Patents

Literature

37results about How to "Controllable air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

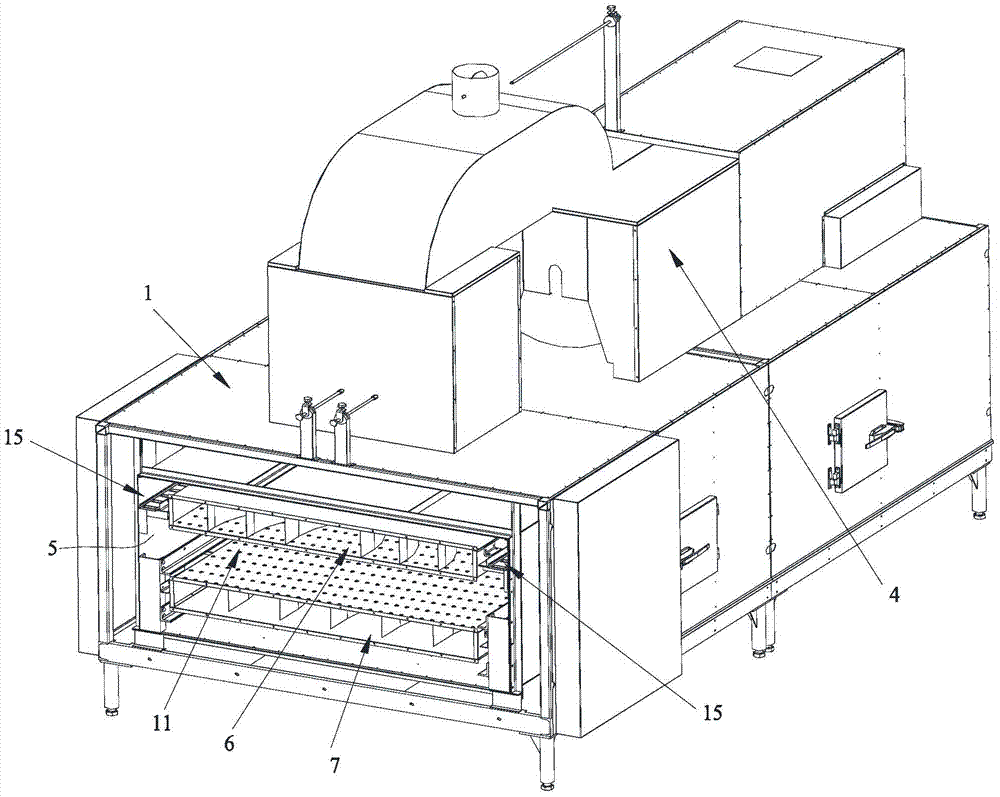

Sectional high-performance strontium ferrite presintering equipment and presintering method thereof

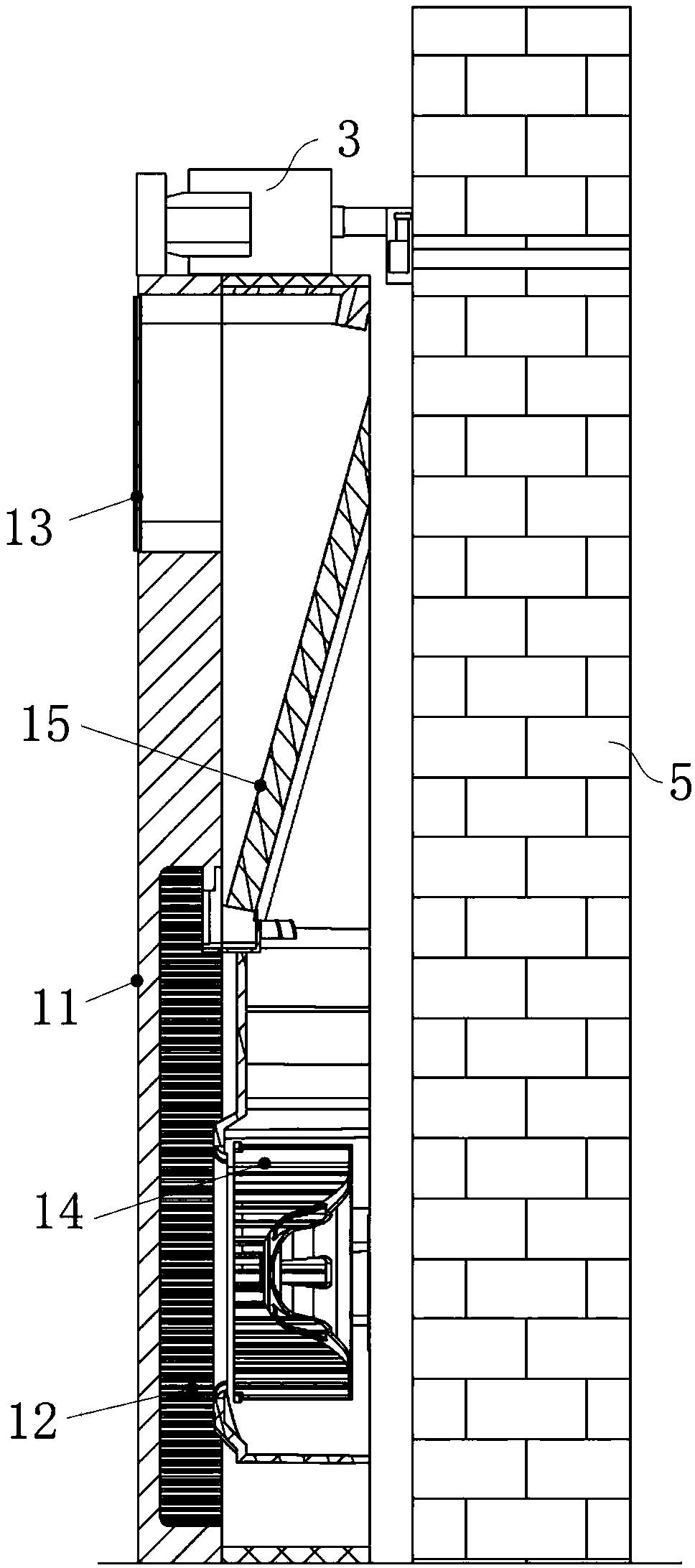

The invention discloses sectional high-performance strontium ferrite presintering equipment and a presintering method thereof and belongs to the technical field of magnetic materials. The equipment is formed by a presintering kiln, a heating system, a variable frequency induced-draft control device and a material transferring device; a hydraulic feed mechanism of the material transferring device is mounted outside the inlet end of a kiln body; guide rails are mounted in parallel in the presintering kiln; pushing plates are arranged on the guide rails; the hydraulic feed mechanism is in contact with the pushing plates; the heating system comprises heating elements, a temperature control instrument and thermocouples; the heating elements, the thermocouples and the temperature control instrument are electrically connected; the heating elements and the thermocouples are respectively mounted in one third to four ninth section, four ninth to five ninth section and two third to seven ninth section of the kiln body; an air duct of the variable frequency induced-draft control device is formed in one side of the bottom of the presintering kiln; air pipes are communicated with the air duct and arranged below the pushing plates; an air inlet of a variable frequency induced draft fan is formed above presintering kiln and close to the outlet end; an air outlet is connected with the air duct. The sectional high-performance strontium ferrite presintering equipment is convenient to use, not only ensures the temperature in a low temperature region, but also ensures the sufficient oxidoreduction atmosphere in the kiln and saves energy.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

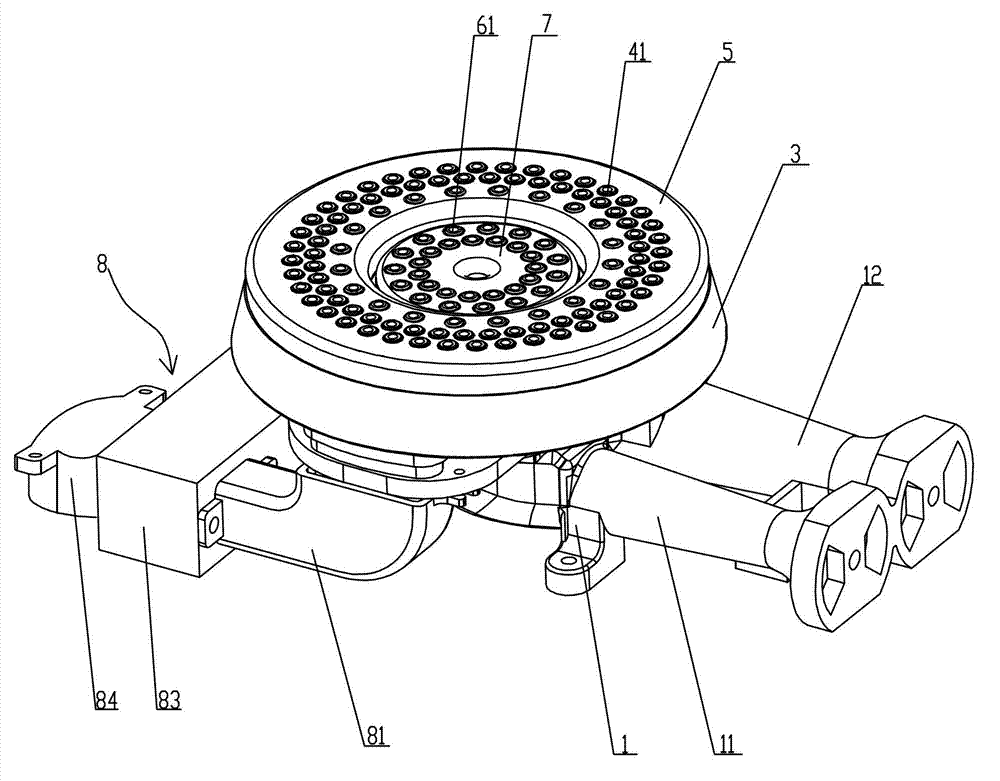

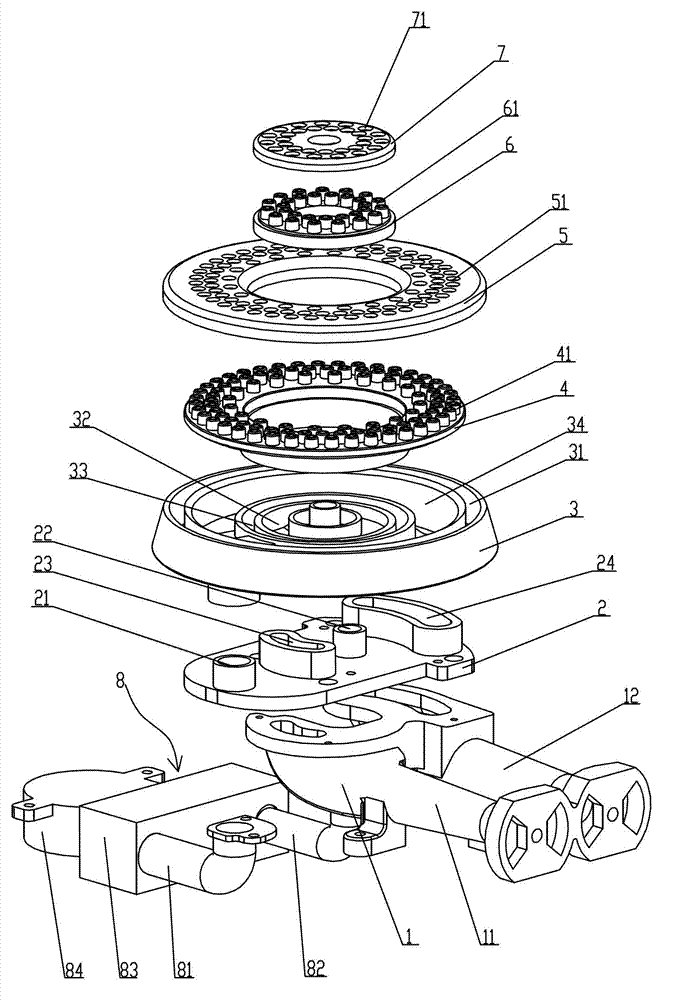

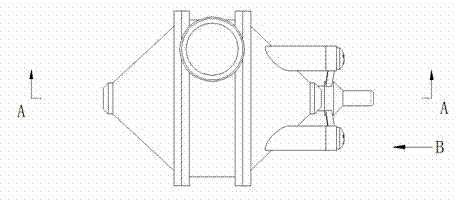

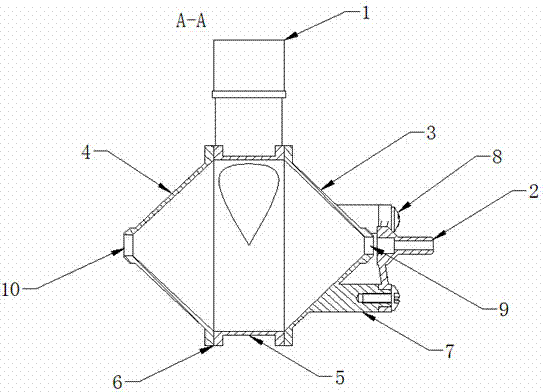

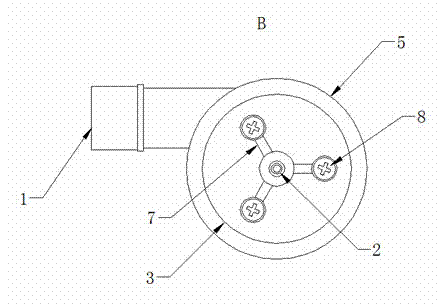

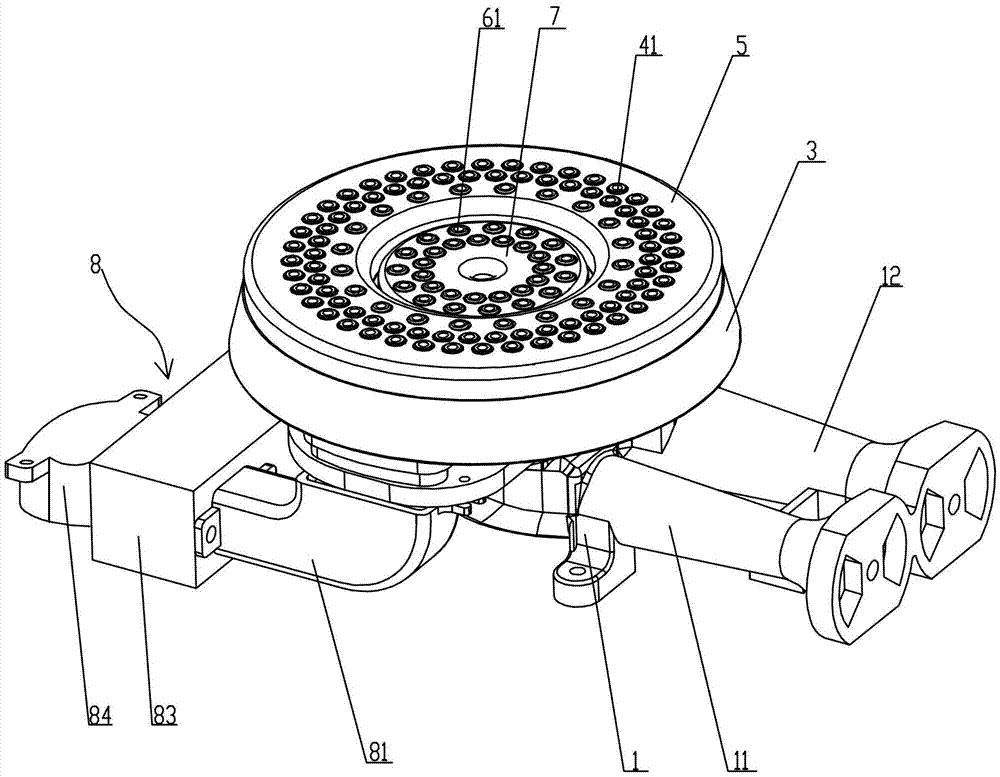

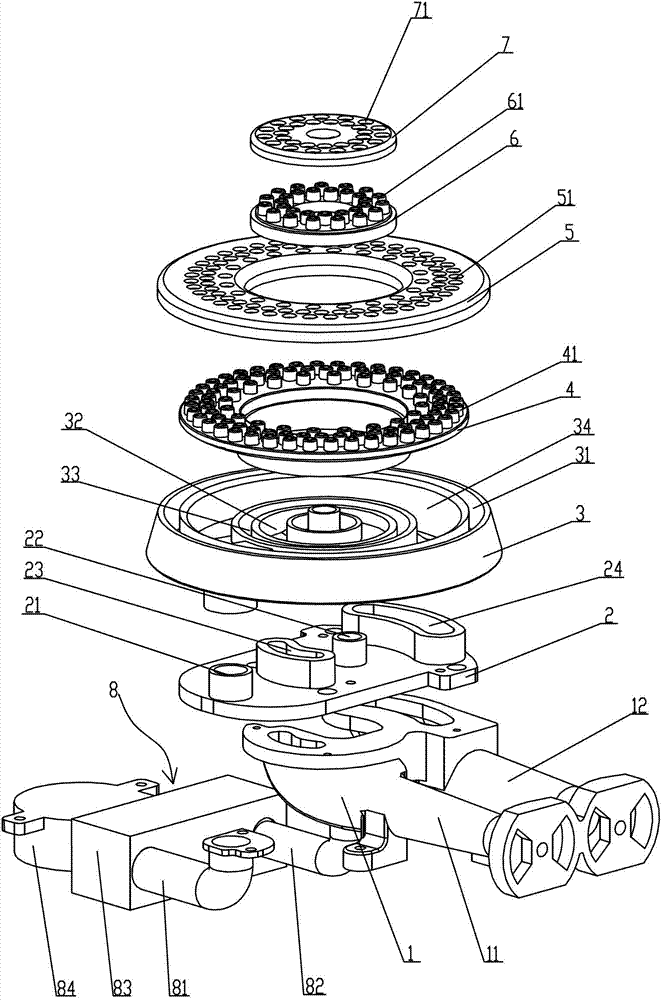

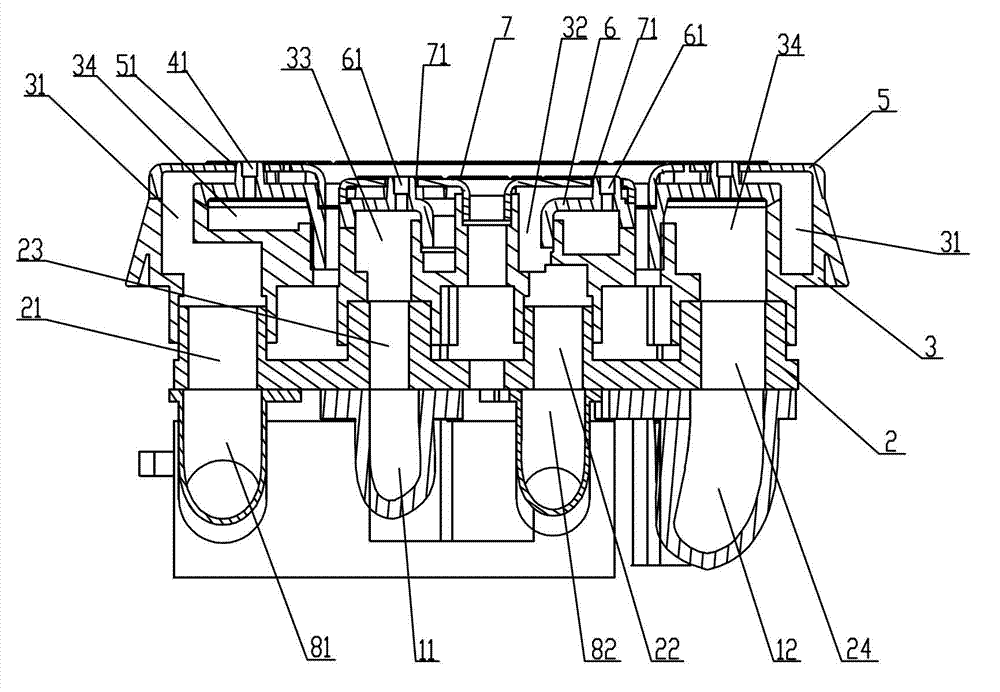

Blast type combustor

The invention relates to a blast type combustor, comprising a furnace end, wherein an inner injection pipe, an outer injection pipe and a furnace end base are arranged on the furnace end. According to the technical main points, a first outer ring air channel, a first inner ring air channel, a first inner ring gas channel and an first outer ring gas channel are arranged on the furnace end base; a blast device is mounted on the furnace end base; an outer ring air pipe and an inner ring air pipe are arranged on the blast device; a distributor is further arranged on the furnace end base; a second outer ring air channel, a second inner ring air channel, a second inner ring gas channel and a second outer ring gas channel are arranged on the fire distributor; an outer fire cover and an inner fire cover are arranged on the fire distributor; an outer ring cover is arranged on the outer fire cover; a plurality of outer ring fire holes are formed in the outer fire cover; an outer ring cover hole is formed in the outer ring cover; an inner ring cover is arranged on the inner fire cover; a plurality of inner ring fire holes are formed in the inner fire cover; and an inner ring cover hole is formed in the inner ring cover. According to the blast type combustor provided by the invention, each fire outlet can individually supply secondary air; an air amount is controllable and air can be uniformly distributed, so that the combustion efficiency is higher.

