Patents

Literature

44 results about "Reactive magnesia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive magnesia is also variously known as caustic calcined magnesia, caustic magnesia or CCM. The temperature of firing has a greater influence on reactivity than grind size as excess energy goes into lattice energy.

Reactive magnesium oxide cements

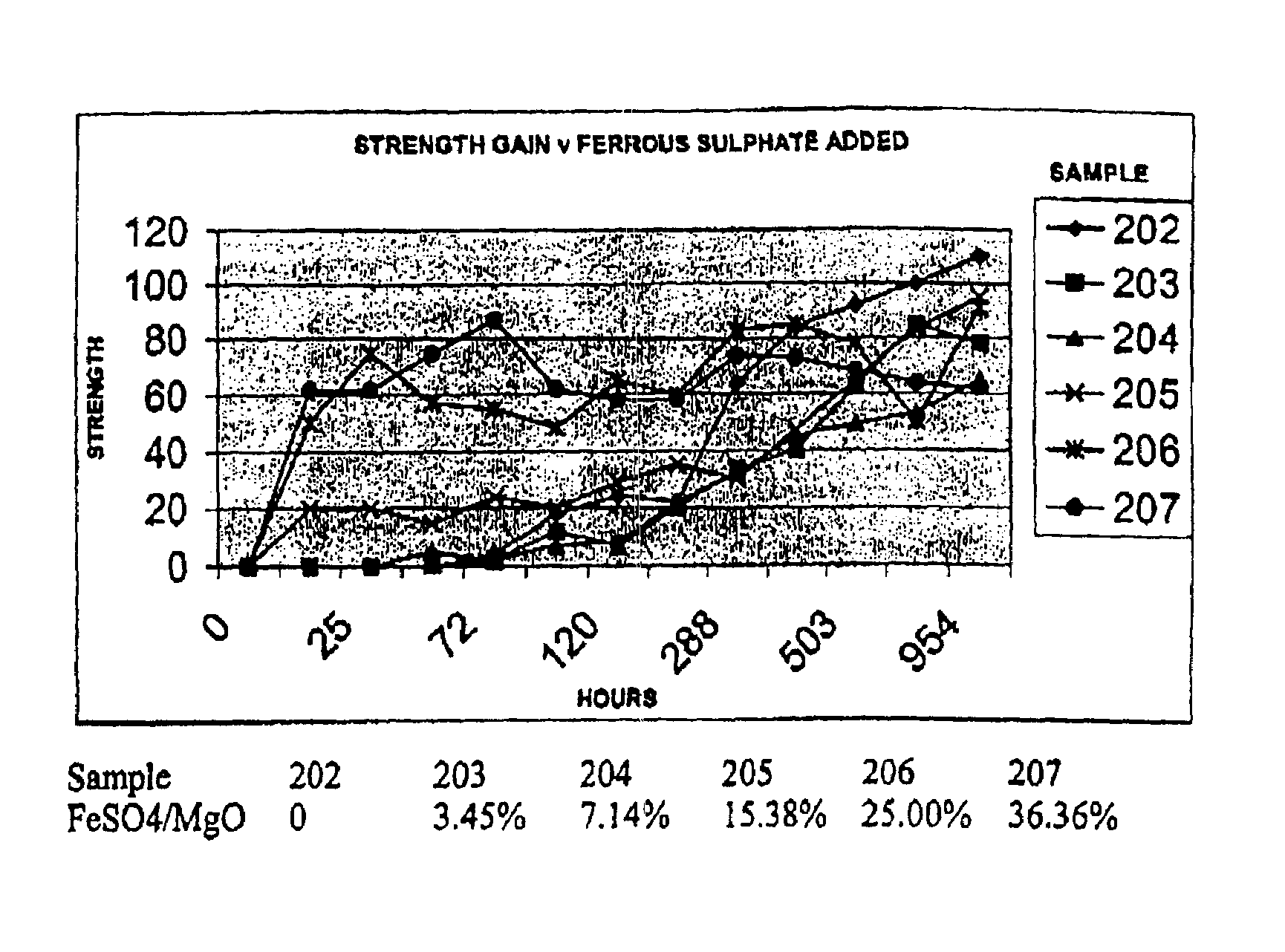

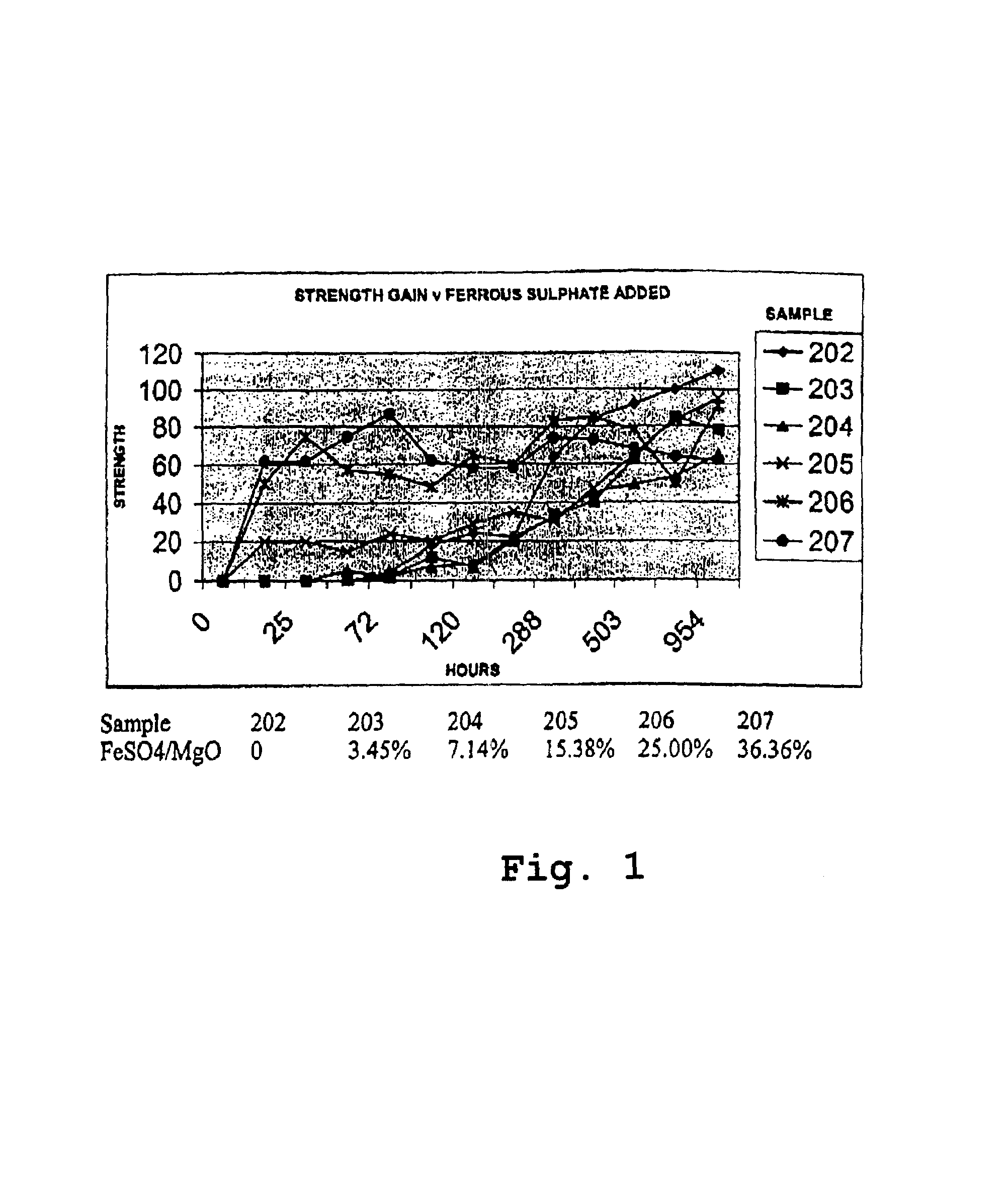

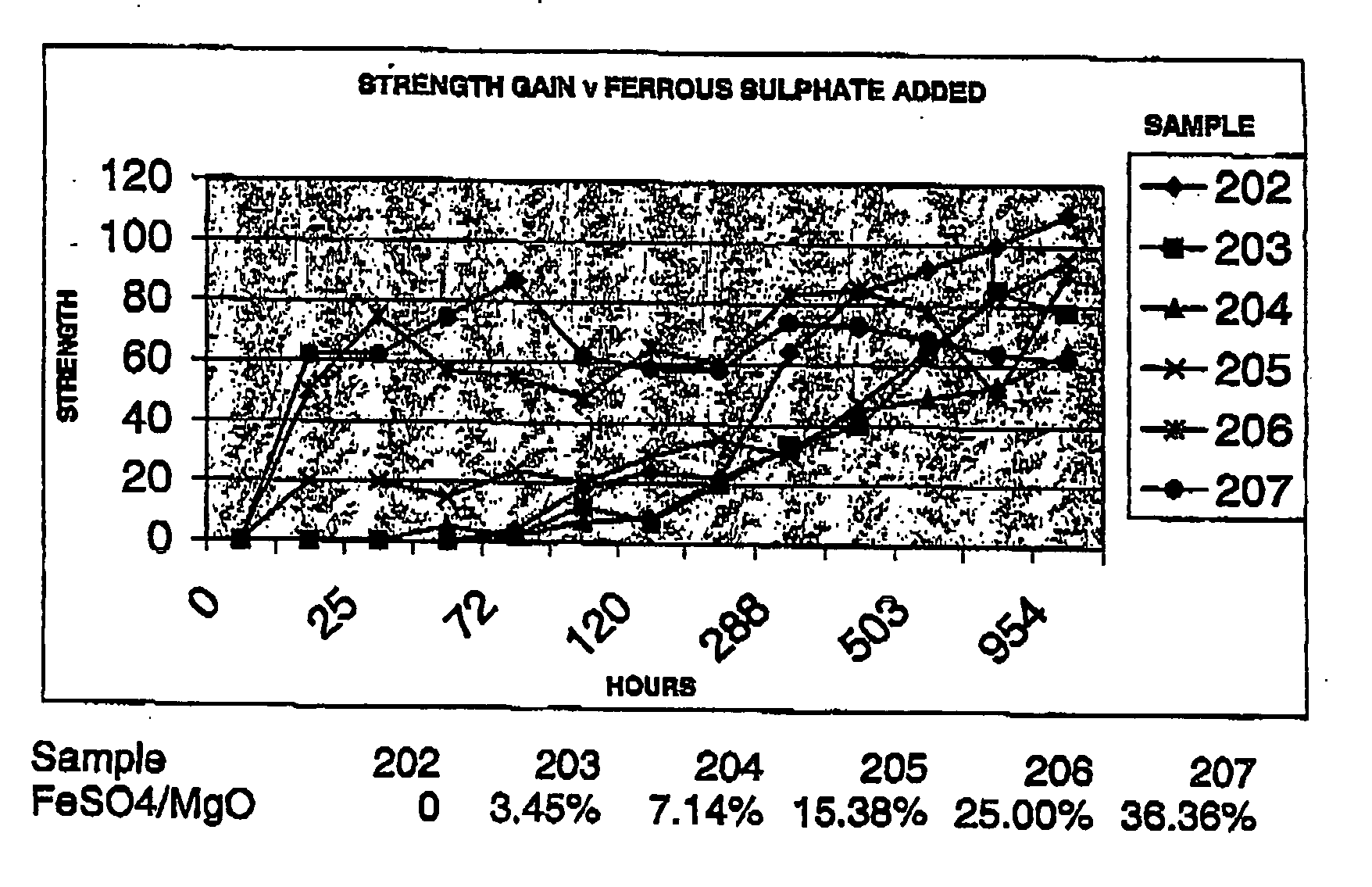

Novel hydraulic cements are disclosed that include reactive magnesium oxide prepared by low temperature calcination. The cements can be formulated to suit a large number of applications with various setting times, strength and levels of sustainability either by adding iron salts such as ferrous sulfate or blending with other compatible faster setting hydraulic cements such as Portland cement or by using both methods.The compositions are able to incorporate relatively large amounts of low cost pozzolans such as fly ash to advantage as well as wastes. Many excellent properties are exhibited and in particular good comprehensive strength and resistance to sulfates is able to be achieved.

Owner:TECECO

Reactive magnesium oxide cements

Novel hydraulic cements are disclosed that include reactive magnesium oxide prepared by low temperature calcination. The cements can be formulated to suit a large number of applications with various setting times, strength and levels of sustainability either by adding iron salts such as ferrous sulfate or blending with other compatible faster setting hydraulic cements such as Portland cement or by using both methods. The compositions are able to incorporate relatively large amounts of low cost pozzolans such as fly ash to advantage as well as wastes. Many excellent properties are exhibited and in particular good comprehensive strength and resistance to sulfates is able to be achieved.

