Patents

Literature

62 results about "Citric Acid / tartaric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tartaric acid comes from grapes while citric acid comes from citrus fruit. Both are used as souring agents and can give a pleasantly sour taste to your dishes. Tartaric acid is the source of acidity in wines made from grapes and is commonly used in combination with baking soda to make cream of tartar.

Stable and Water-Soluble Plant Growth Regulator Liquid Compositions and Methods for Use of Same

InactiveUS20080039322A1Effective amountAccurate measurementBiocidePlant growth regulatorsSolubilityAntioxidant

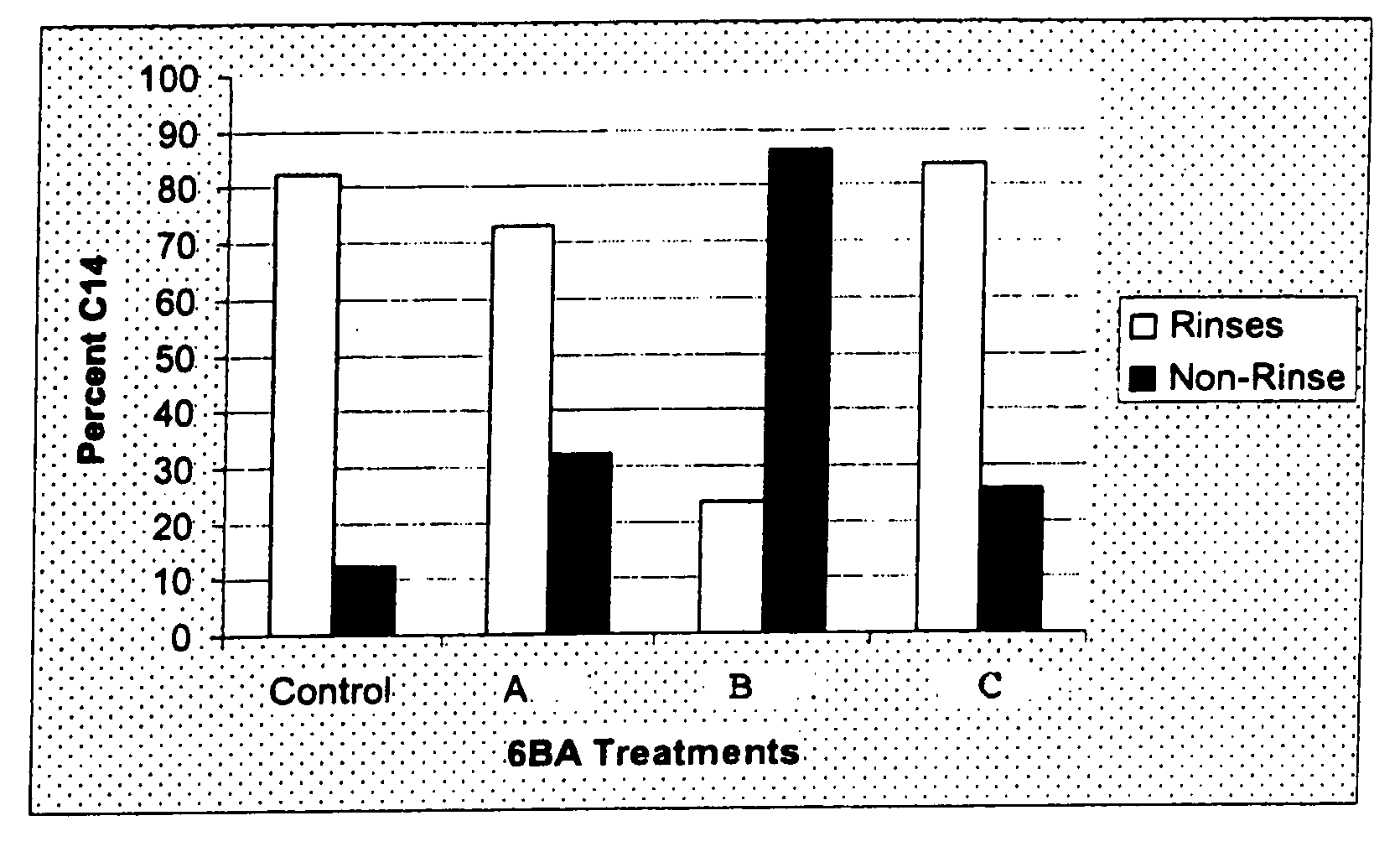

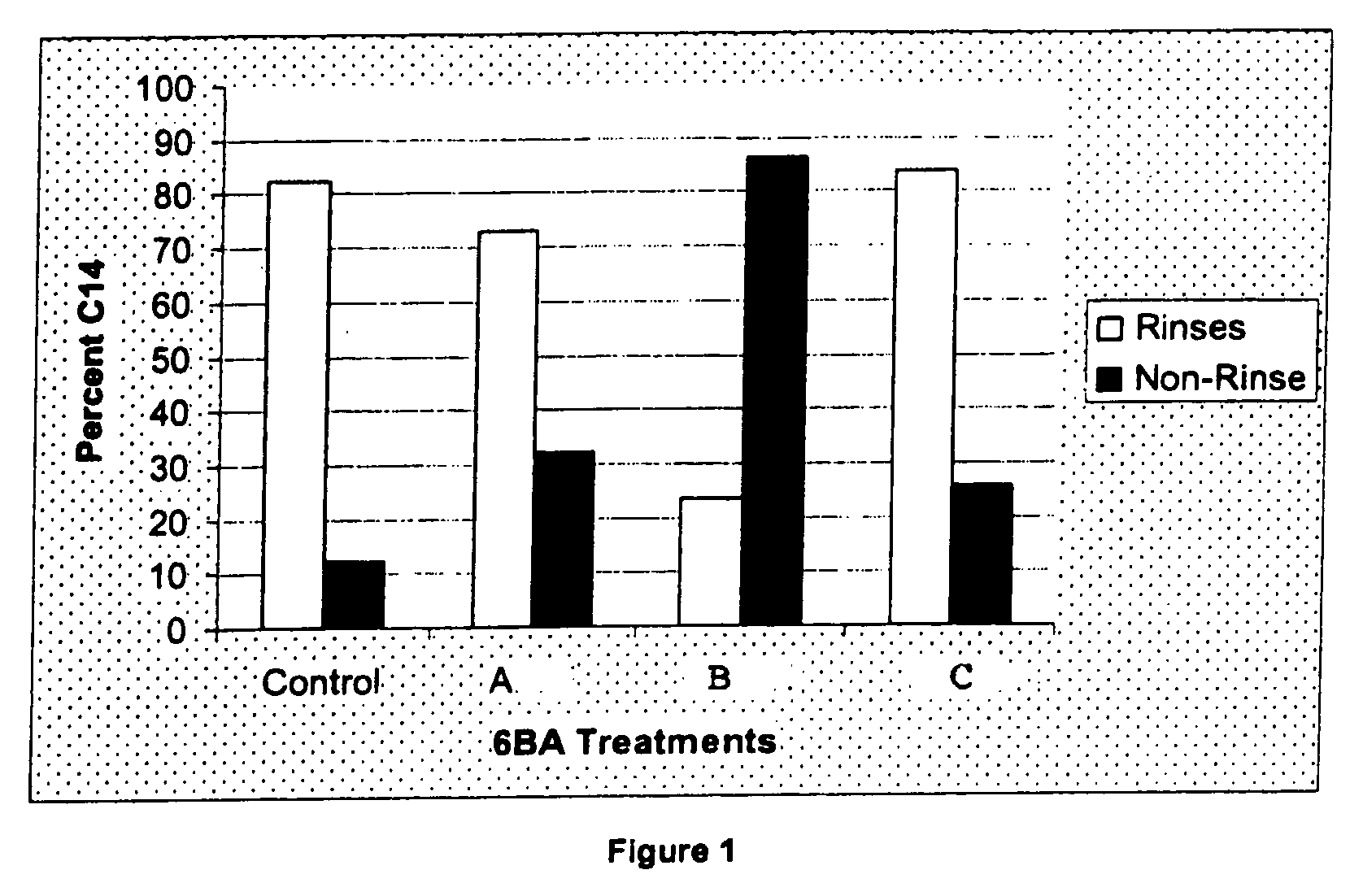

Soluble and stable liquid compositions containing a plant growth regulator selected from the group consisting of cytokinin and a gibberellin, an acid solubilizer such as citric acid, tartaric acid or glycolic acid and a solvent; as well as methods for making and using the composition are disclosed. The compositions improve solubility, handling, stability, safety, as well as activity improvements such as improved plant growth, yield, fruit thinning or sizing and quality. The compositions are soluble and stable by adding an ethoxylated alkyl alcohol wherein the growth regulator is 6-benzyladenine (6-BA) or forchlorfenuron (CPPU) and the ethoxylated alcohol surfactant is C12-15 alkyl alcohol in propylene glycol. The compositions may also contain a cytokinin such as 6-benzyladenine (6-BA) or forchlorfenuron (CPPU) that is increased in solubility and activity and by synergistically combined with GA3 or GA4A7 as well as in storage stability by adding an antioxidant. The compositions are formulated in a ready-to-mix formulation.

Owner:WANG YUEH +6

A kind of aluminum product chemical polishing liquid and preparation method thereof

The invention discloses chemical polishing solution for aluminum products and a preparation method thereof, which relate to chemical polishing solution. The invention provides chemical polishing solution for aluminum products, which has the advantages of producing little yellow smoke, avoiding polluting environment, containing no nitric acid and the like, achieves the same polishing effect as a nitric acid improved 'three-acid' polishing process which is equal to the conventional 'three-acid' process and can reduce release of nitric oxides to protect the environment from being polluted, and apreparation method thereof. The chemical polishing solution for aluminum products is prepared from the following raw materials: sulfuric acid, phosphoric acid, boric acid, passivator, antifog brightener, citric acid, tartaric acid and water. The preparation method comprises the following steps: adding the solid raw materials into water; after the solid raw material dissolve, adding phosphoric acid and sulfuric acid in turn; and after the solution is cool, transferring the solution to a volumetric flask to fix the volume. The using method of the chemical polishing solution for aluminum products comprises: heating the chemical polishing solution for aluminum products to 95 to 110 DEG C; immersing dry and clean aluminum products to be polished into the chemical polishing solution for aluminum products, treating for 30 to 100 seconds, and taking aluminum products out; and immersing the collected aluminum products to be polished in nitric acid for bright dipping for 25 to 120 seconds, washing and thus, accomplishing the polishing of aluminum products.

Owner:XIAMEN UNIV

Rust remover for ultrasonically cleaning metal mould and preparation method thereof

InactiveCN102337545AIncrease surface tensionOptimum viscosity coefficientMetallic material coating processesO-Phosphoric AcidEthyleneglycol monobutyl ether