Owner:VATTI CORP LTD

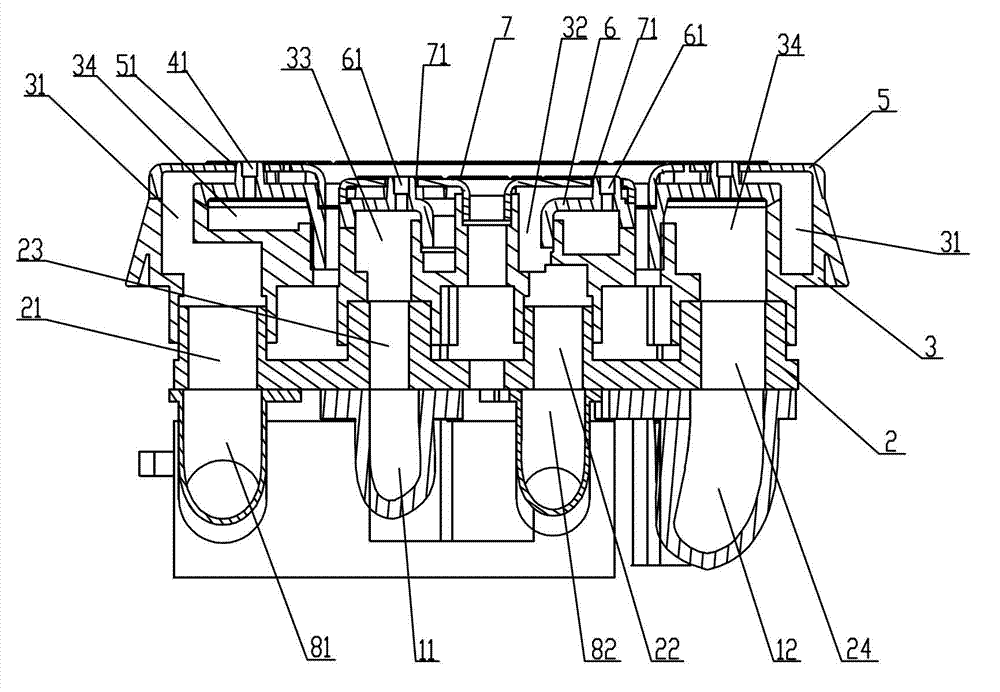

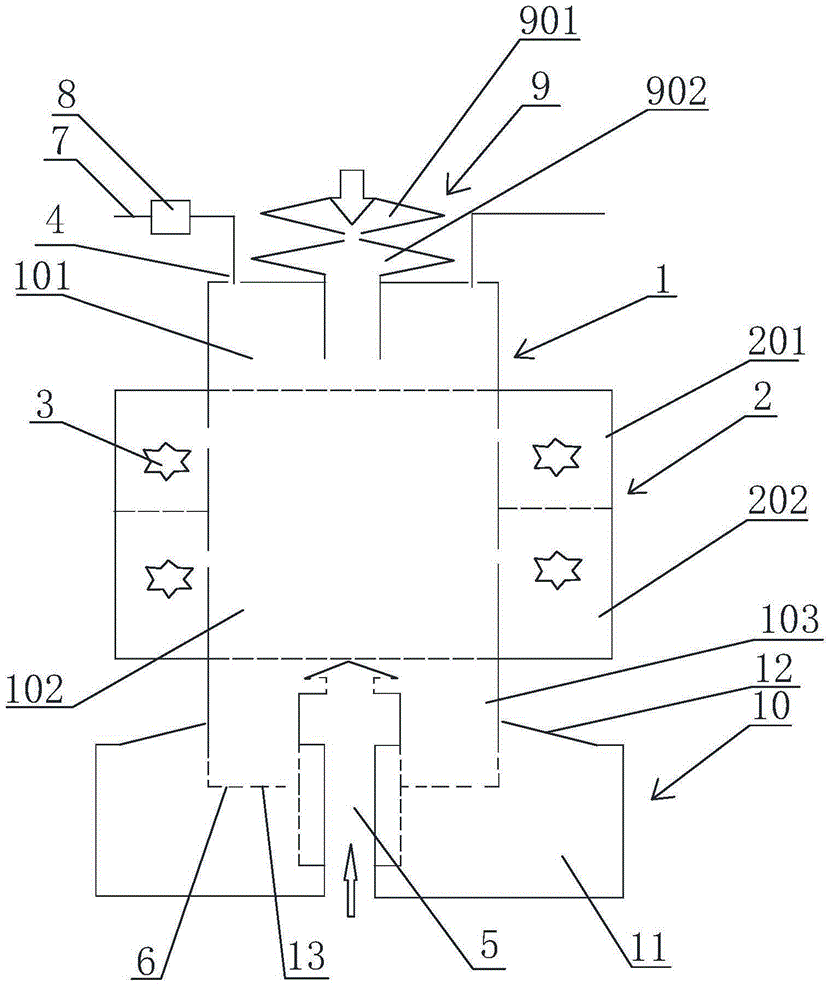

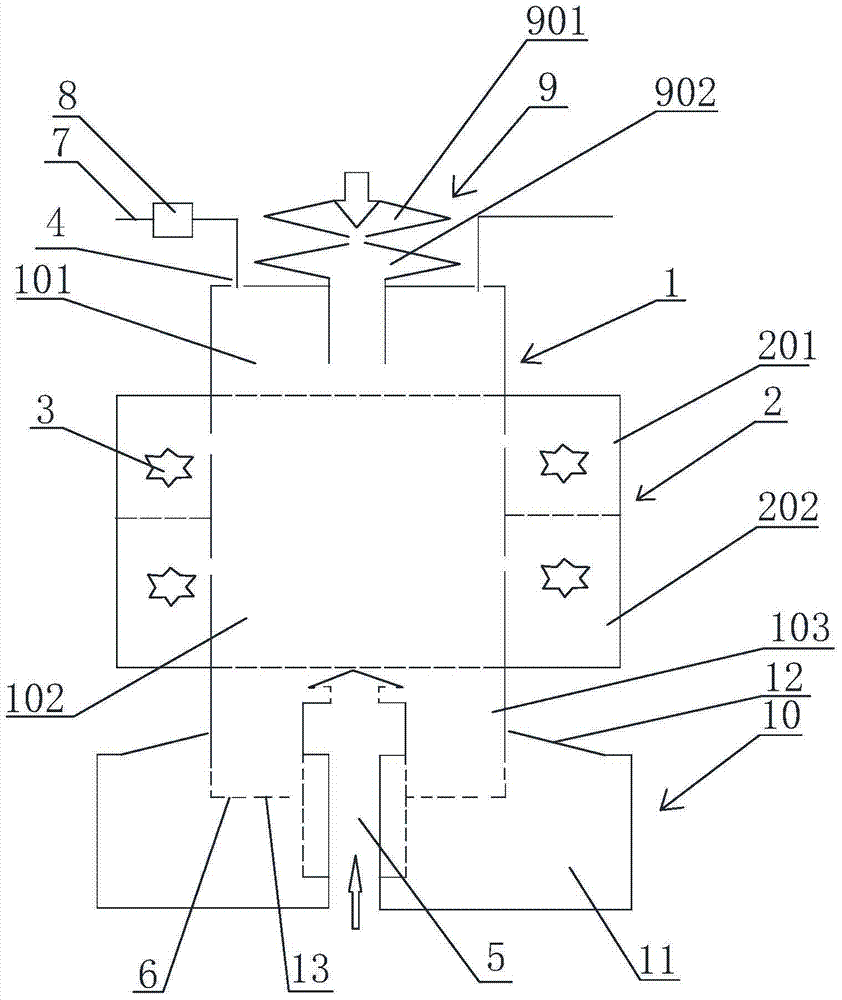

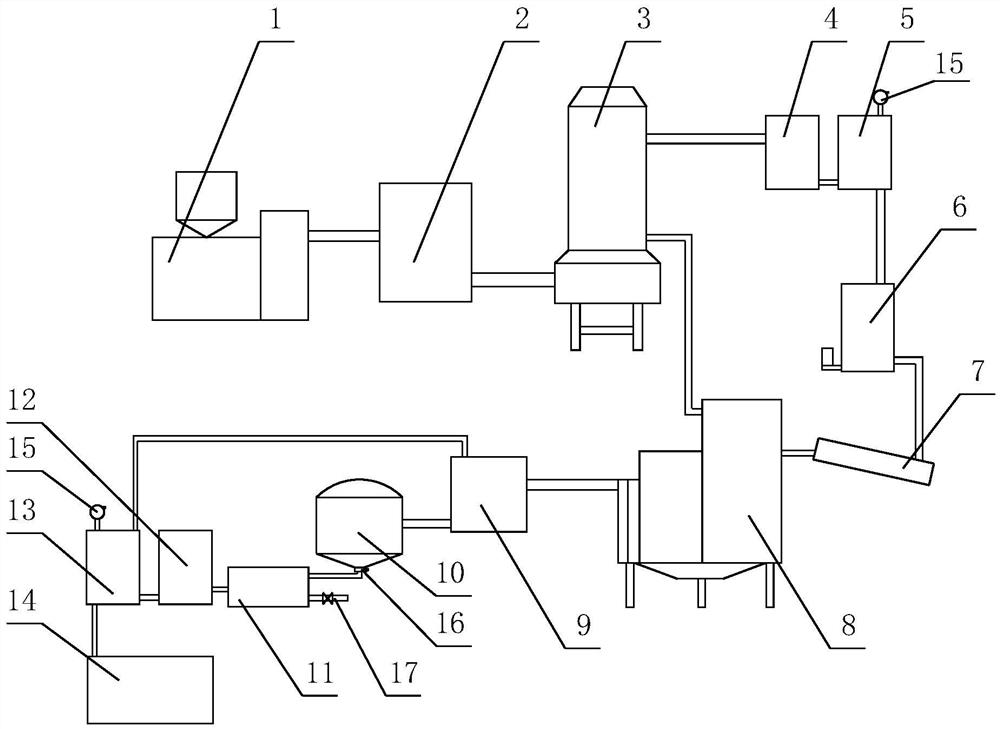

Device for producing high-activity magnesium oxide by using magnesite tailings

ActiveCN107324670AFeeding speed can be controlledFully thermally decomposedLime productionMagnesiumOxide

The invention relates to a device for producing high-activity magnesium oxide by using magnesite tailings. The device comprises a gas-fired hot air furnace, a filter cake feeder, a flash vaporization drier, cyclone separators, bag-type dust collectors, a preheater, a screw feeder, a flash cyclone dynamic calciner, a gas-solid separator, a clinker silo, an air cooling system and a product stock bin, wherein the gas-fired hot air furnace is connected with the filter cake feeder; the filter cake feeder is connected with the flash vaporization drier; an outlet of the flash vaporization drier is connected with the first cyclone separator and the first bag-type dust collector; the first bag-type dust collector is connected with the preheater; the preheater is connected with the flash cyclone dynamic calciner through the screw feeder; an outlet of the flash cyclone dynamic calciner is connected with the gas-solid separator; the gas-solid separator is respectively connected with the clinker silo and the second bag-type dust collector; the clinker silo is connected with the air cooling system; the air cooling system is connected with the second cyclone separator and the second bag-type dust collector; the second bag-type dust collector is connected with the product stock bin; the flash cyclone dynamic calciner introduces waste heat into the flash vaporization drier.

Owner:LIAONING DONGHE NEW MATERIAL CO LTD

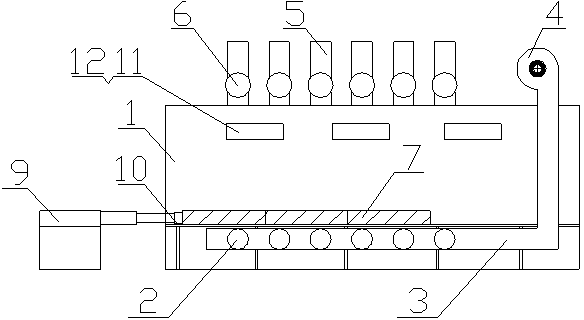

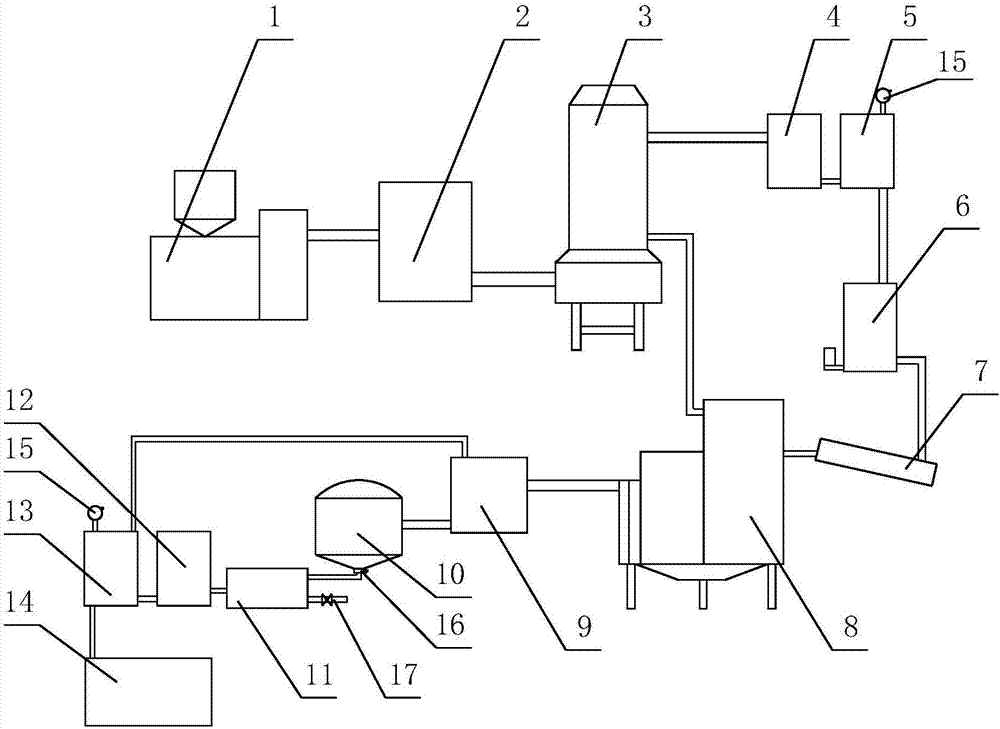

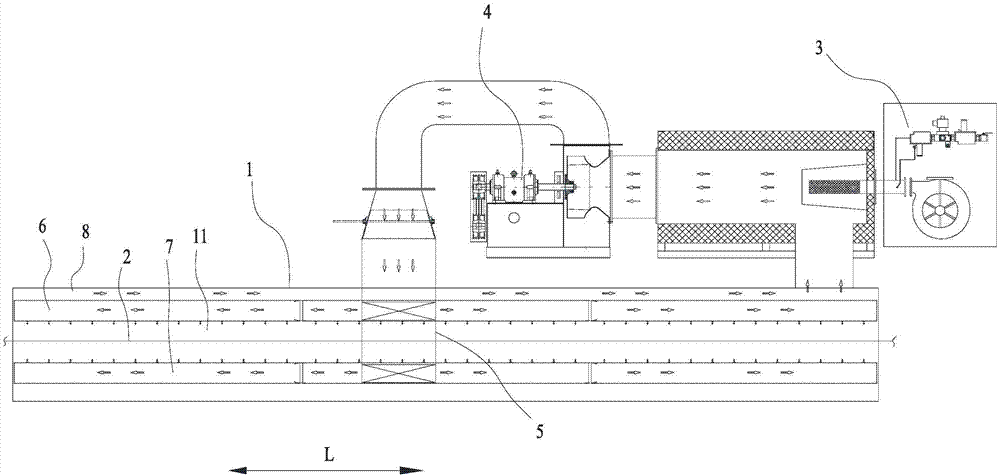

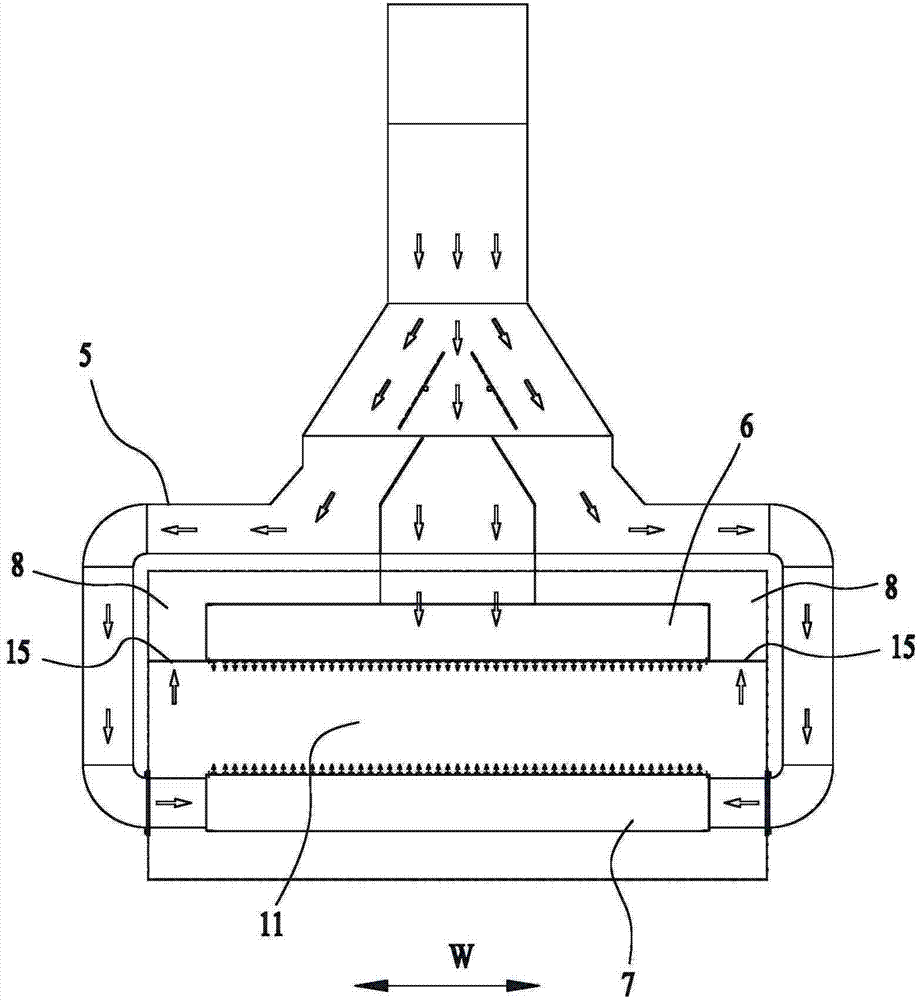

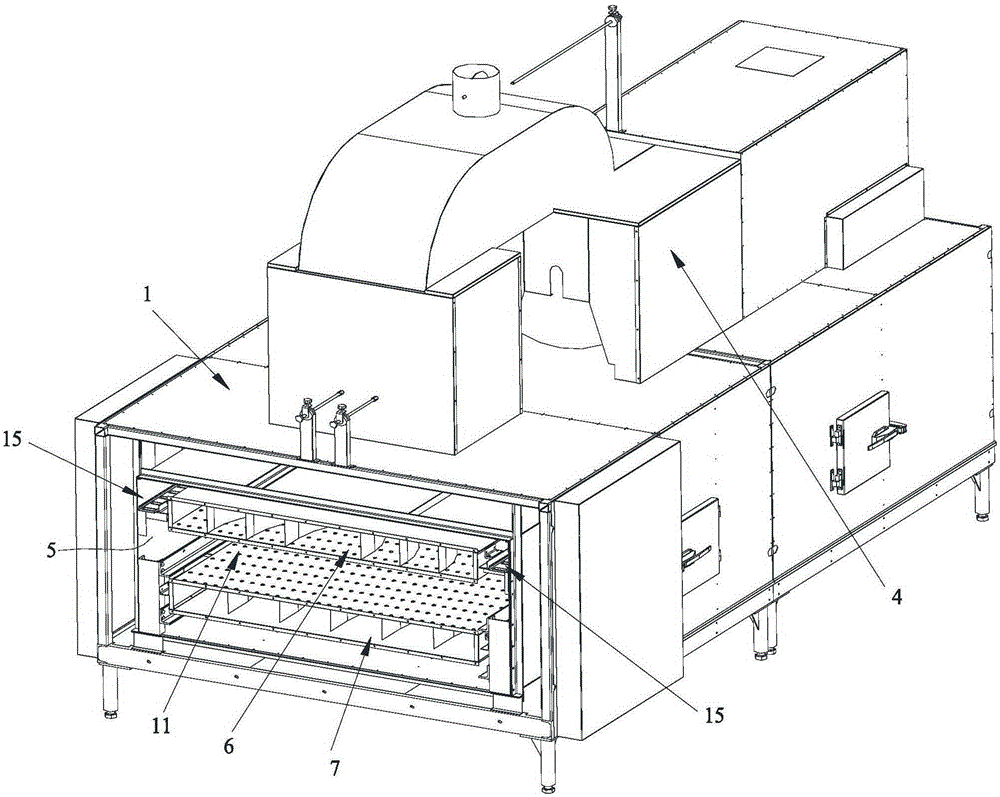

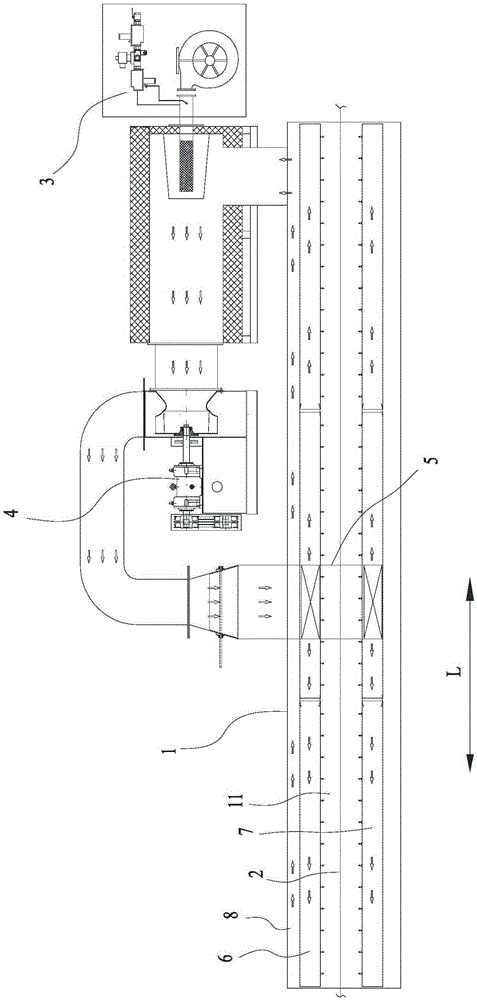

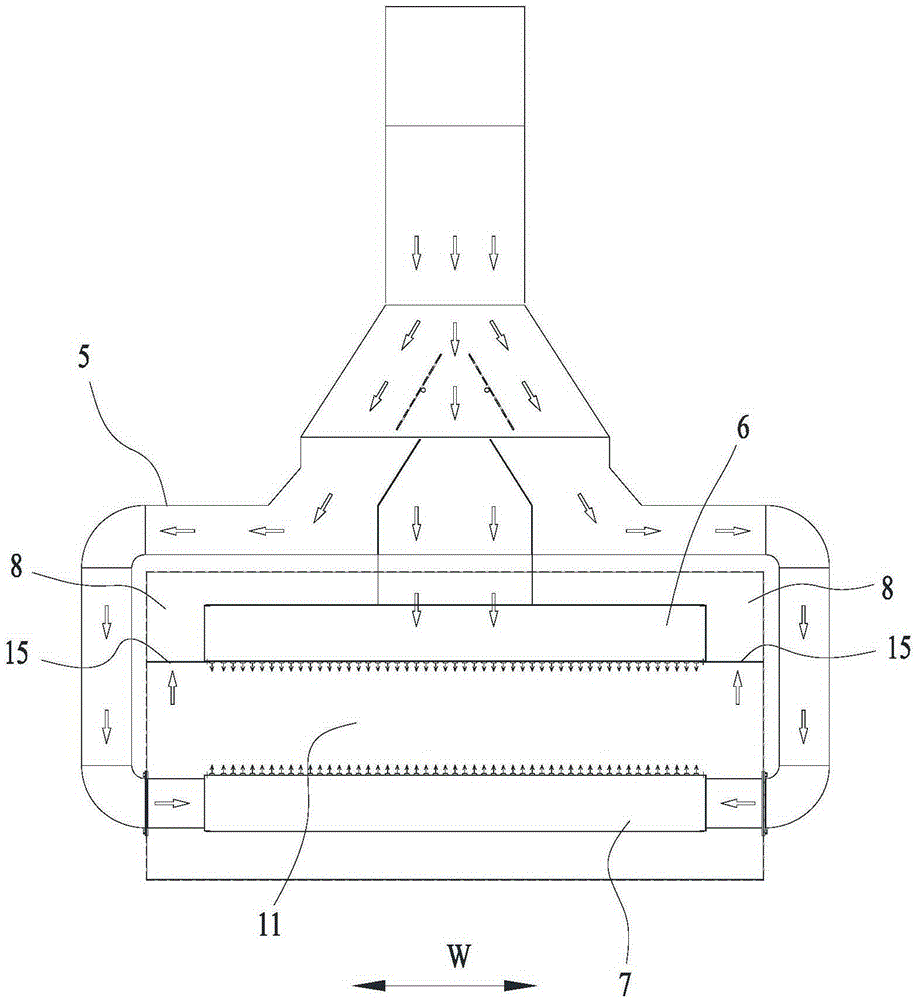

Tunnel type hot air circulation tunnel furnace

The invention discloses a tunnel type hot air circulation tunnel furnace. The tunnel type hot air circulation tunnel furnace comprises a furnace body, a hot air circulation device, a conveying belt and a heating device. The hot air circulation device comprises a hot air generator, a draught fan, a four-way connector, an upper air box and a lower air box. The four-way connector comprises a horizontal air inlet shell and two air distribution shells, wherein the two ends of the air inlet shell vertically extend to form the two air distribution shells. The top face of the air inlet shell is provided with an inlet. The bottom face of the air inlet shell is provided with a first outlet. The upper ends of the two air distribution shells are communicated with the inlet. The lower end of each air distribution shell is provided with a second outlet. The outlet of the draught fan is communicated with the inlet. The first outlet is communicated with the upper air box. The second outlets are communicated with the lower air box. The bottom of the upper air box is provided with a plurality of first air outlet holes. The top of the lower air box is provided with a plurality of second air outlet holes. A return air passage is arranged in the furnace body. The first air outlet holes and the second air outlet holes are connected with the hot air generator through the return air passage. According to the tunnel type hot air circulation tunnel furnace, hot air output by the hot air circulation device can be evenly and circularly led to products to be baked, and the air temperature, the air volume and the air speed can be controlled.

