A device for producing high-activity magnesium oxide using magnesite tailings

A magnesium oxide device and magnesite tailings technology, which is applied in the field of refractory material production, can solve the problems of dust leakage, pollution of the environment, waste of resources, and damage to the environment, and achieve clean working environment, stable product quality, and full use of heat sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

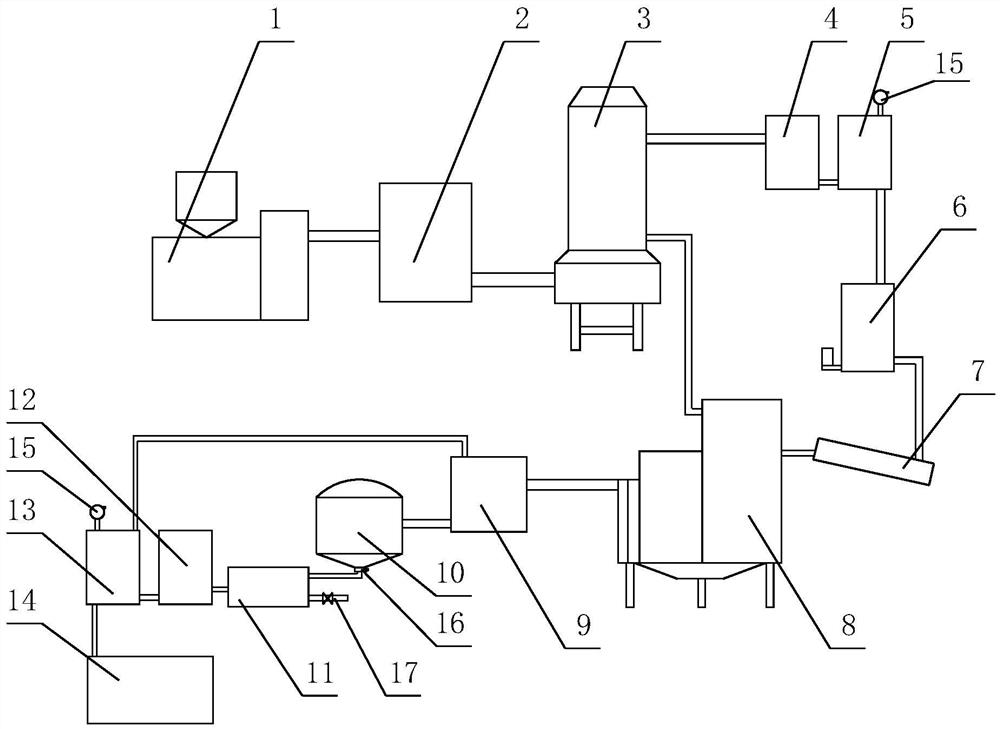

Image

Examples

Embodiment 1

[0026] A production process for utilizing magnesite tailings to produce a high-activity magnesium oxide device, specifically comprising the following steps:

[0027] 1) After the magnesite tailings flotation, the concentrate powder and the recovered magnesium oxide powder are mixed and processed. The MgO content of the concentrate powder is 42-43%, and the MgO content of the recovered magnesium oxide powder is greater than 95-97.5%. The ratio is 6.5:1;

[0028] 2) The wet material is continuously transported into the flash dryer through the filter cake feeder. Under the combined action of the rotating blade of the main engine and the high-speed hot air flow, the wet material is quickly dispersed into powder, which expands the evaporation area, and the material is heated with hot air. High-speed mass transfer and heat transfer, instantaneous vaporization and evaporation of water molecules, drying and dehydration to ≤1~0.5%, and materials that meet the requirements of restoring ...

Embodiment 2

[0032] A production process for utilizing magnesite tailings to produce a high-activity magnesium oxide device, specifically comprising the following steps:

[0033] 1) After the magnesite tailings flotation, the concentrate powder and the recovered magnesium oxide powder are mixed and processed, the MgO content of the concentrate powder is 43-44%, and the MgO content of the recovered magnesium oxide powder is greater than 95-96%. The ratio is 7:1;

[0034] 2) The wet material is continuously transported into the flash dryer through the filter cake feeder. Under the combined action of the rotating blade of the main engine and the high-speed hot air flow, the wet material is quickly dispersed into powder, which expands the evaporation area, and the material is heated with hot air. High-speed mass transfer and heat transfer, instantaneous vaporization and evaporation of water molecules, drying and dehydration to ≤1~0.5%, and materials that meet the requirements of restoring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com