Baking method for lower tobacco leaves of Chinese tobacco 101

A method of curing tobacco leaves, which is applied in the field of flue-cured tobacco and can solve problems such as inaccurate control of curing characteristics, high requirements for baking personnel, and difficulty in curing tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

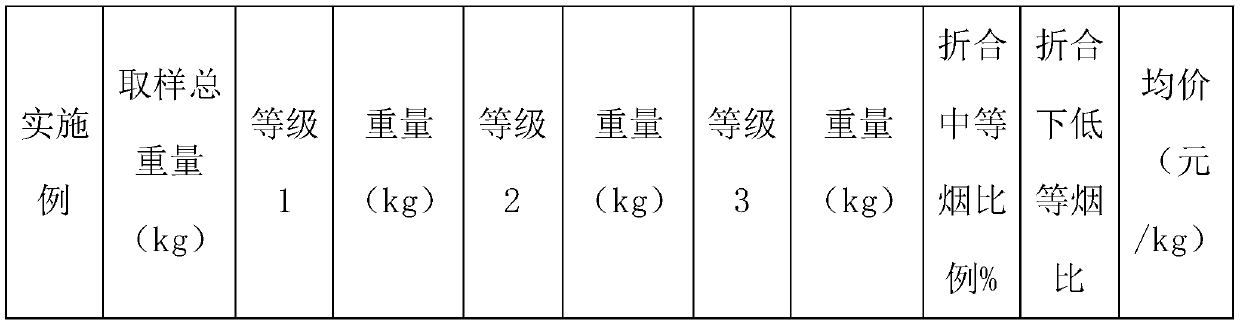

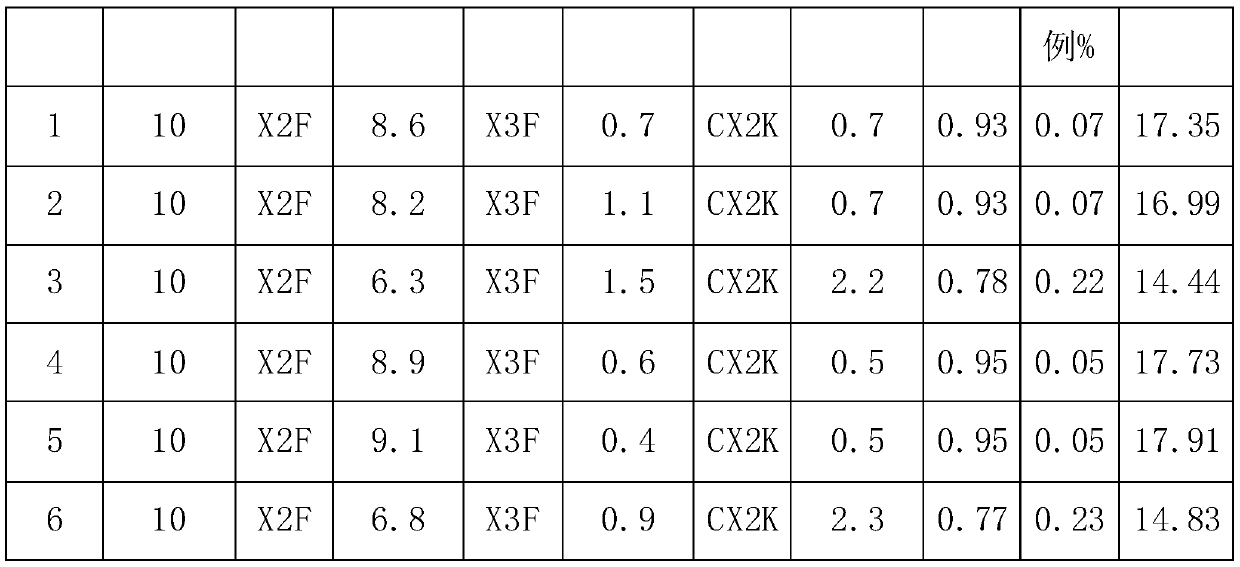

Examples

Embodiment 1

[0026] A method for curing the lower tobacco leaves of China Tobacco 101, comprising the following steps: the harvested lower tobacco leaves are relatively heavy in green and difficult to fall yellow normally,

[0027] Step 1: Ignite after installing the furnace, turn on the internal circulation of the fan, and keep the fan running at a low speed. After 4 hours, raise the temperature of the dry bulb to 38°C and the temperature of the wet bulb to 37°C. Keep the temperature stable for 10 hours, and the tips of the tobacco leaves turn yellow. , the overall degree of yellowing reaches 30%, and the leaves begin to wither and lose water.

[0028] Step 2: Raise the dry bulb temperature to 40°C at a rate of 1°C / hour, keep the wet bulb temperature at 37°C, 36°C, and 35°C, and stabilize the temperature for 10 hours. The fan circulates inside and operates at a low speed, the tobacco leaves reach 5-6 percent yellow, the leaves become soft and collapse, and the tobacco leaves in the high t...

Embodiment 2

[0037] A method for curing the lower tobacco leaves of China Tobacco 101, comprising the following steps: the harvested lower tobacco leaves are relatively heavy in green and difficult to fall yellow normally,

[0038]Step 1: Ignite immediately after installing the furnace, turn on the internal circulation of the fan, and keep the fan running at a low speed for 5 hours, then the dry bulb temperature rises to 38°C, the wet bulb temperature rises to 37°C, and the temperature is stabilized for 9 hours. At this time, the tip of the tobacco leaf changes Yellow, the overall degree of yellowing reaches 30%, and the leaves begin to wither and lose water.

[0039] Step 2: Raise the dry bulb temperature to 40°C at a rate of 1°C / hour, keep the wet bulb temperature at 37°C, 36°C, and 35°C, and stabilize the temperature for 10 hours. The fan circulates inside and operates at a low speed. At this time, the tobacco leaves reach 50% yellow, the leaves become soft and collapse, and the tobacco...

Embodiment 3

[0048] A method for curing the lower tobacco leaves of China Tobacco 101. For the lower tobacco leaves that are heavy in green and hard to fall yellow after harvesting, the conventional three-stage curing process is adopted for curing:

[0049] The baking process is divided into three stages: yellowing, color fixation, and gluten drying. The yellowing stage: the starting temperature of the dry bulb is 32°C, and the temperature in the yellowing stage is raised to 38°C at 0.5°C / h, and the temperature stabilizes and turns yellow. The temperature for the completion of yellowing is 42°C, and the wet bulb temperature is 1-4°C lower than the dry bulb temperature, so that the yellow leaves are slightly green and the main veins become soft; the color fixing stage: the heating rate is about 3 hours on average, and the temperature is raised by 1°C, and the wet bulb temperature It should be controlled at 38°C to make the tobacco rod fully turn yellow; after that, the heating rate should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com