Owner:TECECO

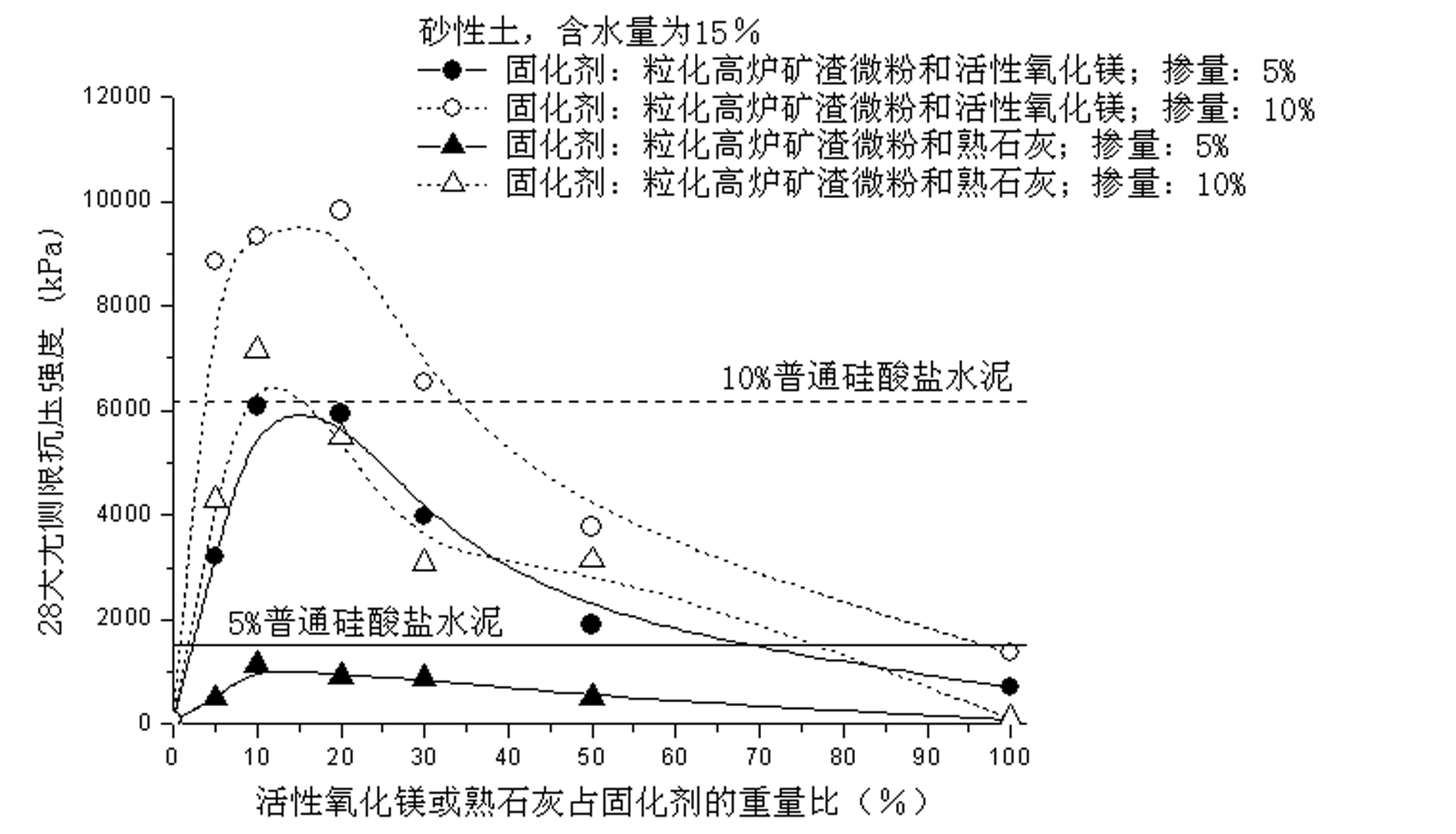

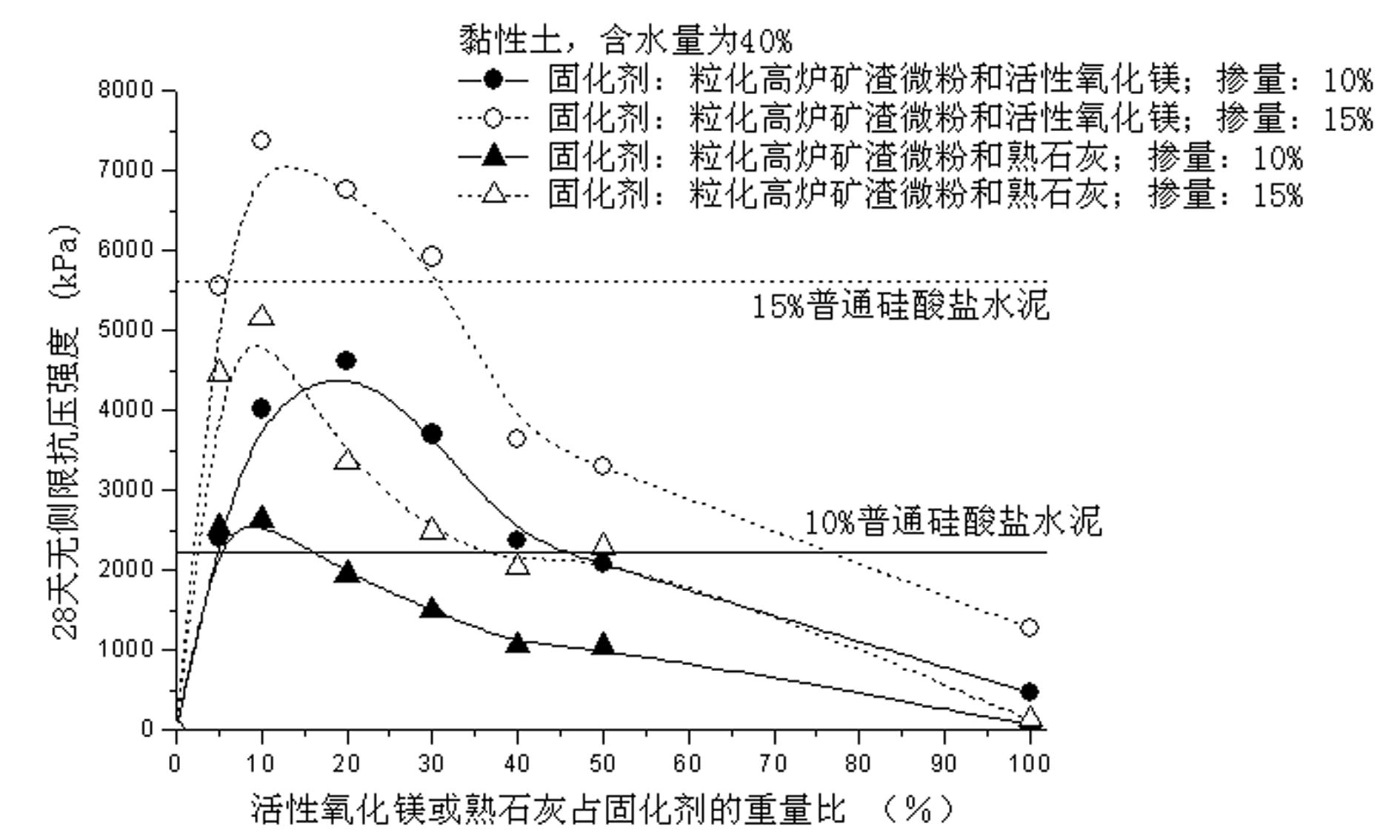

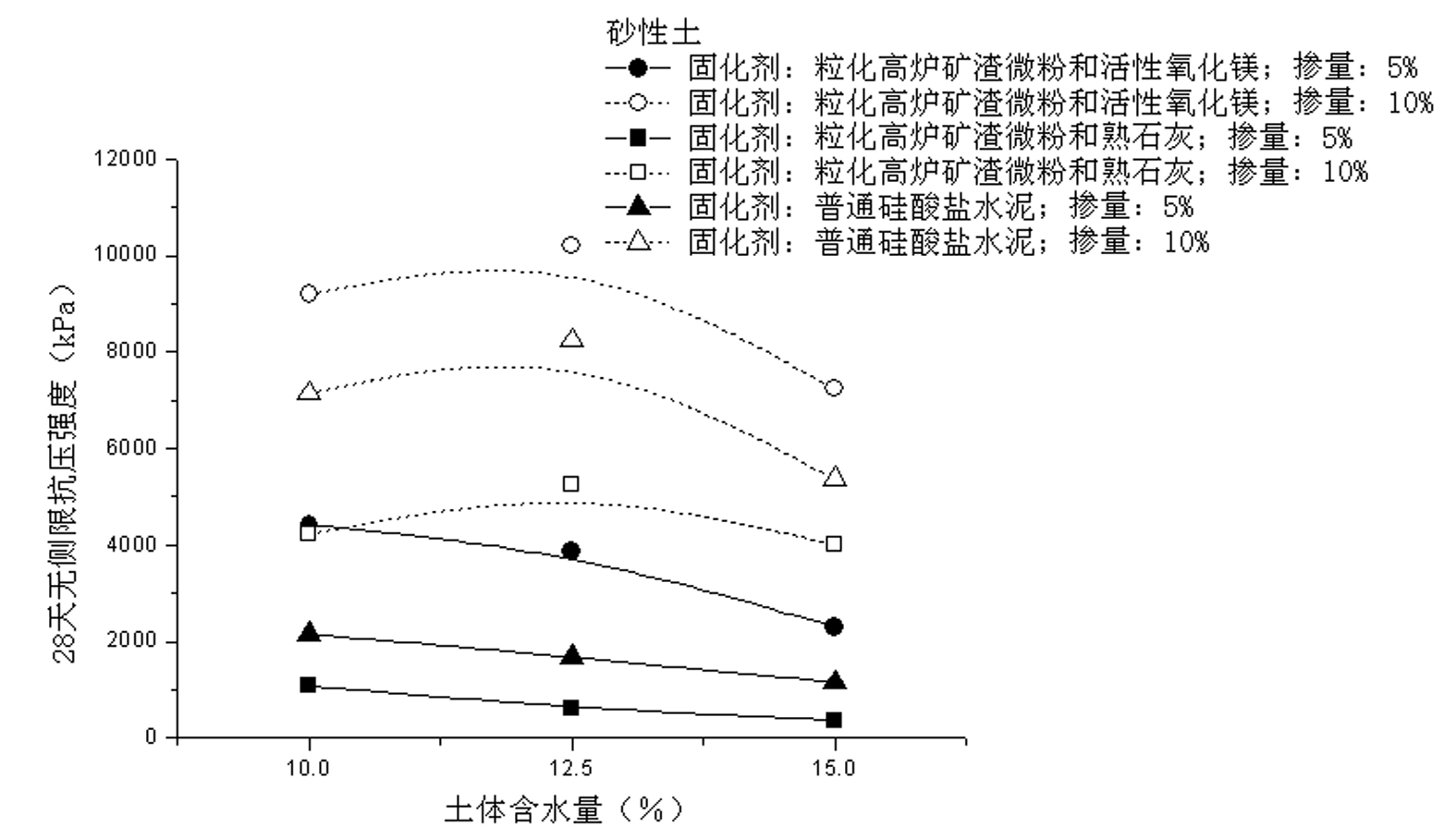

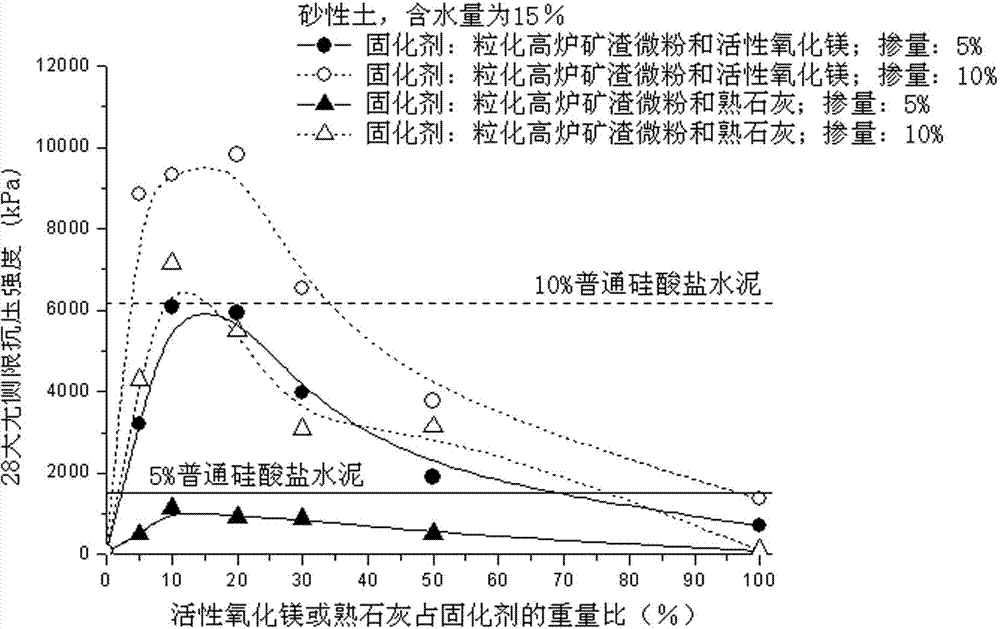

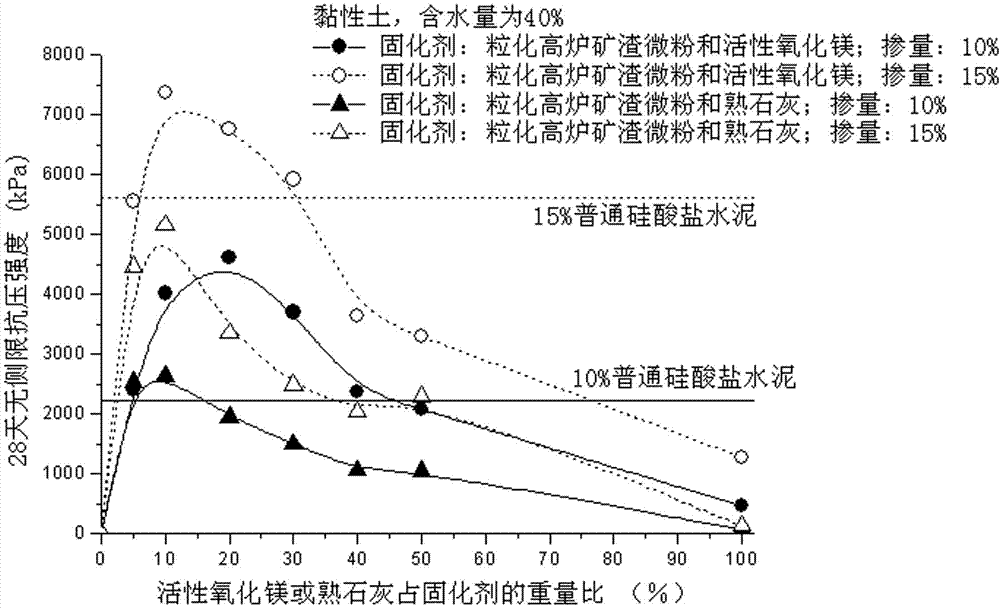

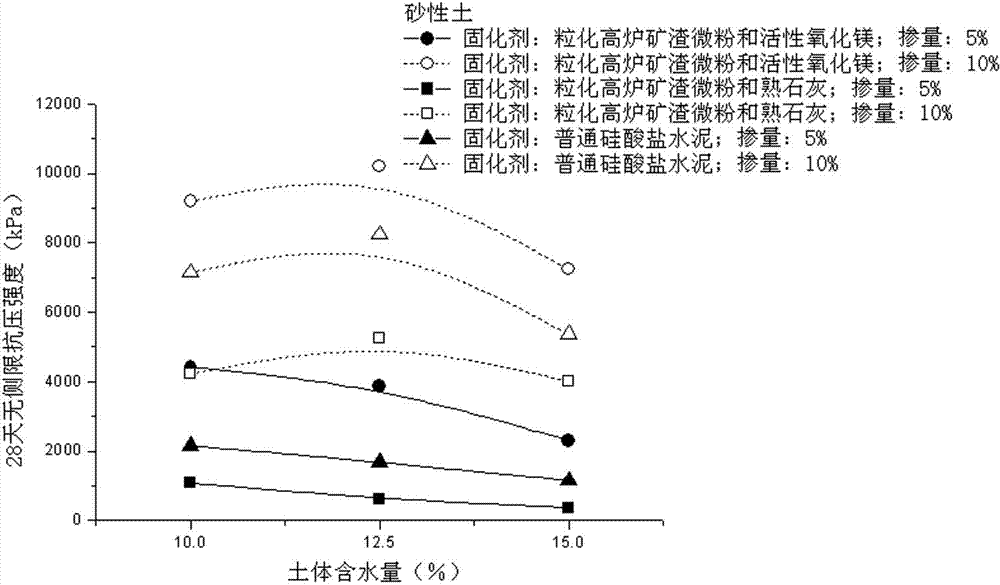

Green low-carbon curing agent for soil curing

ActiveCN102071029AEmission reductionLow costBuilding constructionsOrganic fertilisersSoil scienceSlag

The invention discloses a green low-carbon curing agent for soil curing. The soil curing agent is characterized by comprising granulated blast furnace slag micro powder and exciting agent, wherein the exciting agent comprises active magnesia, the exciting agent is 30 to 5 percent of the total mass of the soil curing agent, and the granulated blast furnace slag micro powder is 70 to 95 percent of the total mass of the curing agent. The exciting agent comprises slaked lime, wherein the slaked lime is 10 to 90 percent of the mass of the active magnesia. The exciting agent comprises calcined lime, wherein the calcined lime is 7 to 66 percent of the mass of the active magnesia.

Owner:SOUTHEAST UNIV

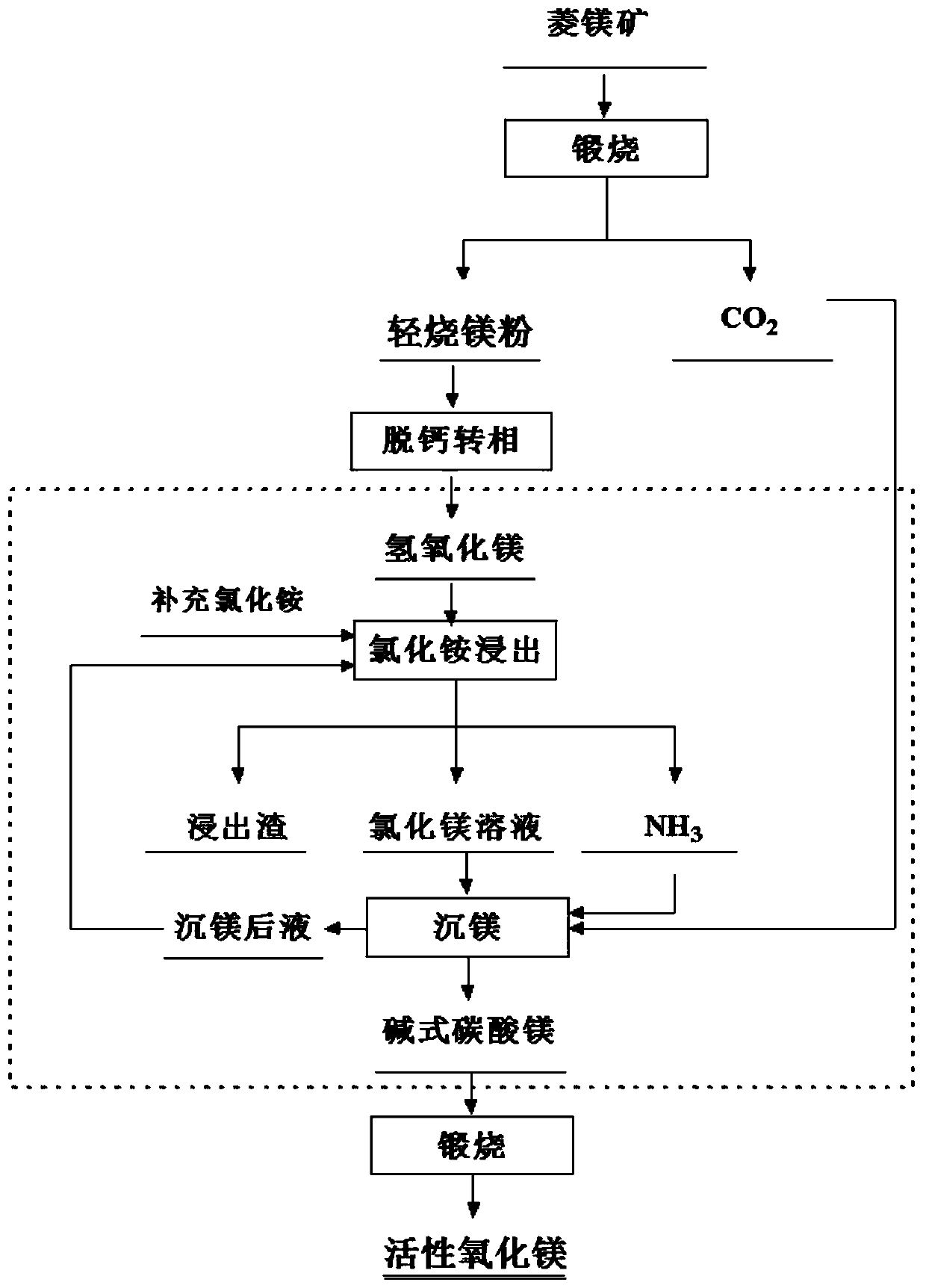

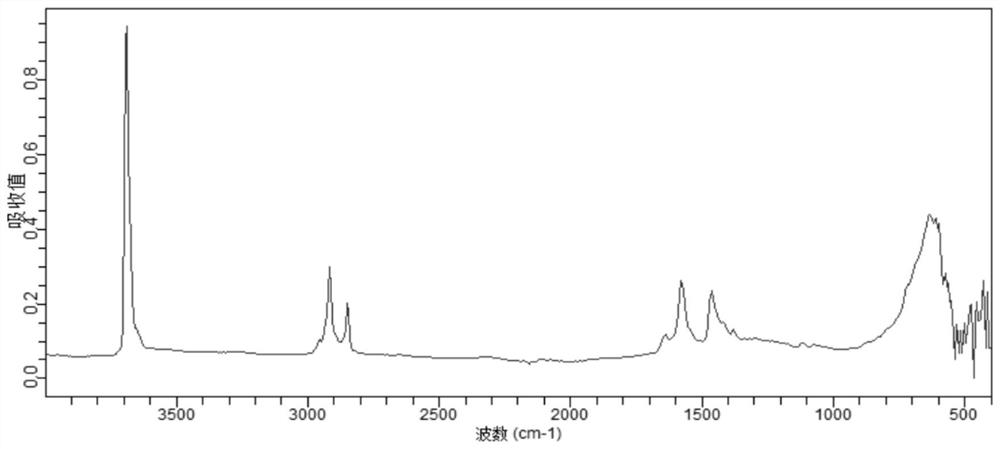

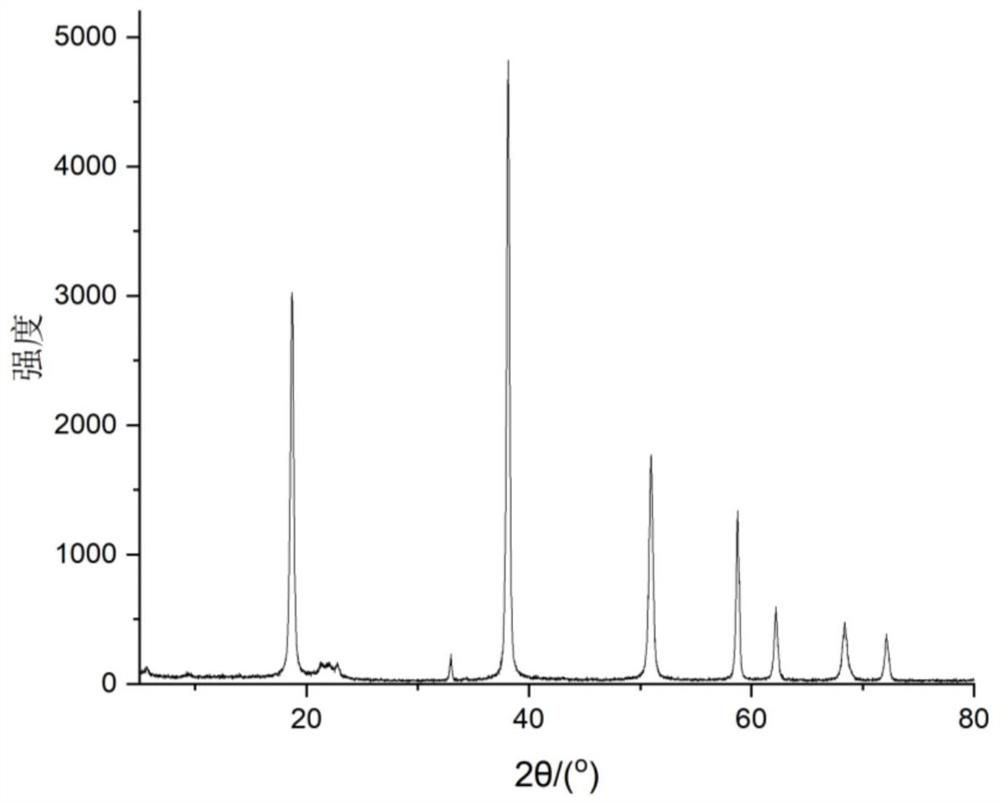

Activated magnesia, and preparation method and application thereof

ActiveCN110921688AHigh purityHigh activityProcess efficiency improvementNickel oxides/hydroxidesCarbonateMagnesium chlorate

