Bulk curing barn leaf scrap insertion tobacco filling continuous heating roasted fragrant and roasted soft roasting method

A technology of intensive curing room and curing method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of long duration of temperature stabilization stage, influence of hydrolase activity, low moisture content of tobacco leaves, etc., and achieve concise and concise curing process. , the effect of improving industrial availability and improving baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

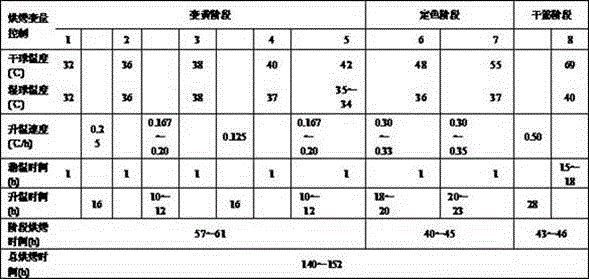

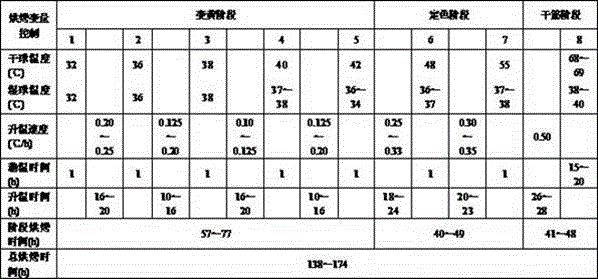

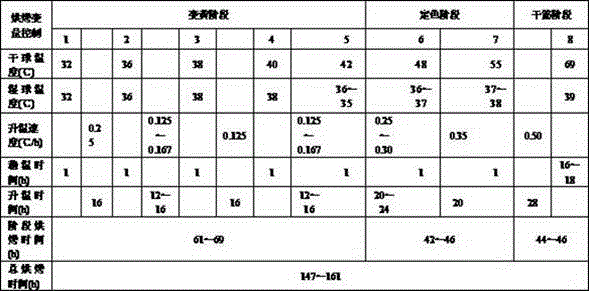

[0027] Provides a method for roasting tobacco with loose leaf inserts in a dense barn and continuously increasing the temperature, including the following steps:

[0028](1) Use the prescribed method of loose leaf insertion to install cigarettes. First, place the loose leaf air divider on the cigarette holder in the barn; adopt the stacking method of loose leaves with the tip of the leaf facing up and the leaf base facing down. Load the tobacco evenly; the width (front and rear distance) of each grid is 30-35cm, and the tobacco leaves in each layer and each square rod must be filled without gaps. After each cigarette is installed, immediately put the bamboo poles (upper and lower rows) for fixing the tobacco leaves into the fixing holes on both sides of the wall and the steel ring welded on the middle cigarette rack to fix the tobacco leaves. And alternately insert bamboo sticks along the upper and lower rows of bamboo poles to fix the tobacco leaves. Be careful not to bend t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com