The invention discloses non-corroding ultrasonic cleaning equipment. A rust remover for ultrasonically cleaning a metal mould is used for rapidly and completely removing rusts on the surface of the metal mould, generating a dense and complete passivation film at the same time and avoiding a secondary oxidization. The rust remover is prepared from the following raw materials by mass percent: 8-30% of phosphoric acid, 6-25% of room-temperature steel surface conditioning agent, 1-4% of citric acid, 1-5% of tartaric acid, 1-4% of phytic acid, 1-8% of polyethylene glycol, 1-3% of penetrant JFC, 1-6% of ethylene glycol monobutyl ether and the balance of water. A preparation method of the rust remover comprises the following steps of: firstly, adding water with a calculated amount into a stainless steel reaction kettle, starting an agitator and controlling a rotary speed of the agitator to 40-60 r / min; then respectively taking the calculated amount of the phosphoric acid, the room-temperature steel surface conditioning agent, the citric acid, the tartaric acid, the phytic acid, the polyethylene glycol, the JFC and the ethylene glycol monobutyl ether and sequentially and slowly adding the materials into the reaction kettle; and adding the materials while agitating until the solution becomes a light-green transparent liquid.

Owner:DALIAN SANDAAOKE CHEM

Effervescent tablet for rinsing mouth and preparation process thereof

InactiveCN102166171AImprove solubilityImprove the bactericidal effectCosmetic preparationsToilet preparationsSodium bicarbonatePolyethylene glycol

The invention discloses an effervescent tablet for rinsing the mouth and a preparation process thereof. The effervescent tablet for rinsing the mouth is prepared from the following components: thymol, menthol, sodium benzoate, sodium bicarbonate, cassia bark, anise seed, rebaudioside, citric acid, tartaric acid, mannitol and polyethylene glycol. The components are sieved, mixed, granulated and pressed to obtain the effervescent tablet for rinsing the mouth. The effervescent tablet for rinsing the mouth has the functions of sterilizing and cleaning the oral cavity, eliminating the peculiar smell in the oral cavity, relieving the oral ulcer and the like, and is convenient to use and carry.

Owner:吴克

Special treating agent for galvanizing surface chemical conversion and treating technique thereof

ActiveCN104498921AReduce pollutionSimple methodMetallic material coating processesSodium phosphatesActive agent

The invention discloses a special treating agent for galvanizing surface chemical conversion and a treating technique thereof, belonging to the field of surface protection of transmission and transformer equipment components. The conversion treating method mainly comprises the steps of pretreatment, water washing, chemical conversion, water washing, natural drying and the like. The pretreatment agent is composed of Na2CO3, NaH2PO4, NaHPO4, sodium pyrophosphate, copper salt, nickel salt and titanium salt. In the treatment process, the conversion agent is composed of H3PO4 and ZnO, the corrosion inhibitor is one or both of thiocarbamide and hexamethylenetetramine, the complexing agent is composed of one or more of citric acid, tartaric acid and monobutyric acid, the surfactant is composed of one or more of OS-15, OP-10 and sodium dodecyl benzene sulfonate, and the accelerator is composed of one or more of sodium nitrate, sodium nitrate, hydrogen peroxide, potassium permanganate and potassium chlorate. The galvanizing substrate surface treated by the technique is a compact corrosion-resistant film with insulation resistance. The treating agent and treating technique can effectively enhance the corrosion resistance of the material and enhance the corrosion resistance and service life of the transmission and transformer equipment metal components.