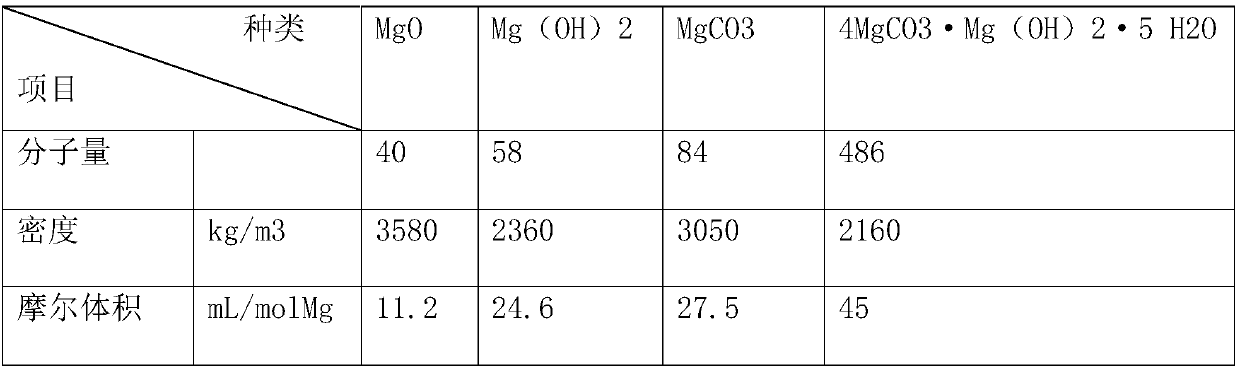

The invention relates to the technical field of inorganic salts, and provides an activated magnesia, and a preparation method and an application thereof. The preparation method comprises the followingsteps: mixing light burned magnesia powder, magnesium chloride and water, and carrying out a hydrothermal reaction to obtain a magnesium hydroxide precipitate and a calcium chloride solution; soakingthe magnesium hydroxide precipitate in an aqueous ammonium chloride solution for leaching to obtain a magnesium chloride solution, ammonia gas and leaching residues; mixing the magnesium chloride solution, ammonia gas and carbon dioxide, and carrying out a magnesium precipitation reaction to obtain a basic magnesium carbonate precipitate; and sequentially drying and calcining the basic magnesiumcarbonate precipitate to obtain the activated magnesia. Insoluble silicon, calcium and other impurities are left in ammonium chloride leaching residues through magnesium chloride decalcifying and ammonium chloride magnesium leaching, so the improvement of the purity and activity of the final product is benefited. The magnesia obtained through the method is high in purity and activity, the mass content of MgO in the activated magnesia is larger than or equal to 98%, and the activity is larger than 95%.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Magnesium oxysulfate cement-based building block and production method thereof

The invention discloses a magnesium oxysulfate cement-based building block. The magnesium oxysulfate cement-based building block comprises 100 parts of active magnesium oxide powder, 140-270 parts of a filler, 1-2 parts of a foaming agent and 200-600 parts of an aqueous solution of magnesium sulfate. The magnesium oxysulfate cement-based building block has small unit weight, and can effectively reduce the bearing of a building. The invention also discloses a production method of the magnesium oxysulfate cement-based building block. The production method comprises the following steps: 1, uniformly mixing 100 parts of the active magnesium oxide powder with 140-270 parts of the filler to obtain a first mixture; 2, adding 200-600 parts of the aqueous solution of magnesium sulfate to the first mixture, and uniformly mixing to obtain a second mixture; 3, adding 1-2 parts of the foaming agent to the second mixture, and uniformly mixing to obtain a third mixture; and 4, placing the third mixture in a die, and curing the third mixture to obtain the magnesium oxysulfate cement-based building block. The production method has the advantages of no high-temperature or high-pressure curing technology and low production cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Chlorinated polyethylene cable material

InactiveCN107778674ARaise the vulcanization temperatureImprove vulcanization efficiencyPlastic/resin/waxes insulatorsAntioxidantEngineering

The invention discloses a chlorinated polyethylene cable material. The cable material comprises the following components in parts by weight: 34-38 parts of chlorinated polyethylene, 2-5 parts of ethylene-propylene-diene monomer, 10-15 parts of active calcium carbonate, 20-25 parts of ultra-fine talc powder, 10-15 parts of ultra-fine kaolin, 3-5 parts of carbon black, 1-1.5 parts of bis(tert-butylperoxyisopropyl)benzene, 1-1.5 parts of triallyl isocyanurate, 3-6 parts of dioctyl adipate or bis(2-ethylhexyl)adipate, 3-6 parts of active magnesium oxide, 0.5-1 part of calcium stearate, 0.5-1 partof an antioxidant and 0.5-1 part of PE wax. The cable material produced by utilizing the formula provided by the invention has good electrical performance and mechanical physical properties, and goodweathering resistance and high-temperature resistance.

Owner:嘉兴创奇电缆有限公司

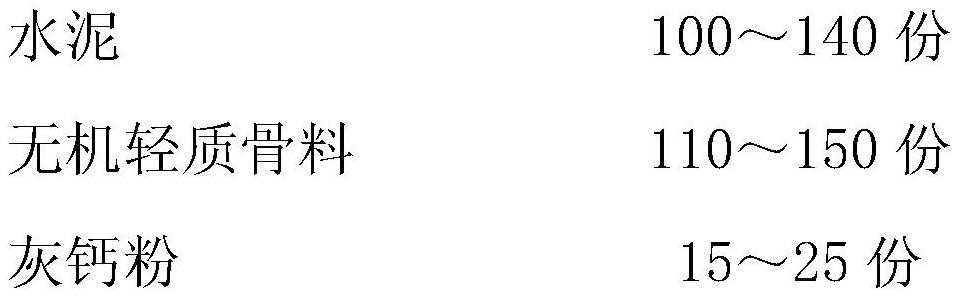

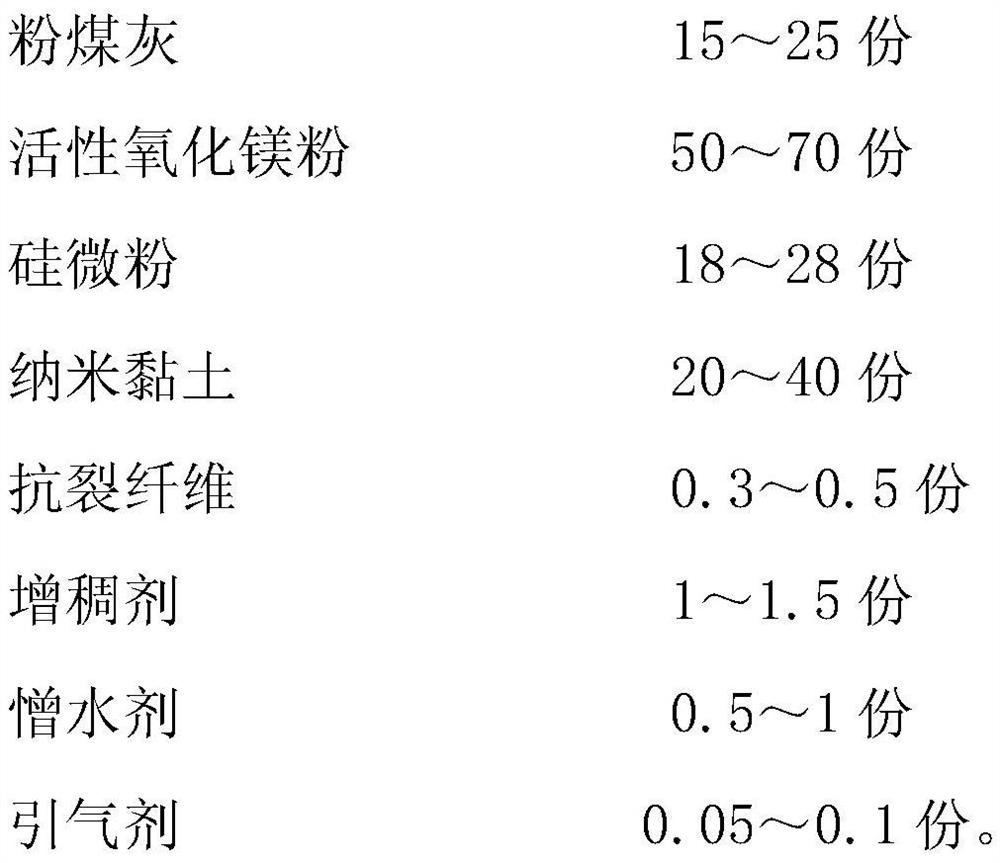

Inorganic active thermal-insulation mortar

The invention provides inorganic active thermal-insulation mortar. The inorganic active thermal-insulation mortar is prepared from the following raw materials in parts by weight: 100 to 140 parts of cement, 110 to 150 parts of inorganic lightweight aggregate, 15 to 25 parts of ash calcium powder, 15 to 25 parts of fly ash, 50 to 70 parts of active magnesium oxide powder, 18 to 28 parts of silica powder, 20 to 40 parts of nano clay, 0.3 to 0.5 part of anti-crack fibers, 1 to 1.5 parts of a thickening agent, 0.5 to 1 part of a water repellent and 0.05 to 0.1 part of an air entraining agent. The inorganic active thermal-insulation mortar provided by the invention has the characteristics of environmental protection, no toxicity, aging resistance, pressure resistance, impermeability and high strength, is safe and reliable, realizes A-level fire prevention, presents good heat insulation performance and has a heat conductivity coefficient as low as 0.059; the waterproof and anti-cracking performance of the motor is excellent, a waterproof film is formed on the surface of the produced motor after the motor is naturally dried, and the waterproof and anti-cracking performance is achieved; and the anti-freezing and anti-thawing performance of the motor is excellent, and construction can be performed at a temperature of -15 DEG C.

Owner:河南省宜居建材科技有限公司

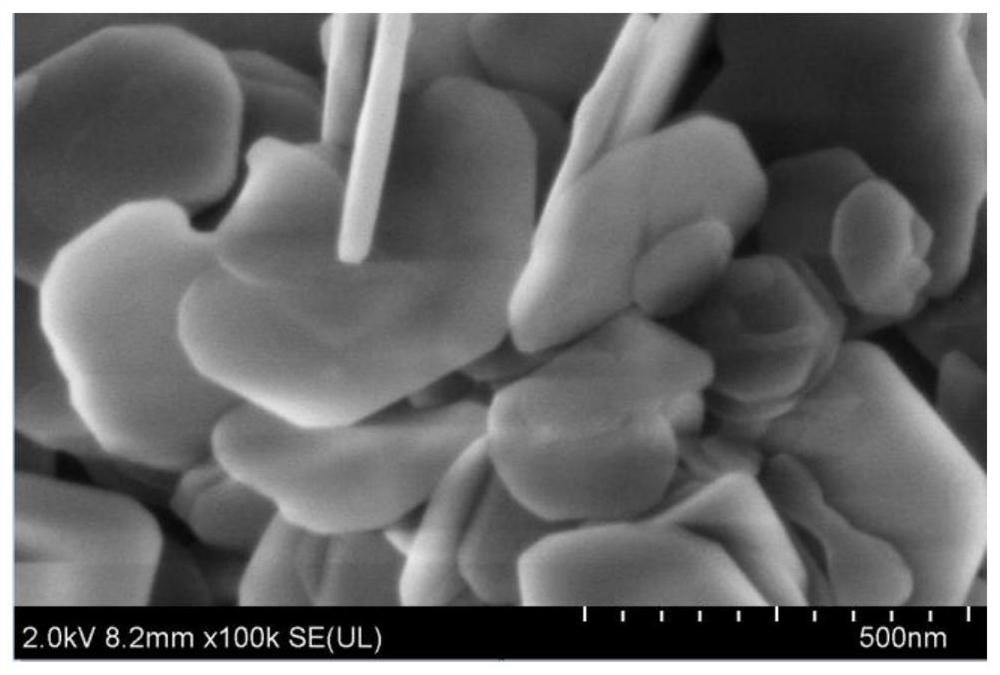

Method for preparing modified magnesium hydroxide flame retardant from salt lake produced light-burned active magnesium oxide

PendingCN113072084AReduce typesThe production will notMagnesium hydroxideSodium stearateStearic acid

The invention discloses a method for preparing a modified magnesium hydroxide flame retardant from salt lake produced light-burned active magnesium oxide. The method comprises the following steps: adding a proper amount of deionized water into a reaction kettle, weighing the salt lake produced light-burned active magnesium oxide as a raw material, adding the weighed salt lake produced light-burned active magnesium oxide into the reaction kettle, uniformly stirring, weighing a modifier according to the amount (molar ratio) of 1-3% of magnesium oxide, adding the modifier into the reaction kettle, and reacting for a specified time at a certain temperature and a certain stirring speed; and filtering, washing and drying the reaction product to obtain the hexagonal flaky modified magnesium hydroxide flame retardant. The salt lake produced light calcined magnesia is used as a raw material, stearic acid, sodium stearate, oleic acid, sodium oleate and silane are used as modifiers, the process is simple, the needed raw materials are few in variety, the production cost is low, and the obtained hexagonal flaky oily magnesium hydroxide is high in purity and good in compatibility with high polymer materials and has great application value and market value.

Owner:WESTERN MINING GROUP +2

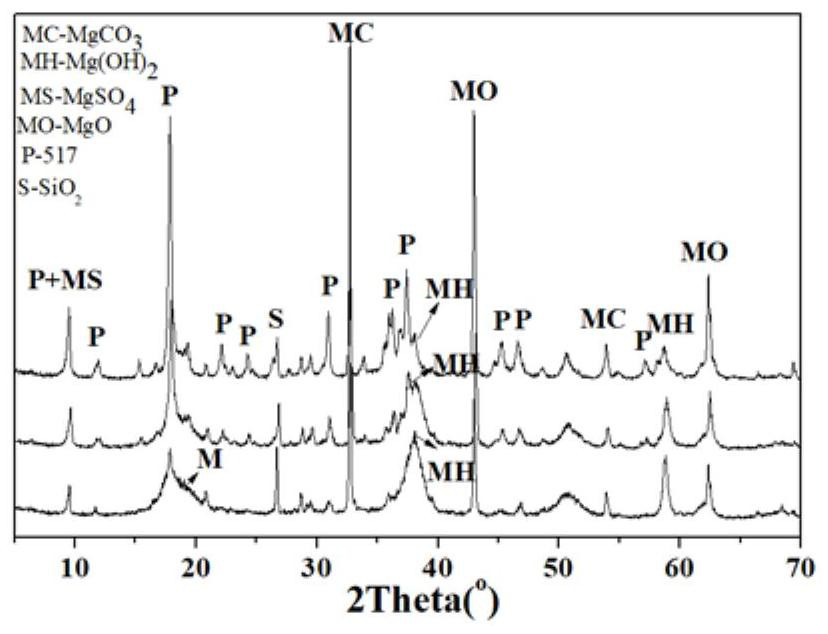

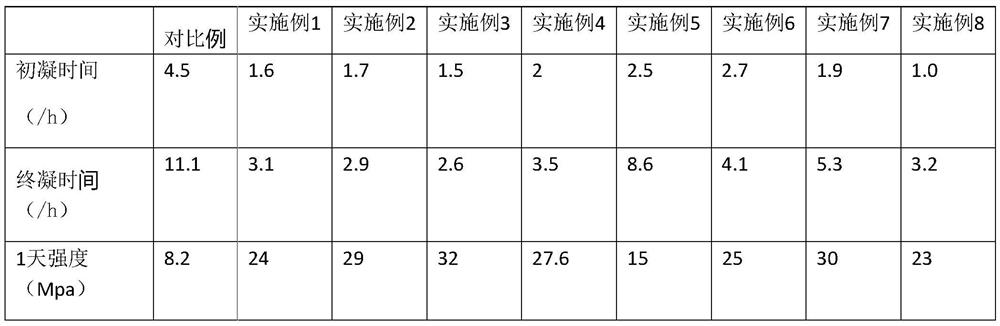

Basic magnesium sulfate cement and preparation method thereof

The invention discloses basic magnesium sulfate cement which comprises the following components in parts by mass: 100 parts of active magnesium oxide powder, 30-100 parts of a magnesium sulfate solution, 0.01-0.05 part of an additive and 0.1-5 parts of a magnesium oxysulfate crystal nucleating agent, the magnesium sulfate solution is an aqueous solution of crystallized magnesium sulfate, and the mass fraction of the magnesium sulfate solution is 15-20%; the magnesium oxysulfate crystal nucleating agent is prepared by the following method: step 1, mixing 50-100 parts by mass of light calcined magnesite powder with the active MgO mass fraction of 55%-85%, 70-300 parts by mass of a magnesium sulfate solution with the active MgO mass fraction of 10%-25% and 0.01-0.05 part by mass of phosphoricacid; and 2, putting the paste obtained in the step 1 into a sealed bag, curing at 20+ / -3 DEG C for 28 days to promote hardening, and finally grinding the hardened sample into powder through ball milling to obtain the actual magnesium oxysulfide crystal nucleating agent. The basic magnesium sulfate cement has the advantages of short setting time, early strength, high strength and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

