Pyrochlore type high-entropy oxide solidified body and preparation method thereof

A technology of oxides and solidified bodies, which is applied in the field of pyrochlore-type high-entropy oxide solidified bodies and its preparation, can solve the problems of not being able to solidify multiple radionuclides at one time, and achieve excellent chemical stability, high-efficiency solidification, and a preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of pyrochlore type high entropy oxide solidified body:

[0038] Will Y 2 o 3 , La 2 o 3 、Nd 2 o 3 Raw powder (~ particle size 1μm, purity >99wt%, Shanghai Diyang Industrial Co., Ltd.) and TiO 2 , ZrO 2 , HfO 2 (~Particle size 0.2 μm, purity>99wt%, Sinopharm Chemical Reagent Co., Ltd.) Dosing at a molar ratio of 1:1:1:2:2:2. With ethanol as the medium, ZrO 2 The ball is a grinding ball, and the ball mill is mixed at a speed of 560 rpm for 8 hours on a planetary ball mill, and then a dry mixed powder with a uniform composition is obtained by rotary evaporation; the obtained mixed powder is first dry-pressed at 5 MPa, and then cooled at 50 MPa. Isostatic pressing, the green body is put into an alumina crucible, and then placed in a muffle furnace. In an air atmosphere, the temperature is raised at a rate of 1°C / min, and sintered at 1300°C for 1h to prepare a high-entropy oxide solidified body.

