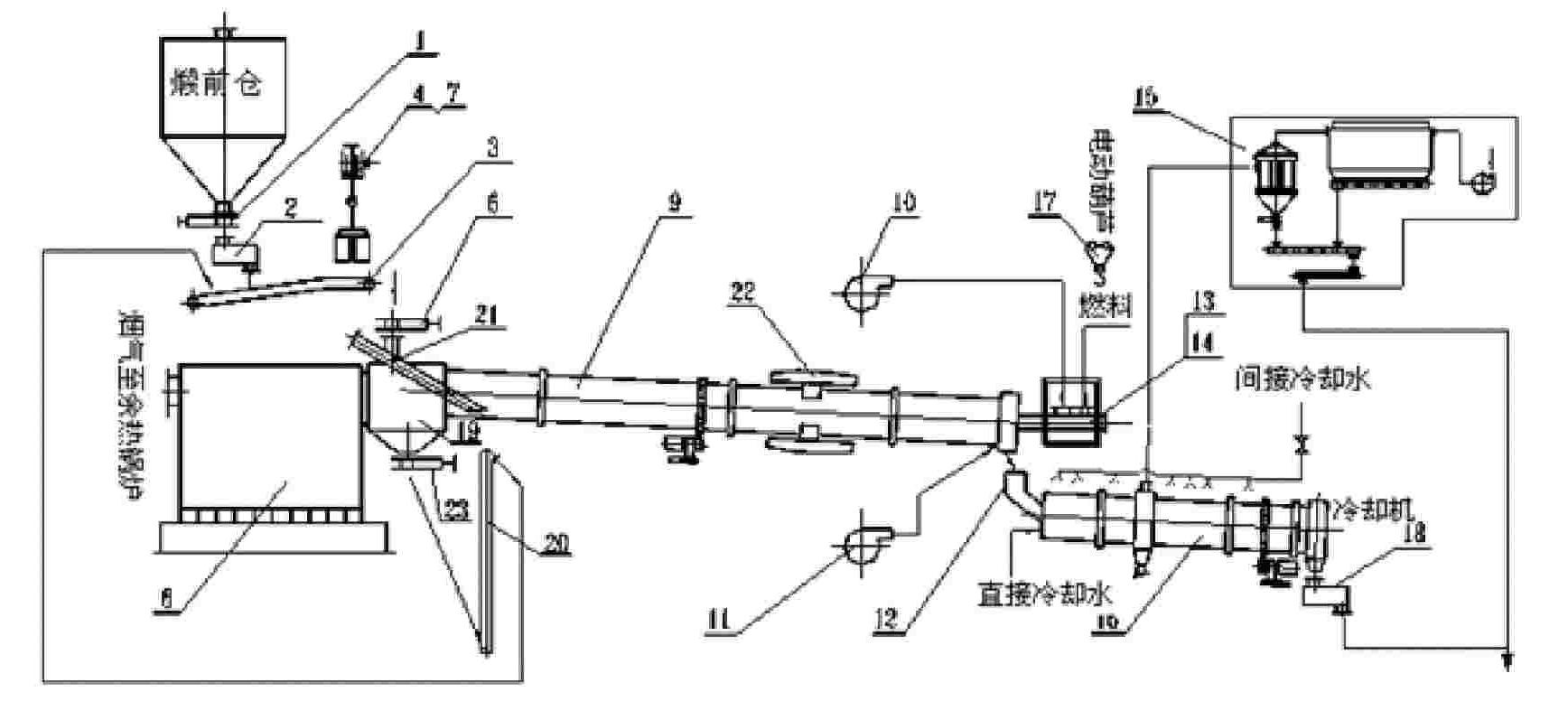

Rotary kiln for calcining refinery coke

The invention discloses a petroleum coke calcining rotary kiln, which comprises a rotary kiln(9); an insert plate valve(1) is arranged below a calcining front chamber; an adhesive tape constant feeder(2) is arranged below the insert plate valve, and an adhesive tape conveyer(3) is arranged behind the adhesive tape constant feeder (2) and connected with the rotary kiln(9) by an oblique cutting feed tipping tube of an electric insert plate valve(6); the tail part of the rotary kiln(9) is connected with a dust deposition chamber(8), and the head part of the rotary kiln(9) is connected with a cooling machine(16) and provided with a burner nozzle(13) and a burner nozzle hanger(14); the petroleum coke calcining rotary kiln is also provided with a one-time combustion fan(10) matched with the burner nozzle; and a dust-containing waste gas processing system(15) is arranged beside the cooling machine(16). The petroleum coke calcining rotary kiln has the advantages of improving the unit volume capacity, greatly enhancing comprehensive utilization of waste heat and adaptability of other calcining materials such as needle coke, anthracite and the like, reducing burning loss of charcoal, saving raw materials and energy, improving automatization level and reducing labor intensity of a worker.

