Flue-cured tobacco topping method

A technology for flue-cured tobacco and tobacco plants, applied in horticultural methods, botanical equipment and methods, horticulture, etc., can solve problems such as unfavorable purity and management of tobacco seeds, inability to change the morphological characteristics of upper leaves, and inability to fully meet industrial needs, and to improve the Formulation value, effect of improving upper leaf quality, increasing industrial availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

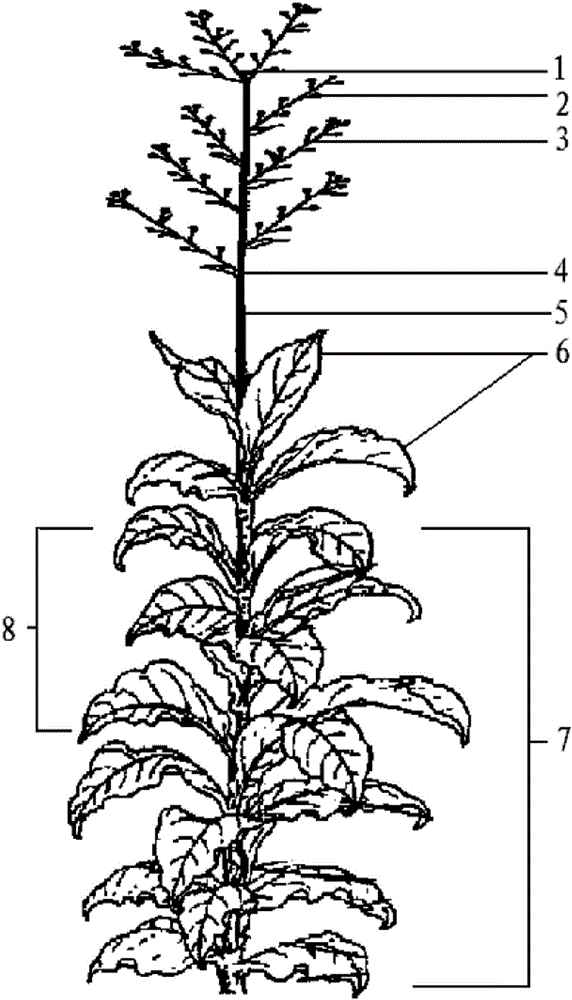

[0029] Example 1 Topping method of flue-cured tobacco "threshing leaves and leaving stems"

[0030] The experimental tobacco strains were selected from the experimental station of the University of Science and Technology of China. The experiment was repeated three times and carried out in three plots, with 20 strains in each plot. Seven days before the opening of the central flower, top the experimental tobacco plants according to the method of "threshing leaves and leaving stems", remove the invalid leaves and inflorescences on the upper part of the tobacco plants, keep 18 effective leaves, and keep 2 nodes at the upper end of the effective leaves stems.

[0031] In addition, in the same plot, 20 tobacco plants with the same production management, such as variety, transplanting time, fertilization, planting density, and number of leaves left, and with the same growth and appearance were selected as control tobacco plants. 7 days before the central flowers of the control toba...