Owner:STATE GRID CORP OF CHINA +1

Processing method for haw electuary

InactiveCN103315361AMaintain nutrientsMaintain propertiesFood preparationBiotechnologySodium bicarbonate

The invention provides a processing method for a haw electuary. The processing method comprises the following steps: crushing haw to obtain haw puree, subjecting the haw puree to enzymatic hydrolysis, adding tea polyphenol, lactose and mannitol, carrying out uniform mixing, drying an obtained mixture, grinding the mixture into fine powder, subjecting the ground fine haw powder, citric acid, tartrate, CMS-Na, PVP and sodium bicarbonate to granulation with an absolute ethyl alcohol solution as a binder and carrying out drying so as to obtain an electuary particle. The haw electuary prepared by using the method has unique taste and fragrant and sweet mouthfeel, maintains original nutritional ingredients and special efficacy of haw, is convenient to drink and is leisure food easily acceptable by people.

Owner:靖西县科学技术情报研究所

Catalyst for producing MTBE (Methyl Tert-Butyl Ether) by virtue of C4 fractions in refinery plant

ActiveCN104923286AHigh load rateExcellent selective catalyticMolecular sieve catalystsEther preparation by compound additionBULK ACTIVE INGREDIENTChemistry

The invention discloses a catalyst for producing MTBE (Methyl Tert-Butyl Ether) by virtue of C4 fractions in a refinery plant, and relates to the technical field of catalyst synthesis. A ZSM-5 zeolite molecular sieve serves as a carrier, platinum or nickel serves as an active ingredient, alumina, titanium dioxide, zinc oxide or zirconia serves as an adhesive, citric acid, tartaric acid, hydrochloric acid, oxalic acid, lactic acid or trichloroacetic acid serves as a competitive adsorbent, and the catalyst is prepared by an ultrasonic-microwave impregnation method. According to the catalyst, by the microporous structure of the ZSM-5 zeolite molecular sieve, the load ratio of the active ingredient can be increased, and the obtained catalyst has high selective catalytic performance; the ultrasonic-microwave impregnation method is used, so that the load ratio of the active ingredient can be increased, and time for preparing the catalyst is shortened.

Owner:ANHUI HAIDE PETROCHEM

Special calcium remover for edition developing machine and preparation method of special calcium remover

InactiveCN103666840AGood removal effectChemical paints/ink removersAmpholytes/electroneutral surface-active compoundsSilver inkEthylic acid

The invention discloses a special calcium remover for an edition developing machine. The special calcium remover is prepared from the following raw materials in parts by weight: 5-6 parts of citric acid, 20-30 parts of tartaric acid, 2-3 parts of acetic acid, 3-4 parts of nano silicon dioxide, 5-6 parts of stearic acid, 1-2 parts of diethylene glycol, 2-5 parts of dodecyldimethyl betaine, 3-4 parts of cocoanut fatty acid diethanolamide, 3-5 parts of nonylphenol ethoxylates, 4-5 parts of composite auxiliaries and 40-50 parts of water. The special calcium remover for the edition developing machine, disclosed by the invention, can be used for effectively removing calcium salt on an ink roller and particularly used for turning ink from a dark color to a light color and cleaning gold ink and silver ink and is low in dosage and very good in ink cleaning effect.

Owner:BENGBU TIMES ELECTRONICS

Sulfamic acid rust removing liquid and rust removing method using same

The embodiment of the invention provides sulfamic acid rust removing liquid and a rust removing method using the same. The rust removing liquid is prepared from following components in percent by mass: 5%-20% of sulfamic acid, 1%-3% of chlorine salt, 1%-3% of citric acid, 1%-3% of tartaric acid, 0.6%-2.5% of an assistant, 0.2%-0.5% of an anionic surfactant and the balance water. According to the sulfamic acid rust removing liquid, the performance of the rust removing liquid with the sulfamic acid as a body is improved through the synergistic effect of the chlorine salt, the citric acid, the tartaric acid and the anionic surfactant, a good washing effect on plain carbon steel and low-alloy steel is achieved, the washing capacity is high, the washing speed is high, and the service life is long.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Electrochemical method for preparing tin coating rear earth or molybdate passive film

InactiveCN104060254AGood corrosion resistanceImprove corrosion resistanceMetallic material coating processesMagnetic stirrerChemistry

The invention relates to an electrochemical method for preparing tin coating rear earth or a molybdate passive film. The electrochemical method comprises the steps of mixing 25g / L of sodium molybdate with 5g / L of cerous nitrate, adjusting the pH value of the mixed solution to be 4.0-6.0 with citric acid, adding 4g / L of citric acid and 8g / L of tartaric acid, stirring by a magnetic stirrer, wherein the constant current is 0.2-0.6A / dm<2> and the temperature is 30-50DEG C, putting the passivated sample with oil and rust removed into a passive liquor for passivating for 3-10 seconds, so as to obtain the product. The electrochemical method has the advantages that the sodium molybdate and cerous nitrate are mixed to be used as a base liquid, then additives are added, the magnetic stirrer is used for stirring, the tin coating passive film is obtained through electrochemical passivation, and the passive film has the characteristics of uniformity, compactness, and good corrosion resistance.

