Patents

Literature

48results about How to "Improve bake quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

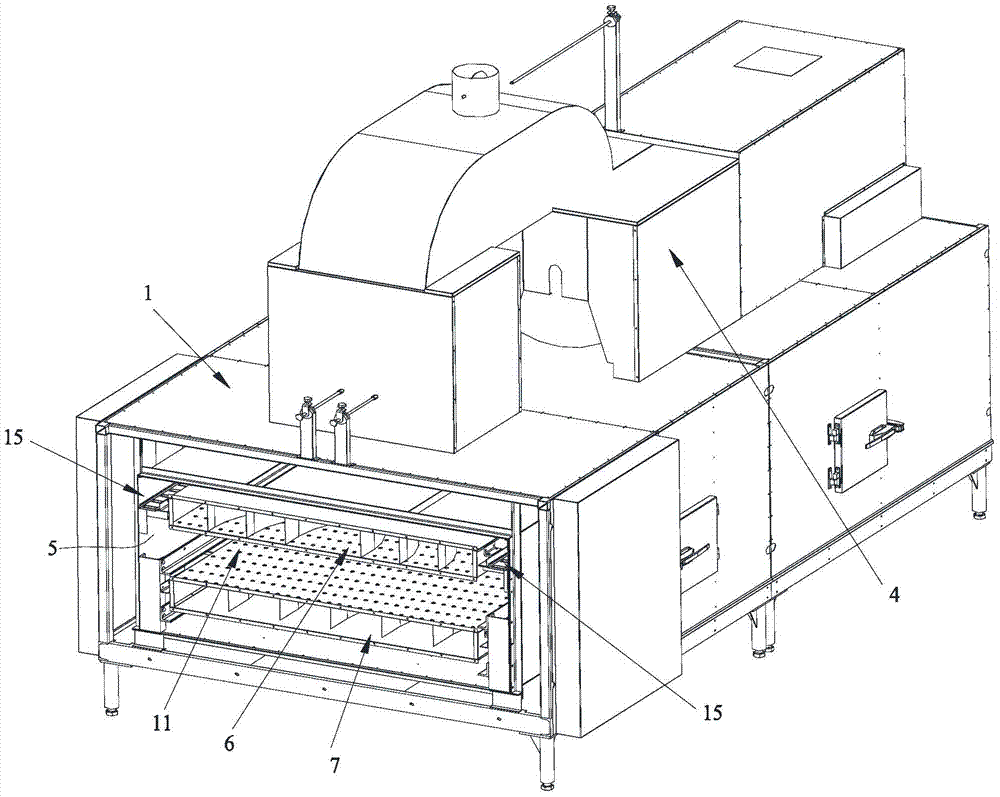

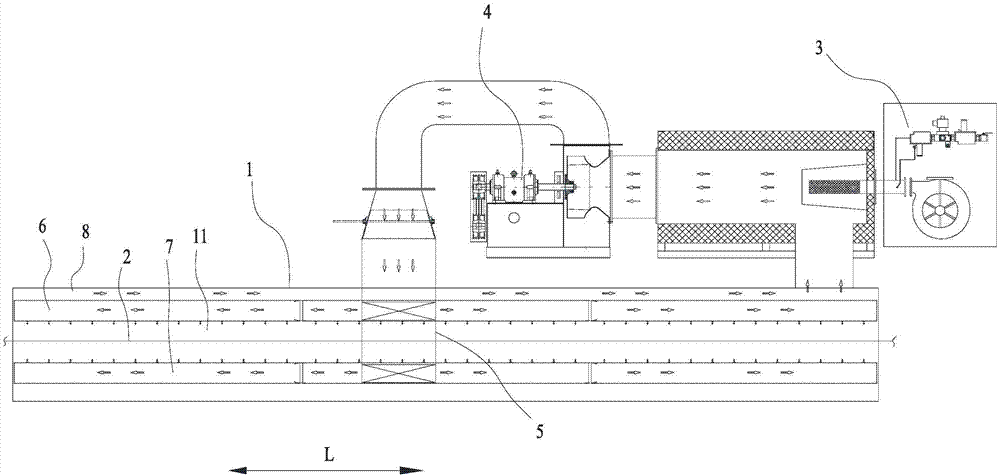

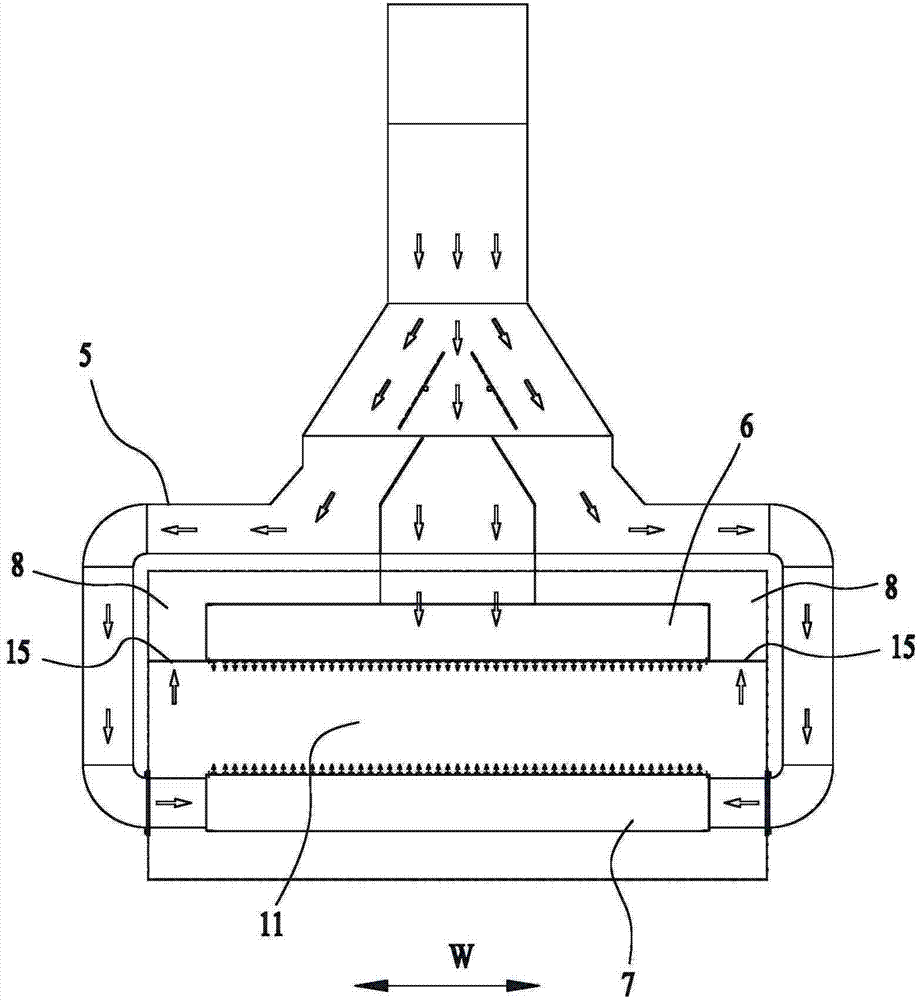

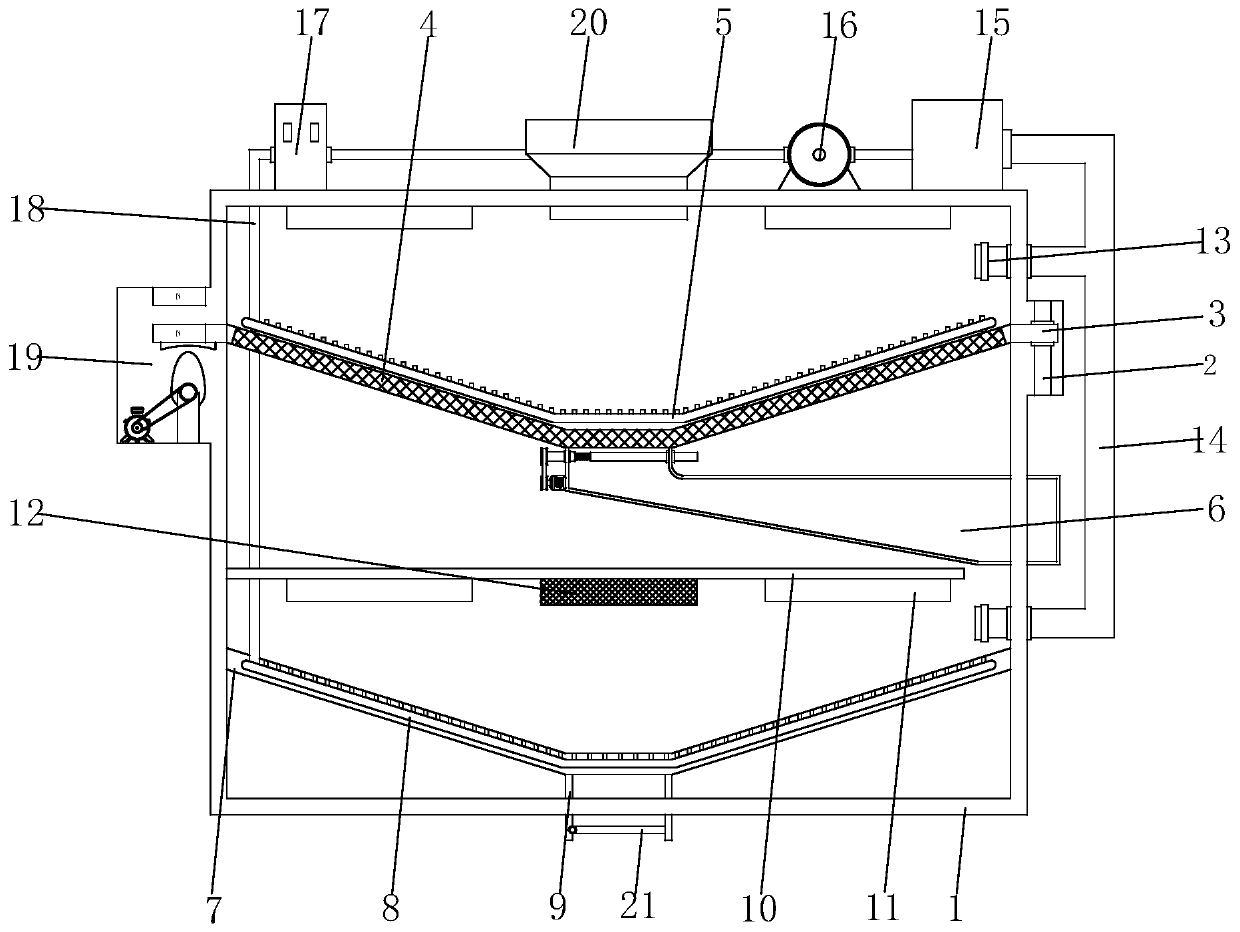

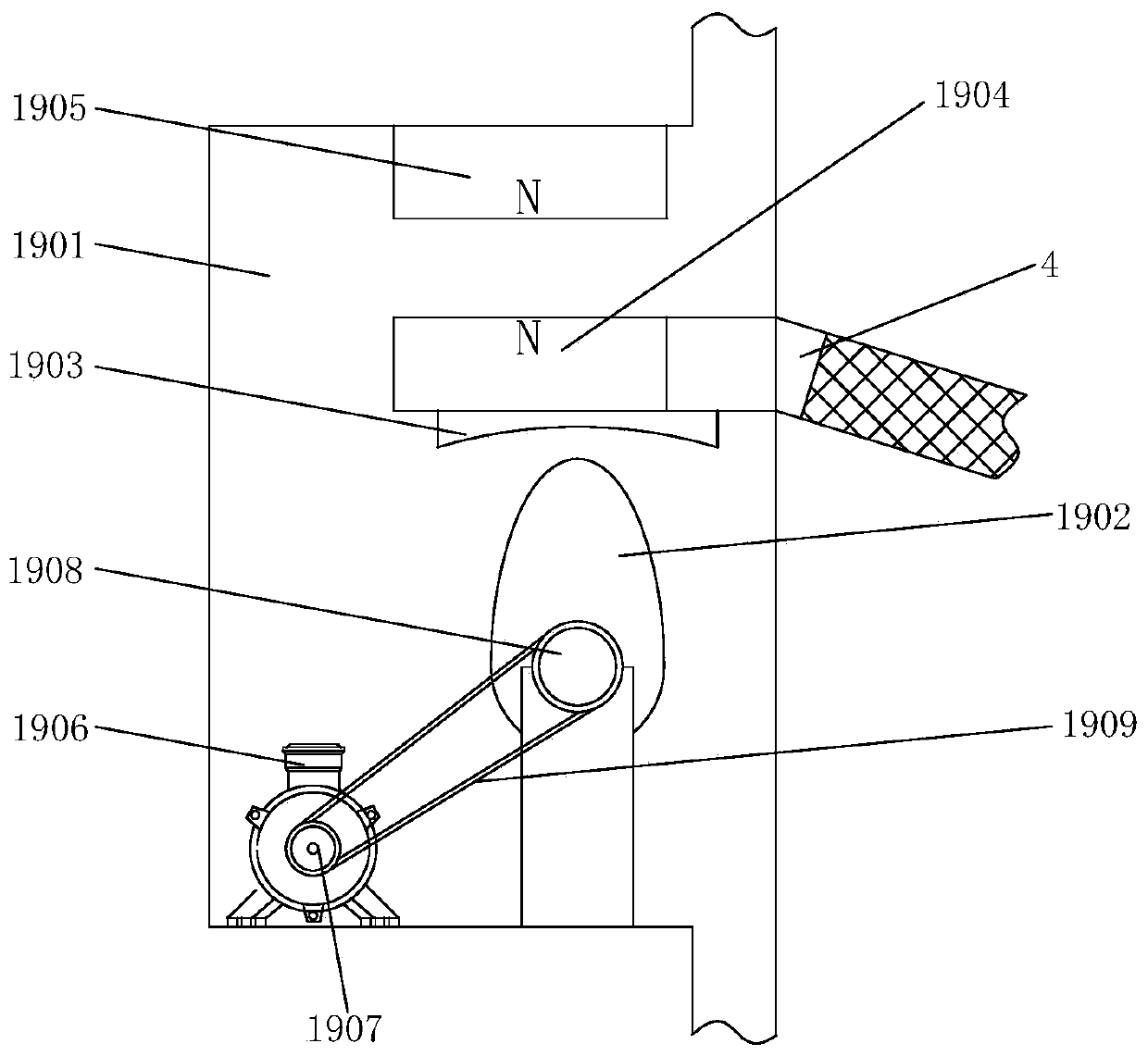

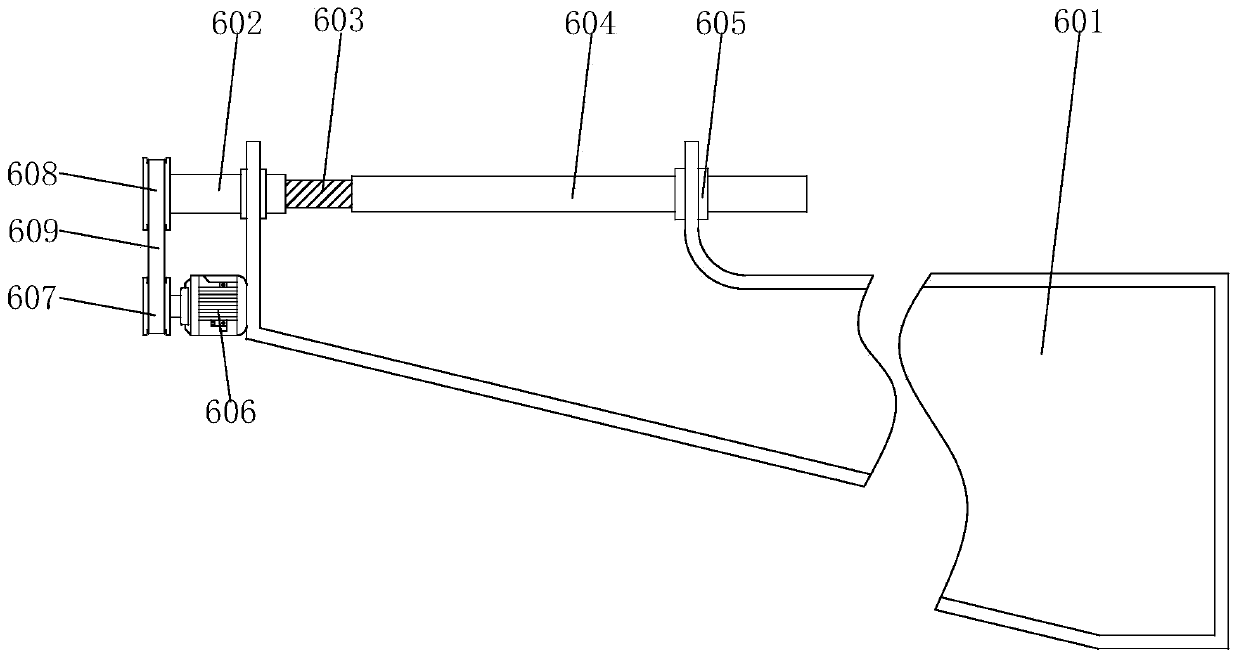

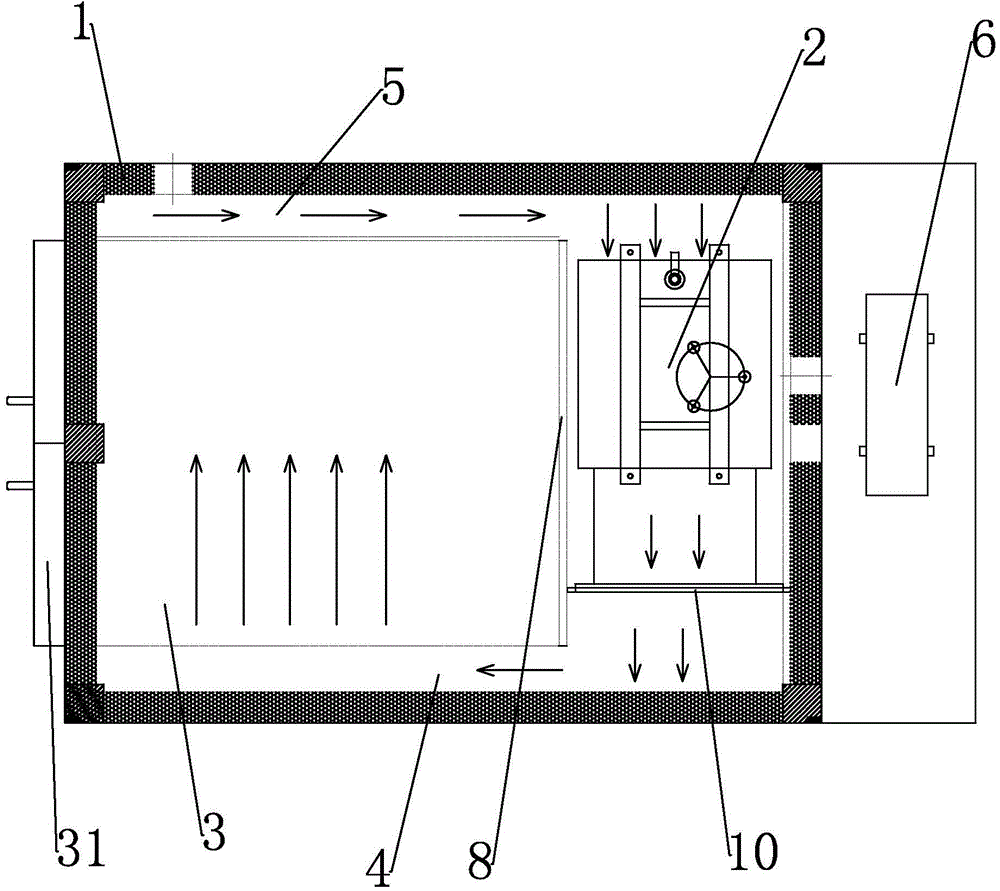

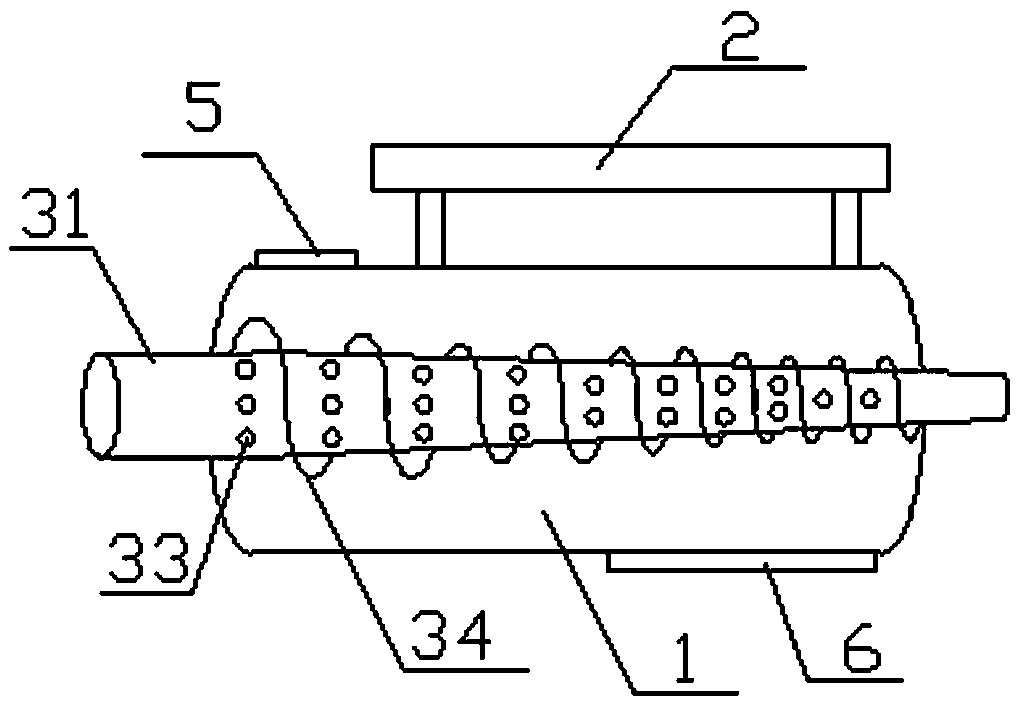

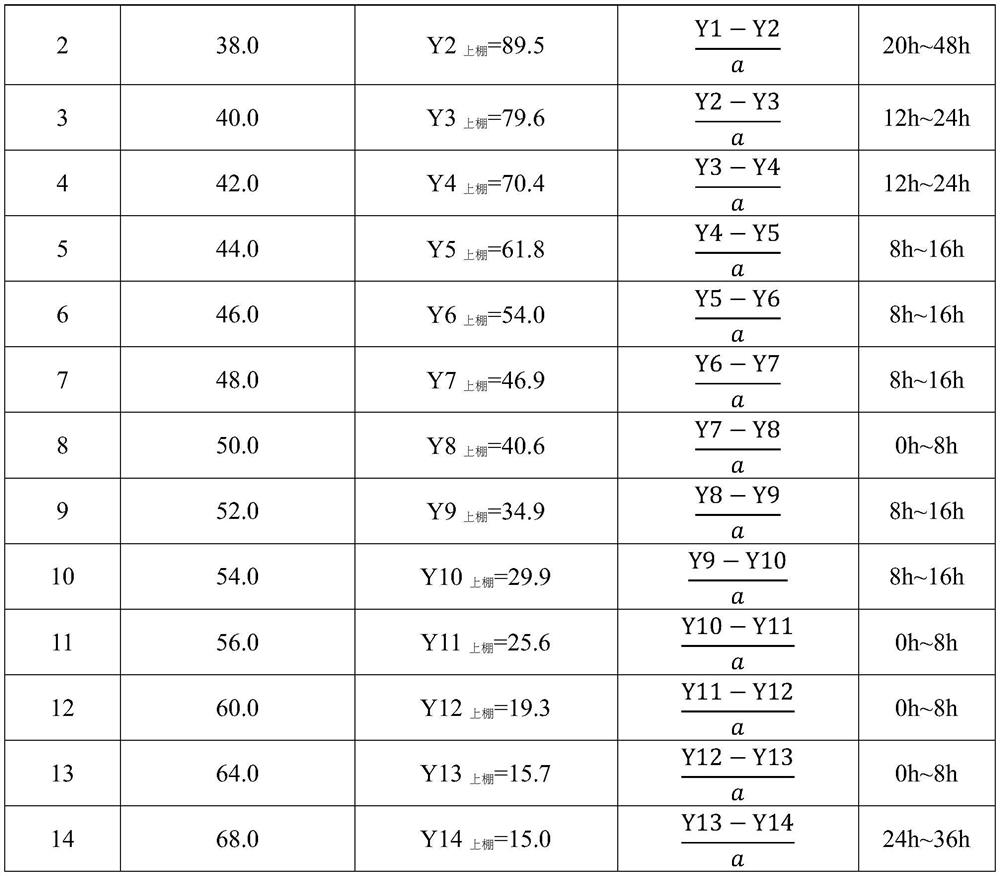

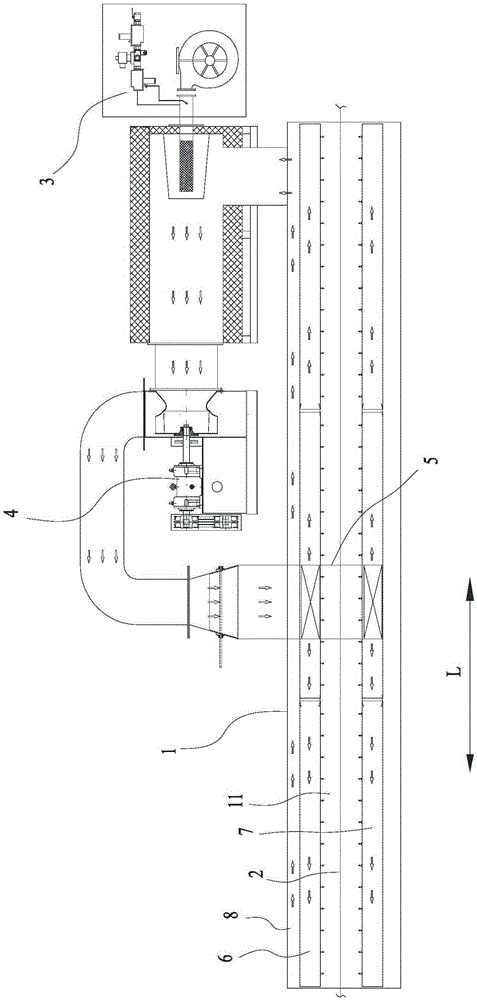

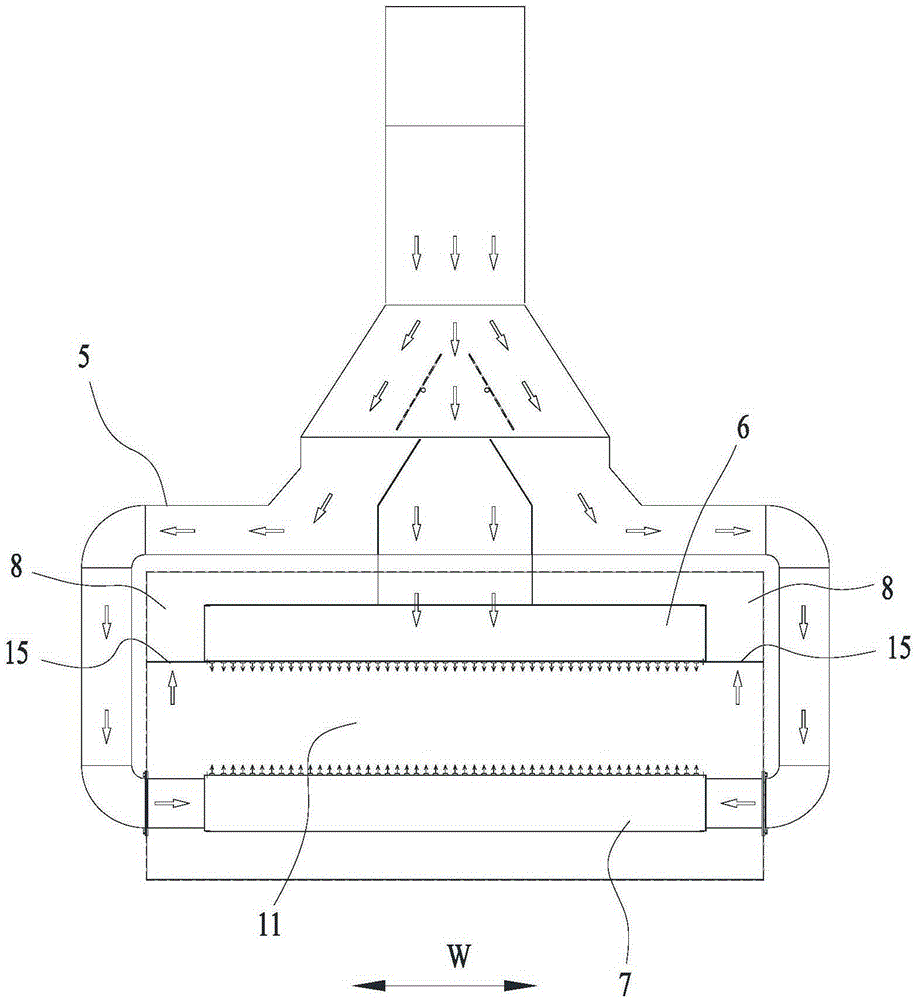

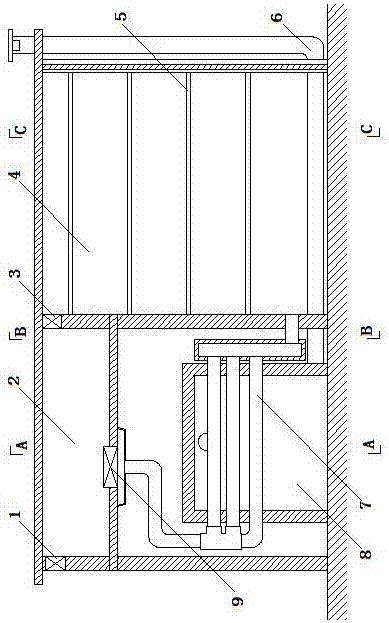

Tunnel type hot air circulation tunnel furnace

The invention discloses a tunnel type hot air circulation tunnel furnace. The tunnel type hot air circulation tunnel furnace comprises a furnace body, a hot air circulation device, a conveying belt and a heating device. The hot air circulation device comprises a hot air generator, a draught fan, a four-way connector, an upper air box and a lower air box. The four-way connector comprises a horizontal air inlet shell and two air distribution shells, wherein the two ends of the air inlet shell vertically extend to form the two air distribution shells. The top face of the air inlet shell is provided with an inlet. The bottom face of the air inlet shell is provided with a first outlet. The upper ends of the two air distribution shells are communicated with the inlet. The lower end of each air distribution shell is provided with a second outlet. The outlet of the draught fan is communicated with the inlet. The first outlet is communicated with the upper air box. The second outlets are communicated with the lower air box. The bottom of the upper air box is provided with a plurality of first air outlet holes. The top of the lower air box is provided with a plurality of second air outlet holes. A return air passage is arranged in the furnace body. The first air outlet holes and the second air outlet holes are connected with the hot air generator through the return air passage. According to the tunnel type hot air circulation tunnel furnace, hot air output by the hot air circulation device can be evenly and circularly led to products to be baked, and the air temperature, the air volume and the air speed can be controlled.

