Multifunctional oven with automatic rotating disc

A multi-functional, turntable technology, applied in the field of ovens, can solve problems affecting the quality of food baking, fuel smoke, time-consuming and labor-consuming, etc., to achieve high use value, improve efficiency and quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

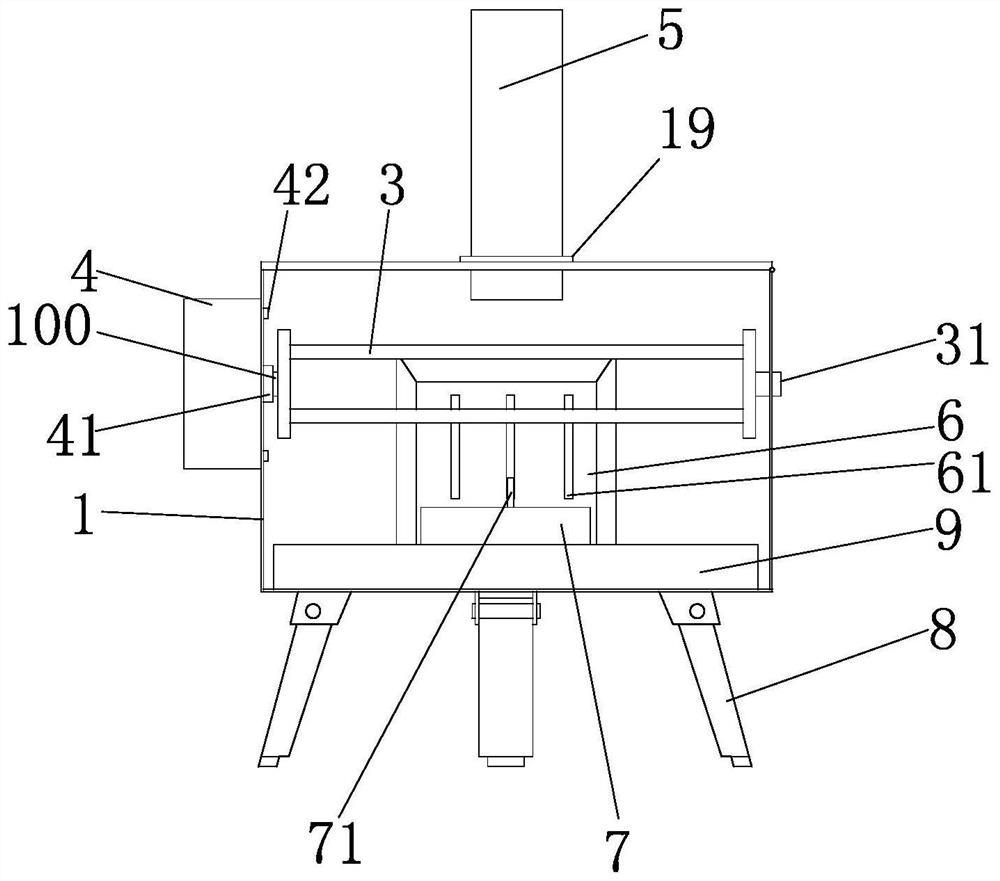

[0036] refer to Figure 1-8 , a multifunctional oven with an automatic turntable, comprising a furnace body 1, a turntable 2, a grill 3, and a clockwork device 4, the furnace body 1 is provided with a baking chamber 11, a combustion chamber 12, and the baking chamber 11 It communicates with the combustion chamber 12, and the baking chamber 11 communicates with a smoke outlet for exhausting smoke to the outside;

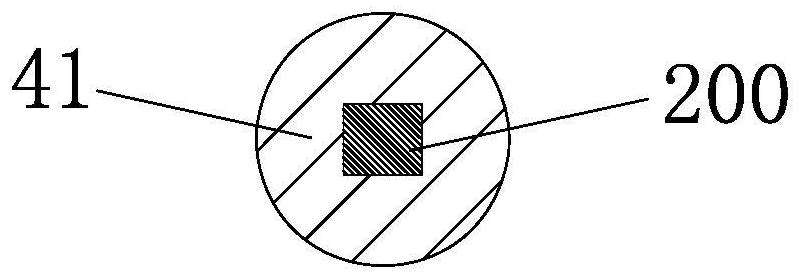

[0037] The furnace body 1 is provided with a first installation area and a second installation area, the first installation area is located on the side wall of the furnace body 1, and the second installation area is located on the bottom wall of the furnace body 1. The clockwork device 4 is detachably installed on the first installation area or the second installation area. The clockwork device 4 includes a housing, a clockwork mechanism located in the housing, an output shaft 41 driven by the clockwork mechanism to rotate, Drive the turning handle of the clockwork m...

Embodiment 2

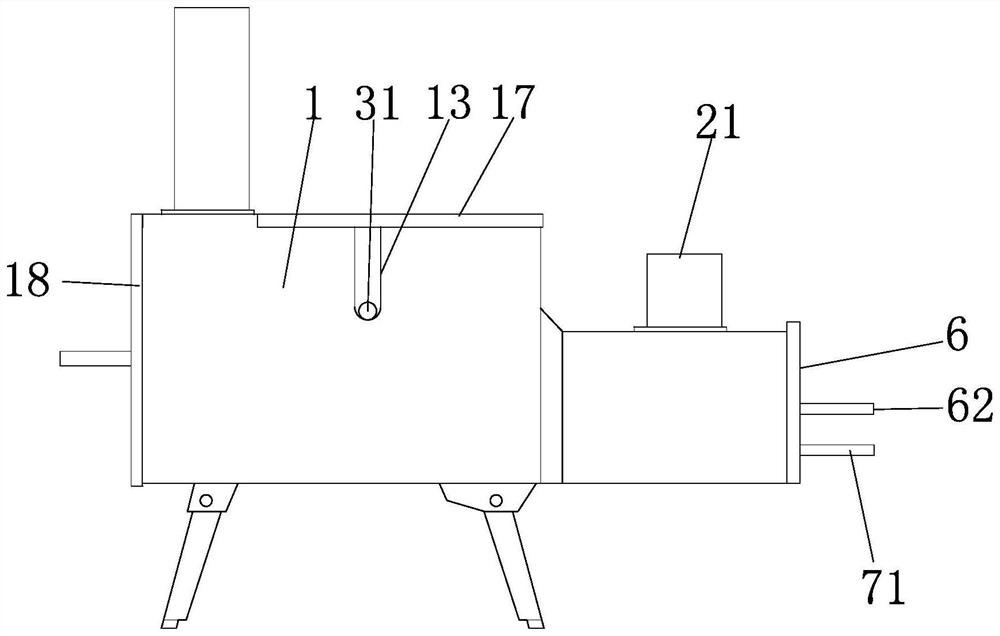

[0053] refer to Figure 9 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, a mounting base is placed under the furnace body 1, and the second hanging hole 16 is installed on the mounting base. On the installation plate 10, the installation base and the furnace body 1 are arranged separately without connection, so as to facilitate storage. Described mounting base comprises bottom support, is located at the mounting plate 10 of bottom supporting upper end, and described clockwork device 4 is installed on the bottom surface of mounting plate 10, and described mounting plate 10 is provided with for the output shaft 41 of clockwork device 4 The transmission slot passing through is provided with a unilateral opening so that the output shaft 41 of the clockwork device 4 is inserted into the transmission slot.

[0054] In this embodiment, a sliding support structure for stably rotating the turntable 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com