Patents

Literature

55results about How to "Increased Industrial Availability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

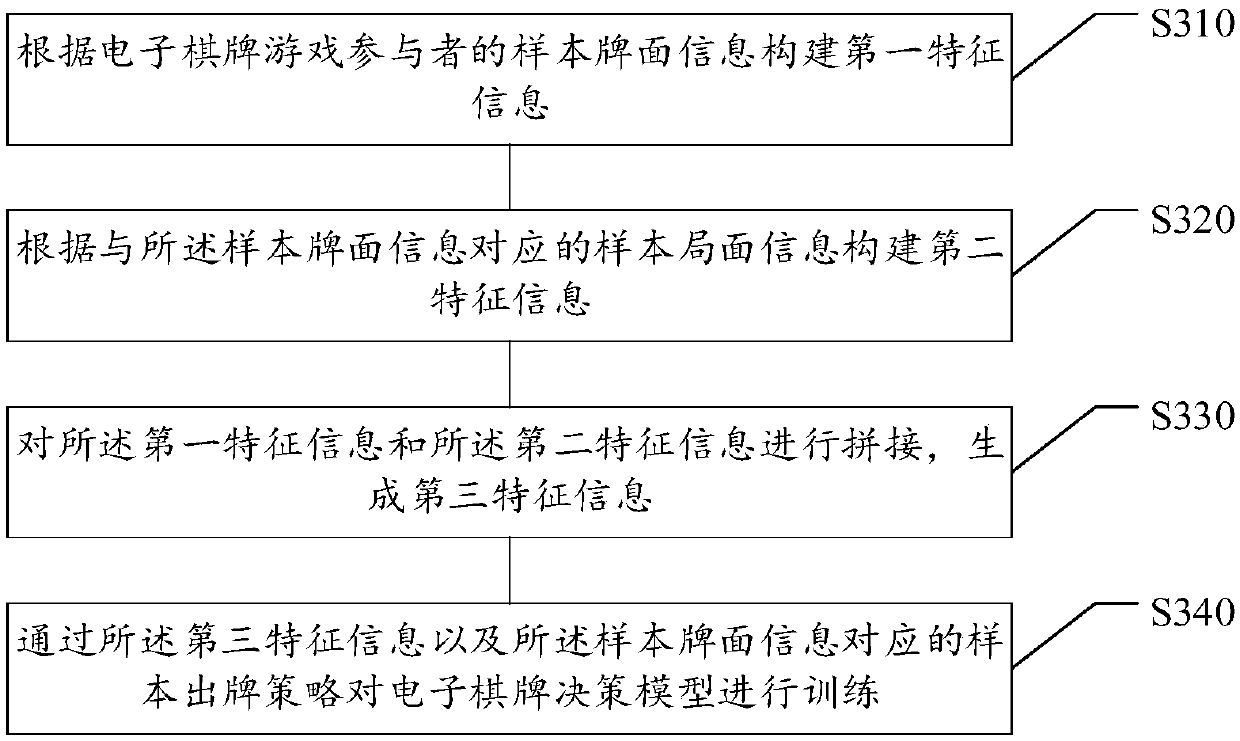

Electronic chess and card decision-making model training method and device and strategy generation method and device