Owner:GUANGZHOU BAKE OVEN MACHINERY

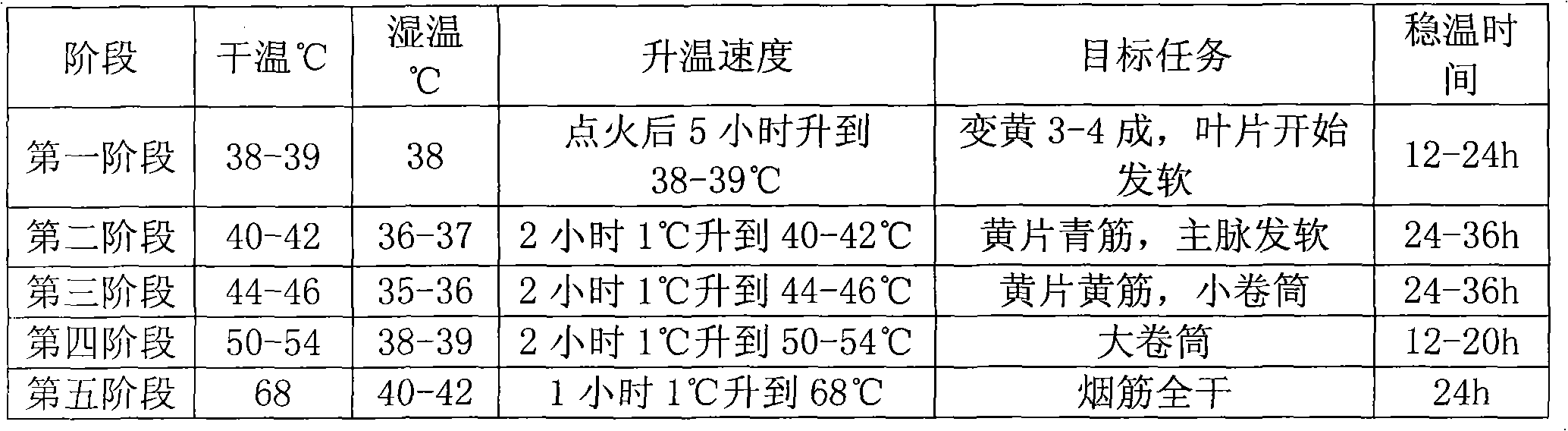

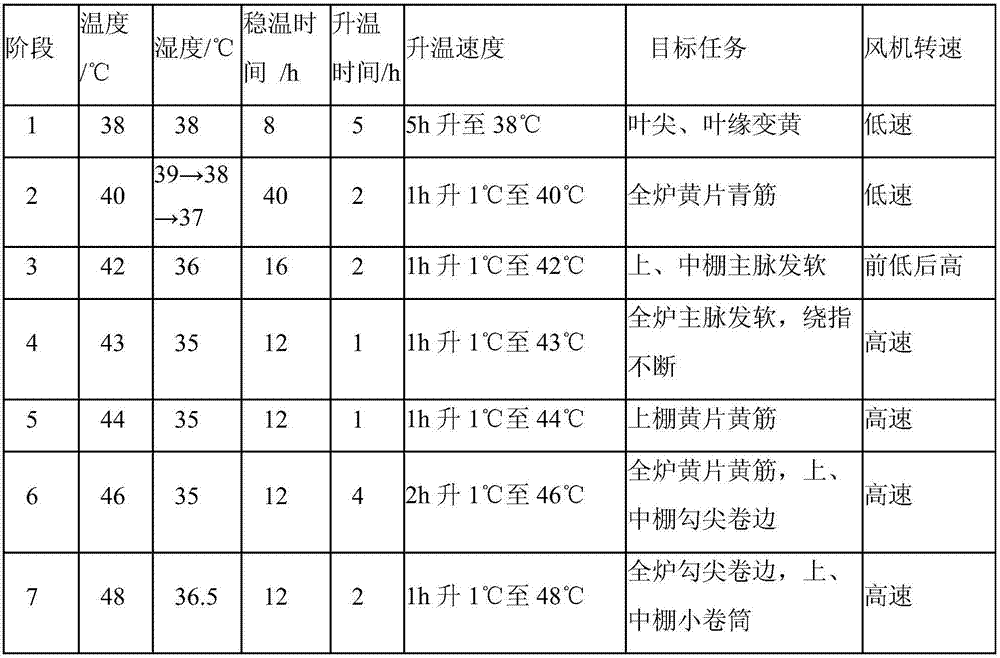

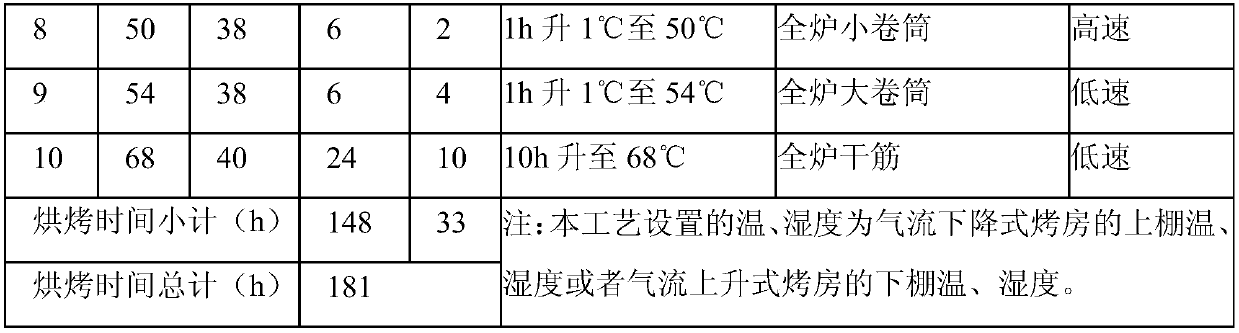

Intensive baking process for unique flue-cured tobacco variety CB-1

InactiveCN102106598ASimple and safe operationStrong maneuverabilityTobacco preparationFlueTobacco processor

The invention discloses an intensive baking process for unique flue-cured tobacco variety CB-1. In the process, on the basis of the conventional three-section type baking, a baking stage is divided into five stages, namely two yellow-turning stages, two color fixing stages, and a stem-drying stage, wherein in the baking process the yellow-turning time is prolonged by 12 to 24 hours, the main yellow-turning temperature is improved by 1 to 2 DEG C, and the wet bulb temperature in the later stage of yellow turning and the early stage of color fixing is reduced by 2 to 3 DEG C, so that the bakingprocess condition is more accurate. The intensive baking process has the advantages of scientific practicality and high operability, is easy, convenient and safe to operate, can reduce green tobacco rate and ash-hanging tobaccos obviously, avoid stiff slick tobaccos, better solve the problems of greened leaves, ash hanging, stiffening and the like of the CB-1, overcome the defect of the conventional baking process effectively, and improve the baking quality of the tobaccos obviously.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

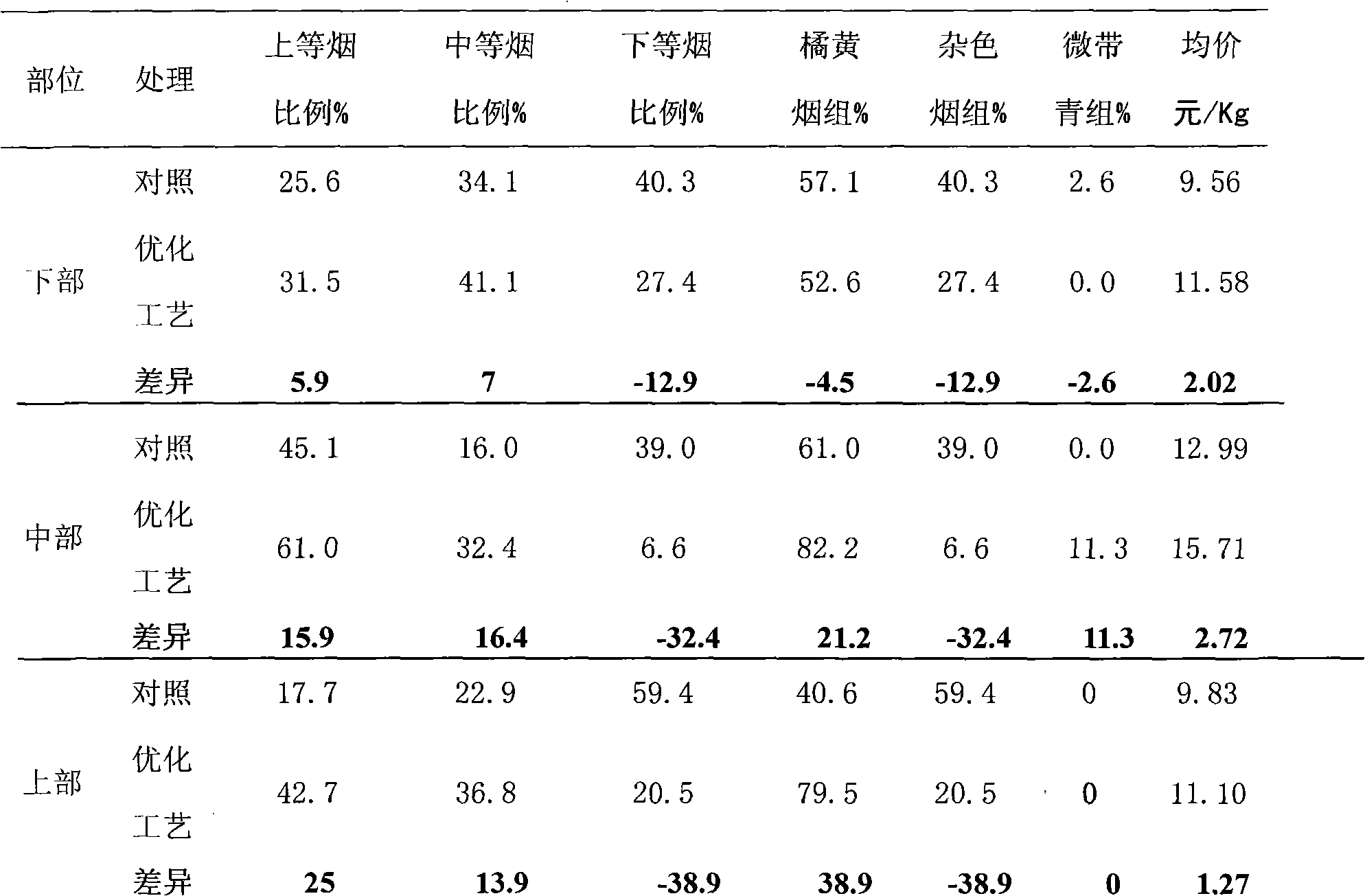

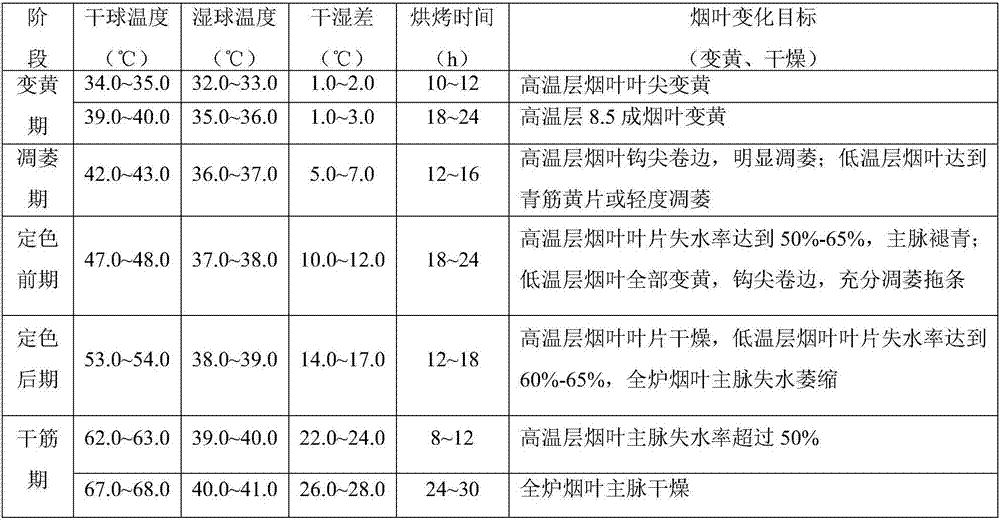

Tobacco curing process suitable for curing Yunyan (Yunnan tobacco) 116 variety tobacco leaves

ActiveCN107028214AImprove bake qualityImprove suction qualityTobacco preparationEconomic benefitsEngineering