Owner:GUANGZHOU BAKE OVEN MACHINERY

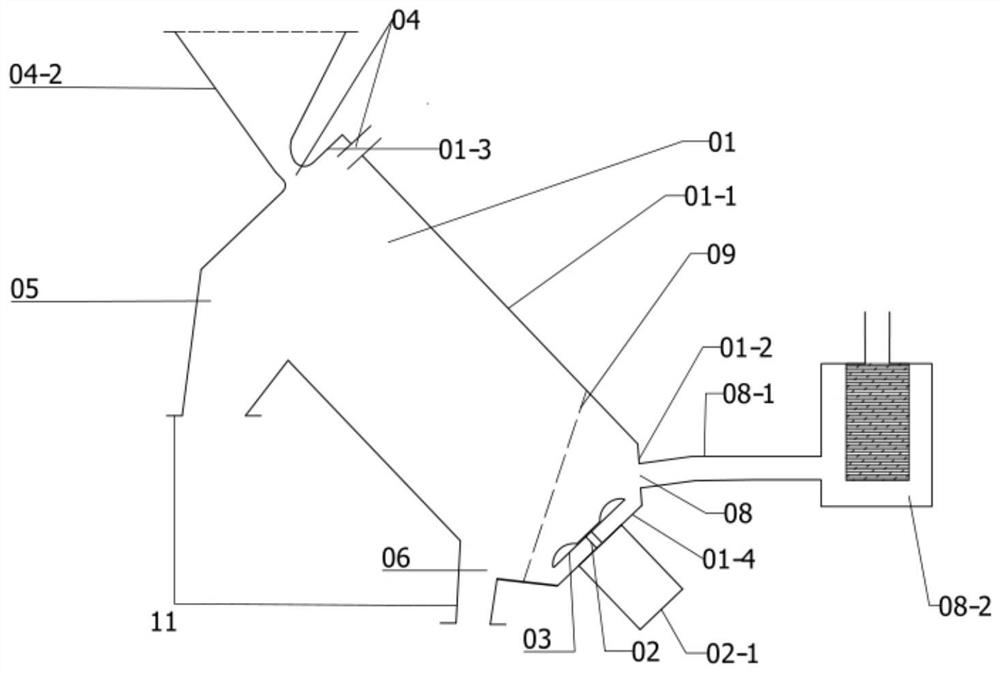

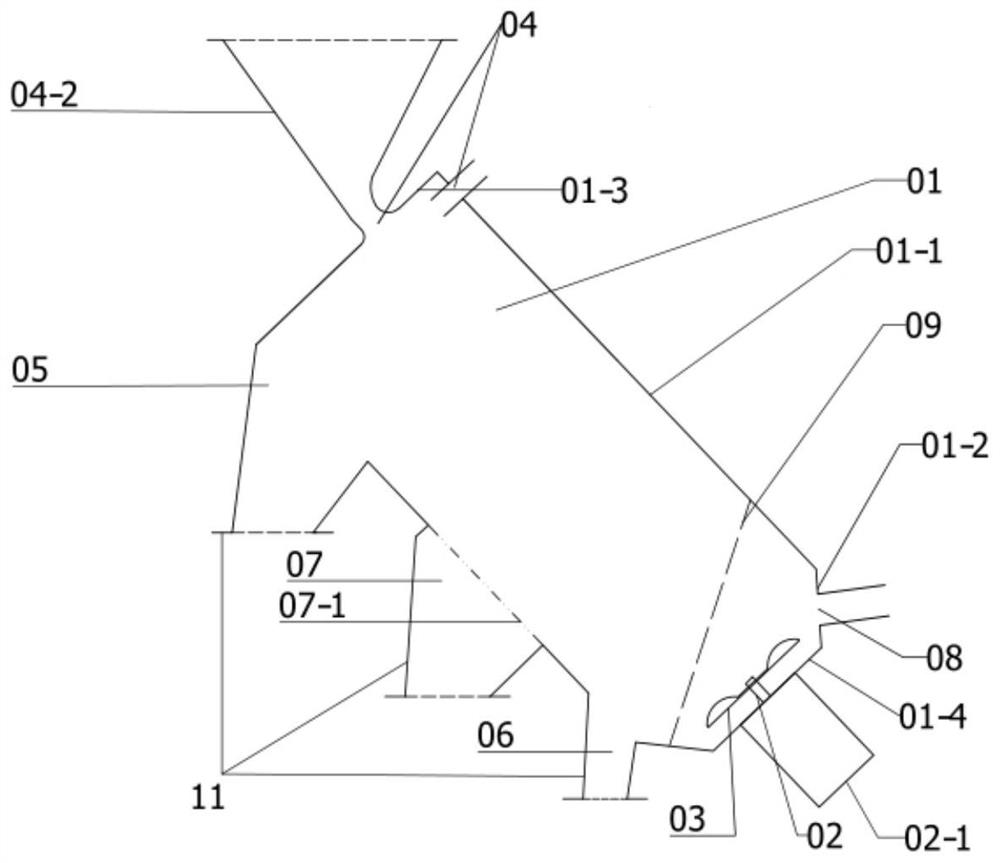

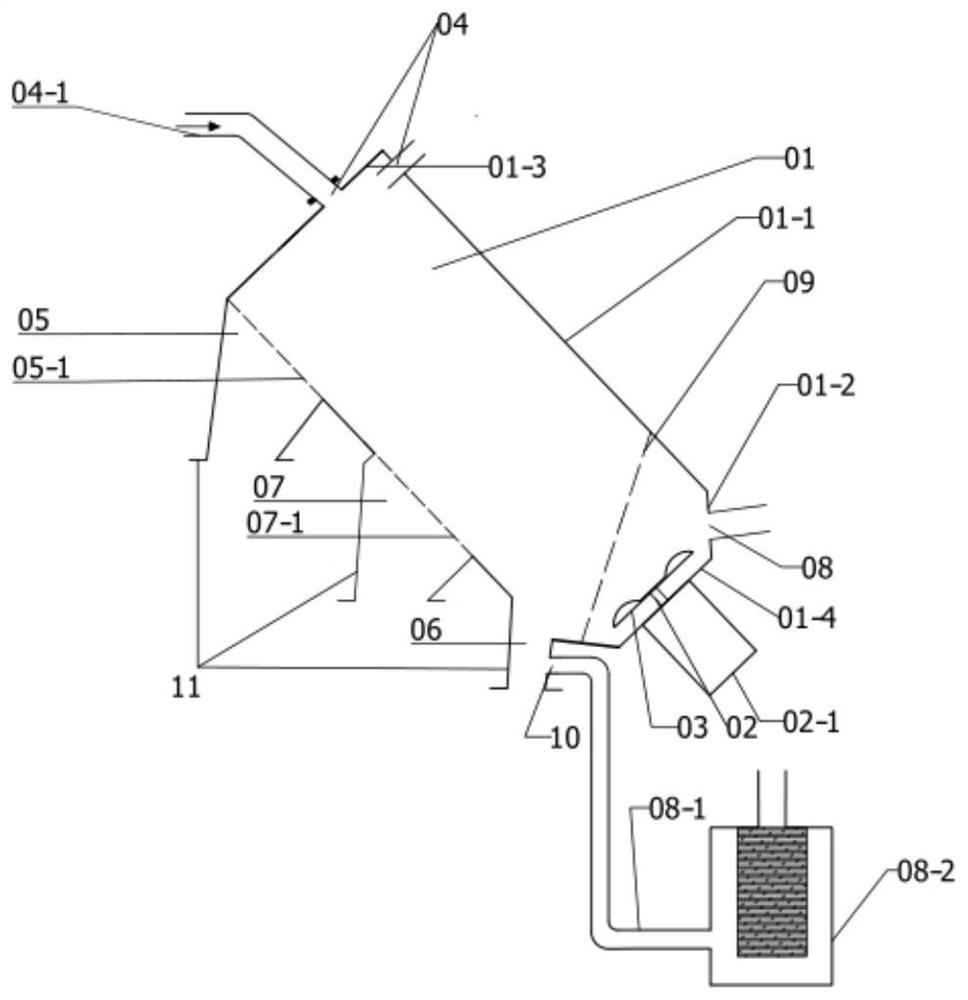

Coal powder injection mineral roasting device and technology

The invention discloses a coal powder injection mineral roasting device which comprises a furnace body, wherein the furnace body is divided into a preheating section, a roasting section and an air cooling section from the top down sequentially; a combustion chamber is arranged at the roasting section, and connected with a coal powder injection device; a smoke discharge port is formed in the preheating section; a circulation smoke inlet and a material outlet are formed in the air cooling section; a circulation air duct is formed between the smoke discharge port and the circulation smoke inlet; a directional pressure device is arranged on the circulation air duct; a feeding section is arranged at the top of the furnace body, and provided with an automatic sealing device; and a finished mineral collection section is arranged at the bottom of the furnace body. With the adoption of the mode of heating minerals through combustion of injected coal powder, the roasting and processing cost of the minerals is reduced effectively; in addition, smoke generated due to the combustion of the coal powder is treated circularly, so that the problem of pollutant emission is effectively solved; and energy conservation and environmental protection are facilitated.