Owner:TENCENT TECH (SHENZHEN) CO LTD

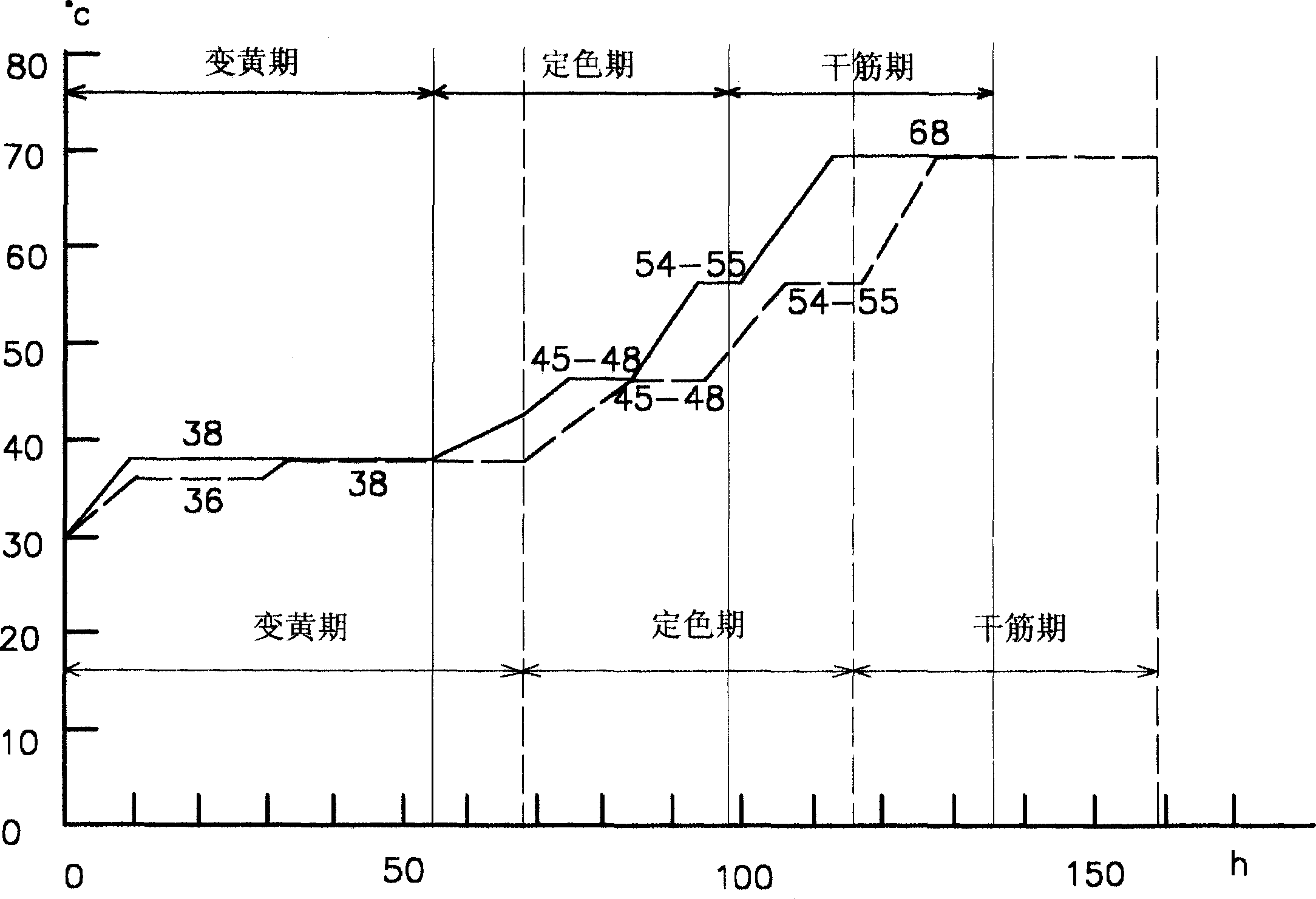

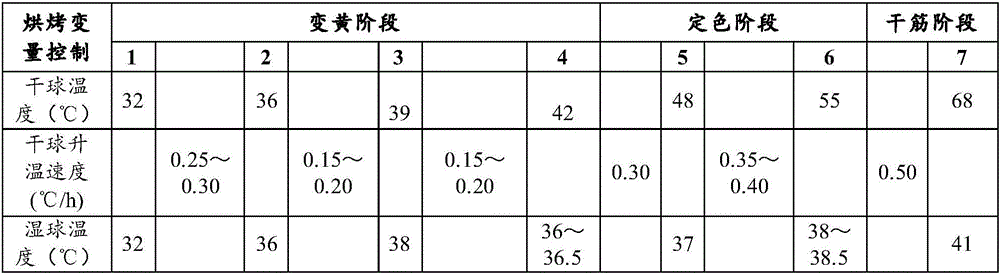

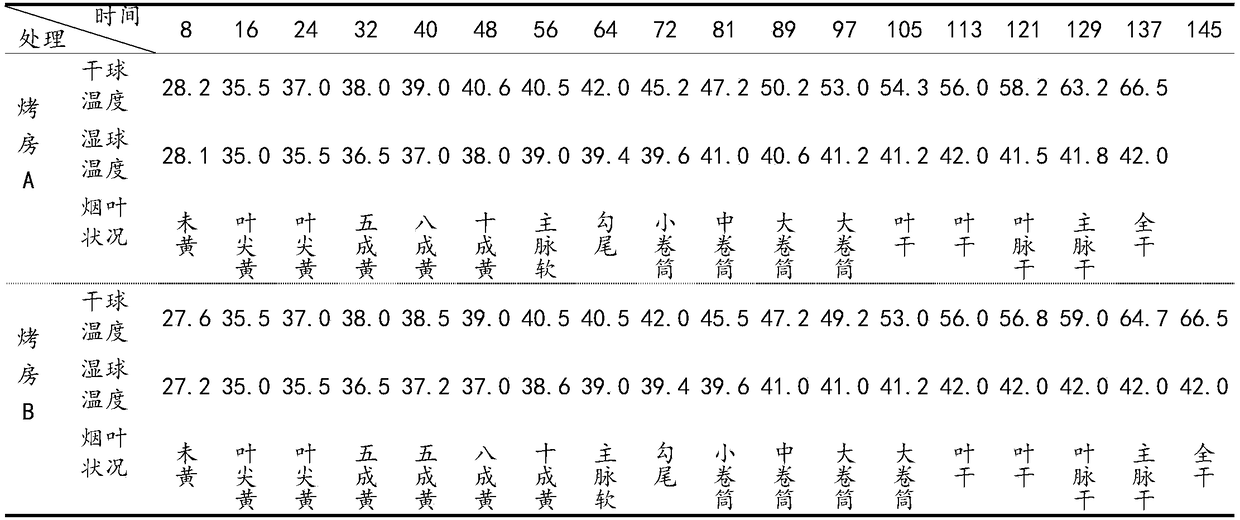

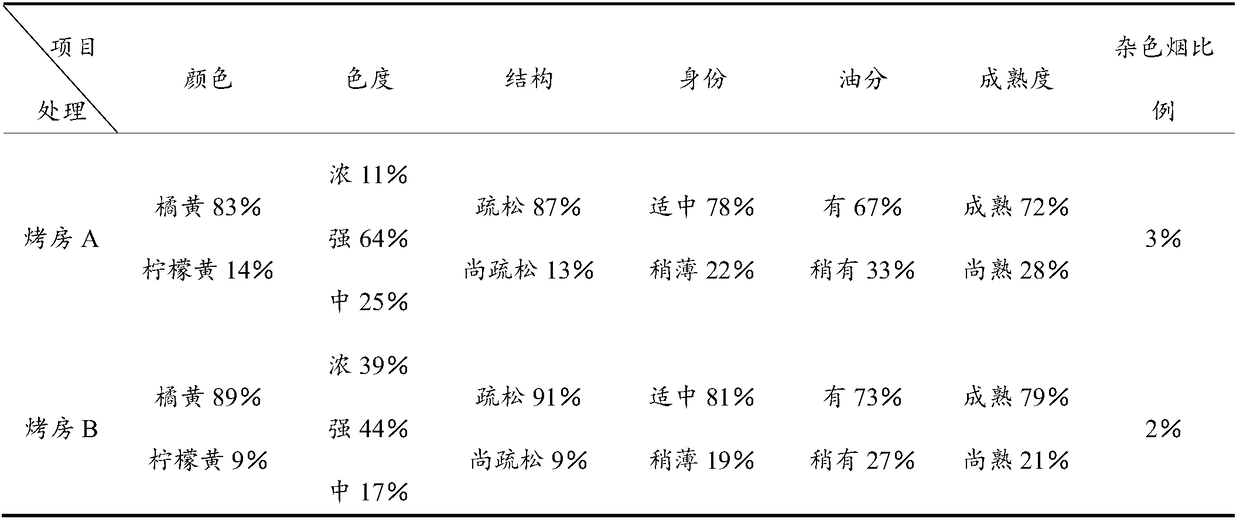

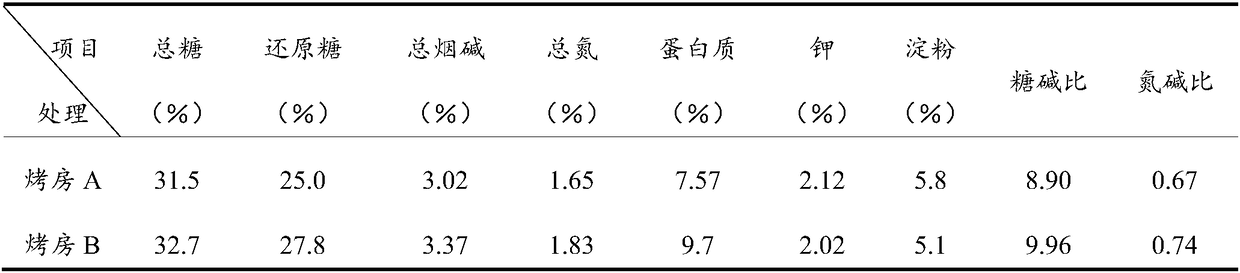

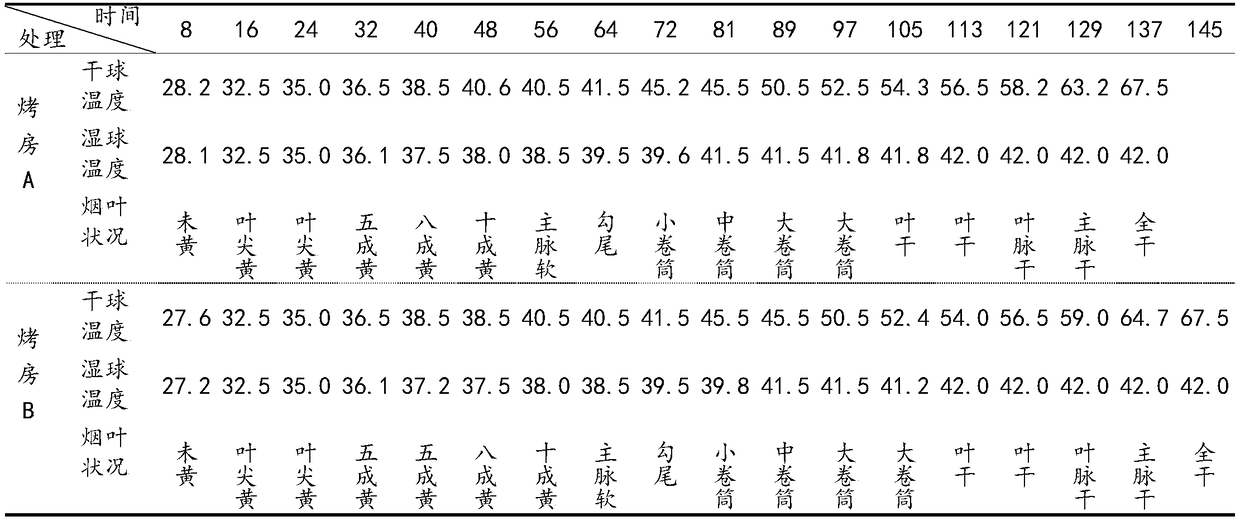

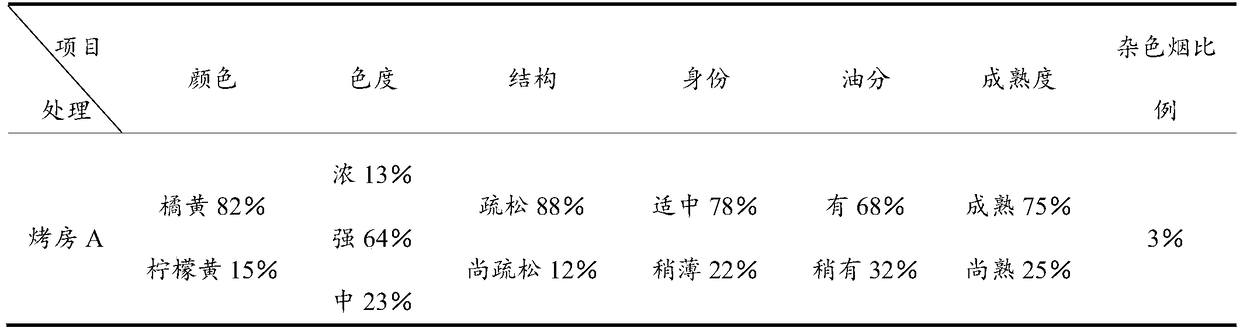

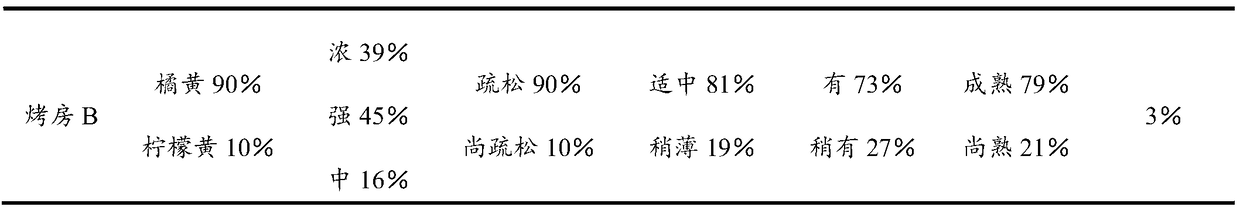

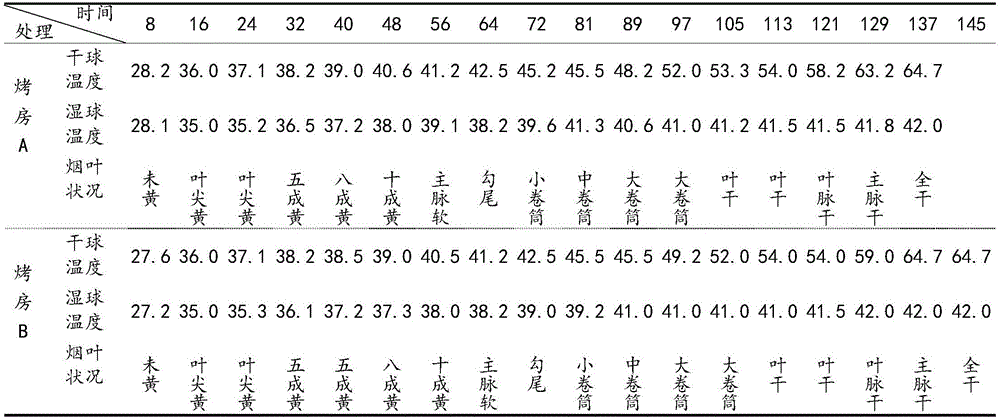

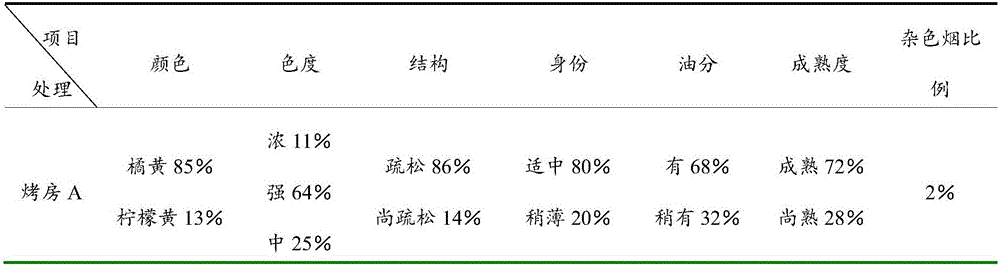

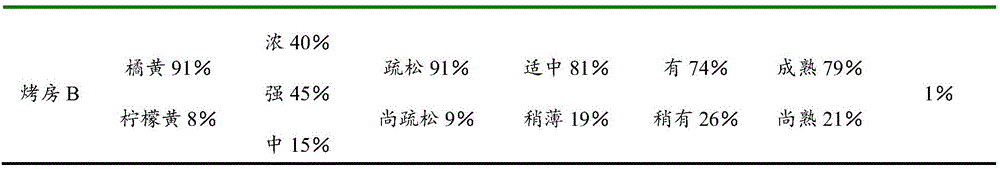

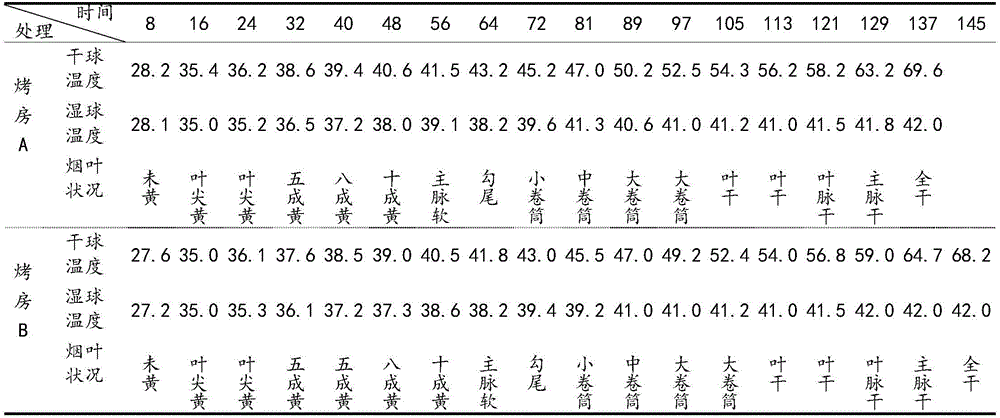

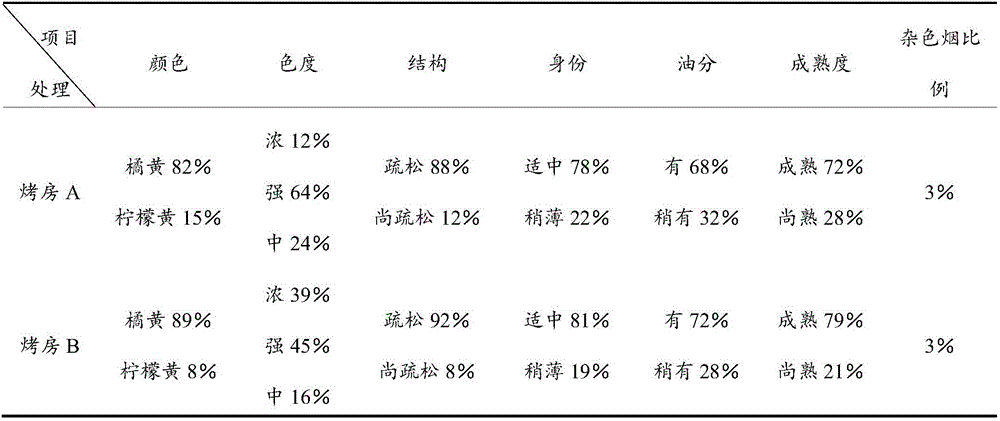

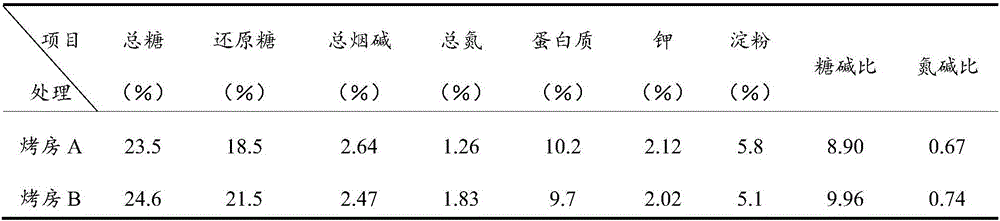

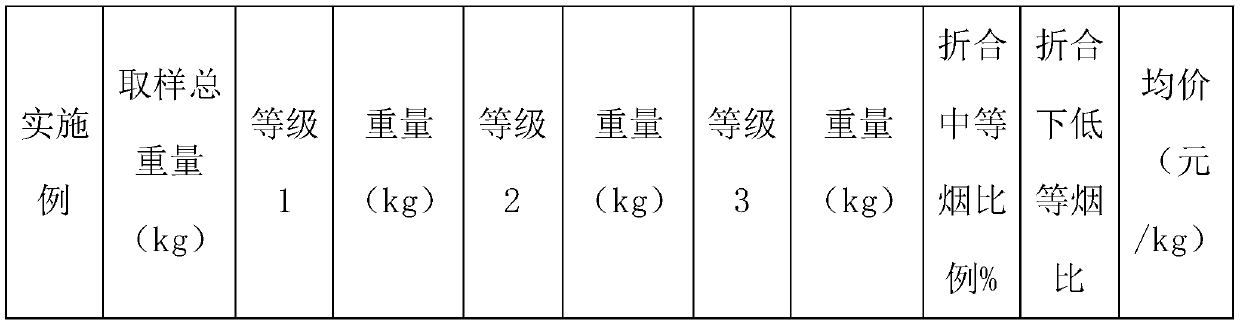

Flue-cured tobacco upper smoke baking method

InactiveCN1589685AIncrease orange smoke rateImprove industrial qualityTobacco preparationPreparation proceduresBiology

The invention discloses an upper cured tobacco baking method belonging to the field of cured tobacco baking concocting technology. The feed preparation procedure selects the upper tobacco in delay harvest or half plant harvest mode which harvests leaf and main trunk one time. Rod hanging procedure bakes the half plant of upper cured tobacco stem and leaf together without separating the same. Baking procedure employs three-section baking method, wherein all sections of the baking time are prolonged for more than 3 hours, and the early temperature of bake-yellowing is reduced for 1 to 2 DEG C. After-baking procedure picks the leaf off from the trunk when the leaf becomes a little soft and the main trunk becomes hard and brittle after being taken off from bed. The invention can, in average, enhance orange smoke rate of the upper tobacco for 5.0 % and first-rate tobacco rate for about 4.0 %, price of original tobacco for 1 Yuan per kilogram.

Owner:WUHAN TOBACCO GROUP

Flue-cured tobacco composite foliage fertilizer

InactiveCN101423438AImprove effectivenessFully developedMagnesium fertilisersAmmonium salt fertilisersPotassium nitrateSouth china

The invention discloses a composite type foliage fertilizer for cured tobacco and relates to the field of fertilizer. The foliage fertilizer is prepared from potassium nitrate, magnesium sulfate, borax, ammonium molybdate, NAA, amino acid, humic acid and a spreader which are dissolved in water. The composite type foliage fertilizer has the characteristics of having comprehensive nutrition, remarkably promoting the leaf-opening of the upper leaves, improving the quality of tobacco leaves and the like, can be widely used in tobacco-rice rotation regions in south China where soil commonly lacks magnesium, boron, molybdenum and other microelements, and is the foliage fertilizer special for the cured tobacco, which has good application effect.

Owner:湖南省烟草公司永州市公司

Method for fermenting cigar filling leaves

The invention discloses a method for fermenting cigar filling leaves. The method is characterized by comprising the following steps: controlling the water content of the cigar filling leaves which are subjected to impurity removal and modulation to be 30+ / -2%, and tidying the cigar filling leaves into cigar leaf bundles of which the leaf tips are towards the same direction; stacking the cigar leaf bundles to form a rectangular cigar leaf stack; covering a layer of hessian cloth on the surface of the cigar leaf stack to be used as an air permeable heat-insulating layer; inserting temperature measuring probes into the cigar leaf stack; overturning the stack when the stack filling temperature measured by any temperature measuring probe reaches the alarm upper limit temperature or is in the trend of reducing; after the fermentation is finished, airing the cigar leaves, reducing the moisture of the cigar filling leaves to be 20+ / -2%, and packaging for storage. According to the method, the appearance, the absorbed smell and the quality consistency of the cigar filling leaves can be obviously improved, the content of a harmful ingredient NNK in raw materials can be reduced, and the industrial availability of the cigar leaves can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