Owner:GUIYANG AL-MG DESIGN & RES INST

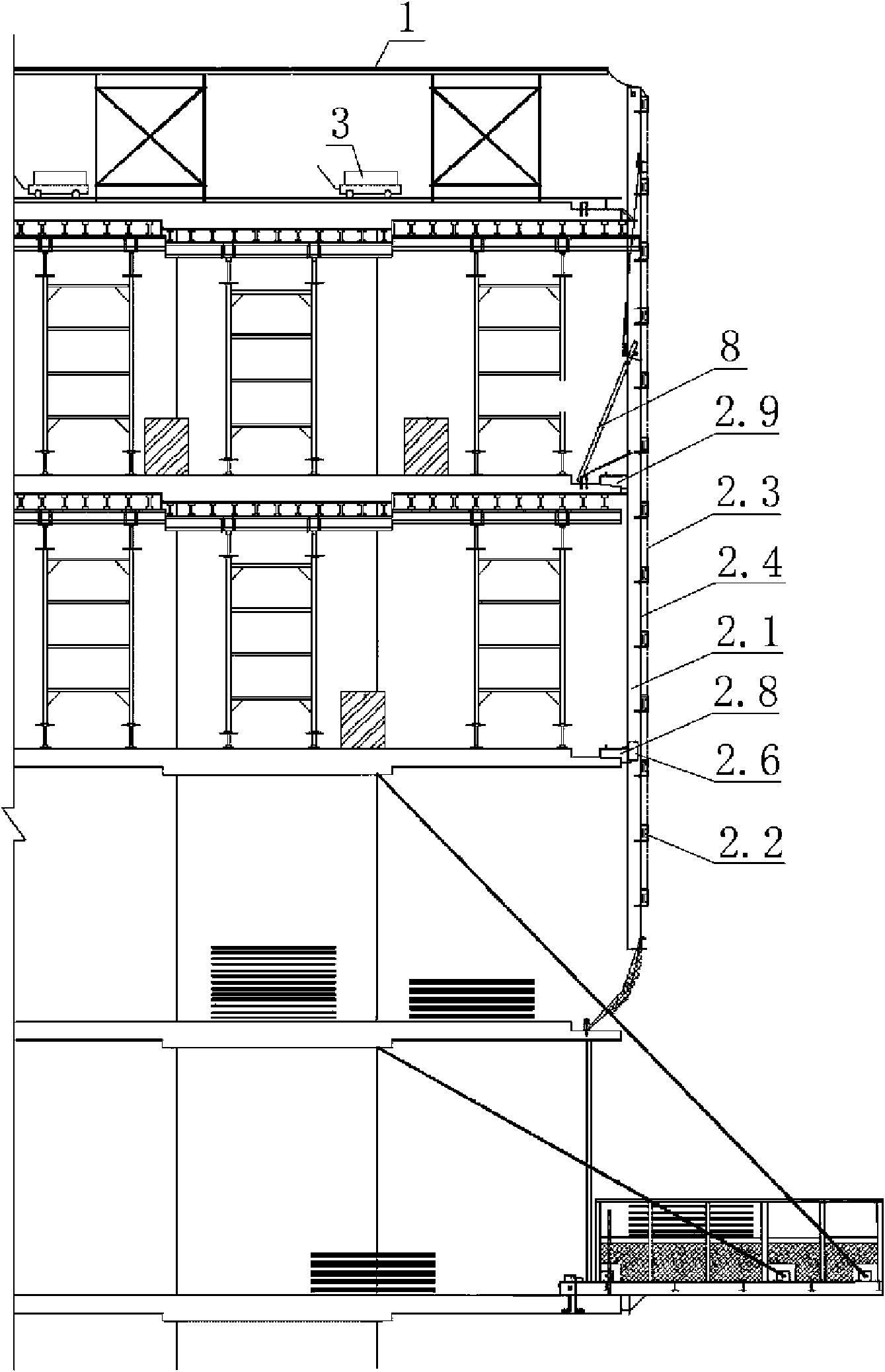

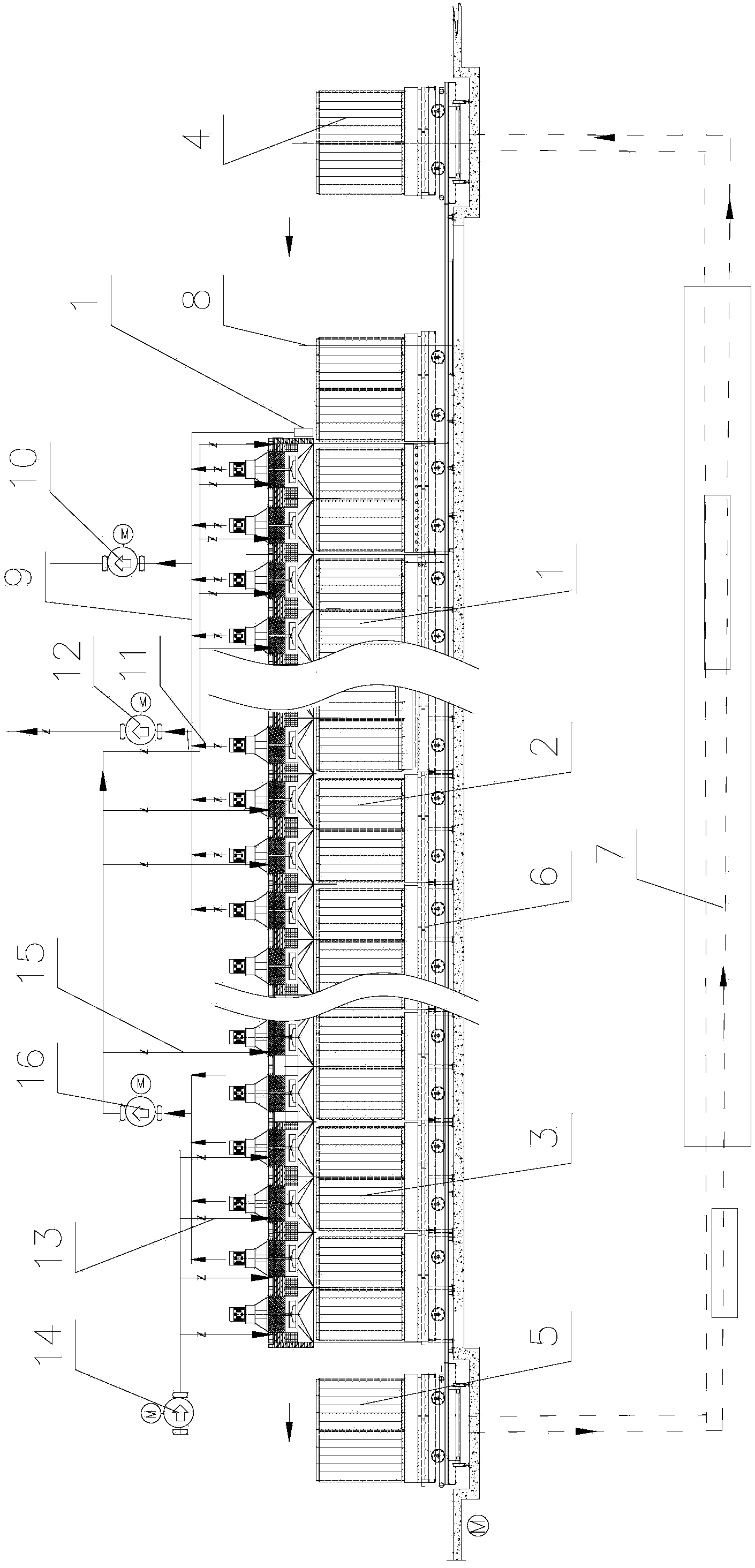

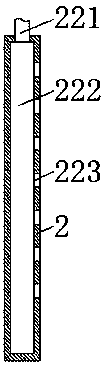

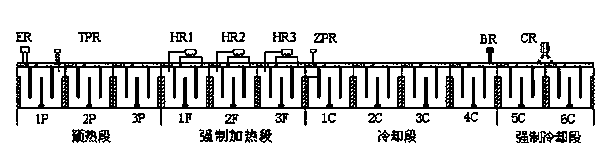

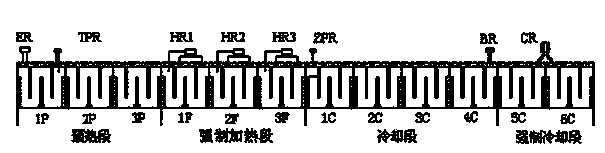

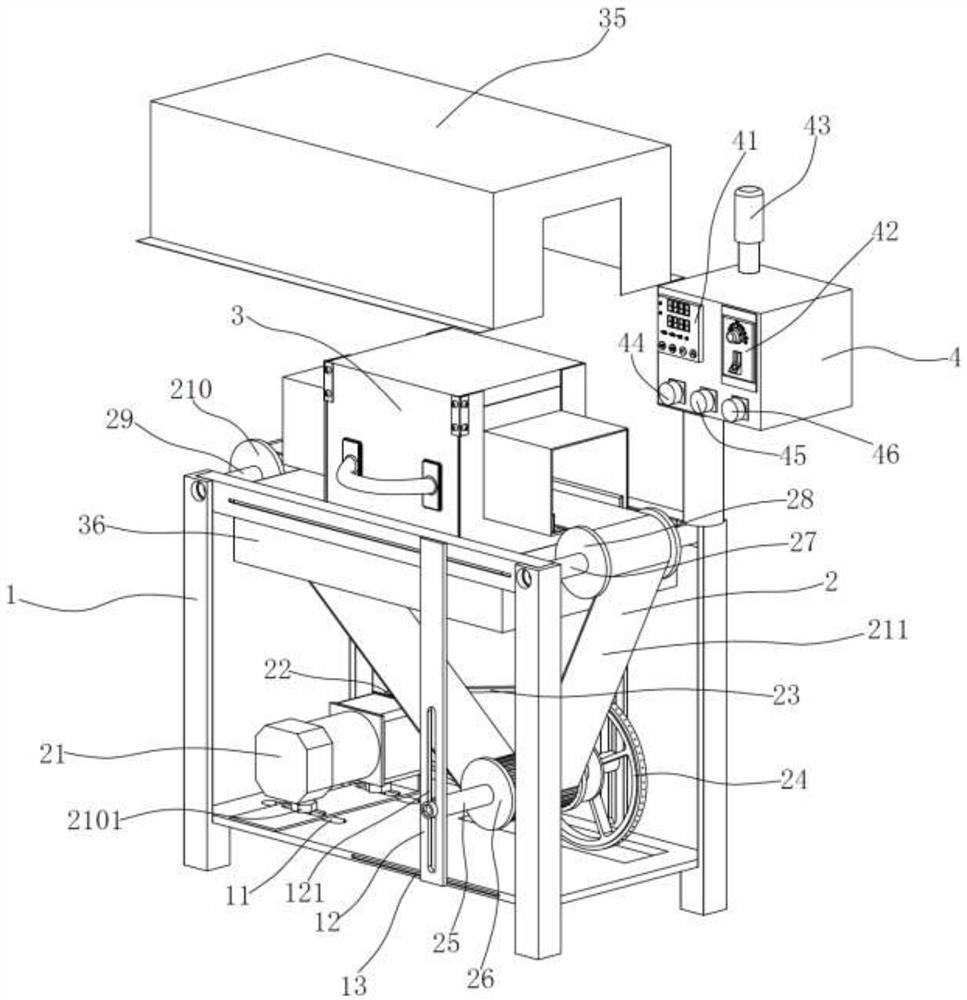

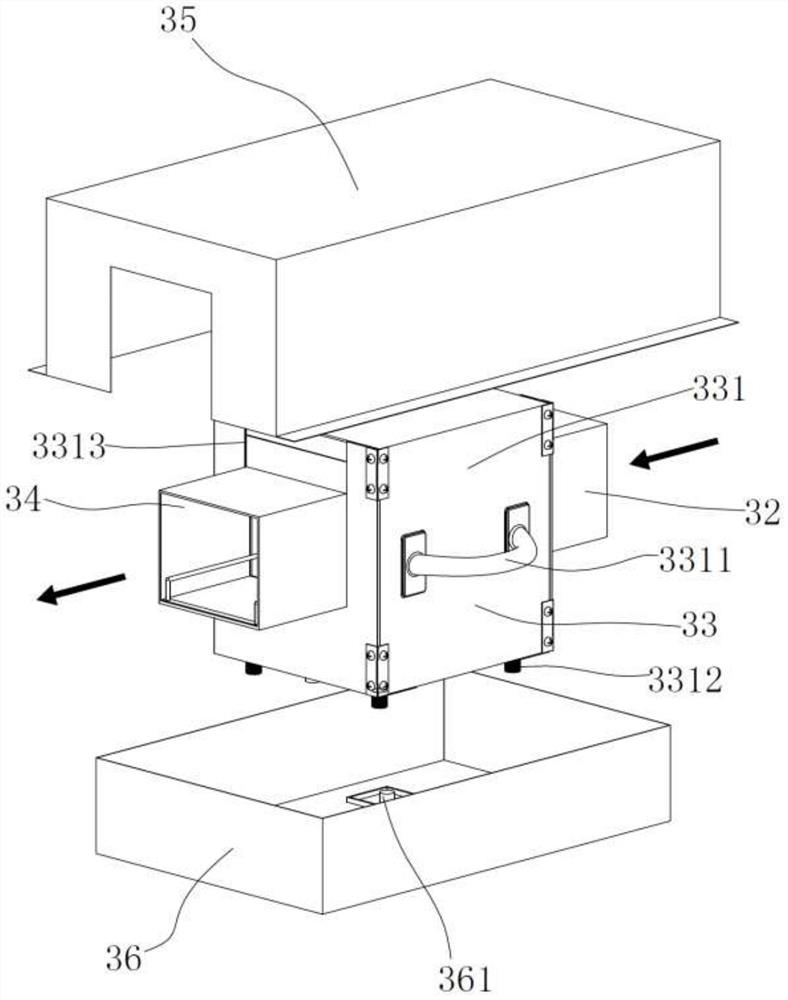

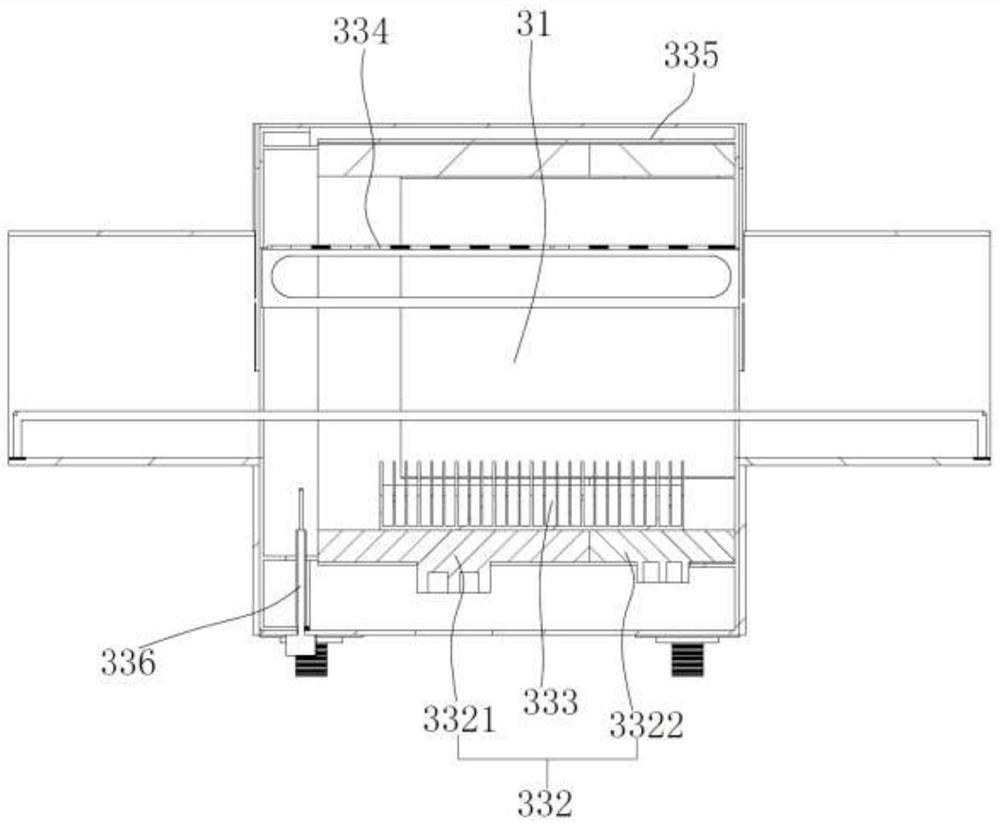

Vertical recycling, drying and calcining furnace for SCR (selective catalytic reduction) denitration catalysts

InactiveCN104315843AGuaranteed heating rateGuaranteed cycleFurnace typesWaste heat treatmentField uniformityControl system

The invention discloses a vertical recycling, drying and calcining furnace for SCR (selective catalytic reduction) denitration catalysts. The vertical recycling, drying and calcining furnace comprises a furnace body, a material transport return system, a fire-resistant heat-insulation system, a drying zone, a calcining zone, a cooling zone, a first electric heating system, a second electric heating system, a first internal hot-air circulation unit, a second internal hot-air circulation unit, a third internal hot-air circulation unit, a moisture removing system, a waste gas exhaust system, a cooling and aerating air system, a waste heat recycling system and a control system. The material transport return system is matched with the furnace body, the fire-resistant heat-insulation system is arranged in the furnace body, the drying zone, the calcining zone and the cooling zone are sequentially arranged in the furnace body, the first electric heating system is arranged in the drying zone, the second electric heating system is arranged in the calcining zone, the first internal hot-air circulation unit is arranged in the drying zone, the second internal hot-air circulation unit is arranged in the calcining zone, the third internal hot-air circulation unit is arranged in the cooling zone, the moisture removing system is matched with the drying zone, the waste gas exhaust system is matched with the calcining zone, the cooling and aerating air system is matched with the cooling zone, the waste heat recycling system is connected between the cooling zone and the calcining zone, and the calcining furnace can work under the control of the control system. The vertical recycling, drying and calcining furnace has the advantages that calcining conditions such as heating rates, product calcining cycles, waste gas contents and product temperature field uniformity can be accurately controlled and guaranteed, and accordingly quality index requirements on products can be assuredly met.

Owner:HUANGGANG CITY ZHONGRUI KILN

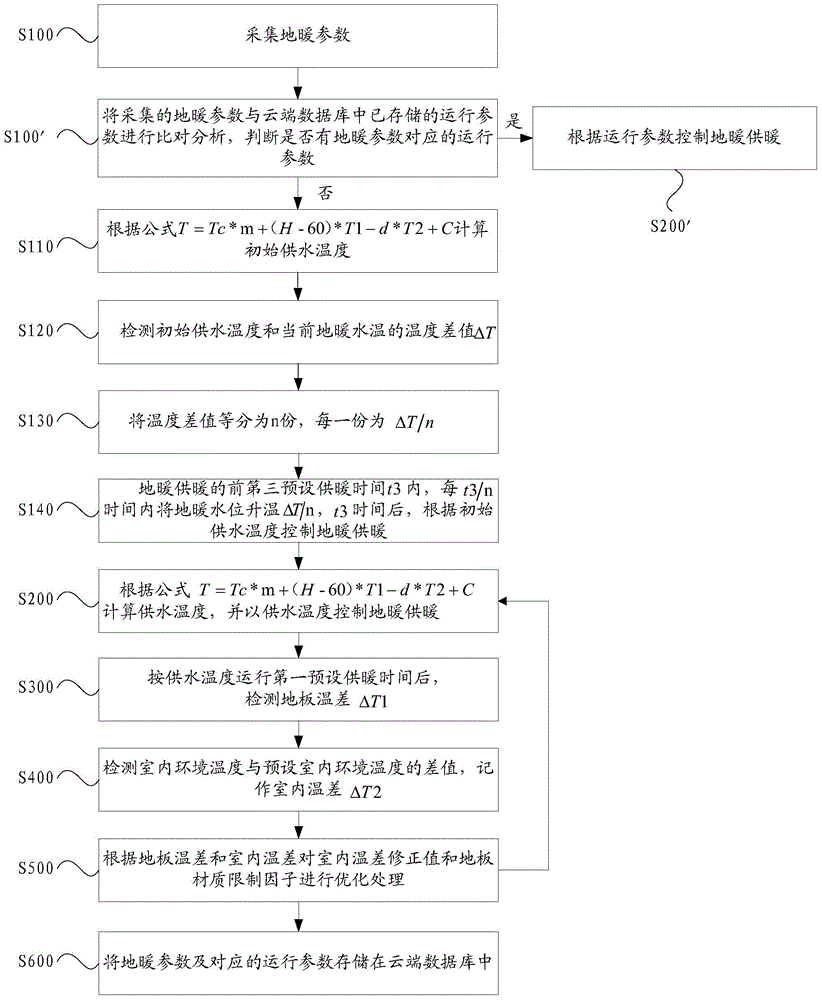

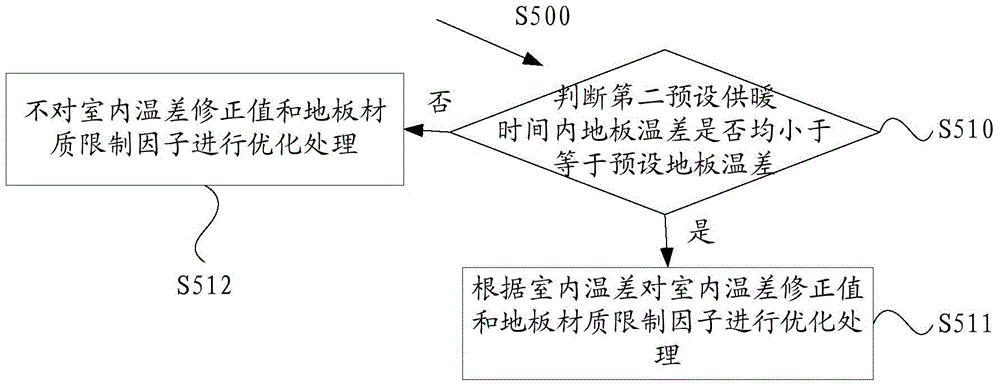

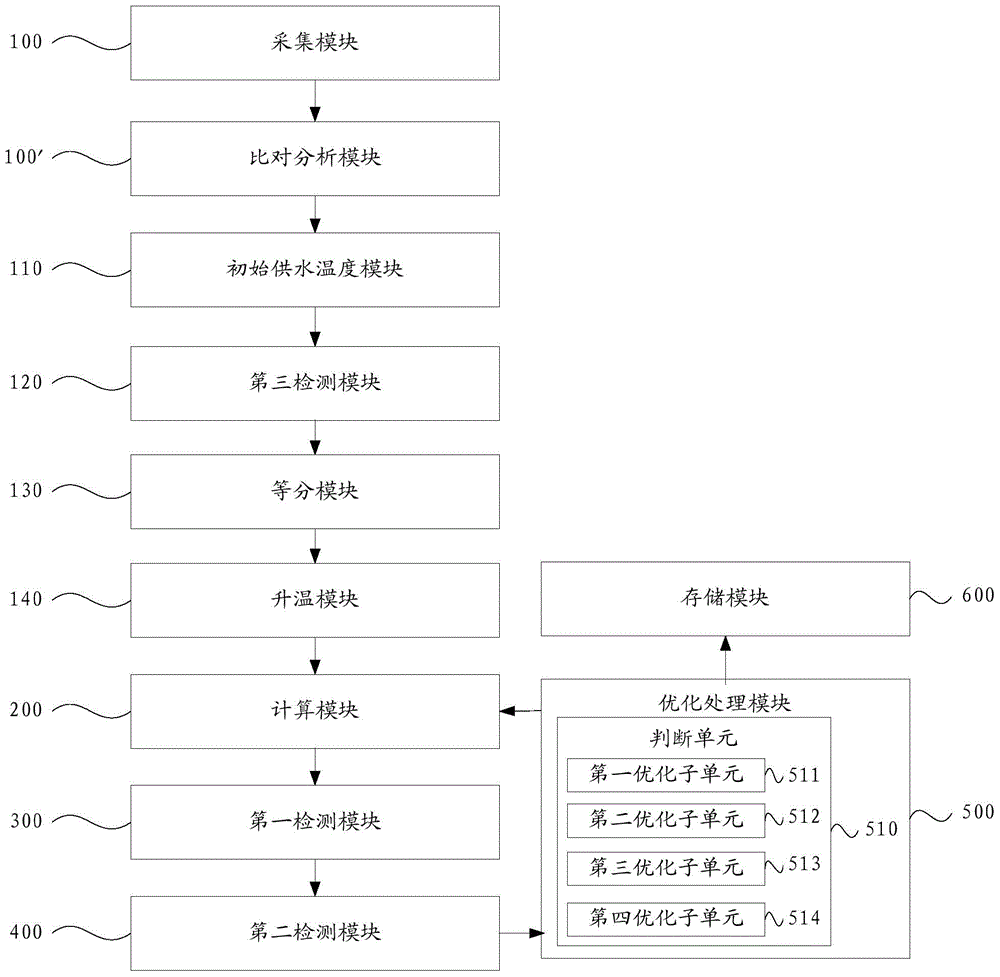

Floor heating water temperature control method and system

ActiveCN105371355AGuaranteed heating rateAvoid crackingLighting and heating apparatusTemperatue controlHeating timeTemperature difference

The invention provides a floor heating water temperature control method and system. The method comprises the following steps that floor heating parameters are collected and comprise the floor material, the floor thickness and the floor heating pipe distributing distance; the water supply temperature is calculated according to the formula: T=Tc*m+(H-60)*T1-d*T2+C, and the floor heating is controlled for heating according to the water supply temperature; after the floor heating runs the preset first heating time according to the water supply temperature calculated in advance, the temperature difference of floors is detected; the indoor temperature difference between the indoor environment temperature and the preset indoor environment temperature is detected; and according to the floor temperature difference and the indoor temperature difference, the indoor temperature difference correction value and the floor material limitation factor are optimized, and the step of calculating the water supply temperature is executed repeatedly. Different water supply temperatures can be automatically set according to different materials, the temperature rising rate and the indoor comfort degree of the floors are guaranteed, the floors are prevented from being heated rapidly so that cracking can be prevented, and it is also prevented that temperature rising is low while the heating time is too long; and the indoor temperature difference correction value and the floor material limitation factor are optimized constantly, the indoor environment is more comfortable, and more energy is saved.

Owner:GREE ELECTRIC APPLIANCES INC

Crystallization equipment for edible salt production

InactiveCN110339590AImprove efficiencyGood effectSolution crystallizationCrystallization by component evaporationInsulation layerEngineering

The invention relates to the technical field of edible salt production equipment and discloses crystallization equipment for edible salt production. The crystallization equipment comprises an equipment body; the inside of the equipment body is provided with a crystallization box; the inside of the crystallization box is provided with a crystallization chamber; and a heat insulation layer surroundsthe outer wall of the crystallization box. According to the crystallization equipment for edible salt production, a motor is started to drive a lead screw to rotate, and a scraping plate is driven tomove horizontally and stably by utilizing the support and limitation of a supporting rod, so that edible salt crystals separated out from the top, bottom and periphery of the crystallization chamberare scraped, the scraped edible salt crystals are pushed to a discharging hole, a sealing plate is jacked in advance by using a contact lever on the scraping plate to expose the discharging hole, andfurthermore, the edible salt crystals are pushed out of the crystallization chamber and are collected by a collecting box. The equipment is high in automation degree and capable of improving the efficiencies and effects of clearing and collecting the edible salt crystals, avoiding resource waste and saving manpower and time.