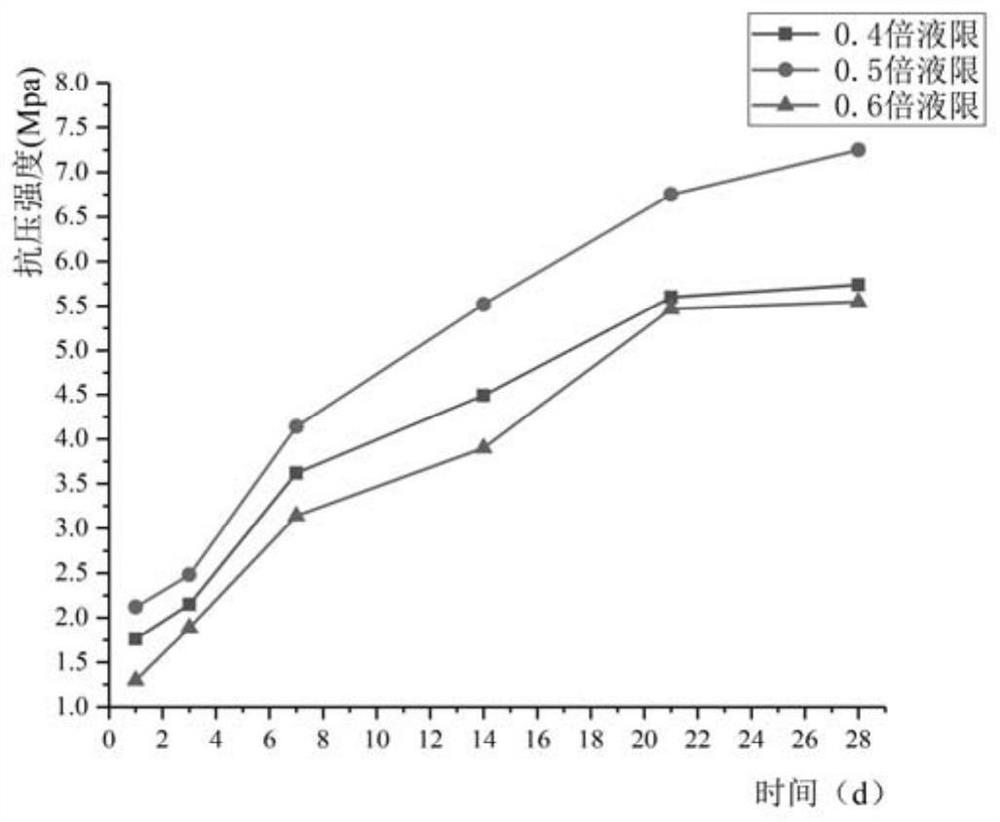

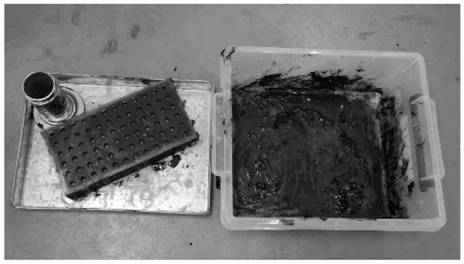

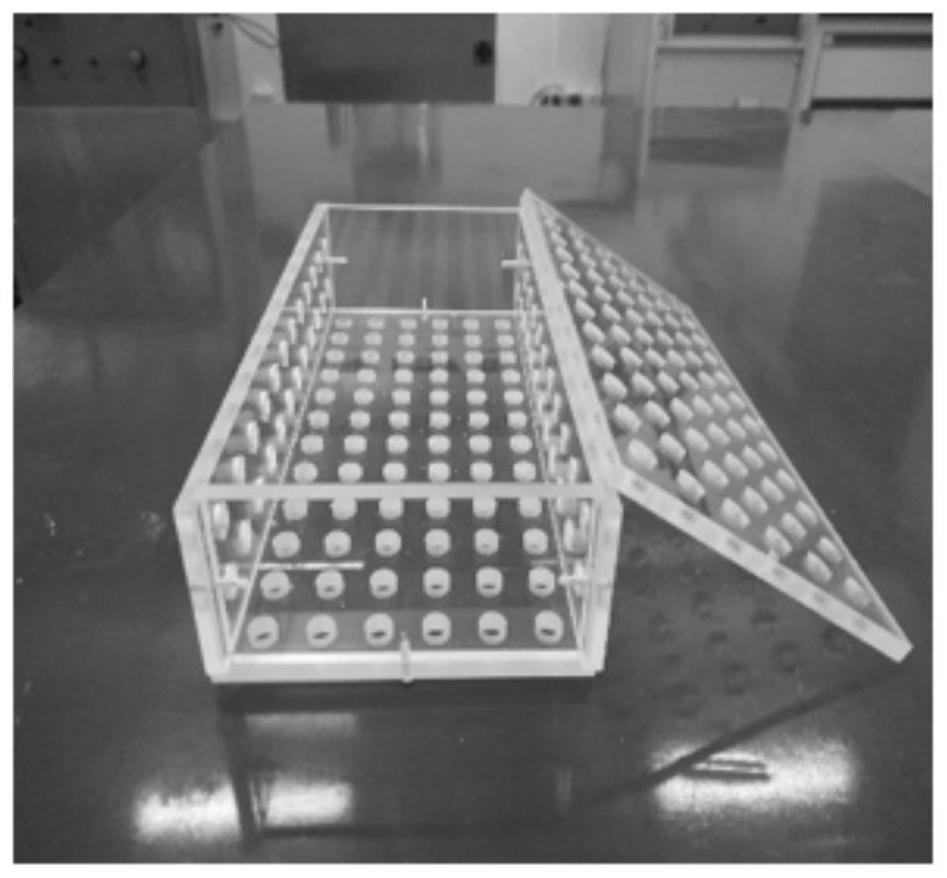

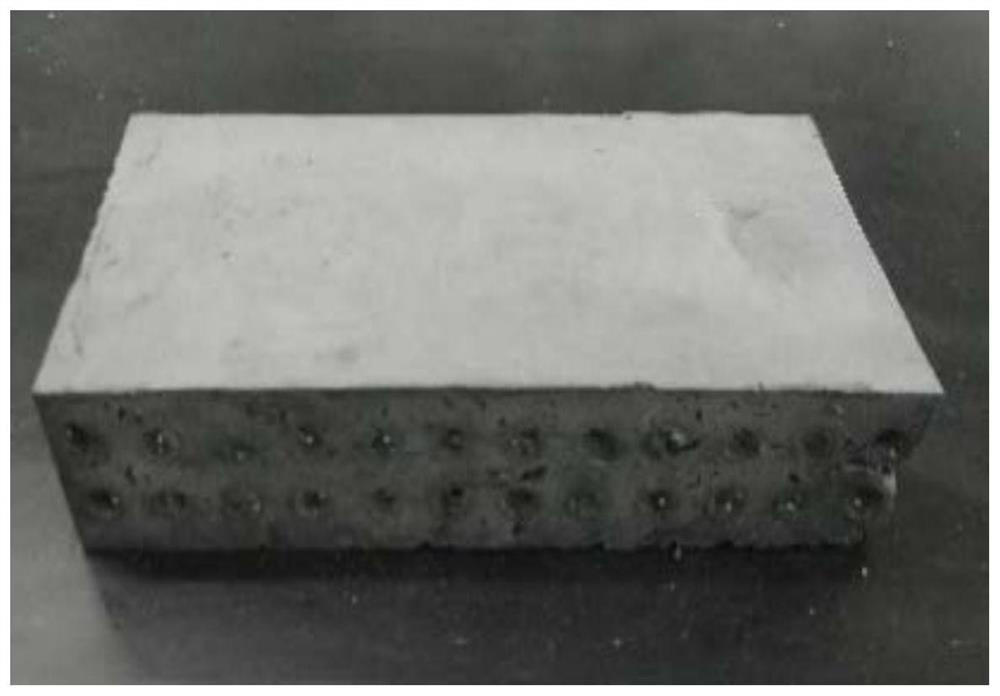

Negative carbon emission modified raw soil-based building block and manufacturing method thereof

The invention discloses a negative carbon emission modified immature soil base building block and a manufacturing method thereof, and the negative carbon emission modified immature soil base building block is prepared from active magnesium oxide, cement, fly ash, immature soil and the like. The manufacturing method comprises the following steps: (1) selecting silty soil or clay, silty clay, expansive soil and the like, and passing through a screen with the aperture of 2mm; 2) preparing a mixture of magnesium oxide, cement, fly ash and immature soil according to a mass ratio of 7: 7: 6: 80, uniformly stirring, adding water, and stirring again to obtain a modified immature soil-based material; (3) putting the modified raw soil base material into a customized mold to be pressed into raw soil building blocks; and 4) putting the pressed building blocks into a carbonization box for carbonization treatment. The obtained modified raw soil building block has the characteristics of negative carbon emission, early strength, high performance, recyclability and the like. And the negative carbon emission modified immature soil base building block is environment-friendly, contributes to realizing carbon peak reaching and carbon neutralization, and can be widely applied to the fields of using local materials for earthwork, saving energy, protecting environment and the like.

Owner:扬州邗江中科南工建设工程与信息化研究中心

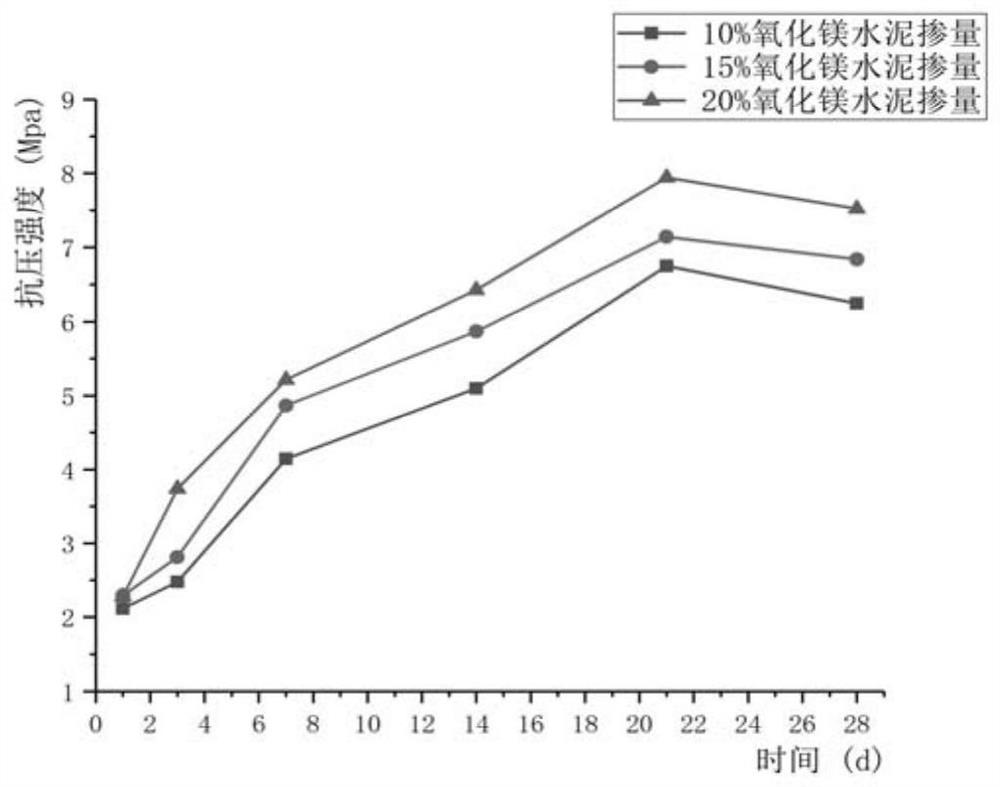

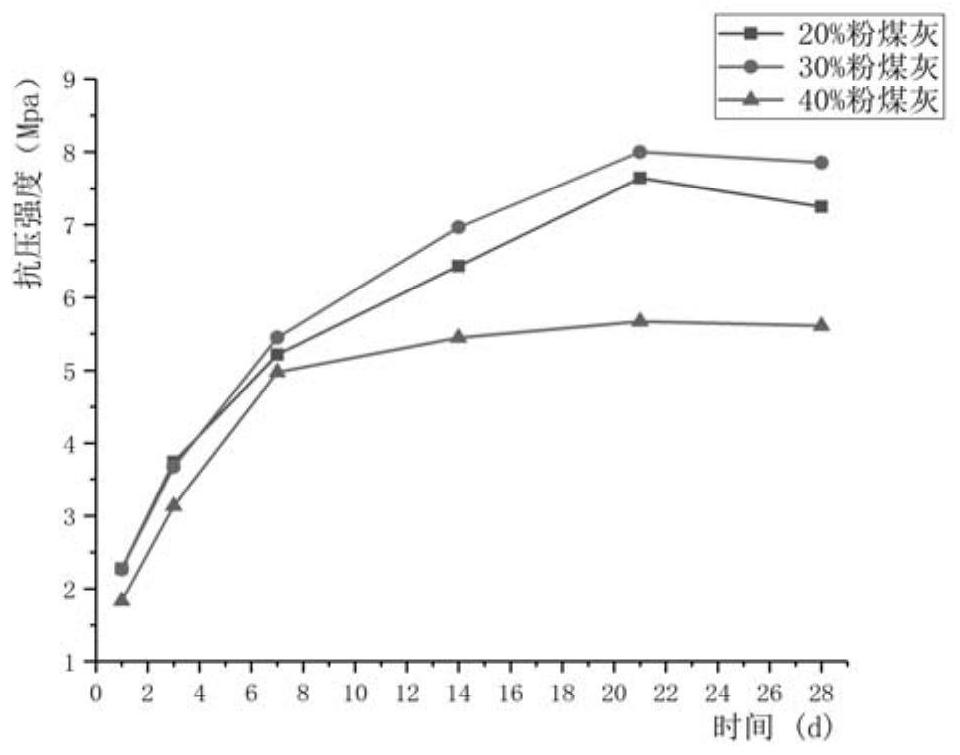

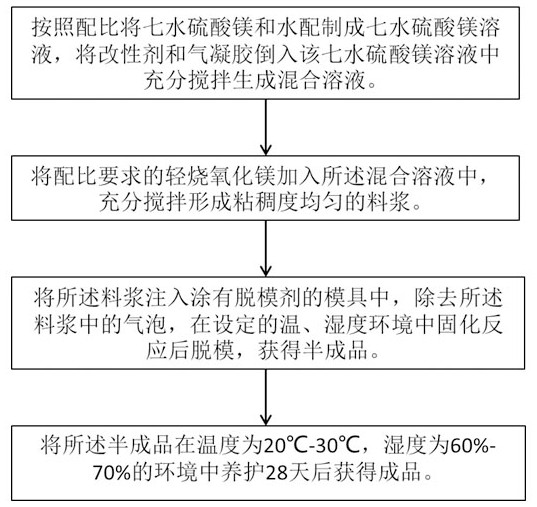

Preparation method of magnesium oxysulfate cementing material adopting silicon dioxide aerogel and building component

ActiveCN113979716AReduce thermal efficiencyImprove mechanical propertiesSolid waste managementCitric Acid / tartaric acidPhysical chemistry

The invention provides a magnesium oxysulfate cementing material adopting silicon dioxide aerogel, a preparation method of the magnesium oxysulfate cementing material and a building component. The magnesium oxysulfate cementing material adopting the silicon dioxide aerogel comprises a component A and a component B, wherein the component A comprises, by mole, 1 part of magnesium sulfate heptahydrate, 8-12 parts of light calcined magnesia and 15-22 parts of water, and the content of active magnesium oxide in the light calcined magnesia ranges from 55% to 65%; the component B comprises a modifier and aerogel; the modifier is one of citric acid, tartaric acid and sodium malate or a mixture of the citric acid and the tartaric acid, the citric acid accounts for 0.7%-0.8% of the mass of the light calcined magnesia, and the tartaric acid and the sodium malate both account for 1.3%-1.8% of the mass of the light calcined magnesia; and the mass of the aerogel is 6% or less of that of the light calcined magnesia. According to the magnesium oxysulfate cementing material adopting the silicon dioxide aerogel, the mechanical property and the thermal insulation property of the magnesium oxysulfate cementing material can be improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