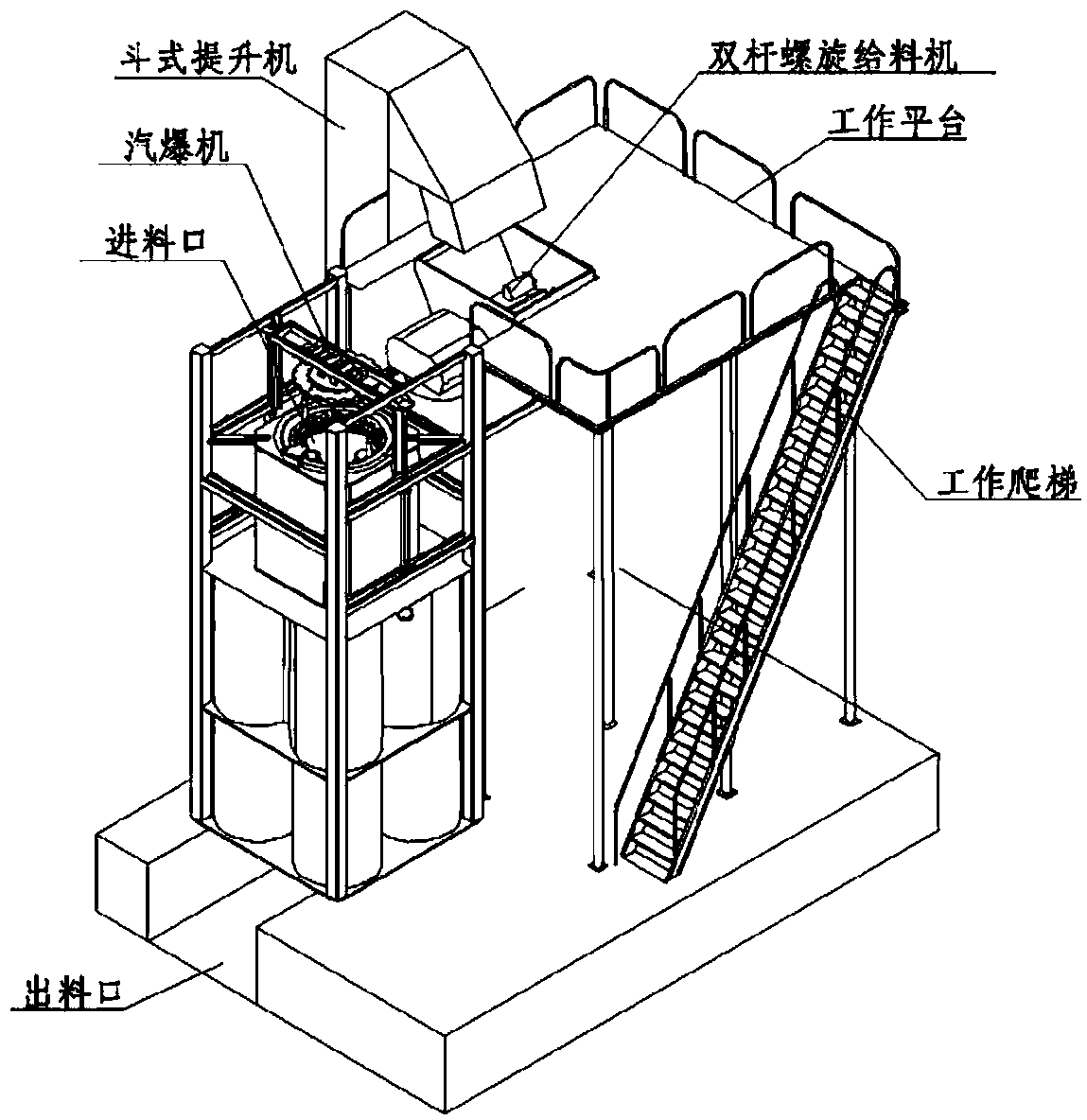

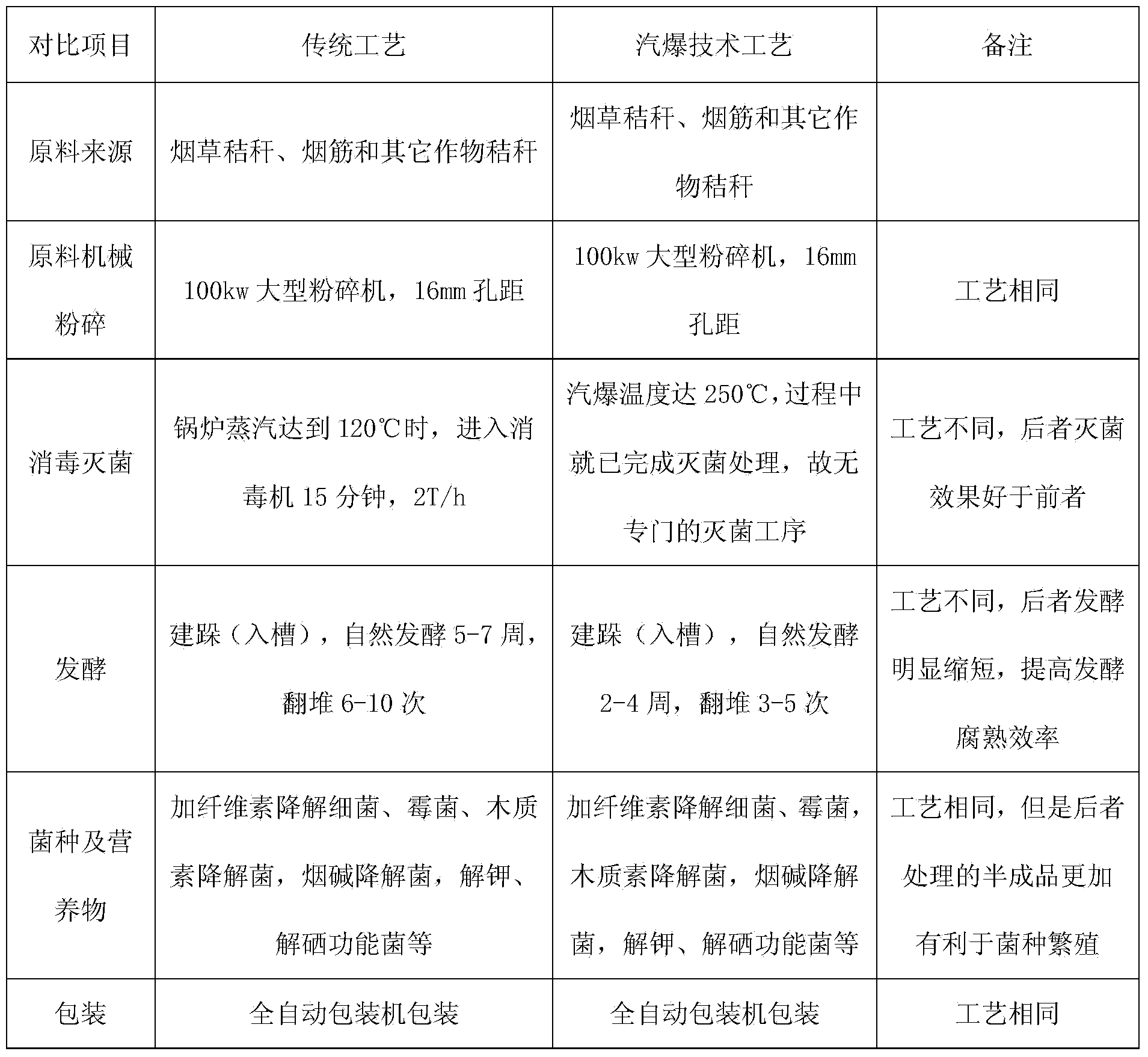

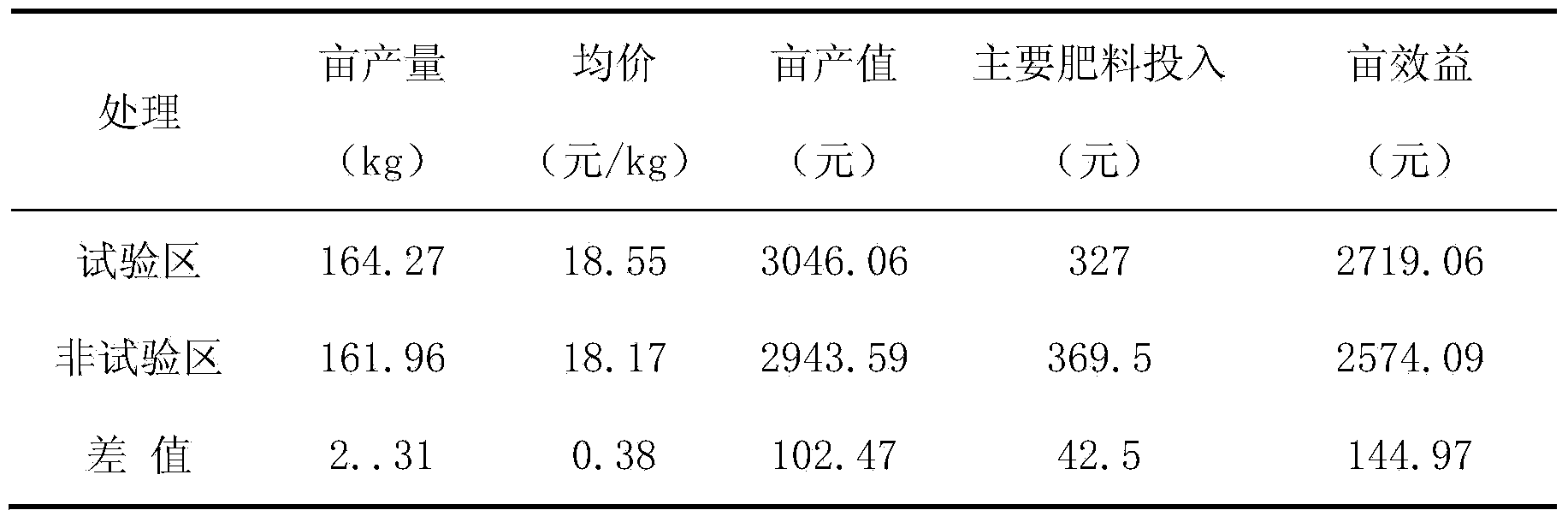

Method for of producing bioorganic tobacco fertilizer by steam explosion technology

InactiveCN104355708AImprove qualityEnsure safetyBio-organic fraction processingOrganic fertiliser preparationEngineeringBacterial strain

The invention provides a method for of producing a bioorganic tobacco fertilizer by a steam explosion technology. The bioorganic tobacco fertilizer is characterized by being produced according to the following steps: a, mechanically grinding raw materials; b, pressurizing and exploding; c, adding a bacterial strain; d, fermenting; e, mixing proportionally. The steam explosion technology has the effect of improving the inherent quality of the bioorganic fertilizer: after steam explosion, straws contain a large amount of saccharides and have the humic acid content as high as more than 30%, so that the bioorganic fertilizer is very suitable for growth and breeding of microbes; by adopting a porous structure, the bioorganic fertilizer is beneficial for solid fermentation; the microbes can grow fast on a fermented material treated through the steam explosion because of pressure change; in the steam explosion technology, high temperature and high pressure can effectively kill pathogenic bacteria and eggs in the straws, so that the safety of the bioorganic fertilizer can be ensured; by the steam explosion technology, a link of sterilizing the raw materials is omitted; compared with the conventional process, the steam explosion technology has the advantages as follows: the fermentation time can be shortened by about 10-15 days and the problem of a large floor area of a fermenting workshop is solved.

Owner:湖北省烟草公司恩施州公司

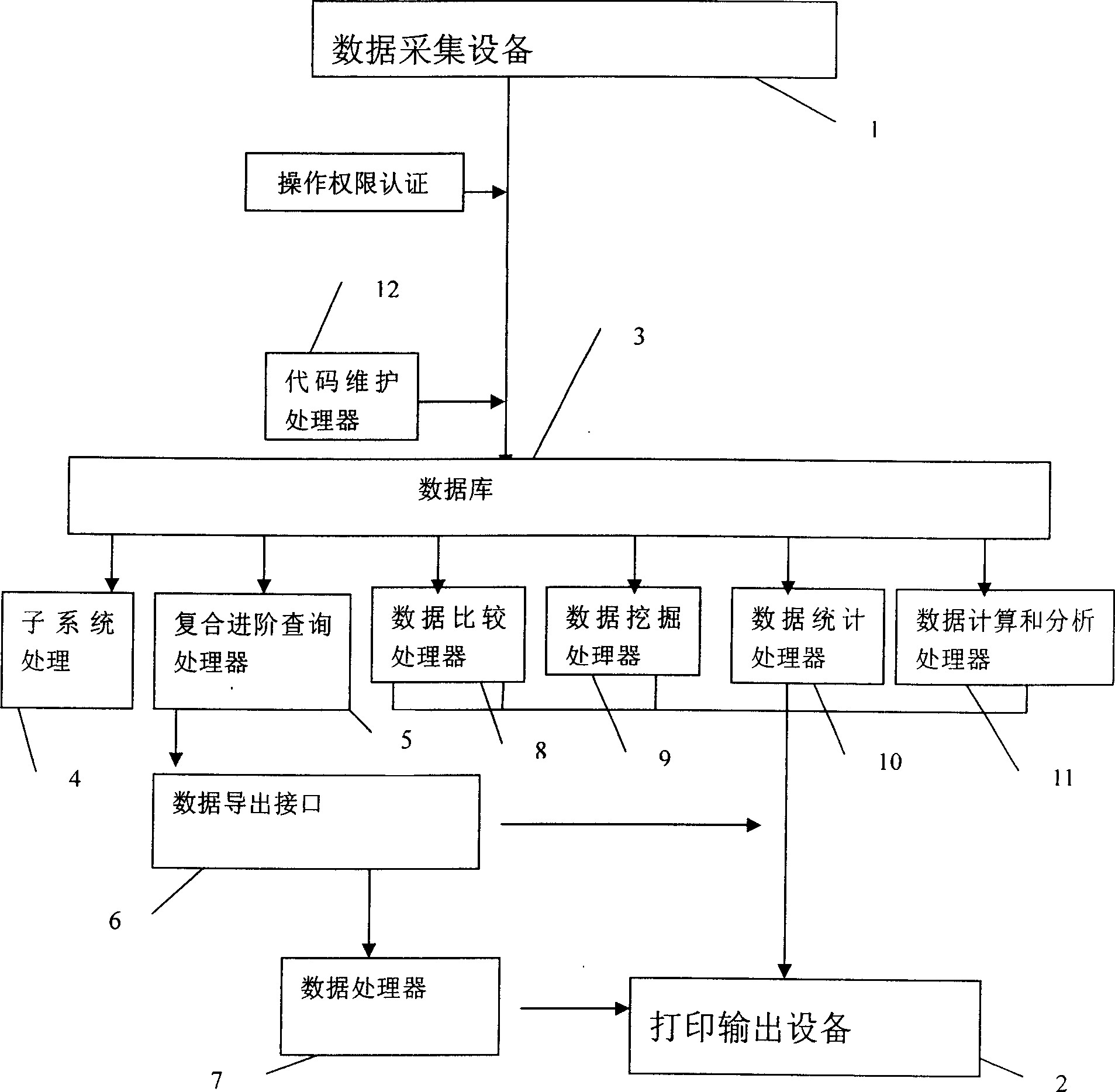

Tobacco leaf quality management system and method

ActiveCN1744115AIncrease aromaIncrease the amount of aromaResourcesEcological environmentQuality assurance

Through a database, statistical analysis is carried out for information related to quality of tobacco leaves. Each index of tobacco leaves can be obtained expediently. Thus, the method is in favor of making correct evaluation for quality, raising work efficiency and strengthening information circulation among producing areas. Through analyzing environment, diversified tastes of products of tobacco, the invention raises quality and quantity of fragrance and industrial usability correctly and effectively so as to provide quality assurance and data support for research and development of product.