Owner:徐州市龙头山酿造有限公司

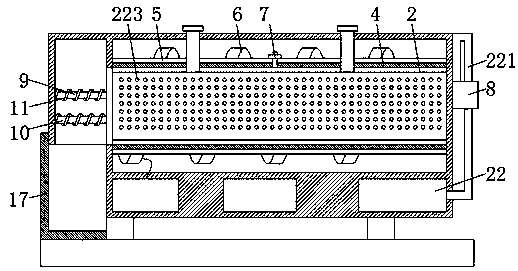

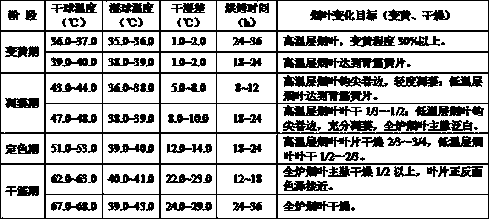

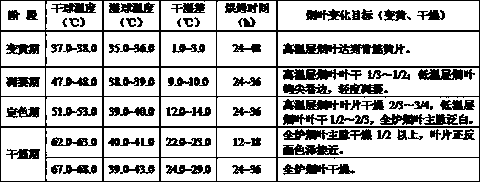

Primary baking process for improving tobacco leaf aroma volume

The invention discloses a primary baking process for improving tobacco leaf aroma volume . The process comprises a tobacco leaf yellowing stage, a withering stage, a color fixing stage and a stem drying stage. The technical key points of the process are as follows: (1) in the yellowing period, carrying out full yellowing under high temperature and humidity conditions; (2) in the withering period,carrying out temperature stabilization and moisture removal, and carrying out full withering; (3) in the color fixing period, carrying out cooling and humidifying and slowly drying the leaves; and (4)in the stem drying stage, controlling the temperature, adjusting the humidity and slowly drying the stems.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

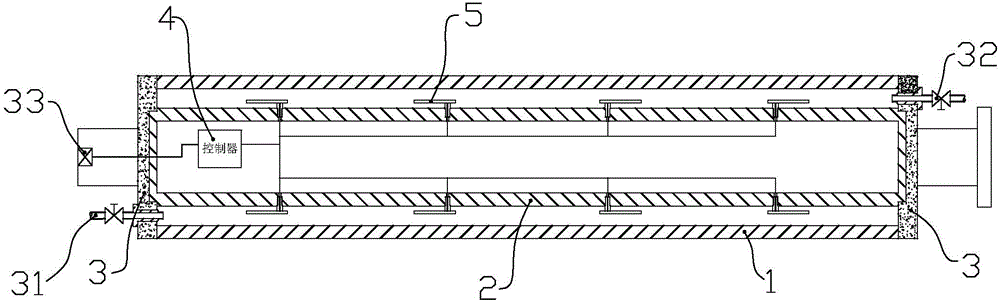

Mold for producing GRE winding pipe

The invention relates to a mold for producing GRE winding pipe, and belongs to the technical field of pipeline production. The mold comprises an outer pipe, an inner container, end covers, a controller and heaters. The outer diameter of the end cover is not larger than that of the outer pipe, the end covers are arranged at the two ends of the outer pipe and the two ends of the inner container, and a sealed cavity is formed between the inner wall of the outer pipe and the outer wall of the inner container. The heaters are arranged in the sealed cavity, and the controller is fixed in the inner container and connected with the heaters. An oil discharge outlet communicating with the sealed cavity is formed in the lower side of one end of the sealed cavity, and an oil inlet communicating with the sealed cavity is formed in the upper side of the other end of the sealed cavity. The outer diameter of the outer pipe of the involved mold can be increased to 1,000 mm to 2,200 mm, and heating efficiency and heating uniformity required by curing can be guaranteed; and the GRE winding pipe with the inner diameter ranging from 1,000 mm to 2,200 mm is produced, and the dimension range of the GRE winding pipe meets the needs for a high-pressure high-convey-capacity pipeline in current construction.

Owner:曹如锋

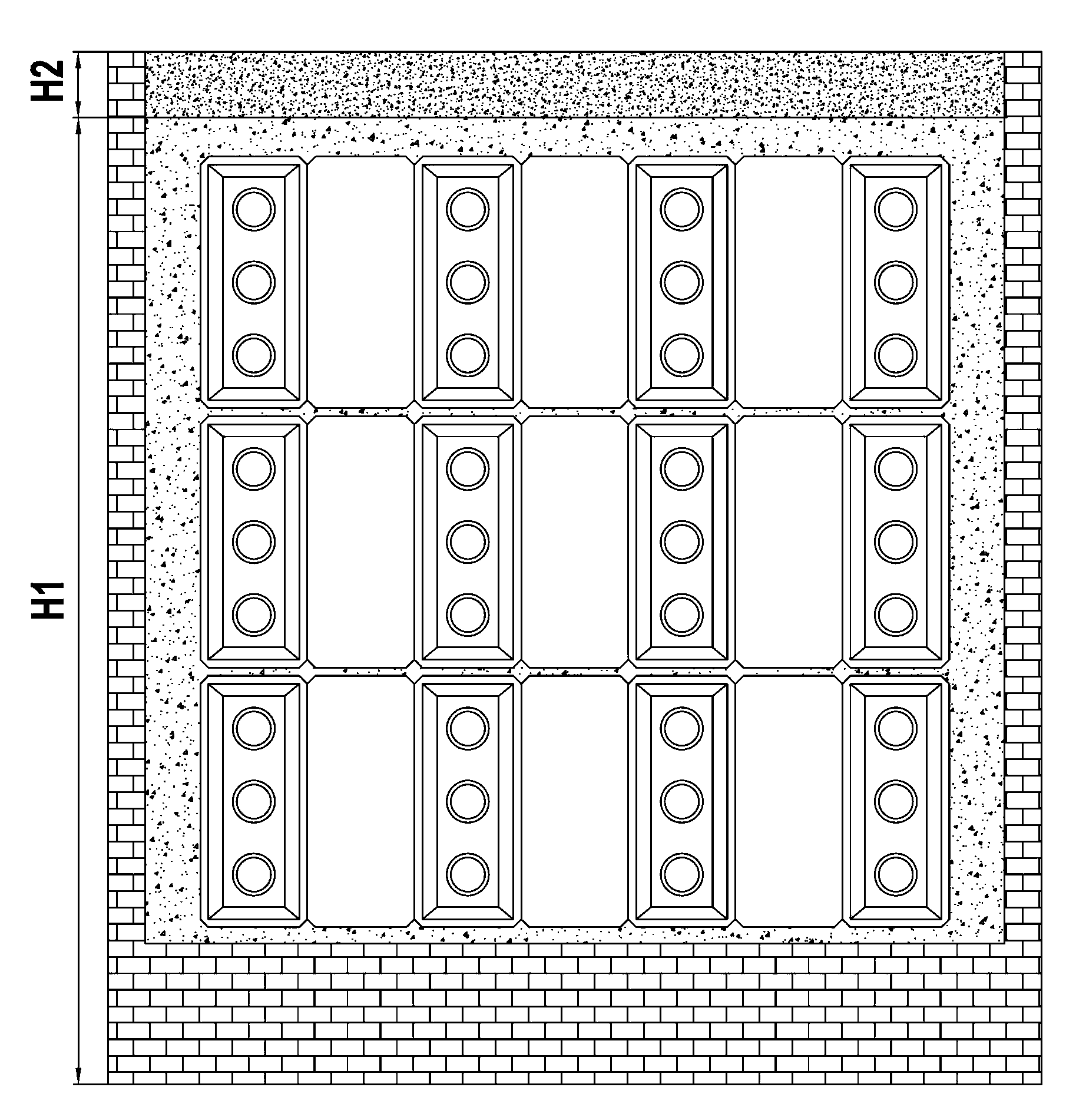

Method of opening type roasting filling material filling

ActiveCN103134327AImprove sealingGuaranteed burning lossEnergy inputCharge manipulationCold airGranularity

The invention relates to a method of filling material filling, in particular to a method of opening type roasting filling material filling used for a carbon industry. An area with a standing seam in a fire way wall is filled by the filling material with a regular granularity. An area without a standing seam of the fire way wall on the upper portion of a material box is filled by a layer of fine filling materials and the fine filling materials are concentratedly to be operated in and out of a furnace. Convenience and feasibility of the operation are guaranteed. The method of the opening type roasting filling material filling has the advantages that the filling materials with different granularities are filled in the upper position and the lower position of the opening type roasting furnace material box, thus the good sealing effect of the material box is achieved. The fact that oil tar and volatile matter in a heating stage of a roasting product which smoothly enter the fire way to burn is guaranteed. A Cold air quantity leaking in the fire way from the material box is reduced. A pre-heating air quantity which enters the material box from the fire way after the roasting product enters the cooling state is reduced. Regular temperature rising speed in the heating stage and cooling speed in the cooling stage of the roasting product are guaranteed. Burning losses of the filling materials in the cooling stage of the roasting product are reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