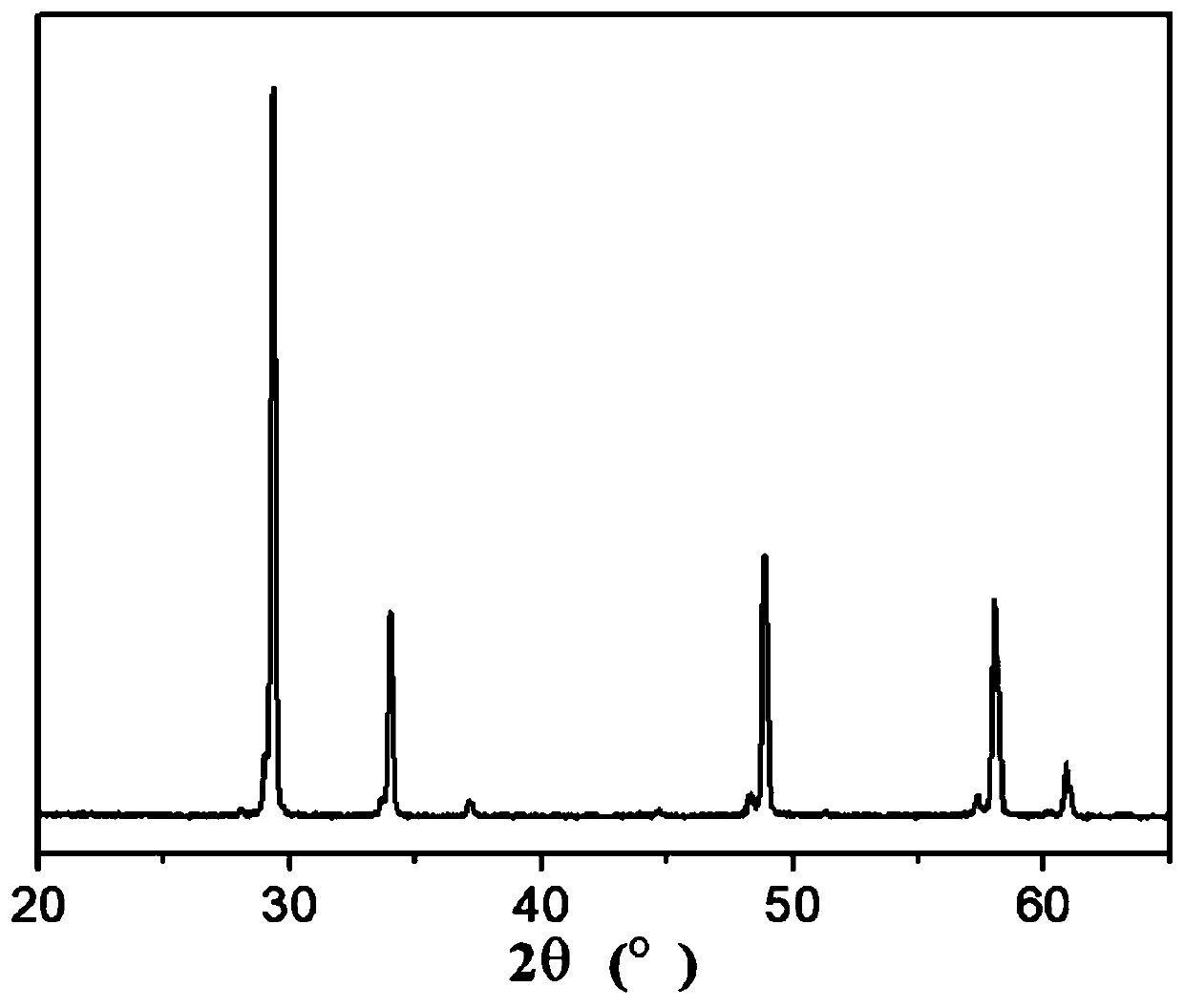

[0039] After analysis: the XRD spectrum of th...

Embodiment 2

[0041] The preparation method of pyrochlore type high entropy oxide solidified body:

[0042] Will Y 2 o 3 , La 2 o 3 、Nd 2 o 3 Raw powder (~ particle size 5μm, purity >99wt%, Shanghai Diyang Industrial Co., Ltd.) and TiO 2 , ZrO 2 , HfO 2 , Nb 2 o 5 Powder (~ particle size 0.5μm, purity >99wt%, Sinopharm Chemical Reagent Co., Ltd.) is compounded at a molar ratio of 1:1:1:2:2:2:1, with ethanol as the medium, ZrO 2 The ball is a grinding ball, and the ball milling is carried out on a planetary ball mill at a speed of 500 rpm for 16 hours, and a dry mixed powder with a uniform composition is obtained by rotary evaporation; the obtained mixed powder is first dry-pressed at 10MPa, and then cooled at 100MPa Isostatic pressing, the green body is put into an alumina crucible, and then placed in a muffle furnace. In an air atmosphere, the temperature is raised at a rate of 10°C / min, and sintered at 1400°C for 3h to prepare a high-entropy oxide solidified body.