Owner:CHINA TOBACCO SHANDONG IND

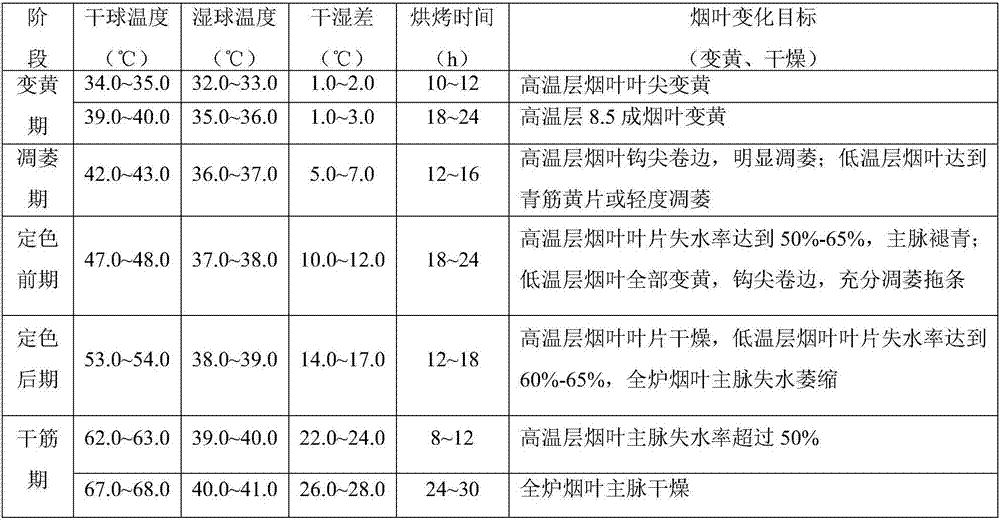

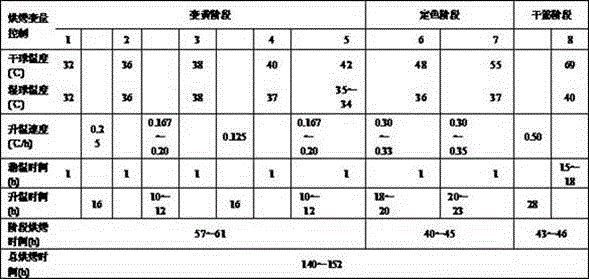

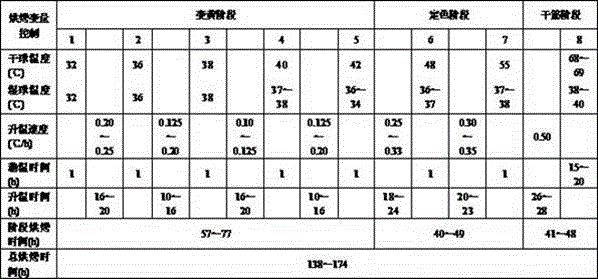

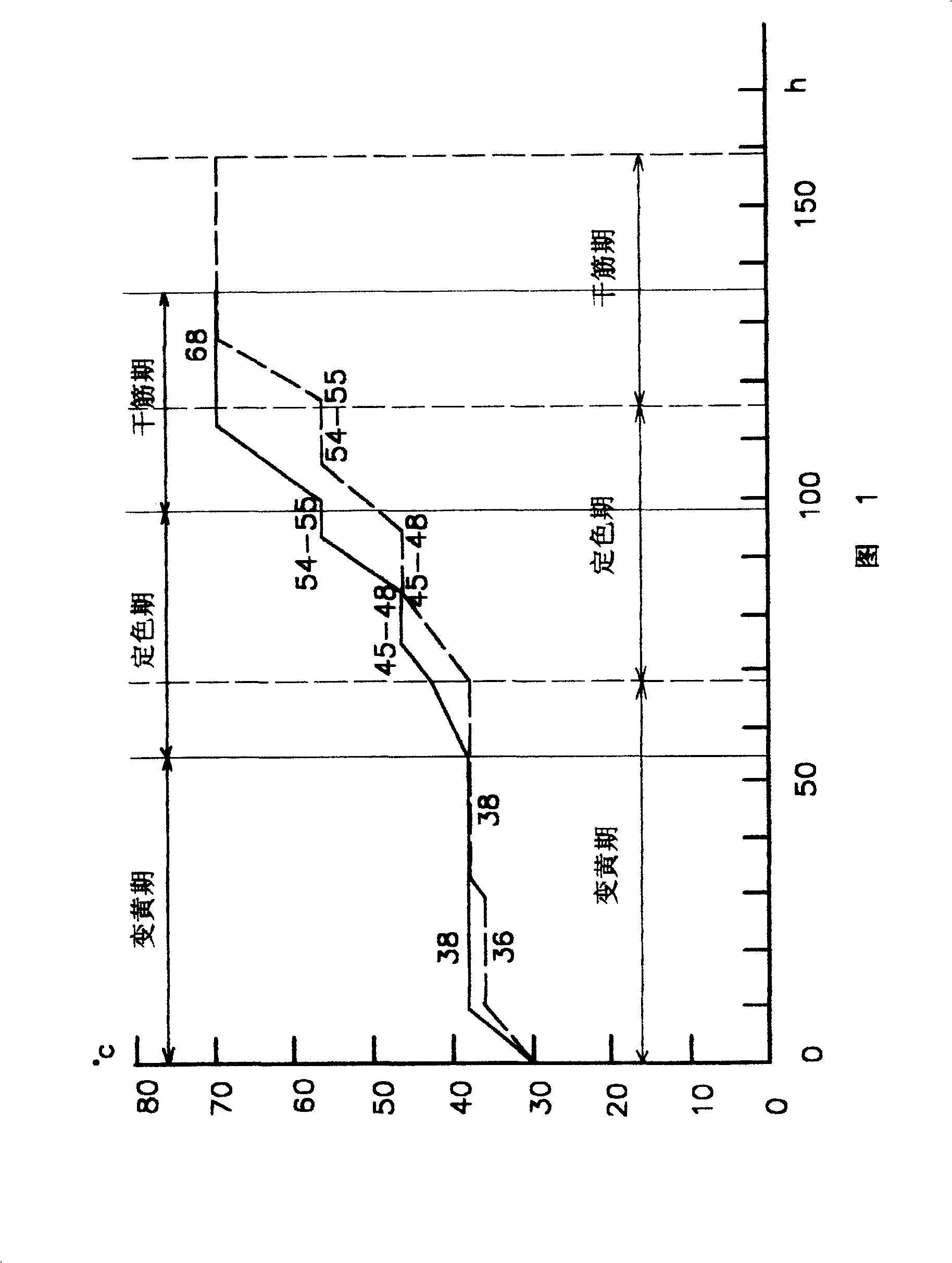

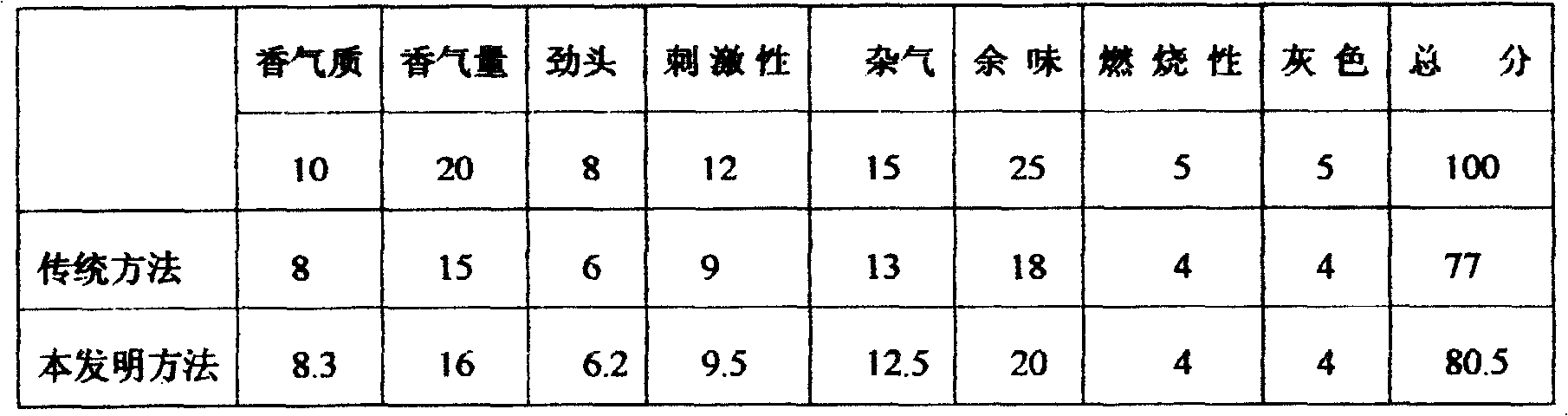

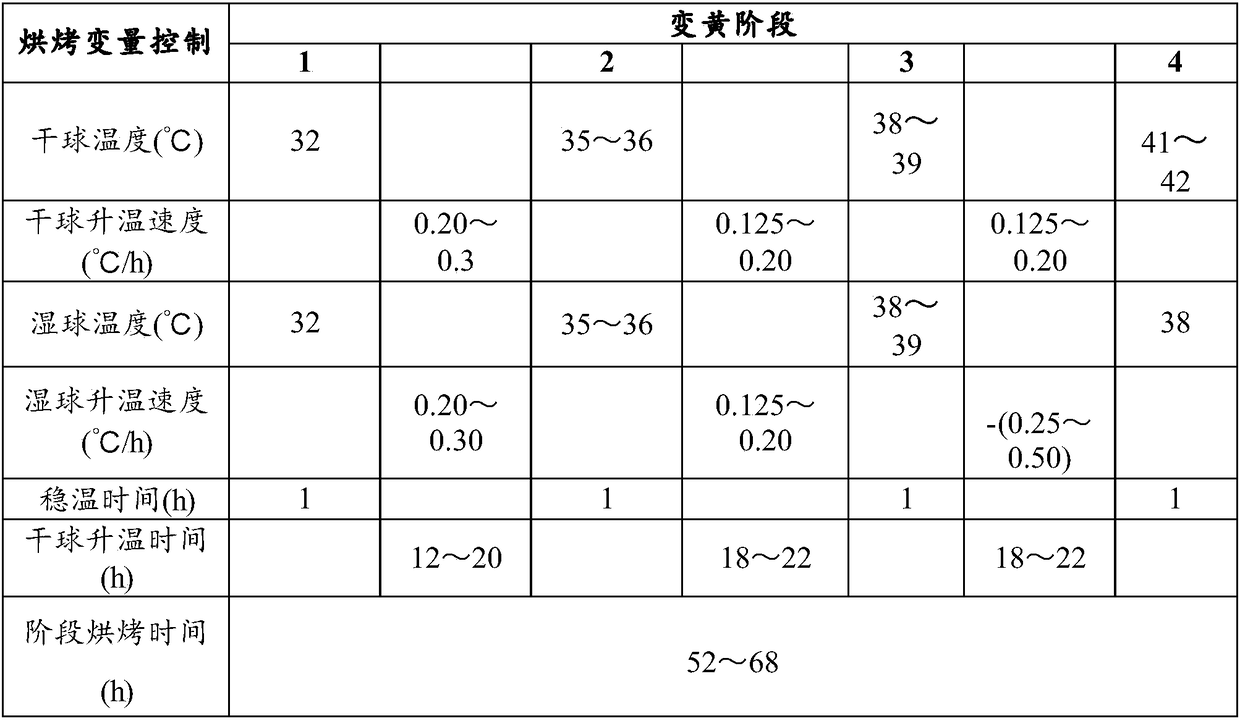

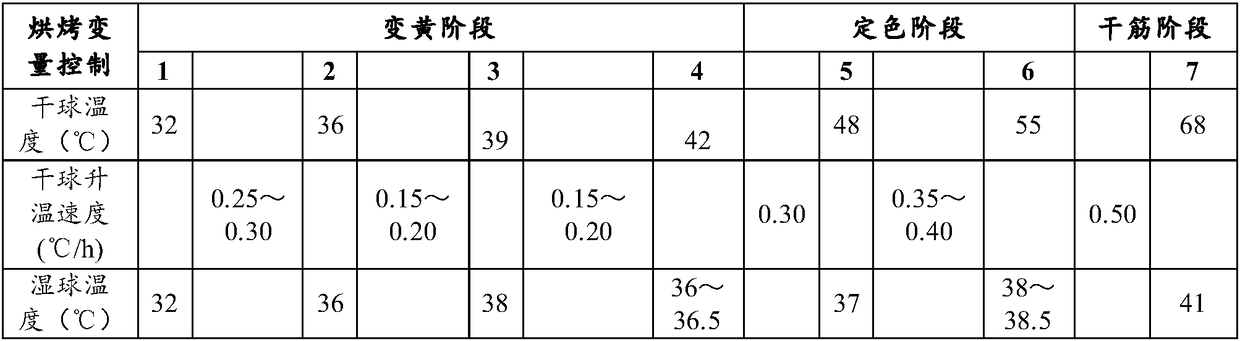

Tobacco curing process suitable for curing Yunyan (Yunnan tobacco) 116 variety tobacco leaves

ActiveCN107028214AImprove bake qualityImprove suction qualityTobacco preparationEconomic benefitsEngineering

The invention relates to a tobacco curing process suitable for curing Yunyan (Yunnan tobacco) 116 variety tobacco leaves, and belongs to the technical field of processing of tobacco leaves. The tobacco curing process comprises a yellowing stage, a withering stage, a previous color fixing stage, a later color fixing stage and a stem drying stage, and upper tobacco leaves, middle tobacco leaves and lower tobacco leaves are cured. In comparison with a conventional curing process, the process provided by the invention, when used for curing the fresh Yunyan 116 variety tobacco leaves, is higher in chroma fullness; average price of the tobacco leaves, obtained from the curing process, can reach 29.56 Yuan / kg, 2.40 Yuan / kg higher than the conventional process which is 27.16 Yuan / kg; and value caused by each furnace of tobacco leaves is more than 1000 Yuan higher than that of the conventional process. Meanwhile, the tobacco leaves, obtained from the curing process, is high in curing quality and better in smoking quality; and moreover, industrial availability of the cured tobacco leaves is also improved and economic benefit is obviously increased, so that the tobacco leaves are easy for popularization and application.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Mature-delay tobacco leaf baking process

The invention discloses a mature-delay tobacco leaf baking process, which relates to putting tobacco leaves in a baking barn and igniting. The process comprises the following steps: a, keeping dry-bulb temperature at 38 plus or minus 0.5 DEG C changelessly to roast for 4-6h; b, keeping the dry-bulb temperature at 40 plus or minus 0.5 DEG C changelessly to roast for 24-26h, keeping wet-bulb temperature at 39 plus or minus 0.5 DEG C within the first half of baking time, and keeping the wet-bulb temperature at 38 plus or minus 0.5 DEG C within the second half of baking time; c, keeping the dry-bulb temperature at 42 plus or minus 0.5 DEG C to roast for 26-28h; d, keeping the dry-bulb temperature at 44 plus or minus 0.5 DEG C to roast for 16-18h; e, keeping the dry-bulb temperature at 46 plusor minus 0.5 DEG C to roast for 14-16h; f, keeping the dry-bulb temperature at 48 plus or minus 0.5 DEG C to roast for 10-12h; g, keeping the dry-bulb temperature at 50 plus or minus 0.5 DEG C to roast for 8-10h; h, keeping the dry-bulb temperature at 54 plus or minus 0.5 DEG C to roast for 5-7h; i, keeping the dry-bulb temperature at 60 plus or minus 0.5 DEG C to roast for 7-9h; j, enabling the dry-bulb temperature to rise to 65-68 DEG C at the rate of heating up 1 DEG C every hour; keeping the dry-bulb temperature between 65 DEG C and 68 DEG C to roast for 19-21h; and finishing roasting.

Owner:陕西省烟草公司宝鸡市公司 +1

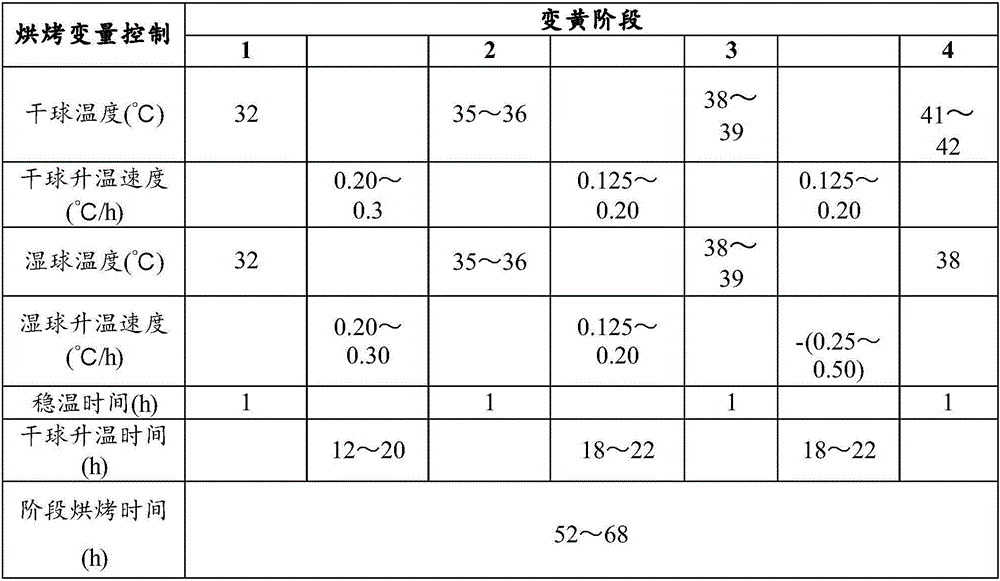

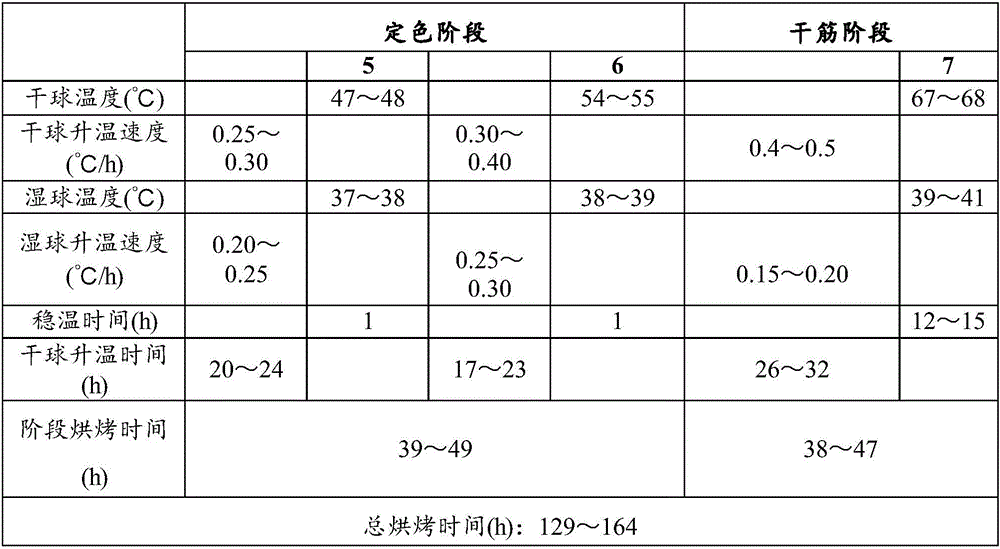

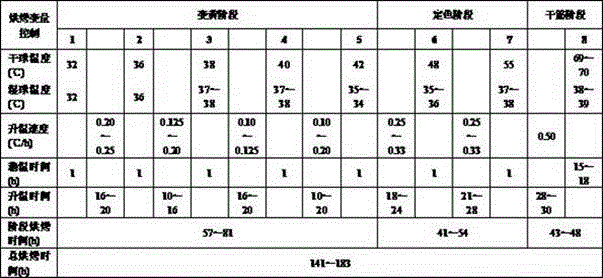

Bulk curing barn hanging rod continuous heating fragrant and soft roasting method