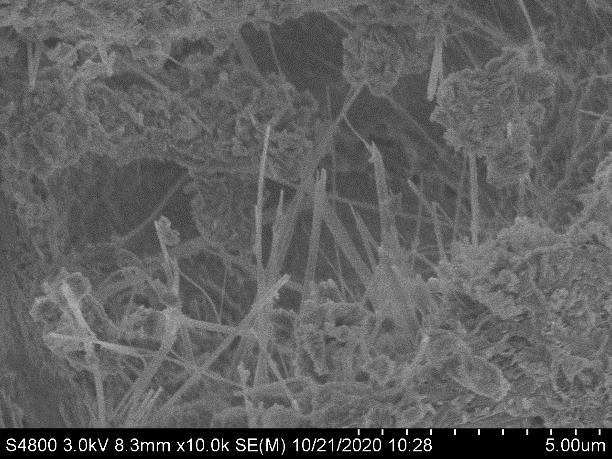

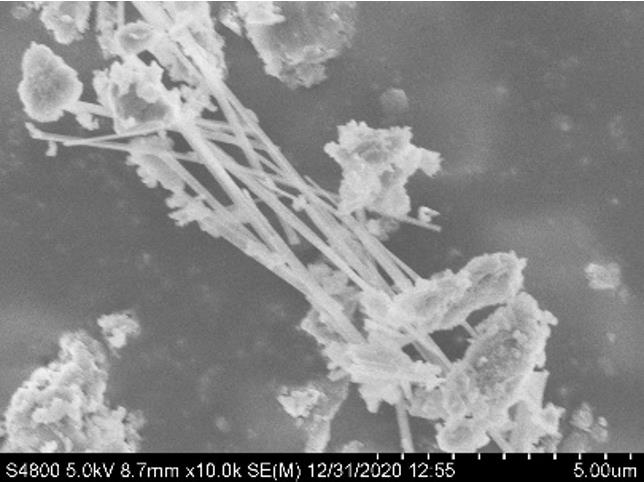

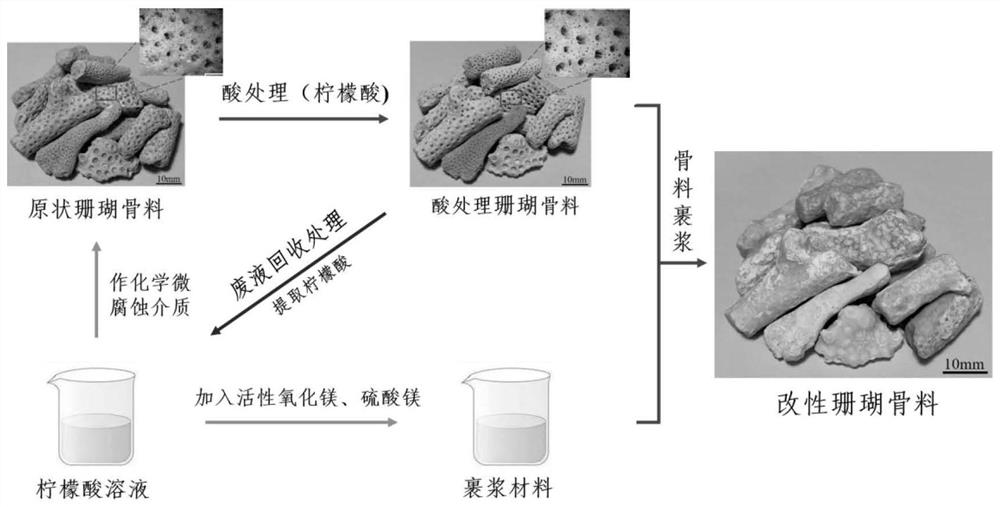

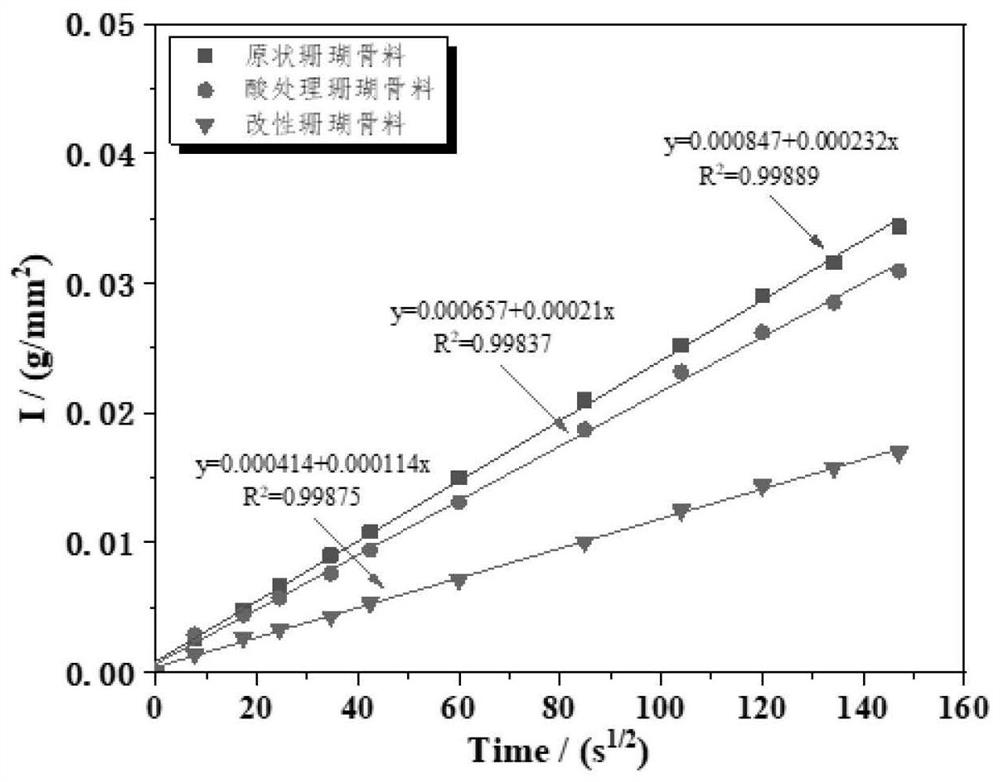

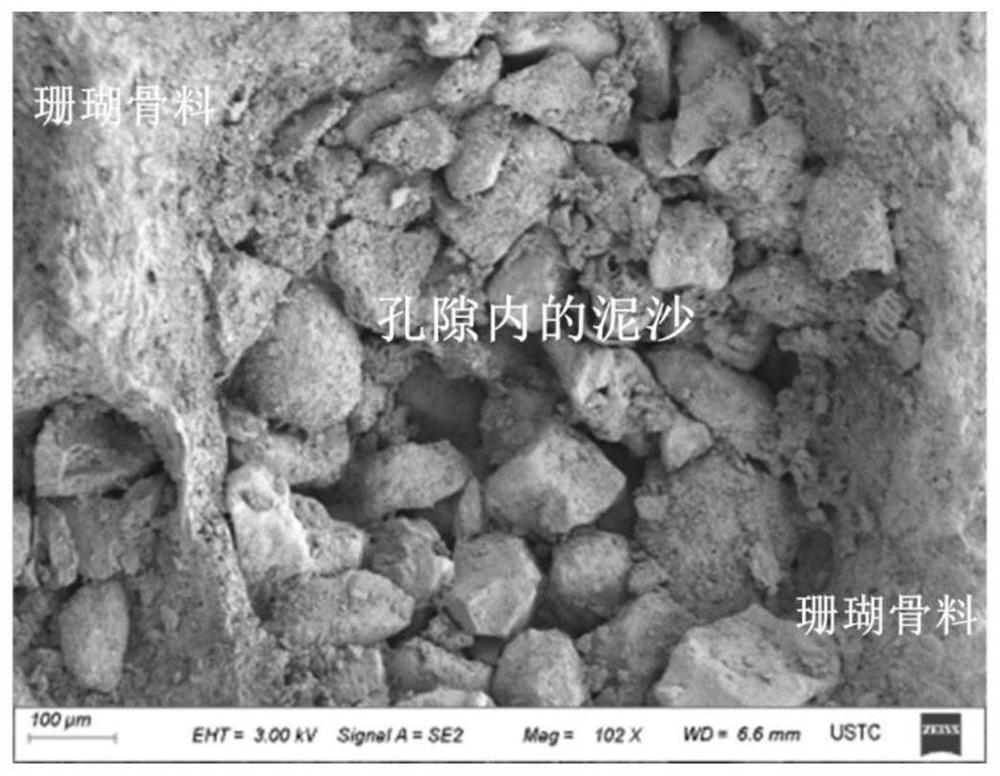

Preparation method of modified coral aggregate and basic magnesium sulfate cement gradient composite coral aggregate concrete

The invention relates to the technical field of concrete, and particularly discloses a preparation method of modified coral aggregate and basic magnesium sulfate cement gradient composite coral aggregate concrete. The preparation method comprises the following steps: firstly, soaking original coral aggregate in a weak acid aqueous solution for micro-corrosion to obtain acid-treated coral aggregate, and then soaking the acid-treated coral aggregate in a basic magnesium sulfate cement-based slurry coating material prepared from active magnesium oxide, magnesium sulfate heptahydrate, citric acid and water to obtain modified coral aggregate; and preparing the basic magnesium sulfate cement-based coral aggregate concrete from the aggregate, active magnesium oxide, magnesium sulfate heptahydrate, citric acid and water as raw materials. Based on a core admixture and a gradient composite technology, the invention provides a method for enabling basic magnesium sulfate cement whiskers to grow in communicated pores of coral aggregate, and external pores of the coral aggregate are fully filled with gradient composite basic magnesium sulfate cement. The effects of reducing the overall porosity of the coral aggregate concrete, optimizing the concrete interface transition area and improving the working performance and the mechanical property of the concrete are achieved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

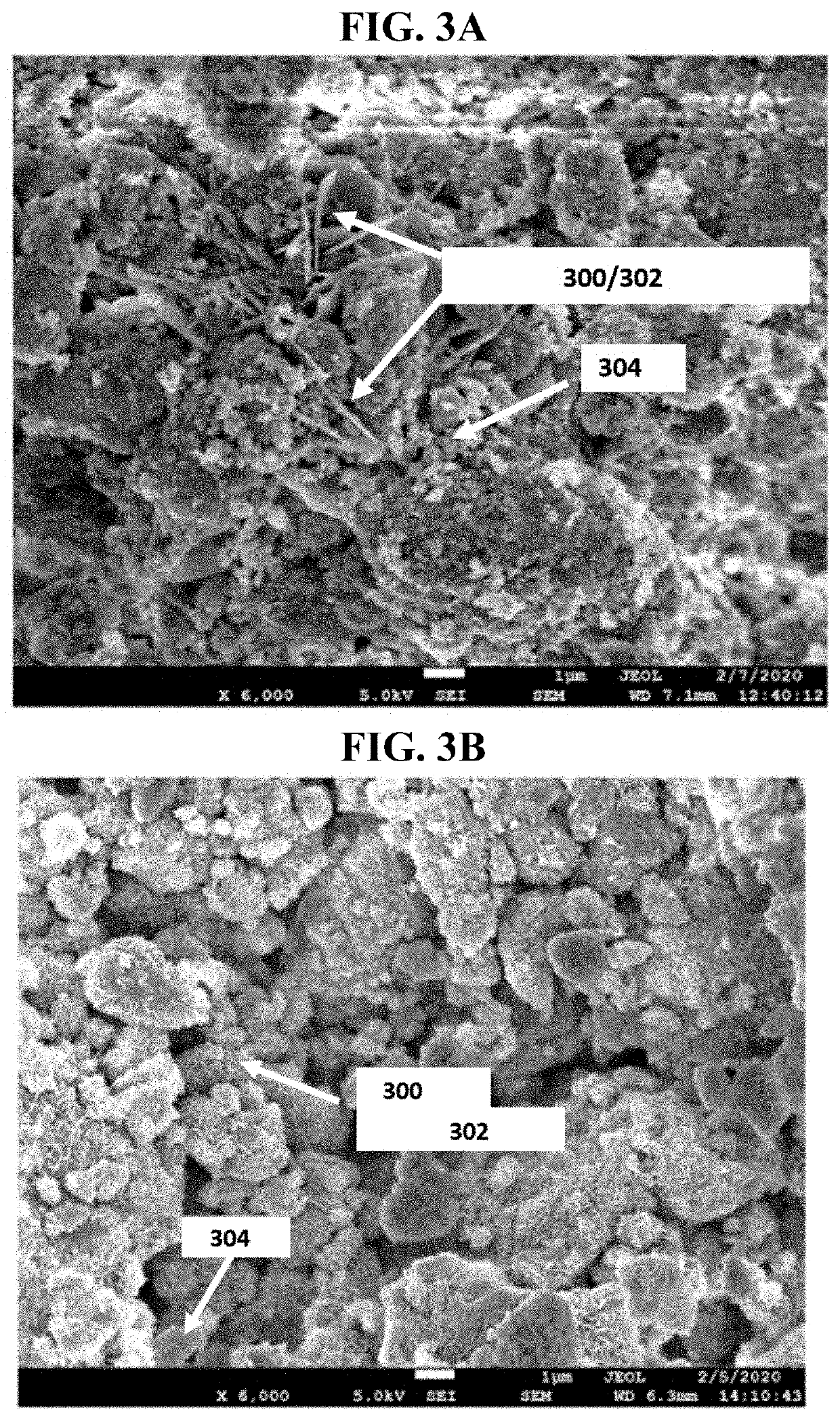

Method of Reducing Cadmium and Lead in Hazardous Waste From a Foundry or Steel Mill Using Micronized Particulate Reactive Magnesium Oxide or Magnesium Hydroxide Having High Surface Area

Methods of using micronized particulate, reactive magnesium oxide or magnesium hydroxide to treat hazardous waste having high zinc content and hazardous levels of cadmium and lead. The reactive magnesium oxide or magnesium hydroxide has a median particle size in the range of 2-3 μm. The hazardous waste material is generated by a foundry or steel mill.

Owner:STANFORTH ROBERT

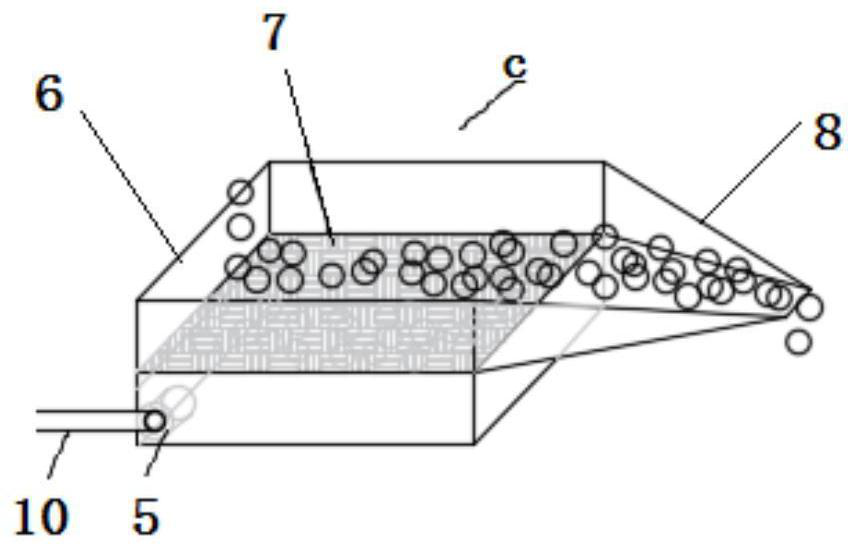

Mine filling method, material and equipment

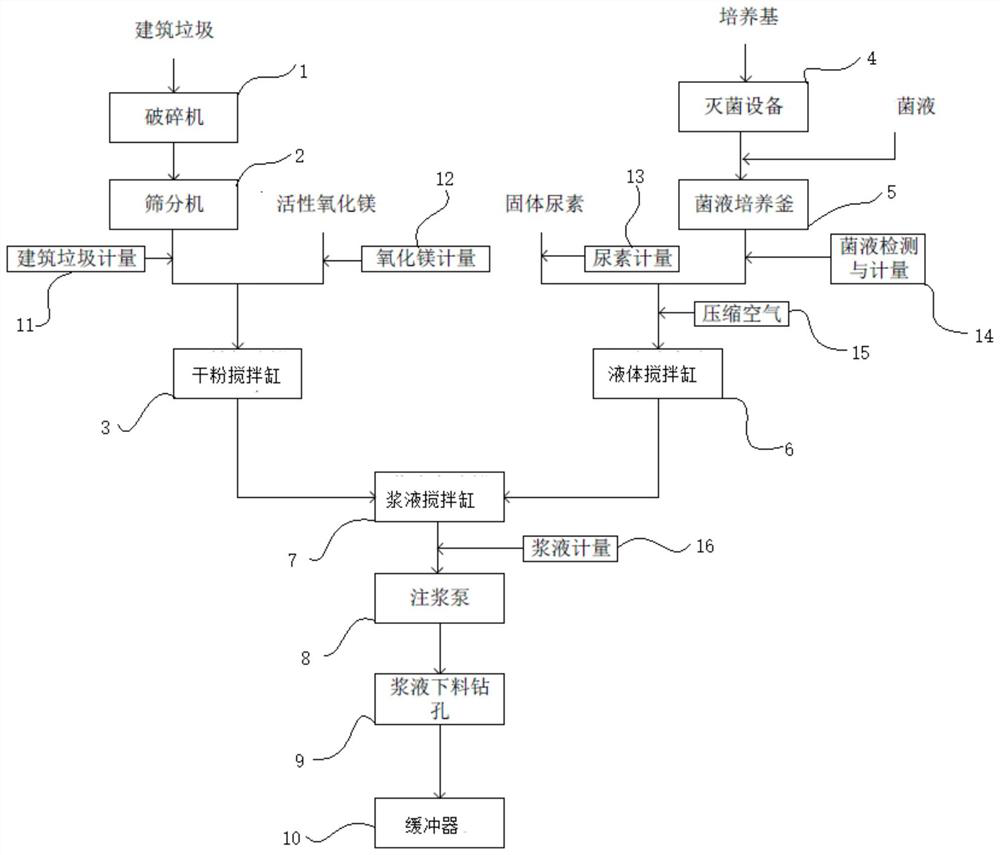

ActiveCN113735540AEfficient curingEasy to transportSolid waste managementMaterial fill-upUrease enzymeSlurry