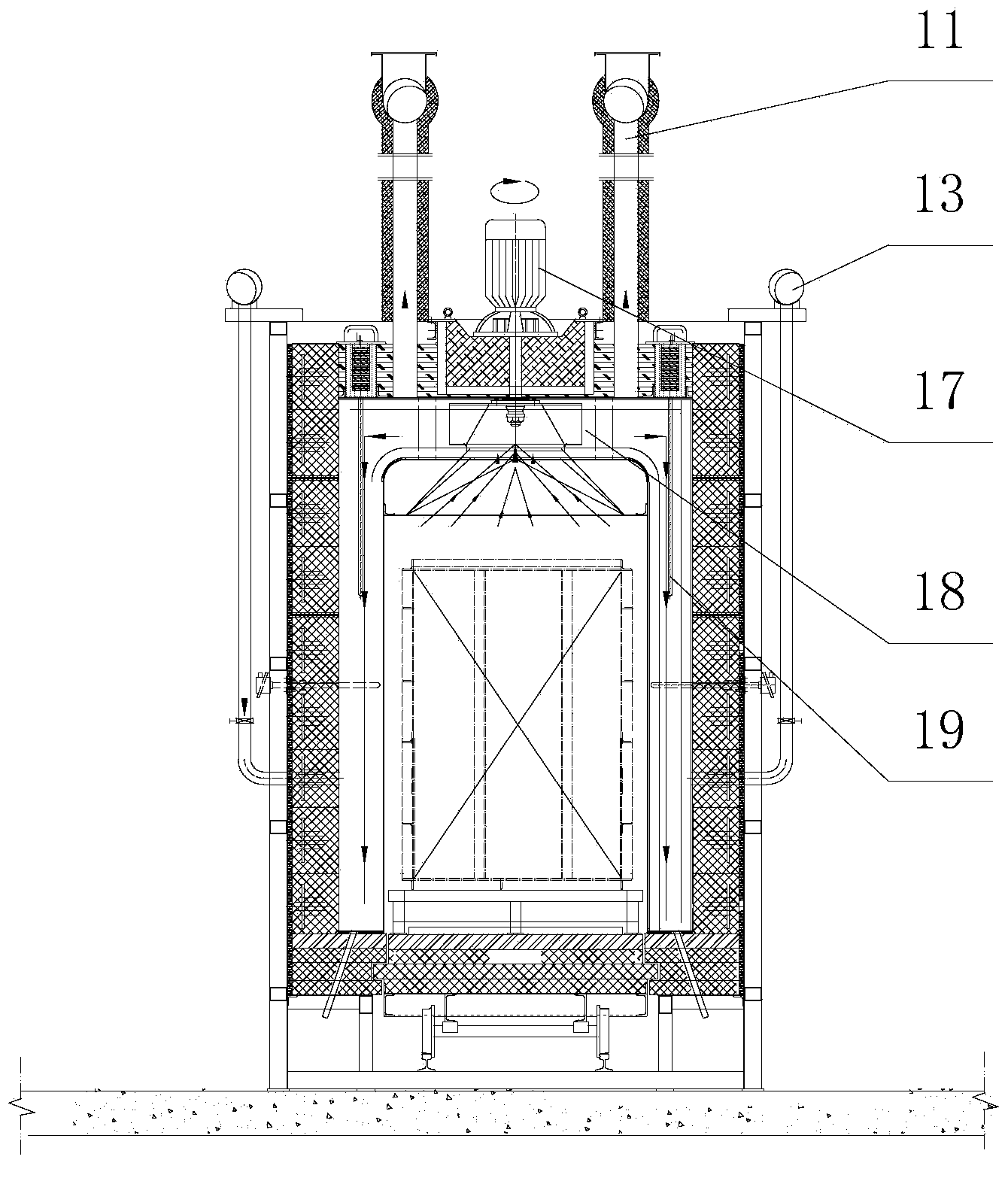

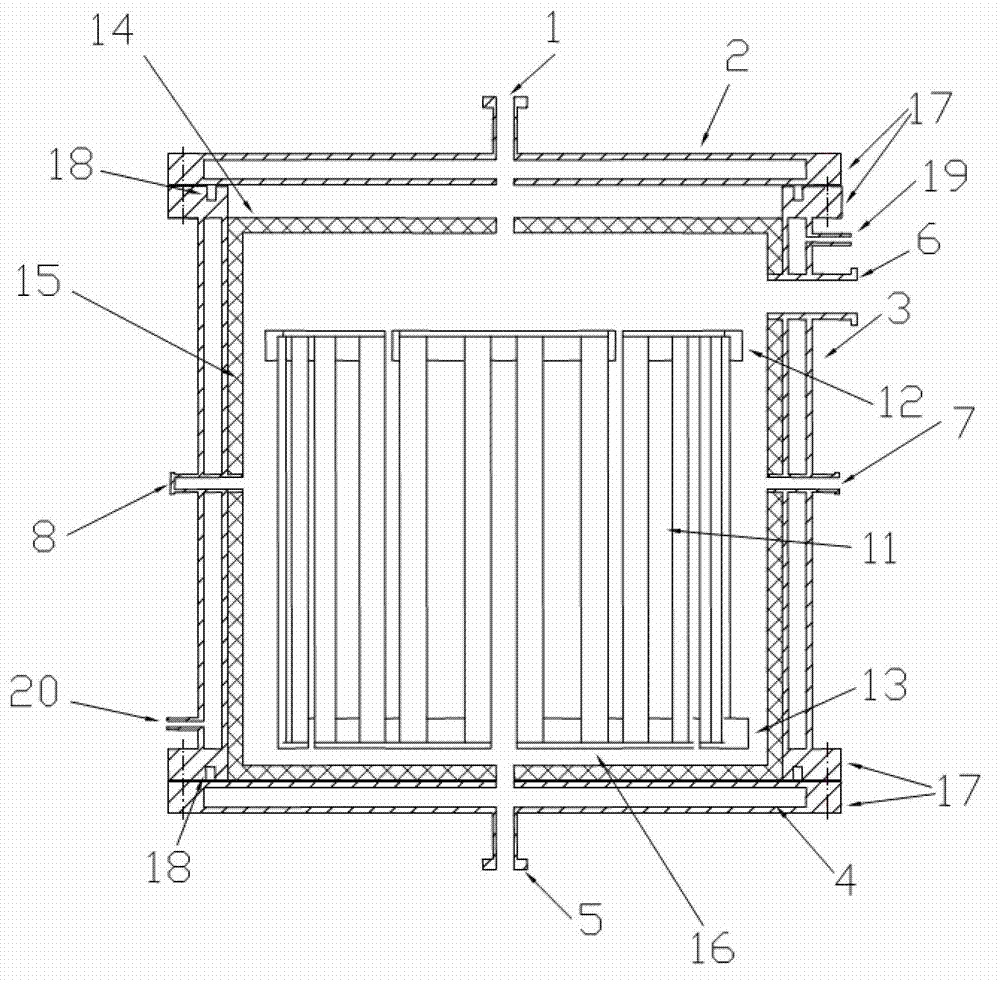

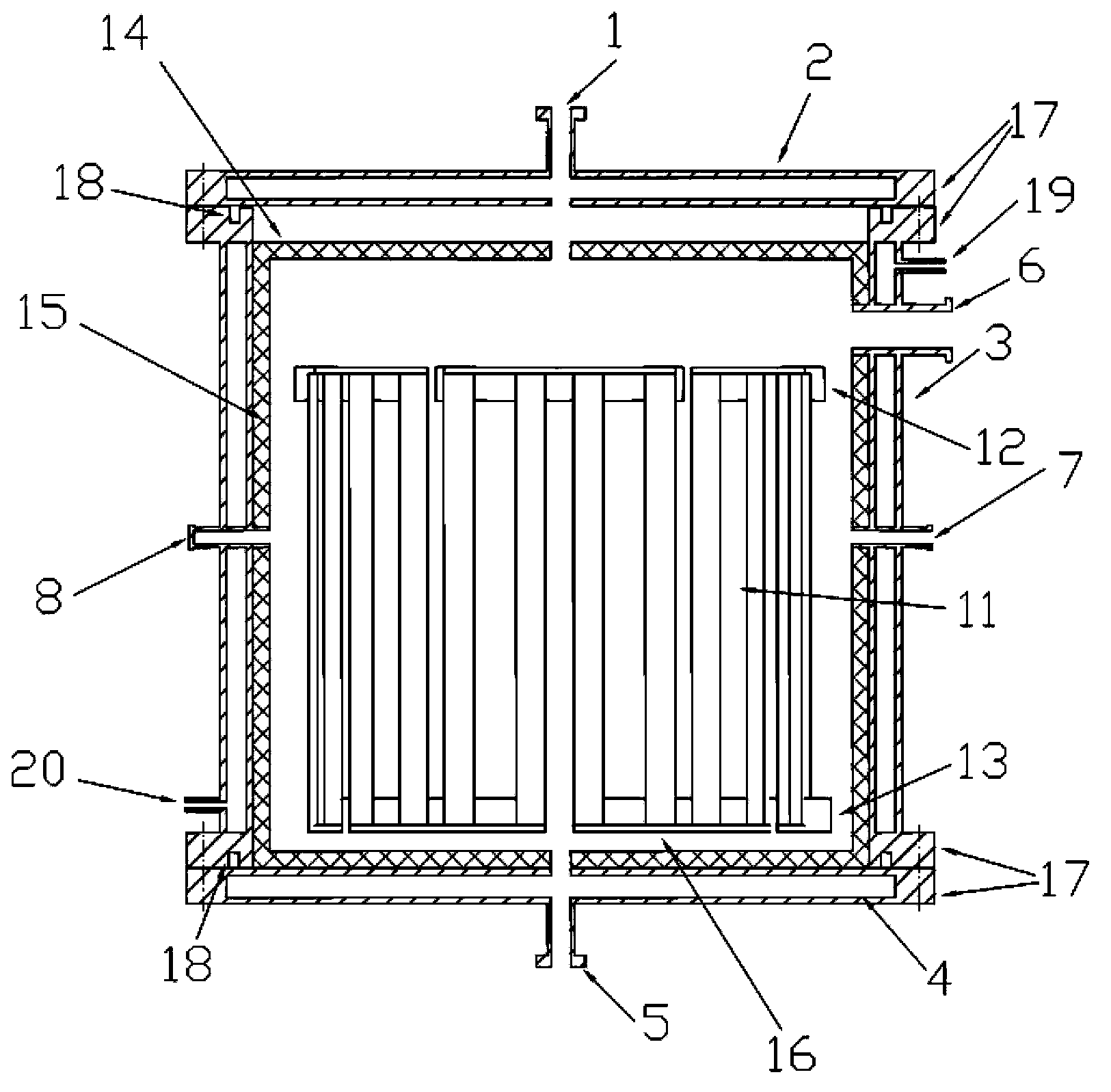

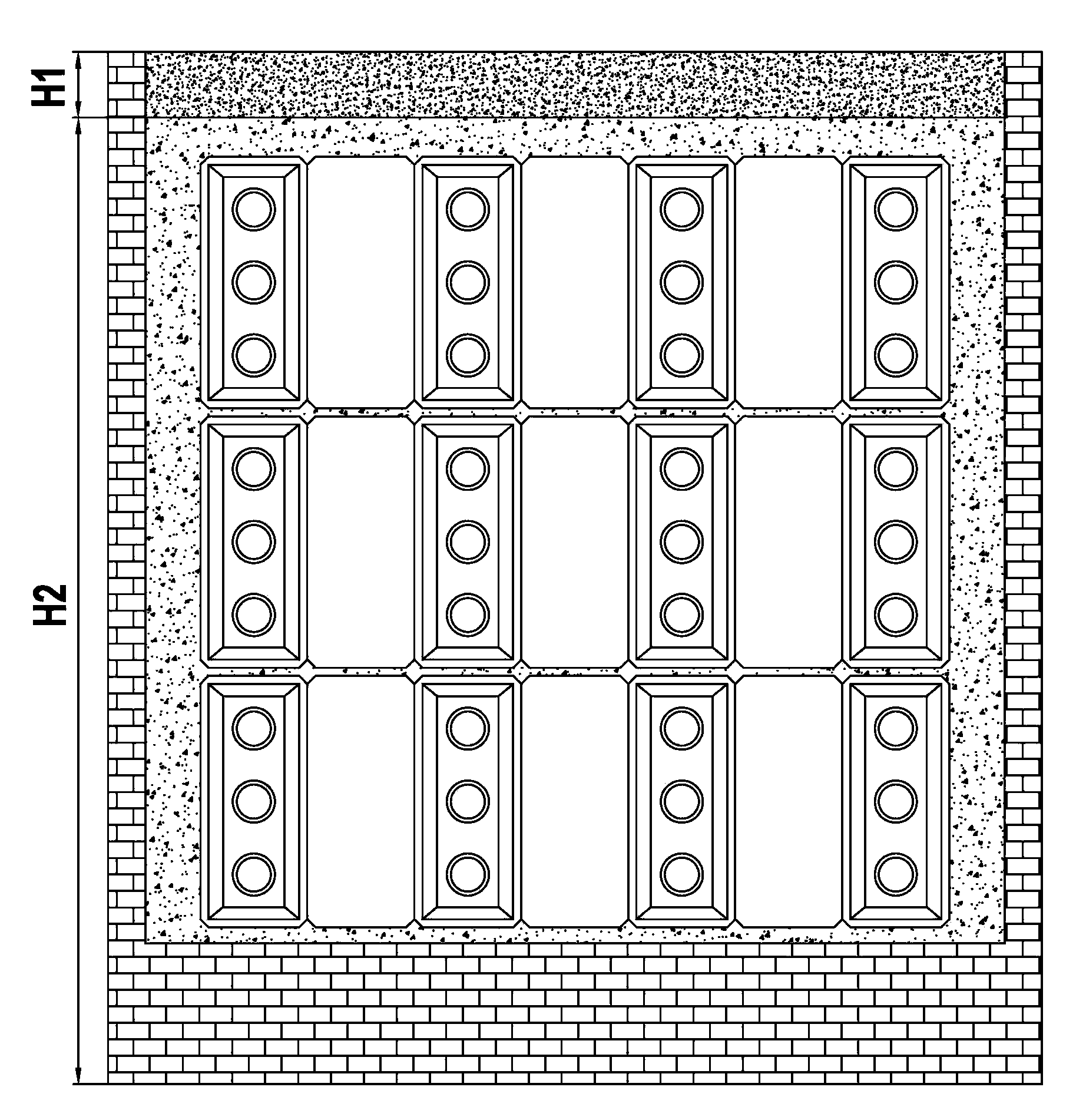

Well type high-temperature resistance furnace for heat treatment of PAN (polyacrylonitrile) based carbon felt

ActiveCN102878796ASimple structureLow costElectric heating for furnacesVertical furnacesInsulation layerCarbon felt

The invention discloses a well type high-temperature resistance furnace for the heat treatment of a PAN (polyacrylonitrile) based carbon felt. A heating body is placed at a center position in a furnace body; an upper circulation water tank is fixed at the upper surface of an upper heat insulation cover; and a lower circulation water tank is fixed at the lower end of the furnace body. The graphite plates of the heating body and annular graphite connection plates are arranged via the way that every two are connected in parallel and every four are connected in series, and are connected in a triangular shape by three electrodes. A water channel is arranged in the upper circulation water tank and the lower circulation water tank. The housing of the furnace body is an interlayer; and the interlayer space forms a channel of circulation water. With the adoption of the heating body, the temperature difference of a hearth uniform temperature zone ranges from 10 degrees centigrade below zero to 10 degrees centigrade. The circulation water of the cover and the bottom of the furnace body and the furnace body can uniformly and directionally flow, so that the heat radiation of the hearth can be effectively shielded, and the outer wall temperature of the furnace body is not higher than 25 degrees centigrade. With the adoption of the heat insulation layer in the furnace body, the hearth can be effectively heated, so that energy consumption is reduced; and the channel, which is simple in structure and reasonable to arrange, is convenient to maintain and exchange.

Owner:XIAN KANGBEN MATERIAL

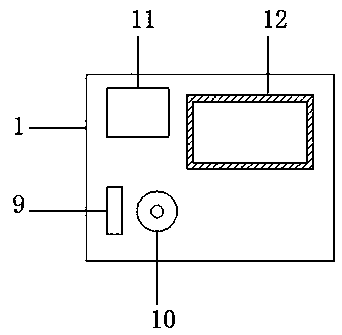

Determination instrument for softening point of ointment

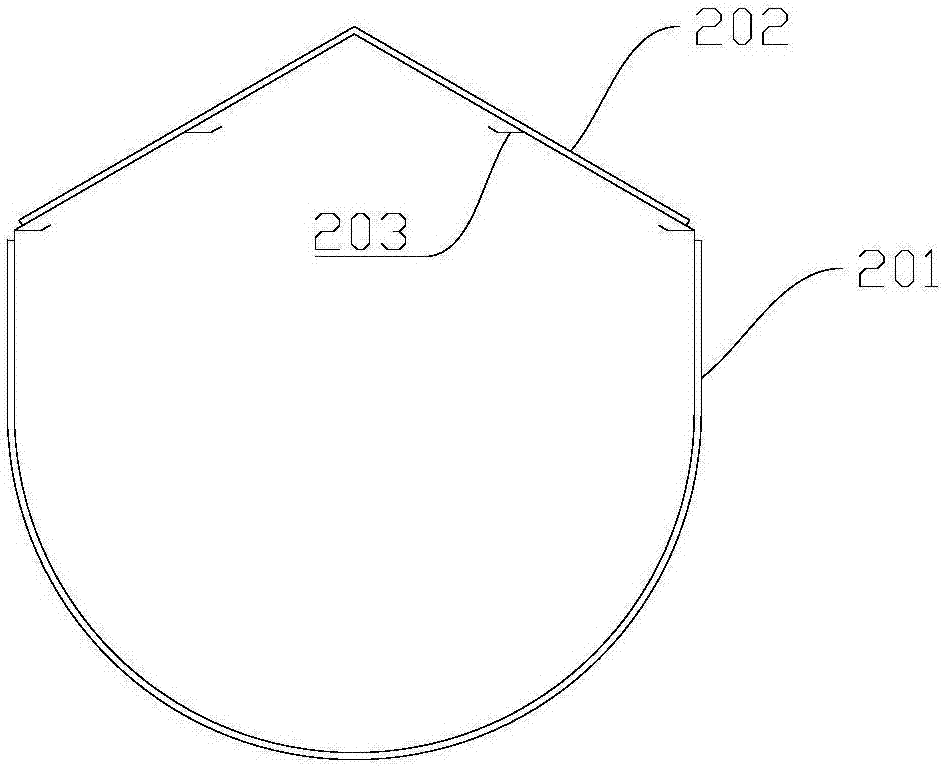

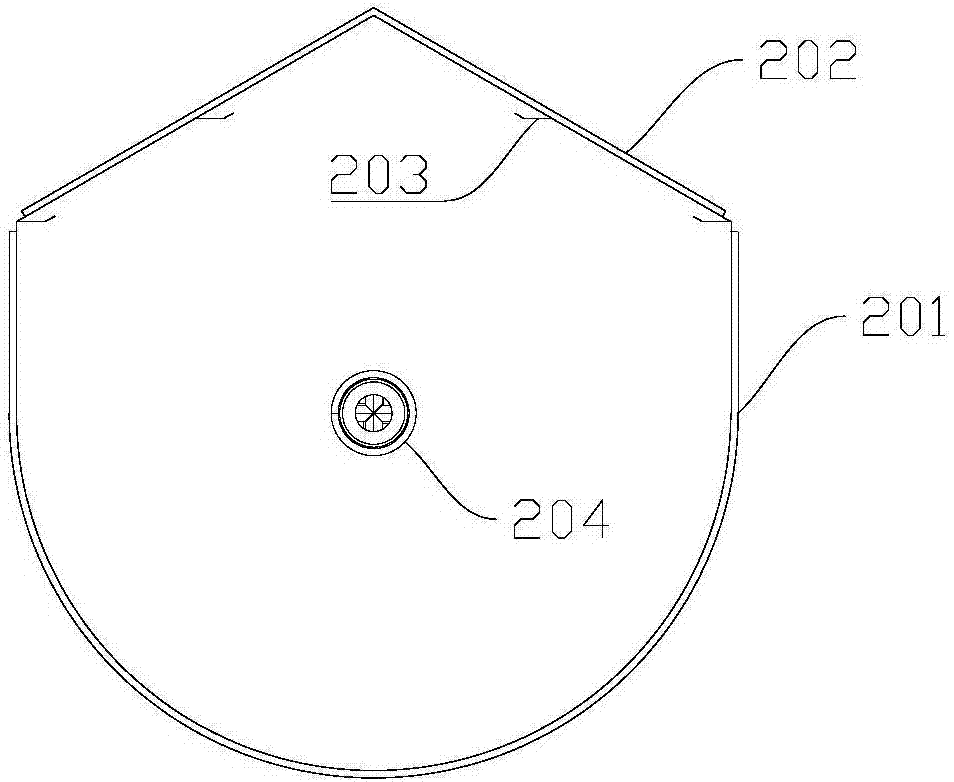

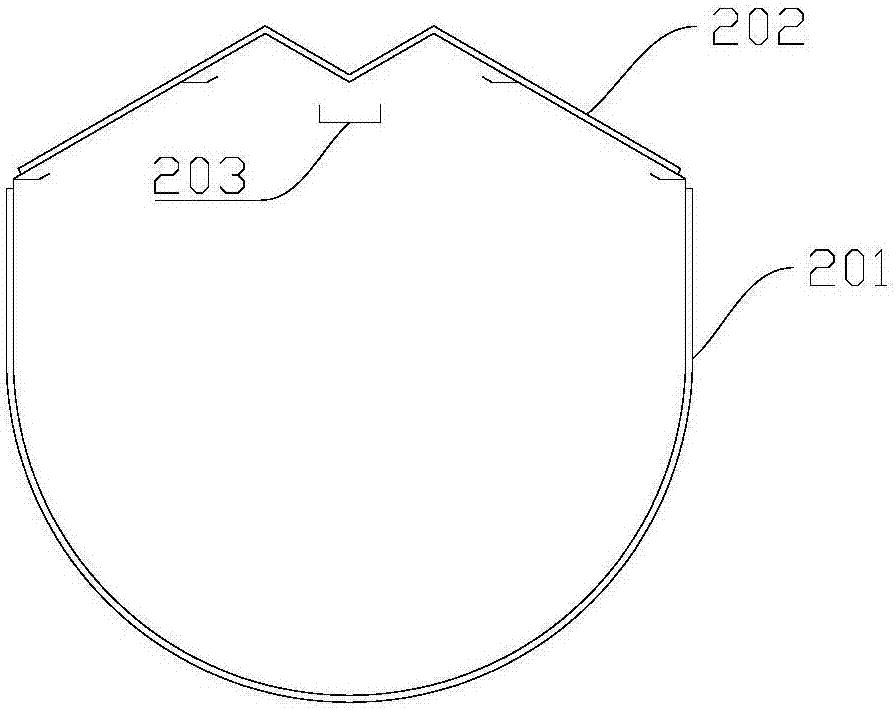

InactiveCN1793877AGuaranteed heating rateGuaranteed temperatureInvestigating phase/state changeWater bathsAutomatic control

An analyzer of plaster softening point is prepared as setting beaker positioning ring at center of heating plate being set between its top cover and bottom cover, fixing said bottom cover on support frame through support column, setting fan in box and fixing it on box base through bolts. It is featured as using control circuit to control on and off of solid relay according to water bath temperature collected by temperature transducer, controlling water bath temperature by controlling the heating wire for satisfying requirement of each stage in analyzing course.