ActiveCN106579531AGuaranteed baking qualityImprove roast qualityTobacco preparationUsabilityEngineering

The invention provides a bulk curing barn hanging rod continuous heating fragrant and soft roasting method, and the method employs a technology of moisturizing and yellowing, slow color fixing, slow continuous heating, and temperature and humidity dynamic changing, guarantees that when the baking time of tobacco leaves at each layer in a curing barn is within a temperature and humidity range suitable for quality modulation is enough and has little difference, i.e., enabling the tobacco leaves at each layer to be yellowed fully and macromolecule materials to be fully or moderately degraded and converted into more aroma components, achieving the timely color fixing and reinforcement of quality, achieving the yellowing, fragrant roasting, soft roasting and mature roasting of tobacco leaves at each layer in the curing barn, and improving the tobacco leave baking quality and the industrial usability. The method provided by the invention is simple and clear, and is convenient for a baking person to master, set and modify.

Owner:UNIV OF SCI & TECH OF CHINA

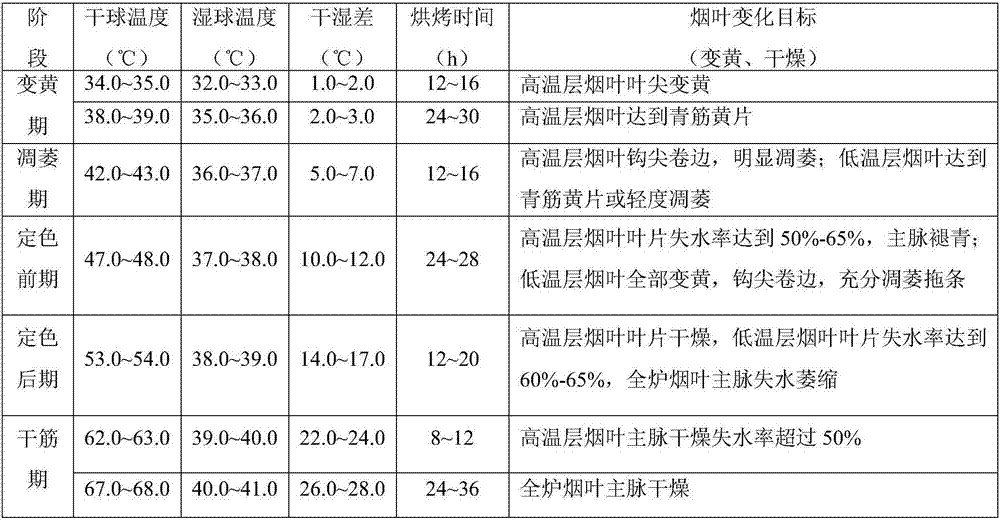

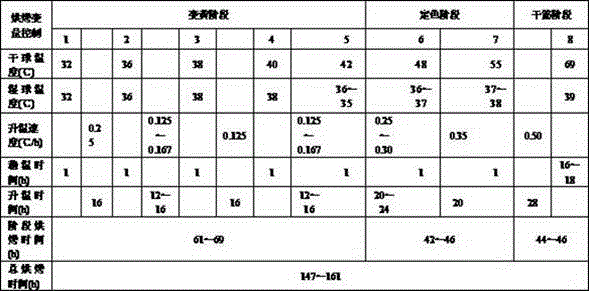

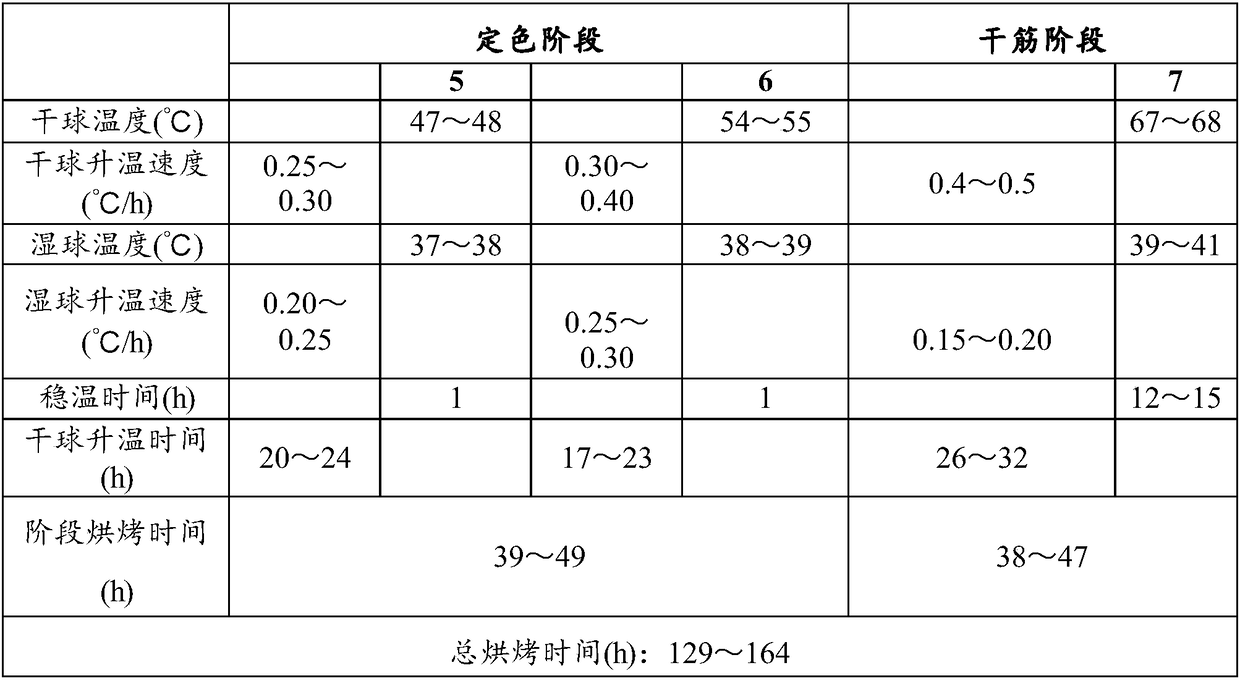

Curing method with dispersed leaf stacking type tobacco leaf loading type sustained temperature-increasing curing, fragrant curing and soft curing for bulk curing barn

ActiveCN106235371AGuaranteed baking qualityEnough time to bakeTobacco preparationTobacco processorMoisture

The invention discloses a curing method with dispersed tobacco leaf-stacking loading type sustained temperature-increasing curing, fragrant curing and soft curing for bulk curing barn. The curing method comprises the following steps of (1) adopting a dispersed tobacco leaf-stacking loading type; (2) setting and executing a dispersed tobacco leaf-stacking loading type sustained temperature-increasing curing, fragrant curing and soft curing technology of the bulk curing barn by a controller of the bulk curing barn, and curing in the air flow ascending type bulk curing barn for the dispersed tobacco leaf-stacking loading type; after yellowing period, color-fixing period and rib drying period, returning moisture, and unloading tobacco leaves. The curing method has the advantages that the curing quality of whole-curing tobacco leaves is ensured; by adopting the technique of moisture maintaining and yellowing, slow color-fixing, slow sustained temperature increasing, and dynamic change of temperature and humidity, the total content of fragrance in the cured tobacco leaves is averagely improved by 9.5%, the number of smooth tobacco leaves is averagely decreased by 38.9%, and the ratio of high-grade tobacco leaves is averagely increased by 13.6%.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP +1

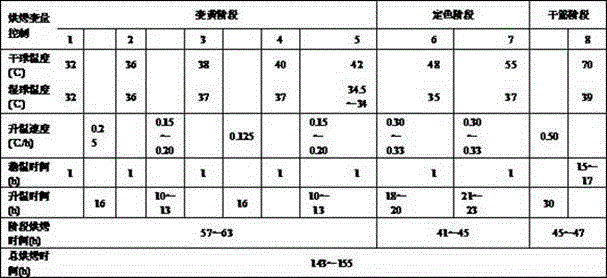

Flue-curing method for flue-cured tobacco NC87 tobacco leaves

InactiveCN108113040AImprove appearance qualityReduce starch contentTobacco preparationChemical compositionFrequency conversion

The invention belongs to the technical field of tobacco processing, and particularly relates to a flue-curing method for flue-cured tobacco NC87 tobacco leaves. The method comprises the steps that purple soil is planted to obtain lower tobacco leaves, middle tobacco leaves and upper tobacco leaves of NC87 to be flue-cured in different curing barns separately, the temperature is increased slowly inthe tobacco leaf yellowing period inside the curing barns, frequency conversion control is performed on a circulating fan adopted in different flue-curing stages of the yellowing period, the fixationperiod and the stem-drying period, and the whole flue-curing stage is divided into ten small stages; meanwhile, the temperature is increased at low speed in the yellowing period, and the temperatureof the yellowing period is controlled to be 389 DEG C or below; the high and medium temperature yellowing steady temperature period is prolonged by 12 h, and the fixation middle and later period steady temperature period is prolonged by 12 h; finally, the NC87 obtained after flue-curing is superior in appearance and quality, chemical components inside the tobacco leaves can be coordinated, the tobacco leaf sensory evaluation quality is improved, and economic benefits are improved.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL

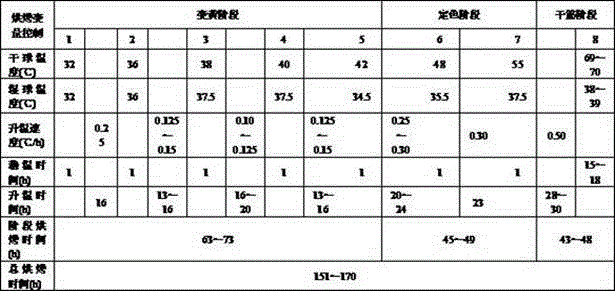

Bulk curing barn leaf scrap insertion tobacco filling continuous heating roasted fragrant and roasted soft roasting method

ActiveCN106235372AGuaranteed baking qualityImprove roast qualityTobacco preparationTobacco processorMaterials science

The invention discloses a bulk curing barn leaf scrap insertion tobacco filling continuous heating roasted fragrant and roasted soft roasting method. The method includes following steps: (1), adopting a leaf scrap insertion specified mode for tobacco filling; (2), inspecting a bulk curing barn with a curing barn controller, adopting a lower air dividing partition for control on the controller in the airflow-up bulk curing barn, going through a yellowing period, a color fixing period and a stem drying period, wetting back, and unloading the tobacco, wherein the bulk curing barn is an airflow-up bulk curing barn for roasting. By the method, fragrance ingredient content of tobacco can be averagely increased by 9.3% while roasting quality of all-kang tobacco, smooth cigarette amount can be averagely reduced by 28.7%, and first-glass cigarette proportion can be averagely increased by 12.1. The roasting method is terse and concise, convenient for roasting personnel to master, set and modify and capable of increasing income of tobacco growers.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP +1

