Filling method of open roaster

A filling material and roasting furnace technology, which is applied in the field of filling material filling, can solve the problems of affecting the heating rate of roasted products, reducing the temperature of the fire path, and increasing the burning loss of filling materials, so as to ensure the normal heating rate and reduce the amount of cold air , Reduce the effect of burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

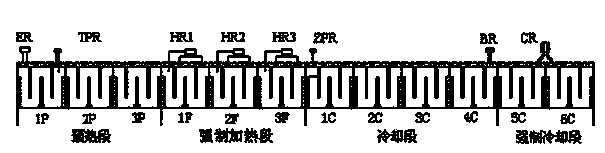

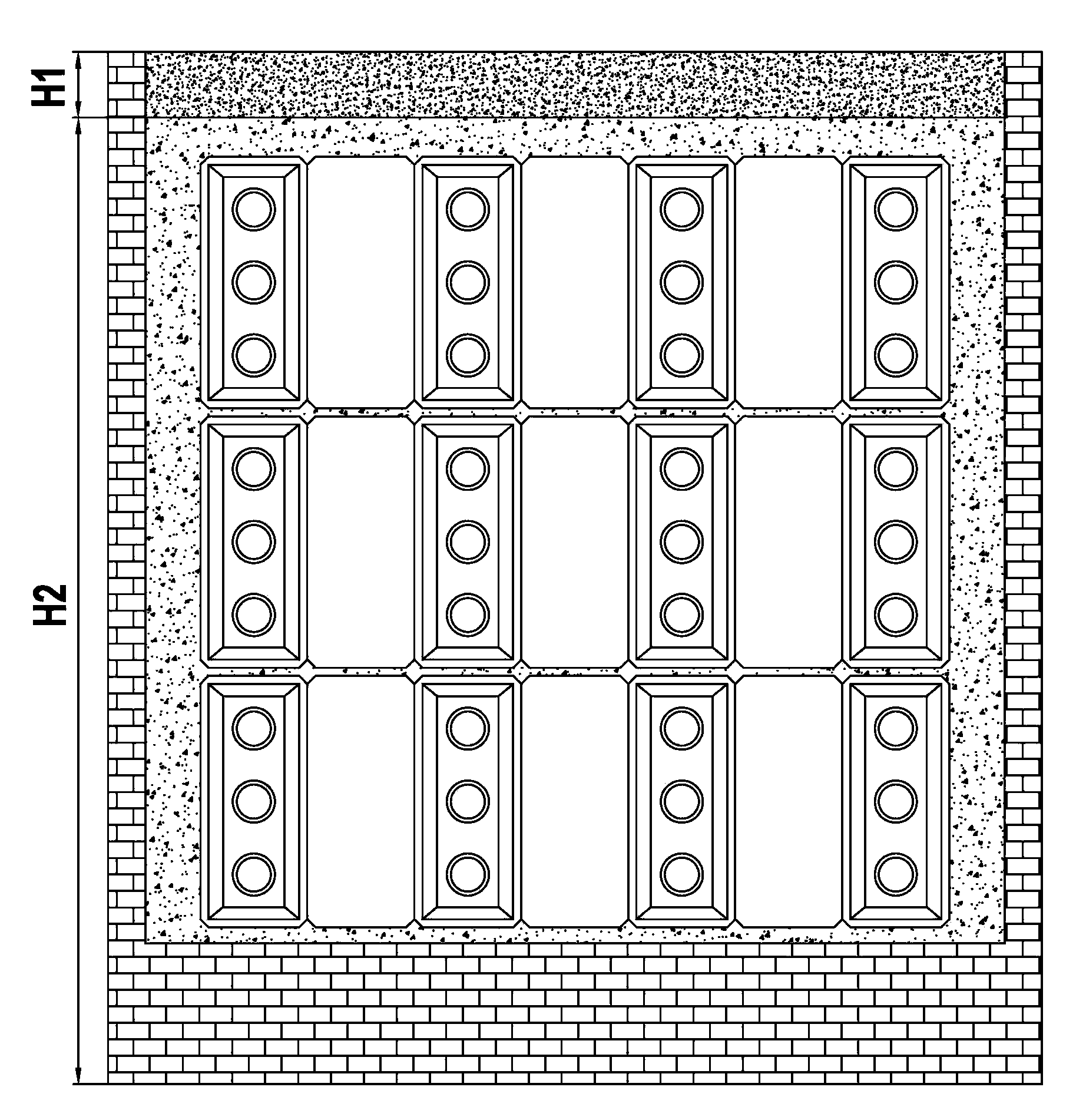

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] As shown in the figure, the filling method of the open roaster of the present invention uses fillers with normal particle size in the area where the flue wall has a standing seam, and fills a layer of fine grain in the area where the flue wall does not have a standing seam on the upper part of the material box. Filler, fine filler less than 1mm average particle size.

[0020] In the area where there is a standing seam in the flue wall, fill with normal particle size filler, and reserve an area 300~400mm away from the furnace surface without filling filler. After filling the other material boxes in the furnace chamber in the same way, Concentrate on filling all the material boxes of the furnace chamber with fine fillers; when the roasted product enters the forced cooling stage through the heating section and cooling section, suck out the 300~400mm thick fine fillers i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com