Method of quality improving and harm reducing of tobacco leaves

A technology for tobacco leaves and flue-cured tobacco, which is applied in the fields of tobacco, tobacco processing, and cigar manufacturing, etc. It can solve the problems of affecting the style and taste of tobacco leaves, increasing the difficulty of cigarette formula, and obvious local characteristics, so as to improve the use value and industrial usability, reduce the Unusable amount of tobacco leaves, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

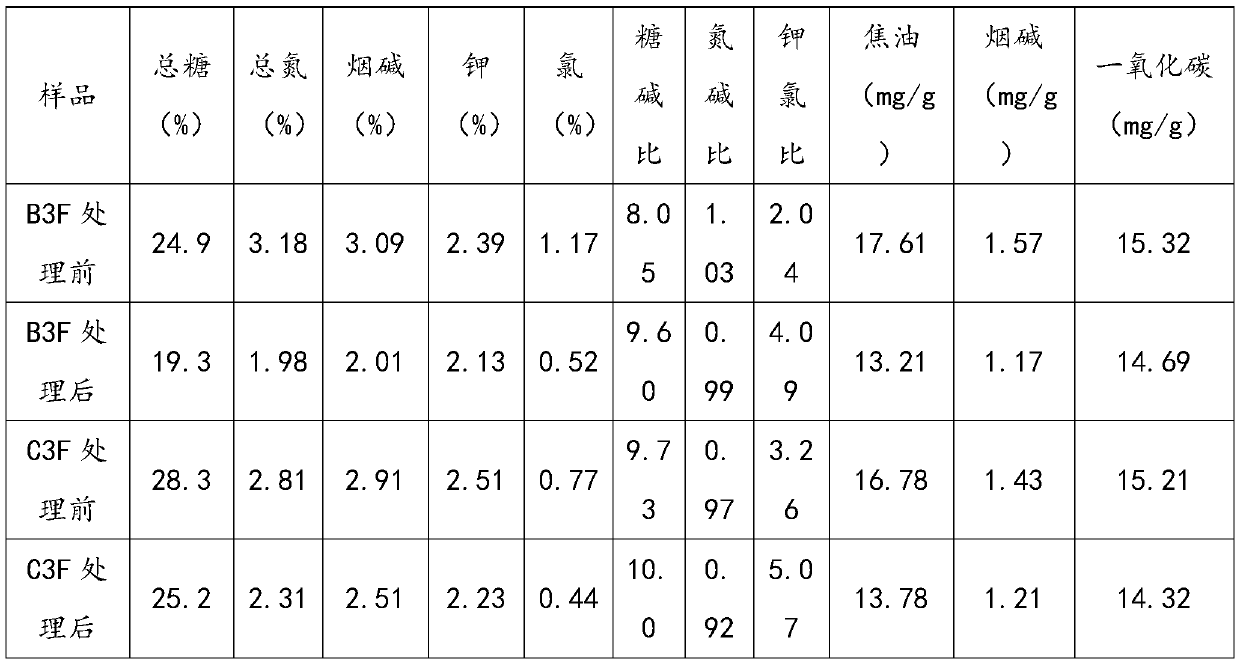

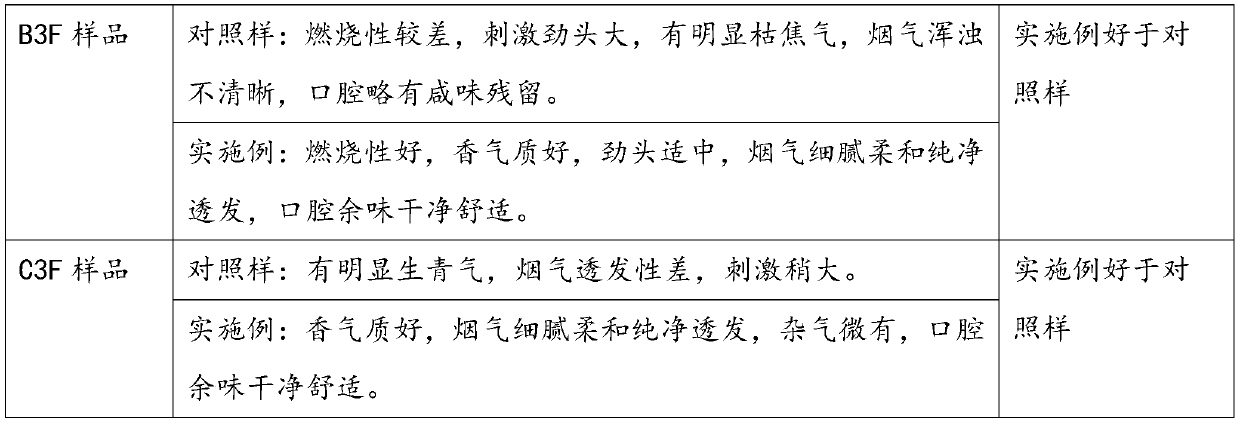

Embodiment 1

[0051] The method for tobacco leaf quality improvement and harm reduction of the present embodiment comprises the following steps:

[0052] 1) Add Shandong B3F rebaked tobacco into the device;

[0053] 2) Add 1% sodium sulfate aqueous solution, synergist, and hydrolyzing agent to the container for hydrolysis, the mass ratio of tobacco leaves to sodium sulfate aqueous solution is 1:8, the synergist is ethanol, and the synergist and sodium sulfate The mass ratio of the aqueous solution is 0.5:1, the added amount of the hydrolysis accelerator is 2% of the mass of the tobacco leaves, the hydrolysis accelerator is composed of hydrochloric acid and sulfuric acid with a mass ratio of 1:0.5, the hydrolysis temperature is 80°C, and the hydrolysis time is 6h;

[0054] 3) After the hydrolysis is completed, the hydrolyzed tobacco leaves in step 2) are subjected to solid-liquid separation, the solid content of the separated liquid is 30% of the dry weight of the tobacco leaves, and the sol...

Embodiment 2

[0058] The method for tobacco leaf quality improvement and harm reduction of the present embodiment comprises the following steps:

[0059] 1) Add Sichuan C3F first-cured shredded tobacco into the device;

[0060] 2) add water, synergist, hydrolyzing agent in container and carry out hydrolysis, the mass ratio of tobacco leaf and water is 1:6, synergist is ethanol and propylene glycol by mass ratio 1:1 composition, synergist and water The mass ratio is 0.1:1, the added amount of the hydrolysis accelerator is 1% of the mass of the tobacco leaf, the hydrolysis accelerator is composed of hydrochloric acid and potassium sulfate in a mass ratio of 0.5:0.1, the hydrolysis temperature is 40°C, and the hydrolysis time is 1h;

[0061] 3) After the hydrolysis is completed, the hydrolyzed tobacco leaves in step 2) are subjected to solid-liquid separation, the solid content of the separated liquid is 10% of the dry weight of the tobacco leaves, and the solid-liquid separation method is mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com