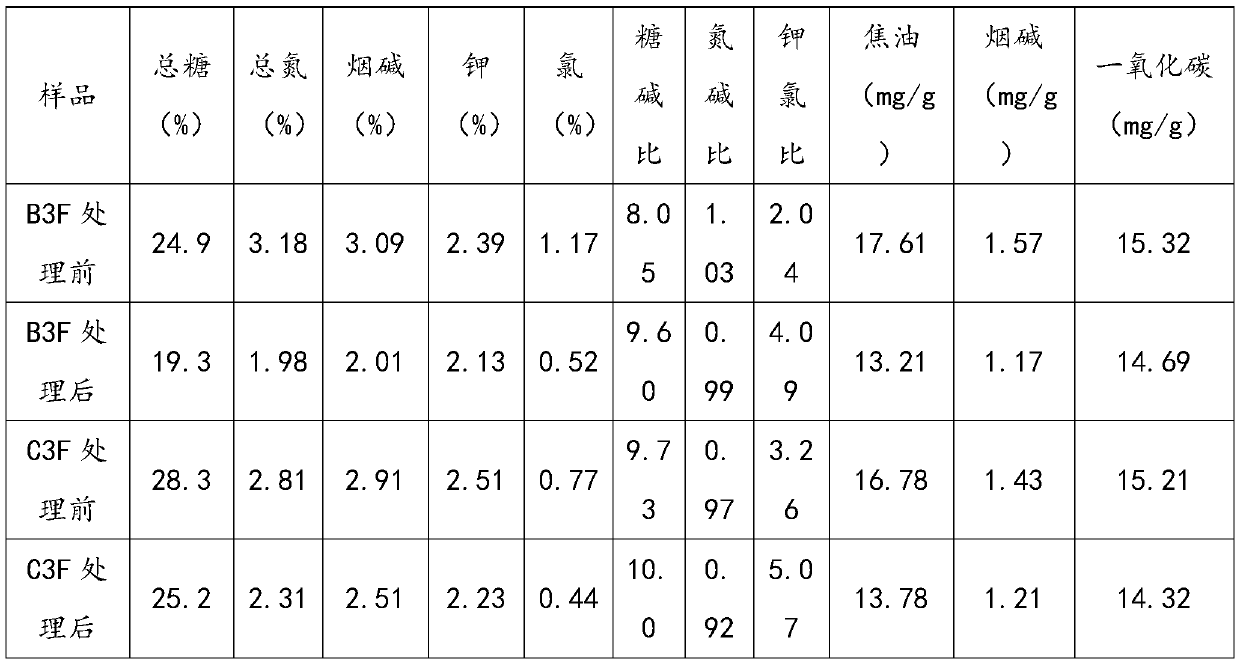

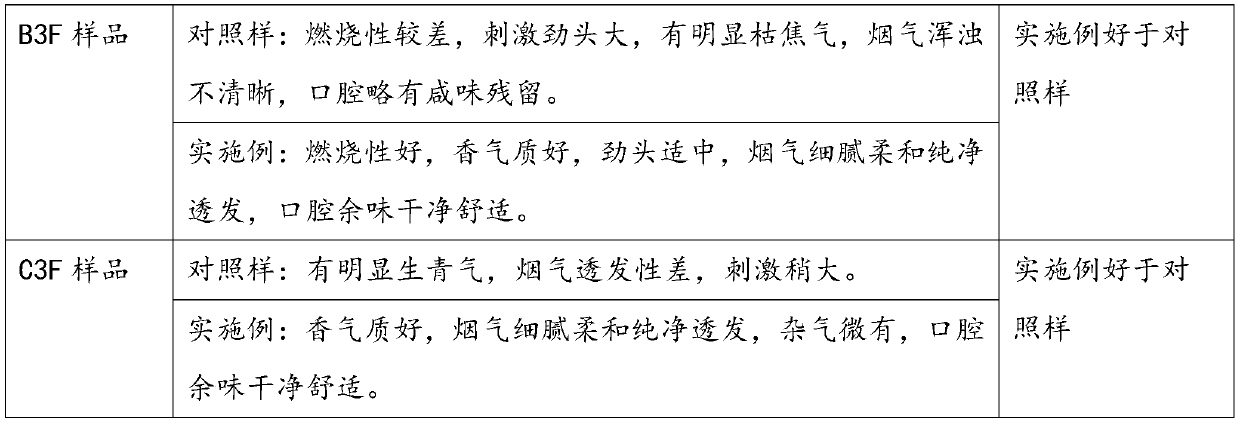

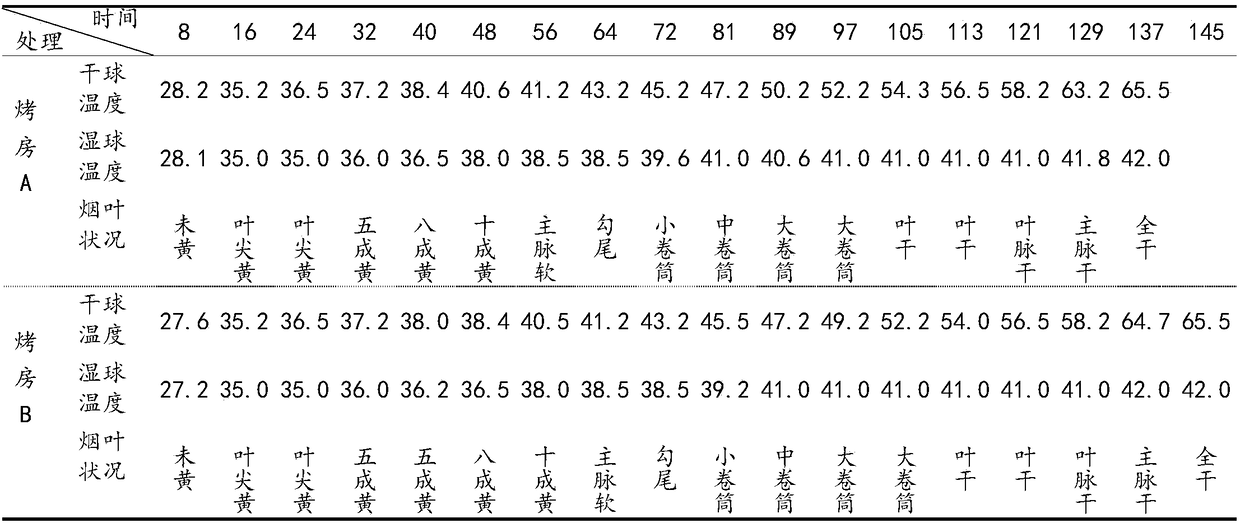

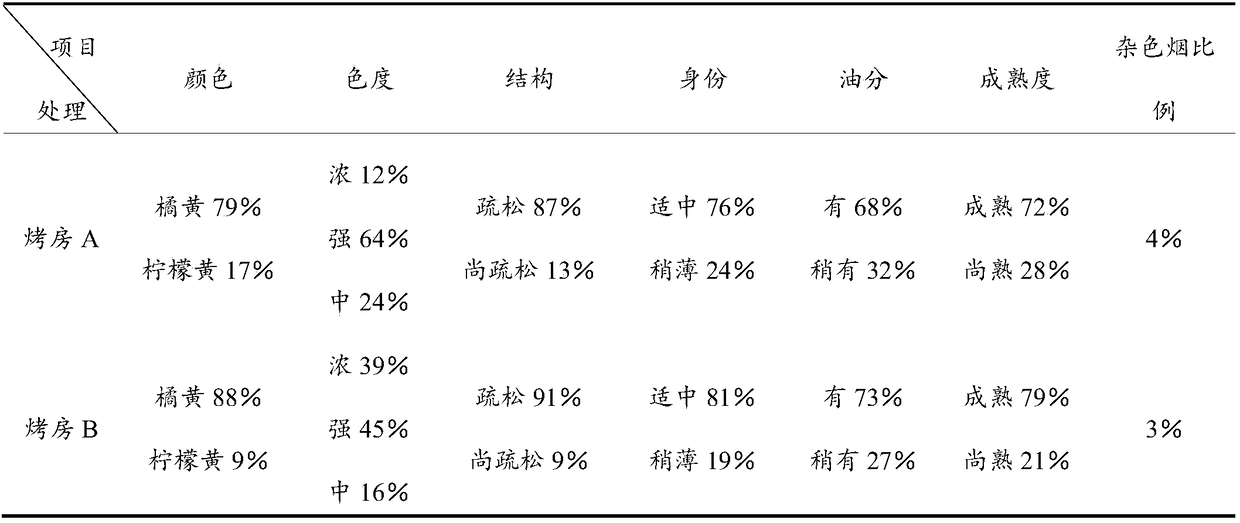

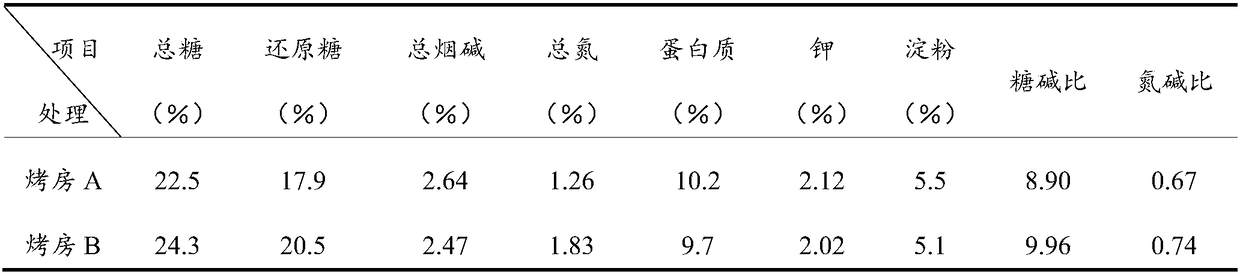

Method of quality improving and harm reducing of tobacco leaves

PendingCN110326813AFragrance texture is clear and transparentClear textureTobacco treatmentCigar manufactureIrritationPhenol

The invention relates to a method of quality improving and harm reducing of tobacco leaves. The method includes the following steps that the tobacco leaves are evenly mixed with water, a synergist anda hydrolysis promoting agent, hydrolysis is conducted, and solid liquid separation is conducted; and the hydrolyzed tobacco leaves are loosened and dried. By adopting the tobacco leaf processing treatment method capable of effectively reducing the negative influences of chemicals contained in the tobacco leaves through the hydrolysis effect and dissolving-out separation of parts of matter, when the treated tobacco leaves are smoked, smoke is fluffy and fine, aroma clarity and purity are better, offensive odors and irritation are reduced, the aftertaste is clean and comfortable, formulation application is improved, meanwhile, harmful components in the tobacco leaves and human body harmful components such as tar, carbon monoxide, methanol, phenol and ammonia in the smoke generated during burning are reduced, and the safety of smoking cigarettes is improved.

Owner:郝连顺 +2

Flue-curing method for flue-cured tobacco NC55 tobacco leaves

InactiveCN108113041AImprove appearance qualityReduce starch contentTobacco preparationChemical compositionLow speed

The invention belongs to the technical field of tobacco processing, and particularly relates to a flue-curing method for flue-cured tobacco NC55 tobacco leaves. The method comprises the steps that brunisolic soil is planted to obtain lower tobacco leaves, middle tobacco leaves and upper tobacco leaves of NC55 to be flue-cured in different curing barns separately, the temperature is increased slowly in the tobacco leaf yellowing period inside the curing barns, frequency conversion control is performed on a circulating fan adopted in different flue-curing stages of the yellowing period, the fixation period and the stem-drying period, and the whole flue-curing stage is divided into ten small stages; meanwhile, the temperature is increased at low speed in the yellowing period, and the temperature of the yellowing period is controlled to be 38 DEG C or below; the high and medium temperature yellowing steady temperature period is prolonged by 12 h, and the fixation middle and later period steady temperature period is prolonged by 12 h; finally, the NC55 obtained after flue-curing is superior in appearance and quality, chemical components inside the tobacco leaves can be coordinated, thetobacco leaf sensory evaluation quality is improved, and economic benefits are improved.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL +1

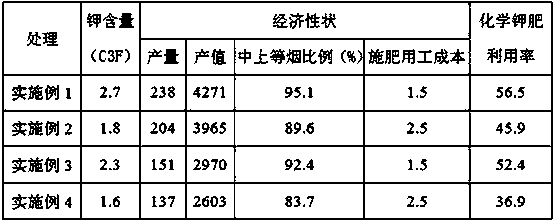

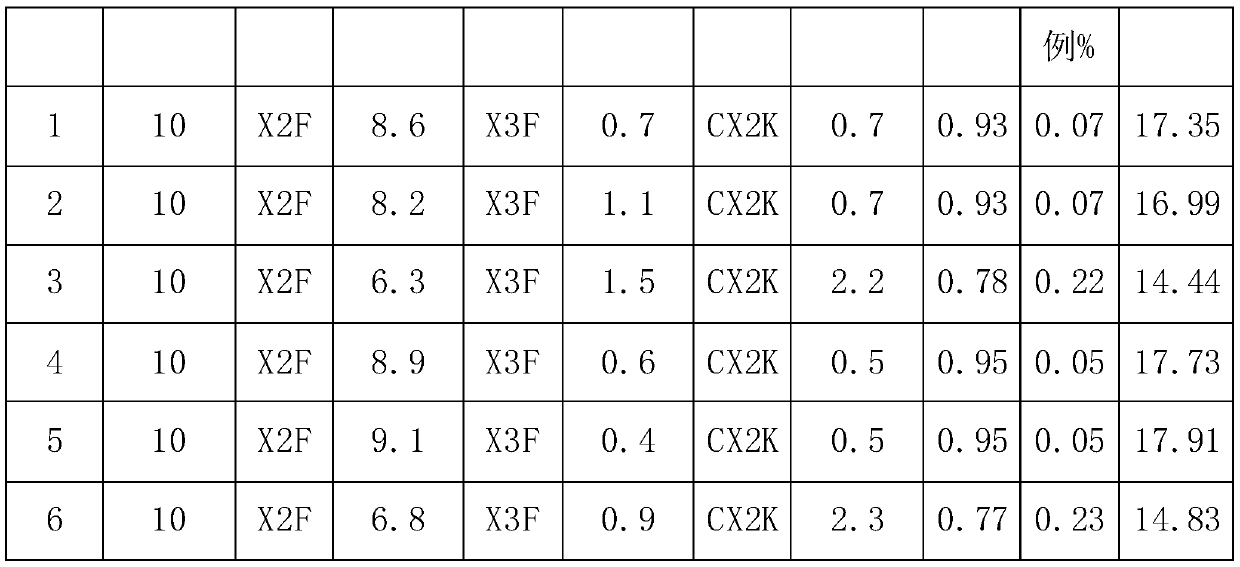

Fertilization method for increasing potassium content of cured tobacco

ActiveCN109258039AIncrease PotassiumImprove utilization efficiencyFertilising methodsTobacco cultivationPotassium nitrateNitrogen

The invention discloses a fertilization method for increasing the potassium content of cured tobacco. The method comprises the following technical steps that 1, base fertilizer is layered, and 30-40 kg / 667m<2> composite fertilizer special for tobacco and 250-300 kg / hm<2> potassium humate are applied to a pond; 2, drip irrigation and dressing of 10-20 kg / 667m<2> potassium nitrate and 5-10 kg / 667m<2> potassium fulvic acid are conducted; 3, 40-50 days after planting, 5-10 kg / 667m<2> potassium fulvic acid is applied to surfaces of leaves, wherein the concentration is 0.2-0.4%; 4, the proportion ofnitrogen to potassium in all chemical fertilizer is 1:(3-3.5). According to the fertilization method, the potassium content of the cured tobacco can be effectively increased, the input of chemical potassium fertilizer is controlled, the utilization efficiency of the potassium fertilizer is improved, the labor input of fertilization is reduced, and the production benefit of the cured tobacco is improved.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

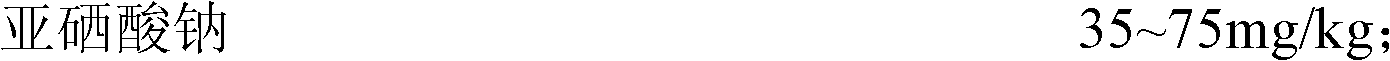

Special foliar spray fertilizer for planting of selenium-rich tobacco

ActiveCN103102195AIncrease selenium contentImprove production levelFertilizer mixturesSodium molybdateAgricultural science

The invention discloses a special foliar spray fertilizer for planting of a selenium-rich tobacco, which belongs to the technical field of tobacco production. A technical scheme of the invention is as follows: the special foliar spray fertilizer for planting of the selenium-rich tobacco comprises, by weight, 0.53 to 1.42% of sodium selenite, 17.01 to 33.03% of borax, 22.45 to 41.43% of zinc sulfate, 23.12 to 41.70% of manganese sulfate and 3.21 to 9.91% of sodium molybdate; before use of the fertilizer, the above-mentioned components are mixed in proportion and water is added so as to prepare a spray. The fertilizer is uniformly sprayed on the front and the back of tobacco leaves in rain-free weather 4 to 7 days before maturity and harvest of lower leaves of the tobacco, and spraying amount is 48 to 52 kg / Mu. The invention has the following advantages: the special foliar spray fertilizer provided by the invention can increase selenium content in the tobacco leaves, improve the commercial grade and industrial availability of the tobacco leaves and greatly enhance inherent quality of a selenium-rich tobacco leaf and safety of raw tobacco leaves at the same time, thereby ensuring sustainable development of production of the high-quality selenium-rich tobacco leaf.