Owner:天津市罗根科技有限公司

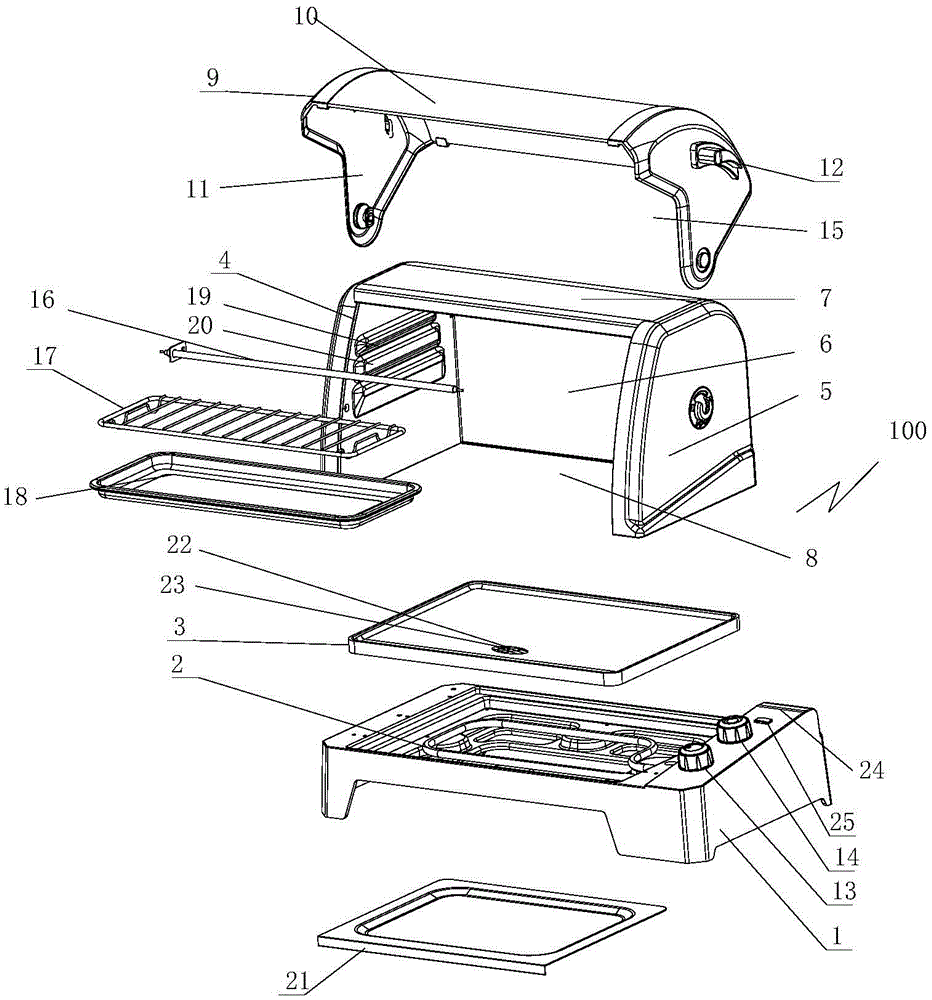

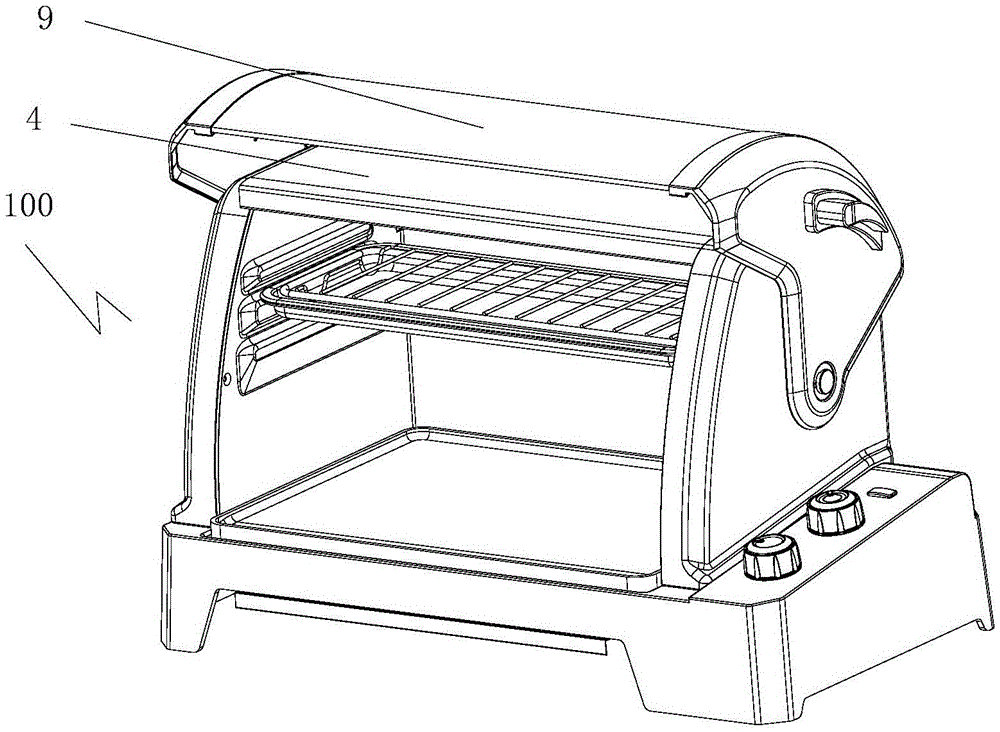

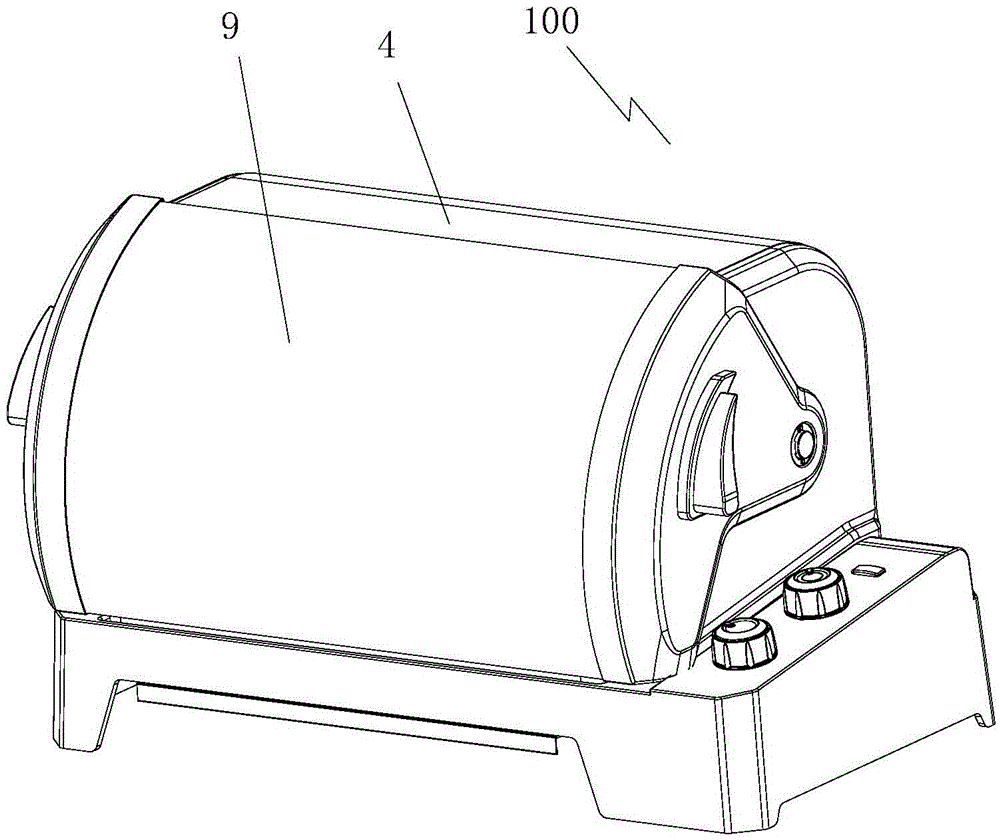

Frying and baking machine

InactiveCN105534333AReduce energy lossGuaranteed heating rateFrying pansEngineeringMechanical engineering

The invention provides a frying and baking machine which comprises a base, a lower heating piece, a baking plate and an oil shielding assembly. The lower heating piece is arranged on the base. The baking plate is detachably arranged on the base and located above the lower heating piece. The oil shielding component is connected with the base and comprises two side plates and a rear plate, wherein the two side plates are oppositely arranged on the two sides of the baking plate, and the rear plate is connected with the two side plates and arranged on the rear side of the baking plate. The frying and baking machine can prevent oil stains from splashing around when frying and baking food, and thus the cleanness of the surrounding environment is maintained.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Energy-saving heat-preservation oil tank

InactiveCN110254980AGuaranteed heating rateGuaranteed cooling speedLarge containersTank wagonsEngineeringControl switch

The invention discloses an energy-saving heat-preservation oil tank. The energy-saving heat-preservation oil tank comprises a shell, a feeding port, a tank body, a heating plate, a control cabinet, a refrigerating plate, supporting legs, a discharging port, a control switch, a button, a controller and a display screen, wherein the feeding port is formed right above the shell, the feed port is fixed on the shell through a screw, the discharging port is fixed at the bottom of the inner side of the shell through a screw, an electromagnetic valve is arranged at the discharging port, the tank body is arranged below the feeding port, the tank body is fixed inside the shell through a screw, a crude oil is poured into a tank body device, the tank body device is electrified, the controller, the control cabinet and the temperature sensor are started by the control cabinet, and the heating plate or the refrigerating plate is started; and the electromagnetic valve is arranged at the discharging port, buttons are connected with the electromagnetic valve through cables, and the control cabinet is fixed on the shell through a screw, the temperature sensor is fixed to the right side of the inner side of the shell through a screw. The energy-saving heat-preservation oil tank is used for controlling the switch, the buttons, the display screen and the temperature sensor in real time through the controller, the contact area is designed through the circular truncated cone at the bottom of the tank body, the heat energy consumption speed of the crude oil storage tank is reduced, and the energy-saving and heat-preserving effects are achieved.

Owner:重庆金徽博鑫工艺品有限公司

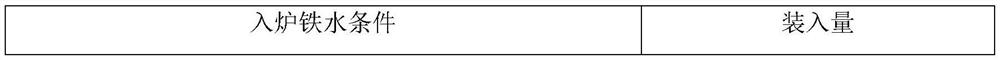

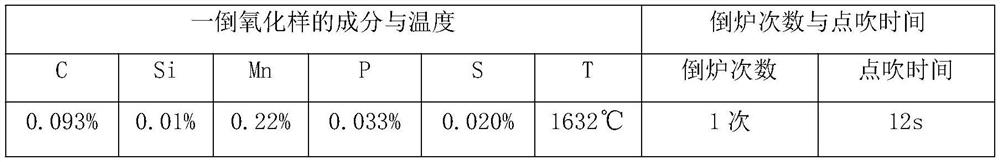

Method for improving proportion of residual manganese at end point of converter

ActiveCN114622054AIncreased manganese ratioIncreased manganese contentManufacturing convertersSlagManganese

The invention provides a method for increasing the proportion of residual manganese at the end point of a converter. The method comprises the following steps: controlling the temperature of molten iron entering the converter to be more than or equal to 1350-1380 DEG C, the C content of the molten iron to be more than or equal to 4.5%, the Si content of the molten iron to be less than or equal to 0.5% and the Mn content of the molten iron to be less than or equal to 0.45%, and ensuring that Mn / Si is controlled In the blowing process, low-gun high-pressure operation is adopted in the early stage; medium-low gun and medium-pressure cooperative control is adopted in the middle stage; adjusting slag by adopting a high gun and medium and high pressure in the later stage; therefore, it is guaranteed that the proportion of residual manganese in molten steel at the end point is stably controlled to be 55%-65% on the whole, the proportion of the residual manganese in the molten steel is increased by 10%-15%, the content of the residual manganese is increased by 0.043%-0.065%, the content of the residual manganese is increased to 0.24%-0.28%, and the cost of per ton of steel is reduced by 4.96 yuan / t to 7.5 yuan / t; and the end point molten steel C is increased by 0.02%, the end point slag TFe is reduced by about 2%, and the Mn alloy yield is increased by 2.7%.

Owner:SHANDONG IRON & STEEL GRP YONGFENG LINGANG CO LTD

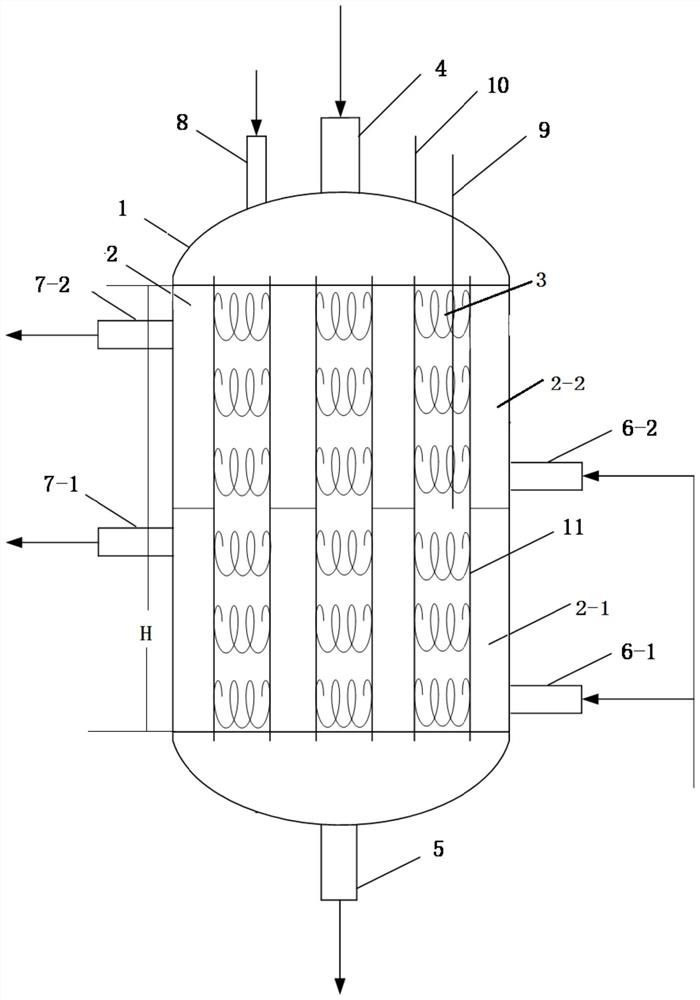

Static crystallizer and static crystallization method

ActiveCN113877235AImprove compactnessGuaranteed heat transfer efficiencyHeat exchange cooling cystallizationCrystallization regulation/controlProcess engineeringIndustrial engineering

The invention relates to the technical field of static crystallization, and particularly discloses a static crystallizer and a static crystallization method. The static crystallizer comprises a shell and a cavity formed in the shell, wherein at least one heat exchange pipe is arranged in the cavity, telescopic parts are arranged in the heat exchange pipes, and the telescopic direction of the telescopic part is not parallel to the axial direction of the heat exchange pipe. The method is carried out in the specific static crystallizer, so the heat exchange efficiency of a static crystallization process can be remarkably improved, the uniformity of crystallization and sweating processes is ensured, a high-purity and high-yield crystallization product is obtained, and the energy consumption of the crystallization process can be further reduced; and the method can be applied to industrial production of static crystallization, especially to purification and separation of high-end fine chemicals or high-added-value products with high purity requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

