Temperature control method and system, semiconductor device

A temperature control method and technology of a temperature control system, which are applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and vacuum evaporation plating, etc., can solve problems such as the reduction of heating efficiency, reduce broken disks, reduce fluctuations in heating power, Guaranteed heating rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order for those skilled in the art to better understand the technical solutions of the present invention, the temperature control method, system and semiconductor device provided by the present invention are described in detail below with reference to the accompanying drawings.

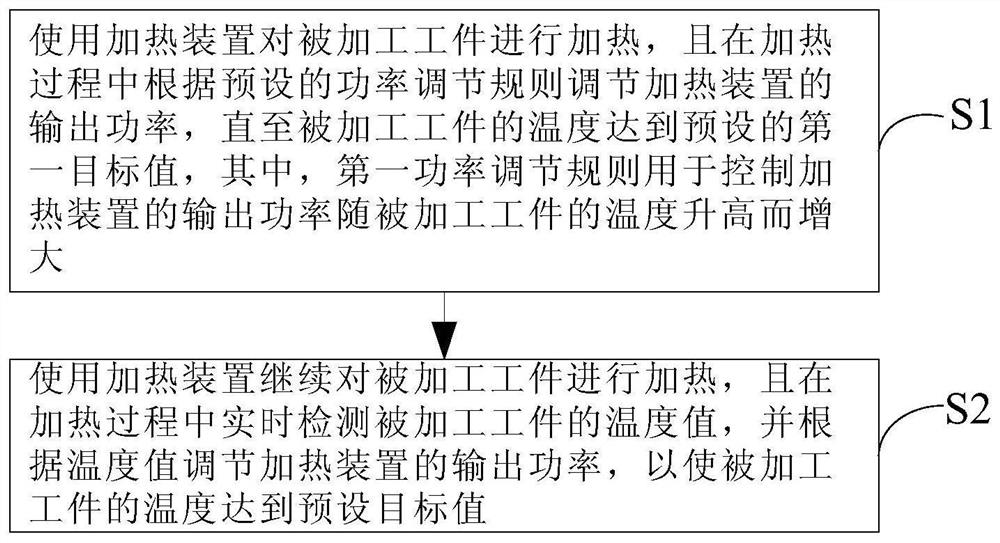

[0038] see image 3 , an embodiment of the present invention provides a temperature control method for a semiconductor device, which includes:

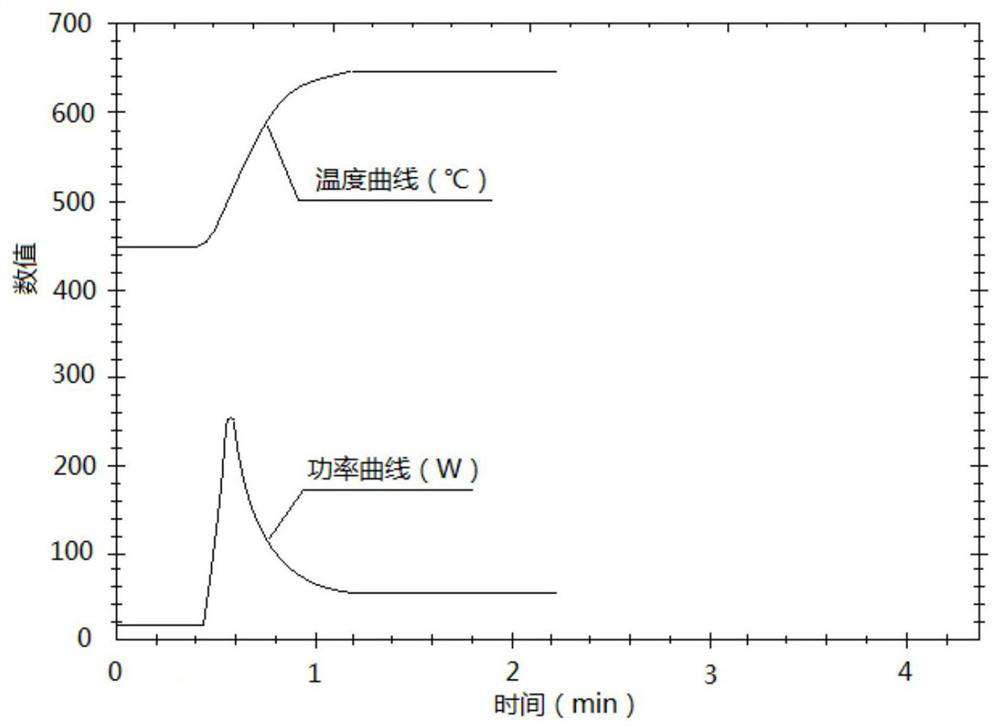

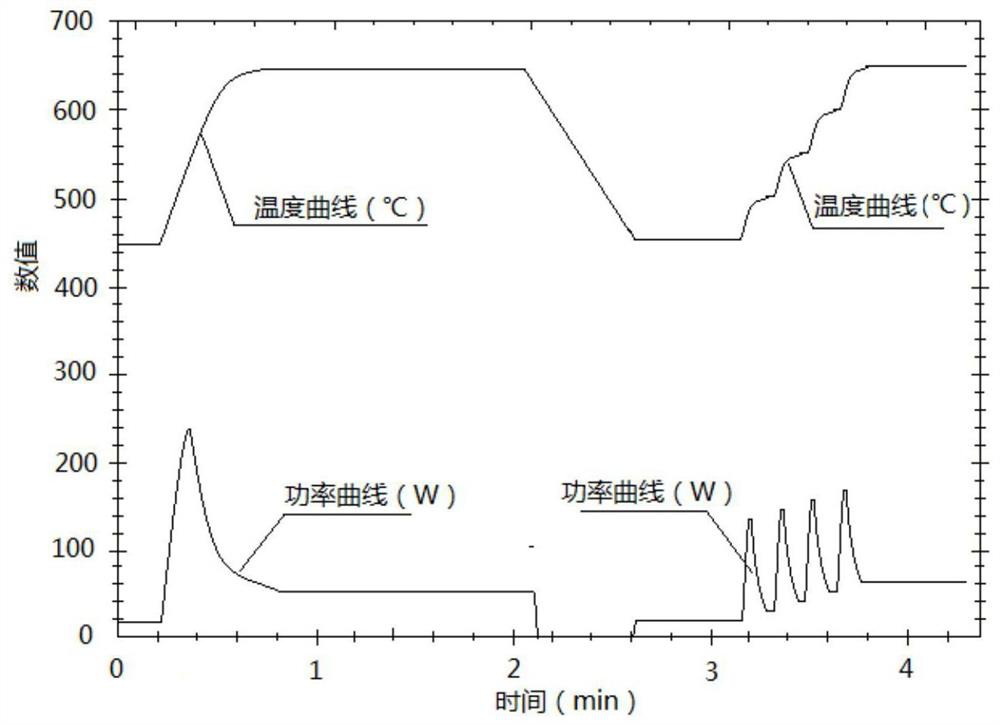

[0039] Step S1, use a heating device to heat the workpiece to be processed, and adjust the output power of the heating device according to a preset power regulation rule during the heating process, until the temperature of the workpiece to be processed reaches a preset first target value, wherein, The above-mentioned first power regulation rule is used to control the output power of the heating device to increase as the temperature of the workpiece to be processed increases;

[0040] Step S2, use the heating device to continue to heat the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com