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

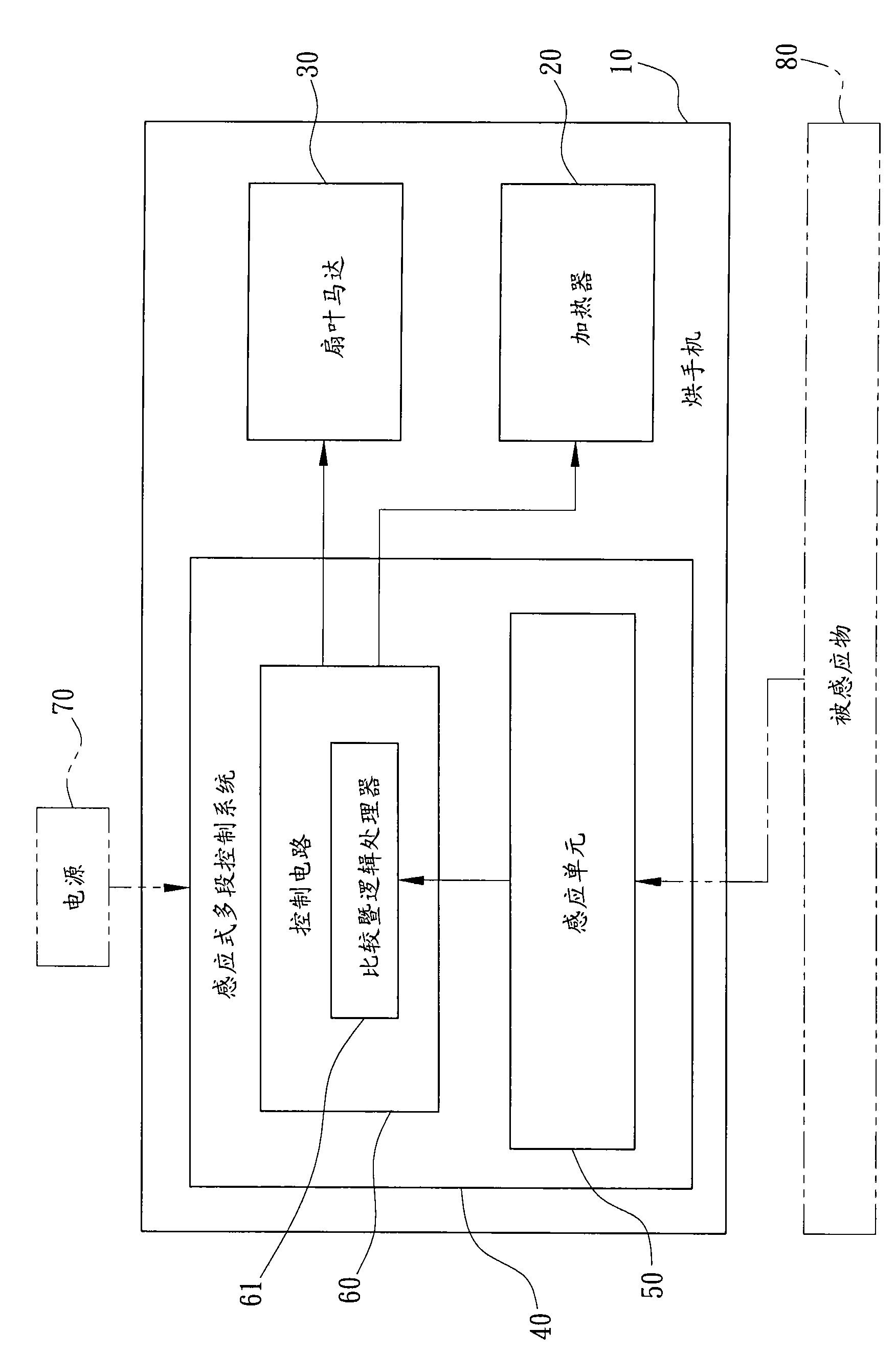

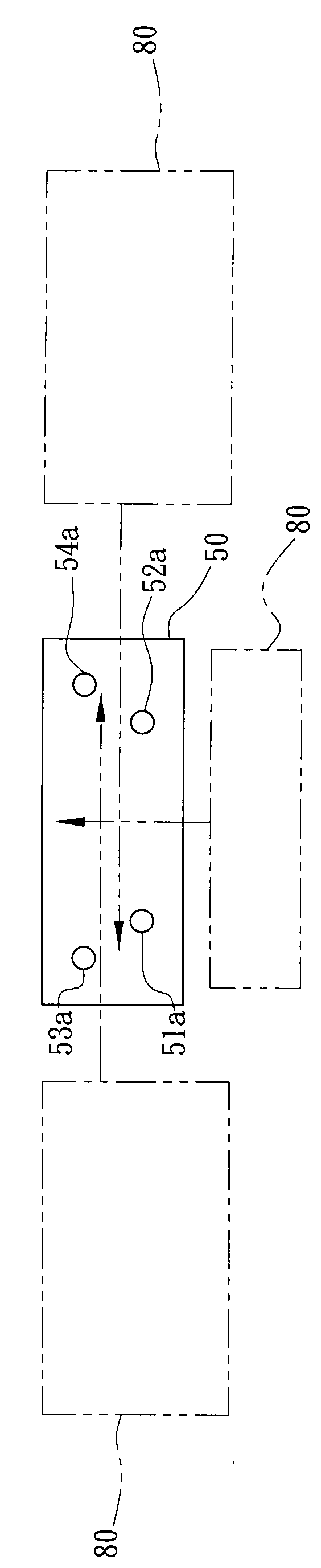

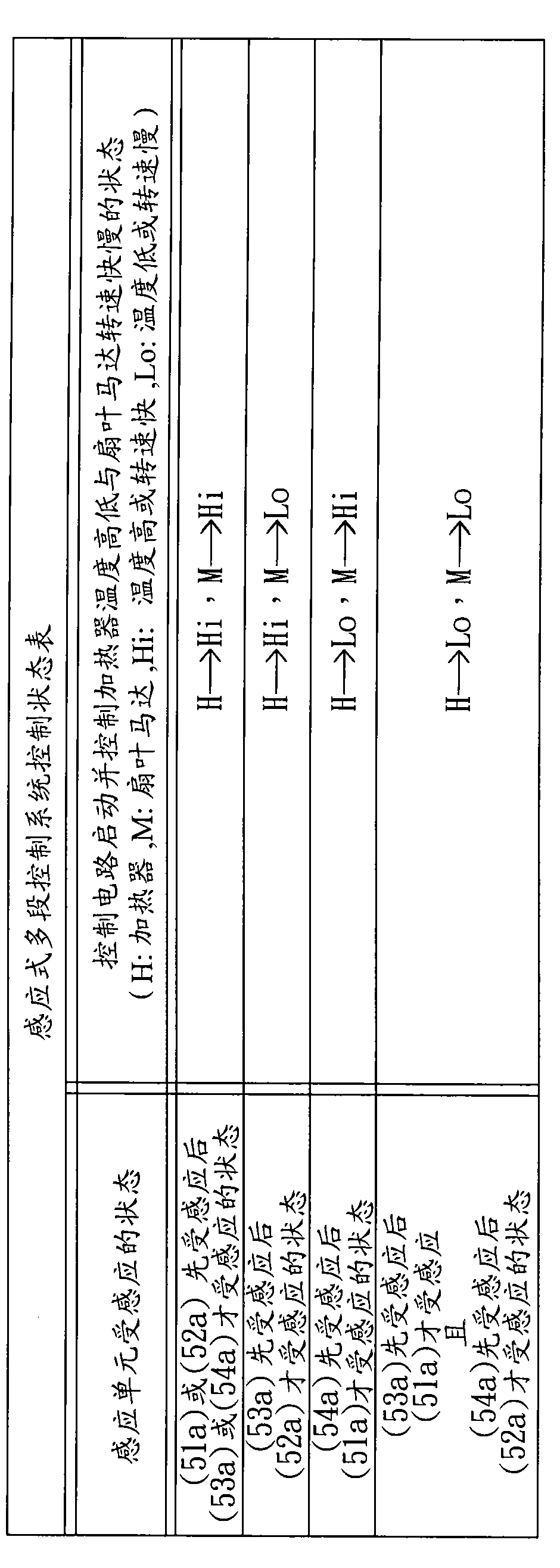

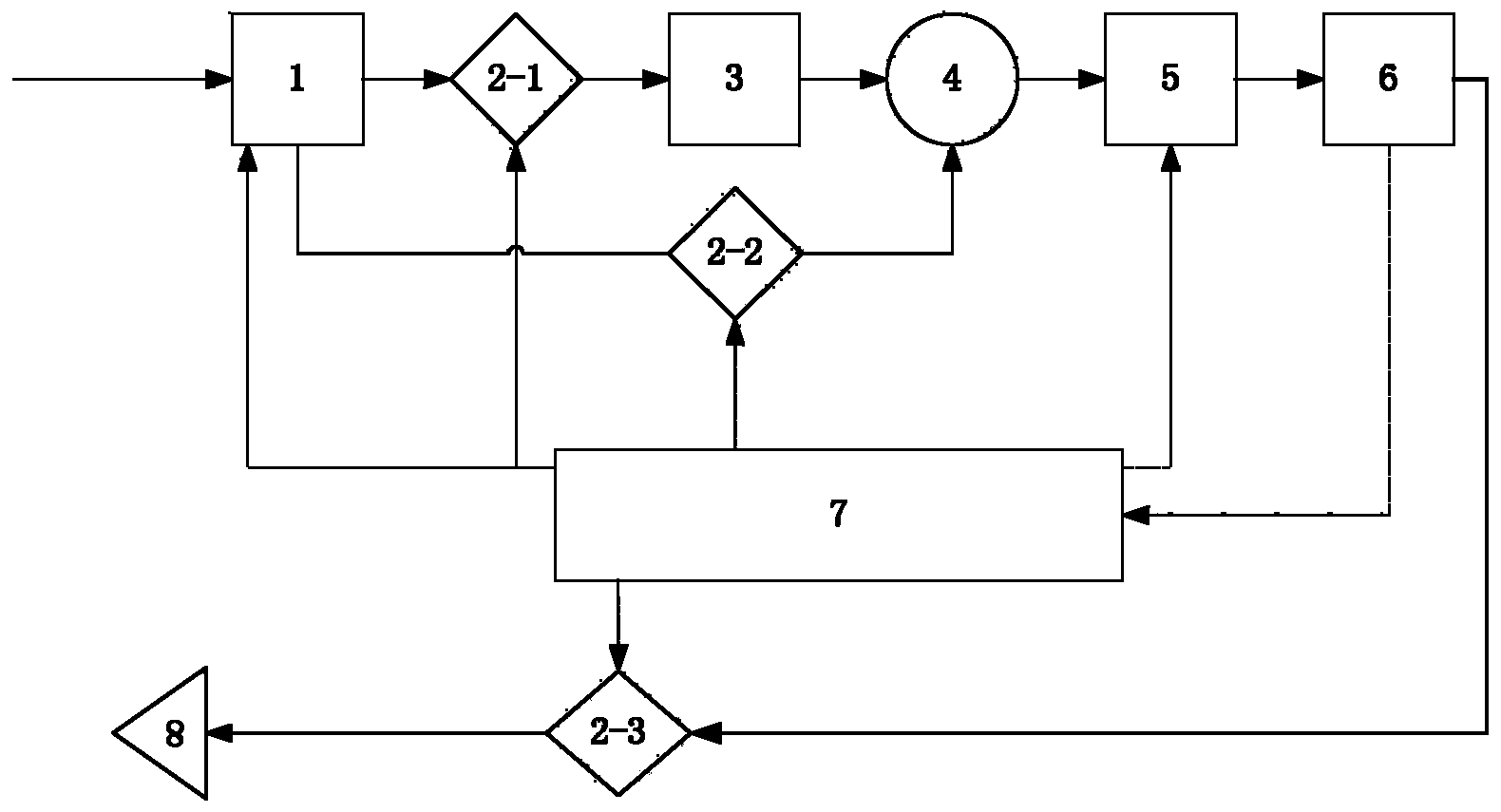

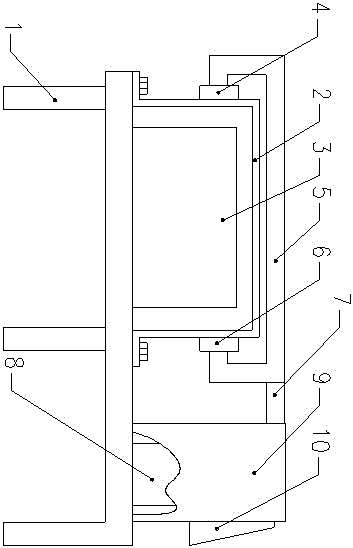

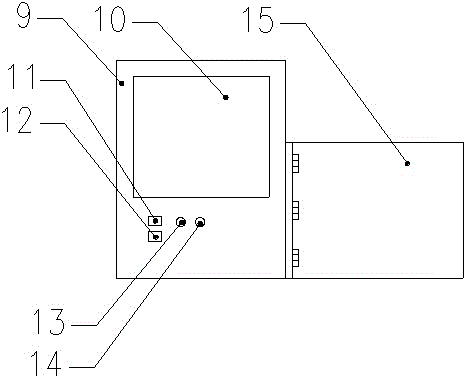

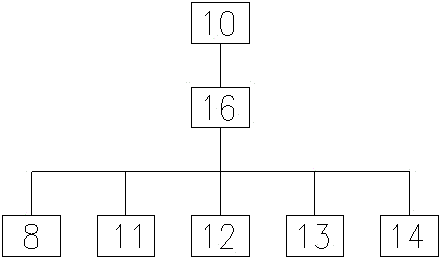

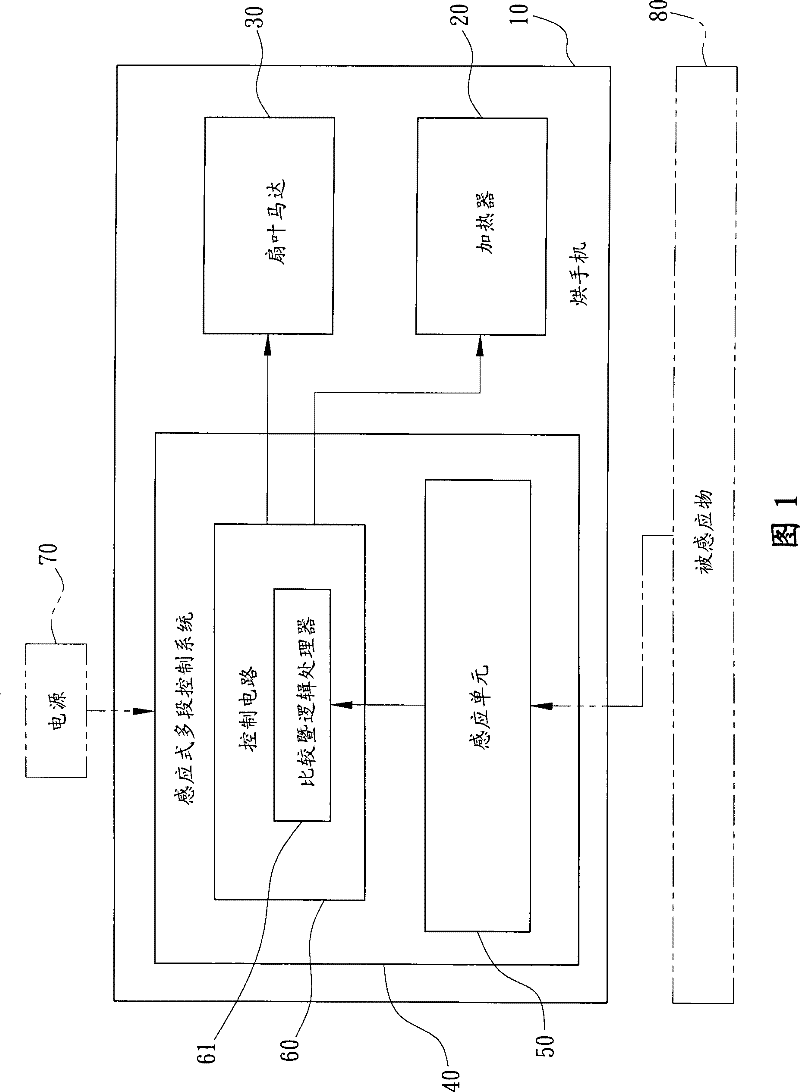

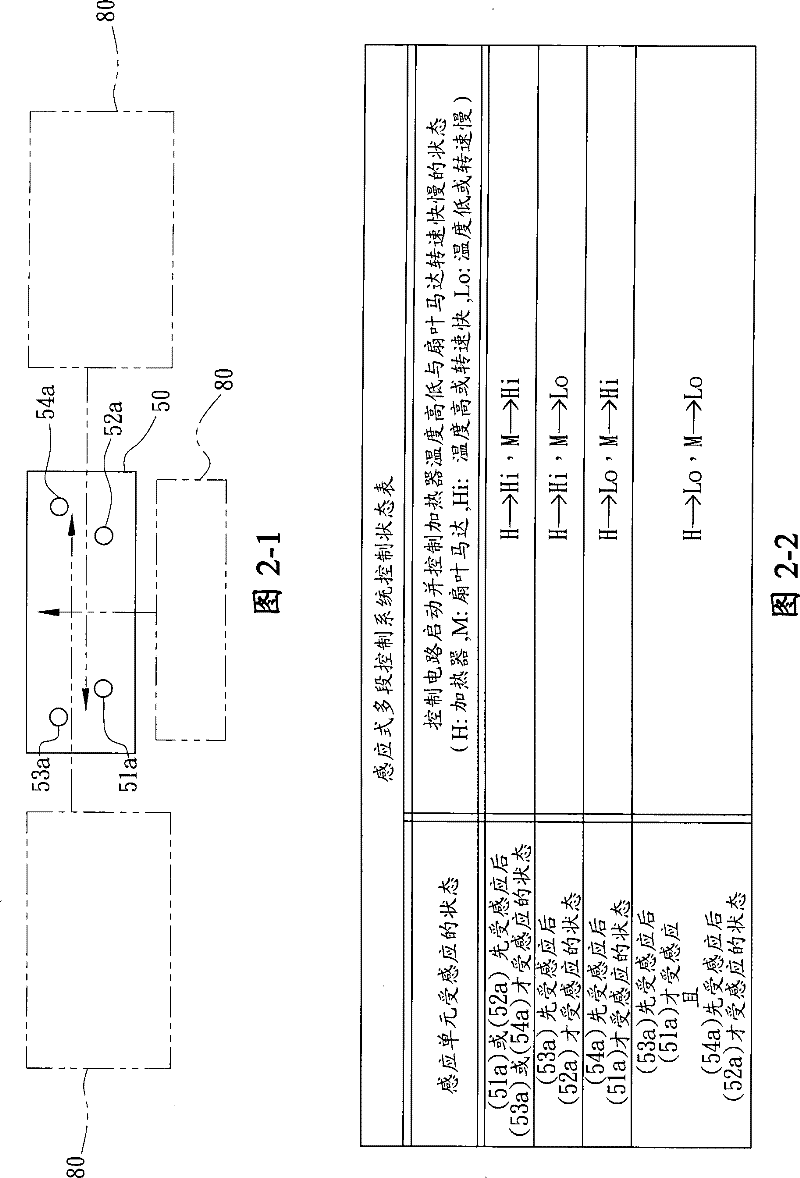

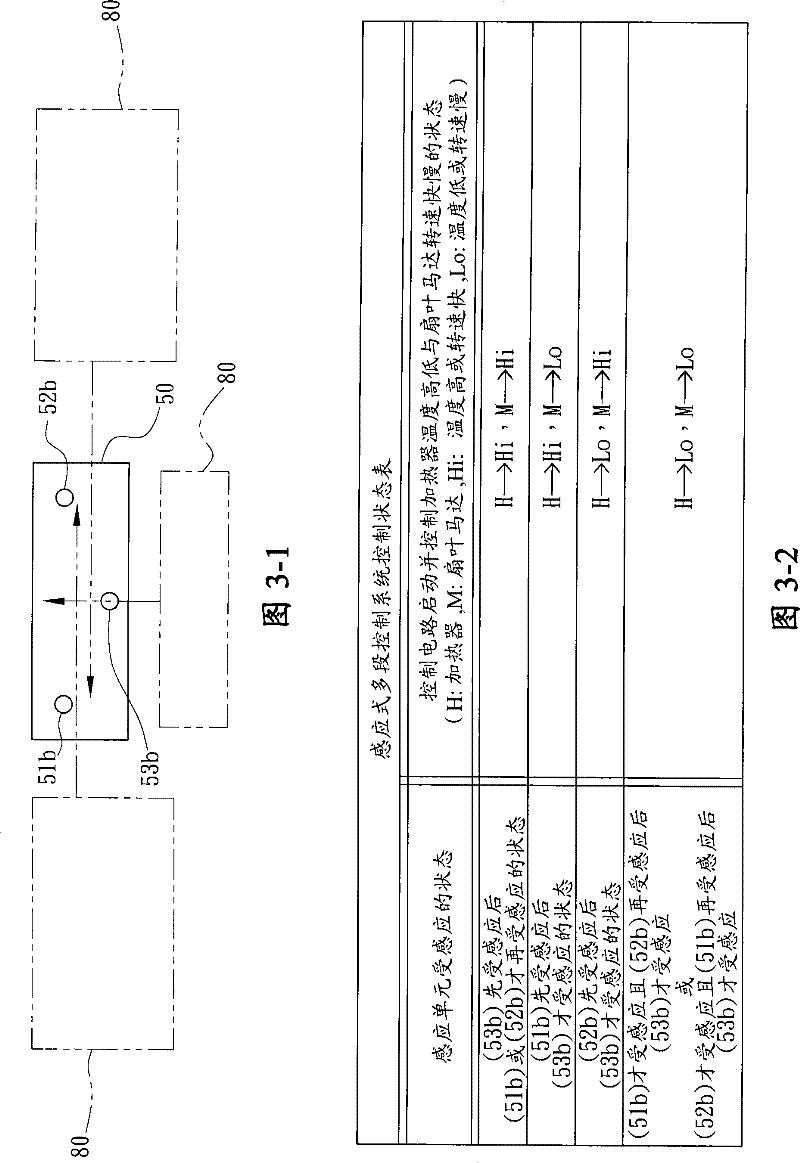

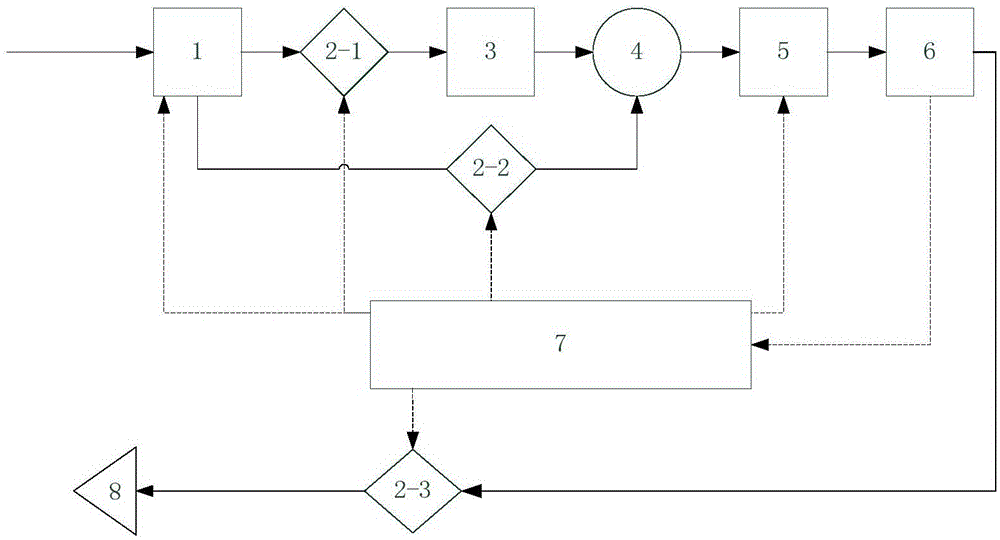

Inductive multistratum control system of hand dryer

InactiveCN101596079AControllable air volumeDemandingOptical detectionDomestic applicationsElectricityMotor speed

The invention relates to an inductive multistratum control system of a hand dryer, in particular to a control system which is usually arranged in a toilet, generates heat and wind through power to dry hands of a human and improves the hand dryer incapable of controlling the wind rate and the temperature in real time. The hand dryer comprises a heater, a blade motor and an induction unit and is characterized in that the induction unit is at least provided with two groups of induction sets arranged at an air outlet of the hand dryer and is electrically connected with a control circuit capable of turning on and off the heater and the blade motor and controlling the temperature of the heater and the rotation speed of the blade motor, thereby forming the inductive multistratum control system. The over two groups of induction sets are matched with a comparing and logic processor to process a signal, thus the control circuit has the function of the multistratum control of the temperature of the heater and the rotation speed of the blade motor, and the aim that the user can easily, rapidly, hygienically and safely operates the wind rate and the temperature can be achieved.

Owner:HOKWANG IND

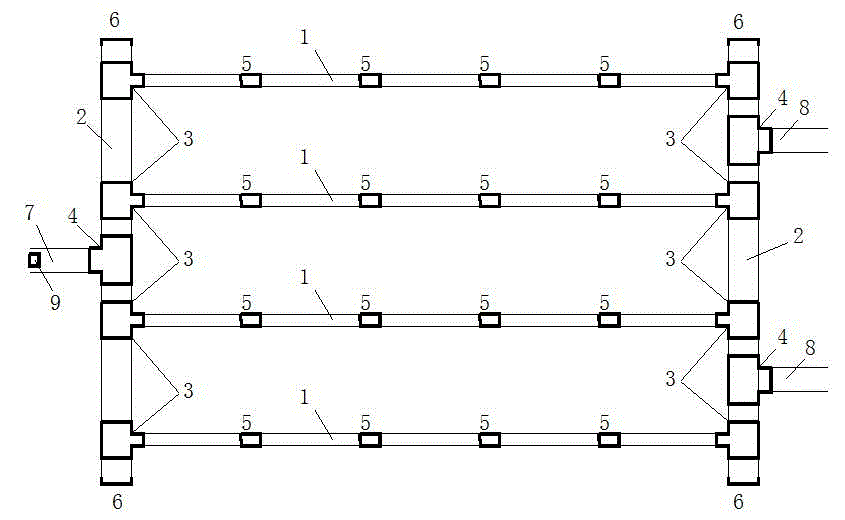

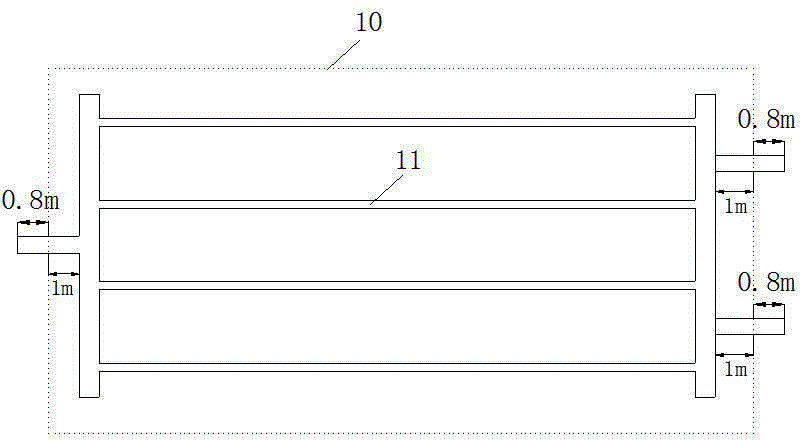

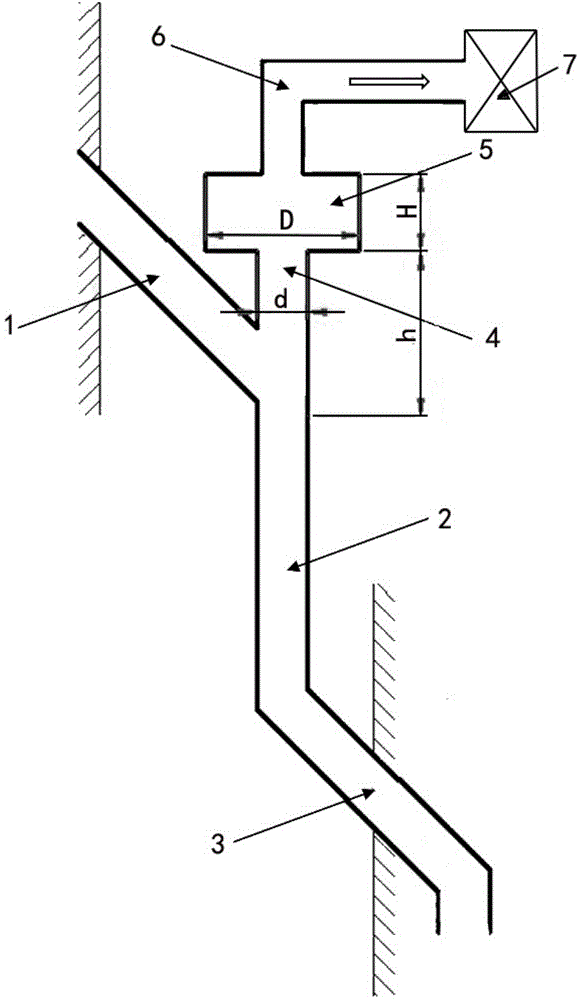

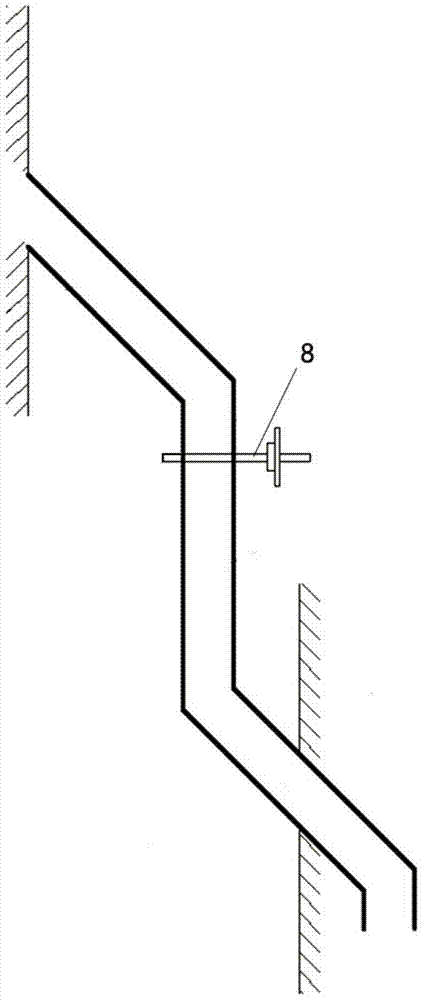

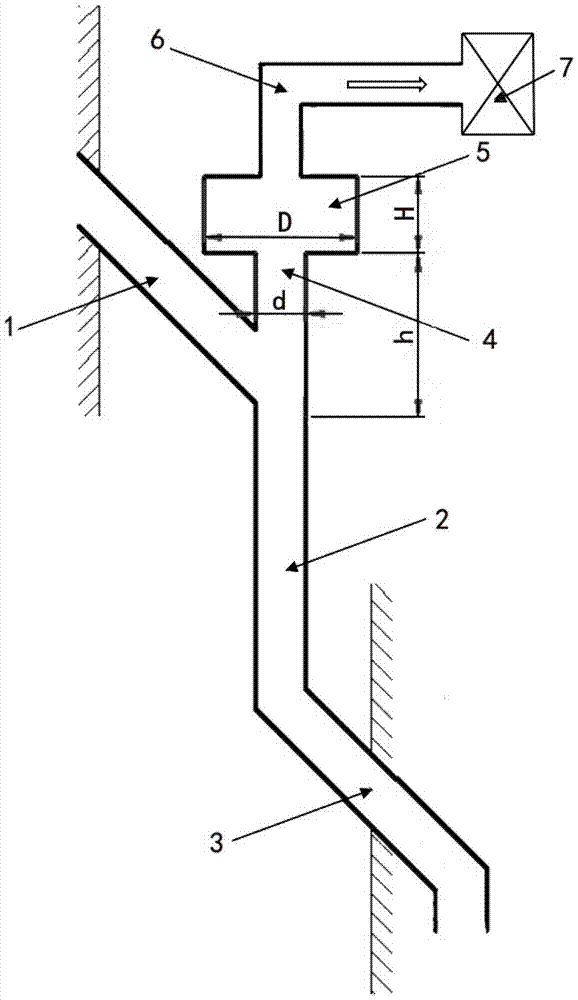

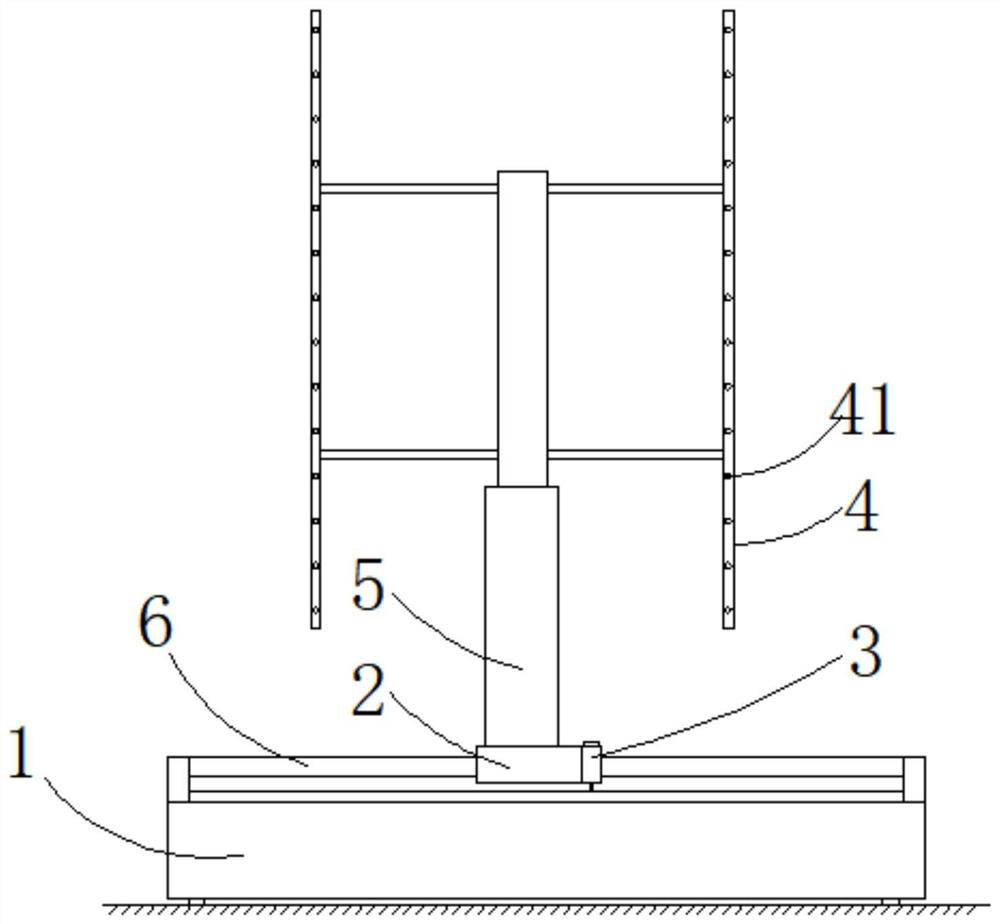

Mandatory diffuse type cooling ventilating pipeline system for large-scale frozen earth roadbed and construction method thereof

The invention relates to a mandatory diffuse type cooling ventilating pipeline system for a large-scale frozen earth roadbed and a construction method thereof. The traditional roadbed ventilating pipeline system is limited in temperature reduction effect and is adverse to the stability of frozen earth by increasing the temperature of a roadbed by introducing hot air in summer. The mandatory diffuse type cooling ventilating pipeline system comprises a plurality of horizontal ventilating pipes and a plurality of longitudinal ventilating pipes, which are horizontally and longitudinally crossed and mutually communicated, wherein the longitudinal ventilating pipes positioned on the end parts of two sides are respectively connected with an air inlet and air outlets, which protrude out of the horizontal direction of the roadbed; one air inlet is formed, and an air suction equipment and a temperature controlled switch are arranged on the air inlet; and a plurality of the air outlets are form in the front and back sides along a longitudinal direction. According to the mandatory diffuse type cooling ventilating pipeline system, cold air is introduced from the air suction equipment arranged in the air inlet, circulated through the longitudinal ventilating pipes and the horizontal ventilating pipes and then emitted from the air outlets, and the air is subjected to heat exchange with the roadbed in a pipe internal-circulation process, so that the effect of reducing the temperature of the roadbed is achieved. The mandatory diffuse type cooling ventilating pipeline system disclosed by the invention can only be started when external air temperature is lower than the temperature of the roadbed to prevent the entrance of the hot air in summer and is controllable in air quantity and obvious in cooling effect.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Wind-heat cleaning system for automobile glass

The invention discloses a wind-heat cleaning system for automobile glass. The wind-heat cleaning system comprises an air compressor, a tail gas waste heat exchanger, a temperature and pressure sensor, a controller and an air blast opening, an air inlet of the air compressor is communicated with air outside an automobile, an air outlet of the air compressor is connected with an air inlet of the tail gas waste heat exchanger, an air outlet of the tail gas waste heat exchanger is connected with the air blast opening, an air outlet of the air blast opening is formed in the edge of the bottom of the automobile glass, the tail gas waste heat exchanger is arranged in an automobile exhaust pipe, passing air is heated through absorbed automobile tail gas heat, and the temperature and pressure sensor is arranged in a pipeline between the tail gas waste heat exchanger and the air blast opening, and transmits temperature and pressure signals to the controller. The controller controls pressure of compressed air of the air compressor according to the temperature and pressure signals received from the temperature and pressure sensor. The wind-heat cleaning system can achieve the good rain blocking and cleaning functions on a windshield, rearview mirrors and side windows of the automobile by utilizing automobile tail gas heat exchange. Heat energy is recycled and reused, and energy waste is effectively avoided.