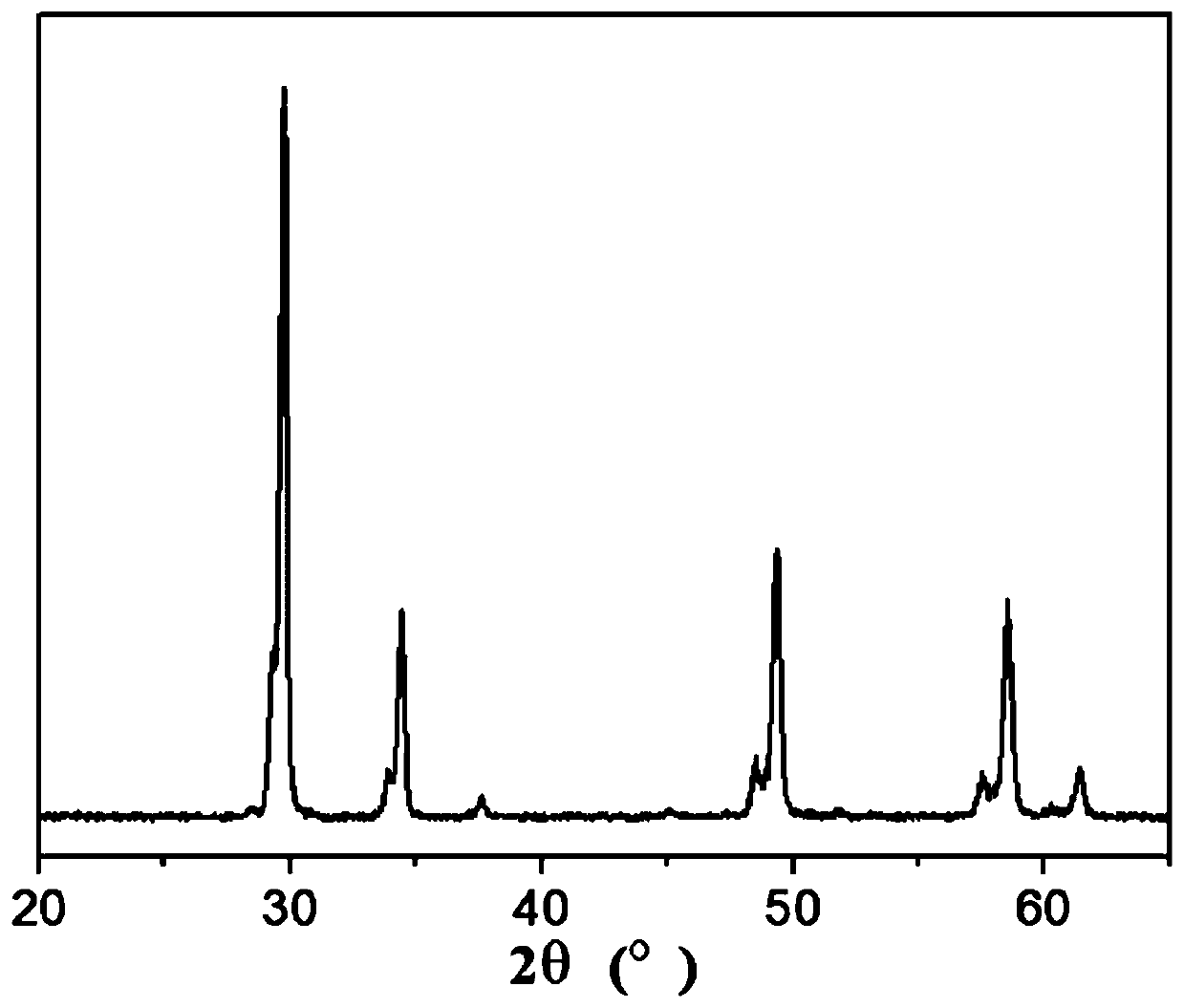

[0043] Afte...

Embodiment 3

[0045] The preparation method of pyrochlore type high entropy oxide solidified body:

[0046] Will Y 2 o 3 , La 2 o 3 、Nd 2 o 3 Raw powder (~ particle size 10μm, purity >99wt%, Shanghai Diyang Industrial Co., Ltd.) and TiO2 , ZrO 2 , HfO 2 , Nb 2 o 5 、TaO 2 Powder (~ particle size 1.0 μm, > purity 99wt%, Sinopharm Chemical Reagent Co., Ltd.) is compounded at a molar ratio of 1:1:1:2:2:2:1:2, with ethanol as the medium, ZrO 2 The ball is a grinding ball, and the ball mill is mixed at a speed of 450 rpm for 20 hours on a planetary ball mill, and a dry mixed powder with uniform components is obtained by rotary evaporation; the obtained mixed powder is first dry-pressed at 15MPa, and then cooled at 200MPa Isostatic pressing, the green body is put into an alumina crucible, and then placed in a muffle furnace. In an air atmosphere, the temperature is raised at a rate of 15°C / min, and sintered at 1500°C for 8h to prepare a high-entropy oxide solidified body.