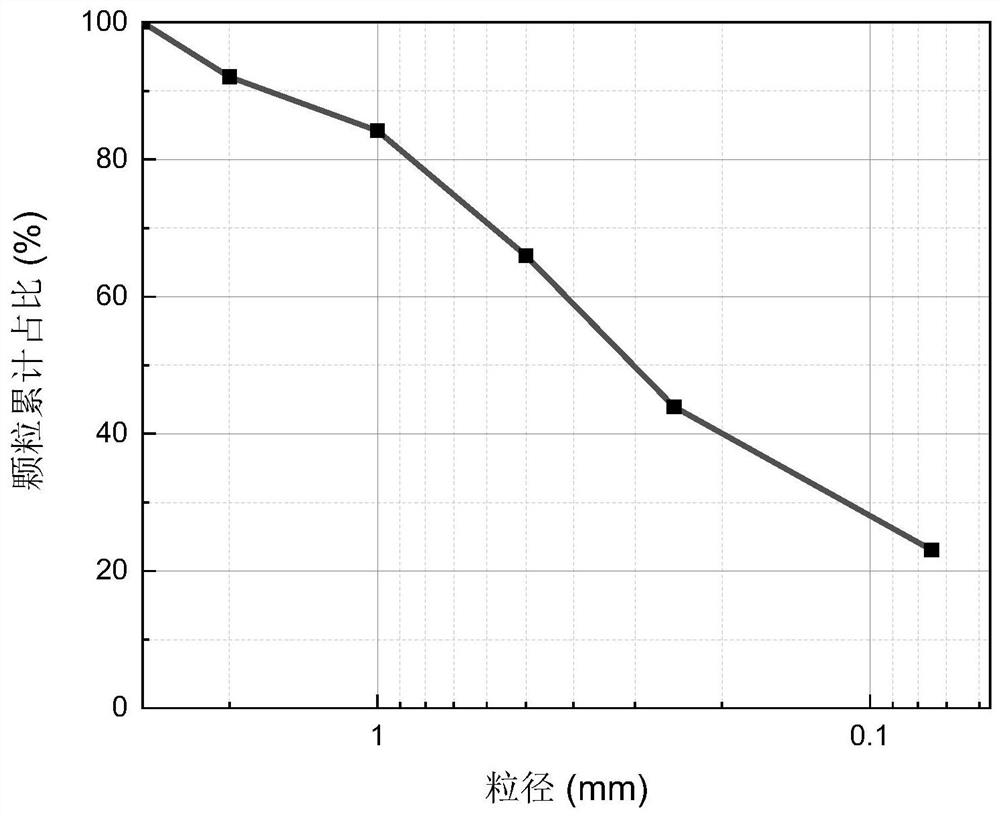

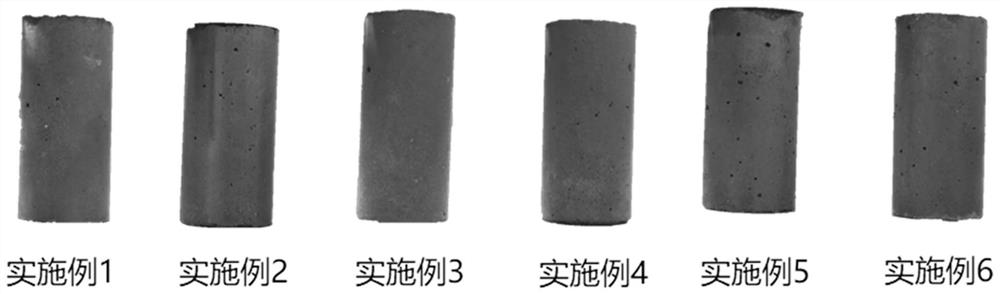

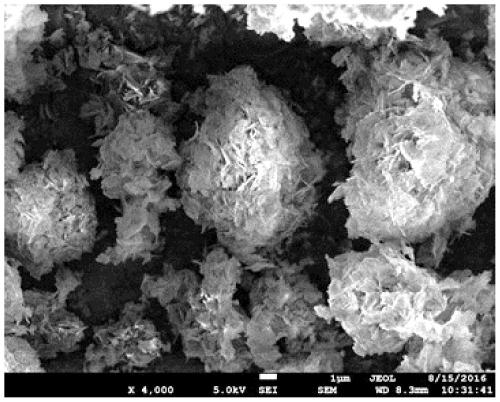

The invention discloses a mine filling method, a material and equipment. The mine filling method comprises the following steps: A, mixing 60-80 parts by mass of particles of construction waste and 2-7 parts by mass of active magnesium oxide into a solid mixture; b, mixing bacterial liquid and urea into a liquid mixture, wherein the bacterial liquid contains urease-producing bacteria, and the concentration of the urea is 2-6 mol / L; and C, uniformly mixing the solid mixture and the liquid mixture according to the mass ratio of 70: (20-35) to form flowable slurry or paste, injecting the flowable slurry or paste into the goaf, and performing standing for curing. On the premise that a good curing effect is guaranteed, the construction waste is used for replacing cement to fill the mine, cement is not used, and meanwhile good fluidity is achieved.

Owner:NANJING UNIV +1

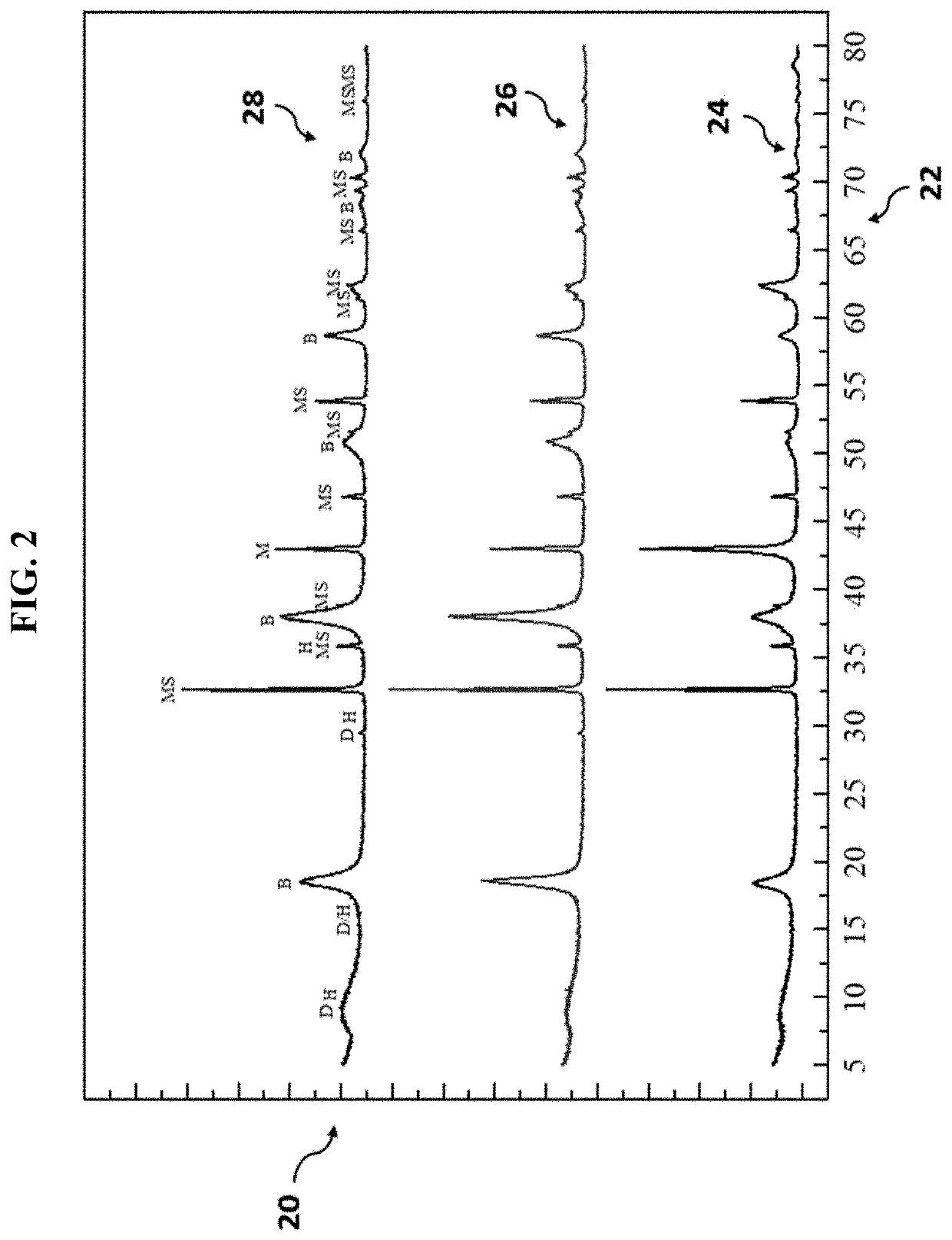

Enhanced reactive magnesia cement-based concrete mixes

ActiveCN110446685AMagnesium carbonatesCarbonate/bicarbonate preparationHydration reactionCement composites

According to the present disclosure, a method of producing a hydrated magnesium carbonate based cement composite (HMCs) is provided. The method comprising providing an aqueous solution comprising a hydration agent and hydrated magnesium carbonate seed particles; contacting the aqueous solution with a magnesium oxide based cement to form magnesium hydroxide from the hydration agent and the magnesium oxide based cement, and on the hydrated magnesium carbonate seed particles; and exposing the magnesium hydroxide to carbon dioxide to form the hydrated magnesium carbonate based cement composite. The use of hydration agent and seed particles not not only increases formation of HMCs but also improves the mechanical performance of RMC based concrete formulations.

Owner:NANYANG TECH UNIV

Method for preparing active magnesium oxide from carbide slag and preparation method of magnesium cement

The invention discloses a method for preparing active magnesium oxide from carbide slag and a preparation method of magnesium cement. The method for preparing the active magnesium oxide from carbide slag comprises the following steps of: S1, preparing carbide slag and magnesium chloride into slurry, and carrying out reaction to generate a precursor; and S2, calcining the precursor at 500-900DEG Cfor less than 60min to obtain a calcined product, wherein the activity of magnesium oxide in the calcined product is 80% or more. The preparation method of magnesium cement comprises the following steps of: conducting the above steps of preparing the active magnesium oxide from the carbide slag; then mixing the calcined product, magnesium chloride and water according to a certain ratio to obtain magnesium cement; wherein the mass ratio of the active magnesium oxide to the magnesium chloride is 5-8:1, and the mass ratio of the magnesium chloride to water is 1:8-19. The two processes have greatsignificance in solving the treatment problem of salt lake by-products magnesium chloride and carbide slag.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Green low-carbon curing agent for soil curing

ActiveCN102071029BEmission reductionLow costBuilding constructionsOrganic fertilisersSoil scienceSlag

The invention discloses a green low-carbon curing agent for soil curing. The soil curing agent is characterized by comprising granulated blast furnace slag micro powder and exciting agent, wherein the exciting agent comprises active magnesia, the exciting agent is 30 to 5 percent of the total mass of the soil curing agent, and the granulated blast furnace slag micro powder is 70 to 95 percent of the total mass of the curing agent. The exciting agent comprises slaked lime, wherein the slaked lime is 10 to 90 percent of the mass of the active magnesia. The exciting agent comprises calcined lime, wherein the calcined lime is 7 to 66 percent of the mass of the active magnesia.

Owner:SOUTHEAST UNIV

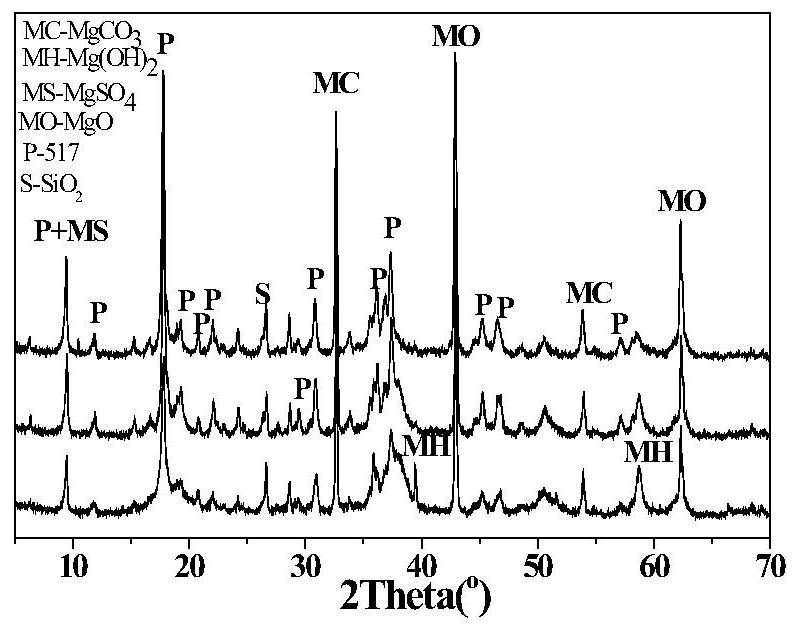

Novel high-strength phosphorus magnesium silicate cement and preparation method thereof

ActiveCN114213047ASolve the problem of too fast condensationImprove mechanical propertiesMagnesium phosphateMagnesium orthophosphate

The invention discloses novel high-strength phosphorus magnesium silicate cement and a preparation method thereof. The novel high-strength magnesium phosphate silicate cement comprises first active magnesium oxide, second active magnesium oxide, a raw material containing active silicon dioxide, monohydrogen phosphate and basic magnesium sulfate whiskers, and the first active magnesium oxide is obtained by calcining a magnesium-containing raw material at 900-1000 DEG C; the second active magnesium oxide is obtained by mixing a magnesium-containing raw material with phosphate and calcining at 1000-1600 DEG C; according to the preparation method of the novel high-strength magnesium phosphate silicate cement provided by the invention, the low-temperature calcined magnesium oxide raw material is used, so that the production energy consumption and the production cost are reduced, and the problem of too fast cement setting caused by the low-temperature calcined raw material is solved. Meanwhile, the basic magnesium sulfate whisker is added, so that the mechanical property and the water resistance of the cement can be enhanced, and the prepared novel high-strength magnesium phosphosilicate cement has good mechanical property and water resistance.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A kind of early strong basic magnesium sulfate cement and preparation method thereof

The invention provides high-early-strength basic magnesium sulfate cement and a preparation method thereof. The preparation method includes: mixing first active magnesium oxide, a dispersing agent, afirst additive and magnesium sulfate aqueous solution to obtain emulsion; mixing the emulsion with second active magnesium oxide and a second additive, and hardening to obtain the high-early-strengthbasic magnesium sulfate cement. By adoption of the preparation method, the high-early-strength basic magnesium sulfate cement can be prepared, and product production efficiency can be greatly improved.

Owner:开平市赤牛水泥制品有限公司

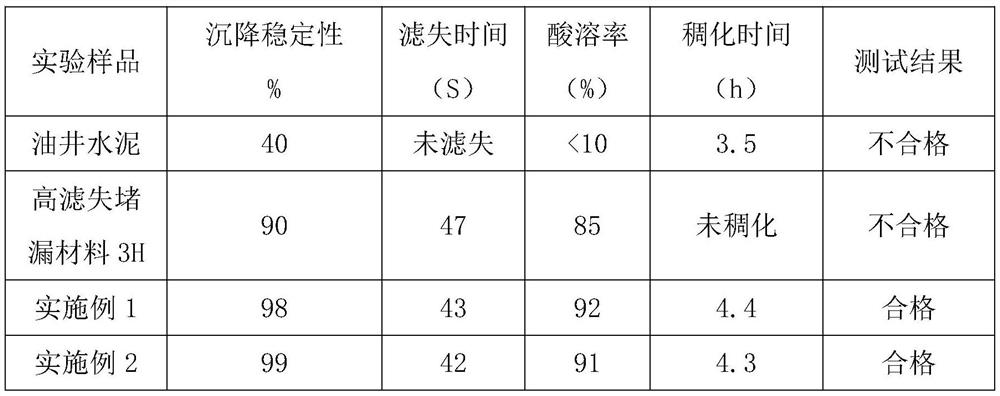

A multifunctional consolidation plugging agent for drilling fluid

The invention discloses a multifunctional consolidation plugging agent for drilling fluid, which comprises the following components in mass percentage: 45-60% of inorganic mineral materials, 4-5% of fibers, 15-20% of curing agent, and filter aids 5-10%, 3-5% retarder, 5-10% expansion agent, 3-5% dispersant; the inorganic mineral material is that the particle size is 200 mesh ash calcium and active magnesium oxide according to the weight ratio of 0.5: 1 or a 1:1 mix. The fiber is a brucite fiber with an aspect ratio of 10-50:1 and a diameter of 0.5-15um. The components are uniformly mixed to obtain a multifunctional consolidation plugging agent for drilling fluid. The lost circulation agent uses clean water or water-based drilling fluid as the base fluid to directly prepare the lost circulation slurry. It can adopt three construction methods: while drilling, high filtration loss, and overall consolidation; it is easy to use, no need to clean the tank and change the drilling tool assembly; and the settlement stability is high. If clean water is used as the base fluid, it can be directly aggravated to the required density. .