Owner:WUHAN JINGLI ELECTRONICS TECH

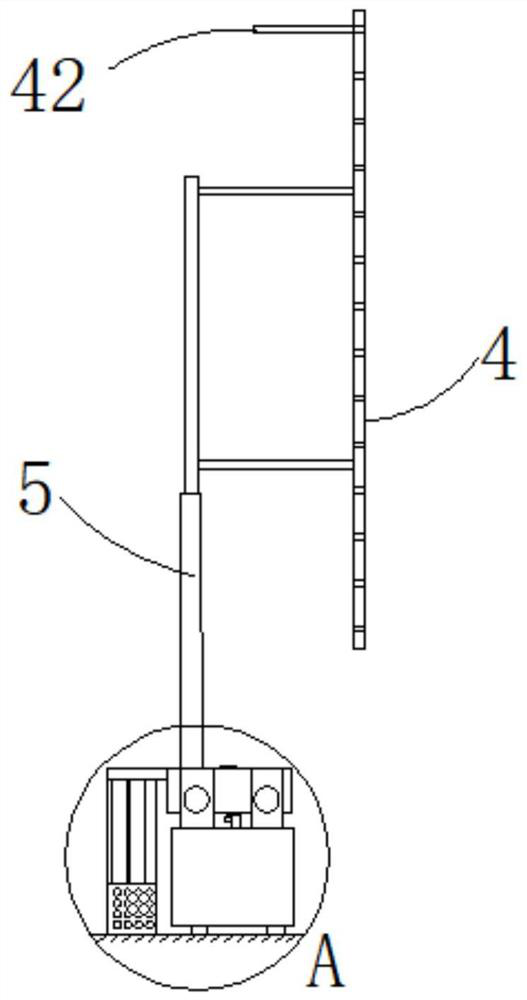

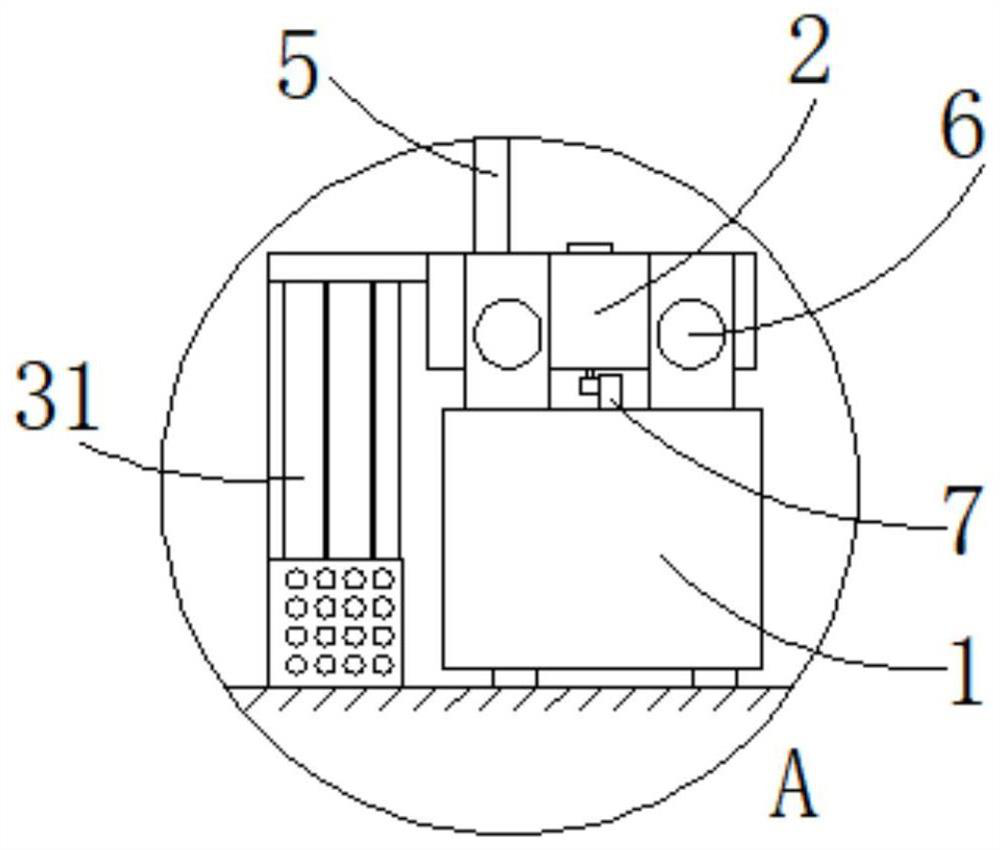

Dust collection system for rewinding machine

InactiveCN106238430ARealize the collectionRealize cleaning and replacementDirt cleaningWebs handlingEngineeringControl switch

The invention relates to a dust collection system for a rewinding machine. The dust collection system comprises a rack and a shell fixed to the rack through bolts. A rewinding device is arranged on the lower side of the shell. Suction openings A are formed in the left side of the shell and connected with a suction branch pipe. The other end of the suction branch pipe is connected with suction openings B, and the suction openings B are fixed to the right side of the shell. The suction branch pipe is connected with a suction main pipe. The suction main pipe is connected with a suction fan. A housing is arranged outside the suction fan. A control display screen is embedded in one side face of the housing. A control switch is arranged on the portion, below the control display screen, of the housing. A reset switch is arranged below the control switch. An operating state display lamp is arranged at the right side of the control switch, and a fault display lamp is arranged at the right side of the operating state display lamp. A recovery box is fixed to the other side of the housing through bolts. The dust collection system for the rewinding machine has the advantages that the air suction speed can be controlled, the environmental friendliness is good, and the health of personnel is guaranteed.

Owner:贾新霞

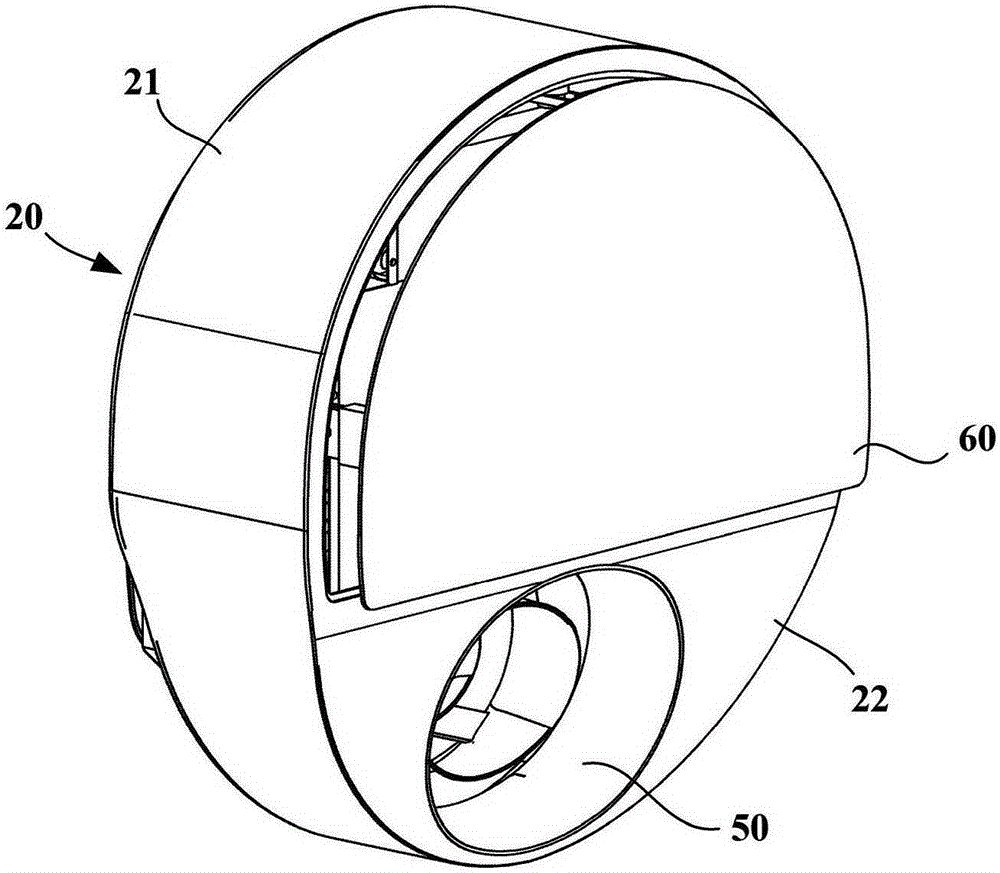

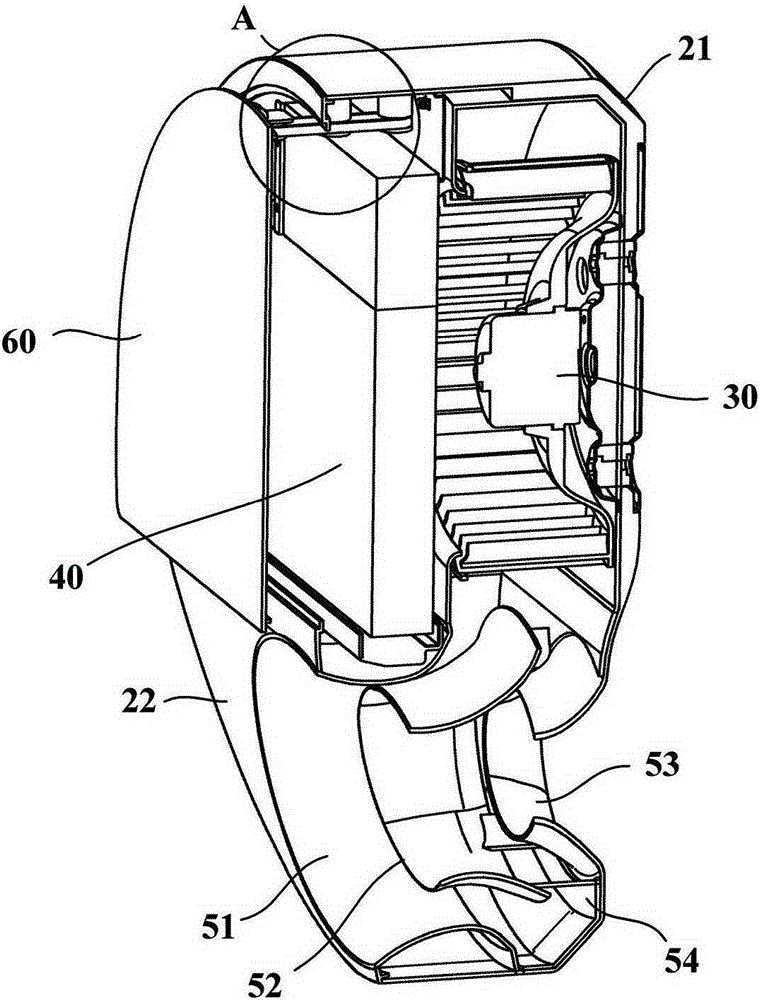

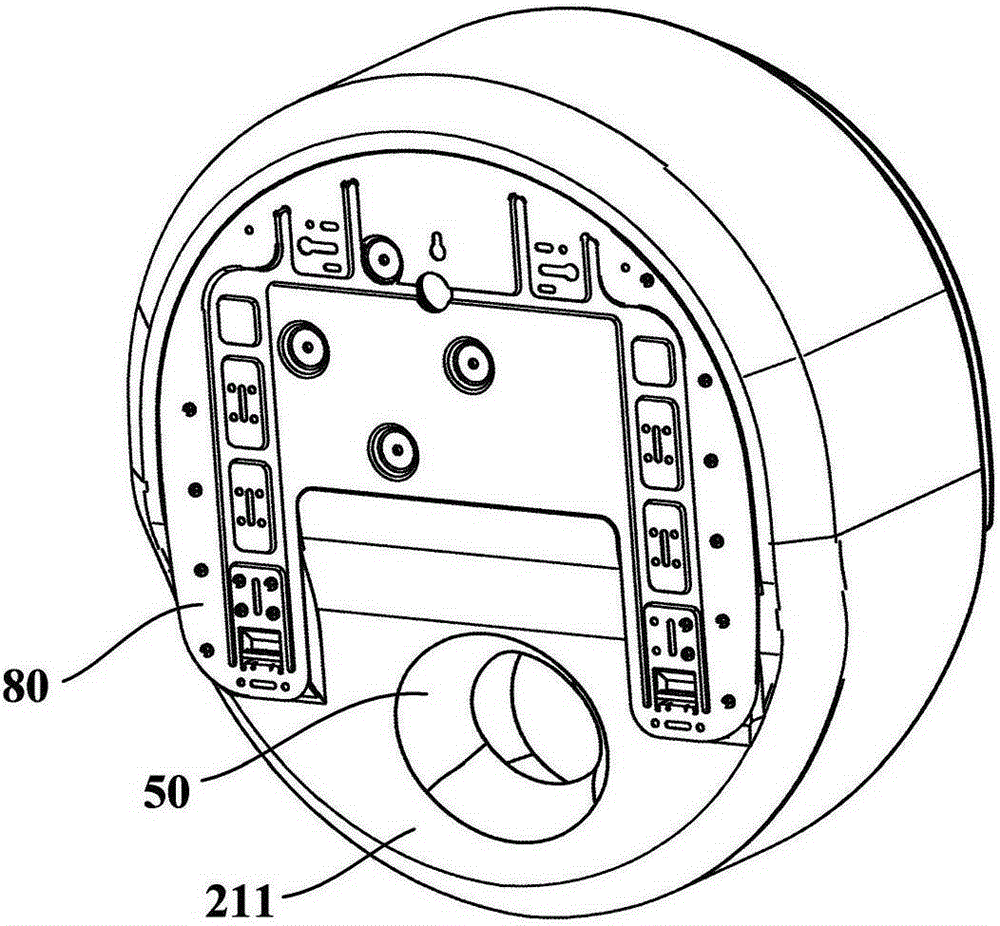

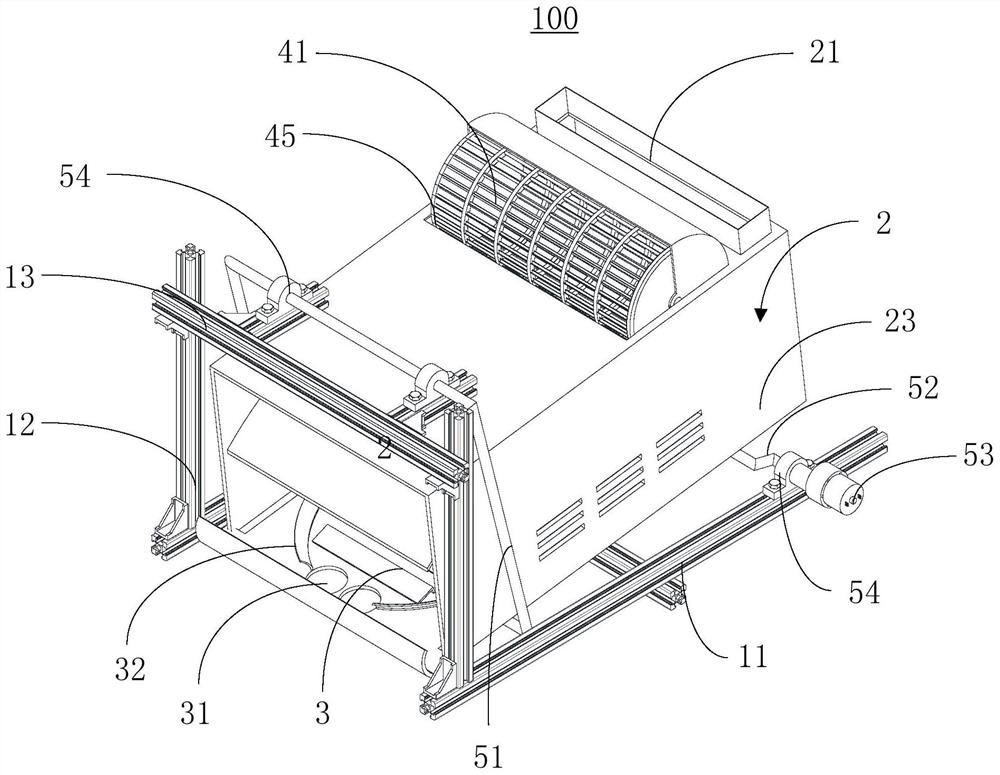

Air conditioner indoor unit

ActiveCN105318434AImprove heat transfer efficiencyReduce volumeLighting and heating apparatusAir conditioning systemsAir volumePlate heat exchanger

The invention provides an air conditioner indoor unit. The air conditioner indoor unit comprises a shell, a centrifugal fan, a heat exchanger, a drainage air guide device, a baffle plate and a horizontal moving mechanism, wherein the shell is provided with a first air inlet, a second air inlet and an air outlet; the centrifugal fan is arranged in the shell, and the rotary axis or the extension line of the rotating axis of the centrifugal fan passes through the first air inlet; at least part of a heat exchange section of the heat exchanger is in a flat plate shape, and the heat exchanger is located between the centrifugal fan and the first air inlet; the drainage air guide device is arranged in the shell and used for guiding airflow from the centrifugal fan and airflow from the second air inlet into the drainage air guide device to be mixed, and the mixed airflow is blown out of the air outlet in a velocity component mode in the direction parallel to the rotating axis of the centrifugal fan; the horizontal moving mechanism is used for driving the baffle plate to move in the direction parallel to the rotating axis of the centrifugal fan so as to open or close the first air inlet. The air conditioner indoor unit is large in air supply volume and capable of blowing out gentle mixed air with a moderate temperature.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