Owner:SHENYANG LIGONG UNIV

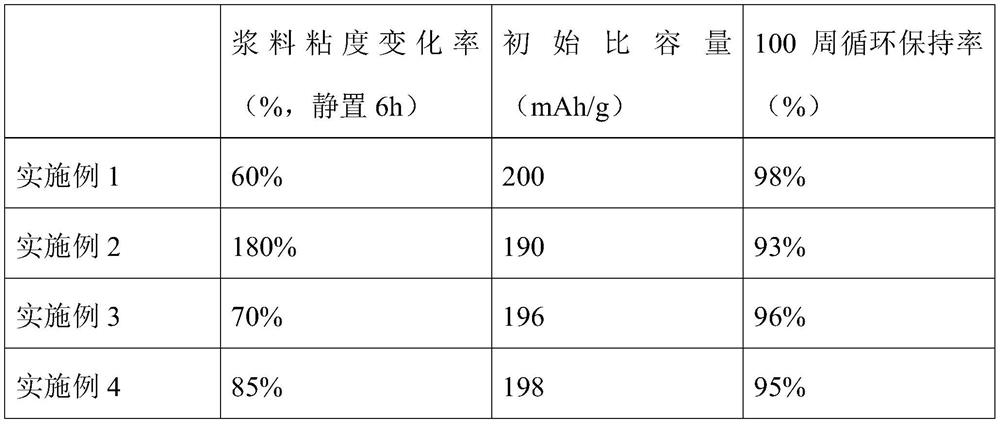

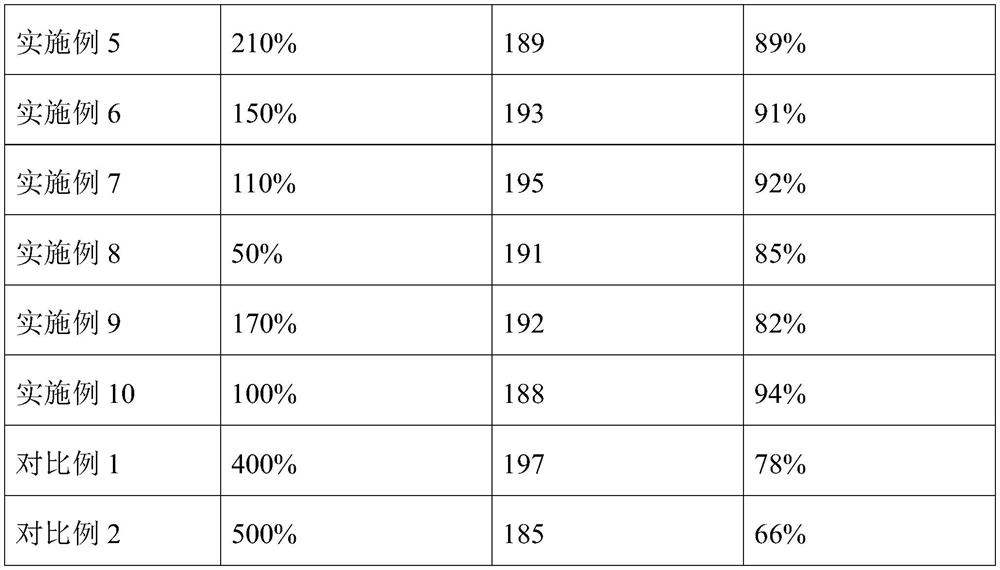

Positive electrode slurry and application thereof

ActiveCN112510192AEasy to operateEasy to industrializePositive electrodesSecondary cells servicing/maintenanceOXALIC ACID DIHYDRATEElectrical battery

The invention relates to a positive electrode slurry and an application thereof, the positive electrode slurry comprises a high-nickel positive electrode material and an additive, and the additive comprises at least one of LiPF6, boric acid, oxalic acid, citric acid, tartaric acid, tetraethyl silicate, LiPO2F2 and HPF6; the additive can react with residual alkali on the surface of a high-nickel positive electrode material to reduce the alkalinity of positive electrode slurry and improve the stability and processability of the positive electrode slurry, so that the gas production of a battery prepared from the additive in the use process is reduced, the safety of the battery is improved, the application of the waterless high-nickel positive electrode material is facilitated, and the cost ofthe battery is reduced; meanwhile, the preparation process of the positive electrode slurry is simple to operate, and industrialization is easy to realize.

Owner:EVE ENERGY CO LTD

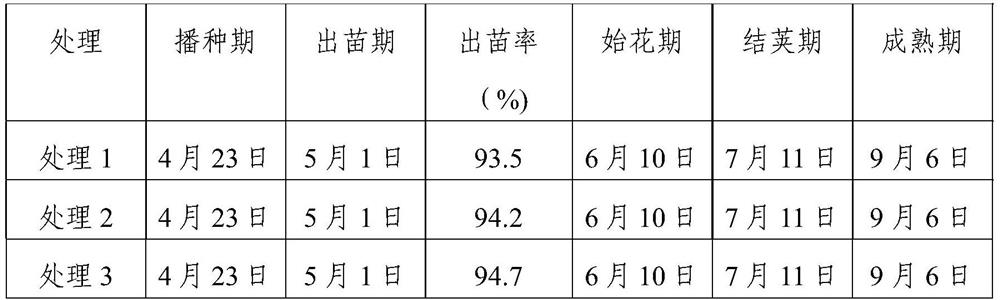

Slow-release synergistic phosphate fertilizer as well as preparation method and application thereof

ActiveCN112028690AImprove MicroecologyImprove living soil and promote rootsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCitric Acid / tartaric acidOligosaccharide

The invention relates to a slow-release synergistic phosphate fertilizer as well as a preparation method and application thereof. The slow-release synergistic phosphate fertilizer has a core-shell structure, the core is prepared from phosphate fertilizer, polyglutamic acid, activated humic acid, alginic acid and polyacrylamide, and the shell is prepared from chitosan oligosaccharide, sulfur, citric acid and tartaric acid, wherein the mass ratio of the phosphate fertilizer to the polyglutamic acid to the activated humic acid to the alginic acid to the polyacrylamide is (80-100):(0.1-10):(0.1-10):(0.1-5):(0.1-5), and the mass ratio of the chitosan oligosaccharide to the sulfur to the citric acid to the tartaric acid is (0.1-4):(0.1-4):(0.1-3):(0.1-3). The raw materials which are biodegradable, chelated, capable of improving the soil structure and high in pertinence are added into the phosphate fertilizer, so that the phosphate fertilizer is good in effect, high in utilization rate, capable of meeting the requirements of various crops for phosphorus, capable of being mixed with other fertilizers for use, suitable for all stages of crops, safe in production, low in energy consumption and free of secondary pollution.

Owner:STANLEY AGRI GRP CO LTD

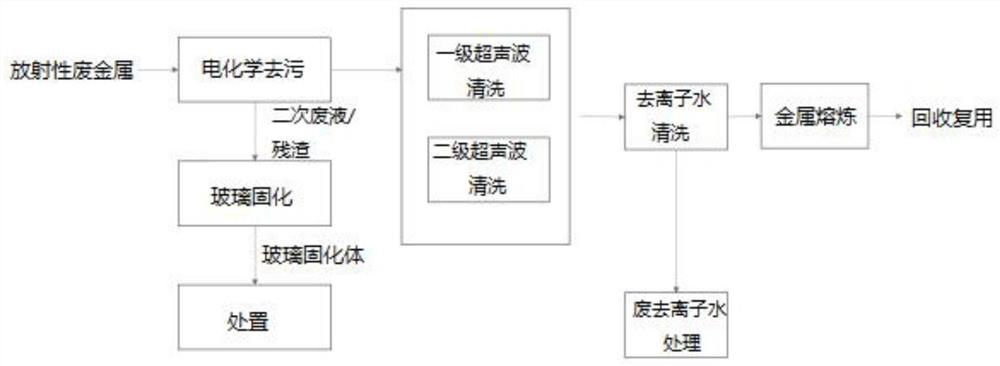

Radioactive waste metal recovery method

ActiveCN112176145ARadioactive decontaminationGas emission reductionOXALIC ACID DIHYDRATEElectrolytic agent

The invention relates to the technical field of radioactive waste treatment, and provides a radioactive waste metal recovery method. The method includes the steps that electrochemical decontamination,ultrasonic cleaning, and water washing are sequentially carried out on radioactive waste metal; smelting is carried out on the washed waste metal; and an electrolyte for electrochemical decontamination is an aqueous solution, and solutes comprises phosphoric acid, oxalic acid, citric acid, tartaric acid, hydrogen peroxide, and glacial acetic acid. The radioactive waste metal recovery method has agood decontamination effect on the radioactive waste metal and is easy to operate, and the decontaminated waste metal can be effectively recycled through smelting. Furthermore, according to the method, substances removed in the decontamination process exist in the form of precipitates and are easy to collect and treat, and generated secondary waste liquid and the precipitates are subjected to glass solidification treatment, so that the minimization of the waste is realized.