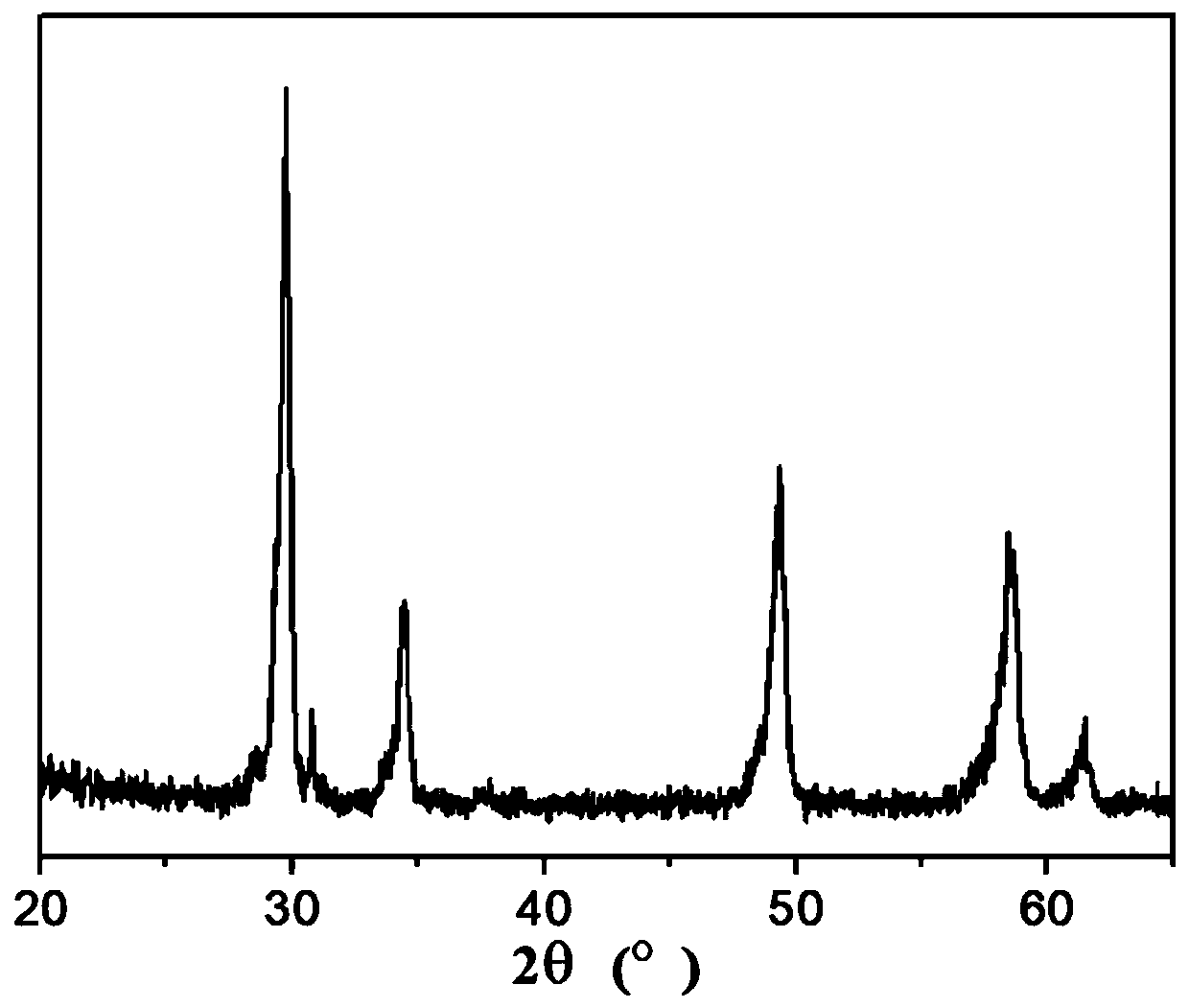

[0047] After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com