Owner:ASTAR PETROTECH

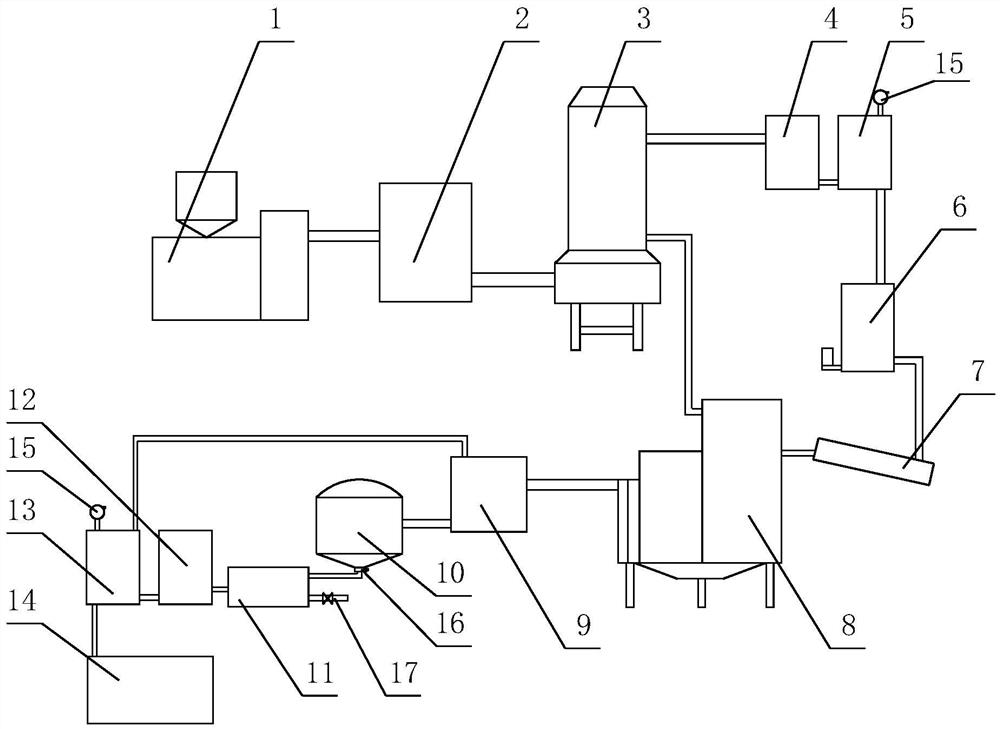

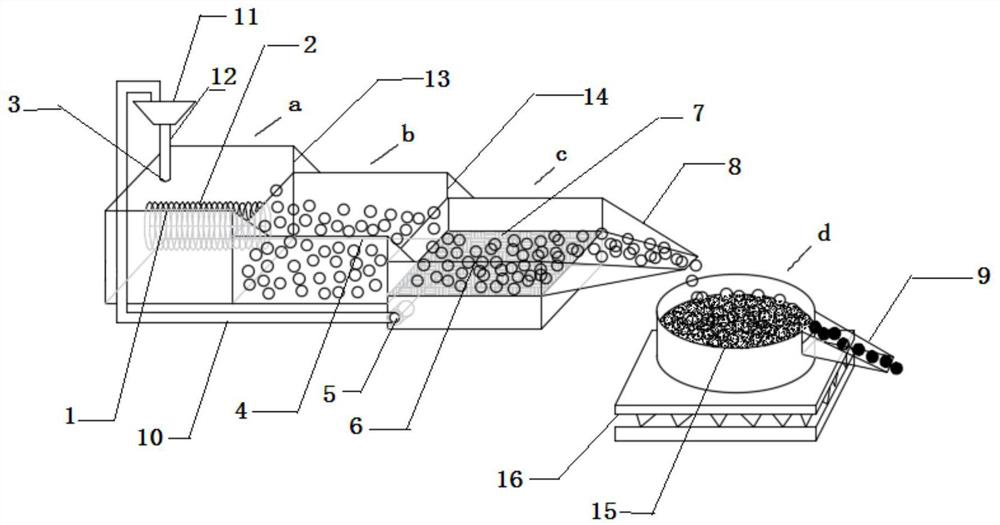

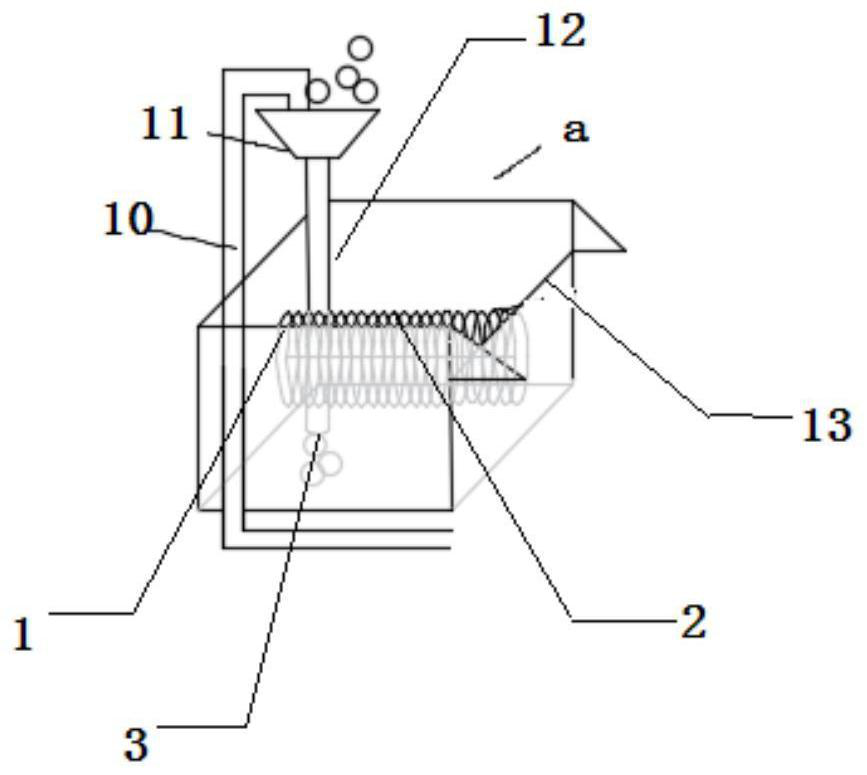

A device for producing high-activity magnesium oxide using magnesite tailings

ActiveCN107324670BSolve the problem that it cannot be directly calcined to produce magnesium oxideAchieving zero emissionsLime productionSiloReactive magnesia

Owner:LIAONING DONGHE NEW MATERIAL CO LTD

Carbonation of reactive magnesia cement (RMC)-based systems

Herein discloses a method of carbonating reactive magnesia cement, which includes: (i) providing an aqueous suspension including a carbon dioxide-producing bacteria; (ii) mixing the aqueous suspension with a precursor which the carbon dioxide-producing bacteria generates carbon dioxide from for a duration to form an aqueous mixture sufficient for substantially carbonating the reactive magnesia cement; (iii) mixing the aqueous mixture with the reactive magnesia cement to form a blend; wherein a nutrient is provided in the aqueous suspension of step (i) or in the reactive magnesia cement of step (iii) to sustain the carbon dioxide-producing bacteria in the reactive magnesia cement; and (iv) curing the blend to carbonate the reactive magnesia cement. A reactive magnesia cement composite formed by the method is also disclosed.

Owner:NANYANG TECH UNIV

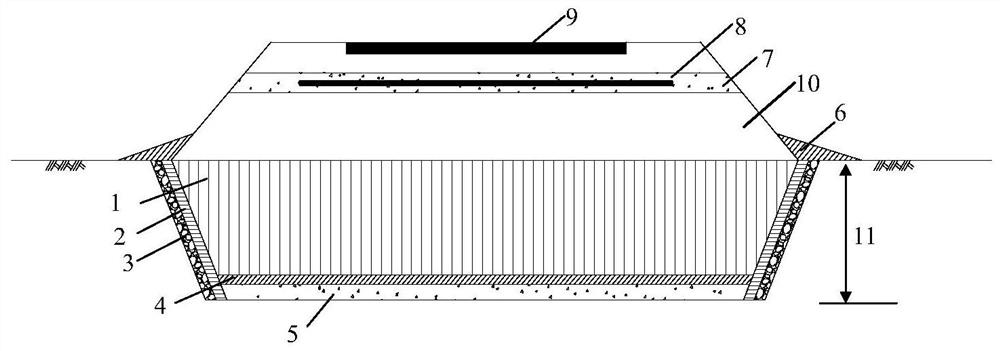

A treatment method for expressway subgrade in permafrost regions

The invention discloses a method for treating a subgrade of a highway in a frozen soil region. The method comprises the following steps: a, thawing a frozen soil subgrade in a frost line in advance; b, excavating all thawed soil; c, laying a layer of coarse-grained soil and a reversed filter layer at the bottom of an excavation layer, and laying lime waterproof layers and gravel expansion guide layers on two sides; d, filling activated magnesia carbonized and cured sludge soil layer by layer and performing tamping reinforcement; e, compacting filled embankment filling soil and setting a coarse-grained soil layer containing an XPS insulation board below a pavement structure; f, setting waterproof protecting feet on two sides of an embankment respectively. Subgrade pre-thawing, filling treatment and soft soil carbonization and curing technologies for the frozen soil region are fully combined, the frozen soil subgrade is effectively reinforced, the engineering problems of refreezing and frost heaving of subgrade soil are well solved, non-uniform settling of the subgrade is further reduced, and the problem of secondary damage of the highway in the cold region is reduced greatly. The method has the advantages of being economic, environmentally friendly, safe, efficient, high in controllability, easy to operate and the like.

Owner:SOUTHEAST UNIV

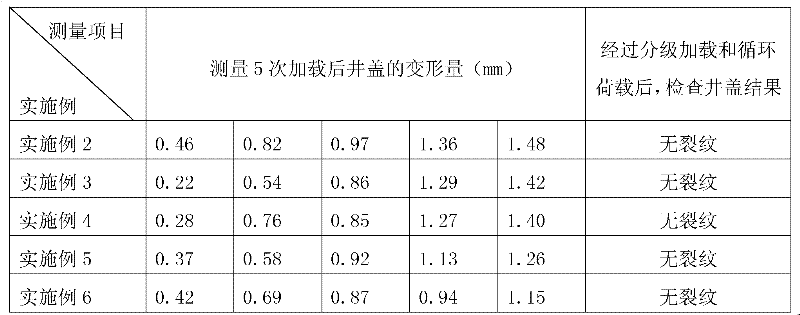

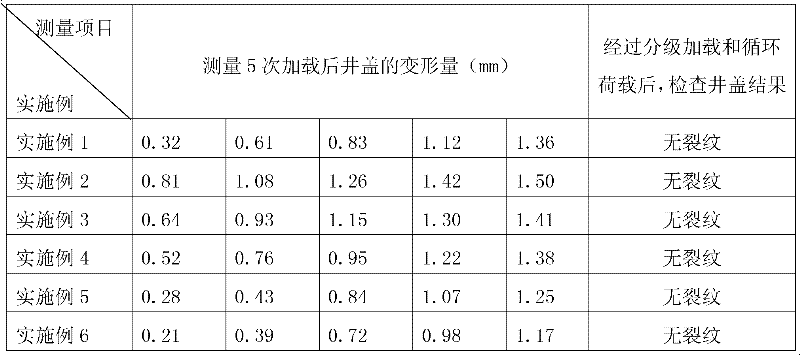

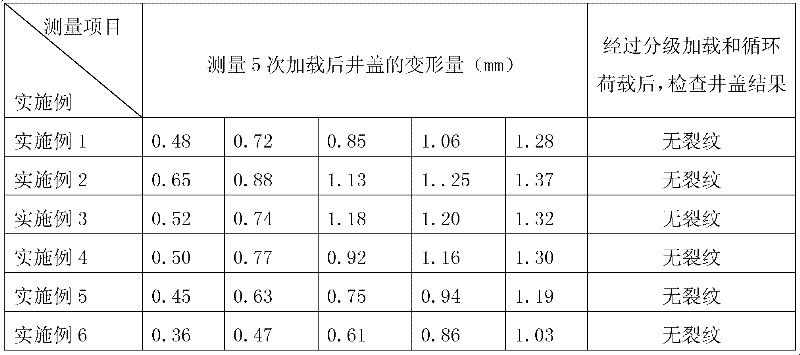

High-strength polyester composite well cover and preparation method thereof

InactiveCN101871219BImprove carrying capacityImpact resistantArtificial islandsUnderwater structuresPolymer scienceFirming agent

The present invention discloses a high-strength polyester composite well cover, the formula of which comprises the following raw materials in parts by weight: 21-22 parts of unsaturated polyester resin, 8-9 parts of low shrink additive, 40-50 parts of heavy calcium carbonate, 1-1.5 parts of zinc stearate, 0.2-0.8 part of active magnesia, 0.12-0.28 part of curing agent, 0.2-0.8 part of carbon black, 10-20 parts of alkali-free glass fiber roving and 10-20 parts of glass fiber woven roving. A production method of the well cover of the invention comprises the following steps of: firstly preparing resin paste, preparing sheets by utilizing the resin paste, and then, forming the sheets by die pressing. The well cover of the invention has the characteristics of strong carrying capacity, shock resistance, ageing resistance, wear resistance, corrosion resistance, novel and attractive appearance, simple structure, environmental protection and the like, and basically solves the problem of well cover pilfering.

Owner:北京泛亚电通工贸有限责任公司

Composite thermal insulation mortar initiated by soluble phosphate and preparation method thereof

The invention discloses composite thermal insulation mortar initiated by soluble phosphate and a preparation method of the composite thermal insulation mortar. The composite thermal insulation mortarcomprises the following components in parts by mass: 1-10 parts of soluble phosphate, 20-70 parts of active magnesium oxide powder, 5-55 parts of fly ash, 2-10 parts of magnesium cement layer EPS particles and 10-70 parts of magnesium salt crystal filled expanded perlite. The magnesium cement layer EPS particles comprise EPS particles and a magnesium cement layer coating the EPS particles, and themagnesium cement layer is a magnesium oxychloride cement layer or a magnesium sulfate cement layer; the expanded perlite filled with the magnesium salt crystals comprises expanded perlite and the magnesium salt crystals filled in open pores of the expanded perlite, and the magnesium salt crystals are magnesium chloride salt crystals or magnesium sulfate salt crystals. During construction, in themixing process of the thermal insulation mortar and water, the soluble phosphate is subjected to hydrothermal reaction to release heat, the reaction process of the magnesium cement is accelerated, andthe construction efficiency is improved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

A kind of cementitious material and its application

ActiveCN109020268BSimple production processReduce energy consumptionCement productionSlagMining engineering

The invention belongs to the technical field of mine filling, and in particular relates to a cementitious material used for a cemented filling body of mine tailings containing sulfide. The cementitious material is made of the following raw materials in parts by weight: 0.1-2 parts of water glass, 0.1-2 parts of carbonate, 1-15 parts of activated magnesium oxide and 81-99 parts of granulated blast furnace slag powder. The filling body cemented by the cementitious material and the sulfide mine tailings will not crack, the compressive strength will not decrease in the later stage, and the economic benefit is good.

Owner:ZHENGZHOU UNIV

Method for solidifying tailings sand based on active magnesium oxide microorganisms and products thereof

The invention discloses a method for solidifying tailings sand based on active magnesia microorganisms and its products. Active magnesia is used as the basic curing agent, and microbial technology is used to provide CO required for carbonization. 2 and reduce the heavy metals in the tailings sand, making full use of the advantages of magnesium oxide solidified soil technology and microbial technology, using the carbonate ions produced by the hydrolysis of urea by Bacillus to carbonize the magnesium oxide solidified soil, improving the strength of the brick body, and using The extracellular complexation, extracellular precipitation and intracellular accumulation of heavy metals by microorganisms can reduce the content of heavy metal ions. The method has the advantages of simple process, no sintering, short construction period, high strength, environmental protection, can realize win-win of environmental benefit and economic benefit, and has good application prospect.