The invention relates to a tobacco curing process suitable for curing Yunyan (Yunnan tobacco) 116 variety tobacco leaves, and belongs to the technical field of processing of tobacco leaves. The tobacco curing process comprises a yellowing stage, a withering stage, a previous color fixing stage, a later color fixing stage and a stem drying stage, and upper tobacco leaves, middle tobacco leaves and lower tobacco leaves are cured. In comparison with a conventional curing process, the process provided by the invention, when used for curing the fresh Yunyan 116 variety tobacco leaves, is higher in chroma fullness; average price of the tobacco leaves, obtained from the curing process, can reach 29.56 Yuan / kg, 2.40 Yuan / kg higher than the conventional process which is 27.16 Yuan / kg; and value caused by each furnace of tobacco leaves is more than 1000 Yuan higher than that of the conventional process. Meanwhile, the tobacco leaves, obtained from the curing process, is high in curing quality and better in smoking quality; and moreover, industrial availability of the cured tobacco leaves is also improved and economic benefit is obviously increased, so that the tobacco leaves are easy for popularization and application.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

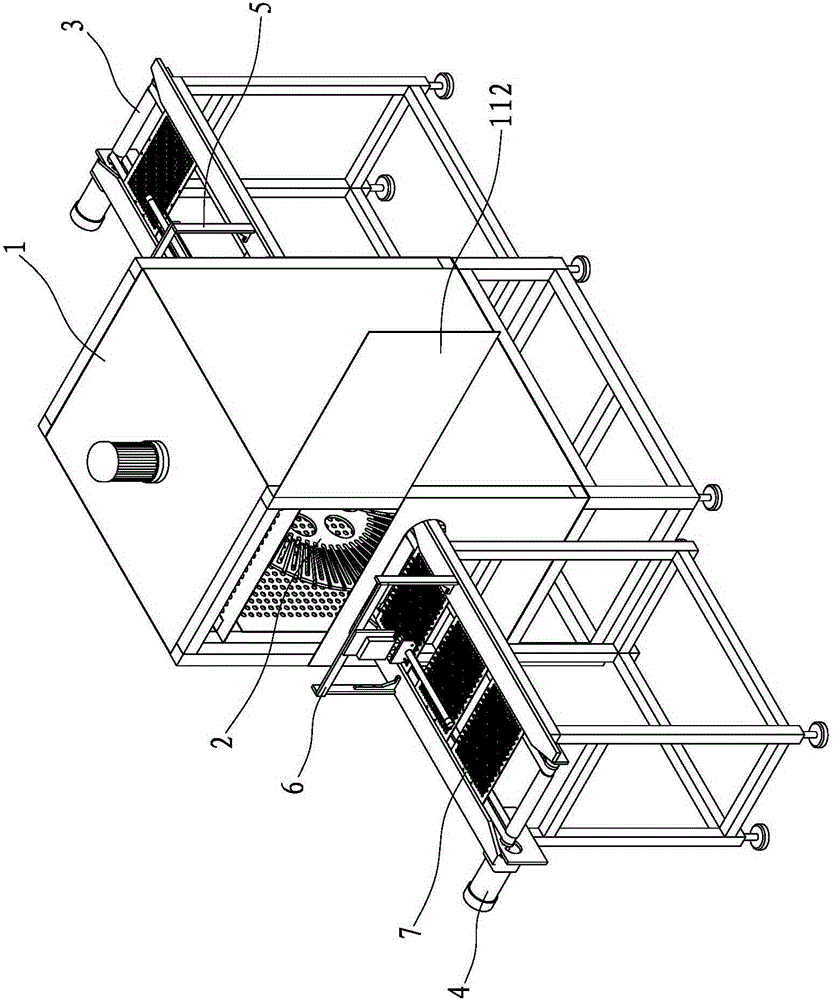

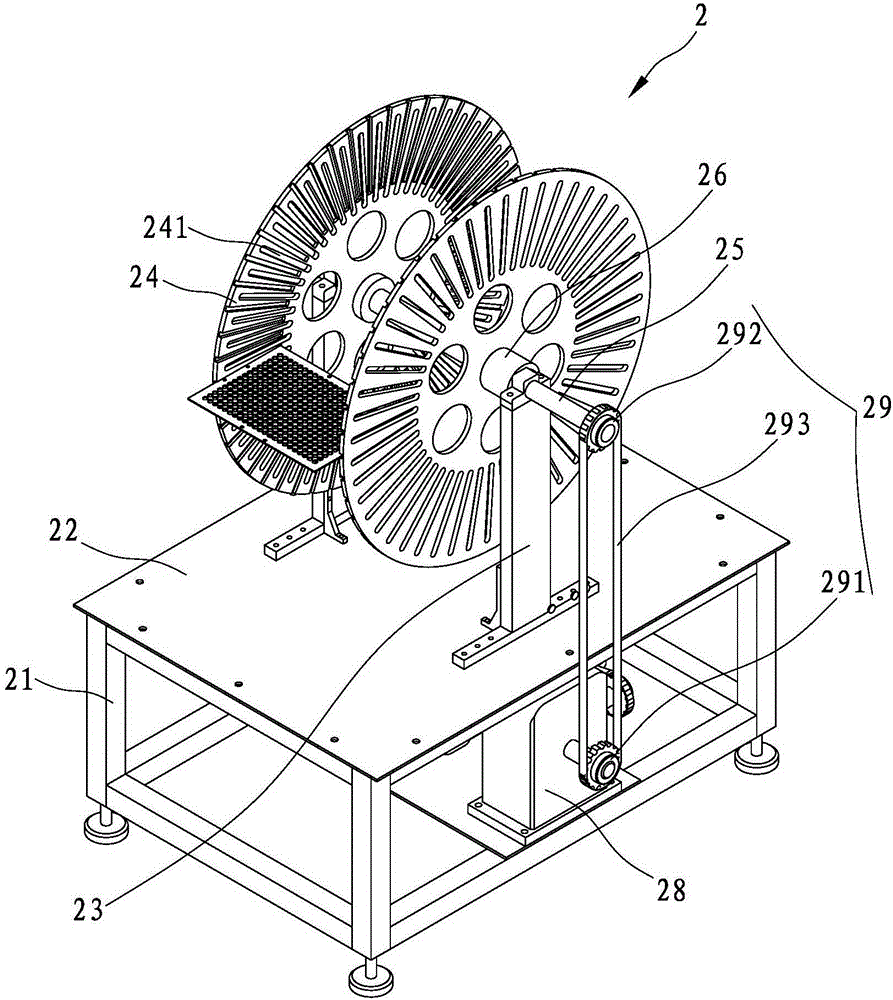

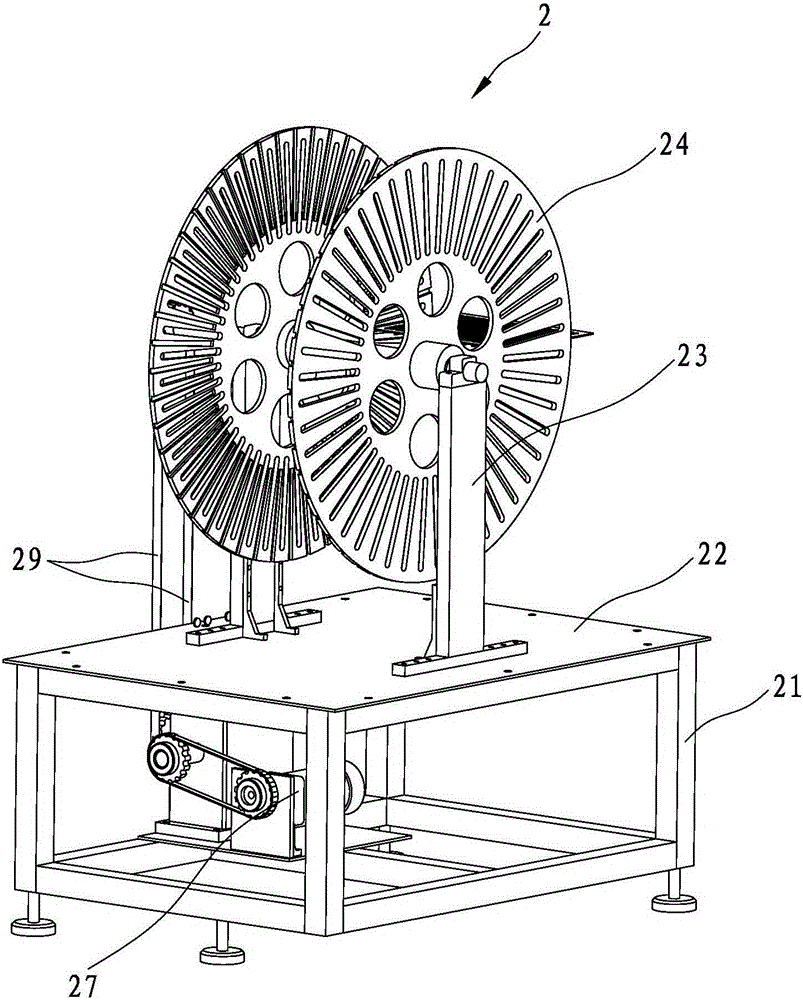

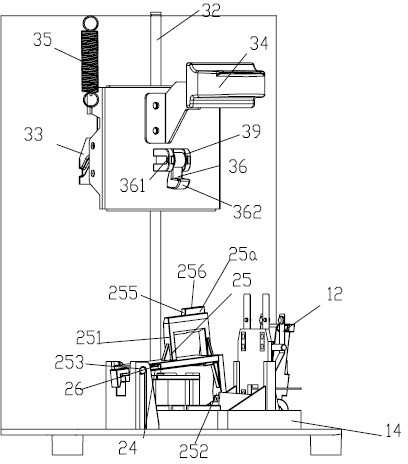

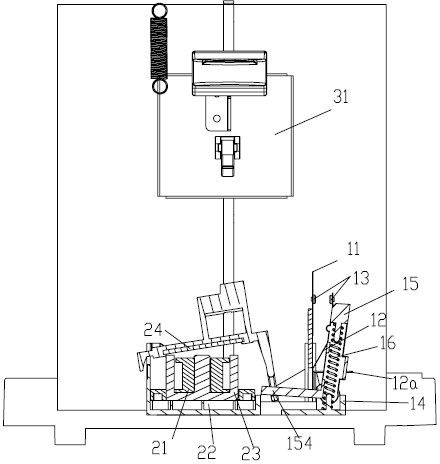

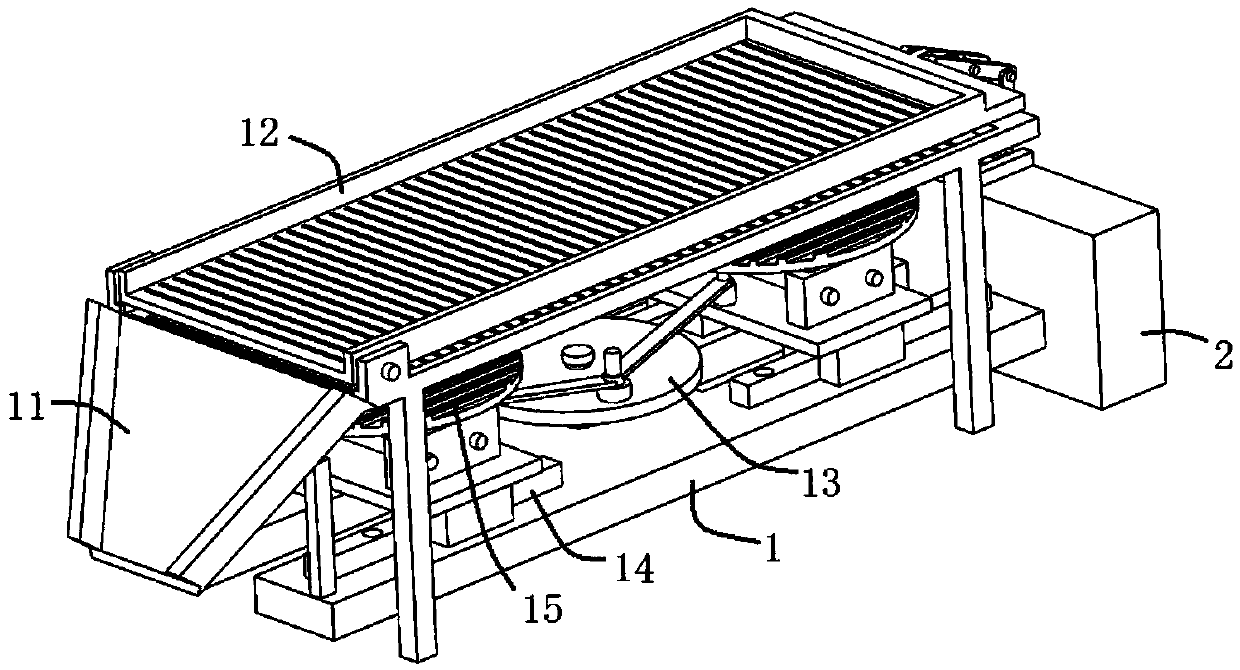

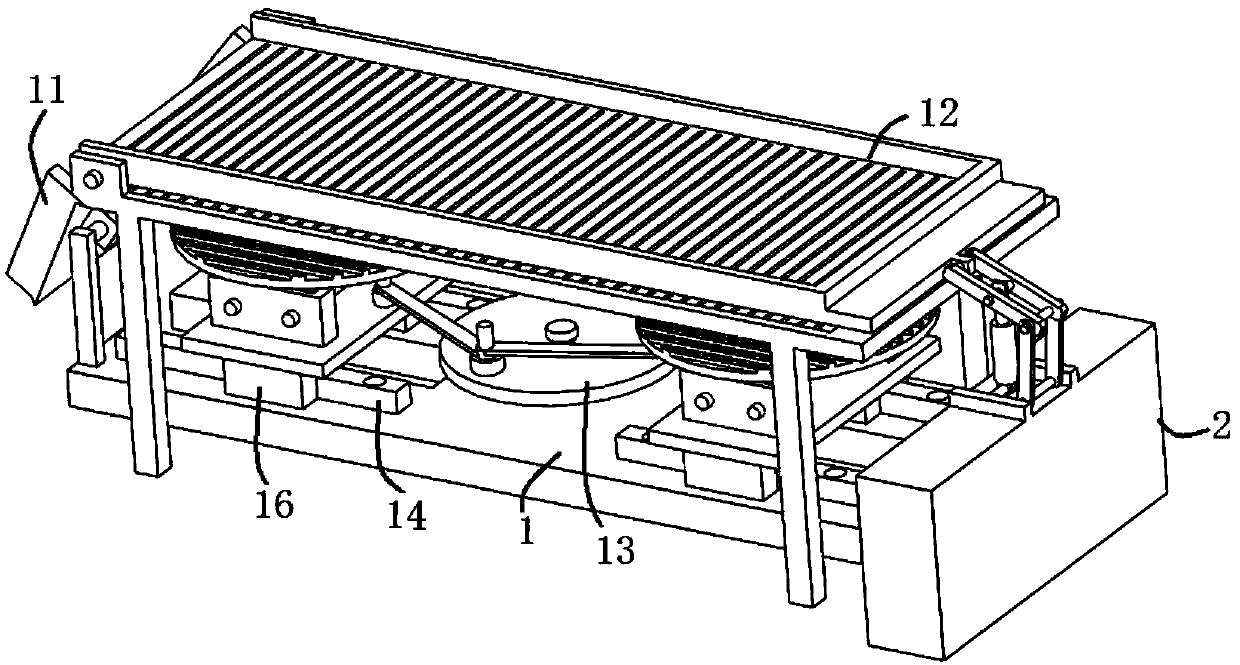

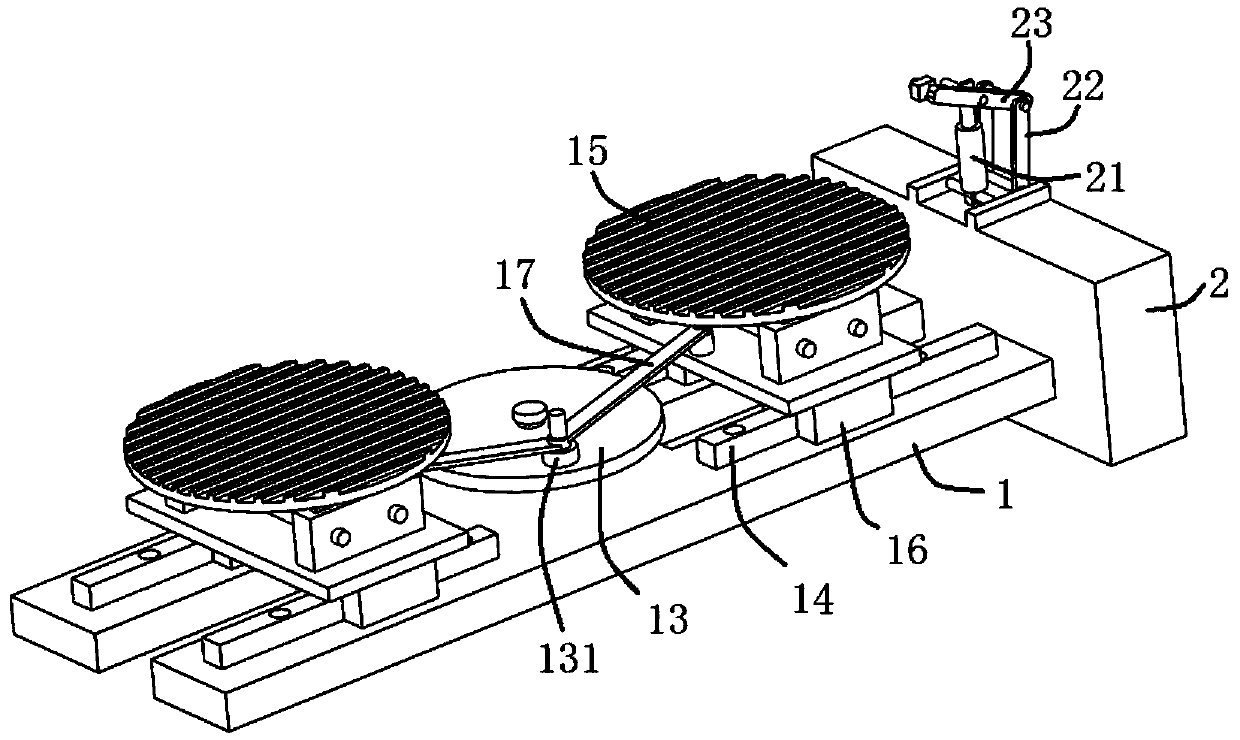

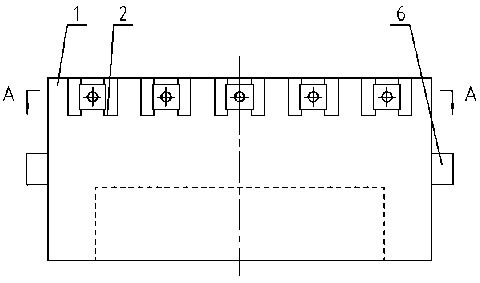

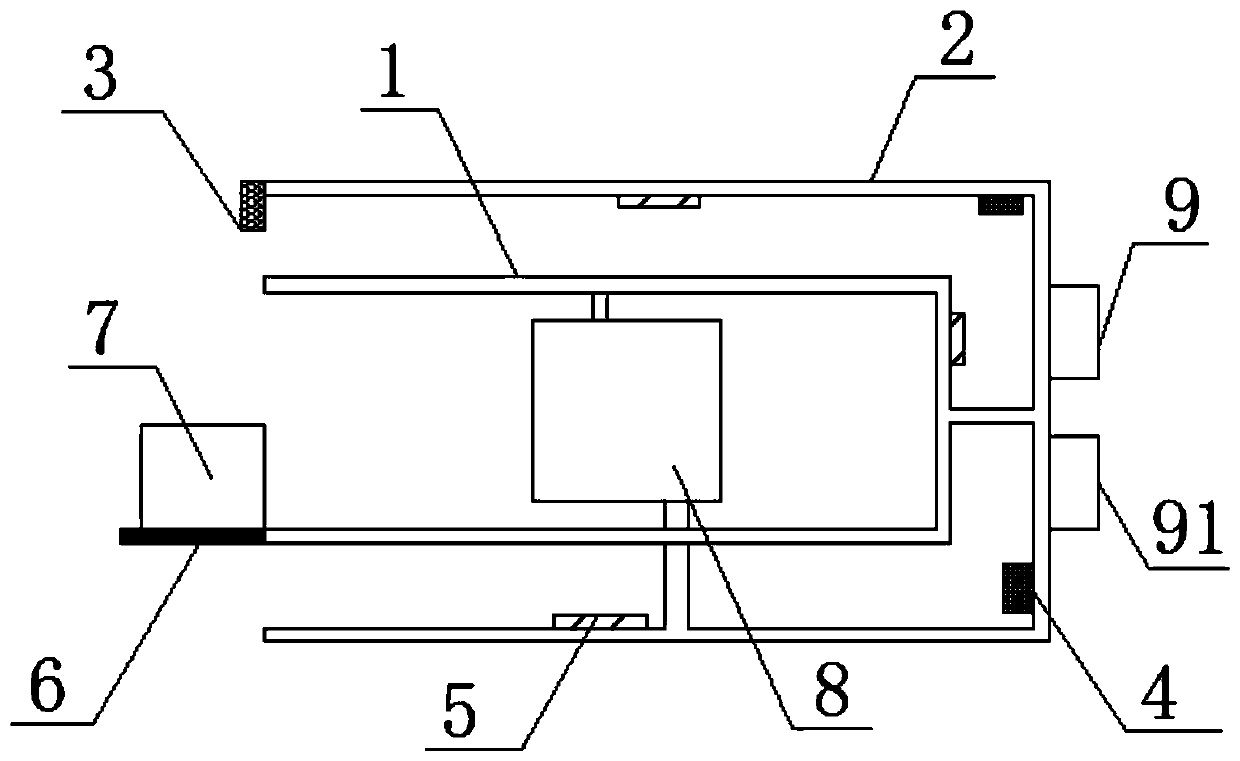

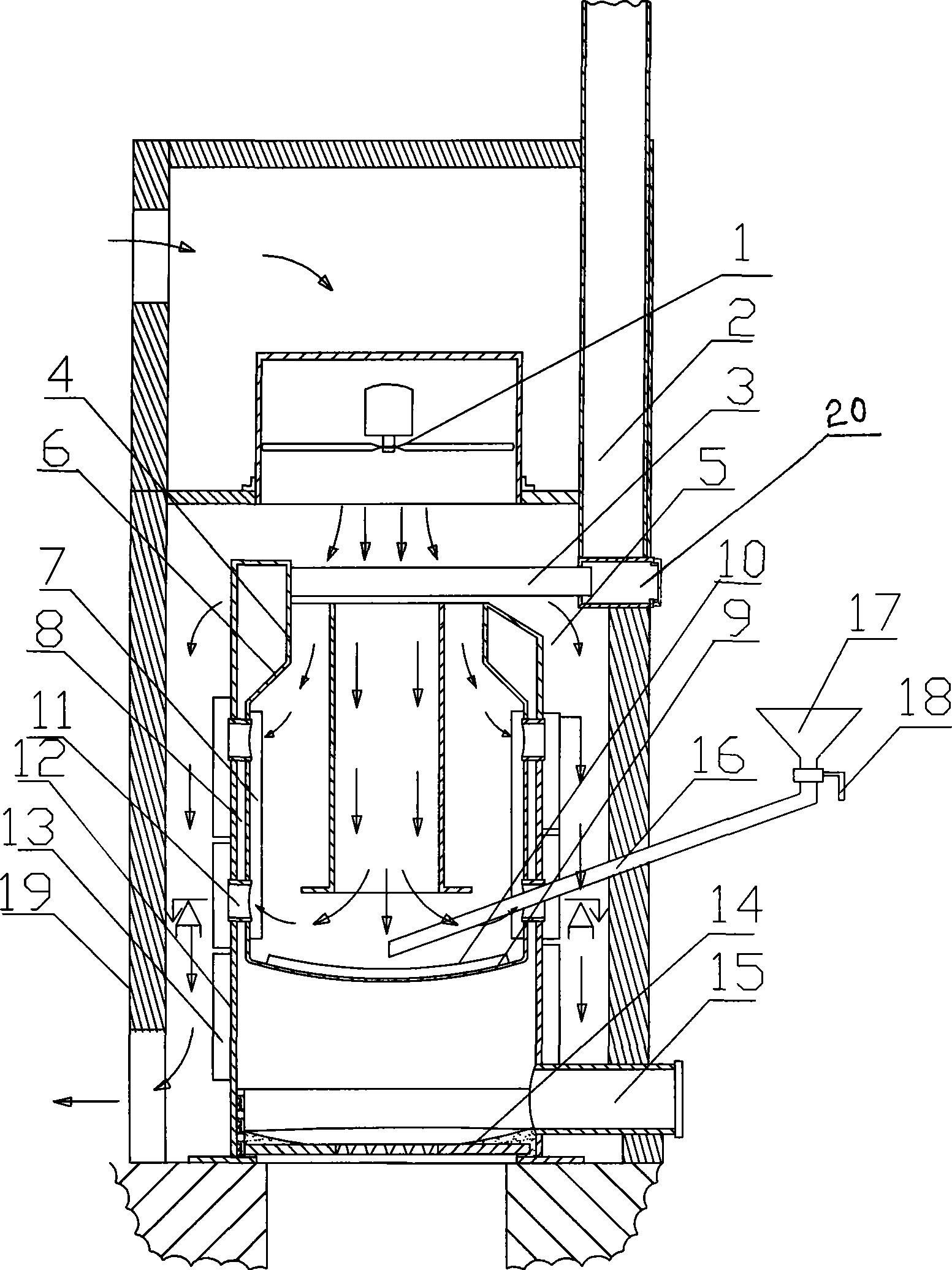

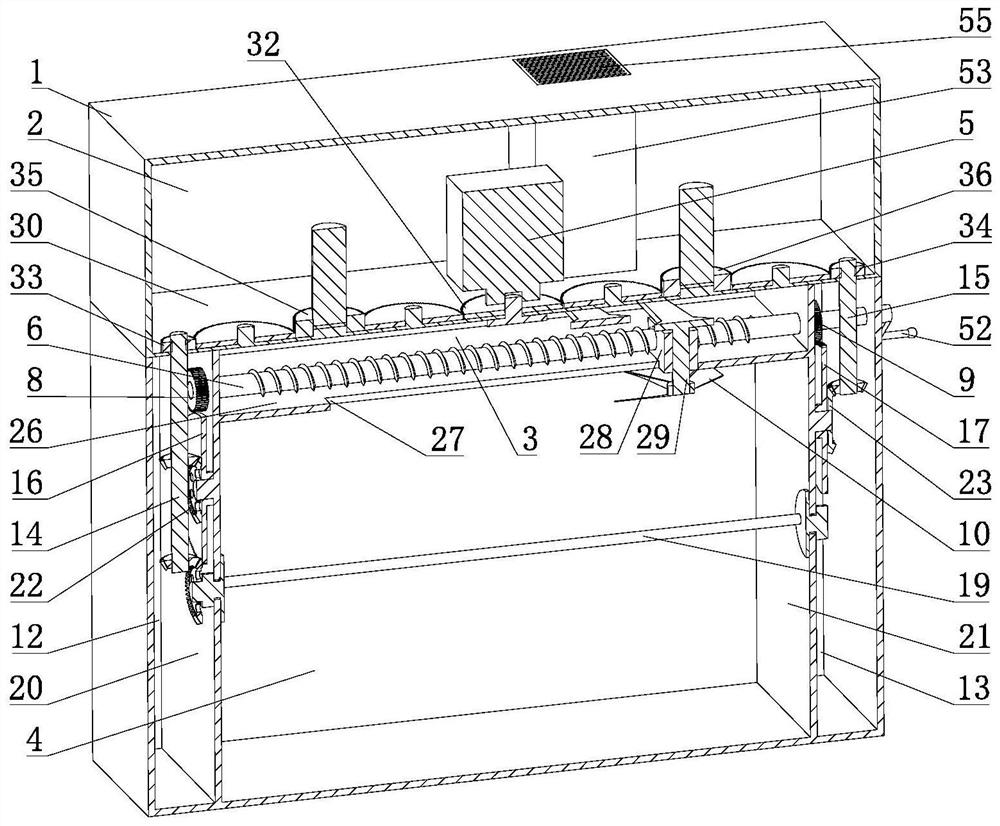

Efficient industrial oven

ActiveCN105214919AEvenly heatedImprove bake qualityPretreated surfacesCoatingsMechanical engineeringConstant speed

The invention discloses an efficient industrial oven which comprises an oven body, a rotary disc mechanism, a feeding conveying mechanism, a discharging conveying mechanism, a product pushing mechanism and a product pulling mechanism. The oven body is provided with a feeding door and a discharging door. The rotary disc mechanism is installed in the oven body. The feeding conveying mechanism and the discharging conveying mechanism are installed on the outer sides of the feeding door and the discharging door respectively. The product pushing mechanism and the product pulling mechanism are installed on the feeding conveying mechanism and the discharging conveying mechanism respectively. Due to the fact that product discs are pushed by the product pushing mechanism to be inserted in a rotary disc of the rotary disc mechanism one by one, the product discs are driven by the rotary disc to rotate up and down at a constant speed, products placed in the product discs are heated evenly, and baking quality is good. In addition, due to the fact that the feeding and discharging purposes of the product discs are automatically completed through the product pushing mechanism and the product pulling mechanism, production efficiency is high.

Owner:XIAMEN YINGTAIER IND & TRADE CO LTD

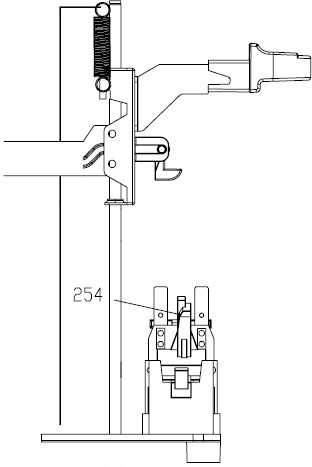

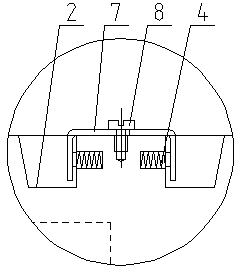

Automatic bread roaster and safety switch thereof

ActiveCN102551560AAvoid Electric Shock or FireAvoid scorchingRoasters/grillsEngineeringMechanical engineering

A safety switch of an automatic bread roaster comprises a lifting mechanism, an electromagnet component and a switch. A slide rack and a bracket of the lifting mechanism are controlled by a second elastic part and can slide along an upright shaft, a hook is fixed on the slide rack, when an armature rack of the electromagnet component is pressed downwards by the hook, effects of a first elastic part are overcome, a spring plate driving the switch contacts with a connecting plate so that the switch is electrified, then a coil is also electrified, an iron core sucks an armature by the aid of the electrified coil, when the coil is controlled to be automatically switched off by a control circuit, the armature rack rotates upwards under the effects of the first elastic part so that the spring plate is separated from the connecting plate, and the hook is fastened with the armature rack from bottom to top after downwards pressing the armature rack, and is separated from the armature rack when the armature rack rotates upwards. The bread roaster which comprises the safety switch can prevent unnecessary and dangerous continuous roasting due to the fact that the lifting mechanism is jammed, effectively improves safety and ensures that bread is not scorched.

Owner:YONG AN ELECTRICAL IND

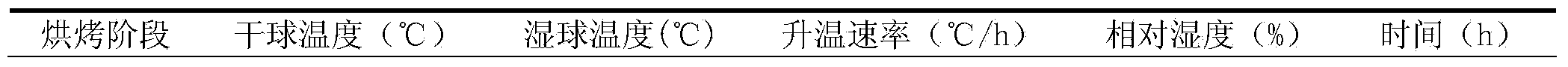

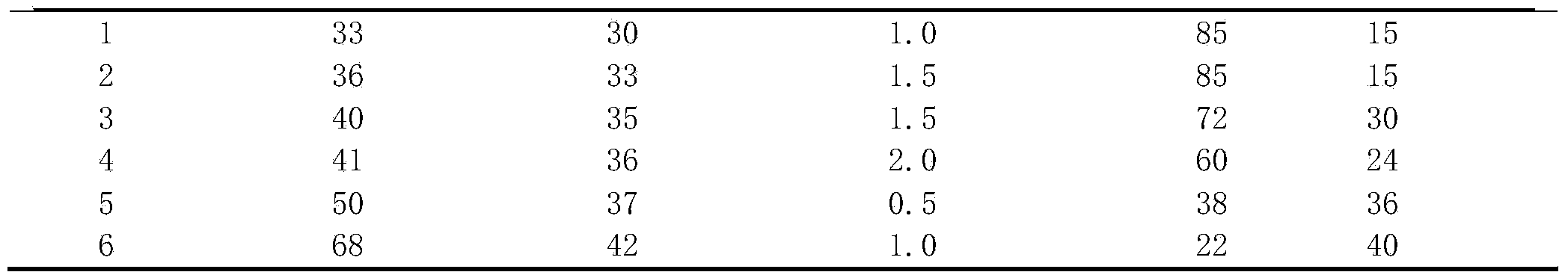

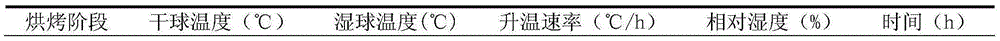

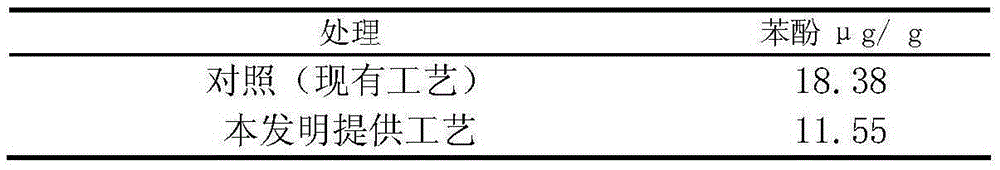

Baking technology method capable of reducing phenol release amount in flue-cured tobaccos

