Primary baking process for improving tobacco leaf aroma volume

A technology of aroma quantity and tobacco leaves, applied in directions such as tobacco, tobacco preparation, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Improving the aroma of tobacco leaves and the initial roasting technology

[0027] Technical key: (1) yellowing period, high temperature and humidity conditions, full yellowing; (2) withering period, stable temperature and dehumidification, fully withered; (3) fixed color period, cooling, humidification, slow Dry leaves; (4) During the dry gluten period, temperature control, suitable humidity, slow dry tendon.

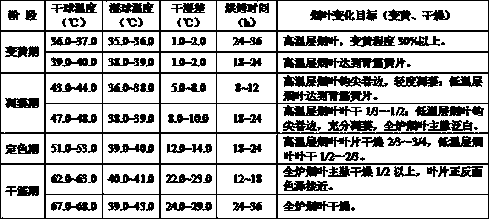

[0028] Taking the K326 variety and the smoking area at an altitude of 1500m to 1800m as an example, see Table 1 for the initial roasting technology to improve the aroma of tobacco leaves.

[0029] Table 1 Initial roasting process to increase the aroma of tobacco leaves

[0030]

[0031] Remarks: ①The temperature rise rate is 2°C / h to 36.0~37.0°C in case of fire; the temperature rise rate between subsequent stages is 1°C / h.

[0032] ②For high-temperature layer tobacco leaves, the air-flow descending curing barn refers to the top layer of the barn; the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com