Owner:SICHUAN ENVIRONMENTAL PROTECTION ENG CO LTD CNNC

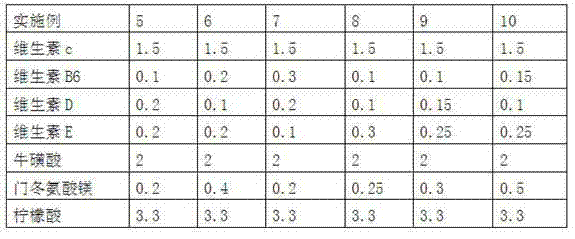

Solid beverage containing vitamin regulator

ActiveCN104489849AGood water solubilityPromote absorptionVitamin food ingredientsFood ingredient functionsVitamin b6Sodium bicarbonate

The invention belongs to the technical field of solid beverages and in particular discloses a solid beverage containing a vitamin regulator. The solid beverage is prepared from the following raw materials including vitamin C, vitamin B6, vitamin D, vitamin E, citric acid, tartaric acid, magnesium aspartate, taurine, sodium carbonate, sodium bicarbonate, lactose, mannitol, sweet orange powder, aspartame, polyethylene glycol 6000, ethanol and a sweetener. The solid beverage is capable of rapidly replenishing energy and strengthening resistance, is a functional beverage preparation for regulating the function of a human body and is suitable for being drunk by sporting people.