The invention discloses a baking technology method capable of reducing the phenol release amount in flue-cured tobaccos. The technology method includes the following steps that A, the flue-cured tobaccos are prepared; B, six continuous braking stages are needed for baking the flue-cured tobaccos and include four short-period baking stages and two long-period baking stages, and the requirements are that the dry-bulb temperature of baking is 28 DEG C -70 DEG C, wet bulb temperature of braking is 20 DEG C-50 DEG C, relative humidity is 20-95%, and baking time is 4 h -72 h; C, in the six baking stages, dry bulb technology temperature and wet bulb technology temperature are continuously increased, the temperature rate is 0.1 DEG C-5 DEG C / h, and baking time is 4 h-72 h; D, the flue-cured tobaccos low in phenol content are obtained after baking. Through the technology conditions, the phenol release amount can be reduced by 20-50%, and appearance quality and interior quality are better than those of flue-cured tobaccos baked through an existing technology. The baking technology method has the advantages of being significant in effect and very high in operability, and chemical agents and cost addition are not needed.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Focus collecting and baking method of upper 6-8 pieces of tobacco leaves

InactiveCN107319625AReduce output ratioNutritional balanceTobacco preparationEngineeringTobacco processor

The invention discloses a focus collecting and baking method of upper 6-8 pieces of tobacco leaves, belongs to the technical field of baking of the tobacco leaves and solves problems about poor overall quality of the baked tobacco leaves and too high total nicotine content of the tobacco leaves in the prior art. The method includes: performing two rounds of harvest at one step after full maturity of the upper 6-8 pieces of the tobacco leaves; performing rod tying and cigarette clamping; performing charging respectively; baking, namely adopting a medium upper tobacco leaf drying process on the middle and upper 4-5 pieces of the leaves, wherein the humidity is set to be 36DEG C in steady temperature of 42DEG C, the humidity is controlled to be 35DEG C in the temperature of 43DEG C to 46DEG C, the humidity is set to be 38DEG C in the temperature of 54DEG C, and the humidity is set to be 40DEG C in the temperature of 68DEG C; adopting a top tobacco leave baking process on the top 2-3 pieces of the leaves, wherein the baking time is set to be 50 hours in the steady temperature of 40DEG C, the humidity is set to be 36DEG C in the steady temperature of 42DEG C, the humidity is set to be 34DEG C in the temperature of 43DEG C to 46DEG C, the humidity is set to be 38DEG C in the temperature of 54DEG C, and the humidity is set to be 40DEG C in the temperature of 68DEG C; performing sorting. The focus collecting and baking method is suitable for collecting and baking of the tobacco leaves.

Owner:SHANDONG LINYI TOBACCO

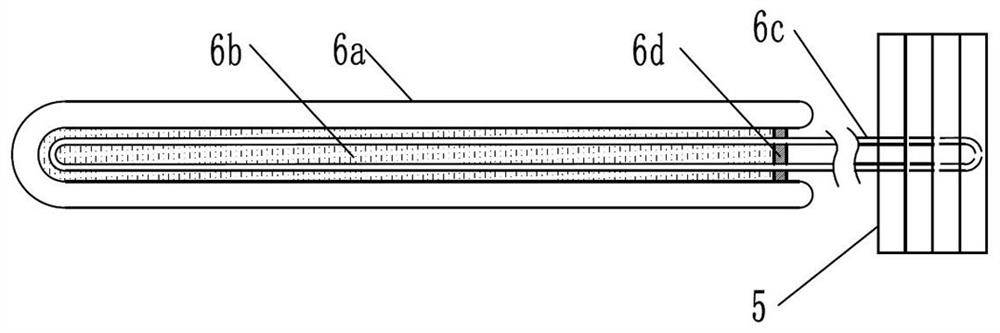

Baking channel device for embossing machine

InactiveCN101786374AReduce labor intensitySmall footprintPrinting press partsMechanical engineeringEngineering

The invention belongs to a baking device of embossing equipment, particularly relating to a baking channel device for a rotary embossing machine. The baking channel device comprises a pipeline, a heating device and a ventilation device, wherein the circular arc-shaped pipeline is provided with a control box, the side wall of the pipeline is provided with a slot for a template to pass through; the heating device is a carbon-wave infrared radiator which is uniformly arranged in the pipeline, the distance H between the carbon-wave infrared radiator and the template is 30 to 35cm; and the control box is connected with the carbon-wave infrared radiator and the ventilation device. The invention has the beneficial effects that the baking efficiency of the embossing machine is improved, the occupied area of the whole baking channel equipment is reduced, the baking quality of printed fabrics is improved and the labor intensity of workers is lowered.

Owner:常州杰盟鞋业有限公司

Environment-friendly energy-saving type oolong tea processing device

ActiveCN110521794AImprove baking efficiencyAvoid OverbakingSievingPre-extraction tea treatmentAgricultural engineeringTea leaf

The present invention discloses an environment-friendly energy-saving type oolong tea processing device. The environment-friendly energy-saving type oolong tea processing device comprises a drying box, a left side of a limiting sleeve block is connected with a tea leaf screening filter screen through a universal joint, a top part of the tea leaf screening filter screen is fixedly connected with anouter spray pipe, a tea residue drying conical plate is fixedly connected in the drying box and at a position close to a lower part, an inner part of the tea residue drying conical plate is fixedly connected with an inner stirring spray pipe, an absorption inner pipe is fixedly connected at a right side in the drying box and located above the tea leaf screening filter screen and the tea residue drying conical plate, and an output end of the absorption inner pipe communicates with a heat preservation pipes. The environment-friendly energy-saving type oolong tea processing device belongs to thetechnical field of oolong tea processing and achieves purposes of accelerating tea leaf baking efficiency, avoiding partial tea leaves to be excessively baked, improving tea leaf baking quality, avoiding a large number of heat losing of baking devices, and improving environmental protection and energy saving.