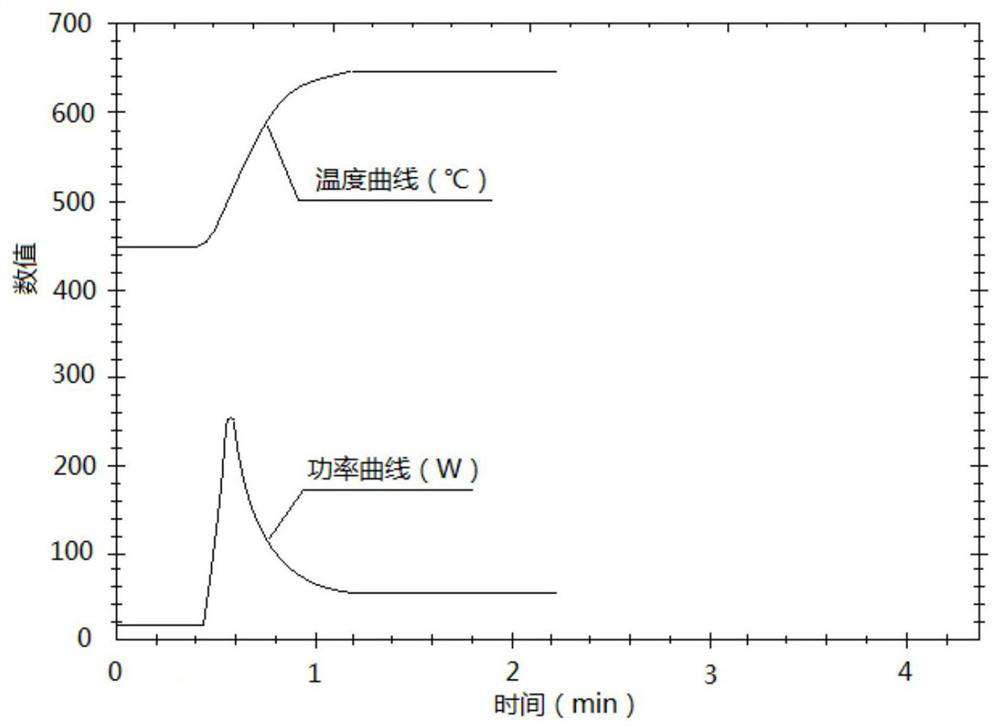

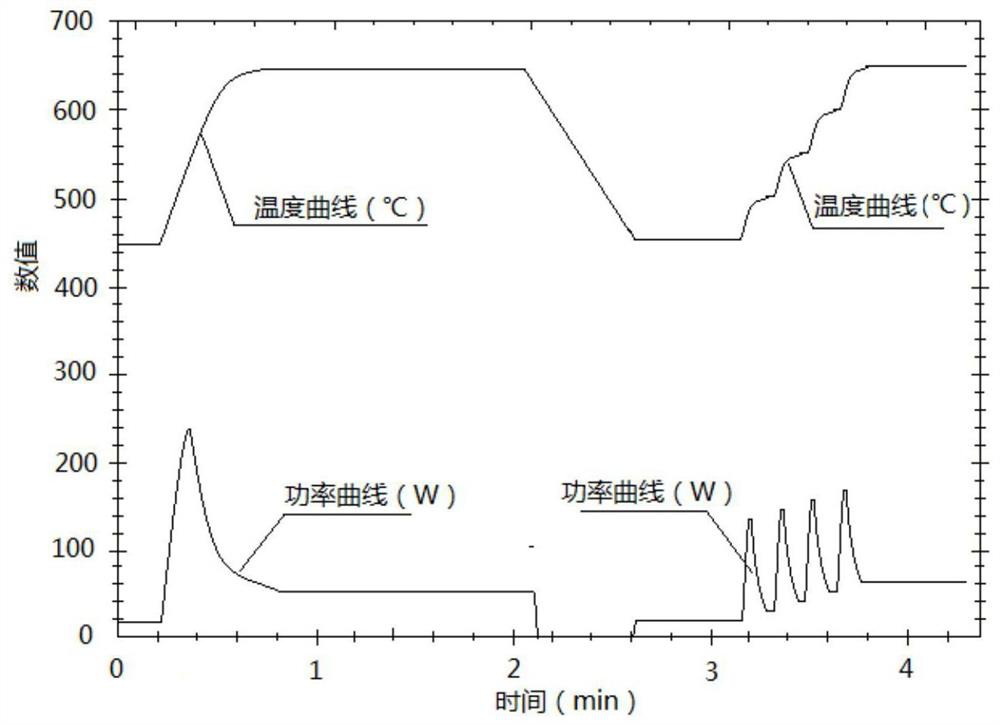

Temperature control method and system, semiconductor device

ActiveCN111501004BGuaranteed heating rateGuaranteed accuracyVacuum evaporation coatingSemiconductor/solid-state device manufacturingTemperature controlDevice material

The present invention provides a temperature control method and system, and semiconductor equipment. The method includes the following steps: S1, use a heating device to heat the workpiece to be processed, and adjust the output power of the heating device according to a preset power adjustment rule during the heating process , until the temperature of the processed workpiece reaches the preset first target value, wherein the first power adjustment rule is used to control the output power of the heating device to increase as the temperature of the processed workpiece increases; S2, using the heating device to continue to The processed workpiece is heated, and the temperature value of the processed workpiece is detected in real time during the heating process, and the output power of the heating device is adjusted according to the temperature value, so that the temperature of the processed workpiece reaches a preset target value. The technical solution of the temperature control method and system provided by the present invention can reduce the fluctuation of heating power and effectively reduce the occurrence of broken disks on the basis of ensuring the heating rate.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Well type high-temperature resistance furnace for heat treatment of PAN (polyacrylonitrile) based carbon felt

ActiveCN102878796BSimple structureLow costElectric heating for furnacesVertical furnacesCarbon feltHearth

The invention discloses a well type high-temperature resistance furnace for the heat treatment of a PAN (polyacrylonitrile) based carbon felt. A heating body is placed at a center position in a furnace body; an upper circulation water tank is fixed at the upper surface of an upper heat insulation cover; and a lower circulation water tank is fixed at the lower end of the furnace body. The graphite plates of the heating body and annular graphite connection plates are arranged via the way that every two are connected in parallel and every four are connected in series, and are connected in a triangular shape by three electrodes. A water channel is arranged in the upper circulation water tank and the lower circulation water tank. The housing of the furnace body is an interlayer; and the interlayer space forms a channel of circulation water. With the adoption of the heating body, the temperature difference of a hearth uniform temperature zone ranges from 10 degrees centigrade below zero to 10 degrees centigrade. The circulation water of the cover and the bottom of the furnace body and the furnace body can uniformly and directionally flow, so that the heat radiation of the hearth can be effectively shielded, and the outer wall temperature of the furnace body is not higher than 25 degrees centigrade. With the adoption of the heat insulation layer in the furnace body, the hearth can be effectively heated, so that energy consumption is reduced; and the channel, which is simple in structure and reasonable to arrange, is convenient to maintain and exchange.

Owner:XIAN KANGBEN MATERIAL

Primary baking process for increasing aroma richness of tobacco leaves

The invention discloses a primary baking process for increasing the aroma richness of tobacco leaves, and discloses a primary baking process for increasing the aroma volume of tobacco leaves. The process comprises a tobacco leaf yellowing period, a withering period, a color fixing period and a stem drying period. The method is technically characterized in that (1) in the yellowing stage, medium temperature and medium humidity are combined, and tobacco leaves are gradually yellowed; (2) in the withering period, high temperature and high humidity are combined, and the tobacco leaves are properlywithered; (3) in the color fixing period, cooling and humidifying are carried out and the leaves are slowly dried; and (4) in the stem drying stage, the temperature is controlled, the humidity is adjusted and stems are slowly dried.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

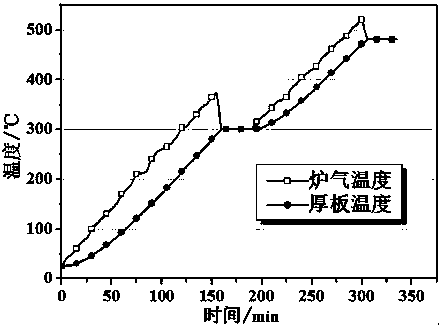

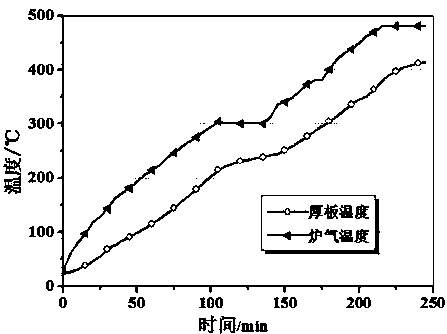

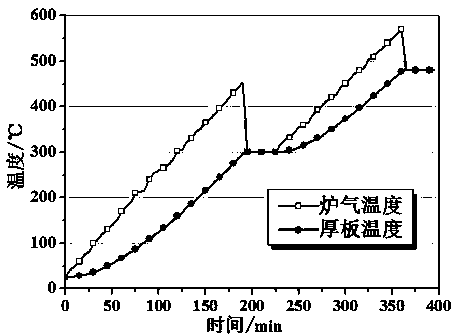

Furnace quick warming method for two-stage solution of aluminum alloy

The invention discloses a furnace quick warming method for a two-stage solution of an aluminum alloy. The method comprises the following steps of: firstly, heating the furnace gas temperature to be far higher than a first-stage solution temperature of the aluminum plate, then quickly reducing the furnace gas temperature to the first-stage solution temperature, and keeping the temperature; and thenquickly heating the furnace gas temperature to be far higher than a second-stage solution temperature of the aluminum plate, then reducing the furnace gas temperature to the second-stage solution temperature, and keeping the temperature. The heating method for each-stage warming can be divided into three stages: a fast heating stage, a fast cooling stage and an insulating stage. The key point isthat the furnace gas heating temperature of the quick heating stage is calculated accurately. The method can heat the temperature of an aluminum alloy material to the solution temperature quickly andefficiently, so that the heat treatment time is shortened and the production efficiency is increased; meanwhile, the performance loss caused by long-time heating can be avoided. The process method issimple to operate and cost-saving, and has actual industrial production and application value.

Owner:CENT SOUTH UNIV

Domestic garbage fermenting container and device

PendingCN107377581AReduce heating rateDelay the ripening processSolid waste disposalTransportation and packagingDecompositionDomestic waste

The invention discloses a domestic garbage fermenting container and device and belongs to the field of environment-friendly equipment. A condensate water stopping device is arranged on the top of the fermenting container and used for stopping condensate water volatilized and condensed in the fermenting process and preventing the condensate water from flowing back to materials again. According to the domestic garbage fermenting container, as the condensate water stopping device is additionally arranged in a cylinder body of the fermenting container and stops the condensate water, fermenting temperature and temperature rising speed can be ensured, and drying and decomposition of materials are accelerated.

Owner:浙江传超环保科技有限公司

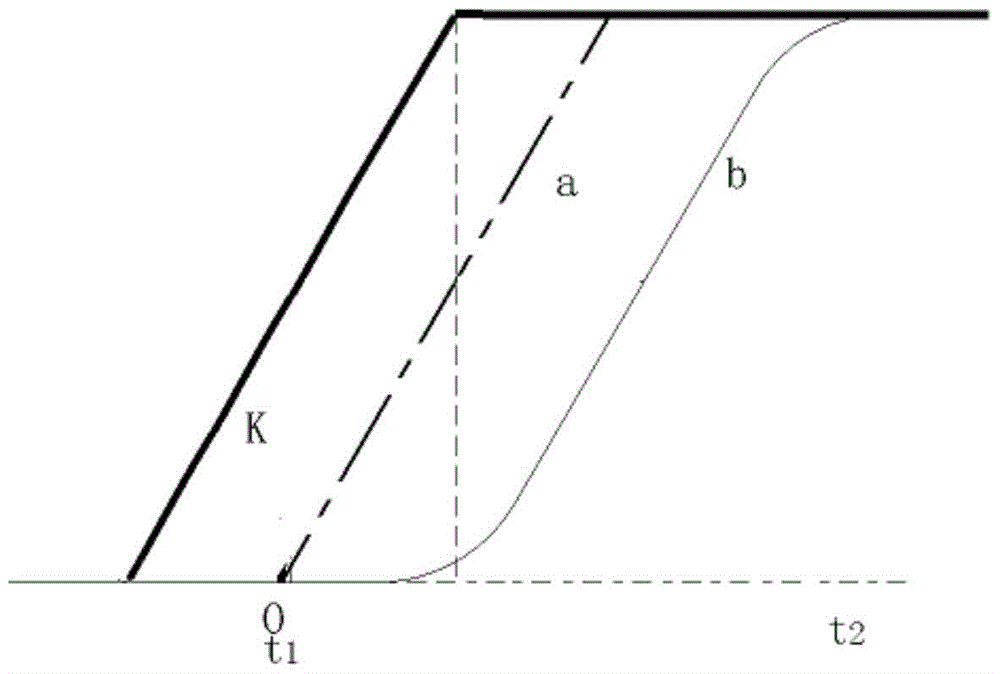

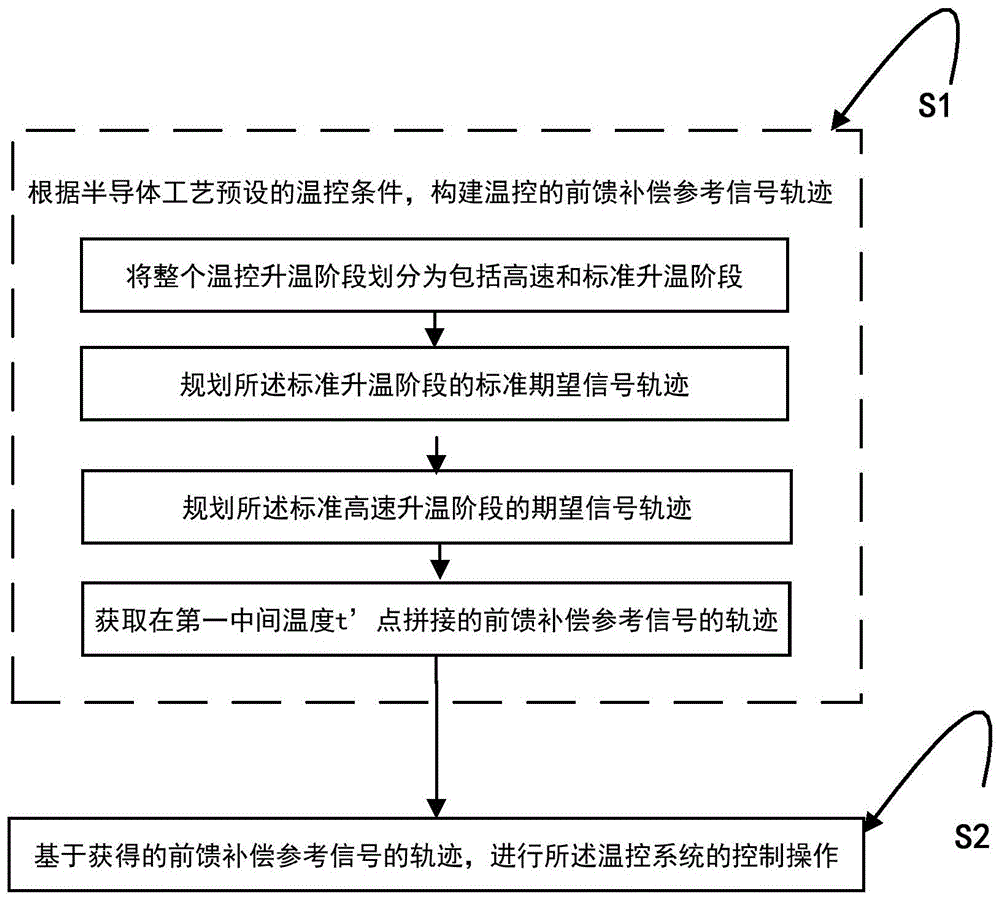

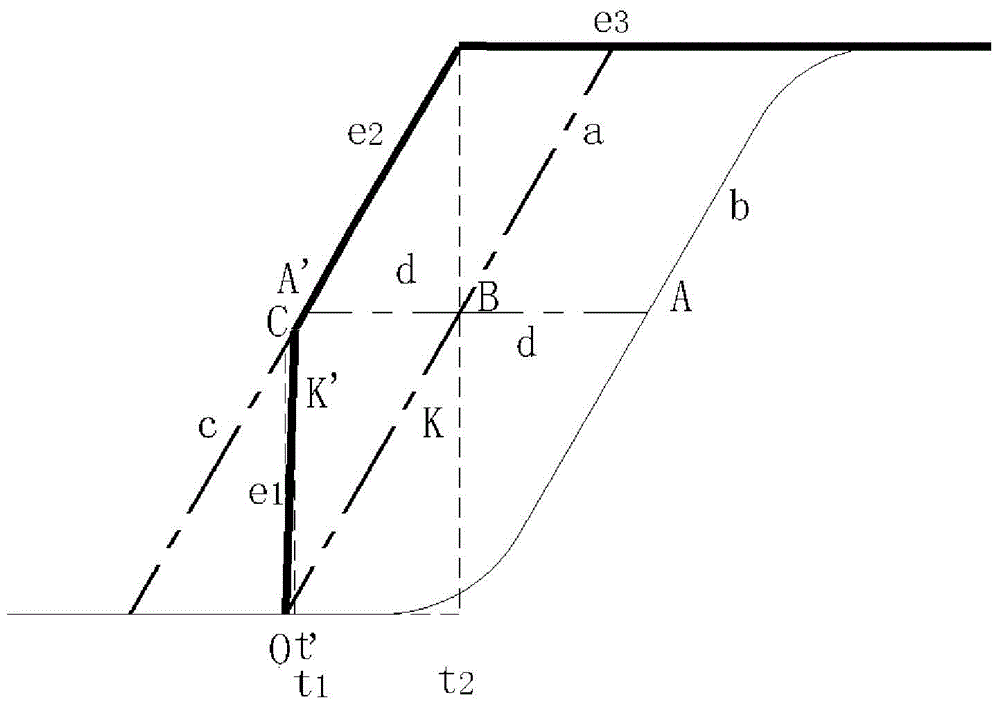

A temperature control method for semiconductor process equipment with feed-forward compensation

ActiveCN104298268BIncrease production capacityReduce the effect of time lagTemperatue controlTemperature controlEngineering

