Bulk curing barn hanging rod continuous heating fragrant and soft roasting method

A technology of intensive curing room and curing method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of non-looseness, long duration of temperature stabilization stage, and unfavorable yellowing of tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

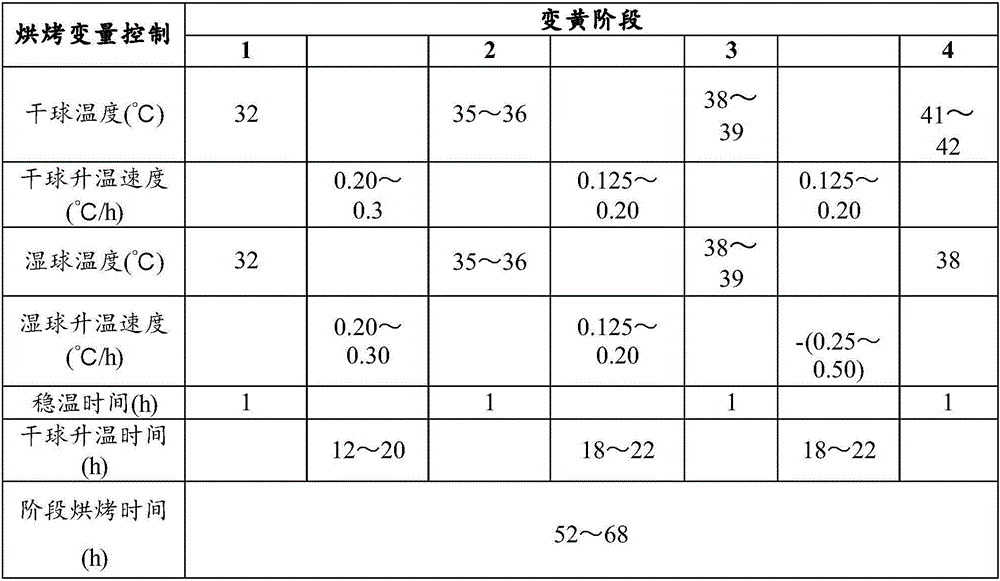

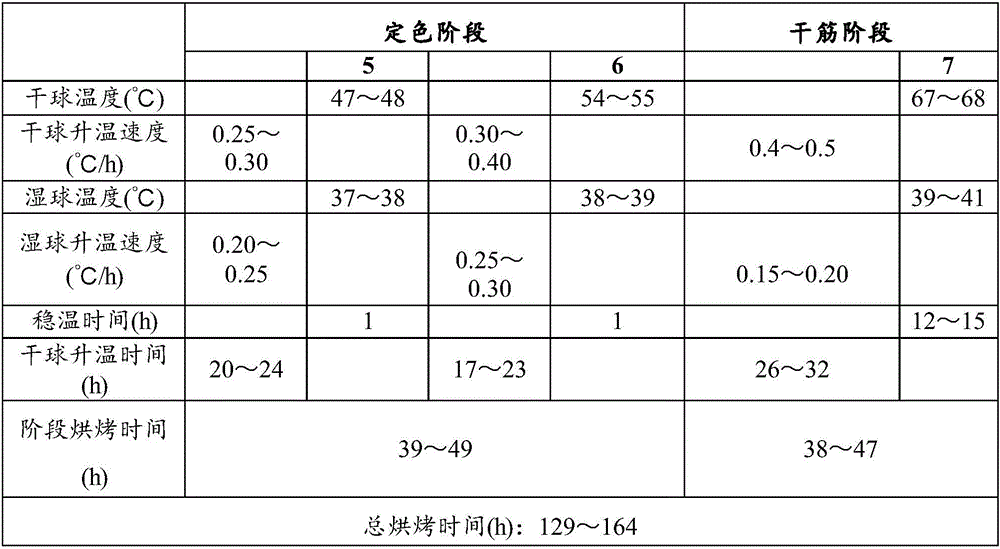

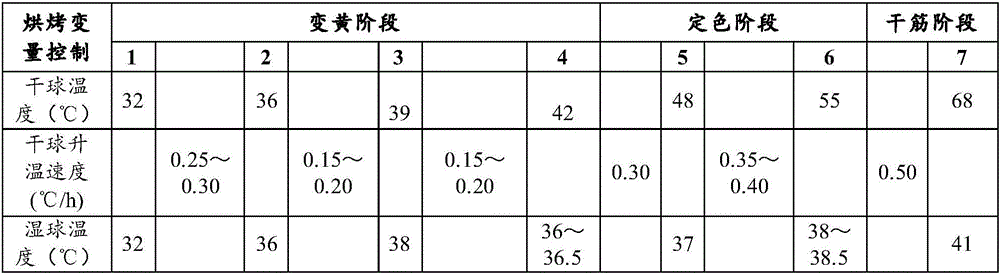

[0078] This example provides a continuous heating-up roasting process of hanging tobacco on a pole in a dense barn:

[0079] A) Tobacco is loaded in a dense barn with a controller by hanging rods. The dense barn with the controller has a length of 8m, a height of 3.3m, and a width of 2.7m.

[0080] In the dense barn of the above-mentioned scale and size, there are 3 sheds with smoke, and the amount of smoke is 400 rods.

[0081] In the present invention, the length of the tobacco rods in the rod-hanging method is 140-145 cm, the amount of smoke per rod is preferably 8.2-8.8 kg, and the distance between the rods is 11-13 cm. The dense barn with a controller is an air-flow rising barn, and the controller is controlled by a lower shed.

[0082] B) The packed tobacco leaves are baked, and the baking process of different parts of the tobacco leaves is different, and the process steps of the lower leaf, the middle leaf and the upper leaf are respectively as follows:

[0083] (1) ...

Embodiment 2

[0113] Aroma components, number of smooth smoke, and proportion of high-quality tobacco were measured on the tobacco leaves obtained above.

[0114] (1) Determination method and results of aroma components

[0115] ① Determination method of aroma components in tobacco leaves

[0116] The smoke samples were separated by simultaneous distillation and extraction (SDE), then the neutral aroma substances were determined by gas chromatography-mass spectrometry (GC / MS), and the acidic aroma substances were determined by GC.

[0117] 1.3.5.1 GC-MS conditions for neutral aroma substances

[0118] Chromatographic column: DB-5 (30m×0.25mmi.d.×0.25μm d.f.); temperature program: 40°C (2min)4°C / min250°C (10min); injection port: 250°C; carrier gas: He; column head Pressure: 100kPa; split ratio: 30:1; injection volume: 1.0μL. Transfer line temperature: 250°C, ion source temperature: 170°C; EI energy: 70eV, scan range: 35-350uam; internal standard: linalool; the collected mass spectra were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com