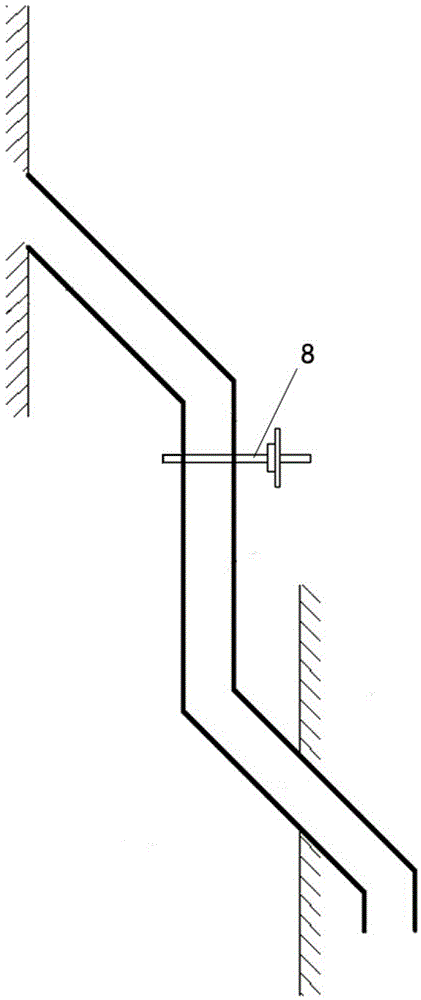

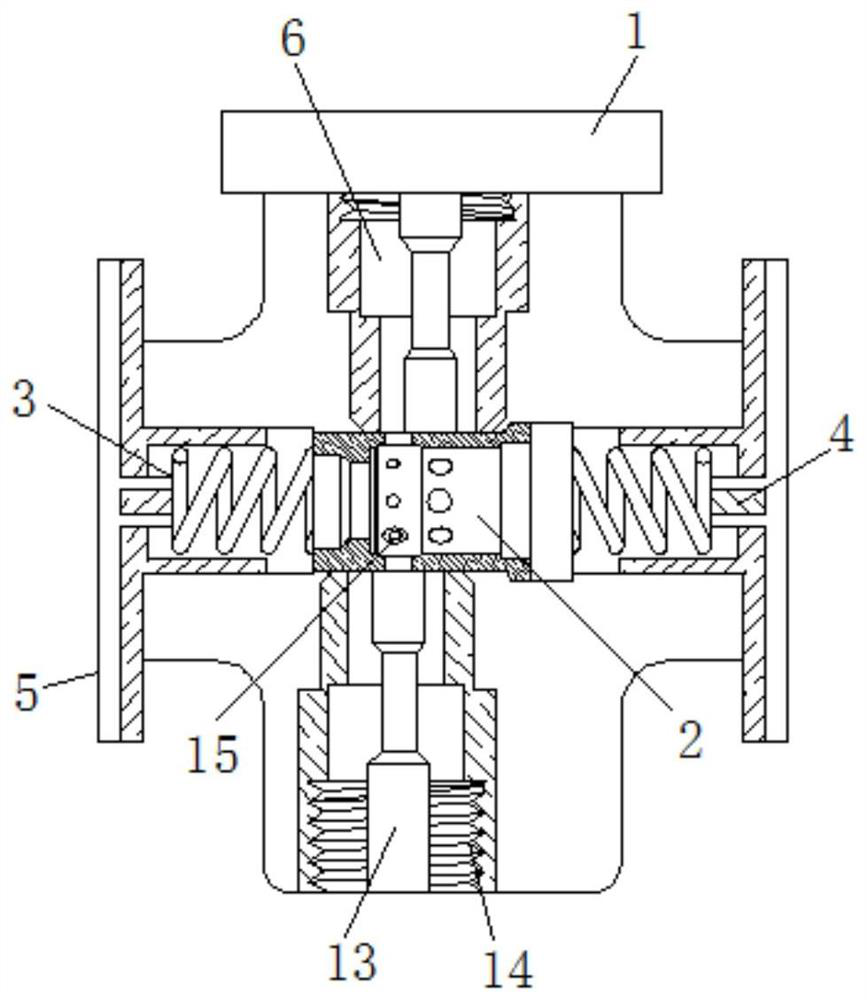

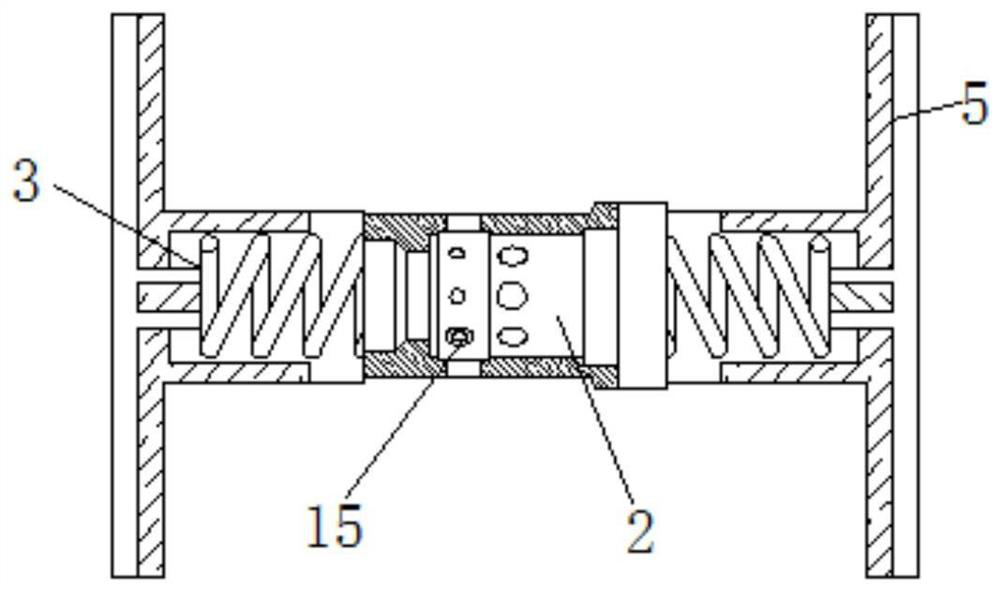

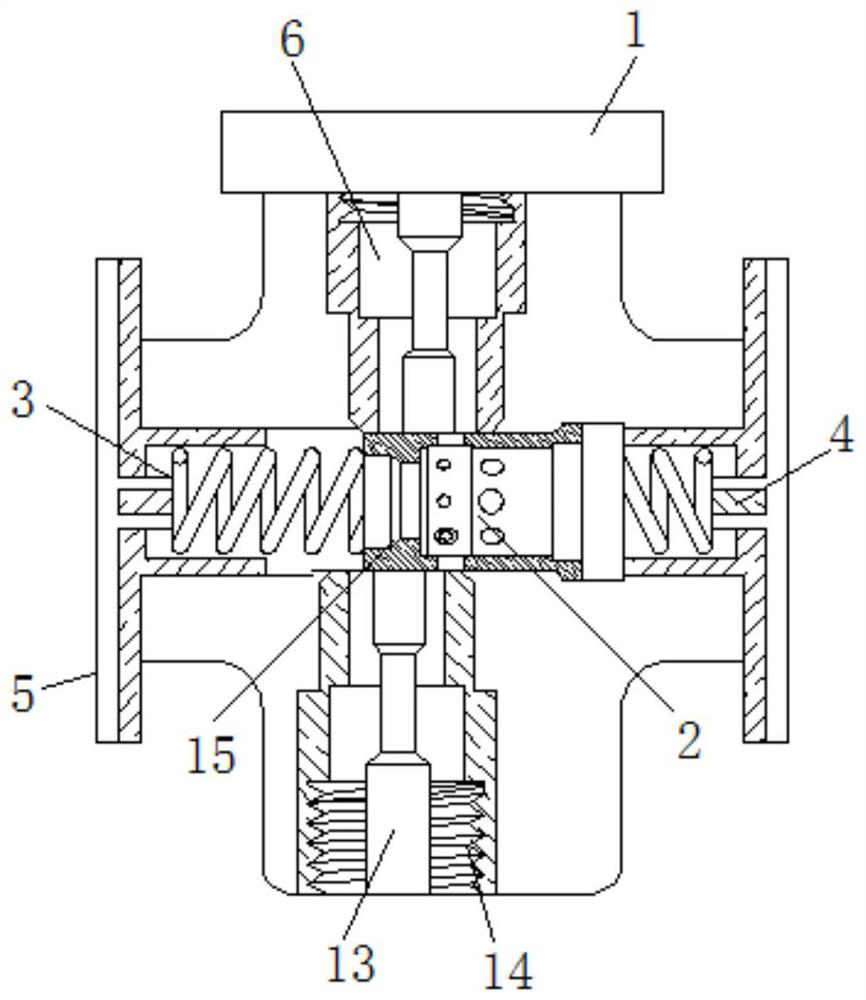

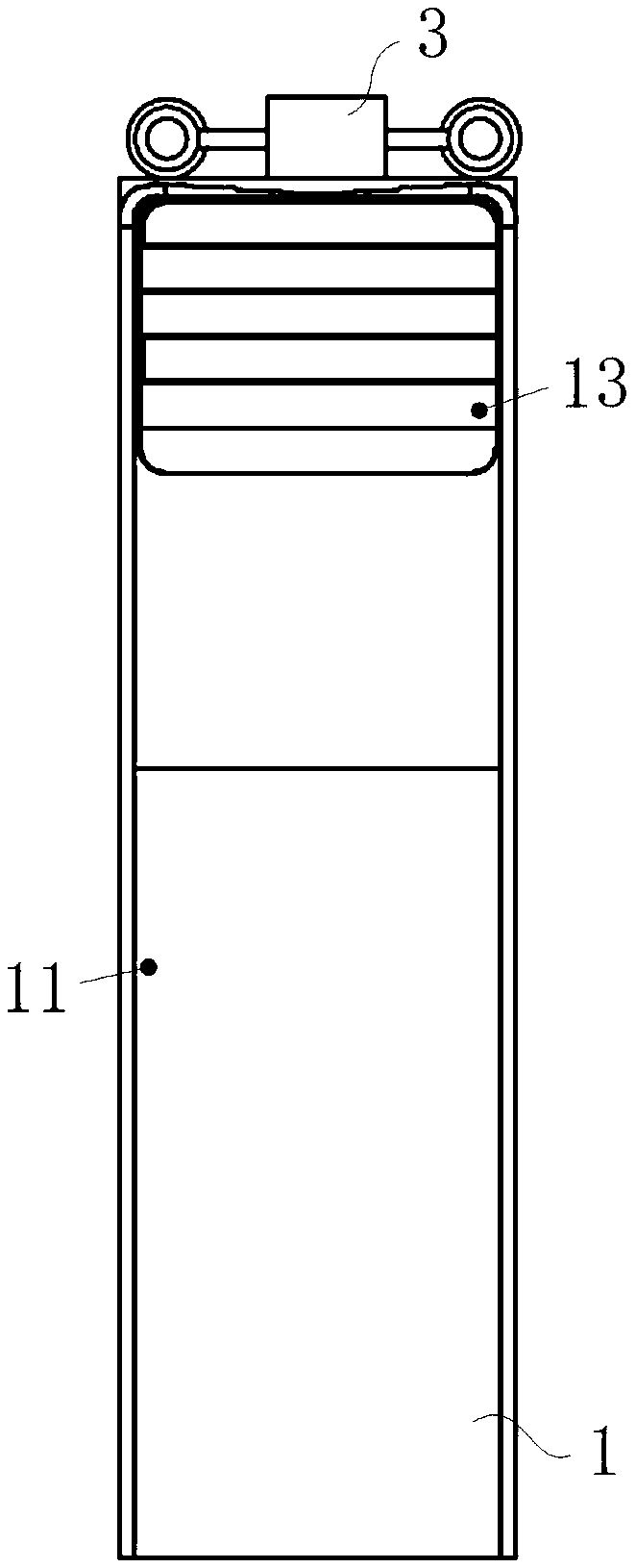

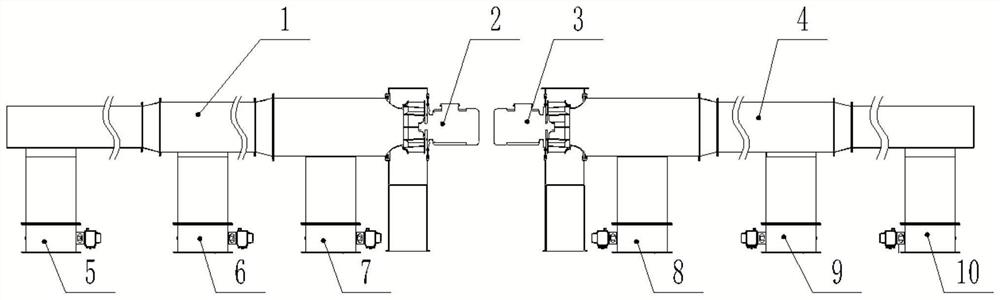

Slag falling device and circulating fluidized-bed boiler

ActiveCN104949116ADoes not affect normal transport capacityChange the circulation areaFluidized bed combustionApparatus for fluidised bed combustionSlagEngineering

The invention discloses a slag falling device and a circulating fluidized-bed boiler. The slag-falling device comprises a slag discharging pipe (1), a conveying pipe (2) and a slag feeding pipe (3), wherein an upper end port of the slag discharging pipe (1) is communicated with a slag discharging port of the boiler, and a lower end port of the slag discharging pipe (1) is communicated with an upper end port of the conveying pipe (2); and an upper end port of the slag feeding pipe (3) is communicated with a lower end port of the conveying pipe (2), and a lower end port of the slag feeding pipe (3) is communicated with a slag feeding port of a slag cooler. The slag falling device also comprises an air inducing component which is communicated with the conveying pipe (2) and can form a low-pressure zone above the conveying pipe (2). The air inducing component forms the low-pressure zone above the conveying pipe, so that the gas flow which is carried into the slag cooler by bottom slag when the bottom slag flows downwards is reduced, and a slag running phenomenon caused by lubrication and fluidization effects of gases is avoided; and at the same time, gases entering the low-pressure zone flow in a single phase, so that the wind volume and the wind speed are easy to control.

Owner:CHINA SHENHUA ENERGY CO LTD +2

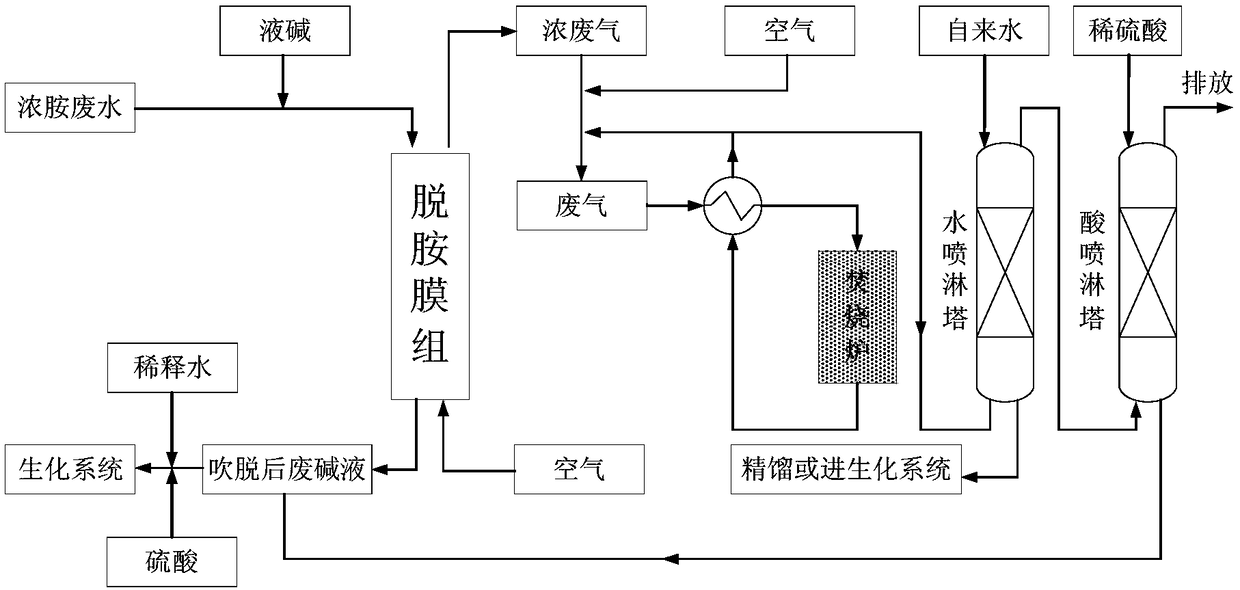

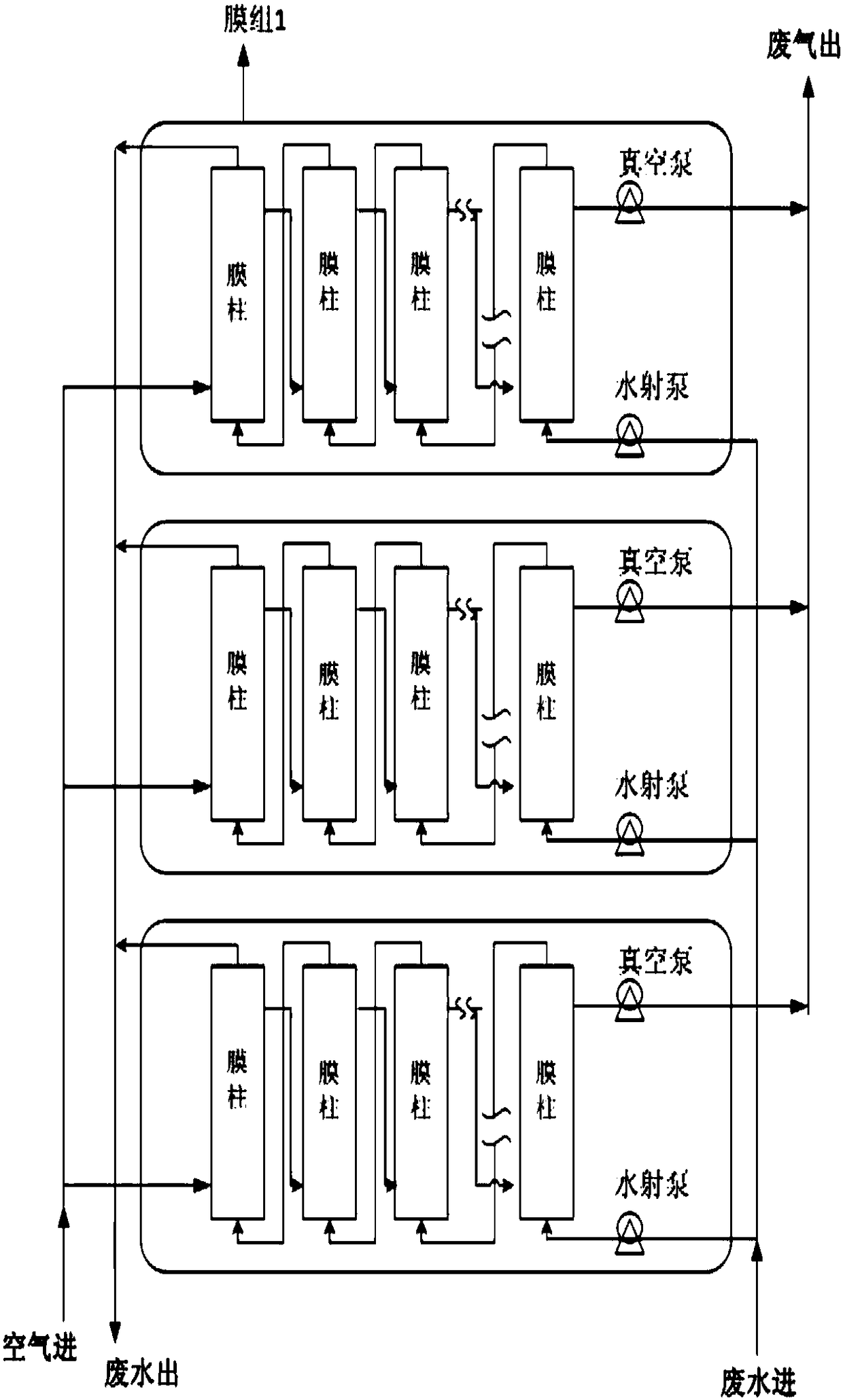

Treatment method of organic amine wastewater

InactiveCN108373233AMake full use of energyReduce energy consumptionWater contaminantsDispersed particle separationReaction temperatureWastewater

The invention discloses a treatment method of organic amine wastewater. The treatment method includes following steps: (1), adjusting pH of the organic amine wastewater to above 10, rising temperatureto 25-80 DEG C, feeding the organic amine wastewater into a degassing membrane system to obtain waste lye and organic amine waste gas, and subjecting the waste lye to diluting, neutralizing and biochemical treatment; (2), feeding the organic amine waste gas into an adjusting tank, adjusting until TVOC concentration is 1000-8000mg / m<3>, and feeding into a catalytic reactor for catalytic burning byair volume of 200-10000m<3> / h, wherein reaction temperature of catalytic burning is 100-550 DEG C; (3), discharging tail gas of catalytic burning after water washing, acid pickling and / or alkali pickling. The treatment method is simple in operation, thorough in purification and free of secondary pollution.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

