Curing method with dispersed leaf stacking type tobacco leaf loading type sustained temperature-increasing curing, fragrant curing and soft curing for bulk curing barn

A technology of dense curing room and curing method, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of affecting the activity of hydrolytic enzymes, low moisture content of tobacco leaves, and low temperature, so as to improve industrial usability, improve curing quality, The effect of concise baking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

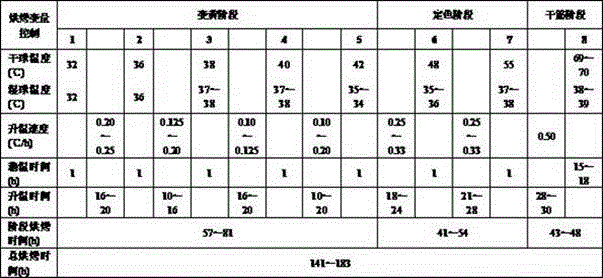

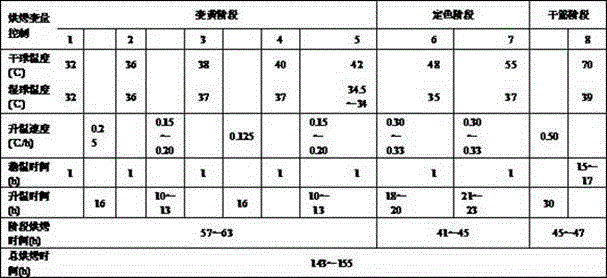

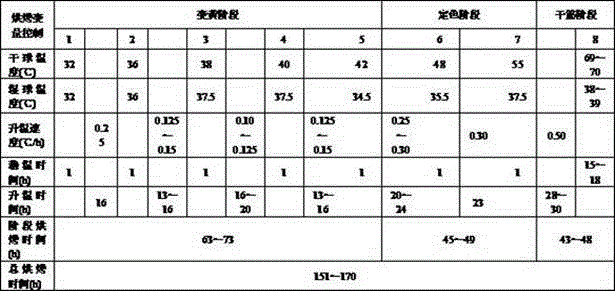

[0029] Provides a method of stacking loose leaves in a dense barn for continuous heating and roasting for fragrant roasting and soft roasting, including the following steps:

[0030](1) Pack the cigarettes in the way of completely loose leaf stacking. On the basis of the classification of suitable ripe harvested tobacco leaves and fresh tobacco, the tobacco is classified, appropriate and evenly packed. First place the tobacco grid (air distribution plate) flat on the tobacco rack in the barn, shake the tobacco leaves lightly, and arrange the base of the leaves relatively evenly; To load the tobacco in the same way; each layer of stacked tobacco leaves should be stacked in the same direction, with a slight inclination to the front, and the angle of stacking the smoke is 85-90 degrees. Each layer of tobacco leaves must be evenly filled without leaving any gaps. Smoke is loaded from the front end of the smoke chamber to the rear, and when one grid is filled with tobacco leaves, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com