Owner:HUBEI CHINA TOBACCO IND

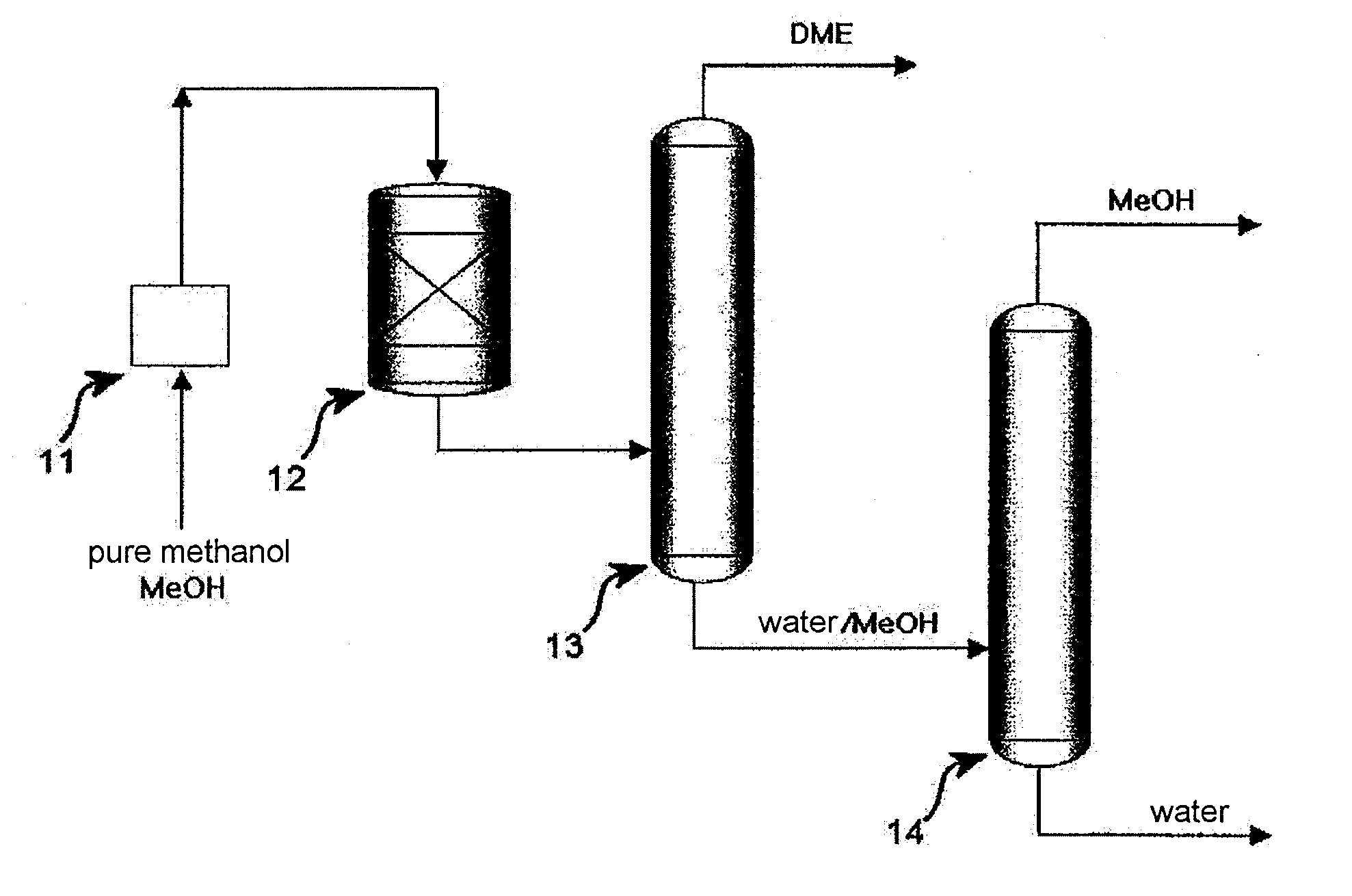

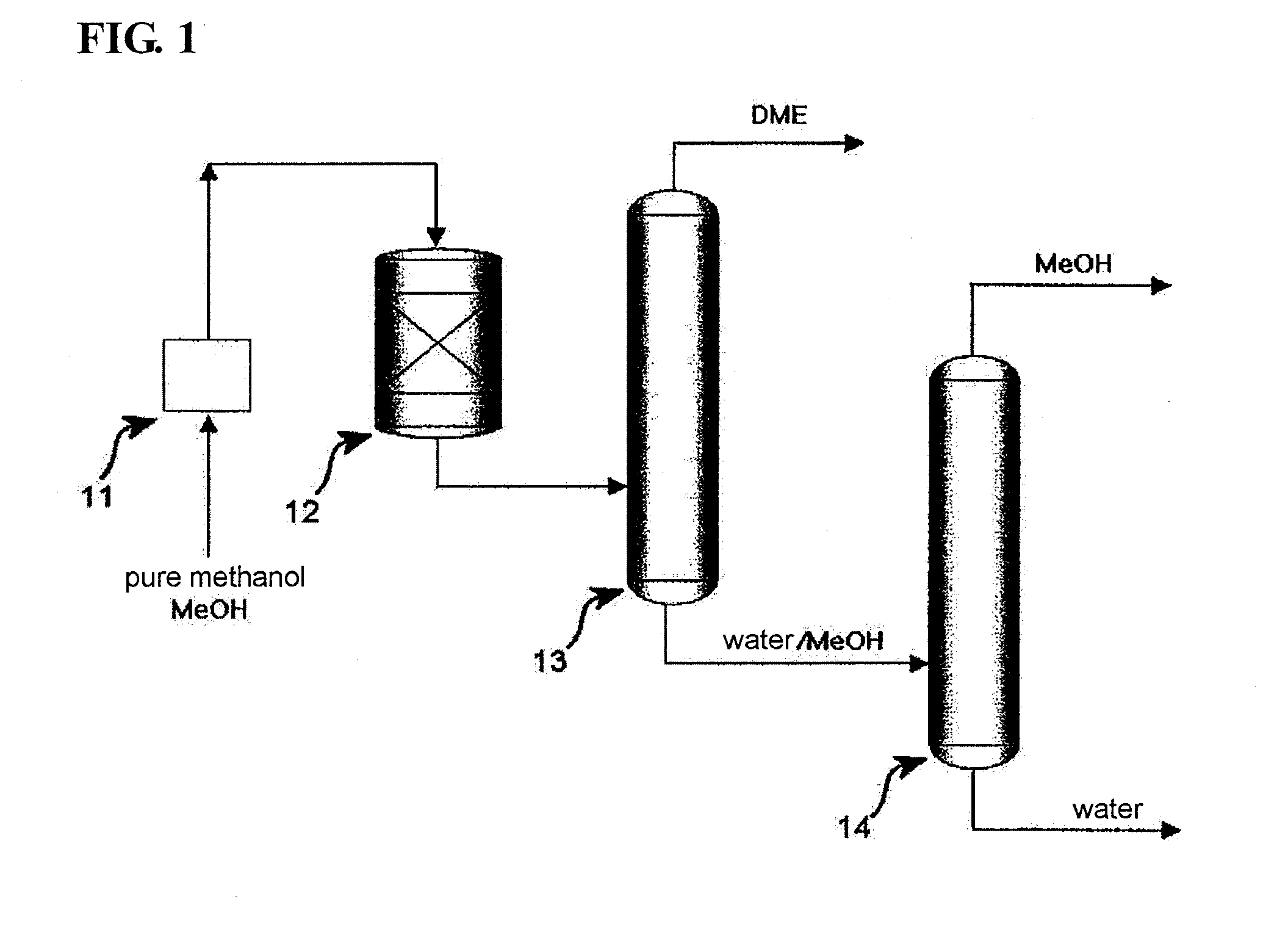

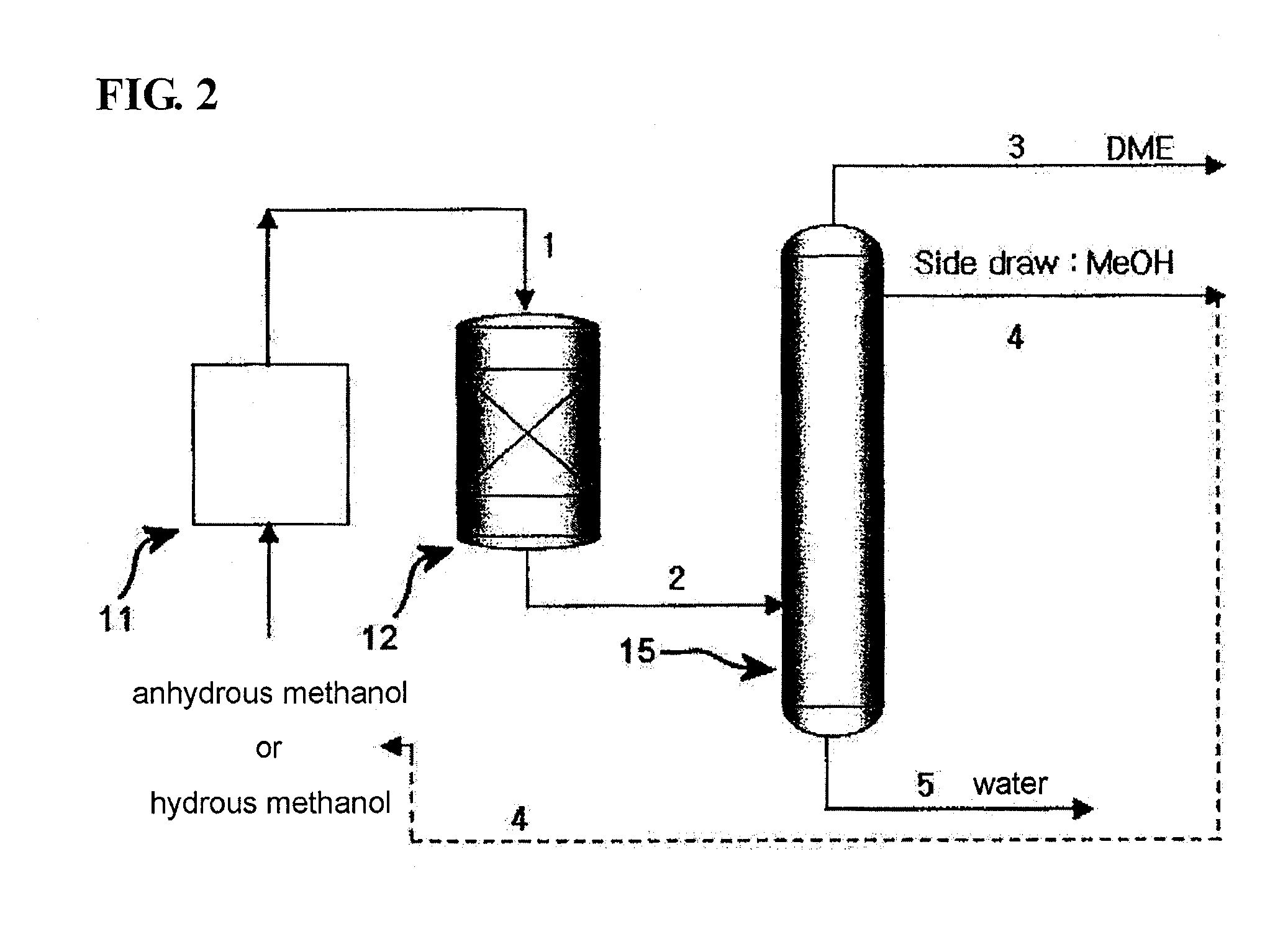

Process for preparing dimethyl ether

InactiveUS20100240932A1Speed up the conversion processRespond effectivelyOrganic compound preparationEther preparation by ester reactionsDimethyl etherSeparation column

Disclosed is a process for preparing dimethyl ether, including a) reacting methanol containing 0-80 mol % of water in the presence of a dehydration catalyst, b) transferring the reaction product into a single separation column, thus separating dimethyl ether, water, and unreacted methanol, c) withdrawing dimethyl ether and withdrawing unreacted methanol from the sidestream of the single separation column, and d) recyling the unreacted methanol to the a) reacting the methanol. Dimethyl ether may be prepared from water-containing methanol, and the separation and withdrawal of dimethyl ether, water, and unreacted methanol may be realized using a single column, thus reducing the investment cost and the operating cost.

Owner:SK ENERGY CO LTD (KR)

Foliar fertilizer for tobacco

InactiveCN107867917AIncrease selenium contentImprove production levelMagnesium fertilisersAlkali orthophosphate fertiliserNicotiana tabacumPhosphate

The invention relates to a tobacco leaf fertilizer, which belongs to the technical field of chemical fertilizers. Tobacco special foliage fertilizer of the present invention is made up of the material of following weight part: sodium selenite 0.5-1.4 part, zinc sulfate 22-41 part, borax 17-33 part, manganese sulfate 23-41 part, sodium molybdate 3-10 part 40-60 parts of potassium dihydrogen phosphate, 20-30 parts of magnesium sulfate heptahydrate, 60-80 parts of L-malic acid, 60-90 parts of uremic acid, and 0.05-0.1 parts of copper sulfate. The invention provides a special foliar spray fertilization that can increase the selenium content of flue-cured tobacco leaves, improve the commodity grade and industrial availability of tobacco leaves, and at the same time greatly improve the intrinsic quality of selenium-enriched tobacco leaves and the safety of tobacco leaf raw materials, increase yield, and improve disease resistance. ability.

Owner:QINGDAO DONGHAO SOFTWARE TECH CO LTD

Method for regulating key chemical component content of reconstituted tobacco

InactiveCN106509975AEasy to controlImproved overall quality and industrial usabilityTobacco preparationFlueChemistry

Provided is a method for regulating the key chemical components of reconstituted tobacco. Chemical component positive regulation and / or chemical component reverse regulation is conducted in the production process of the reconstituted tobacco, so that water-soluble sugars, total alkaloids, the total nitrogen content, the ratio of sugar to nitrogen, the nitrogen-nicotine ratio and the Schmuck value of the reconstituted tobacco reach the ranges of high-quality flue-cured tobacco. Chemical component positive regulation comprises the steps that carbohydrates are introduced to regulate the content of the water-soluble sugars, and / or alkaloids are introduced to regulate the content of the total alkaloids. Chemical component reverse regulation comprises the step that the total nitrogen content is regulated through a biological method. The method for regulating the key chemical components of the reconstituted tobacco is simple and easy to apply, the key chemical components of the reconstituted tobacco can be rapidly regulated, and the water-soluble sugars, the total alkaloids, the total nitrogen content and other key chemical component content as well as the ratio of sugar to nitrogen, the nitrogen-nicotine ratio, the Schmuck value and other key chemical component ratio can partially or completely reach the ranges of the high-quality flue-cured tobacco.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Flue-curing method for flue-cured tobacco Guangdong 98 tobacco leaves

InactiveCN108113046AImprove appearance qualityReduce starch contentTobacco preparationChemical compositionFrequency conversion

The invention belongs to the technical field of tobacco processing, and particularly relates to a flue-curing method for flue-cured tobacco Guangdong 98 tobacco leaves. The method comprises the stepsthat purple soil is planted to obtain lower tobacco leaves, middle tobacco leaves and upper tobacco leaves of Guangdong 98 to be flue-cured in different curing barns separately, the temperature is increased slowly in the tobacco leaf yellowing period inside the curing barns, frequency conversion control is performed on a circulating fan adopted in different flue-curing stages of the yellowing period, the fixation period and the stem-drying period, and the whole flue-curing stage is divided into ten small stages; meanwhile, the temperature is increased at low speed in the yellowing period, andthe temperature of the yellowing period is controlled to be 38.5 DEG C or below; the high and medium temperature yellowing steady temperature period is prolonged by 12 h, and the fixation middle and later period steady temperature period is prolonged by 12 h; finally, the Guangdong 98 obtained after flue-curing is superior in appearance and quality, chemical components inside the tobacco leaves can be coordinated, the tobacco leaf sensory evaluation quality is improved, and economic benefits are improved.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL +1

Method for baking flue-cured tobacco variety Xiangyan No. 3 tobacco

InactiveCN106418643AImprove appearance qualityReduce starch contentTobacco preparationCooking & bakingNicotiana tabacum

The invention belongs to the technical field of tobacco processing and particularly relates to a method for baking flue-cured tobacco variety Xiangyan No. 3 tobacco. According to the method, lower tobacco, middle tobacco and upper tobacco of Xiangyan No. 3 obtained by planting in sandy soil are separated and baked in different baking chambers, the temperatures during the tobacco yellowing period in the baking chambers rise slowly, circulating fans used at different baking periods at a yellowing period, a color fixation period and a dry rib period are regulated in a frequency conversion mode, and the whole baking period is divided into ten small periods; the temperature rises at a low speed during the yellowing period, and the temperature at the yellowing period is controlled below 39 DEG C; the medium-high temperature yellowing constant temperature is prolonged by 12 hours, and the color fixation middle and later period constant temperature is prolonged by 12 hours; finally is not only the baked Xiangyan No. 3 superior in appearance and quality, but also internal chemical ingredients of the tobacco can be coordinated, the sensory evaluation quality of the tobacco is improved, and economic benefits are improved.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL