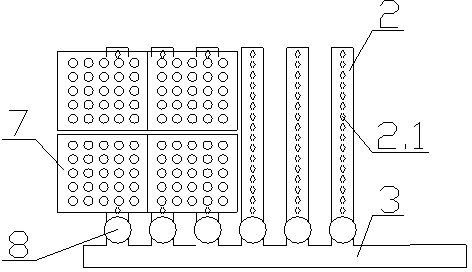

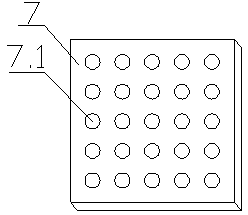

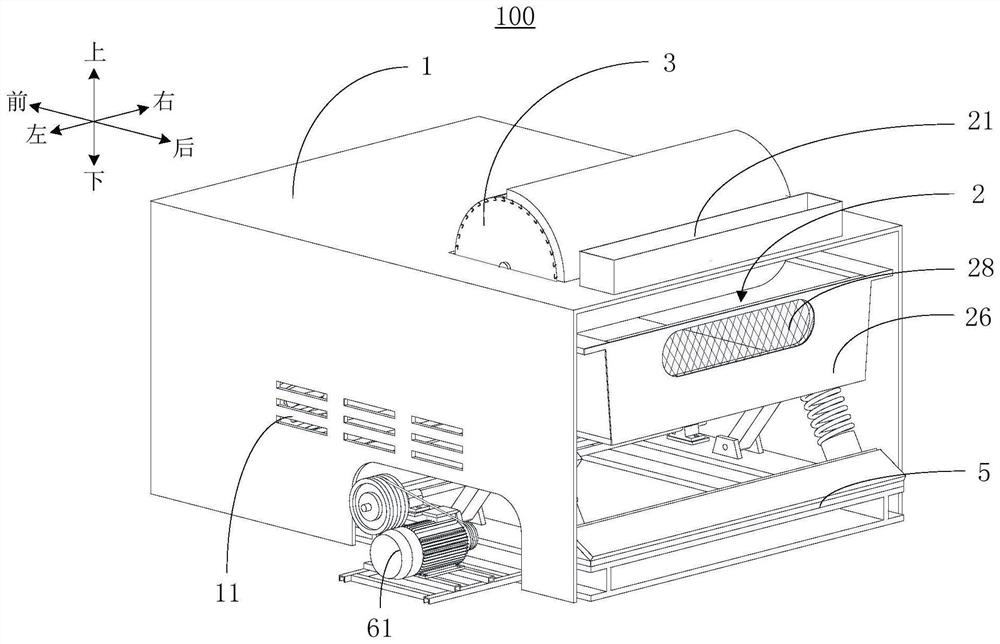

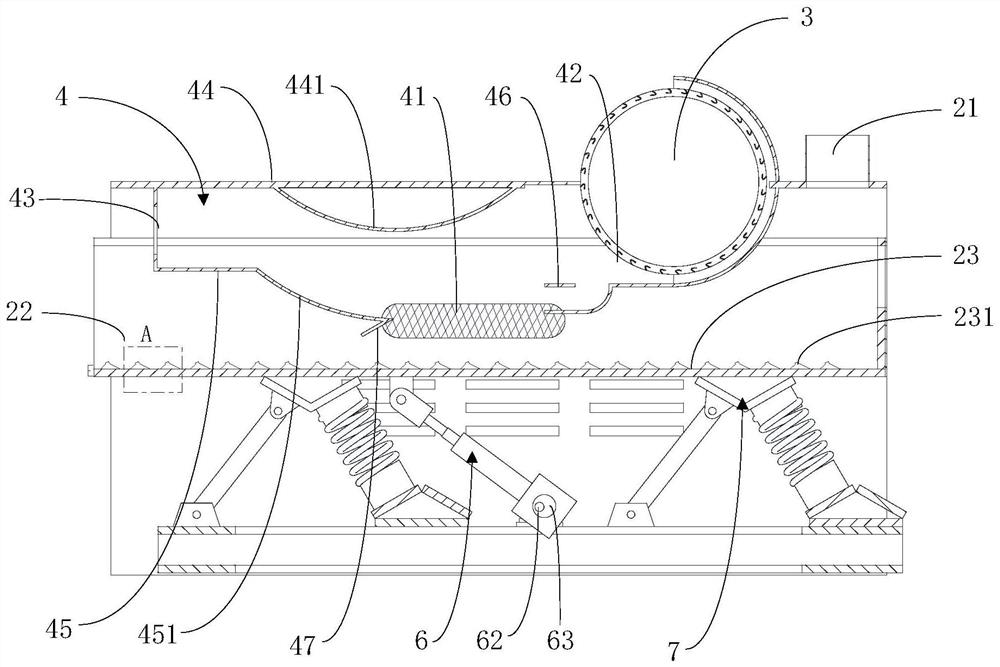

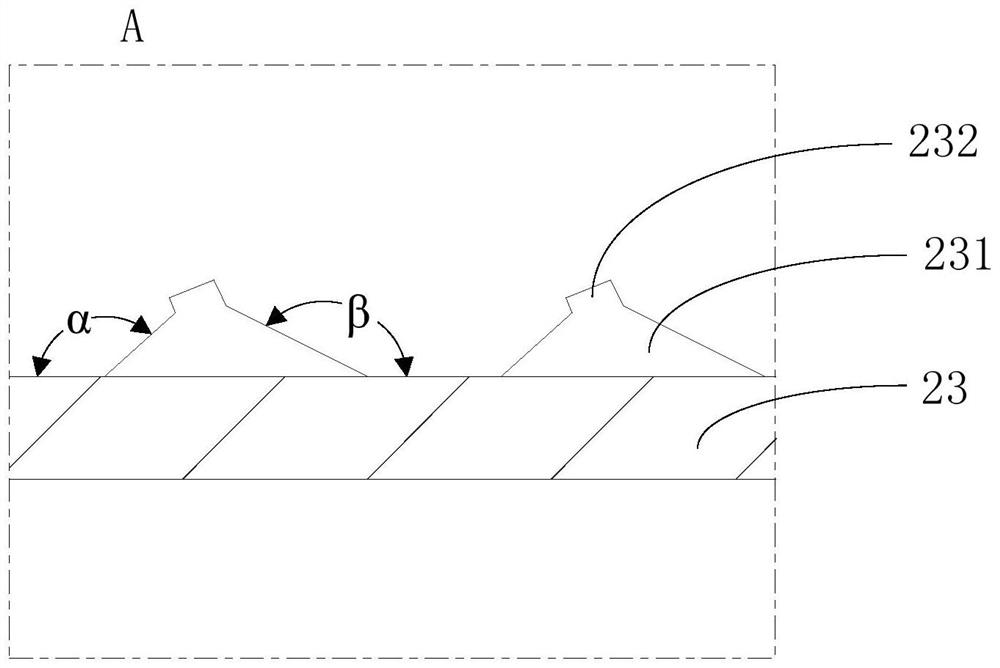

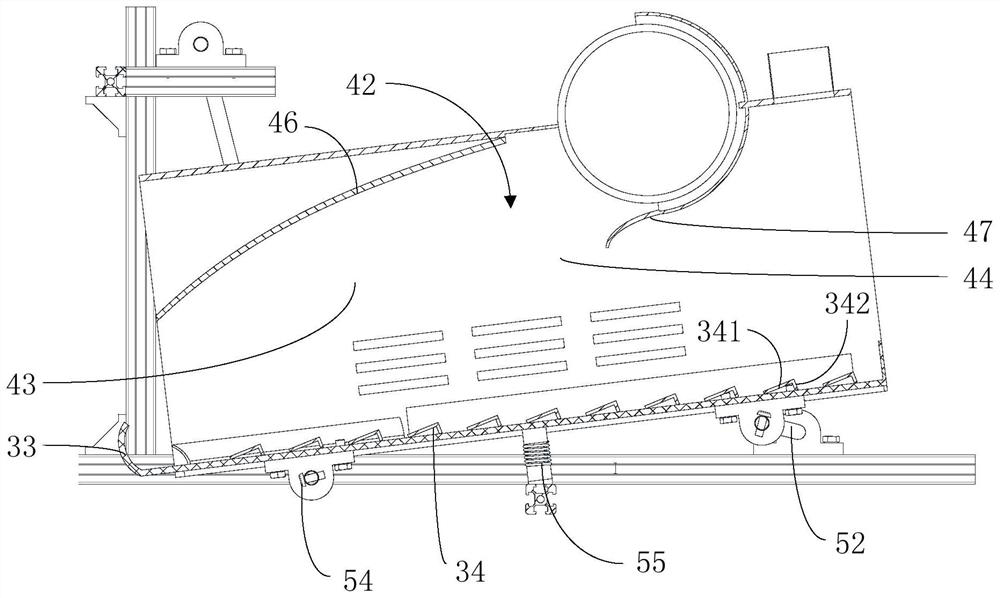

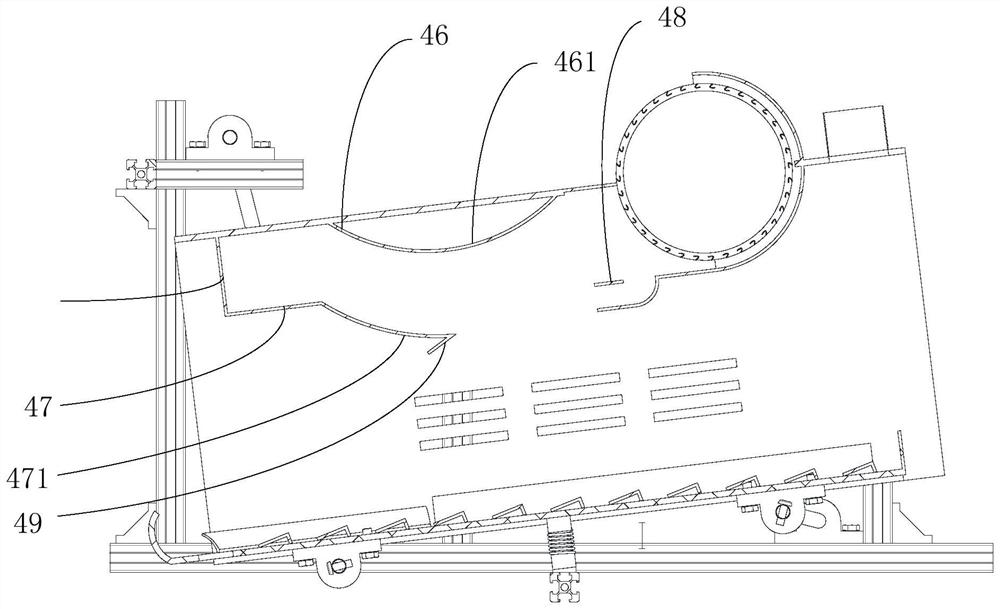

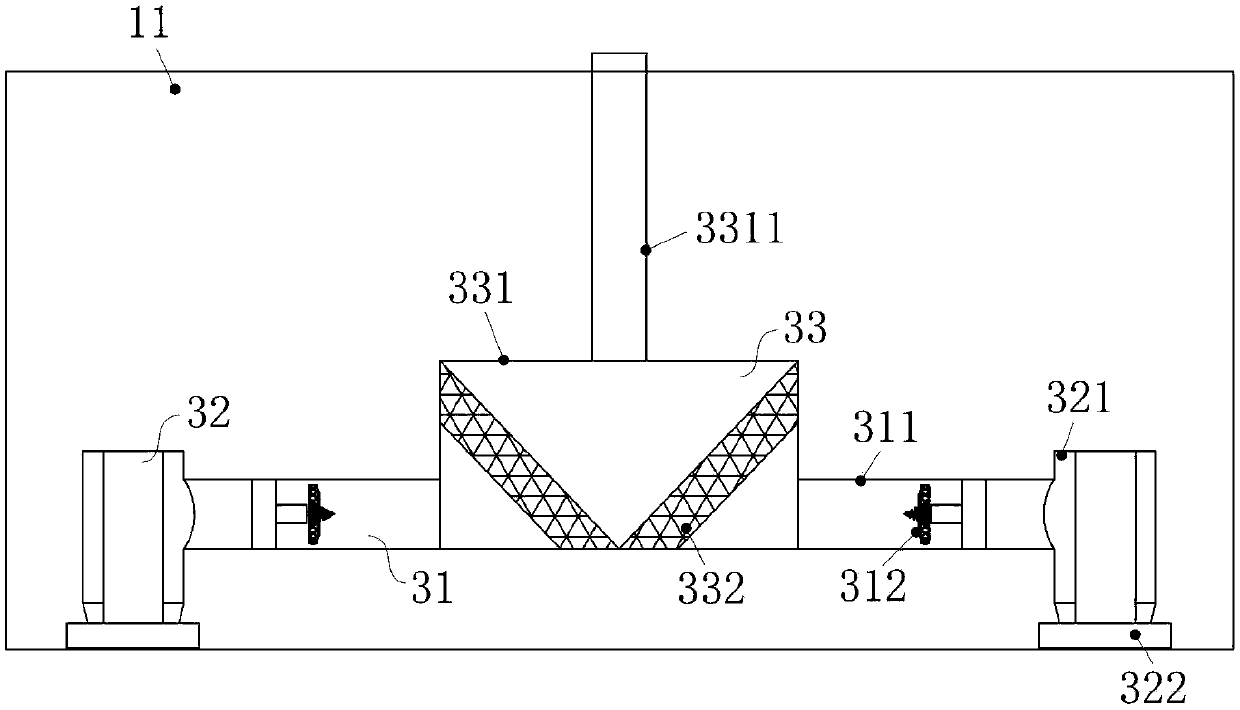

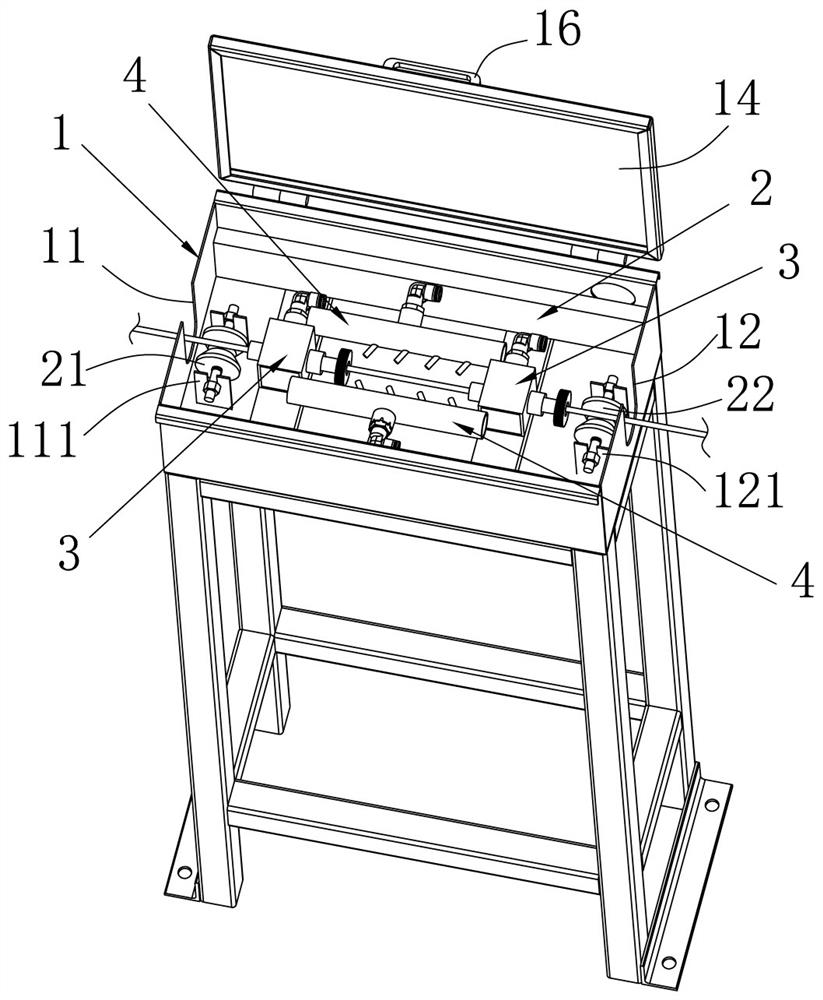

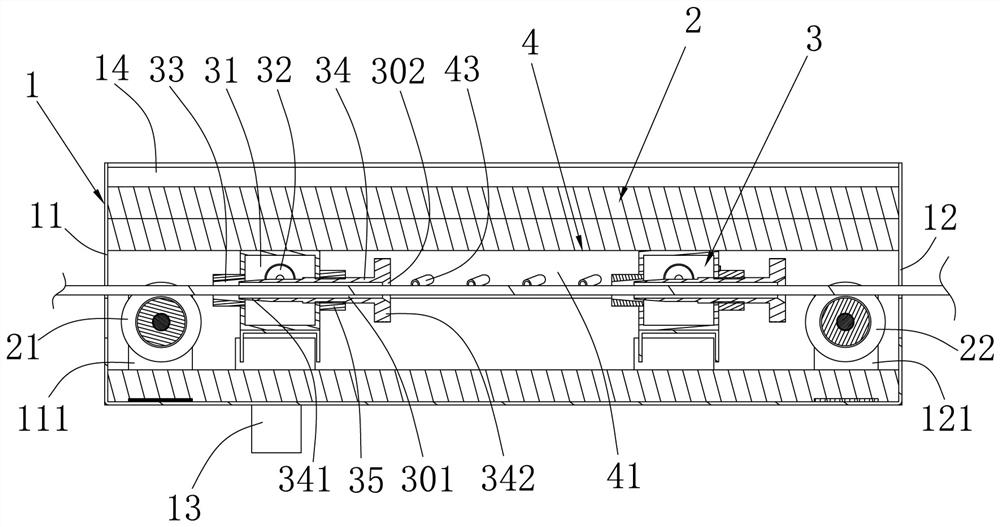

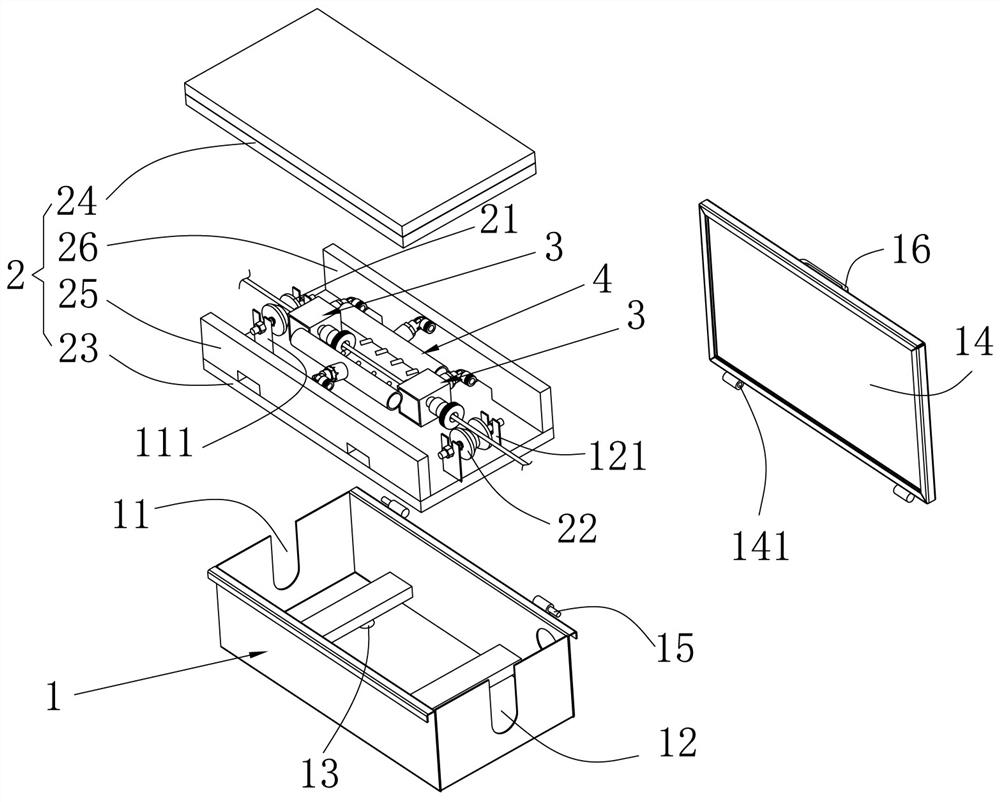

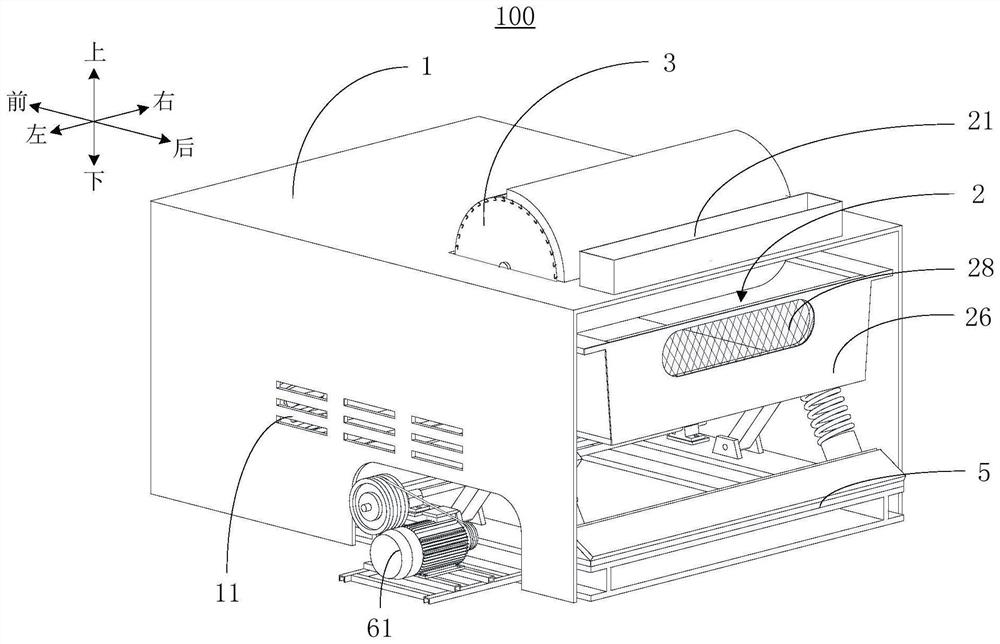

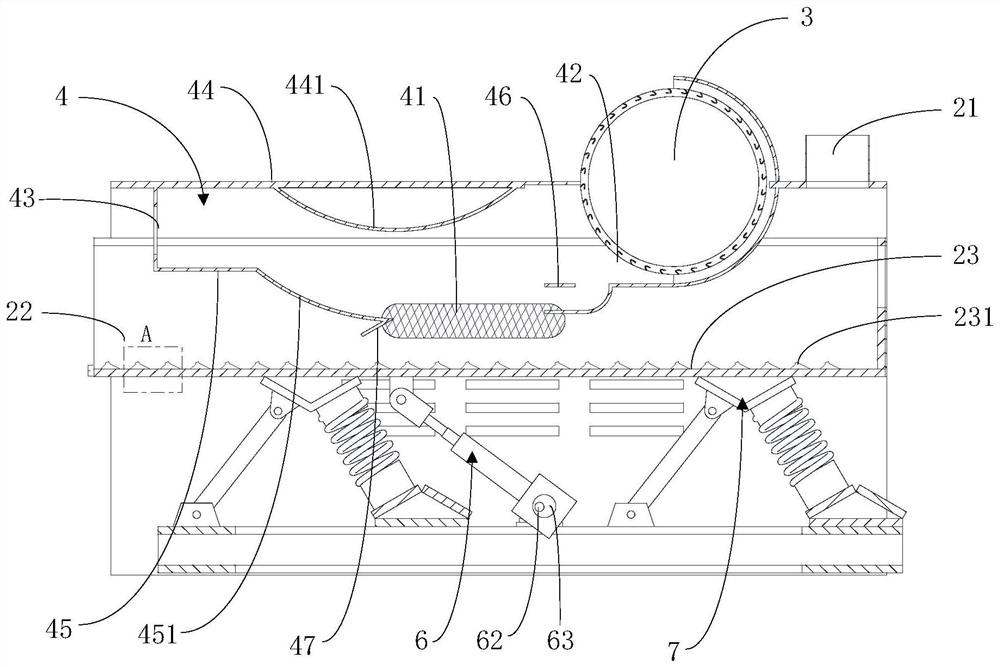

Rice bran and broken rice separation equipment

ActiveCN112337798AAchieve separationReduce air volumeSievingGas current separationBroken riceAir contamination

The invention discloses rice bran and broken rice separation equipment and a rice processing all-in-one machine. The rice bran and broken rice separation equipment comprises a box body, a vibration screening bin, a winnowing device and a vibration driving device. A feeding port is formed in the upper surface of the box body, the vibration screening bin is arranged in the box body, the rear end ofthe vibration screening bin communicates with the feeding port, a discharging port is formed in the front end of the vibration screening bin, and the vibration screening bin comprises a vibration plate extending in the front-back direction. The winnowing device comprises a fan and a separation air duct, and the separation air duct is arranged above the vibration plate and provided with a communication port communicating with the vibration plate. An air inlet and an air outlet of the separation air duct are formed in two sides of the communication port correspondingly, and the fan communicateswith the air inlet. The vibration driving device drives the vibration screening bin to vibrate so that rice bran and broken rice can be layered and flow towards the discharging port. According to theprovided rice bran and broken rice separation equipment, an air pressure difference winnowing method is combined with a vibration method to separate rice bran from broken rice, the rice bran and broken rice separation effect is good, the separation efficiency is high, the air volume is easy to control, and air pollution is small.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Tunnel hot air circulation tunnel furnace

The invention discloses a tunnel type hot air circulation tunnel furnace. The tunnel type hot air circulation tunnel furnace comprises a furnace body, a hot air circulation device, a conveying belt and a heating device. The hot air circulation device comprises a hot air generator, a draught fan, a four-way connector, an upper air box and a lower air box. The four-way connector comprises a horizontal air inlet shell and two air distribution shells, wherein the two ends of the air inlet shell vertically extend to form the two air distribution shells. The top face of the air inlet shell is provided with an inlet. The bottom face of the air inlet shell is provided with a first outlet. The upper ends of the two air distribution shells are communicated with the inlet. The lower end of each air distribution shell is provided with a second outlet. The outlet of the draught fan is communicated with the inlet. The first outlet is communicated with the upper air box. The second outlets are communicated with the lower air box. The bottom of the upper air box is provided with a plurality of first air outlet holes. The top of the lower air box is provided with a plurality of second air outlet holes. A return air passage is arranged in the furnace body. The first air outlet holes and the second air outlet holes are connected with the hot air generator through the return air passage. According to the tunnel type hot air circulation tunnel furnace, hot air output by the hot air circulation device can be evenly and circularly led to products to be baked, and the air temperature, the air volume and the air speed can be controlled.

Owner:GUANGZHOU BAKE OVEN MACHINERY

Spiral-flow type micro bubble generator and micro bubble generation method

ActiveCN104117299ASimple structureAvoid cloggingFlow mixersTransportation and packagingMicro bubbleEngineering

The invention relates to a spiral-flow type micro bubble generator and a micro bubble generation method, and belongs to a plurality of fields of ore dressing, wastewater treatment, waste paper deinking, aquatic products breeding and transportation, and the like. The spiral-flow type micro bubble generator includes three kinds of structures such as a self air-suction type structure, a non self air-suction type structure and a mixed flow type structure; the method comprises determining of the flow-in way of a fluid according to the different structure of the spiral-flow type micro bubble generator, and determining of the flow-out way of the fluid according to the different structure of the spiral-flow type micro bubble generator. The spiral-flow type micro bubble generator has the advantages of good air inflation performance and low energy consumption, generated micro bubbles are uniform and reasonable in size distribution; the shape and size of an air inlet or a flow outlet can be changed according to the actual situation to achieve the self suction air in letting and flow out letting at both ends to generate the micro bubbles; the air supply mode can adopt self suction air supply type or pressurized air supply, air is taken into the micro bubble generator in the manner of taking with the fluid, and the spiral-flow type micro bubble generator has the characteristics of simple structure, uneasy blockage and convenient maintenance.