Owner:安徽省屯溪实验茶场

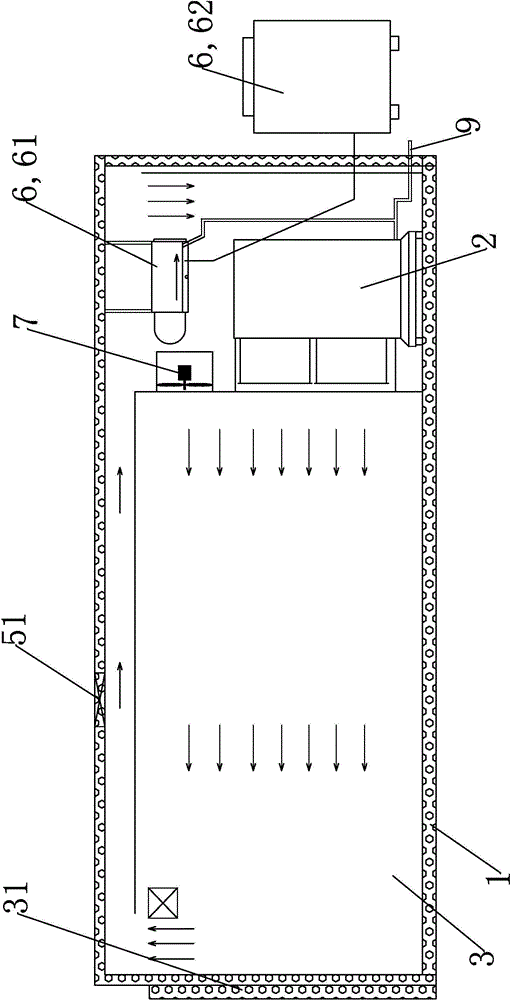

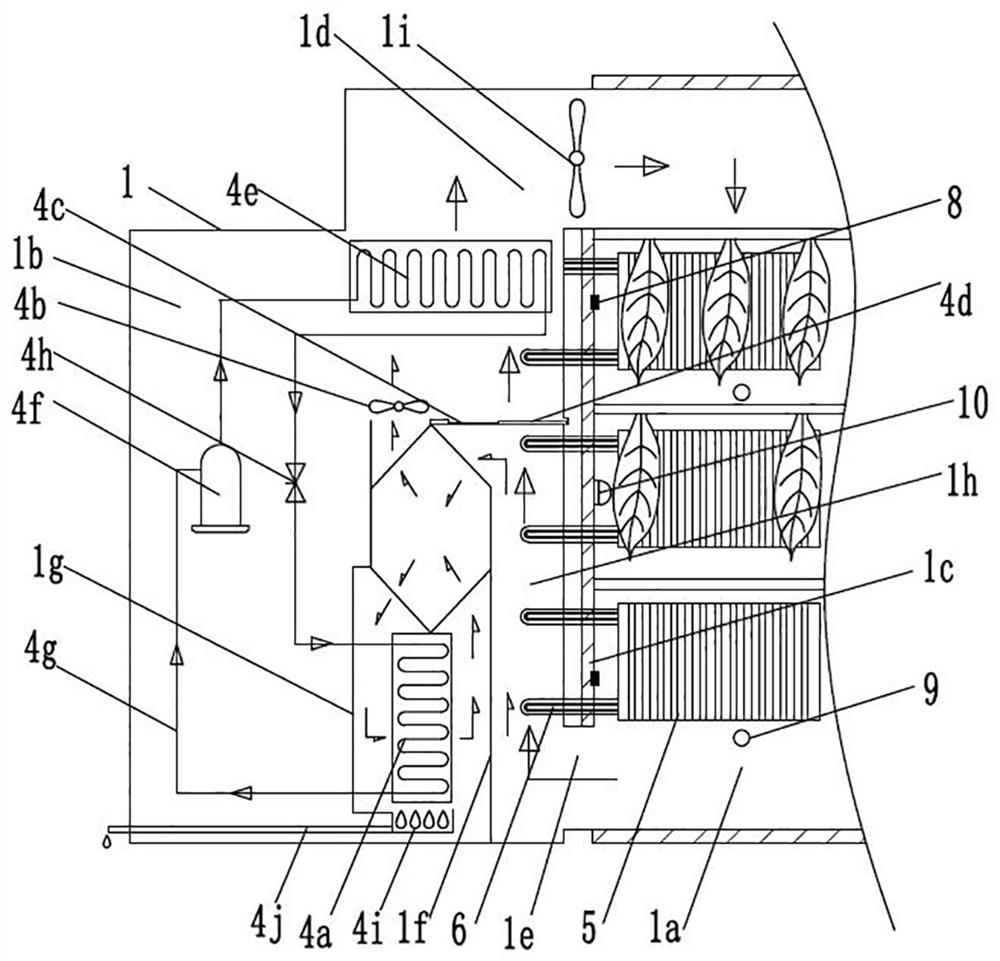

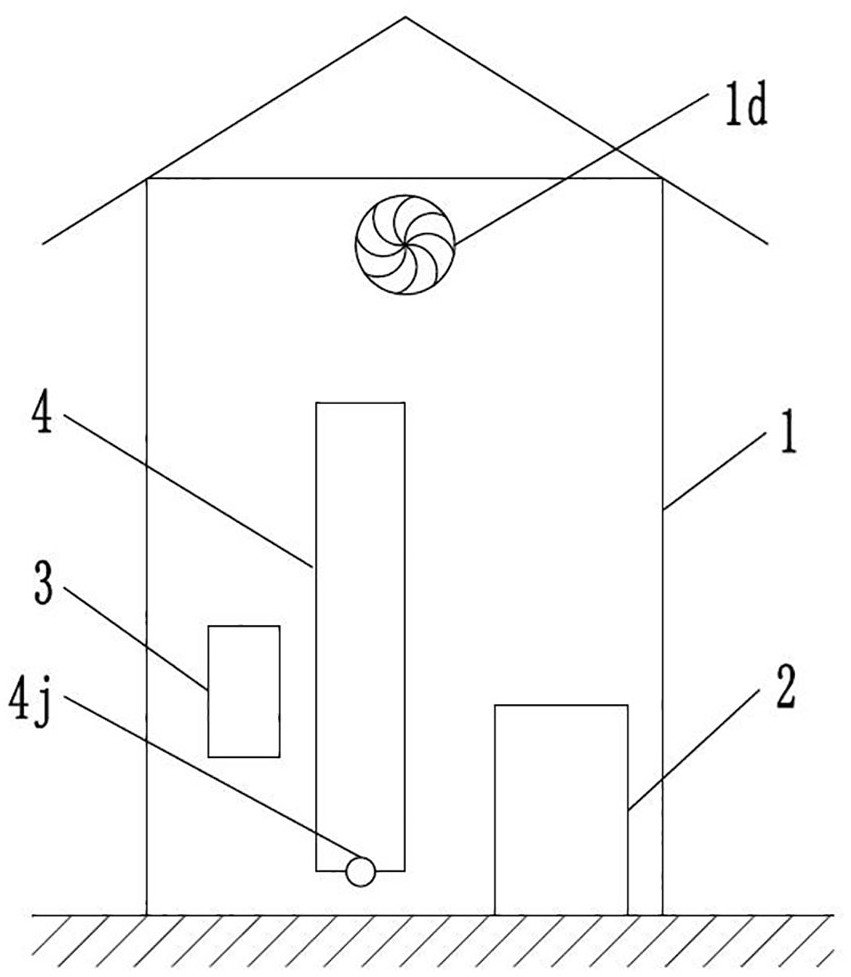

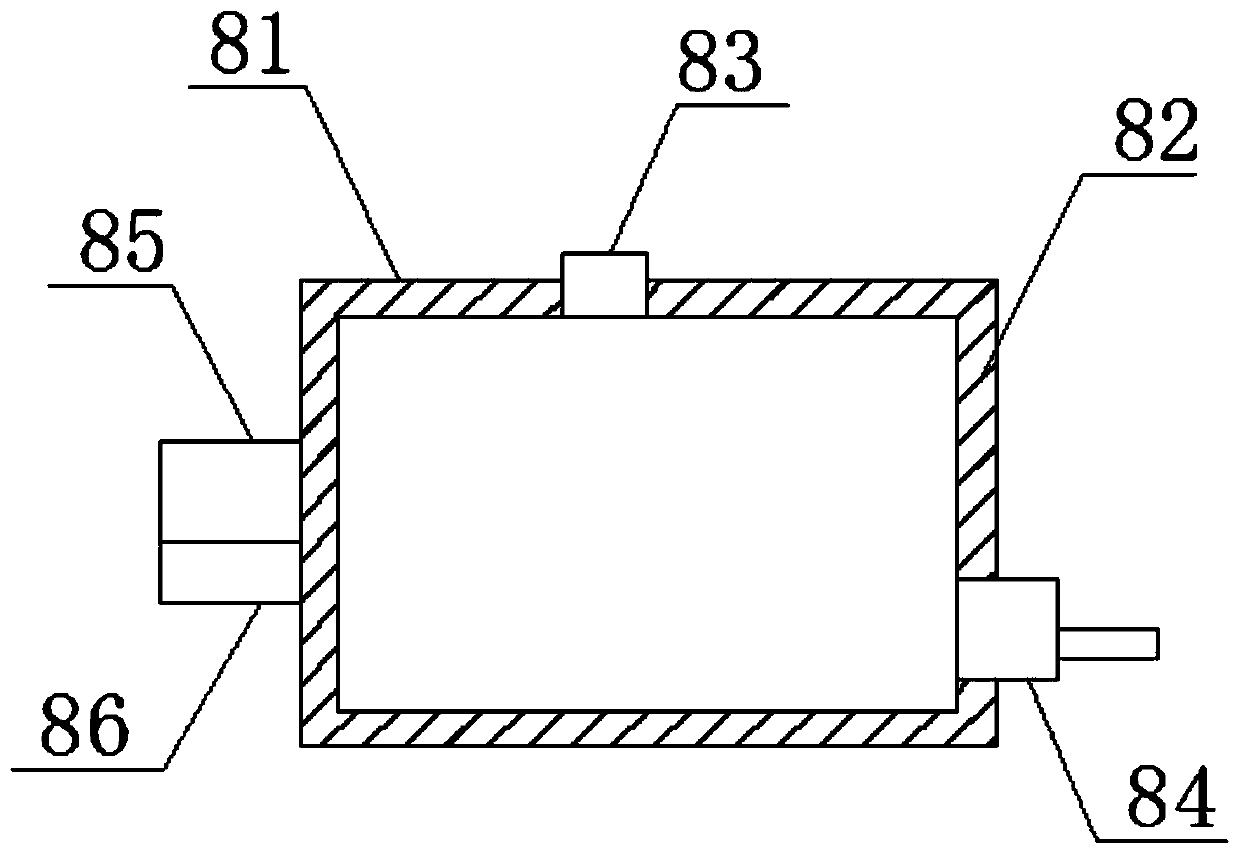

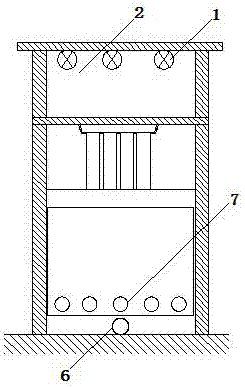

Drying machine

InactiveCN104390435AGood baking qualityImprove efficiencyDrying gas arrangementsDrying machines with local agitationBalancing machineProcess engineering

The invention relates to a drying machine comprising a cabinet. A drying machine body for dehumidifying and heating and a baking chamber for heat and humidity exchange with baked objects are arranged in the cabinet. An air-tight door is arranged on the outer side of the baking chamber. An air outlet channel used for delivering air flow dehumidified and heated by the drying machine body to the baking chamber is arranged at the air outlet end of the drying machine body. An air return channel used for returning the air flow subjected to heat and humidity exchange is arranged at the air inlet end of the drying machine body. A balancing machine capable of assisting in temperature control and dehumidifying and a control template are arranged on the cabinet. The drying machine body and the balancing machine adjust heat and humidity exchange jointly, so that baking time and temperature can be controlled accurately, baking quality and efficiency are high, and full and rapid heat and humidity exchange is realized.

Owner:ZHONGSHAN IMFORTU ELECTRICAL APPLIANCE

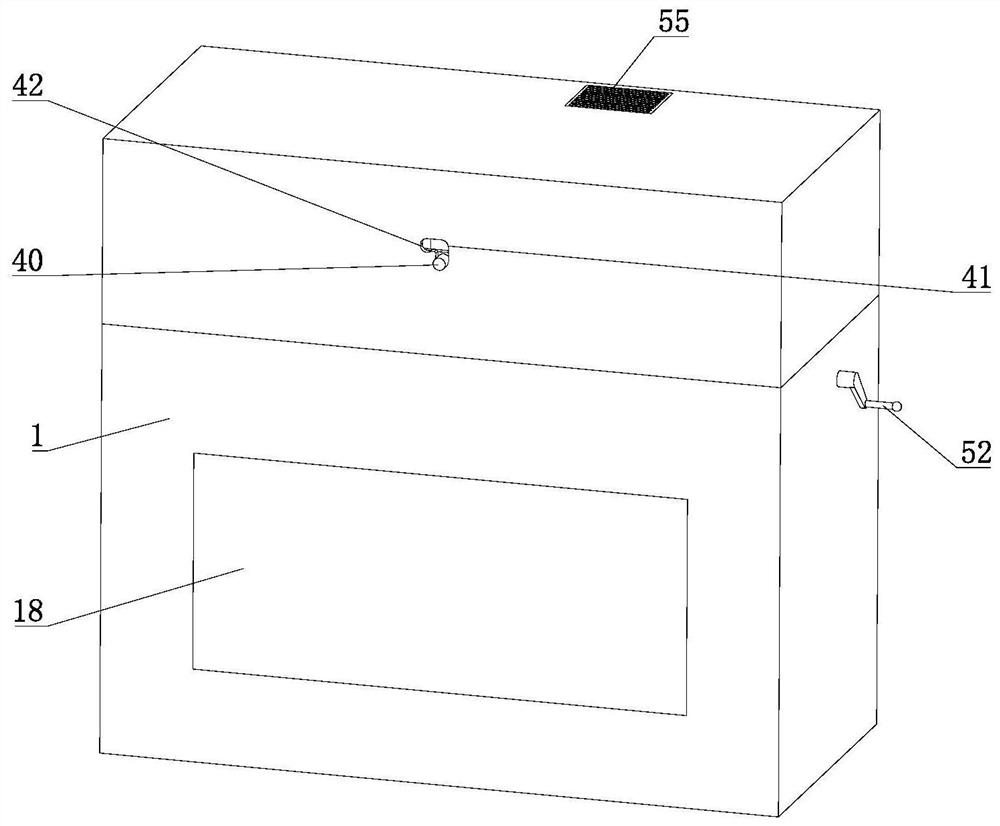

Tool for spraying car rear door trim protecting plate

InactiveCN104249043AQuality assuranceNot easy to produce warping deformationSpraying apparatusPretreated surfacesBack doorCooling methods

The invention discloses a tool for spraying a car rear door trim protecting plate and belongs to the technical field of spraying tools. When the tool is used to spray paint on the car rear door trim protecting plate, a vertical spraying manner is adopted. When the car rear door trim protecting plate is fed into a drying workshop for high-temperature drying after paint spraying, the plastic plate at the bent part at the upper end of the rear door trim protecting plate is cooled, and the plastic plate is allowed to be less prone to buckling deformation. A left window rack and a right window rack are fixedly connected to the lower end of a lifter, an upper transverse rod tube cavity is formed in the upper transverse rod along the axis of each of the left window rack and the right window rack, and the two tube cavities are communicated. The tool further comprises a drive thrust tube, a driven thrust tube and a cooling water reflux cylinder. A sealed space formed by the upper transverse rod tube cavities, a first communicating tube, a second communicating tube and the drive thrust tube is filled with mercury or ethanol. A sealed space formed by the cooling water reflux cylinder, a hose and the driven thrust tube is filled with cooling water in a sealed manner.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

Method for controlling circulating fan of bulk curing barn for improving tobacco smoking quality

InactiveCN109820230ADehydration step by stepYellowing step by stepTobacco preparationDrying gas arrangementsElectric energySmoke tobacco

The invention discloses a method for controlling a circulating fan of a bulk curing barn for improving tobacco smoking quality, which comprises the following steps of: setting time and frequency by sections for a frequency converter of the fan of the curing barn, using 5Hz as an adjusting unit, wherein before the tobacco is cured to 38 DEG C, the frequency of the frequency converter is not more than 35Hz, the rotating speed of the circulating fan is not more than 1050r / min, and when the tobacco is cured to 42 DEG C-54 DEG C, the frequency of the frequency converter is 50Hz, the rotating speedof the circulating fan is kept at 1480r / min, after the tobacco is cured to 54 DEG C, the frequency of the frequency converter is 30-45Hz, the rotating speed of the circulating fan is 900-1200r / min,the power consumption is obviously reduced after the frequency converter of the bulk curing barn is reformed, the electric energy is saved by about 30%, the wind speed is soft, the tobacco is dehydrated, becomes yellow and is dried step by step, a large amount of aroma substances are deposited and accumulated, the chemical components are coordinated, and the industrial use value of the tobacco isimproved.

Owner:云南省烟草公司大理州公司 +2

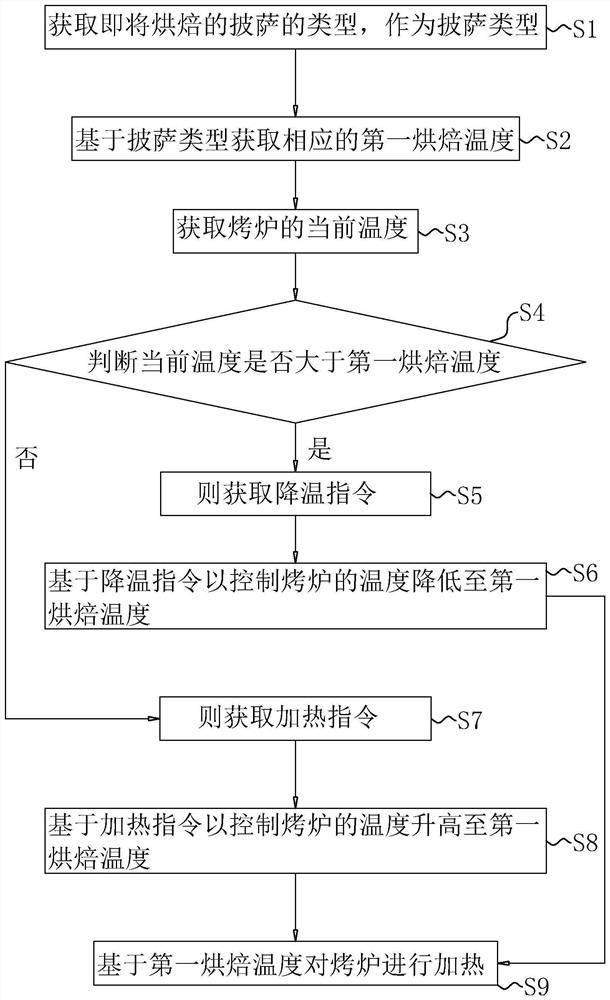

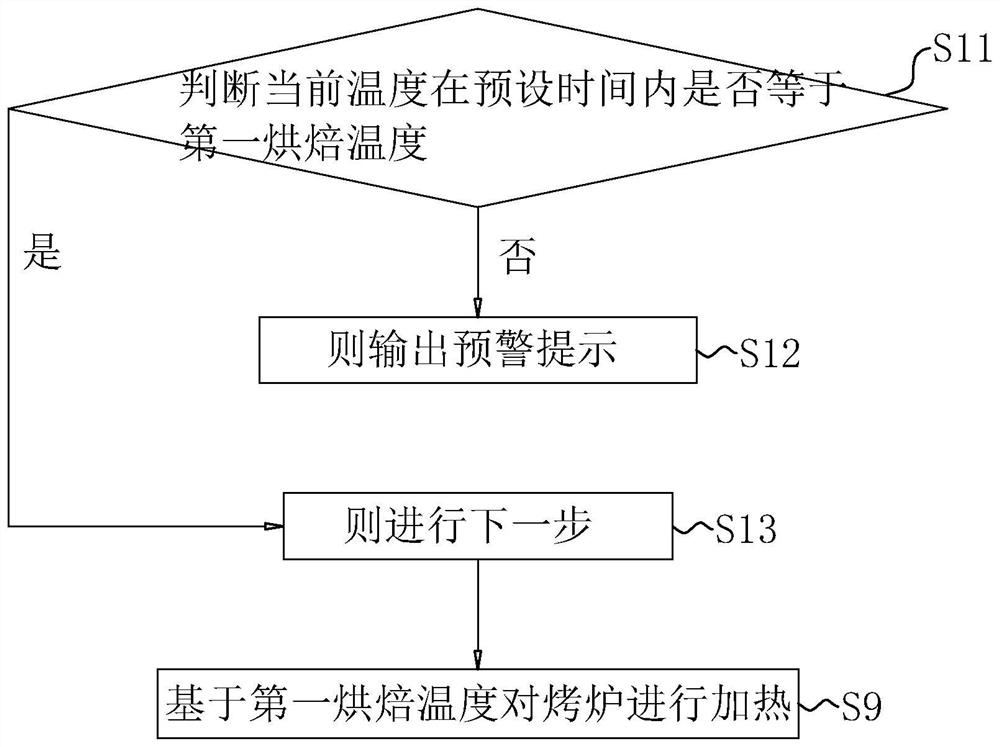

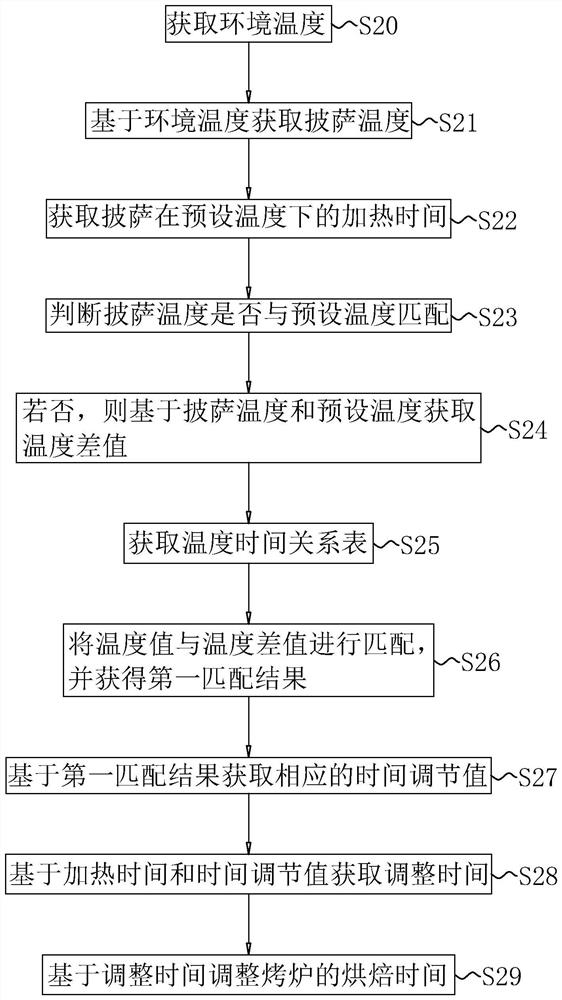

Temperature adjusting method and system of pizza oven

InactiveCN114115382AShorten production timeReduce waiting timeTemperatue controlProcess engineeringIndustrial engineering

The invention relates to a temperature adjusting method and system of a pizza oven, and belongs to the technical field of baking equipment, and the method comprises the following steps: obtaining the type of a pizza to be baked as a pizza type; acquiring a corresponding first baking temperature based on the pizza type; acquiring the current temperature of the oven; judging whether the current temperature is greater than the first baking temperature; if yes, obtaining a cooling instruction; controlling the temperature of the oven to be reduced to a first baking temperature based on the cooling instruction; if not, obtaining a heating instruction; controlling the temperature of the oven to rise to a first baking temperature based on the heating instruction; and heating the oven based on the first baking temperature. The pizza making time is shortened, the waiting time of customers is shortened, and the satisfaction degree of the customers is improved.

Owner:深圳市恒兴盛厨具有限公司

Dual-heat source dynamic baking device and baking method and application thereof

InactiveCN108464358APromote circulationReduce adhesionPre-extraction tea treatmentGlass fiberProcess engineering

The invention relates to a dual-heat source dynamic baking device and a baking method and application thereof, and belongs to the field of baking. The device comprises a glass fiber cylindrical bakingpot, a rotating assembly, a heating draught fan and a xenon lamp light source system; the inside of the baking pot is an empty cavity, and an air outlet, a feeding port and a discharging port are arranged on the pot body; the rotating assembly comprises a rotating shaft and a power device; the inside of the rotating shaft is hollow, and the surface of the shaft is provided with vent holes and a screw blade; one end of the rotating shaft is connected to the gas slip ring, and the gas slip ring is connected to the heating draught fan through a soft tube; a temperature adjusting knob is arrangedon the heating draught fan; and a regulation band which is coated with a nano coating on a flexible substrate is arranged on the baking pot body opposite to the xenon lamp light source system. With the device, the material is heated uniformly, the gas circulation is good, and moisture exhausting is smooth; the baking efficiency is improved by adopting double heat sources of hot air and a xenon lamp light source; and the provided regulation band is beneficial to reducing the loss of beneficial substances and improving baking quality.

