Baking method for increasing output rate of upper deep orange tobacco leaves

A roasting method and a technology of output rate, which are applied in the field of roasting to increase the output rate of upper dark orange tobacco leaves, can solve the problems of reducing amylase activity, low ratio of upper dark orange tobacco leaves, and cannot be sold, so as to improve the yield of upper dark orange tobacco leaves. Quality, simple baking process, and the effect of improving the grade structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present application invention is described in further detail.

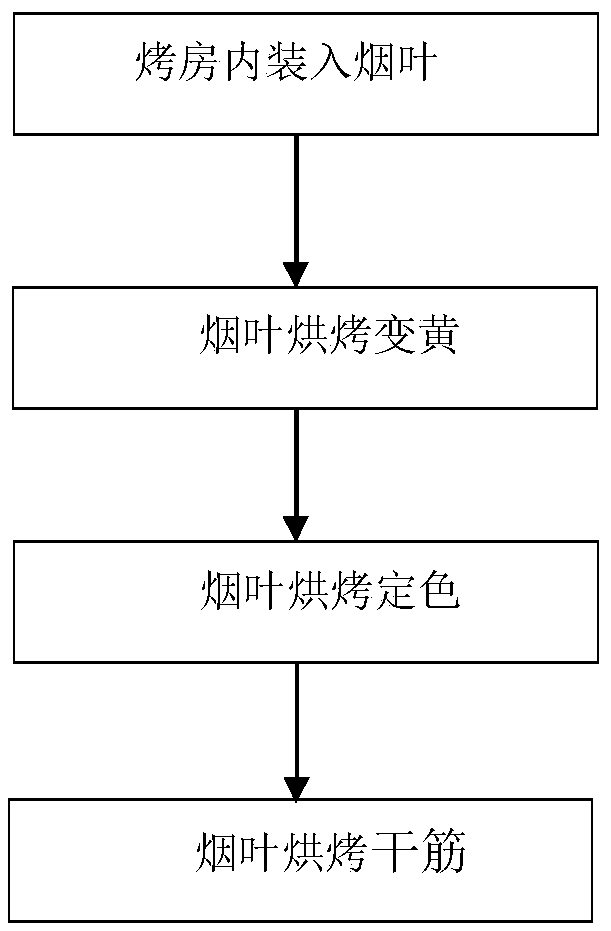

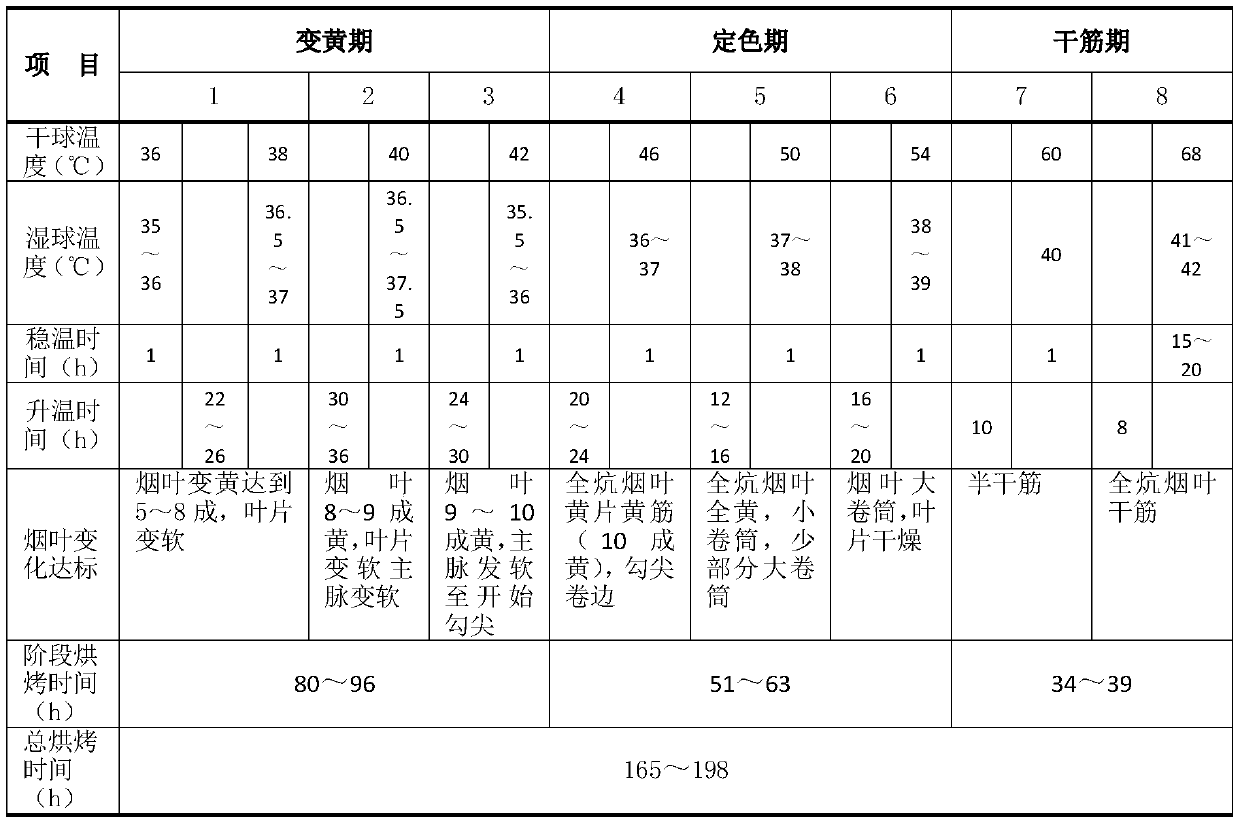

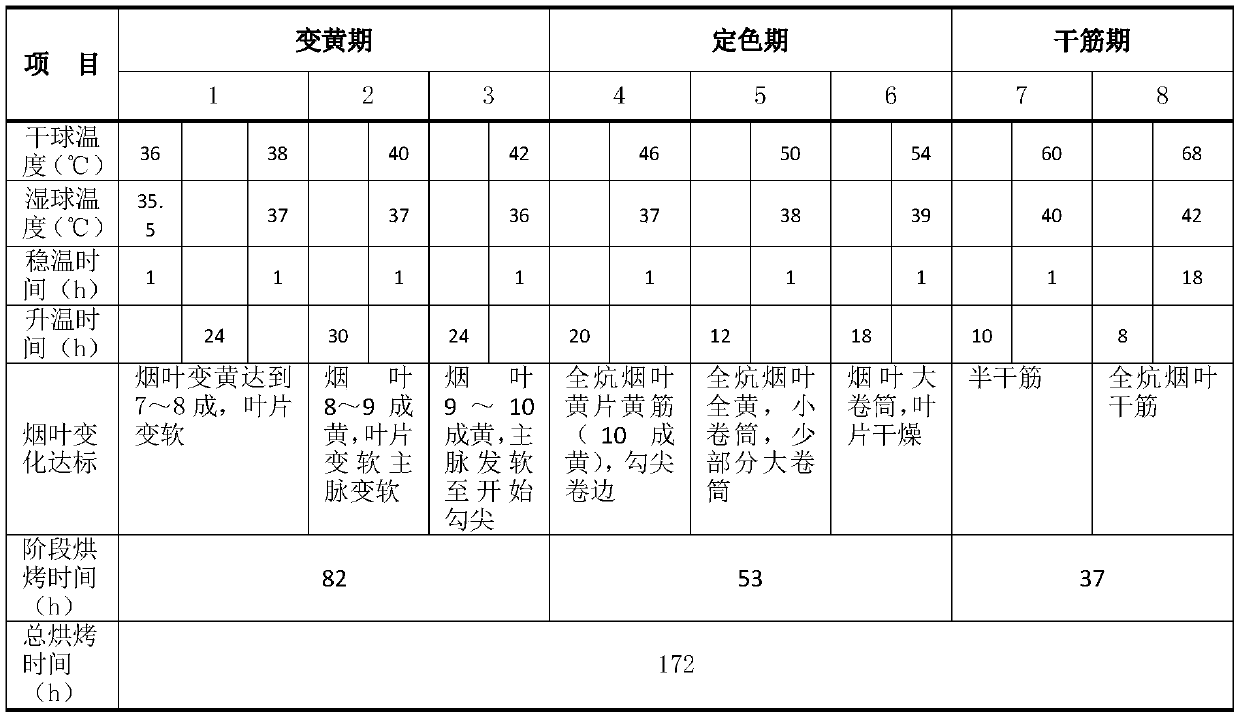

[0021] Under the normal climatic conditions in the southern Anhui tobacco area, 80% of the upper tobacco leaves harvested have reached the mature level, and the maturity of the remaining tobacco leaves is still mature. Tobacco, the top shed with low maturity, the bottom shed with high maturity, and the middle shed (second shed) with middle maturity, the tobacco leaves are filled and evenly packed. See Table 2 for the curing process to increase the yield of upper dark orange tobacco leaves under this condition.

[0022] (1) Yellowing period: After the smoke is installed in the intensive barn, ignite the fuel in the stove, raise the dry bulb temperature to 36°C, and the wet bulb temperature to 35.5°C, stabilize the temperature for 1 hour, and preheat the tobacco leaves; then use it for 24 hours Slowly and uniformly raise the temperature of the dry bulb to 38°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com