Disclosed is a temperature control method of semiconductor technology equipment with feedforward compensation. The semiconductor technology equipment comprises temperature control devices in one or more temperature control areas. The method comprises the steps that according to the preset temperature control condition of a semiconductor technology, feedforward compensation reference signal tracks of the temperature control devices are constructed, the whole temperature control temperature rise period is divided into a high-speed temperature rise period and a standard temperature rise period, the temperature rise process from initial temperature t to first intermediate temperature t' is completed in the high-speed temperature rise period, and the temperature rise process from the first intermediate temperature t' to target temperature T is completed in the standard temperature rise period; reference signal tracks in the standard temperature rise period meet the preset temperature control condition, and the temperature rise speed of the high-speed temperature rise period is higher than that of the standard temperature rise period; control operation of the temperature control system is carried out based on the obtained feedforward compensation reference signal tracks. The influence of the time lag of the temperature control system can be weakened, the temperature rise effect of a furnace can be improved, and the productivity of the semiconductor technology equipment can be improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

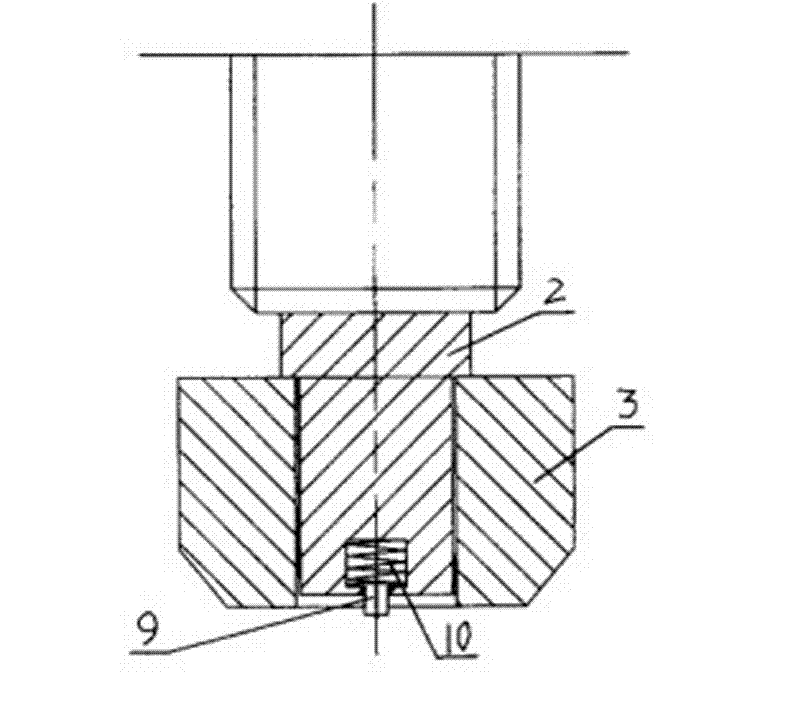

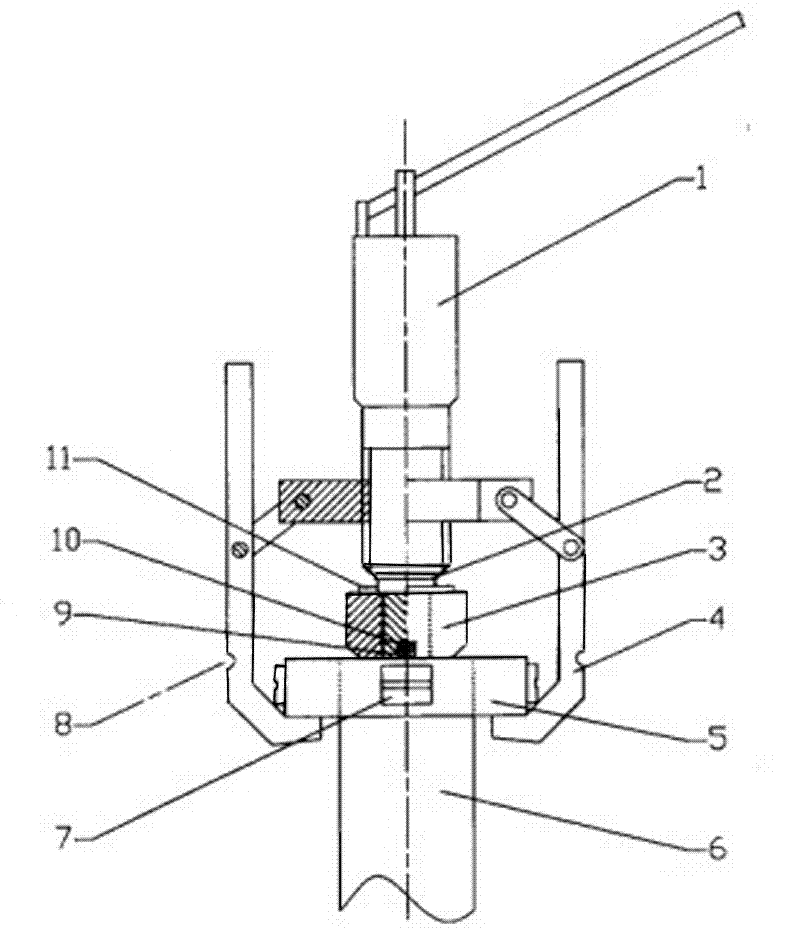

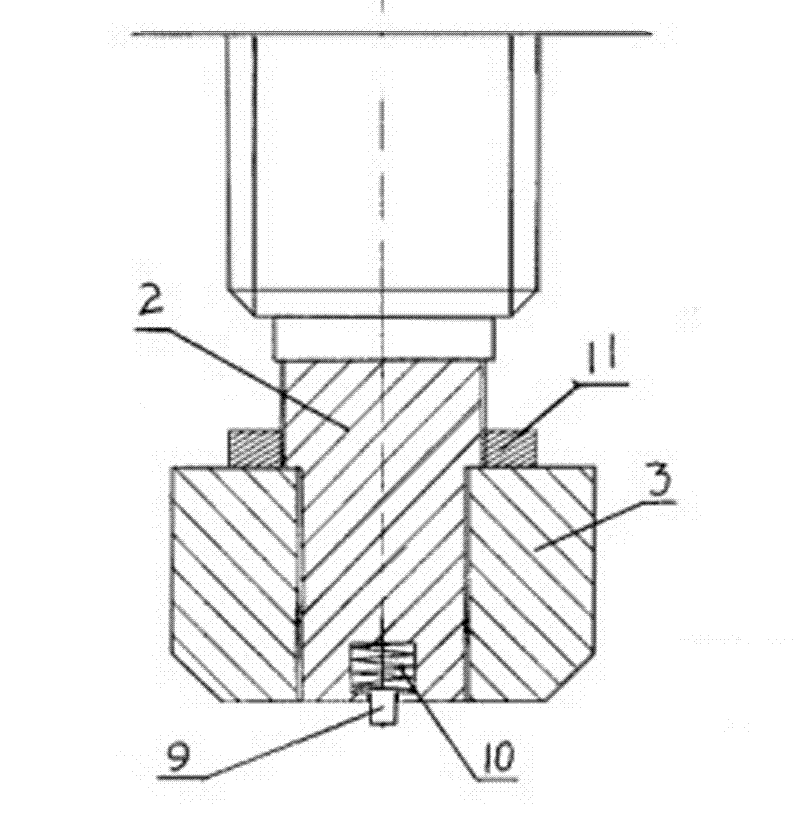

Heating vibration screw extractor

InactiveCN101829974BReduce frictionSolve the difficult situation of disassemblyMetal-working hand toolsScrew extractorInduction heater

The invention relates to a screw extractor, in particular to a heating vibration screw extractor. The invention solves the problem that the existing screw extractor is hard to disassemble some shaft fastening pieces with tight fitness. The heating vibration screw extractor comprises a mandrel and a falcula connected with the mandrel, wherein a vibrator with adjustable vibration frequency is arranged on the top of the mandrel; the screw extractor also comprises a group of high frequency induction heaters, wherein a magnet is arranged on one end of each high frequency induction heater. When in use, the high frequency induction heaters heat the outer surfaces of the parts to be disassembled so as to reduce the interference degree between the parts to be disassembled; and the parts to be disassembled perform strong resonance vibration under the action of the vibrator so as to greatly reduce the friction force between the parts to be disassembled. In order to solve the situation that the friction force between the parts to be disassembled is too large, the vibrator is installed on the mandrel of the screw extractor of the invention to perform forced vibration of the parts to be disassembled and the heating device is added on the screw extractor, thus greatly reducing the friction force between the parts to be disassembled and solving the condition that the original screw extractor is hard to be used for disassembly.

Owner:TAIYUAN COAL GASIFICATION GROUP

Rotary kiln for calcining refinery coke

The invention discloses a petroleum coke calcining rotary kiln, which comprises a rotary kiln(9); an insert plate valve(1) is arranged below a calcining front chamber; an adhesive tape constant feeder(2) is arranged below the insert plate valve, and an adhesive tape conveyer(3) is arranged behind the adhesive tape constant feeder (2) and connected with the rotary kiln(9) by an oblique cutting feed tipping tube of an electric insert plate valve(6); the tail part of the rotary kiln(9) is connected with a dust deposition chamber(8), and the head part of the rotary kiln(9) is connected with a cooling machine(16) and provided with a burner nozzle(13) and a burner nozzle hanger(14); the petroleum coke calcining rotary kiln is also provided with a one-time combustion fan(10) matched with the burner nozzle; and a dust-containing waste gas processing system(15) is arranged beside the cooling machine(16). The petroleum coke calcining rotary kiln has the advantages of improving the unit volume capacity, greatly enhancing comprehensive utilization of waste heat and adaptability of other calcining materials such as needle coke, anthracite and the like, reducing burning loss of charcoal, savingraw materials and energy, improving automatization level and reducing labor intensity of a worker.