Owner:HENAN UNIV OF SCI & TECH

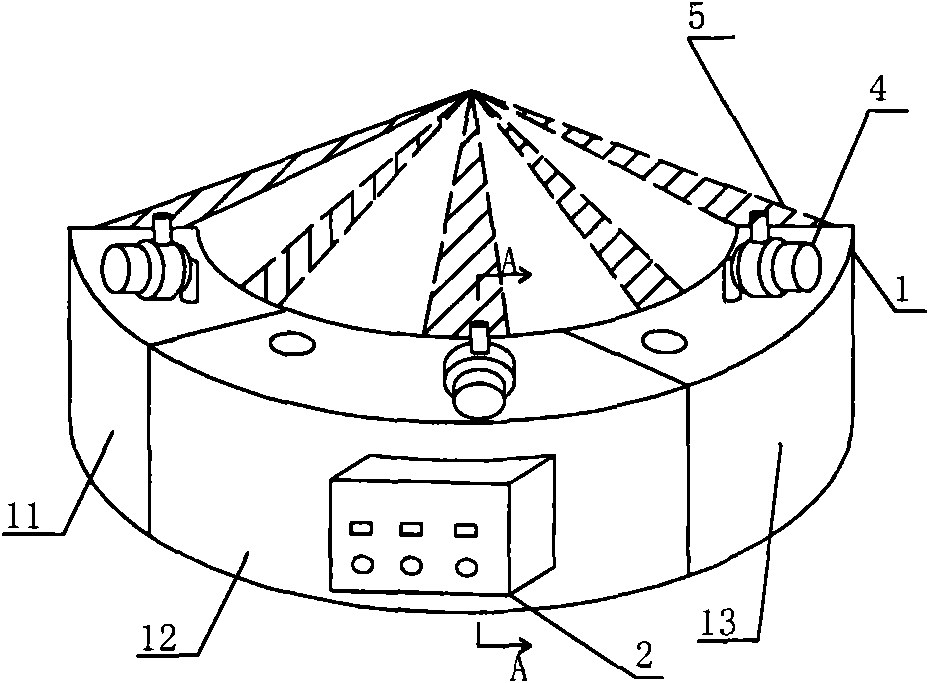

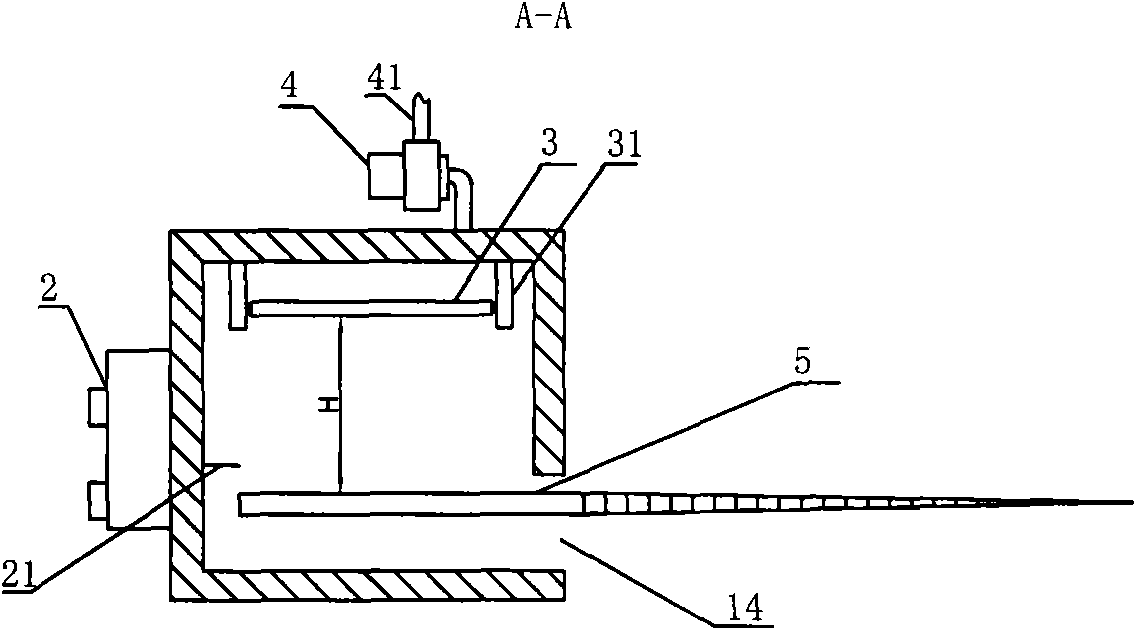

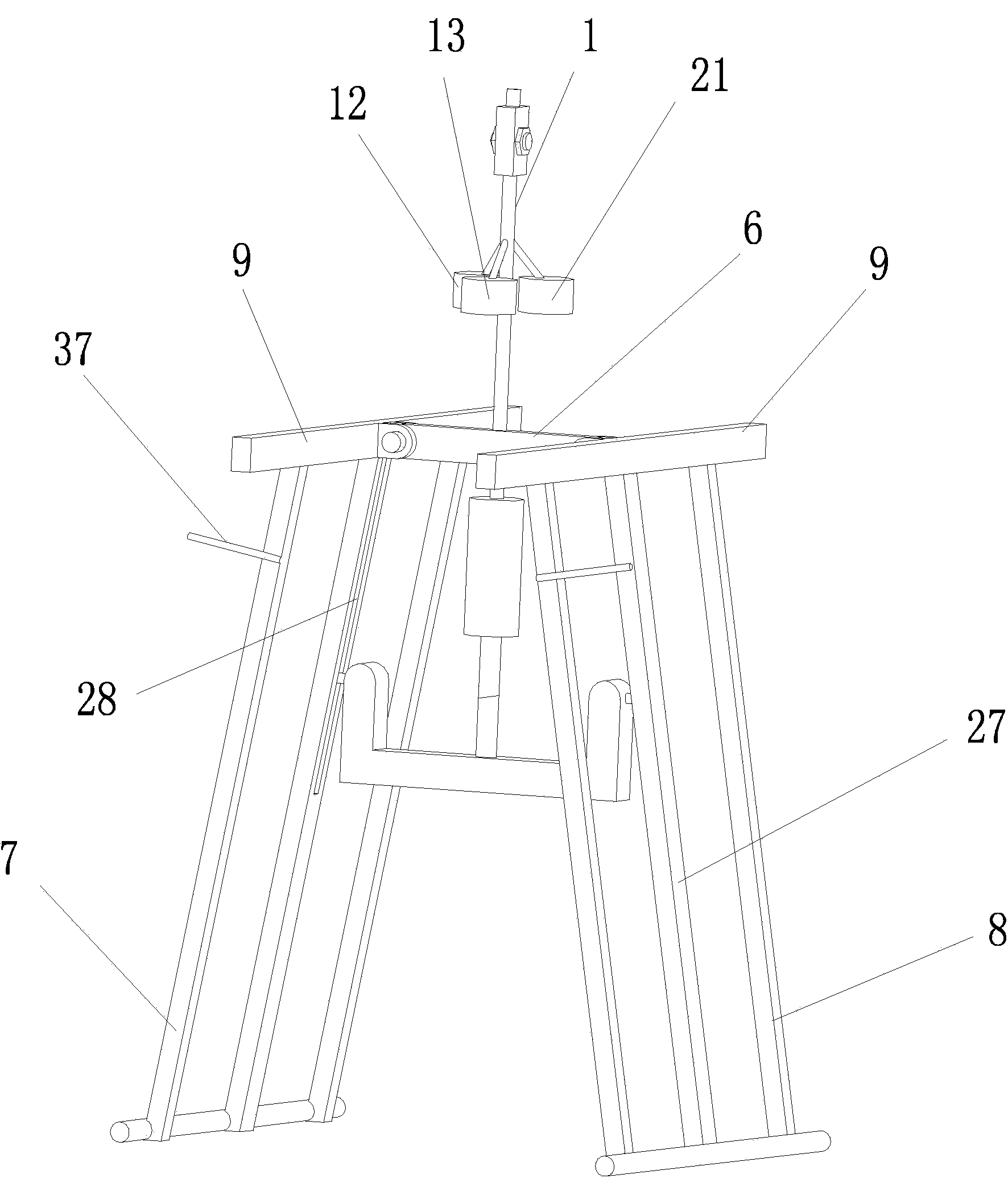

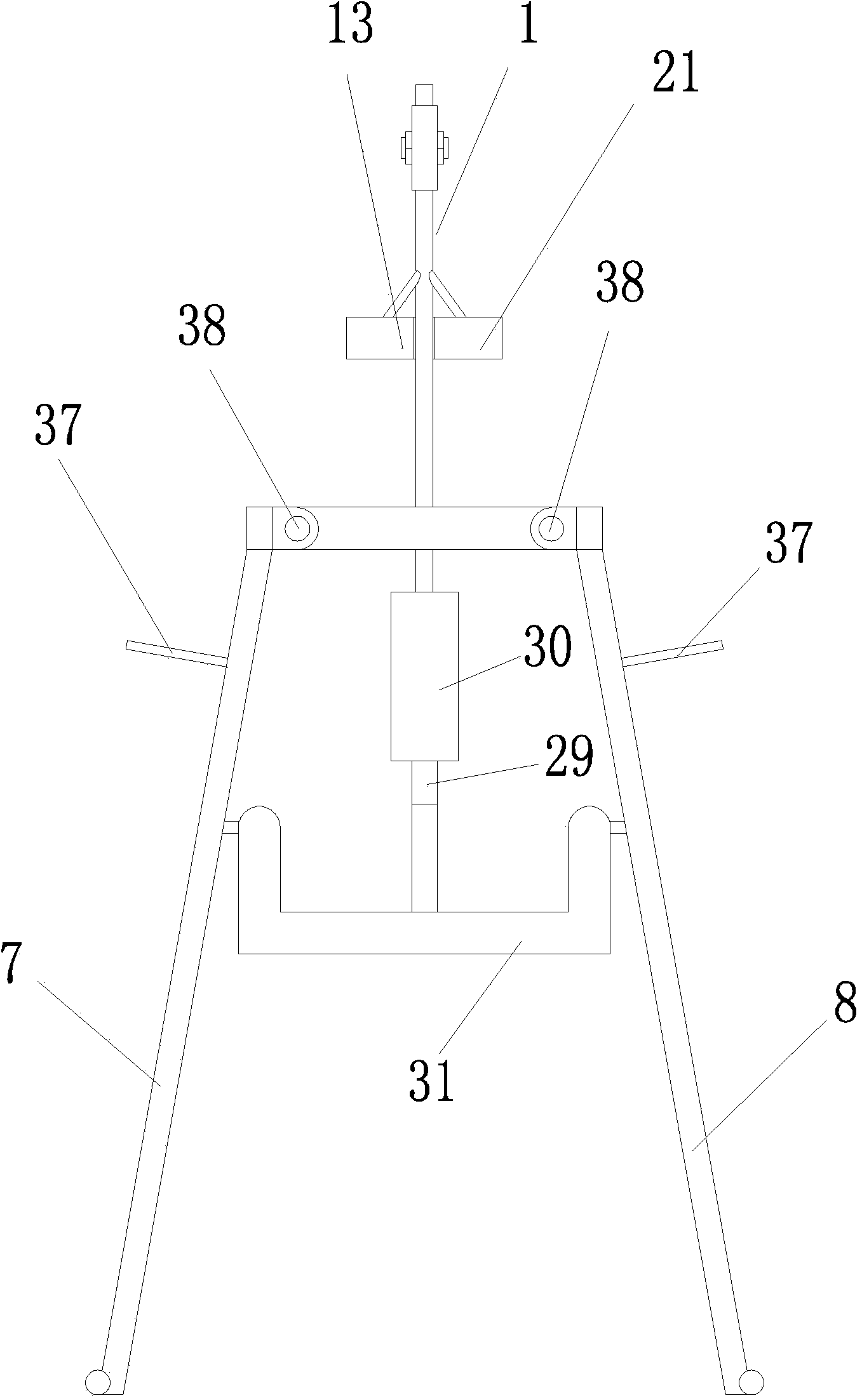

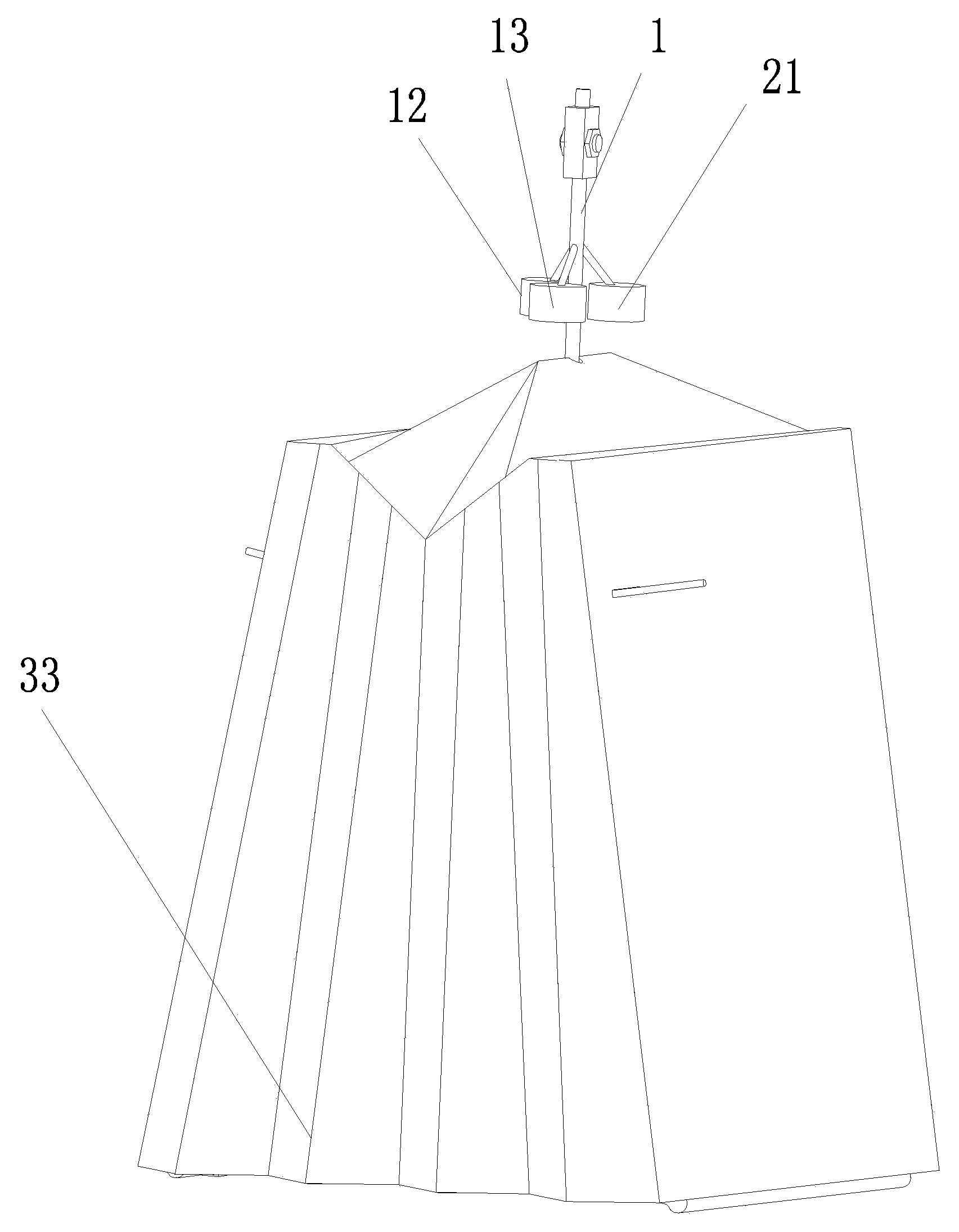

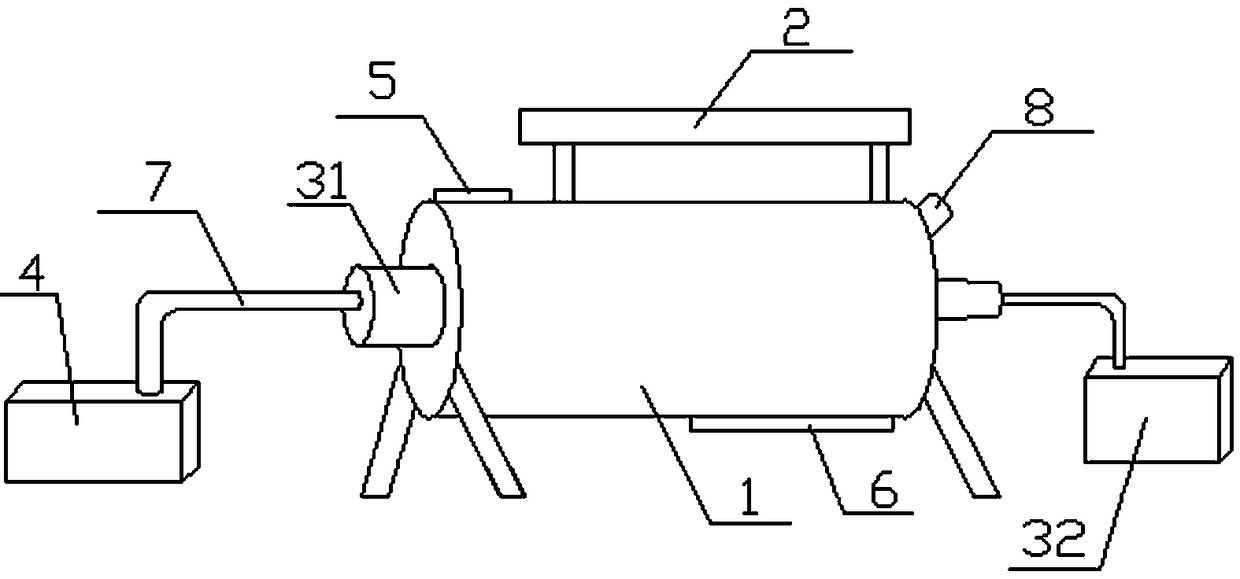

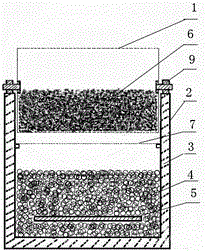

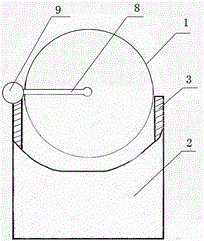

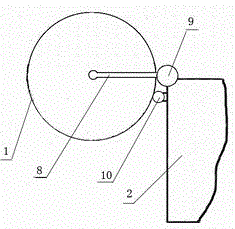

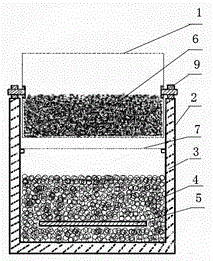

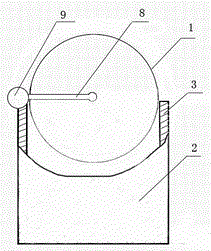

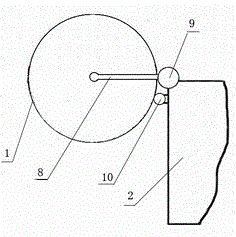

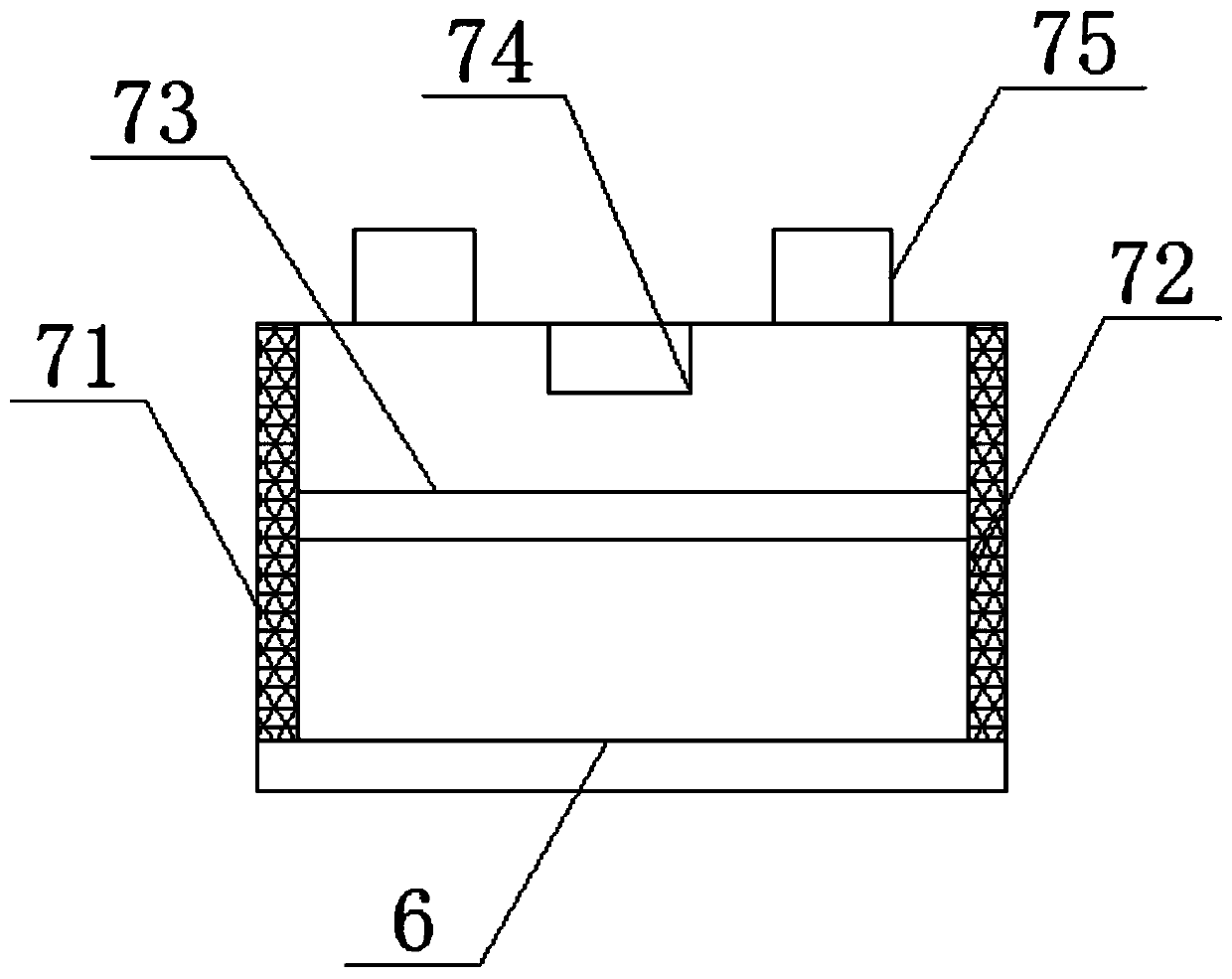

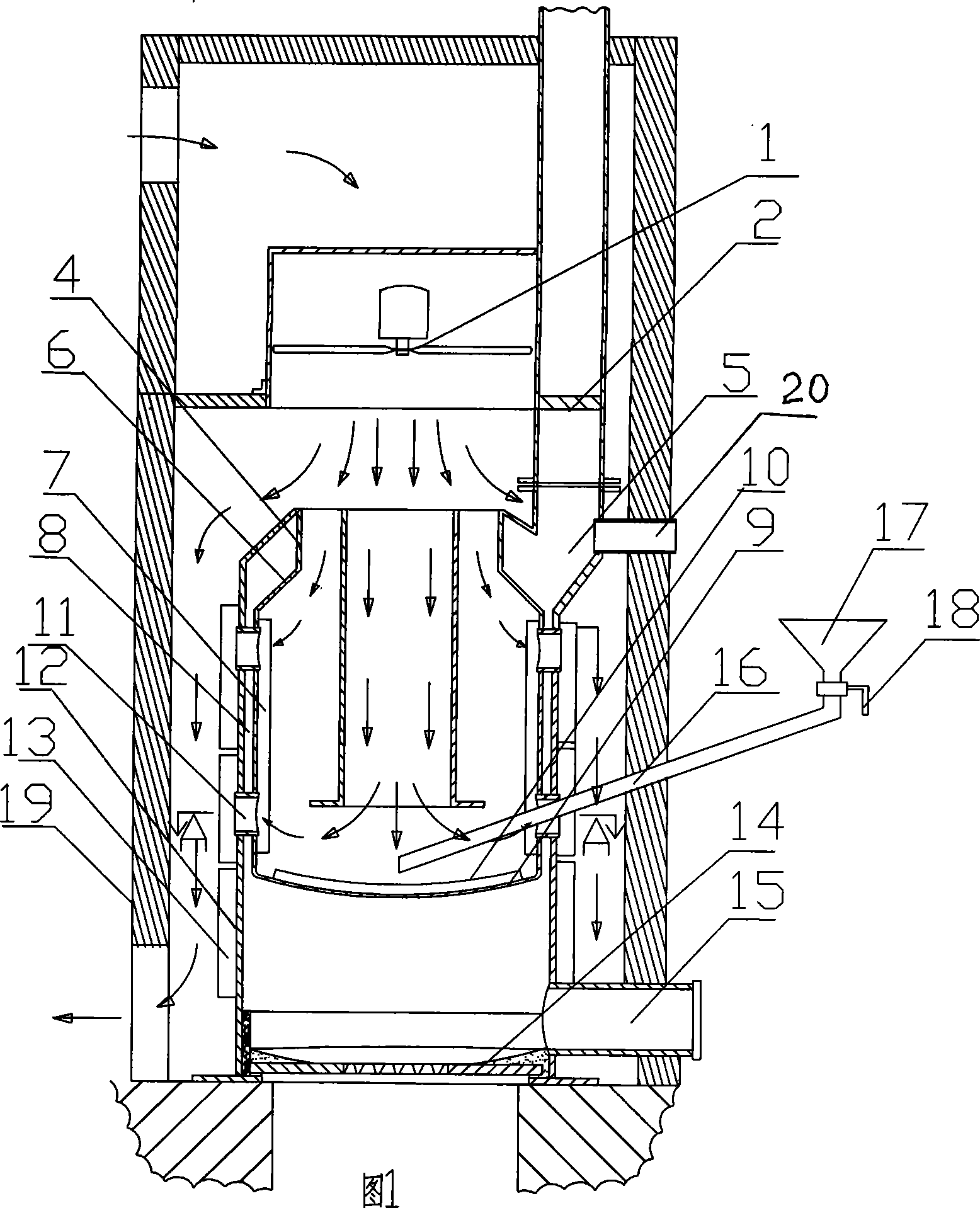

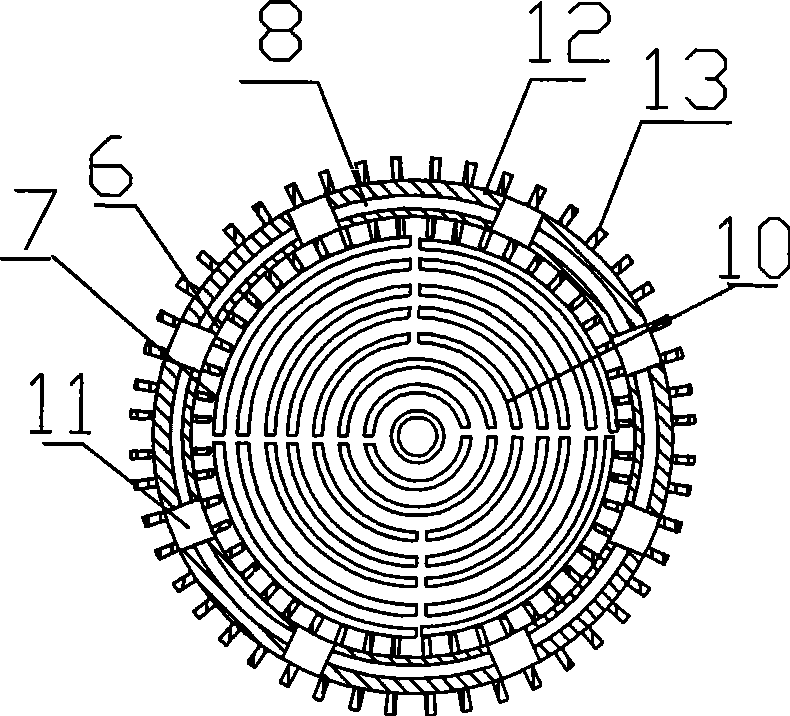

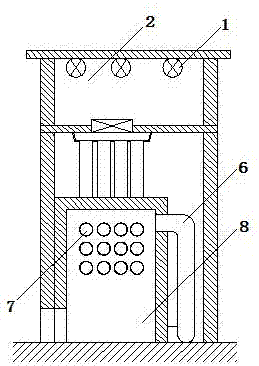

Heat radiation type simulation charcoal baking tea baking machine and using method

InactiveCN106070774APositive technological progressUniform heating surface temperaturePre-extraction tea treatmentCooking & bakingInsulation layer

The invention discloses a heat radiation type simulation charcoal baking tea baking machine. The heat radiation type simulation charcoal baking tea baking machine is characterized by comprising a round barrel-shaped baking cage (1) and a baking machine body; the baking machine body comprises a machine box (2), a heat insulation layer (3), a heat storage particle heap (4), an electric heating device (5) embedded in the heat storage particle heap (4) and a tea dust isolation net (7); the baking machine body is provided with a device for moving the round barrel-shaped baking cage (1) into or out of the baking machine body and a device for driving the round barrel-shaped baking cage (2) to rotate.

Owner:李祥龙

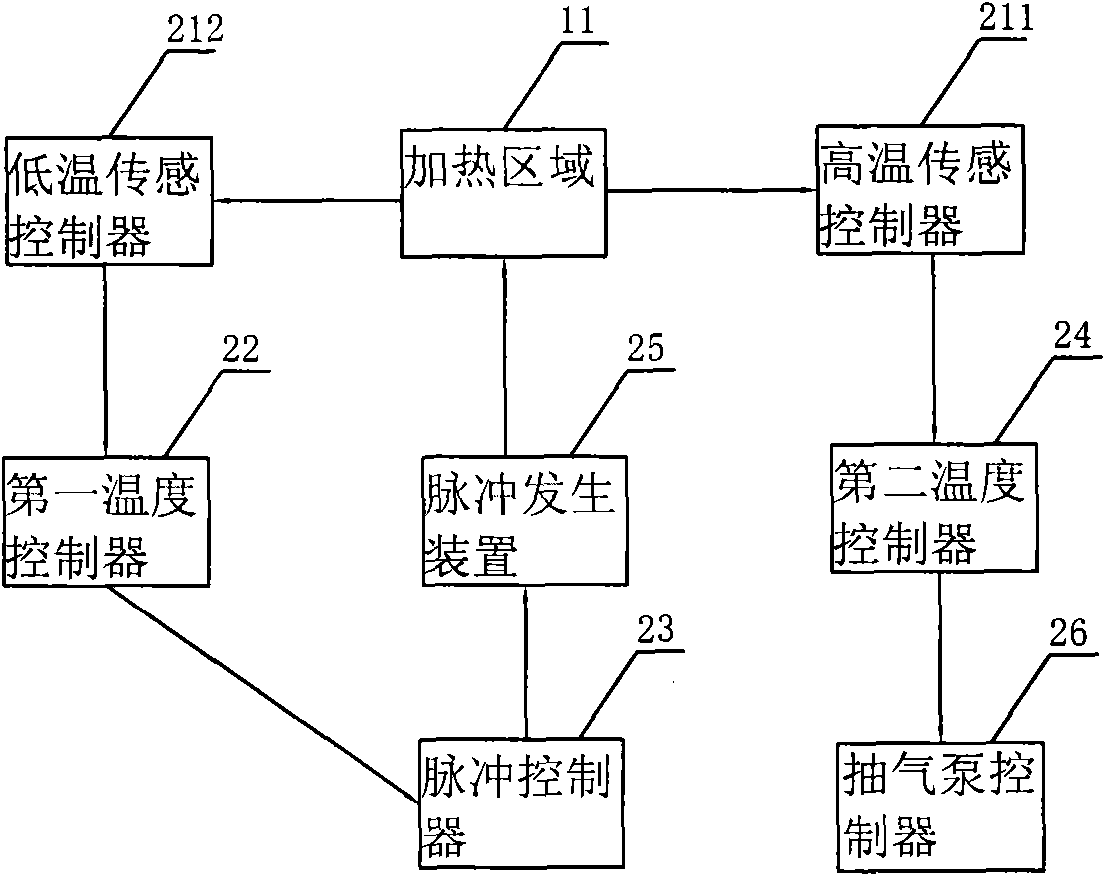

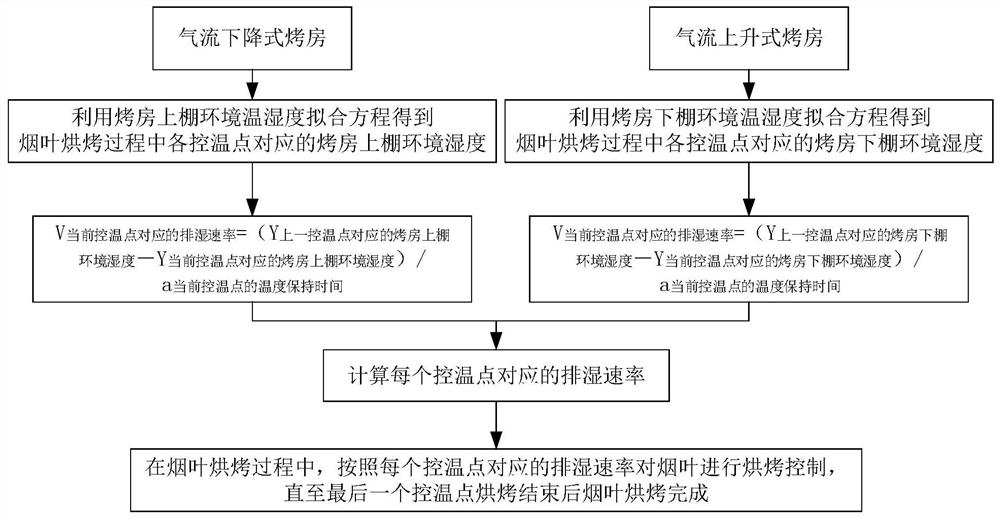

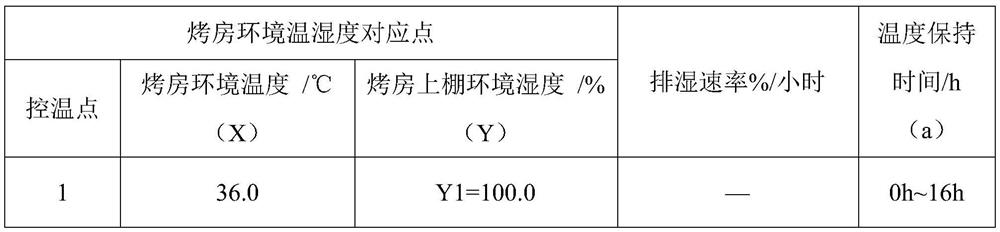

Control method and control system for dynamic-humidity-control baking of tobacco leaves

ActiveCN113796557ASolve yellowingSolve coordination problemsTobacco preparationTemperature controlAtmospheric sciences

The invention provides a control method and control system for dynamic-humidity-control baking of tobacco leaves, belonging to the field of tobacco leaf baking. The method comprises the steps that in a tobacco leaf curing process, curing control is conducted on tobacco leaves at each temperature control point according to a moisture removal rate corresponding to each temperature control point; for an airflow descending type curing barn, the moisture removal rate corresponding to the current temperature control point is calculated according to curing barn upper shed environment humidity corresponding to the current temperature control point and the previous temperature control point and the temperature holding time of the current temperature control point; for an airflow ascending type curing barn, the moisture removal rate corresponding to the current temperature control point is calculated according to curing barn lower shed environment humidity corresponding to the current temperature control point and the previous temperature control point and the temperature holding time of the current temperature control point, wherein the curing barn upper shed environment humidity corresponding to each temperature control point is obtained by using a curing barn upper shed environment temperature and humidity fitting equation; and the curing barn lower shed environment humidity corresponding to each temperature control point is acquired by using the curing barn lower shed environment temperature and humidity fitting equation. According to the invention, tobacco leaf curing quality can be effectively improved, and tobacco leaf curing loss is reduced.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Tunnel hot air circulation tunnel furnace

The invention discloses a tunnel type hot air circulation tunnel furnace. The tunnel type hot air circulation tunnel furnace comprises a furnace body, a hot air circulation device, a conveying belt and a heating device. The hot air circulation device comprises a hot air generator, a draught fan, a four-way connector, an upper air box and a lower air box. The four-way connector comprises a horizontal air inlet shell and two air distribution shells, wherein the two ends of the air inlet shell vertically extend to form the two air distribution shells. The top face of the air inlet shell is provided with an inlet. The bottom face of the air inlet shell is provided with a first outlet. The upper ends of the two air distribution shells are communicated with the inlet. The lower end of each air distribution shell is provided with a second outlet. The outlet of the draught fan is communicated with the inlet. The first outlet is communicated with the upper air box. The second outlets are communicated with the lower air box. The bottom of the upper air box is provided with a plurality of first air outlet holes. The top of the lower air box is provided with a plurality of second air outlet holes. A return air passage is arranged in the furnace body. The first air outlet holes and the second air outlet holes are connected with the hot air generator through the return air passage. According to the tunnel type hot air circulation tunnel furnace, hot air output by the hot air circulation device can be evenly and circularly led to products to be baked, and the air temperature, the air volume and the air speed can be controlled.