Flue-curing method of tobacco leaves of flue-cured tobacco variety NC89

InactiveCN106723265AImprove appearance qualityReduce starch contentTobacco preparationTemperature controlNicotiana tabacum

The invention belongs to the technical field of tobacco processing, and in particular relates to a flue-curing method of tobacco leaves of a flue-cured tobacco variety NC89. The flue-curing method comprises the following steps: separately flue-curing lower tobacco leaves, middle tobacco leaves and upper tobacco leaves of the NC89 obtained by planting in sandy soil in different flue-curing barns; slowly raising the temperature at a yellowing stage of the tobacco leaves in a flue-curing room; carrying out frequency-variable regulation and control by utilizing a circulating draught fan at different flue-curing phases including the yellowing stage, a leaf-drying stage and a stem drying stage, wherein the whole flue-curing phase is divided into 10 sections; meanwhile, slowly raising the temperature at the yellowing stage and controlling the temperature of the yellowing stage to be 39 DEG C or lower; prolonging middle-temperature and high-temperature yellowing stable temperature for 12h; prolonging stable temperature at middle and later stages of the leaf-drying stage for 12h; finally, flue-curing to obtain the NC89. The NC89 has high appearance quality; chemical components in the tobacco leaves can be coordinated; the sensory taste quality of the tobacco leaves is improved, and economic benefits are improved.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL

Baking method for lower tobacco leaves of Chinese tobacco 101

InactiveCN109875090AIncreased Industrial AvailabilityUniform pole spacingTobacco preparationTobacco processorWet-bulb temperature

The invention discloses a baking method for lower tobacco leaves of Chinese tobacco 101. The method comprises the following steps that S1, the tobacco leaves are treated before baking; S2, the tobaccoleaves treated in S1 are placed in a baking room, the dry-bulb temperature of the baking room is raised to 45-50 DEG C at 0.5 DEG C / h, and the tobacco leaves are kept for 10-15 hours under the condition that the wet-bulb temperature is 36-37 DEG C, so that the leaves at the low temperature layer achieve the effects that the leaves and ribs turn yellow, the tips are hooked, the edges are rolled, and there is no green ribs in a whole furnace; S3, the dry-bulb temperature is raised to 50 DEG C at 1 DEG C / h, the wet-bulb temperature is controlled to be 37-38 DEG C, the temperature is kept for 8-10 hours, so that the leaves at the high temperature layer are large coils, and half drying is conducted; S4, the dry-bulb temperature is raised to 54 DEG C at 1 DEG C / h, the wet-bulb temperature is controlled to be 38-39 DEG C, the temperature is kept for 15-20 hours, and therefore the leaves in the whole baking room are completely dried; S5, the dry-bulb temperature is raised to 60 DEG C at 1 DEGC / h, the wet-bulb temperature is controlled to be 39-40 DEG C, and the temperature is kept for 5 hours, so that the tobacco ribs begin to shrink and turn brown, and 2 / 3 or above of the tobacco ribs are dried; S6, the dry-bulb temperature is raised to 68 DEG C at 1 DEG C / h, and the wet-bulb temperature is controlled to be 40-41 DEG C. By means of the method, the appearance and intrinsic quality ofthe lower baked tobacco leaves of the Chinese tobacco 101 can be effectively improved.

Owner:WEIFANG TOBACCO MONOPOLY BUREAU

Relay intercropping planting and returning utilization method for Vicia villosa in cold tobacco area

InactiveCN109588251AIncrease field growth periodIncrease biomassSeed and root treatmentFabaceae cultivationSoil qualityGreen manure

The invention discloses a relay intercropping planting and returning utilization method for Vicia villosa in a cold tobacco area. The method comprises steps as follows: Vicia villosa seed treatment, tobacco field soil preparation and sowing, fertilization management, water management, green manure turning and pressing and fertilization management of later-crop flue-cured tobaccos after green manure turning and pressing. By means of the Vicia villosa seed treatment, seed germination rate and emergence rate of the Vicia villosa can be effectively increased; by means of the fertilization management and the water management, growth and development of the Vicia villosa can be effectively promoted, and biomass of the Vicia villosa is increased; by means of the green manure turning and pressing treatment, the biomass of the overground part of the Vicia villosa can be effectively turned and pressed into a soil layer, and the Vicia villosa is promoted to be sufficiently decomposed and release nutrients; by means of the fertilization management of the later-crop flue-cured tobaccos after green manure turning and pressing, tobacco quality of the later-crop flue-cured tobaccos is improved. Comprehensively, the method has an obvious effect of increasing the biomass of the Vicia villosa as overwintering green manure in the cold tobacco area, improving soil quality of the tobacco field and improving tobacco quality of interplanting flue-cured tobaccos and the later-crop flue-cured tobaccos.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

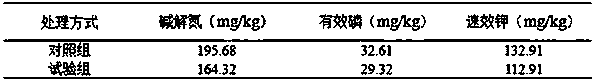

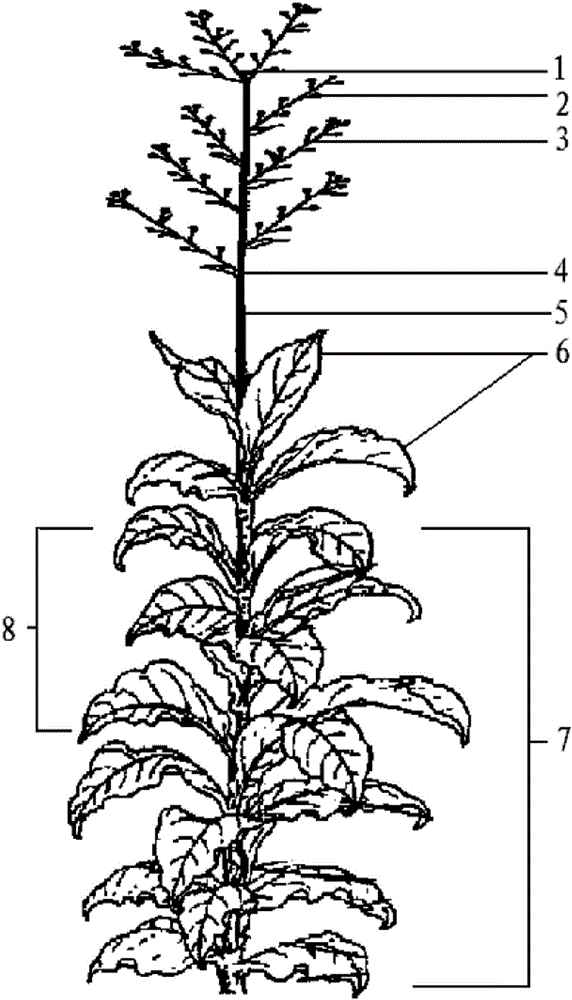

Flue-cured tobacco topping method

InactiveCN106069262AIncrease the value of cigarette formulationsReduce the ratioHorticulture methodsInflorescenceBiology

The invention discloses a flue-cured tobacco topping method. The flue-cured tobacco topping method is characterized in that in a topping process, useless leaves and inflorescences at the upper parts of tobacco plants are removed and useful leaves are kept; and meanwhile, at least two sections of stems at the upper ends of the useful leaves are kept. According to the flue-cured tobacco topping method disclosed by the invention, tender stems at the tops of the tobacco plants are remained, so that the tender stems at the tops of the tobacco plants are organized together to realize certain apical dominance effect, and furthermore, the growth potential of the tobacco plants can be automatically adjusted, the nicotine and special leaf weight of upper leaves are reduced and the sensory quality of the upper leaves is improved.

Owner:UNIV OF SCI & TECH OF CHINA +3

Method for removing offensive odor and improving quality of tobacco leaves by negative pressure regulating method

PendingCN110786541AImprove qualityIncreased Industrial AvailabilityTobacco treatmentBiotechnologyNicotiana tabacum

The invention belongs to the field of tobacco, and particularly relates to a method for removing offensive odor of tobacco leaves and improving the quality and the industrial availability of the tobacco leaves by processing the tobacco leaves by a negative pressure regulating method. The tobacco leaves are processed under the conditions of the vacuum degree of 0.010 to 0.098 MPa and the treatmenttime of 2 to 60 minutes; through controlling the process conditions of the vacuum degree, the processing time and the like, the offensive odor of the tobacco leaves can be well removed; and the quality and the industrial availability of the tobacco leaves are improved. The sensory evaluation results show that the processed sample tobacco leaves are greatly improved in aspects of aroma volume, offensive odor, aroma diffusivity, mouthfeel, aftertaste and the like; and the quality and the industrial availability are obviously improved. The tobacco leaves capable of only being used in a cigaretteformula at the price below 6 Yuan / packet can be used in a cigarette formula at the price about 10 Yuan / packet after being processed.

Owner:CHINA TOBACCO GUANGXI IND

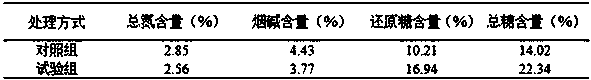

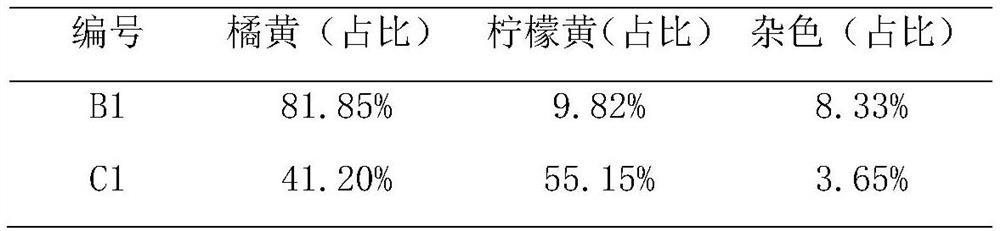

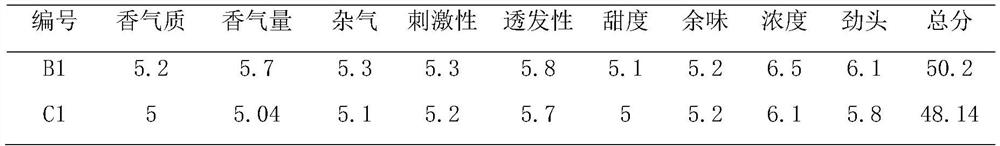

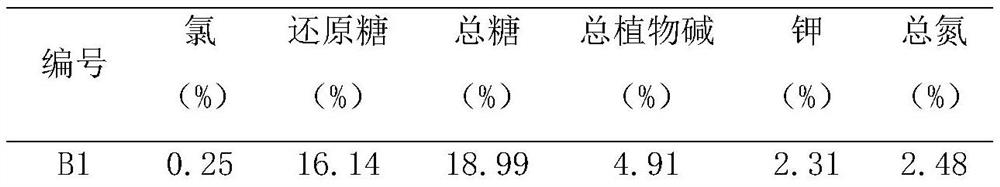

Compound preparation for improving quality of upper tobacco leaves of flue-cured tobacco and preparation method and application of compound preparation

ActiveCN111789282AAvoid quality defectsIncreased Industrial AvailabilityBio-organic fraction processingTobacco treatmentBiotechnologyNicotiana tabacum

The invention belongs to the technical field of tobacco production, and particularly discloses a compound preparation for improving the quality of upper tobacco leaves of flue-cured tobacco and a preparation method and application of compound preparation. The compound preparation comprises a first inoculum containing bacillus cereus 4-a, a second inoculum containing bacillus cereus 4-d and an enzyme preparation, the preservation number of the bacillus cereus 4-a is CGMCC No.3864, and the preservation number of the bacillus cereus 4-d is CGMCC No.5977. By adopting the upper tobacco leaves processed through the scheme, compared with contrast tobacco leaves which do not adopt the technology, the upper tobacco leaves of the flue-cured tobacco treated by adopting the technical scheme have the advantages that more efficient conversion of macromolecular substances in the curing process is facilitated, and the grade structure quality, sensory evaluation score, chemical component coordination and the like of the tobacco leaves are remarkably improved.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Flue-cured tobacco upper smoke baking method

InactiveCN100411550CIncrease orange smoke rateImprove industrial qualityTobacco preparationBiologyPreparation procedures

The invention discloses an upper cured tobacco baking method belonging to the field of cured tobacco baking concocting technology. The feed preparation procedure selects the upper tobacco in delay harvest or half plant harvest mode which harvests leaf and main trunk one time. Rod hanging procedure bakes the half plant of upper cured tobacco stem and leaf together without separating the same. Baking procedure employs three-section baking method, wherein all sections of the baking time are prolonged for more than 3 hours, and the early temperature of bake-yellowing is reduced for 1 to 2 DEG C. After-baking procedure picks the leaf off from the trunk when the leaf becomes a little soft and the main trunk becomes hard and brittle after being taken off from bed. The invention can, in average, enhance orange smoke rate of the upper tobacco for 5.0 % and first-rate tobacco rate for about 4.0 %, price of original tobacco for 1 Yuan per kilogram.

Owner:WUHAN TOBACCO GROUP

Special foliar spray fertilizer for planting of selenium-rich tobacco

ActiveCN103102195BIncrease selenium contentImprove production levelFertilizer mixturesSodium molybdateAgricultural science

The invention discloses a special foliar spray fertilizer for planting of a selenium-rich tobacco, which belongs to the technical field of tobacco production. A technical scheme of the invention is as follows: the special foliar spray fertilizer for planting of the selenium-rich tobacco comprises, by weight, 0.53 to 1.42% of sodium selenite, 17.01 to 33.03% of borax, 22.45 to 41.43% of zinc sulfate, 23.12 to 41.70% of manganese sulfate and 3.21 to 9.91% of sodium molybdate; before use of the fertilizer, the above-mentioned components are mixed in proportion and water is added so as to prepare a spray. The fertilizer is uniformly sprayed on the front and the back of tobacco leaves in rain-free weather 4 to 7 days before maturity and harvest of lower leaves of the tobacco, and spraying amount is 48 to 52 kg / Mu. The invention has the following advantages: the special foliar spray fertilizer provided by the invention can increase selenium content in the tobacco leaves, improve the commercial grade and industrial availability of the tobacco leaves and greatly enhance inherent quality of a selenium-rich tobacco leaf and safety of raw tobacco leaves at the same time, thereby ensuring sustainable development of production of the high-quality selenium-rich tobacco leaf.

Owner:HUBEI CHINA TOBACCO IND

A method of hanging tobacco in a dense barn on a pole and continuously heating up to roast fragrant roasting and soft roasting

ActiveCN106579531BGuaranteed baking qualityImprove roast qualityTobacco preparationCooking & bakingMacromolecular Substances

The invention provides a bulk curing barn hanging rod continuous heating fragrant and soft roasting method, and the method employs a technology of moisturizing and yellowing, slow color fixing, slow continuous heating, and temperature and humidity dynamic changing, guarantees that when the baking time of tobacco leaves at each layer in a curing barn is within a temperature and humidity range suitable for quality modulation is enough and has little difference, i.e., enabling the tobacco leaves at each layer to be yellowed fully and macromolecule materials to be fully or moderately degraded and converted into more aroma components, achieving the timely color fixing and reinforcement of quality, achieving the yellowing, fragrant roasting, soft roasting and mature roasting of tobacco leaves at each layer in the curing barn, and improving the tobacco leave baking quality and the industrial usability. The method provided by the invention is simple and clear, and is convenient for a baking person to master, set and modify.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com