Owner:KUNMING UNIV OF SCI & TECH

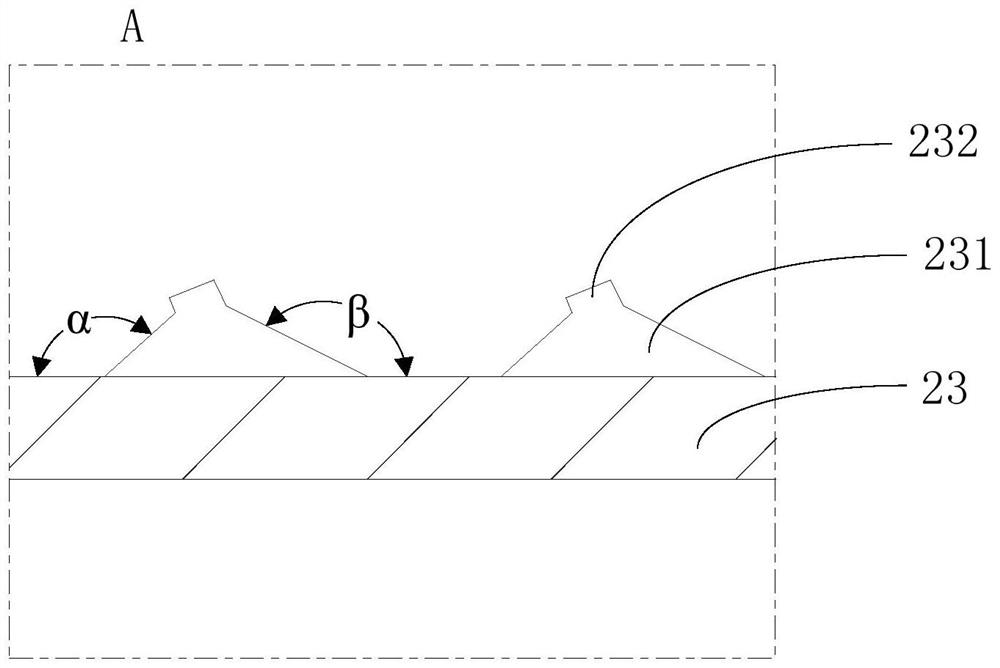

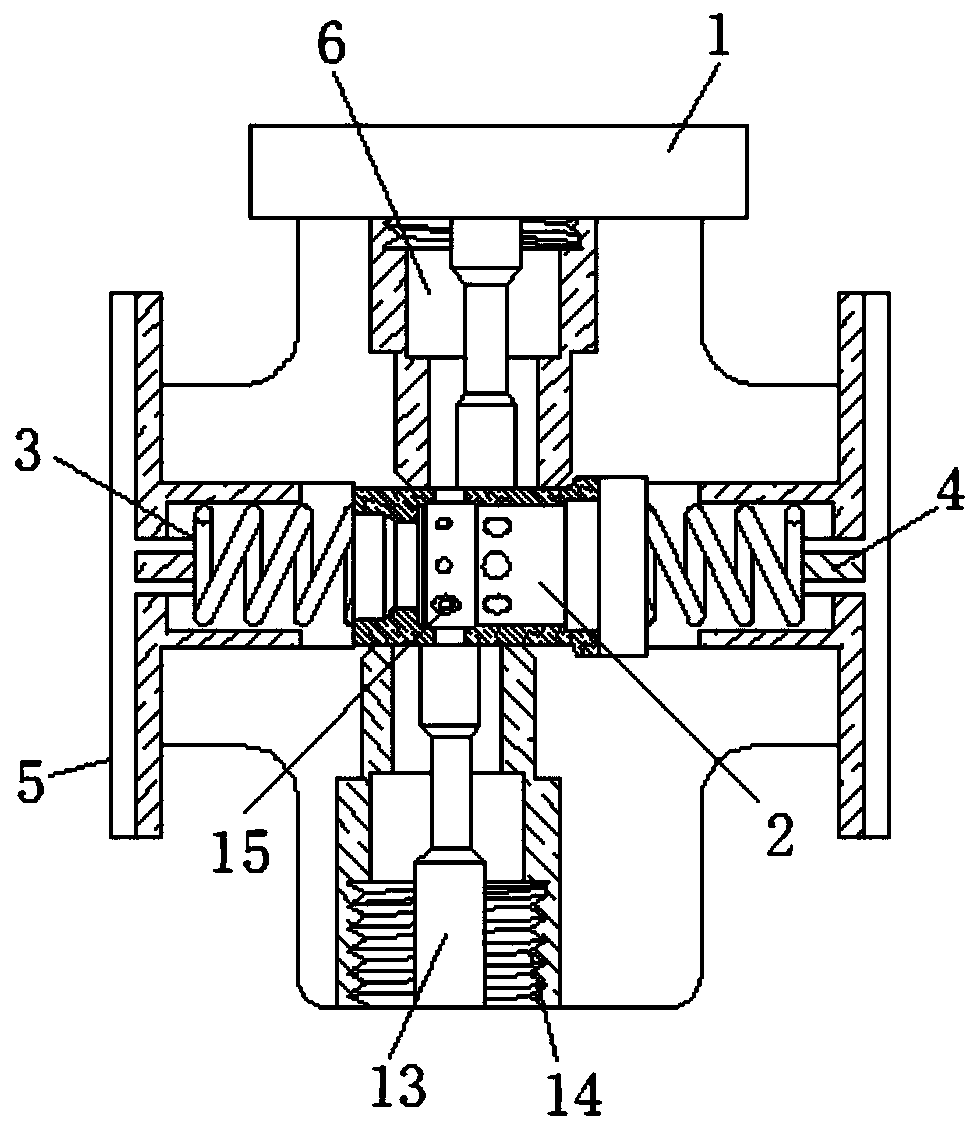

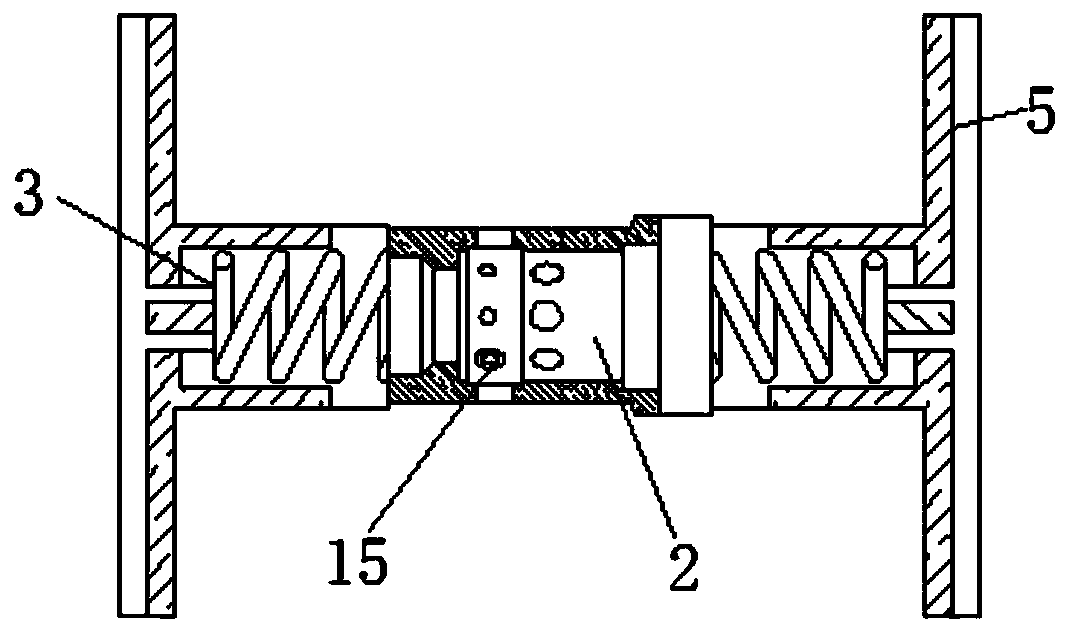

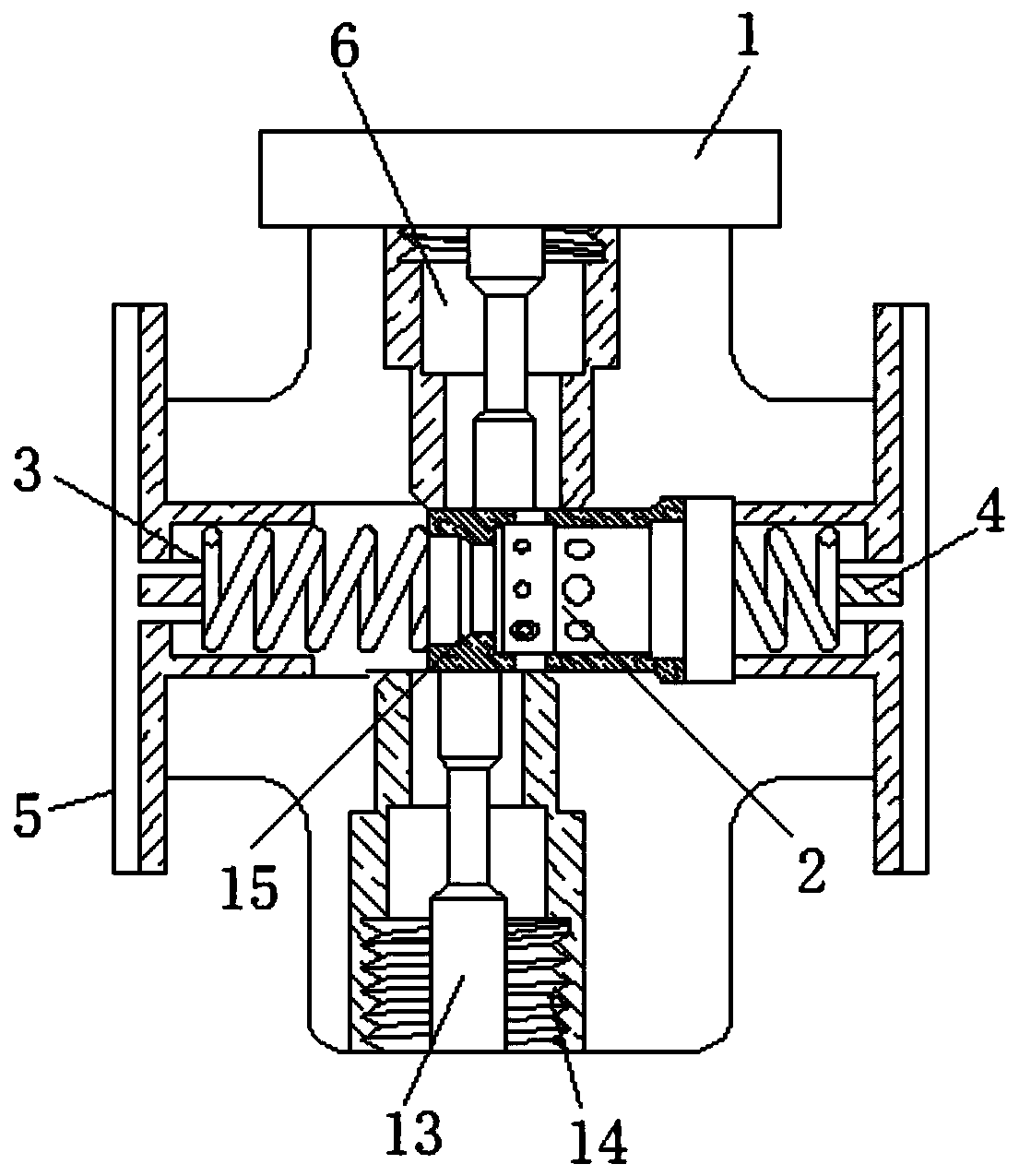

Blast type combustor

The invention relates to a blast type combustor, comprising a furnace end, wherein an inner injection pipe, an outer injection pipe and a furnace end base are arranged on the furnace end. According to the technical main points, an outer ring air channel, an inner ring air channel, an inner ring gas channel and an outer ring gas channel are arranged on the furnace end base; a blast device is mounted on the furnace end base; an outer ring air pipe and an inner ring air pipe are arranged on the blast device; a distributor is further arranged on the furnace end base; an outer ring air channel, an inner ring air channel, an inner ring gas channel and an outer ring gas channel are arranged on the fire distributor; an outer fire cover and an inner fire cover are arranged on the fire distributor; an outer ring cover is arranged on the outer fire cover; a plurality of outer ring fire holes are formed in the outer fire cover; an outer ring cover hole is formed in the outer ring cover; an inner ring cover is arranged on the inner fire cover; a plurality of inner ring fire holes are formed in the inner fire cover; and an inner ring cover hole is formed in the inner ring cover. According to the blast type combustor provided by the invention, each fire outlet can individually supply secondary air; an air amount is controllable and air can be uniformly distributed, so that gas is more sufficiently combusted; and the combustion efficiency is higher.

Owner:VATTI CORP LTD

Rice bran and broken rice separation equipment and rice processing integrated machine

ActiveCN112317319AReduce air volumeControllable air volumeGas current separationSaving energy measuresBroken riceAir contamination

The invention discloses rice bran and broken rice separation equipment and a rice processing integrated machine. The rice bran and broken rice separation equipment comprises a rack, a box body, a vibration plate, an air separation device and a vibration driving device, wherein a material feeding mouth is arranged in the upper surface of the box body, the vibration plate is arranged at the bottom of the box body and extends in the front-back direction, the rear end of the vibration plate communicates with the material feeding mouth, and a broken rice outlet is arranged in the front end of the vibration plate; the air separation device is arranged in the box body and located above the vibration plate and comprises an air fan and a separation air passage, the separation air passage is provided with a communication mouth facing the vibration plate, an air inlet and an air outlet are further formed in the separation air passage, and the air fan is arranged at the air inlet or the air outlet; and the vibration driving device drives the vibration plate to vibrate to make rice bran and broken rice be layered and flow towards the material outlet direction. According to the rice bran and broken rice separation equipment provided by the invention, an air pressure difference air separation method is combined with a vibration method to separate the rice bran from the broken rice, the rice bran and broken rice separation effect is good, the separation efficiency is high, furthermore, the air volume is easy to control, and less air pollution is caused.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Inductive multistratum control system of hand dryer

InactiveCN101596079BControllable air volumeDemandingOptical detectionDomestic applicationsElectricityMotor speed

Owner:HOKWANG IND

Rotational flow screening equipment

PendingCN114713387AReduce the impactControllable air volumeReversed direction vortexPlastic recyclingAir volumeDrive shaft

The invention aims to provide rotational flow screening equipment. A relatively sealed cylindrical container composed of a side wall, a conical side wall, an upper end face and a lower end face is designed; a driving shaft is arranged on the end surface of the lower part, so that the driving shaft is positioned on the central axis of the barrel body; centrifugal fan blades are arranged on the driving shaft; a feeding hole is formed in the upper end surface or the side wall close to the upper end surface; a first discharging opening is formed in the area, close to the upper end face, of the side wall; a second discharge hole is formed in a combined part area of the side wall and the conical surface side wall; the opening directions of the first discharge port and the second discharge port are both downward or inclined downward, so that airflow circulates in the barrel, the quantity of air flowing out of the barrel is small, the influence of dust on the external environment in the working process is small, closed dust-free operation can be achieved, and the working efficiency is improved. Screening and winnowing can be synchronously completed on materials containing light floccules, and convenience and rapidness are achieved.

Owner:BEIJINGLANDINGKECHUANG EQUIP TECH CO LTD

A self-resetting choke shaft

ActiveCN110735734BAdjust opening speedAdjust the degree of opening and closingMachines/enginesCarburettorsRatchetImpeller

The invention relates to the technical field of choke valves, and discloses a self-resetting choke valve shaft. The self-resetting choke valve shaft comprises a door body. A rotating shaft is movablyconnected to the interior of the door body. Springs are movably connected to two sides of the rotating shaft. A push-pull rod is movably connected to the end, far away from the rotating shaft, of eachspring. An air inlet mechanism is movably connected to the end, far away from the corresponding spring, of each push-pull rod. A resetting mechanism is movably connected to the surface of the rotating shaft. The air inlet mechanism comprises an air bellow. The air bellow is internally and movably connected with a ratchet wheel. The ratchet wheel is internally and movably connected with a gear. Amaterial continuously contracts and drives a threaded rod to move in the direction away from the rotating shaft, the threaded rod moves and drives the rotating shaft to rotate, and because the resetting mechanism is not symmetrically placed, the rotating shaft rotates towards one side while rotating, so that the springs pull the push-pull rods to move, the ratchet wheel connected with the push-pull rods is driven to rotate clockwise while the push-pull rods continuously move, and a fan impeller is slowly opened, so that the effect of adjusting the opening speed of a choke valve is achieved.

Owner:浙江省台州市杰特瑞卫浴科技有限公司

Jetting device of cabinet air conditioner and cabinet air conditioner with same

PendingCN110894988AImprove the phenomenon of overcooling/overheating of air supplyReduce noiseDucting arrangementsCondensate preventionEngineeringMechanical engineering

The invention relates to the technical field of air conditioners, in particular to a jetting device of a cabinet air conditioner and the cabinet air conditioner with the jetting device. The jetting device and the cabinet air conditioner aim to solve the problem that an existing air conditioner is too cold or too hot in air feeding and large in noise. For the purposes, the jetting device comprisesa purification unit, an air induction unit and a jetting unit. The purification unit comprises a box body and a purification assembly, and the box body is provided with an air inlet pipe and a first air outlet, wherein the air inlet pipe communicates with the outside. The air induction unit comprises a pipe body, wherein the pipe body is provided with a second air inlet and a second air outlet which is connected with the first air outlet. An induced draft fan is arranged in the pipe body. The jetting unit comprises a cylinder body and an opening and closing mechanism. The cylinder body is provided with a third air inlet and a third air outlet which is connected with the second air outlet. A jetting channel is formed between the third air inlet and the third air outlet. The opening and closing mechanism can adjust the air outlet area of the third air outlet. The jetting device and the cabinet air conditioner can alleviate the too cold or hot air feeding phenomena of an air conditioner and reduce the running noise of the air conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Intelligent smoke exhaust self-cleaning system of baking shaping equipment

InactiveCN112439744AWith self-cleaning functionHigh degree of automationHeating/cooling textile fabricsCleaning using gasesFiberAir volume

The invention discloses an intelligent smoke exhaust self-cleaning system of baking shaping equipment, and belongs to the technical field of textile fabric production. The intelligent smoke exhaust self-cleaning system comprises a smoke exhaust pipe, an ultrahigh negative pressure fan and an air volume adjusting damper, one end of the air volume adjusting damper is connected to a baking room, theother end of the air volume adjusting damper is connected to the smoke exhaust pipe, the ultrahigh negative pressure fan is connected to the smoke exhaust pipe, and the other end of the ultrahigh negative pressure fan is connected to a waste gas purification device. The intelligent smoke exhaust self-cleaning system of the baking shaping equipment has the advantages of being capable of achieving the self-cleaning function, high in automation degree, controllable in air volume and capable of removing various pollutants such as residual oil stains and fabric fibers in the baking room.

Owner:贵州华亿绿色纺织产业科技有限公司

A coal powder-injected mineral roasting device and process

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

Slagging device and circulating fluidized bed boiler

ActiveCN104949116BDoes not affect normal transport capacityDoes not change the flow areaFluidized bed combustionApparatus for fluidised bed combustionAir volumeSlag

The invention discloses a slag falling device and a circulating fluidized-bed boiler. The slag-falling device comprises a slag discharging pipe (1), a conveying pipe (2) and a slag feeding pipe (3), wherein an upper end port of the slag discharging pipe (1) is communicated with a slag discharging port of the boiler, and a lower end port of the slag discharging pipe (1) is communicated with an upper end port of the conveying pipe (2); and an upper end port of the slag feeding pipe (3) is communicated with a lower end port of the conveying pipe (2), and a lower end port of the slag feeding pipe (3) is communicated with a slag feeding port of a slag cooler. The slag falling device also comprises an air inducing component which is communicated with the conveying pipe (2) and can form a low-pressure zone above the conveying pipe (2). The air inducing component forms the low-pressure zone above the conveying pipe, so that the gas flow which is carried into the slag cooler by bottom slag when the bottom slag flows downwards is reduced, and a slag running phenomenon caused by lubrication and fluidization effects of gases is avoided; and at the same time, gases entering the low-pressure zone flow in a single phase, so that the wind volume and the wind speed are easy to control.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Silencing air blower

PendingCN111637719ASimple structureFew partsDrying gas arrangementsDrying machines with progressive movementsAir volumeEngineering

The invention belongs to the technical field of wire and cable production equipment, and particularly relates to a silencing air blower. The silencing air blower comprises a case body, a silencer is arranged in the case body, and an inlet roller and an outlet roller are arranged in the silencer. Two water blowers are arranged between the inlet roller and the outlet roller, and an air blowing barrel is arranged between the two water blowers. Each water blower comprises a box body, wherein an air inlet pipe, an air blowing nozzle and an adjusting rotary shaft are arranged in the box body. A wirepenetrating hole is formed in each adjusting rotary shaft. An electric wire enters the silencer from the inlet roller, and penetrates into the wire penetrating hole through the air blowing nozzle, thereby penetrating through the water blowers. After penetrating through the two water blowers, the electric wire gets out of the silencer from the outlet roller. The air blowing barrel is arranged between the two water blowers, the air output of the air blowing nozzles can be adjusted by adjusting the distances between the adjusting rotary shafts and the inner walls of the air blowing nozzles, airblowing noise is absorbed by the silencer, and thus the noise is effectively lowered. The silencing air blower is simple in structure, few in part, easy to install, convenient to maintain, long in service life, relatively low in production cost, and beneficial to being widely popularized and used.

Owner:DONGGUAN JINGTIE MACHINERY

A device for producing high-activity magnesium oxide using magnesite tailings

ActiveCN107324670BSolve the problem that it cannot be directly calcined to produce magnesium oxideAchieving zero emissionsLime productionSiloReactive magnesia

Owner:LIAONING DONGHE NEW MATERIAL CO LTD

Automatic sand blowing device

PendingCN113231603APrevent movement overrunHeight adjustableFoundry mouldsFoundry coresAir volumeReciprocating motion

The invention provides an automatic sand blowing device, and belongs to the technical field of mechanical equipment. The automatic sand blowing device comprises a fixing frame, a moving part, a driving device, a telescopic rod and an air knife, wherein the driving device is detachably installed on the moving part, and the driving device drives the moving part to reciprocate on the fixing frame. The telescopic rod comprises a fixed rod and a movable rod, the fixed rod and the movable rod can move relatively, the fixed rod is vertically installed on the movable piece, and the movable rod is fixedly connected with the air knife. The air knife can be provided with a plurality of tuyeres and horizontally reciprocate, the height of the air knife is adjustable, and the air volume of the tuyeres is controllable. In this way, floating sand on the surface of a sand mold or in a mold cavity can be effectively cleaned.

Owner:四川共享铸造有限公司

An air-heat cleaning system for automobile glass

The invention discloses a wind-heat cleaning system for automobile glass. The wind-heat cleaning system comprises an air compressor, a tail gas waste heat exchanger, a temperature and pressure sensor, a controller and an air blast opening, an air inlet of the air compressor is communicated with air outside an automobile, an air outlet of the air compressor is connected with an air inlet of the tail gas waste heat exchanger, an air outlet of the tail gas waste heat exchanger is connected with the air blast opening, an air outlet of the air blast opening is formed in the edge of the bottom of the automobile glass, the tail gas waste heat exchanger is arranged in an automobile exhaust pipe, passing air is heated through absorbed automobile tail gas heat, and the temperature and pressure sensor is arranged in a pipeline between the tail gas waste heat exchanger and the air blast opening, and transmits temperature and pressure signals to the controller. The controller controls pressure of compressed air of the air compressor according to the temperature and pressure signals received from the temperature and pressure sensor. The wind-heat cleaning system can achieve the good rain blocking and cleaning functions on a windshield, rearview mirrors and side windows of the automobile by utilizing automobile tail gas heat exchange. Heat energy is recycled and reused, and energy waste is effectively avoided.

Owner:WUHAN JINGLI ELECTRONICS TECH

A kind of rice bran broken rice separation equipment

ActiveCN112337798BAchieve separationReduce air volumeSievingGas current separationAgricultural scienceAir volume

The invention discloses a rice bran and broken rice separation device and a rice processing integrated machine. The rice bran and broken rice separation device includes a box body, a vibrating screening bin, a winnowing device and a vibration driving device. The upper surface of the box body is provided with a material inlet, and the vibrating screening bin is located inside the box body. vibrating plate. The winnowing device includes a blower fan and a separation air duct, the separation air duct is arranged above the vibrating plate, and is provided with a connecting port connected with the vibrating plate; The air inlet is connected. The vibration driving device drives the vibrating screening chamber to vibrate, so that the rice bran and broken rice are stratified and flow towards the discharge port. The rice bran and broken rice separation equipment provided by the present invention adopts the air pressure difference winnowing method combined with the vibration method to separate rice bran from broken rice, and has good separation effect and high separation efficiency of rice bran and broken rice, and the air volume is easy to control and has less air pollution.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Self-resetting choke valve shaft

ActiveCN110735734AAdjust opening speedAdjust the degree of opening and closingMachines/enginesCarburettorsRatchetImpeller

The invention relates to the technical field of choke valves, and discloses a self-resetting choke valve shaft. The self-resetting choke valve shaft comprises a door body. A rotating shaft is movablyconnected to the interior of the door body. Springs are movably connected to two sides of the rotating shaft. A push-pull rod is movably connected to the end, far away from the rotating shaft, of eachspring. An air inlet mechanism is movably connected to the end, far away from the corresponding spring, of each push-pull rod. A resetting mechanism is movably connected to the surface of the rotating shaft. The air inlet mechanism comprises an air bellow. The air bellow is internally and movably connected with a ratchet wheel. The ratchet wheel is internally and movably connected with a gear. Amaterial continuously contracts and drives a threaded rod to move in the direction away from the rotating shaft, the threaded rod moves and drives the rotating shaft to rotate, and because the resetting mechanism is not symmetrically placed, the rotating shaft rotates towards one side while rotating, so that the springs pull the push-pull rods to move, the ratchet wheel connected with the push-pull rods is driven to rotate clockwise while the push-pull rods continuously move, and a fan impeller is slowly opened, so that the effect of adjusting the opening speed of a choke valve is achieved.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com