Mine filling method, material and equipment

A mine filling and equipment technology, which is applied in mining equipment, fillings, earth drilling and mining, etc., can solve problems such as occupation, waste of land resources, and secondary pollution of the environment, and achieve high efficiency, reduce carbon emissions, and reduce hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

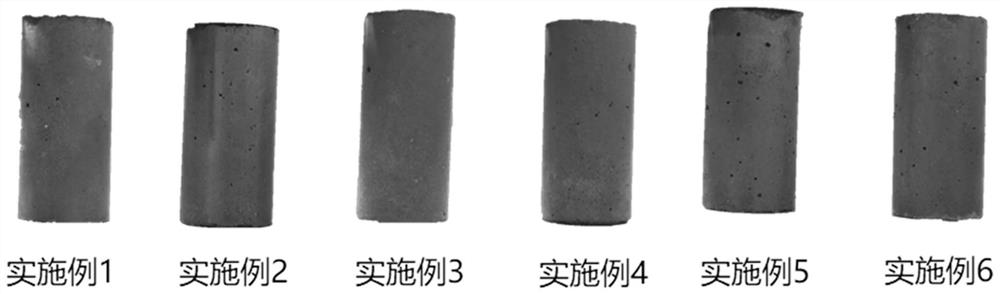

Embodiment 1

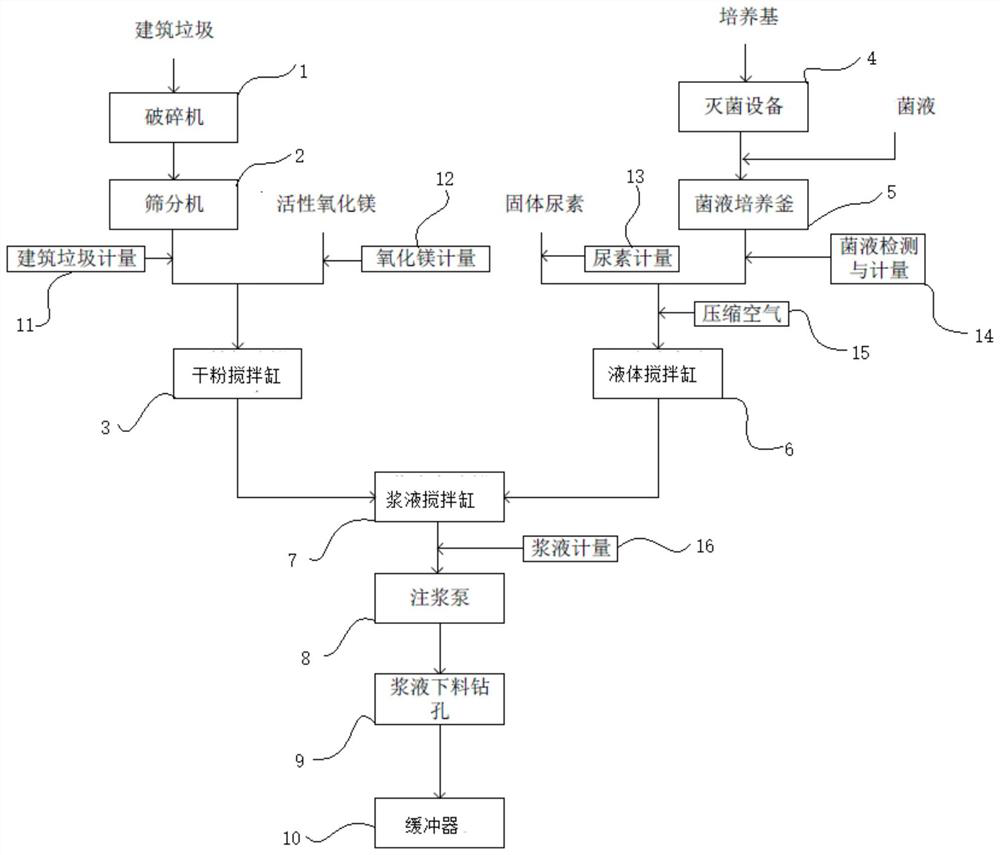

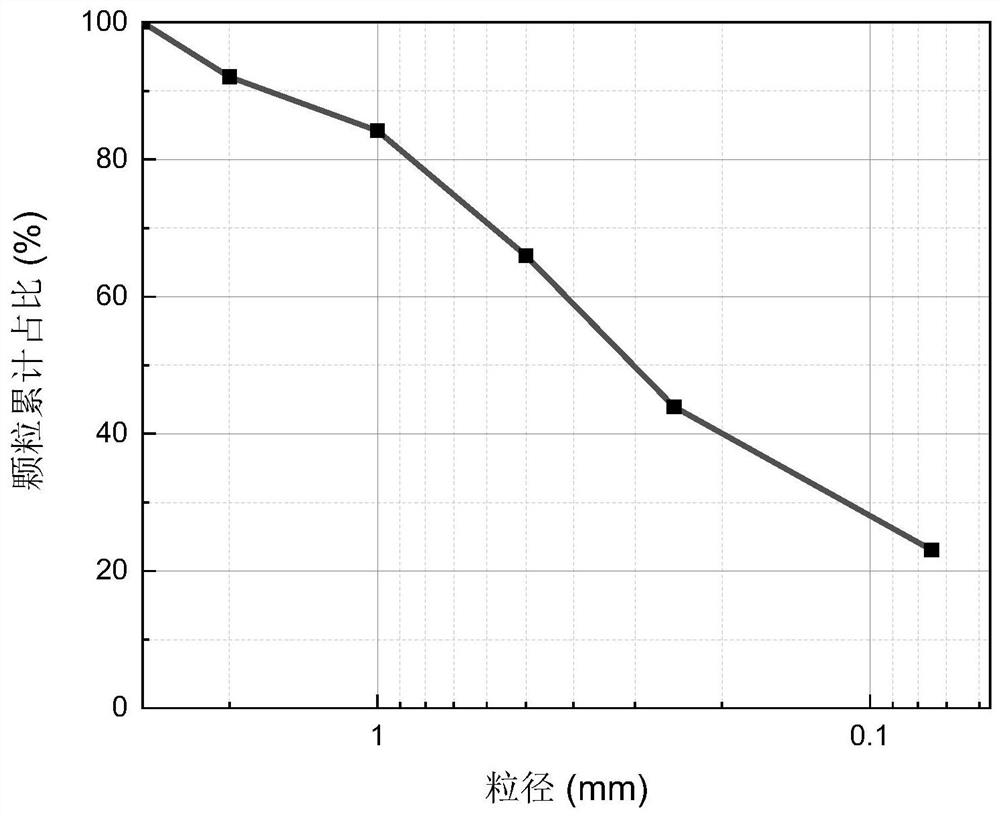

[0073] use figure 1 The shown equipment will be made of bricks (mass percentage is 35%) and concrete, and the construction waste is crushed into particles, and the particle gradation is as follows: figure 2 As shown, the particles smaller than 0.075mm exceed 20% of the total mass of poured waste, and the particle size of the particles is smaller than 2mm.

[0074] According to Table 1, take or measure the granules, active magnesium oxide, and liquid mixture of construction waste, and fill according to the following steps. The purity of activated magnesium oxide is >98%, the particle size is less than 200 mesh, and the activity is 12-25s.

[0075] Mix the weighed construction waste and active magnesium oxide into a solid mixture; mix the solid mixture with the measured liquid mixture evenly to form a fluid paste; fill the paste into a cylindrical mold, and keep it for 28 days carry out testing.

[0076] The ratio of the liquid mixture is as follows: 7.52 parts of solid urea...

Embodiment 2

[0078] The present embodiment is substantially the same as embodiment 1, and the difference is only in the ratio of construction waste and active magnesium oxide and the ratio of solid mixture and liquid mixture, specifically see Table 1.

Embodiment 3

[0080] The present embodiment is substantially the same as embodiment 1, and the difference is only in the ratio of construction waste and active magnesium oxide and the ratio of solid mixture and liquid mixture, specifically see Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com