Owner:JING JING PHARMA

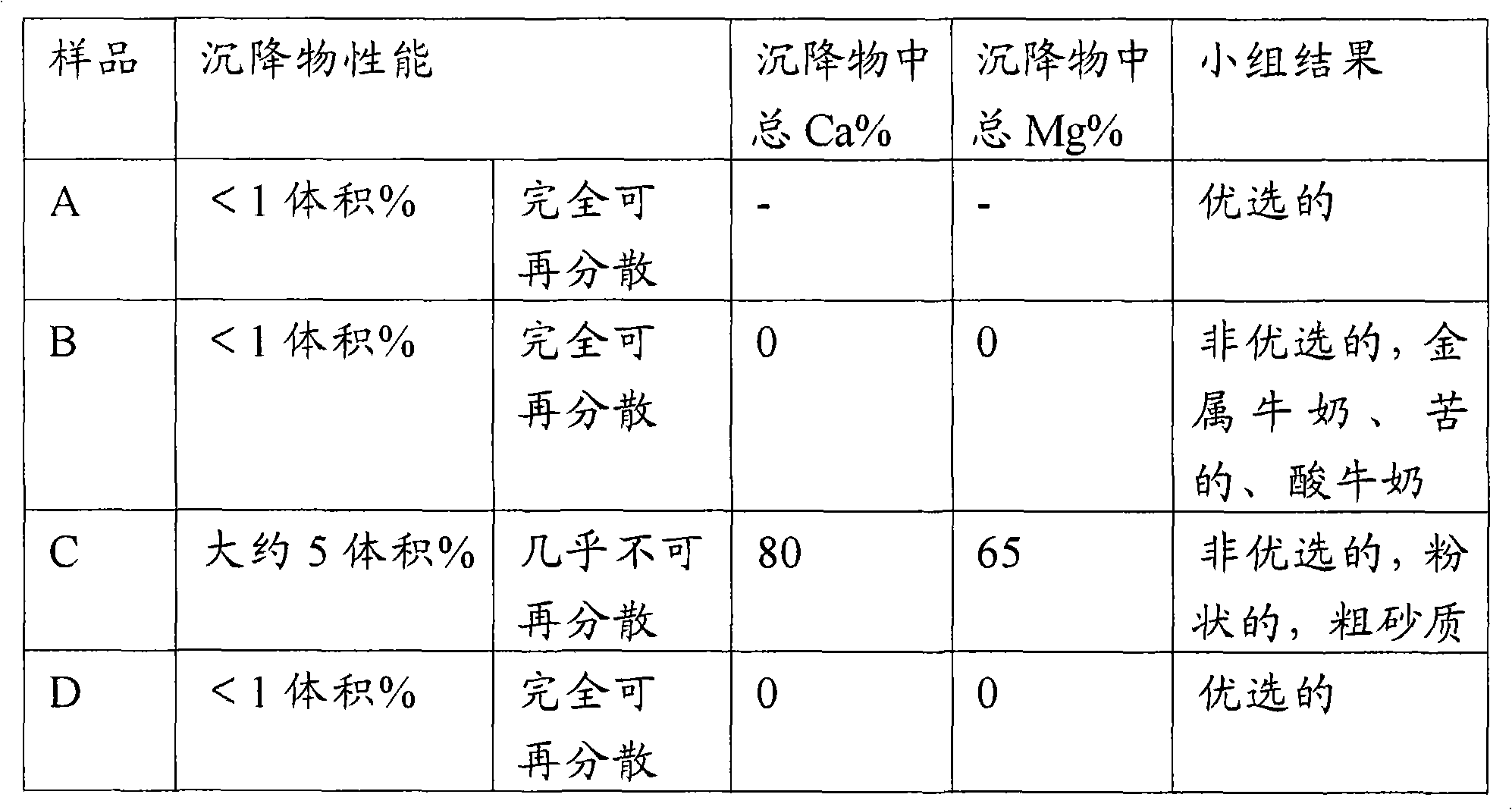

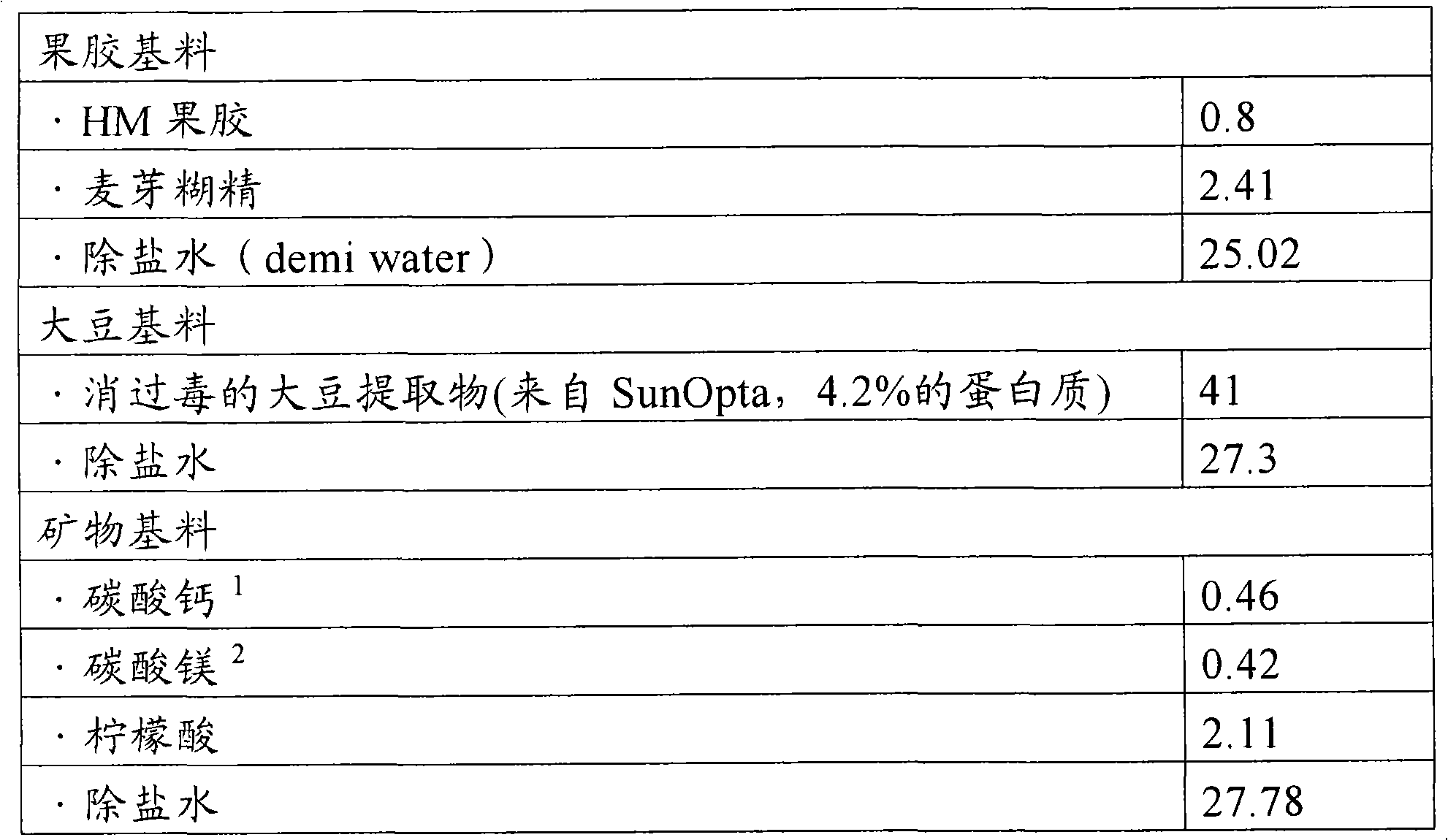

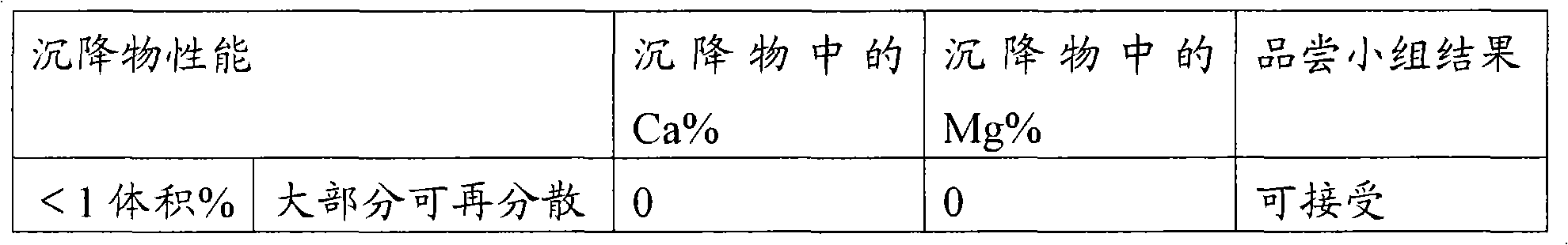

A method of supplementing an edible aqueous liquid composition with two or more mineral salts

InactiveCN101668438AReduce solubilityMake sure to dissolve completelyInorganic active ingredientsFood preparationGramLiquid composition

One aspect of the invention relates to a method for producing an edible aqueous liquid composition that has been supplemented with a first mineral selected from the group of metals consisting of calcium, magnesium, potassium, zinc, copper, iron, manganese and a second mineral, different from the first mineral, that is selected from the same group of metals. Another aspect of the present inventionsrelates to a reconstitutable powder containing: 0.01-3 mmole of the first mineral per gram of powder; 0.02-4 mmole of the second mineral per gram of powder; 0.02-8 mmole of acid per gram of powder, said acid being selected from the group consisting of citric acid, tartaric acid, malic acid, phosphoric acid and combinations thereof; 0.02-0.99 g of soy protein per gram of powder; and less than 10 wt. % of water. The reconstitutable powder is characterised in that 25 grams of the powder can be reconstituted with 1 kg of water to yield an edible aqueous liquid that will not form a salt sediment of the first and / or second mineral when stored under ambient, quiescent conditions for 3 months or longer.

Owner:UNILEVER NV

Resveratrol-containing composition having immunity enhancement effect and preparation containing composition

InactiveCN104523996AColor coordinationThe taste is moderately sweet and sourHydroxy compound active ingredientsGranular deliveryBiotechnologyMedicine

The invention relates to a resveratrol-containing composition having an immunity enhancement effect. The resveratrol-containing composition contains such components as resveratrol, ginseng extract and Chinese wolfberry extract. The invention also provides a preparation containing the composition. The preparation is produced from the resveratrol, the ginseng extract, the Chinese wolfberry extract, anhydrous citric acid, tartaric acid and prebiotics. Experiments discover that the low immunity symptom of volunteers taking the composition can be obviously improved (the volunteers are not prone to catch a cold and suffer from an allergy), and the effective rate of the composition is 80-88%.

Owner:天津药食同源健康产业有限公司

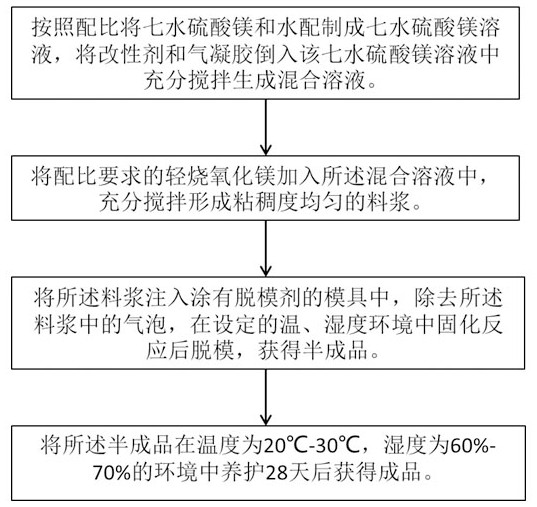

Preparation method of magnesium oxysulfate cementing material adopting silicon dioxide aerogel and building component

ActiveCN113979716AReduce thermal efficiencyImprove mechanical propertiesSolid waste managementCitric Acid / tartaric acidPhysical chemistry

The invention provides a magnesium oxysulfate cementing material adopting silicon dioxide aerogel, a preparation method of the magnesium oxysulfate cementing material and a building component. The magnesium oxysulfate cementing material adopting the silicon dioxide aerogel comprises a component A and a component B, wherein the component A comprises, by mole, 1 part of magnesium sulfate heptahydrate, 8-12 parts of light calcined magnesia and 15-22 parts of water, and the content of active magnesium oxide in the light calcined magnesia ranges from 55% to 65%; the component B comprises a modifier and aerogel; the modifier is one of citric acid, tartaric acid and sodium malate or a mixture of the citric acid and the tartaric acid, the citric acid accounts for 0.7%-0.8% of the mass of the light calcined magnesia, and the tartaric acid and the sodium malate both account for 1.3%-1.8% of the mass of the light calcined magnesia; and the mass of the aerogel is 6% or less of that of the light calcined magnesia. According to the magnesium oxysulfate cementing material adopting the silicon dioxide aerogel, the mechanical property and the thermal insulation property of the magnesium oxysulfate cementing material can be improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of additive