Owner:CHONGQING UNIV

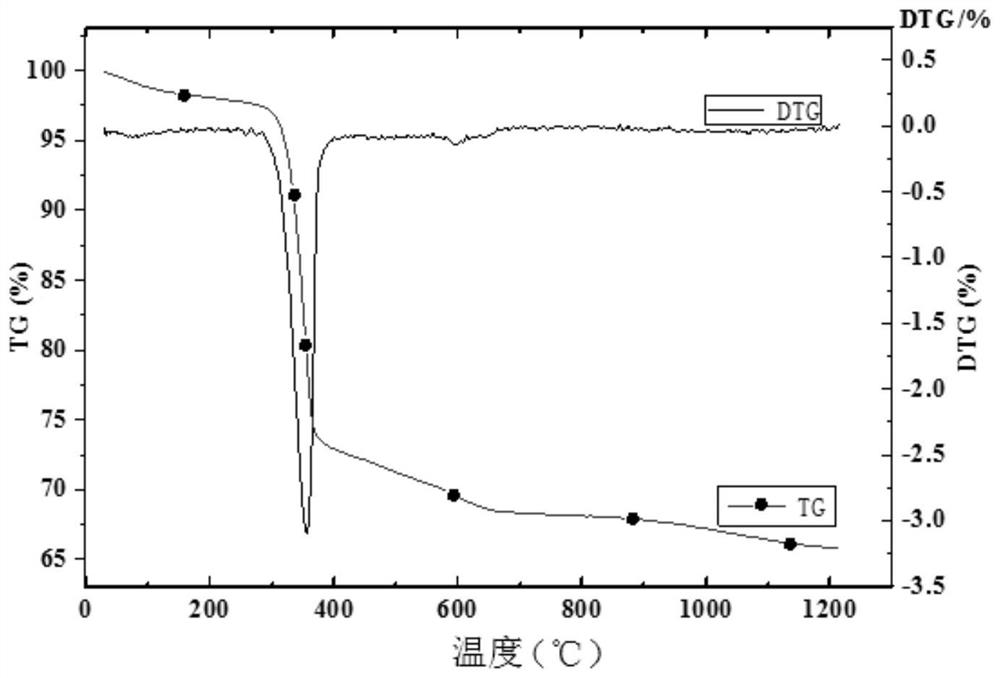

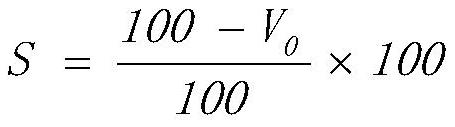

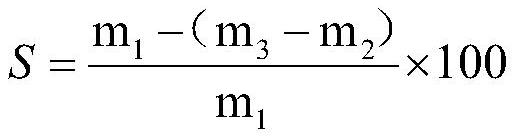

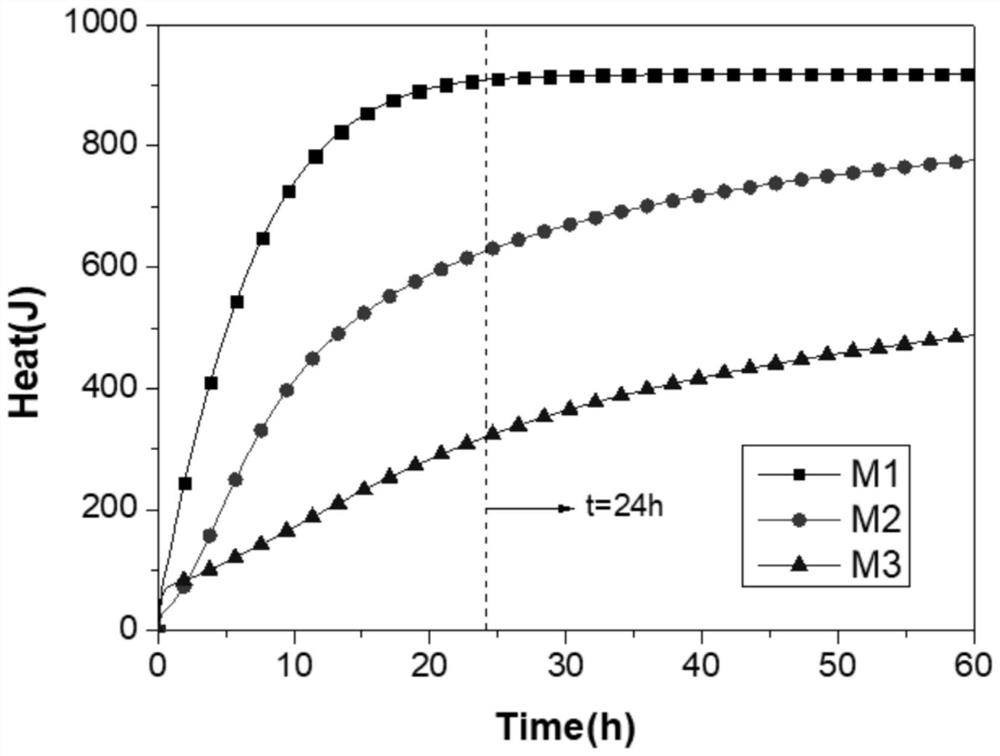

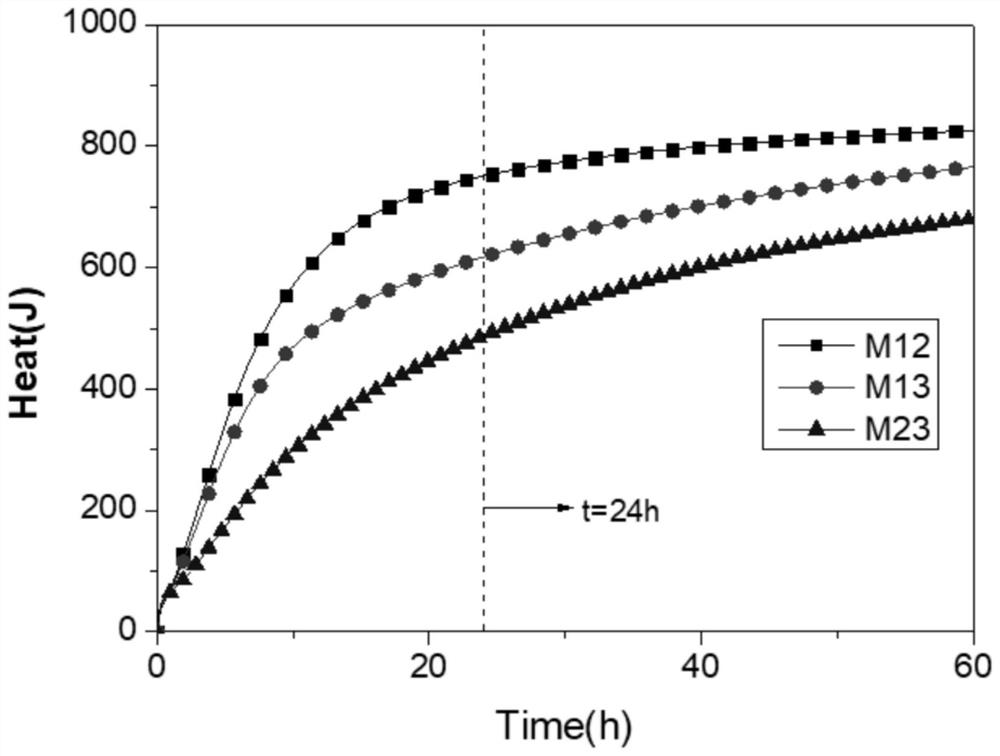

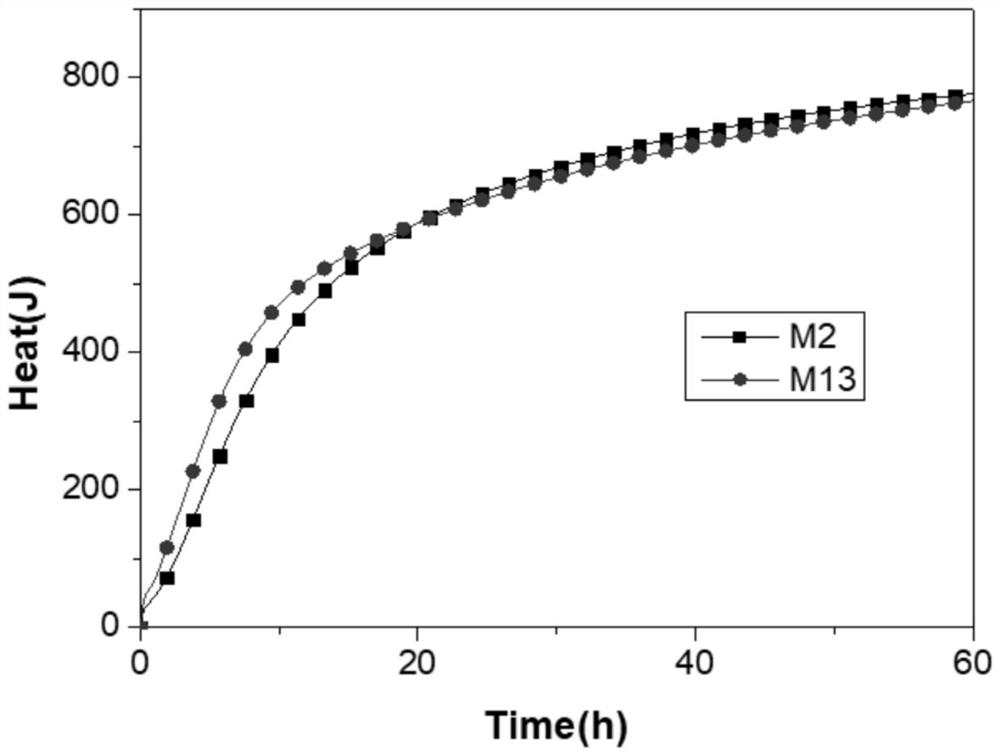

A kind of magnesium oxide expansion agent activity evaluation method

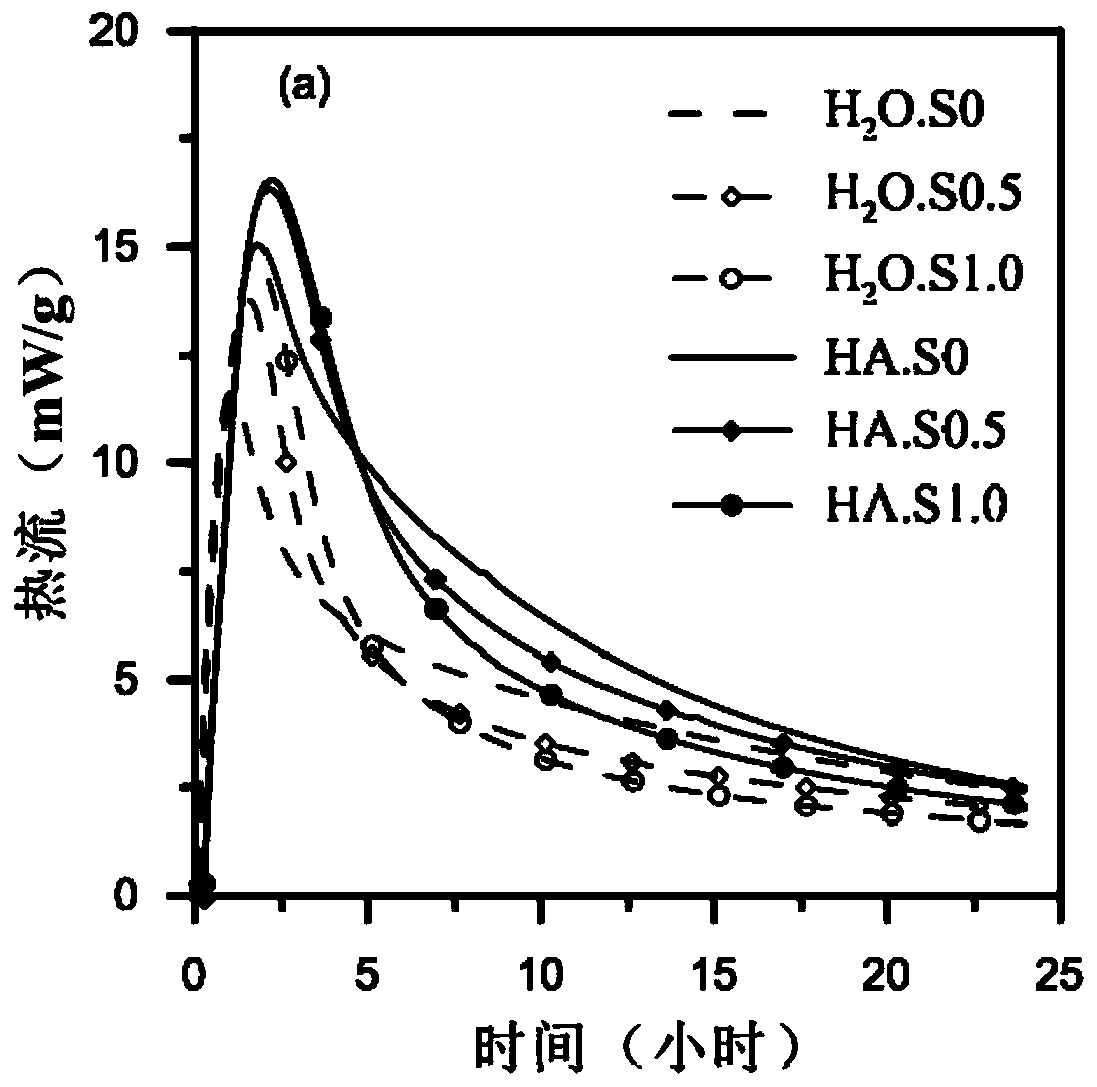

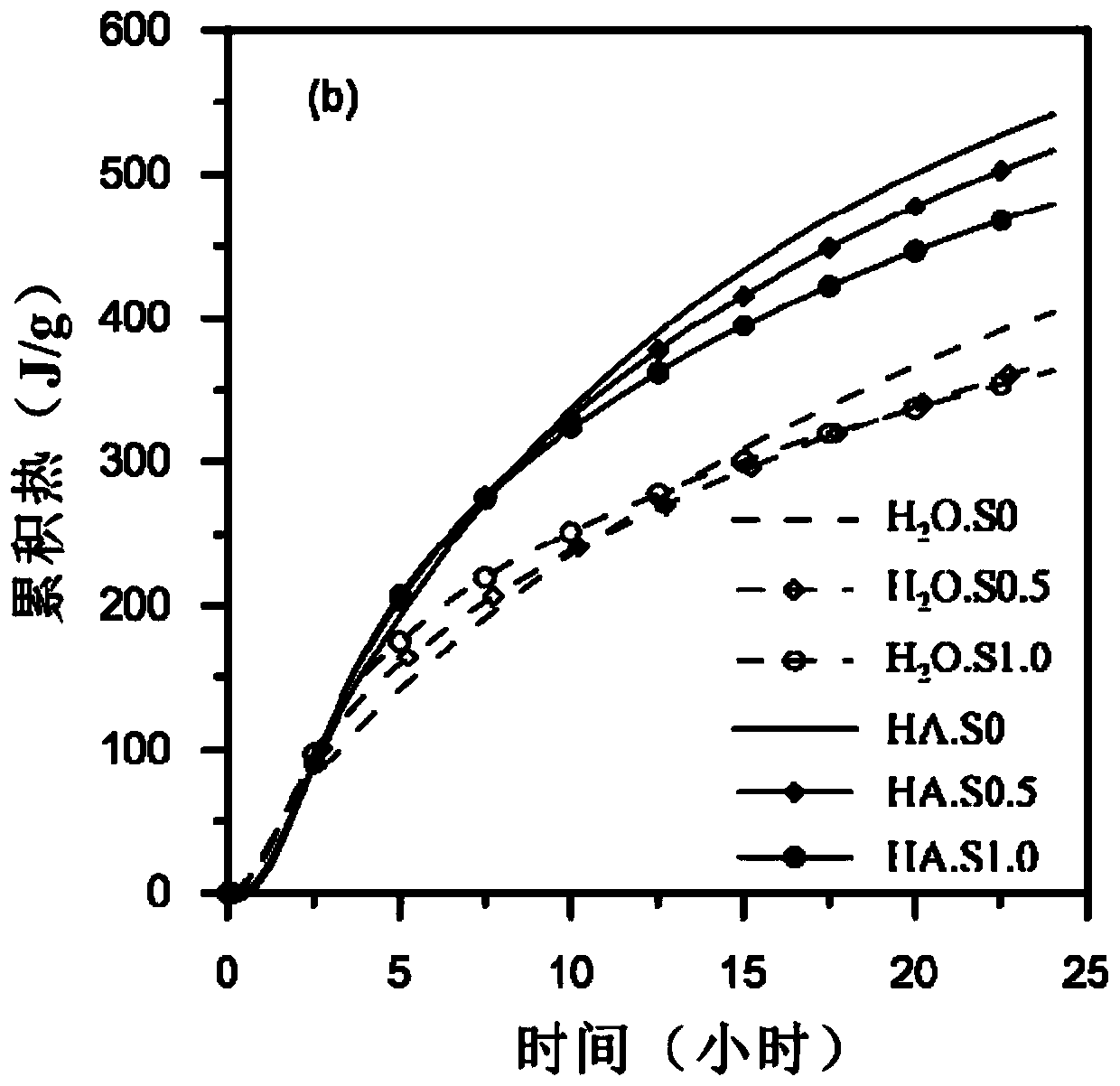

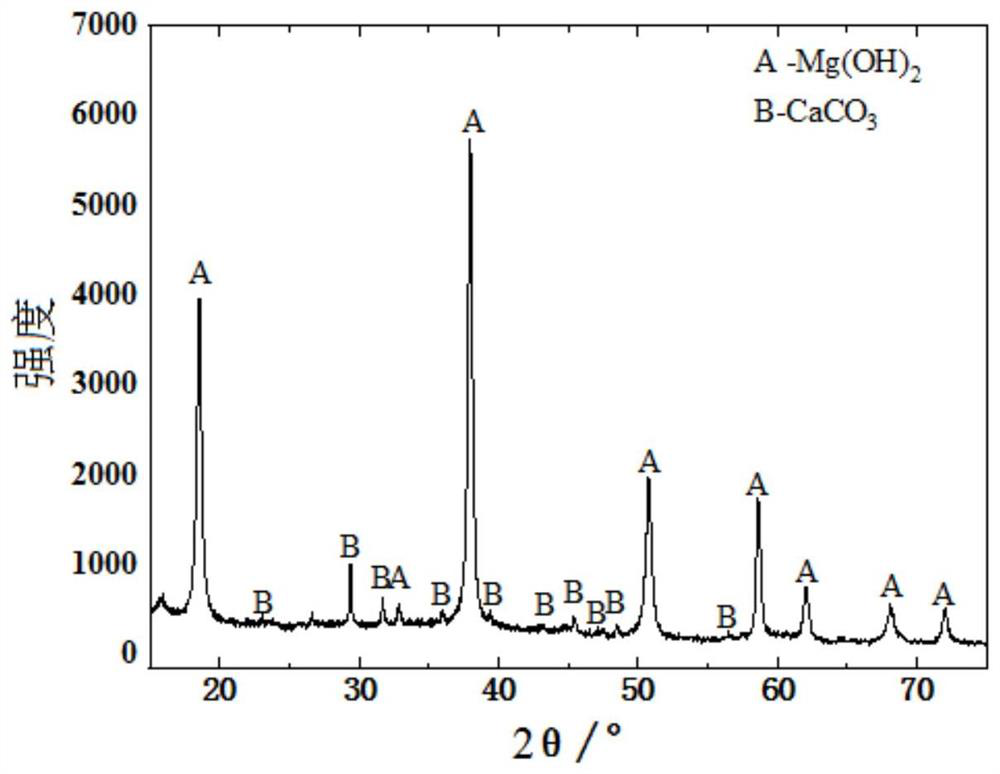

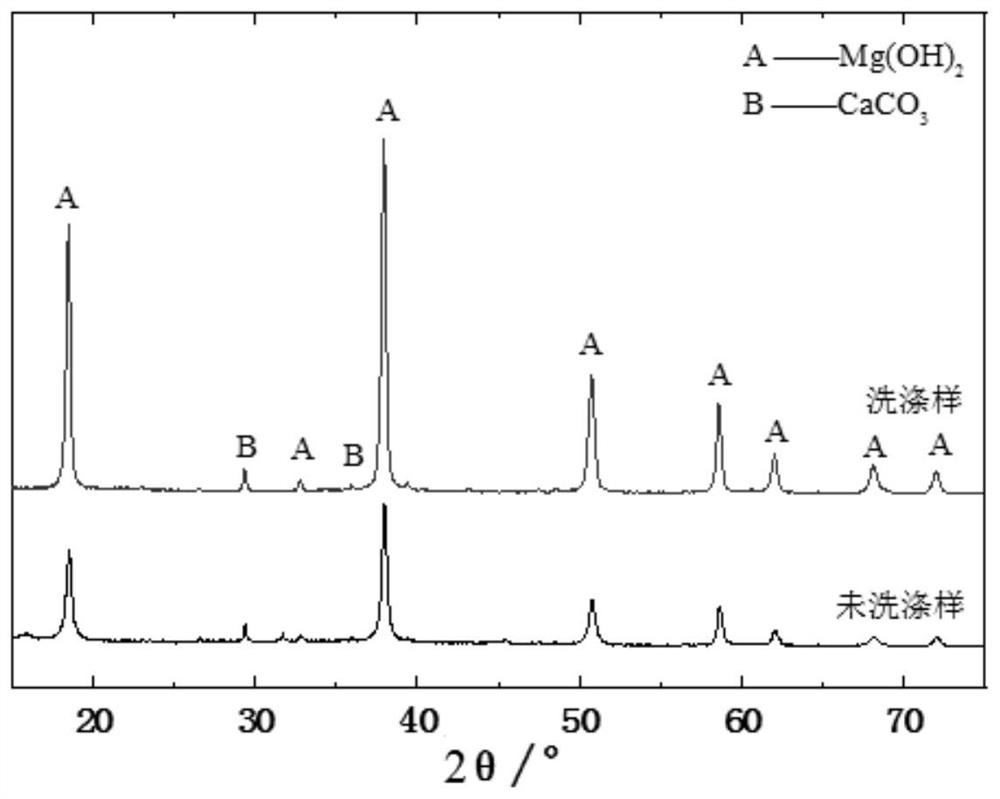

ActiveCN111044566BReasonable Hydration Activity LevelEstimated inflationMaterial heat developmentPhysical chemistryReactive magnesia

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com