Method for thermal shrinkage packaging of battery

A heat shrink, battery technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of complex structure and manufacturing process, energy loss, manufacturing requirements and high manufacturing costs, and achieve cost savings, heat reduction, high The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

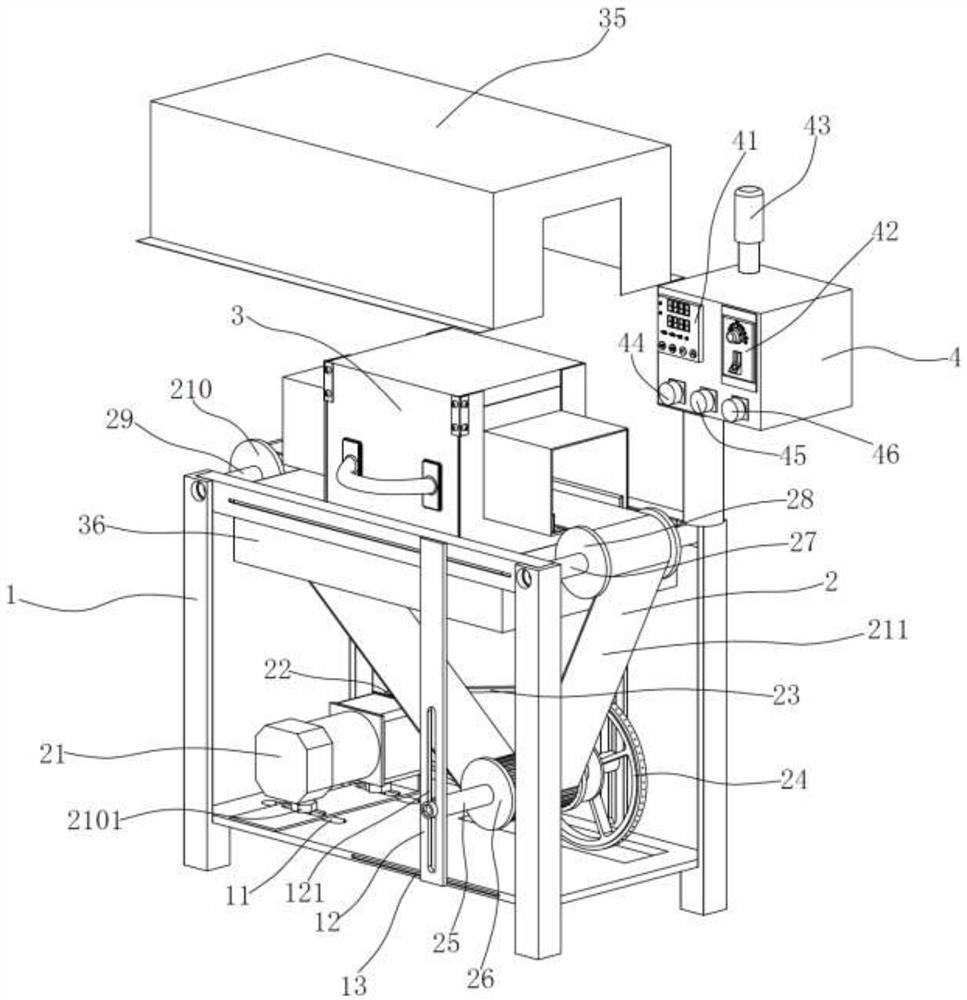

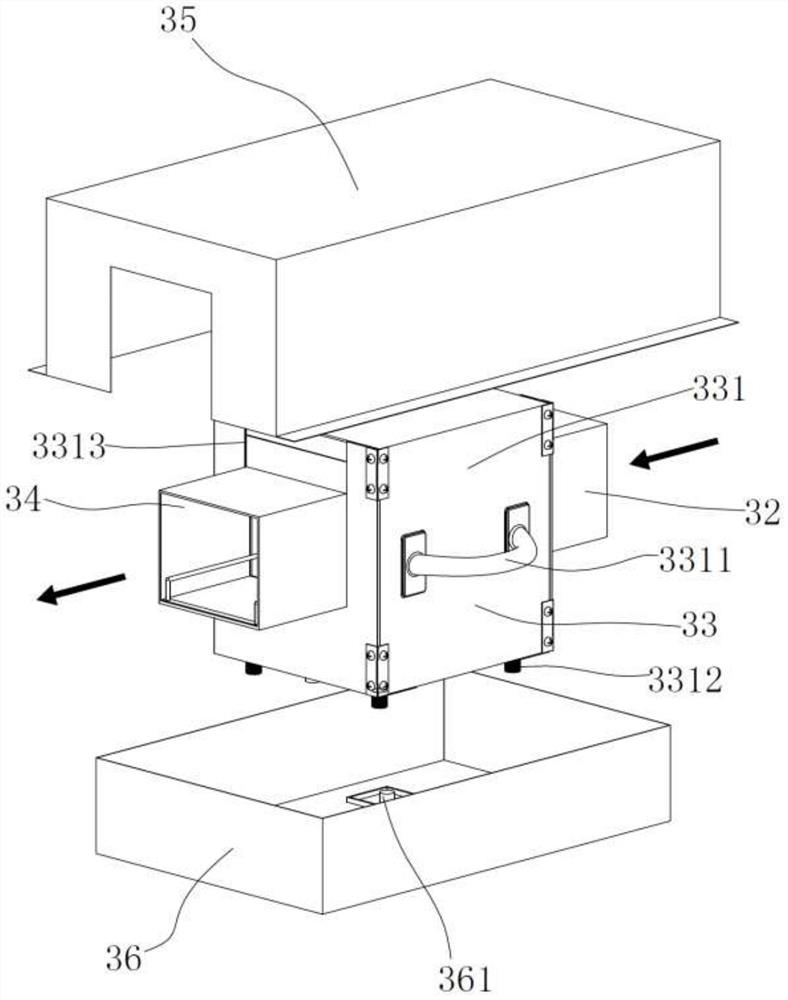

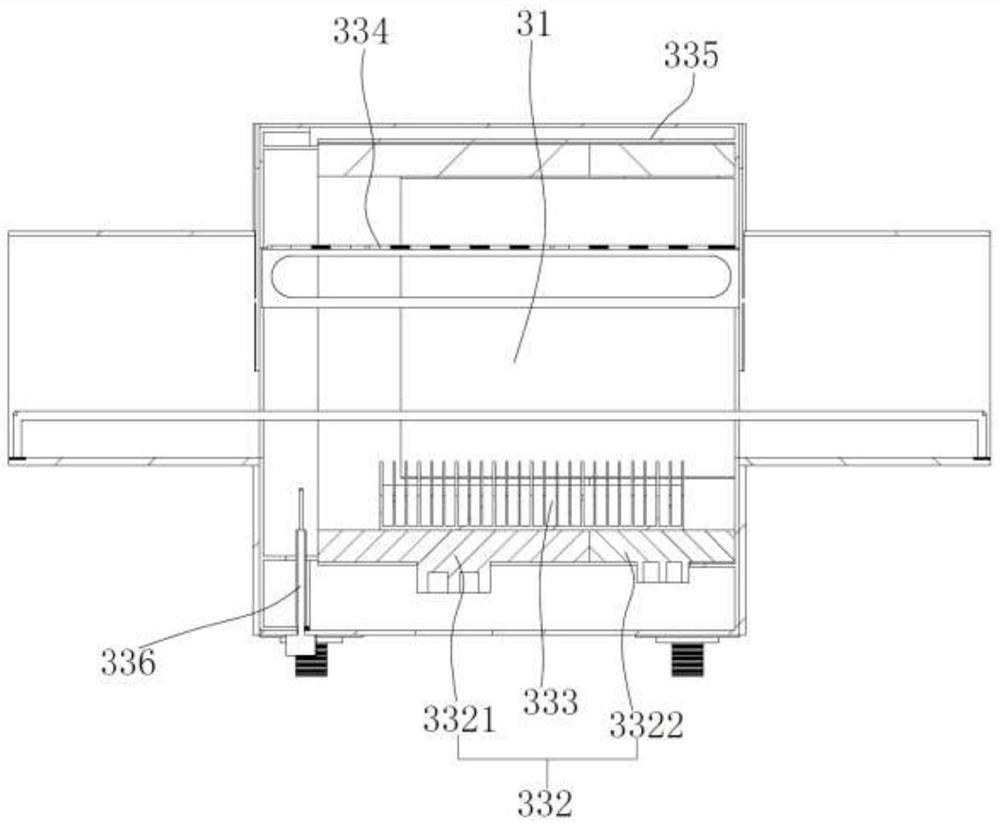

[0040] Such as Figure 1 to Figure 7 As shown, a method for heat shrink packaging of batteries requires the use of a battery heat shrink device. The battery heat shrink device includes a frame 1, a transmission structure 2, a heat shrink drying tunnel 3 and a control and monitoring system 4. The transmission structure 2 and heat shrink The shrinking drying tunnel 3 is installed on the frame 1, the transmission structure 2 includes a metal mesh belt 211, the heat shrinking drying tunnel 3 includes a hollow heat shrinking main drying tunnel 31, and the metal mesh belt 211 passes through the heat shrinking drying tunnel 3. Road 31 is used to transport the parts to be packaged, and the control and monitoring system 4 is used to control the start and stop of the transmission structure 2 and the heat shrinking drying tunnel 3, and monitor whether th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com