Owner:GUIYANG AL-MG DESIGN & RES INST

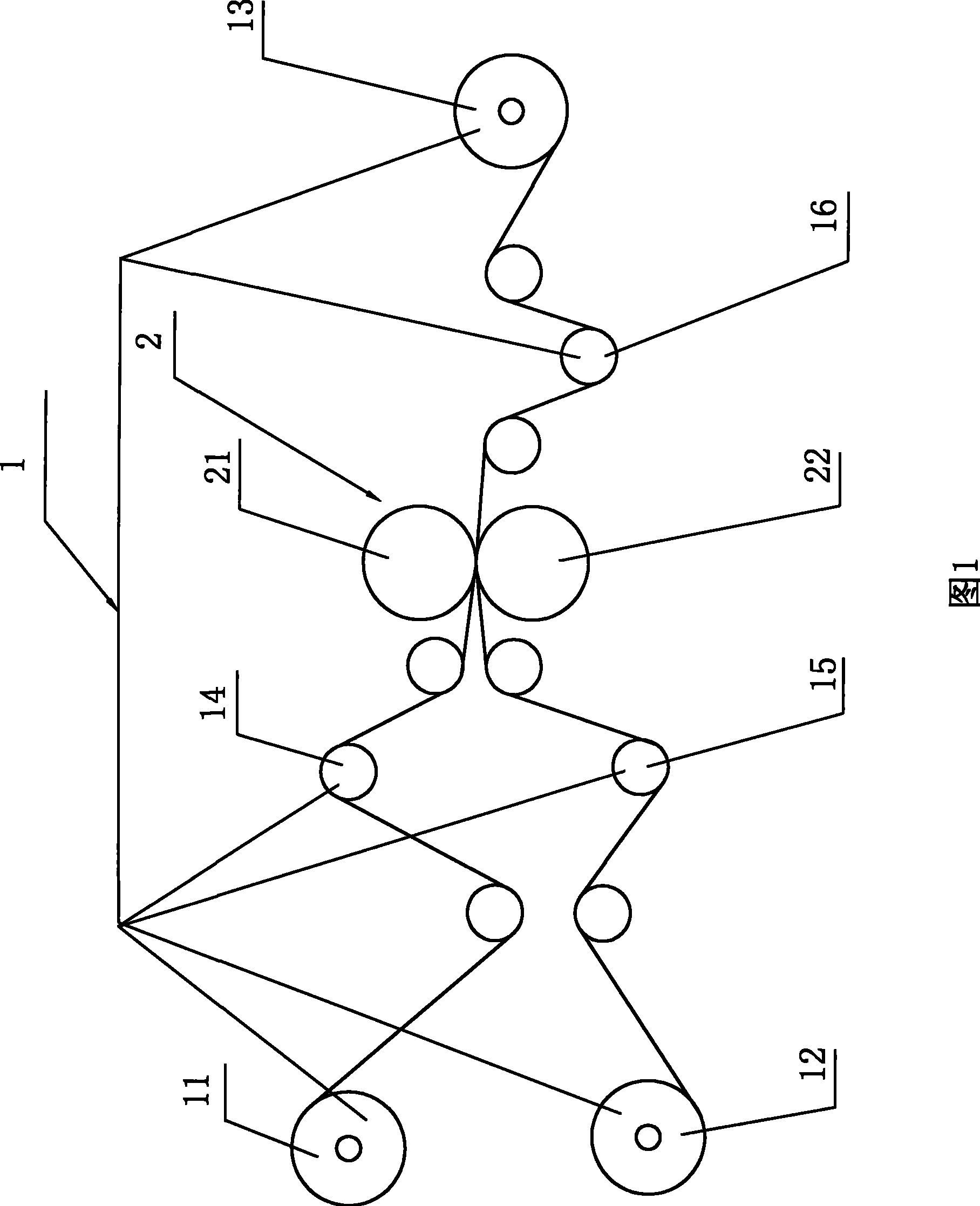

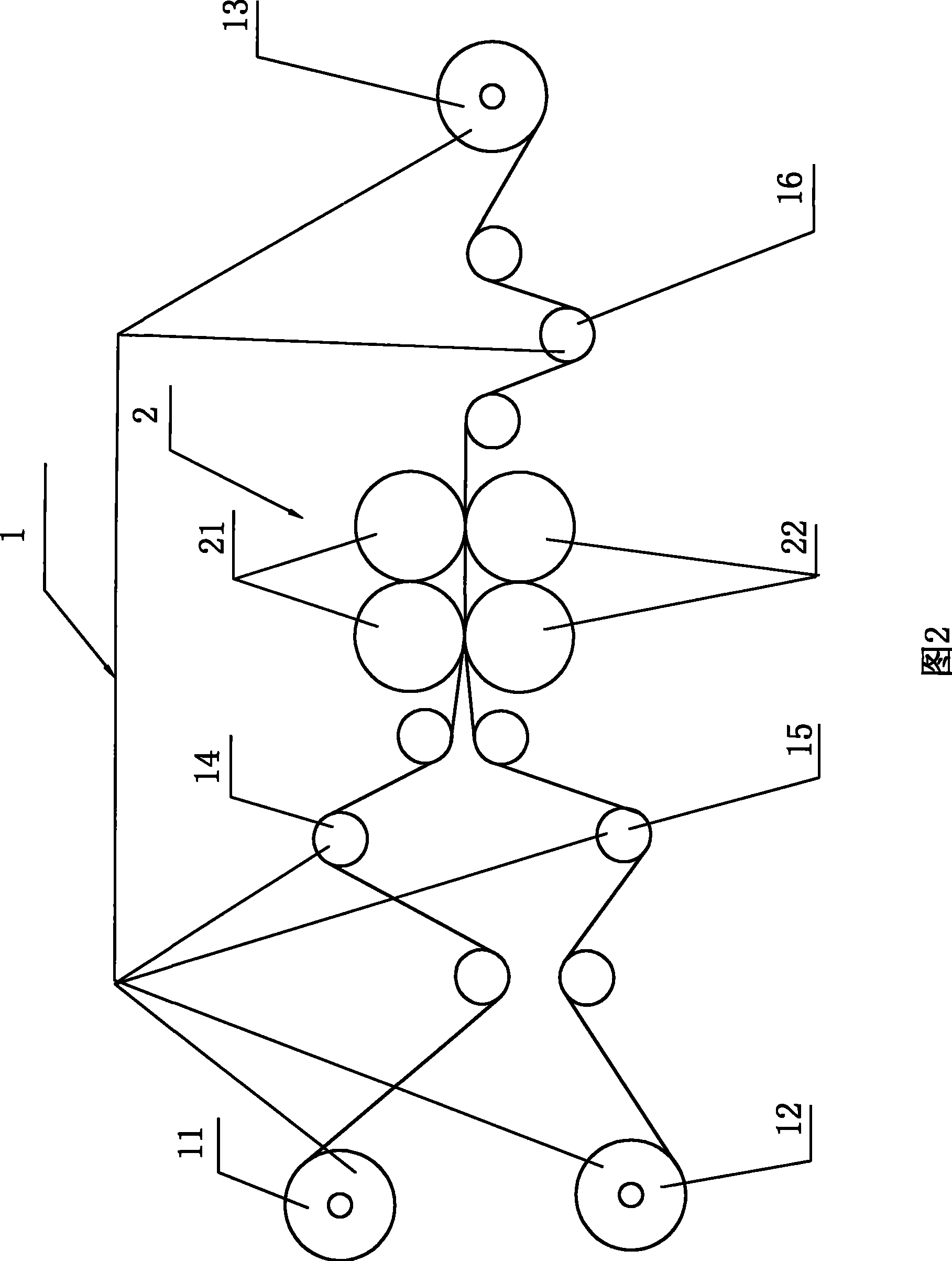

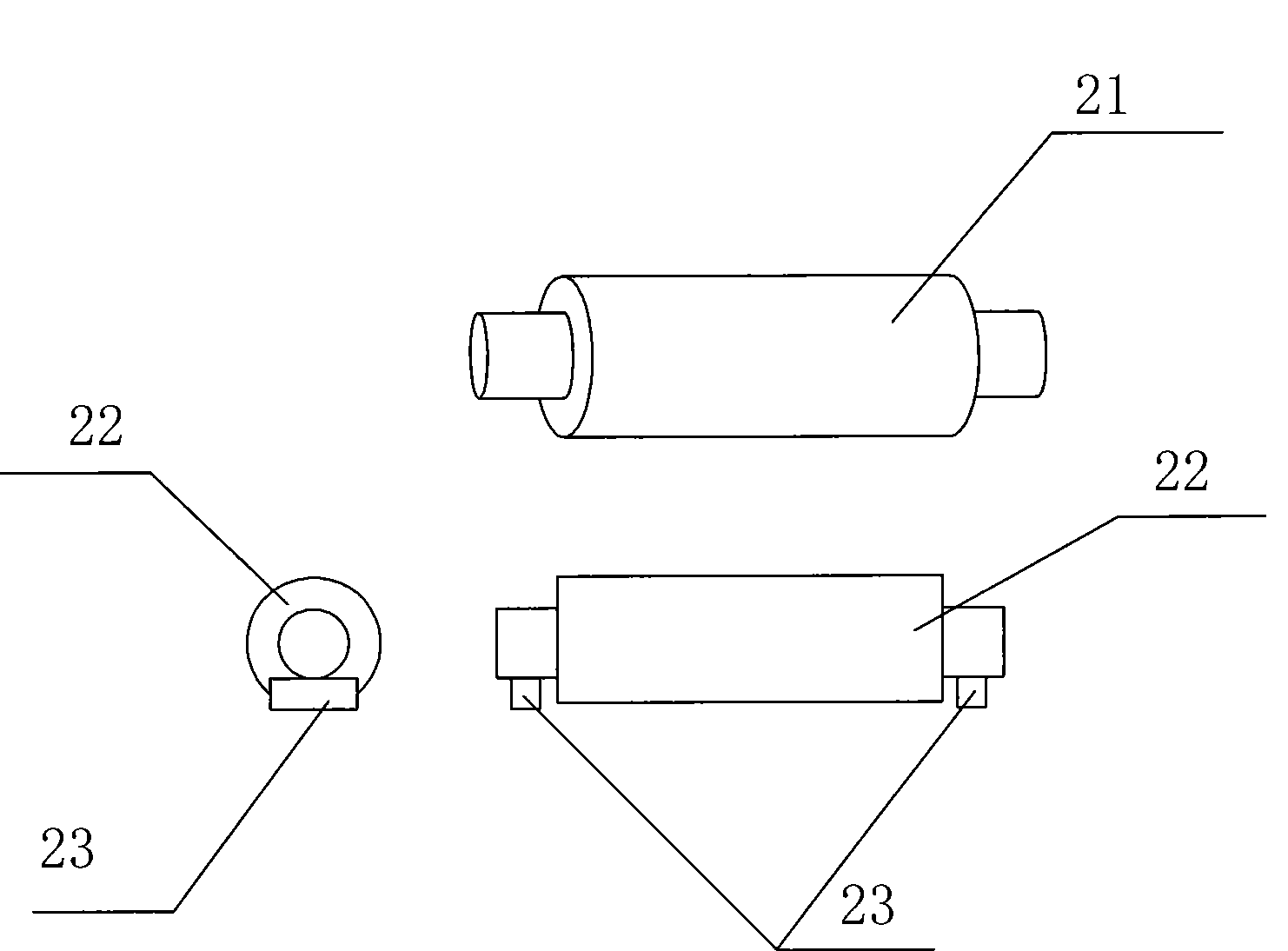

Equipment for manufacturing composite membrane filter of polytetrafluoroethylene

InactiveCN101091883BMeet the industrial production requirements of continuous compounding in large quantitiesImprove shrinkageSemi-permeable membranesTetrafluoroethyleneComposite filter

The invention publishes a preparation plant for producing polytetrafluoroethylene composite filter membrane, which includes feeding windin gearing, stitching device and control device. The feeding winding gearing includes roller of polytetrafluoroethylene, roller of backing material, roller of composite membrane. The characteristic is that the stitching device includes the roller of rotate speed control device and the roller of cooling. The pressure gearing is fixed on either of the roller of rotate speed control device and the roller of cooling. The heater is fixed on the roller of heating. The cooling device is fixed on the roller of cooling. Both of them have measure temperature component. The composite filter membrane can improve the contractibility and mould greatly and can also holdthe shape and structure of polytetrafluoroethylene composite filter membrane.

Owner:NINGBO UNIV

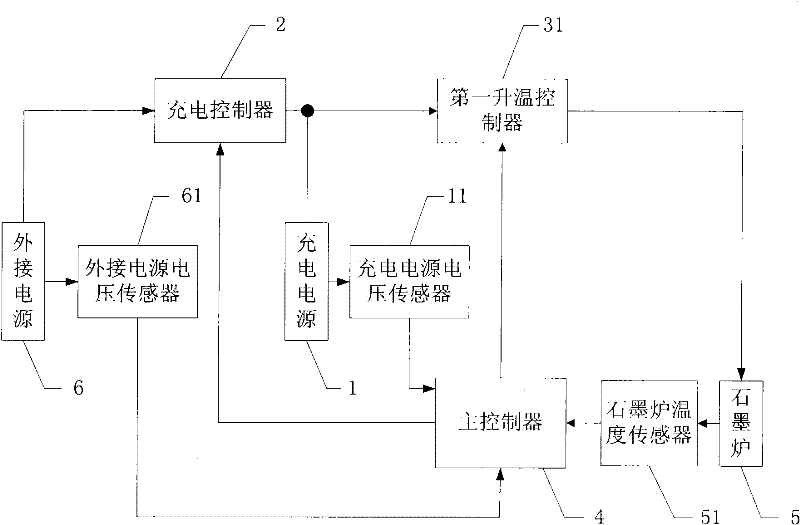

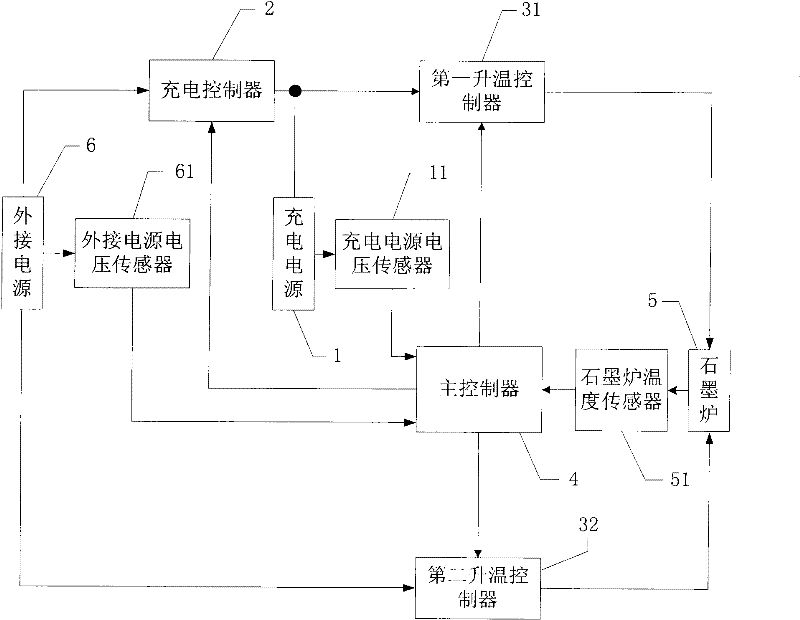

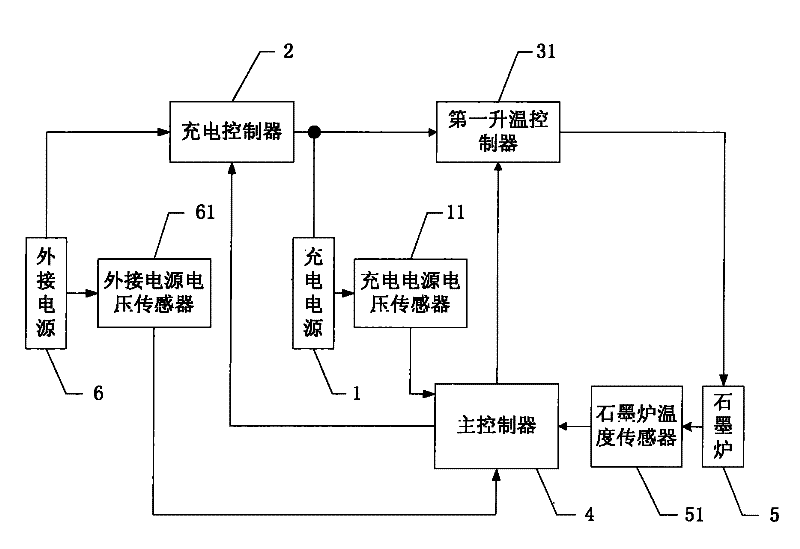

Rechargeable graphite furnace power supply

ActiveCN101799241BGuaranteed heating rateHeat stableFurnace typesColor/spectral properties measurementsFurnace temperatureGraphite

The invention discloses a rechargeable graphite furnace power supply which comprises a charging power supply, a charging controller, a first temperature rise controller, a main controller, a graphite furnace temperature sensor, a charging power supply voltage sensor and an external power supply voltage sensor, wherein the charging controller is used for switching on an external power supply to charge the charging power supply; the first temperature rise controller is used for switching on the charging power supply to supply power to a graphite furnace; the graphite furnace temperature sensor is used for detecting the temperature of the graphite furnace; the charging power supply voltage sensor is used for detecting the voltage of the charging power supply; the external power supply voltage sensor is used for detecting the voltage of the external power supply; and the main controller is used for controlling the charging controller and the first temperature rise controller. By using therechargeable graphite furnace power supply, the charging power supply can be used for individually supplying the power to the graphite furnace; and the external power supply and the charging power supply can also be simultaneously used for supplying the power to the graphite furnace for ensuring power supply stability, thereby ensuring the temperature rise rate of the graphite furnace.

Owner:BEIJING PURKINJE GENERAL INSTR

Filling method of open roaster

ActiveCN103134327BImprove sealingEasy to burnEnergy inputCharge manipulationCold airFilling materials

The invention relates to a method of filling material filling, in particular to a method of opening type roasting filling material filling used for a carbon industry. An area with a standing seam in a fire way wall is filled by the filling material with a regular granularity. An area without a standing seam of the fire way wall on the upper portion of a material box is filled by a layer of fine filling materials and the fine filling materials are concentratedly to be operated in and out of a furnace. Convenience and feasibility of the operation are guaranteed. The method of the opening type roasting filling material filling has the advantages that the filling materials with different granularities are filled in the upper position and the lower position of the opening type roasting furnace material box, thus the good sealing effect of the material box is achieved. The fact that oil tar and volatile matter in a heating stage of a roasting product which smoothly enter the fire way to burn is guaranteed. A Cold air quantity leaking in the fire way from the material box is reduced. A pre-heating air quantity which enters the material box from the fire way after the roasting product enters the cooling state is reduced. Regular temperature rising speed in the heating stage and cooling speed in the cooling stage of the roasting product are guaranteed. Burning losses of the filling materials in the cooling stage of the roasting product are reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Underground household garbage reduction resource integration device and its treatment method

ActiveCN107282601BImprove resource utilizationSolve the problem of shortage of land resourcesSolid waste disposalFermentationPollution

The invention discloses an underground household garbage reduction resource integrated device and a treatment method thereof, and belongs to the field of environment-friendly equipment. The device is integrally located below the ground. A garbage can connected with a pulverizing device is arranged above the ground. The bottom of the can is capable of being opened downwards so that garbage can enter the position below the ground, and subsequent resourceful treatment is finished. Falling garbage is pulverized through the pulverizing device located under the garbage can and then falls into a cascading high-temperature fermentation barrel; a feeding port of the cascading high-temperature fermentation barrel is the position of the above pulverizing device, and a discharging port of the cascading high-temperature fermentation barrel is located in the other end of the barrel and connected with a vibration screen. An oversize product outlet of the vibration screen is connected with an automatic material returning system, the system is internally provided with a plastic blowing and disengaging device. The device is provided with an elevating device. The underground household garbage reduction resource integrated device and the treatment method thereof are suitable for in-situ reduction resourceful utilization of community household garbage, environment is sanitary, and secondary pollution is avoided; and based on PLC module deep control, the automation and intelligence degree is high; and the structure in the device is compact, the civil engineering cost is saved, dismounting and mounting are convenient, and maintenance is easy.

Owner:ZHEJIANG UNIV

Method for preparing medium and low carbon manganese iron nitride by microwave sintering

ActiveCN102776432BUniform temperatureImprove temperature uniformitySolid state diffusion coatingAdhesiveNitrogen gas

The invention discloses a method for preparing medium and low carbon manganese iron nitride by microwave sintering. The method comprises the steps of weighing medium and low carbon manganese iron powder with granularity of 40-60 meshes per inch and accounting for 25% and medium and low carbon manganese iron powder with granularity of 60-80 meshes per inch and accounting for 75%, adding an adhesive which accounts for 8-10% of the mass of the medium and low carbon manganese iron powder, mixing uniformly, under the pressure of 50-60 kilograms, pressing the mixture to a material blank, drying until that the water content is no more than 3% by weight, then placing the mixture to a microwave oven, heating until the temperature is in a range of 350 DEG C to 400 DEG C, feeding nitrogen into the microwave oven, raising the temperature continuously to the range between 880 DEG C and 1000 DEG C at a temperature rising speed of 5-10 DEG C / minute, performing heat preservation, cooling the mixture along with the furnace to the range between 400 DEG C and 500 DEG C, discharging the mixture, and performing air cooling to obtain the medium and low carbon manganese iron nitride. The method is reasonable in process, convenient to operate, short in production period and low in energy consumption. The prepared medium and low carbon manganese iron nitride is high in nitrogen content, the nitrogen is distributed uniformly in the base metal, and the method is suitable for industrial application.

Owner:五矿(湖南)铁合金有限责任公司

Method for thermal shrinkage packaging of battery

InactiveCN112607133ASimplify hole combinationsReduce lossesWrappers shrinkageElectrical batteryHeat conservation

A method for thermal shrinkage packaging of a battery comprises a rack, a transmission structure and a thermal shrinkage drying tunnel, and the transmission structure and the thermal shrinkage drying tunnel are installed on the rack; the transmission structure comprises a metal mesh belt, and the thermal shrinkage drying tunnel comprises a thermal shrinkage main drying tunnel; the metal mesh belt penetrates through the thermal shrinkage main drying tunnel of the thermal shrinkage drying tunnel; the thermal shrinkage drying tunnel comprises a preheating drying tunnel, a main drying tunnel and a heat preservation drying tunnel which are connected in sequence, and the main drying tunnel comprises a heating cover; an electric heater, fins, a heat shielding plate, a radiant plate and a main drying tunnel thermocouple are fixedly arranged in the heating cover; the fins are fixedly arranged above the electric heater, and the heat shielding plate is fixedly arranged above the fins; and an installation opening is formed in the lower portion of the radiant plate, and the main drying tunnel thermocouple is fixedly arranged on the inner wall of the heating cover. The preheating drying tunnel comprises a preheating drying tunnel thermocouple fixedly arranged on the inner wall of the bottom. According to the method, a draught fan, an air duct, accessories of the air duct and a drying tunnel air outlet are omitted, and packaged pieces are heated in a radiation and natural convection mode; and energy losses caused by the heat flow rate are reduced, and cost reduction, energy conservation and emission reduction are facilitated.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com