ActiveCN112481504AEasy to useReduce dosageProcess efficiency improvementZincum oxydatumPolyethylene glycol

The invention relates to a preparation method of an additive. According to the method, the additive is prepared from citric acid, tartaric acid, Tween-80, alkylphenol ethoxylates, fatty alcohol-polyoxyethylene ether, polyethylene glycol, polyacrylamide, iso-tridecanol polyoxyethylene ether, sorbitan trioleate, sulfuric acid, ethylene glycol, triethylamine, gelatin and other substances under a series of conditions. The substances are added to germanium-containing zinc oxide smoke leachate and uniformly mixed, an effective protective layer is formed on the surface of tannin germanium slag precipitate generated in the tannin germanium precipitation process, the capacity of adsorbing impurity ions such as Zn, Fe, Mn and As in the zinc oxide smoke leachate during precipitation is weakened, thegermanium grade in tannin germanium slag is improved, and the quality of a germanium concentrate prepared in the subsequent procedure is improved. The prepared additive is small in dosage and high inefficiency, excessive additives which do not participate in the reaction can be removed in the subsequent excessive tannin removal process, subsequent procedures are not affected, and great economic value is achieved.

Owner:KUNMING UNIV OF SCI & TECH

Radix puerariae gas-containing solid beverage tablets and preparation process thereof

The invention relates to radix puerariae gas-containing solid beverage tablets and a preparation process thereof. The radix puerariae gas-containing solid beverage tablets are prepared from the following raw materials: 150-250 g of a radix puerariae powder, 700-900 g of lactose, 8-15 g of stevioside, 120-150 g of tartaric acid, 180-220 g of citric acid, 3-5 g of a flavoring agent, 180-220 g of polyethylene glycol, 360-400 g of sodium bicarbonate, and 50-70 g of a talcum powder, wherein 1000 pieces of the tablets are prepared. The preparation process comprises the steps: taking the radix puerariae powder, lactose, stevioside, citric acid and tartaric acid, and stirring evenly; preparing a core material with ethanol; heating polyethylene glycol, then adding sodium bicarbonate, cooling, crushing, adding the obtained mixture into the core material, and mixing; and grinding the flavoring agent finely, then adding into the core material, mixing, adding the talcum powder, mixing, and tabletting. The radix puerariae is made into the gas-containing solid beverage tablets with a modern technology, and beneficial ingredients in the radix puerariae are reasonably loaded, so that the tablets are capable of helping produce saliva and slake thirst, and preventing and treating diseases, have a relatively strong health care function, and are suitable for all kinds of people. The gas-containing solid beverage tablets are convenient to take, good in taste, convenient to carry, transport and store, and long in storage period, and are a novel radix puerariae health beverage.

Owner:重庆正里元实业有限公司

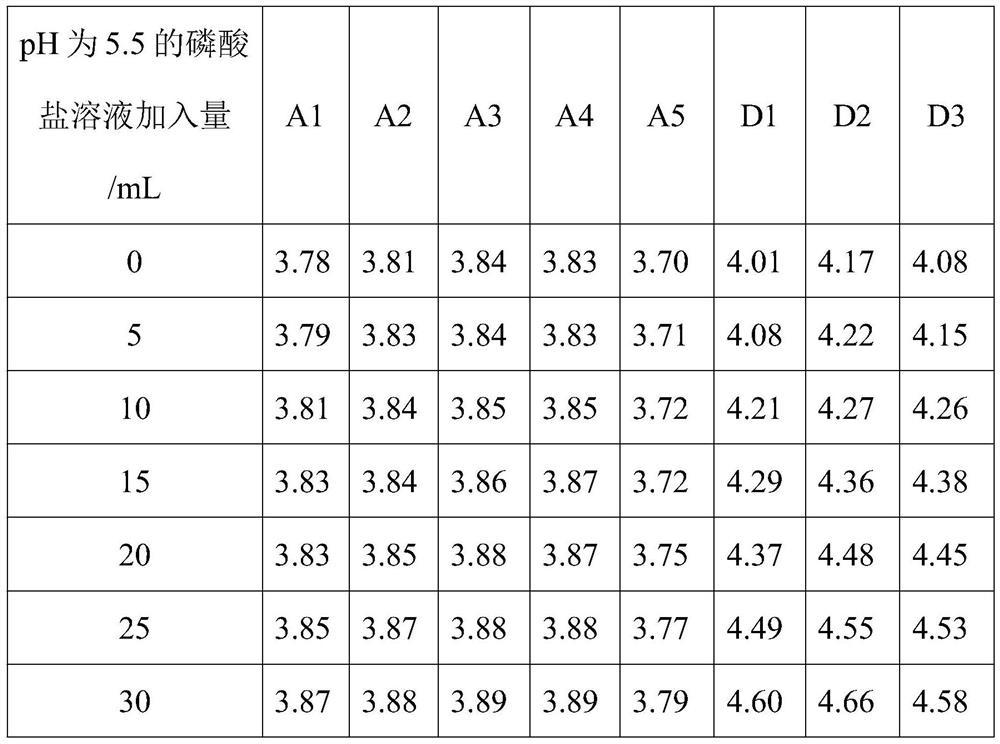

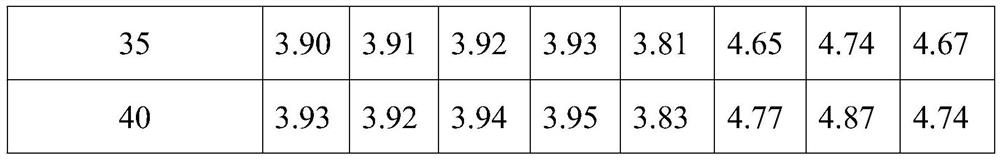

Vagina pH regulator as well as preparation method and application thereof

PendingCN112933109AResists and inhibits growthKeep healthyAntibacterial agentsHydroxy compound active ingredientsPathogenCitric Acid / tartaric acid

The invention relates to the technical field of medicines, and discloses a vagina pH regulator as well as a preparation method and application thereof. The vagina pH regulator contains glucose, urea, potassium hydroxide, carbomer, glycerol, lactic acid, citric acid, tartaric acid, a preservative and water. The vagina pH regulator disclosed by the invention can regulate the vagina pH value to be in a normal range of 3.5-4.5, resist and inhibit the growth of pathogenic bacteria, maintain the microbial environment health in the vagina, and effectively regulate the pH value even in the presence of seminal fluid. Therefore, an acidic environment which is not suitable for the survival of sperms and viruses and bacterial pathogens related to sexual transmission infection but is essential for the survival of healthy bacteria in the vagina is maintained.