Owner:GUANGZHOU BAKE OVEN MACHINERY

Coffee bean baking method adopting temperature monitoring

InactiveCN108606129AAchieve reasonable controlImprove bake qualityGreen coffee treatmentCoffee roasting methodsCooking & bakingTemperature monitoring

The invention discloses a coffee bean baking method adopting temperature monitoring. The coffee bean baking method comprises the following steps of performing preliminary screening on coffee beans according to the particle diameter; selecting a part of coffee beans as detection samples for the water content of the coffee beans, weighing the selected part of the coffee beans in advance, obtaining the water content, and calculating the ratio of the water content to the weight; weighing the quantity of the coffee beans needing to be baked, and calculating the water content corresponding to the weight of the coffee beans needing to be baked; loading the coffee beans needing to be baked into a baking machine totally, and setting the temperature of the baking machine according to the all of calculated water content of the coffee beans; and mounting a temperature sensor in the baking machine, monitoring the temperature in the baking machine in a real-time manner, after the baking machine begins to perform baking for 1-2 hours, reducing the baking temperature by 8-12 DEG C when baking is performed for 10-15 minutes each time, and when the baking temperature is reduced to 60-70 DEG C, performing heat preservation for 1-2h so as to obtain the coffee beans. According to the coffee bean baking method disclosed by the invention, the baking time and the baking temperature of the coffee beanscan be reasonably controlled.

Owner:SICHUAN XINGZHI ZHIHUI INTPROP OPERATION CO LTD

High efficient and energy saving tea leaf baking and fragrance improving machine and use method thereof

InactiveCN105410208APositive technological progressUniform heating surface temperaturePre-extraction tea treatmentMechanical engineeringTea leaf

The present invention discloses a high efficient and energy saving tea leaf baking and fragrance improving machine which is characterized by consisting of a drum-shaped baking cage and a baking machine body. The baking machine body includes a machine box (2), a thermal insulating layer (3), a heat storage granule pile (4), an electrical heating device (5) buried in the heat storage granule pile (4) and a minced tea separation net (7). A drum-shaped baking cage (1) moving in and moving out device from the baking machine body and a drum-shaped baking cage (1) rotation driving device are arranged in the baking machine body.

Owner:李祥龙

Baking tool

InactiveCN107442374ARealize baking dryingSimple structurePretreated surfacesCoatingsEngineeringElectrical and Electronics engineering

Owner:芜湖博康新材料技术有限公司

Intermittent heating tea baking equipment

InactiveCN109566783AConvenient for BakingAdjustable heating timePre-extraction tea treatmentCooking & bakingHeating time

The invention discloses intermittent heating tea baking equipment, which comprises a machine frame, reciprocating heating assemblies and a baking cage assembly, wherein strip-shaped heating holes aredistributed in a top plate of the machine frame; a rotating motor arranged on the machine frame drives a turntable to rotate; the reciprocating heating assemblies are arranged at the two sides of thetop surface of an installing plate; each reciprocating heating assembly comprises two slide rails, a sliding frame, a connecting rod and a heating plate; the connecting rod drives the heating plate toperform reciprocation; the baking cage assembly comprises a rectangular baking cage and a jacking mechanism; the rectangular baking cage is arranged on the top surface of the machine frame; one sideof the rectangular baking cage is rotationally connected with one side of the machine frame; the other side of the rectangular baking cage is connected with the jacking mechanism; the jacking mechanism is used for jacking up one side of the rectangular baking cage during discharging. The intermittent heating tea baking equipment is designed by the invention; the rotating speed of the motor and theon-off operation of the motor are set and controlled; the heating time of the heating plate in each baking region can be regulated; great convenience is provided for the tea baking operation; the time and the labor are saved; the operation efficiency is improved, and the cost is reduced.