Embodiment 2

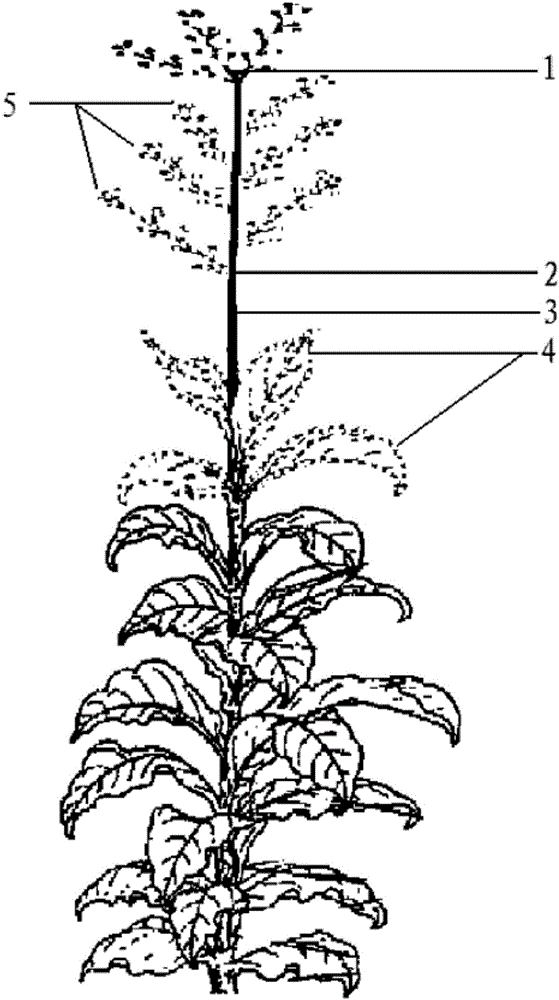

[0033] Example 2 Topping method of flue-cured tobacco "threshing leaves and leaving stems"

[0034] The experimental tobacco strains were selected from the experimental station of the University of Science and Technology of China. The experiment was repeated three times and carried out in three plots, with 20 strains in each plot. When the central flower blooms, top the experimental tobacco plants according to the method of "threshing leaves and leaving stems", remove the invalid leaves and inflorescences on the upper part of the tobacco plants, keep 18 effective leaves, and at the same time retain the stems of the upper 4 nodes of the effective leaves pole.

[0035] In addition, in the same plot, 20 tobacco plants with the same production management, such as variety, transplanting time, fertilization, planting density, and number of leaves left, and with the same growth and appearance were selected as control tobacco plants. When the central flower of the control tobacco pla...

Embodiment 3

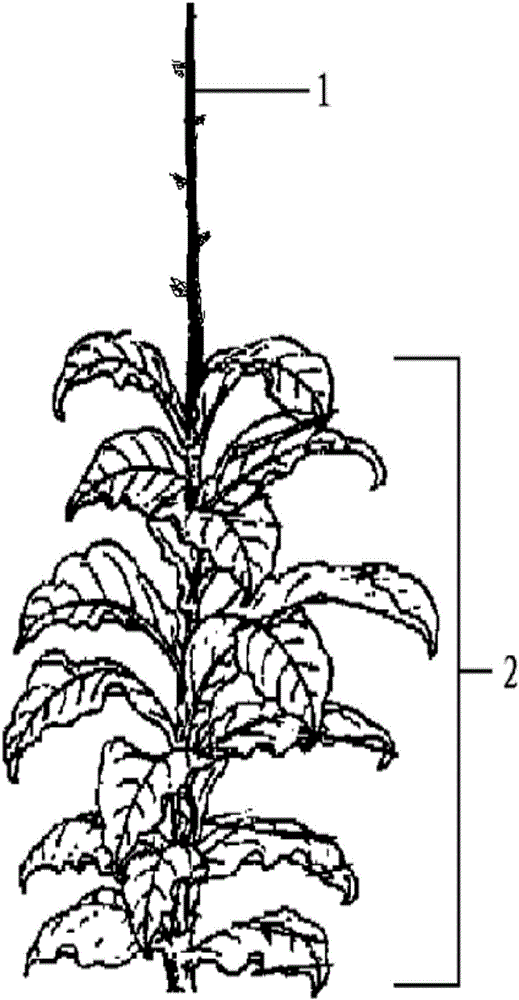

[0037] Example 3 Topping method of flue-cured tobacco "threshing leaves and leaving stems"

[0038] The experimental tobacco strains were selected from the experimental station of the University of Science and Technology of China. The experiment was repeated three times and carried out in three plots, with 20 strains in each plot. 7 days after the central flower bloomed, top the experimental tobacco plants according to the method of "threshing leaves and leaving stems", remove the invalid leaves and inflorescences on the upper part of the tobacco plants, keep 18 effective leaves, and retain 6 nodes on the upper end of the effective leaves stems.

[0039] In addition, in the same plot, 20 tobacco plants with the same production management, such as variety, transplanting time, fertilization, planting density, and number of leaves left, and with the same growth and appearance were selected as control tobacco plants. 7 days after the central flower of the control tobacco plant op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com