Owner:合肥茗满天下茶叶有限公司

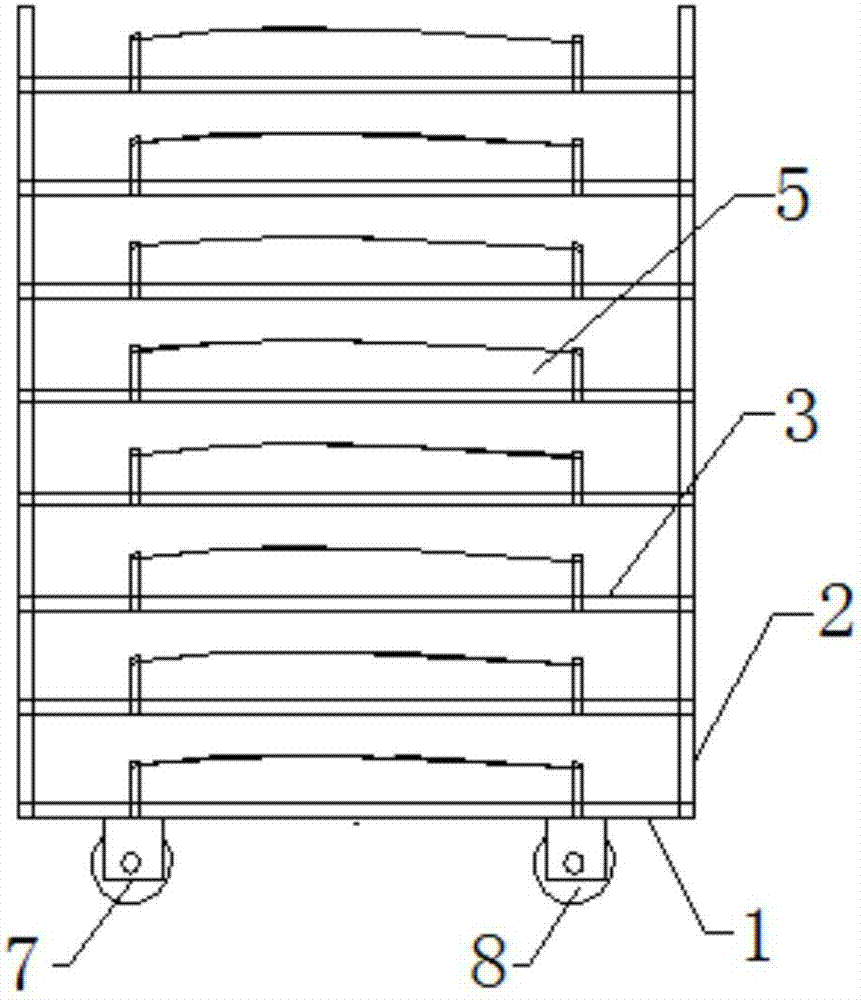

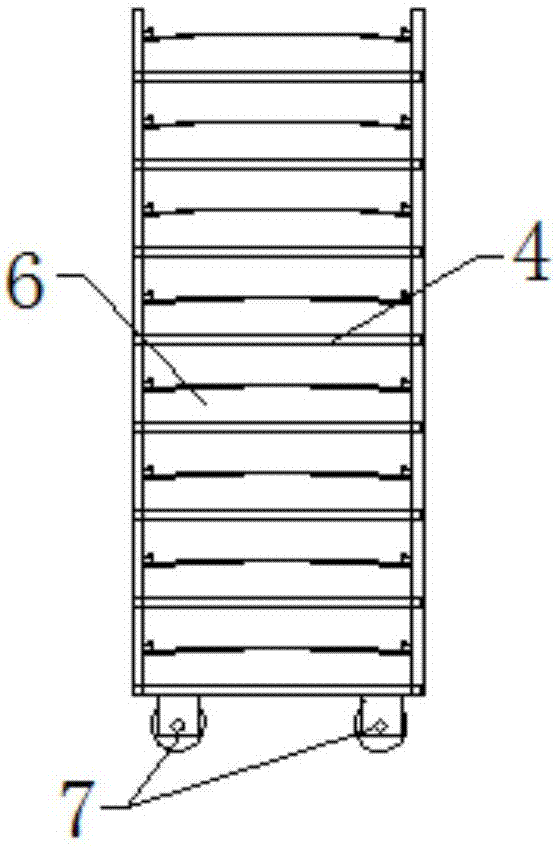

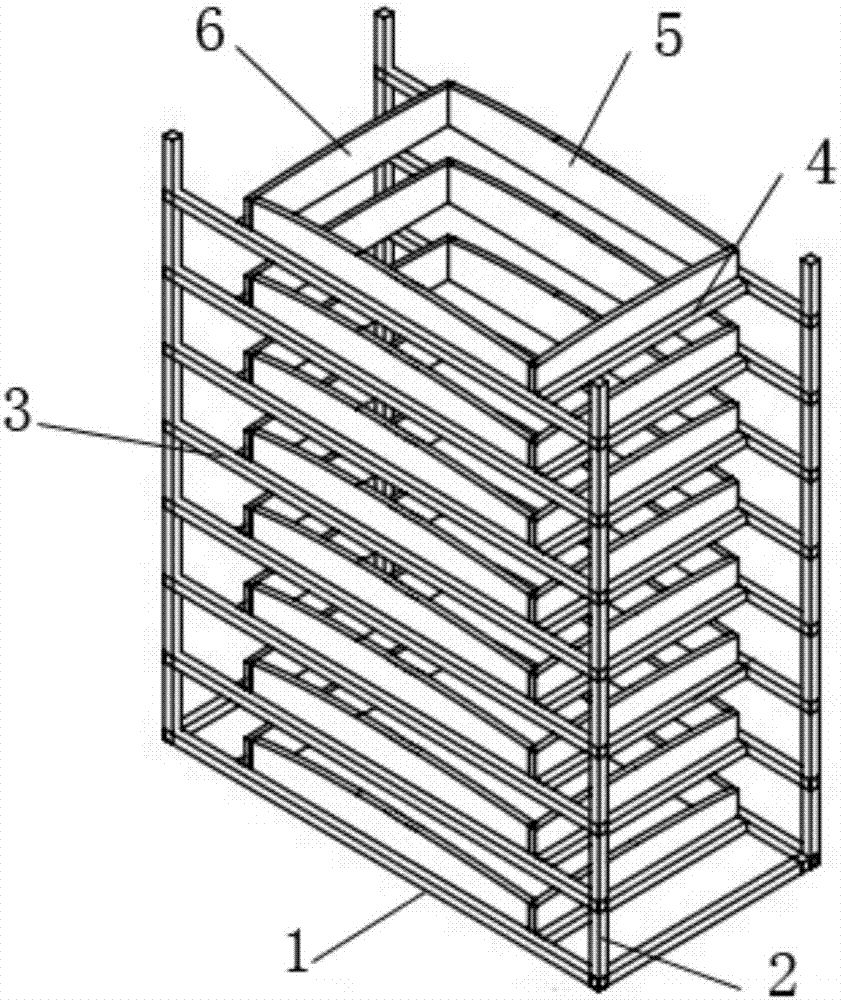

Optical switch collimator baking rack

ActiveCN103512347BSimple structureImprove adhesionDrying chambers/containersEngineeringOptical switch

Owner:广西安捷讯电子科技有限公司

A frequency conversion flue-cured tobacco heat pump dual power barn

ActiveCN109330010BStable wind pressureStable air volumeTobacco preparationAutomatic controlThermodynamics

The invention discloses a frequency conversion flue-cured tobacco heat pump dual-power barn, which comprises a flue-cured tobacco room, a heating room, a heat pump unit, and a biomass fuel furnace. The return air outlet, the heating room is provided with a diversion wall facing the return air outlet, the heat pump evaporator of the heat pump unit is installed directly opposite the vent, the heat exchange device is installed above the heat pump evaporator, and the diversion fan is installed above the heat exchange device. The heat pump condenser of the heat pump unit is arranged at the air inlet, a biomass fuel furnace and a control device are arranged in the heating room, and a monitoring system connected to the control device is arranged in the flue-cured tobacco room. The present invention realizes automatic control through a control device, can precisely control temperature changes, and has high heat utilization efficiency. Compared with other curing methods, the curing cost is low and energy-saving, and the loss of tobacco leaf curing modulation is reduced, and the yellowing of tobacco leaves is coordinated with color fixing. Drying is matched with aroma, and the goal of roasting tobacco leaves to be yellow, dry and fragrant is achieved.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

A drying tunnel device for a printing machine

ActiveCN107856404BIncrease flow rateImprove bake qualityPrinting press partsHeating effectEngineering

The invention discloses a drying tunnel device used for a printing machine. The drying tunnel device comprises an inner tube. An outer tube is arranged on the outer side of the inner tube. An air blower is arranged on one side of the outer tube. Cooling fans are arranged on the inner side of the outer tube. Temperature sensors are uniformly arranged between the inner tube and the outer tube. A ventilating plate is arranged on one side of the inner tube. Ventilating holes are uniformly formed in the surface of the ventilating plate. A ventilating device is arranged at the top of the ventilatingplate. A heating device is arranged at one side of the ventilating device. According to the drying tunnel device, by arranging the cooling fans and the air blower, the air flowing speed is increasedwhen fabric is heated between the inner tube and the outer tube, the heating speed is increased, a constant temperature is kept, gas is exhausted out of a drying tunnel, and in addition, the drying tunnel can be dehumidified; and by arranging the heating device, the inner tube and the outer tube can be heated through circulating heat transfer oil, the heating effect is good, the temperature is easy to control, meanwhile, the occupied area of the drying tunnel overall equipment is reduced, the drying quality for fabric printing is improved, and the labor intensity of workers is relieved.

Owner:淮南晟莱水泵设备有限公司

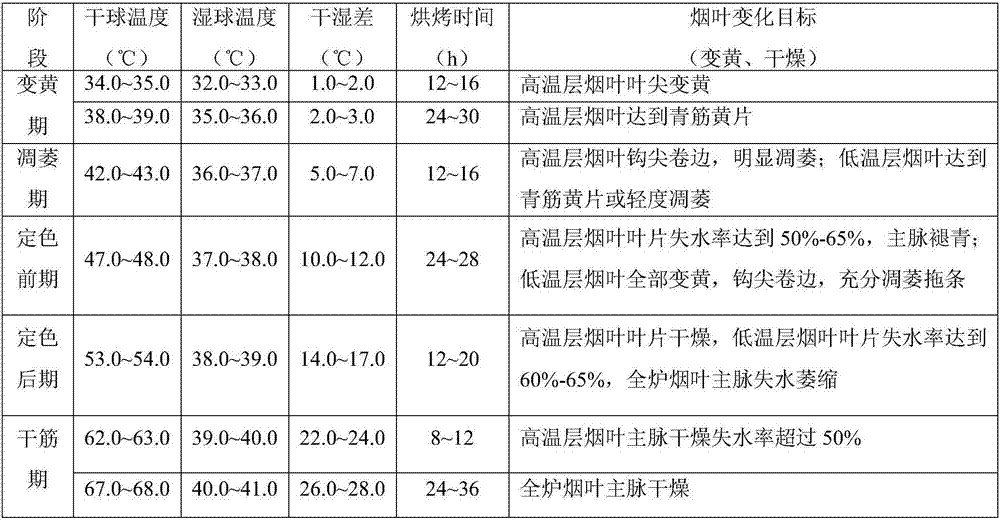

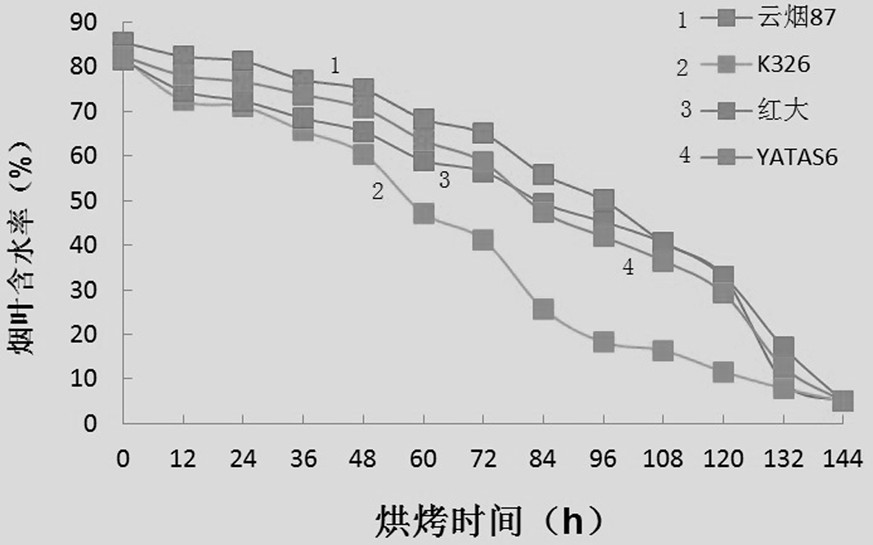

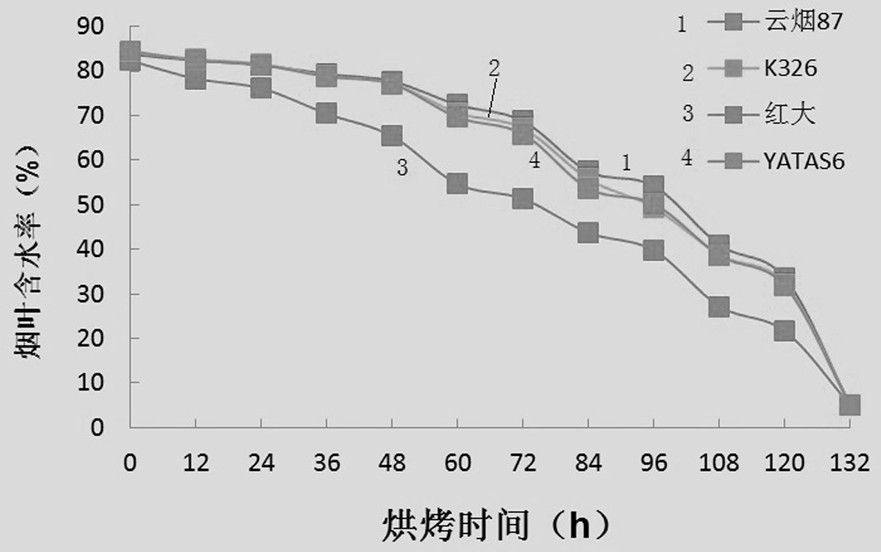

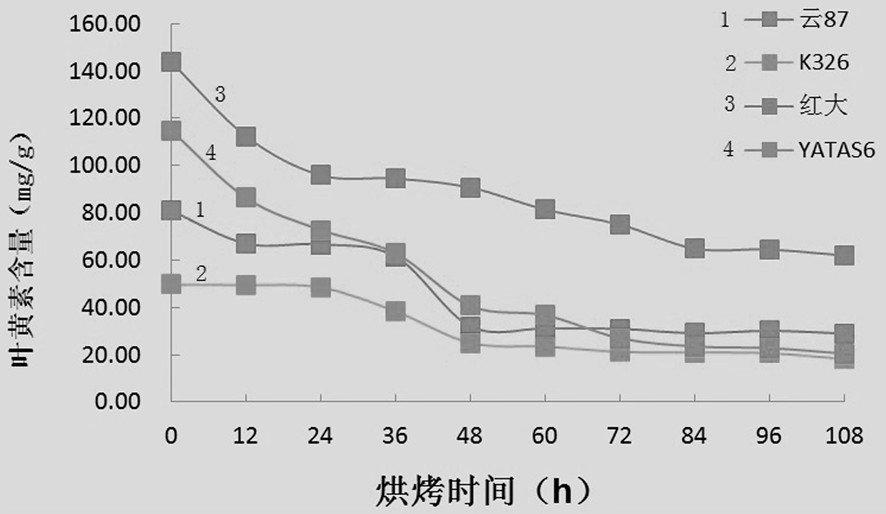

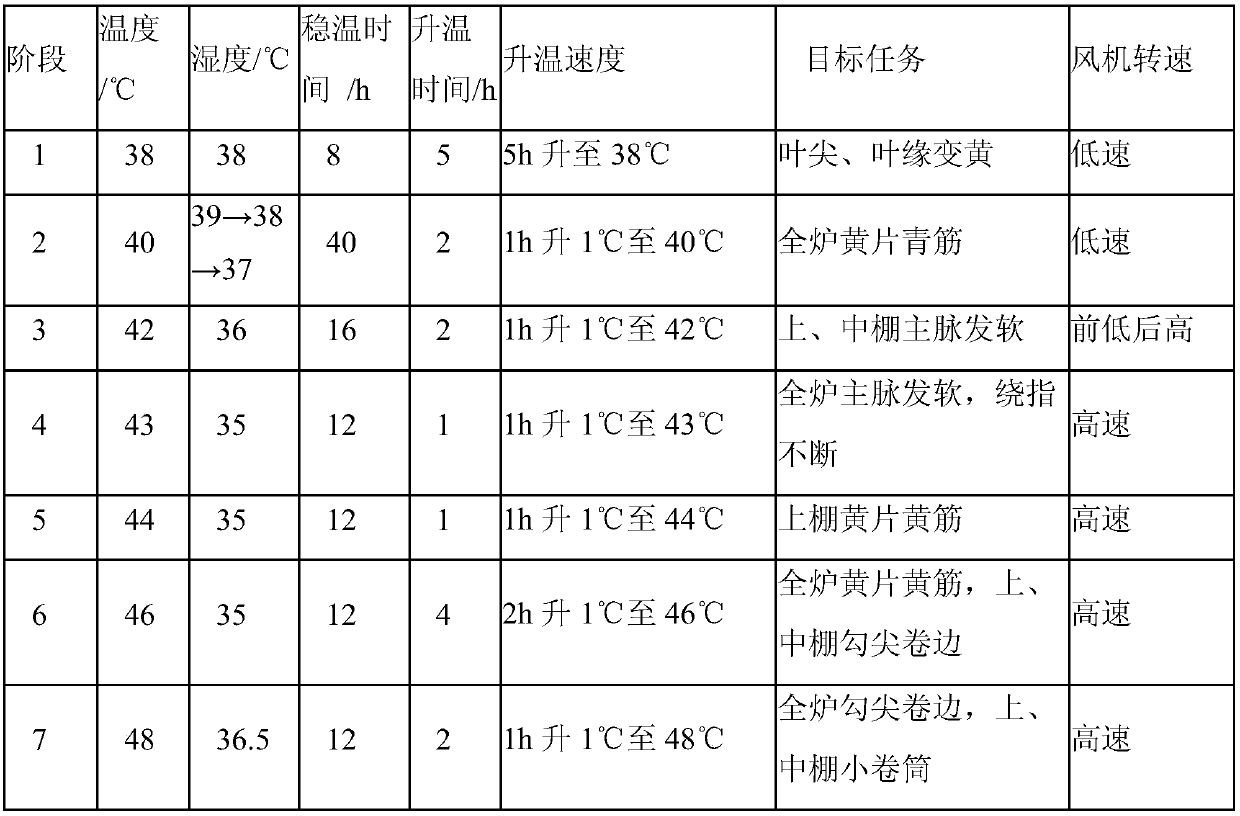

A curing process suitable for flue-cured tobacco variety nc-yatas6 tobacco leaves

ActiveCN109892683BHigh average priceImprove bake qualityTobacco preparationEconomic benefitsEngineering

The invention discloses a curing process suitable for flue-cured tobacco variety NC-YATAS6 tobacco leaves. The curing process harvests mature fresh tobacco leaves of the NC-YATAS6 variety for baking, and the curing includes the yellowing period, withering period, and color fixing The early stage, the late stage of color fixation and the dry gluten stage. The fresh tobacco leaves of the NC-YATAS6 variety are roasted by the process of the present invention. Compared with the conventional roasting process, the chroma is fuller, and the average price of the tobacco leaves is much higher than that of the conventional process technology. At the same time, the tobacco leaves obtained by adopting the curing process of the present invention not only have excellent curing quality and better smoking quality, but also improve the industrial usability of the cured tobacco leaves, significantly increase the economic benefits, and are easy to popularize and apply.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

A centralized method for collecting and roasting 6‑8 upper tobacco leaves

InactiveCN107319625BNutritional balanceImprove Harvest MaturityTobacco preparationEngineeringNicotine

Owner:SHANDONG LINYI TOBACCO

Slit type baking house hot-air stove

InactiveCN101435627AFast flushingHigh thermal efficiencyTobacco preparationDrying gas arrangementsHot blastMechanical engineering

The invention relates to a crack type hot-blast stove for a curing barn, which relates to a drying apparatus, in particular to a drying hot-blast stove for the curing barn. The hot-blast stove is arranged inside a hot-blast heat exchange chamber on the end head of the curing barn and mainly comprises a chimney, an air duct, an inner cylinder, an outer cylinder, a feed opening and a fire grate, wherein the top of the outer cylinder is provided with a draught fan; the chimney is communicated with the upper part of the outer cylinder; the fire grate is positioned in the bottom center of the outer cylinder; and the feed opening is positioned on the lower part of the outer cylinder. The drying hot-blast stove for the curing barn is characterized in that the diameter of the outer cylinder is larger than that of the inner cylinder; an opening on the top of the inner cylinder is hermetically connected with the outer cylinder; a crack flushing flue is arranged between the outer circumference of the inner cylinder and the inner circumference of the outer cylinder; the end part of the inner cylinder which is hermetically connected with the outer cylinder is provided with a horizontal flue; the cylindrical wall of the inner cylinder is communicated with the cylindrical wall of the outer cylinder through a hot-blast tuyere; and the inside of the inner cylinder is provided with the air duct which is positioned under the draught fan. The drying hot-blast stove for the curing barn has a simple structure, good roasting quality and high thermal efficiency, is convenient to control, and can use fuel such as coal, lignite and straws.

Owner:杨光辉

Multifunctional baking room

InactiveCN105707967BAvoid damageExtended service lifeTobacco preparationCooking & bakingAgricultural engineering

The invention discloses a multifunctional baking room. The multifunctional baking room comprises a heating room, a circulating air-supplementing room, a baking room, a grain drying bed and a flue-cured tobacco rack, wherein the heating room, the circulating air-supplementing room and the baking room are isolated from one another; a furnace hearth, a smoke discharge tube and a hot air tube are arranged in the heating room; the hot air tube is arranged in the furnace hearth and the two ends of the hot air tube extend out of the furnace hearth; the outlet end of the hot air tube is communicated with the baking room; the circulating air-supplementing room is provided with a moisture-exhausting air-supplementing hole, a circulating fan and a circulating air flue; the moisture-exhausting air-supplementing hole is provided with a control valve for controlling moisture exhaustion and air supplementation; the inlet of the circulating fan is arranged in the circulating air-supplementing room; the air outlet of the circulating fan is communicated with the inlet of the hot air tube; a pressure valve is arranged in the circulating air flue; the grain drying bed and the flue-cured tobacco rack are arranged in the baking room; the grain drying bed comprises a supporting frame and a bed plate; a ventilation duct is arranged in the bed plate; the two ends of the ventilation duct are open, and externally communicated with a bed plate frame; and a vent hole is formed in the wall of the ventilation duct.

Owner:桂阳县农业机械管理局

Baking method for food processing

ActiveCN112913866AMeet Baking NeedsImprove bake qualityFood processingOven doors/gatesElectric machineryProcess engineering

The invention discloses a baking method for food processing. The baking method comprises the following steps: (1) putting food on a baking frame of a baking cavity of a baking apparatus; (2) selecting a baking mode and entering the corresponding baking mode for baking, wherein the baking mode comprises a first baking mode, a second baking mode and a third baking mode; the first baking mode is that a motor is started to drive a fan to rotate and baking pipes are started for heating; the second baking mode is that the motor is started to drive the fan to rotate and the baking pipes are started for heating, meanwhile, a user rotates a screw handle to drive a screw to rotate, the screw is rotated to enable a screw sleeve on the screw to move along the screw to realize that the fan moves along with the screw sleeve, and finally the situation that the fan moves while being rotated is realized; and the third baking mode is that the motor is started to drive the fan to rotate and the baking pipes are started for heating, and meanwhile the motor drives the screw to alternately rotate forwards and backwards to enable the fan to be rotated while reciprocating leftwards and rightwards; and (3) after baking is performed for a preset time, closing the motor and the baking pipes, and finishing baking. The baking method has the three baking modes, can meet baking requirements of different foods and is good in baking quality.

Owner:广东穗香食品有限公司

Toasting process that can reduce phenol release in flue-cured tobacco

The invention discloses a baking technology method capable of reducing the phenol release amount in flue-cured tobaccos. The technology method includes the following steps that A, the flue-cured tobaccos are prepared; B, six continuous braking stages are needed for baking the flue-cured tobaccos and include four short-period baking stages and two long-period baking stages, and the requirements are that the dry-bulb temperature of baking is 28 DEG C -70 DEG C, wet bulb temperature of braking is 20 DEG C-50 DEG C, relative humidity is 20-95%, and baking time is 4 h -72 h; C, in the six baking stages, dry bulb technology temperature and wet bulb technology temperature are continuously increased, the temperature rate is 0.1 DEG C-5 DEG C / h, and baking time is 4 h-72 h; D, the flue-cured tobaccos low in phenol content are obtained after baking. Through the technology conditions, the phenol release amount can be reduced by 20-50%, and appearance quality and interior quality are better than those of flue-cured tobaccos baked through an existing technology. The baking technology method has the advantages of being significant in effect and very high in operability, and chemical agents and cost addition are not needed.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com