Owner:湖南奥朗特医疗器械有限公司

Flotation method of spodumene ore

InactiveCN110918260AImprove flotation separationIncrease profitFlotationOXALIC ACID DIHYDRATEButanedioic acid

The invention relates to a flotation method of spodumene ore. According to the method, in a spodumene ore flotation process, a regulating agent C2-C6 organic polybasic acid solution or a salt solutionthereof is added into ore pulp and performs pulp regulating, wherein the C2-C6 organic polybasic acid is one or a plurality of materials selected from citric acid, tartaric acid, oxalic acid, succinic acid and malic acid, and the use amount of the C2-C6 organic polybasic acid is 0.05-0.5 kg / t. raw ore. According to the invention, the new regulating agent is added on the basis of the common spodumene flotation method, so that the spodumene flotation separation performance is improved, fine-grain spodumene flotation does not need desliming, the recovery rate is high, the flotation process is simplified, and the utilization rate of lithium resources is increased.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

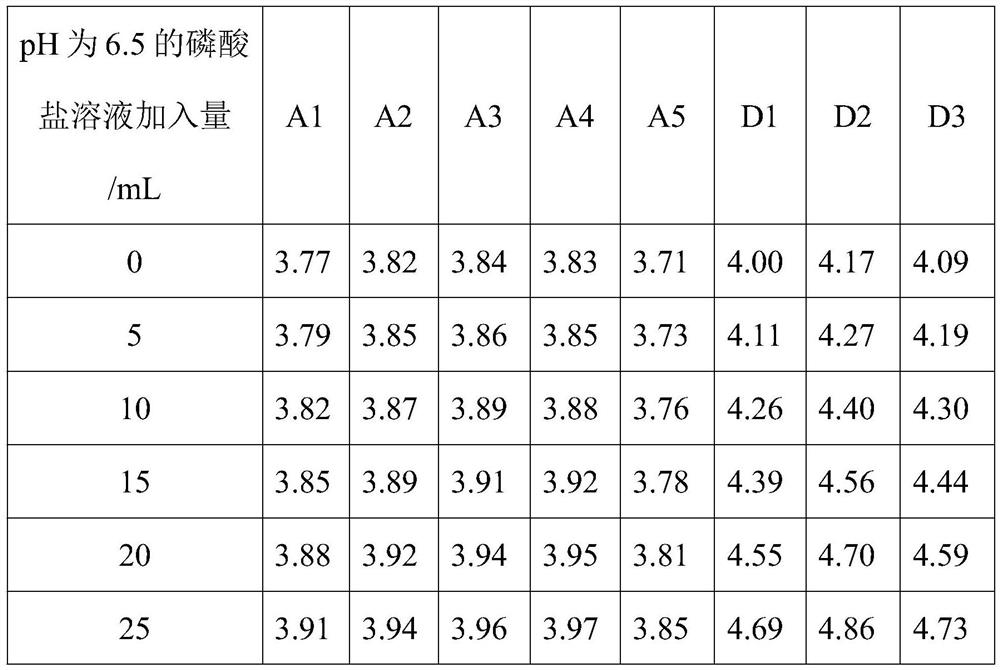

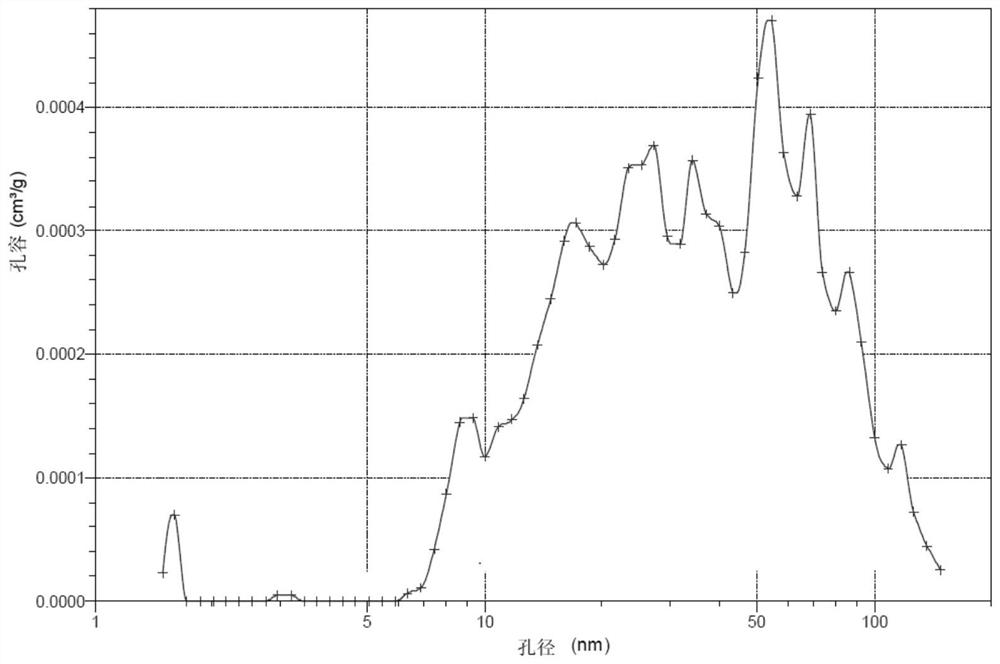

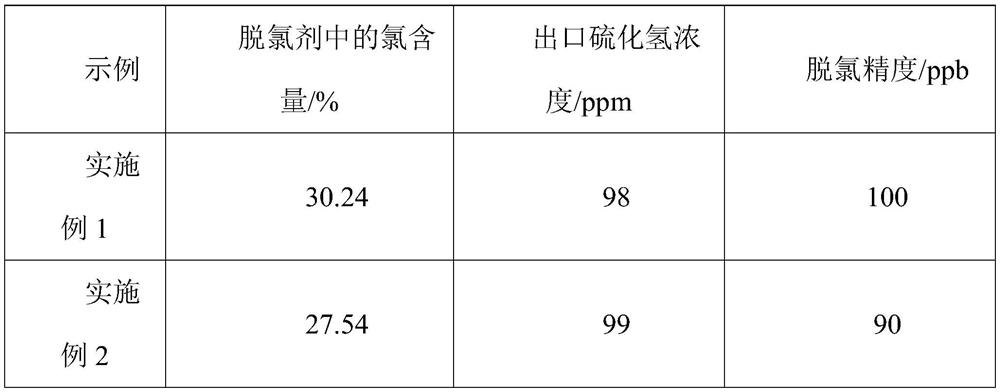

Dechlorinating agent as well as preparation method and application thereof

PendingCN113952945AImprove dechlorination effectImprove adsorption capacityGas treatmentOther chemical processesOXALIC ACID DIHYDRATEMolecular sieve

The invention belongs to the technical field of preparation of dechlorinating agents, and particularly relates to a dechlorinating agent as well as a preparation method and application thereof. The raw materials comprise an X-type molecular sieve, an alkali metal compound, an alkaline earth metal compound, a binder and a pore structure modifier. The pore structure modifier is at least one of citric acid, tartaric acid, ethylenediaminetetraacetic acid, oxalic acid, carboxylic acid or salt compounds formed by the citric acid, the tartaric acid, the ethylenediaminetetraacetic acid, the oxalic acid and the carboxylic acid. The X-type molecular sieve, the pore structure modifier, the alkali metal compound, the alkaline earth metal compound and the binder are used as raw materials, the obtained dechlorinating agent can specifically adsorb inorganic chlorine under the normal temperature condition and the high hydrogen sulfide condition, and the dechlorinating agent is a gas-phase dechlorinating agent; the dechlorinating agent has a good dechlorinating effect especially in the fields of dechlorinating products for preparing propylene through propane dehydrogenation and the like, inorganic chlorine can be selectively adsorbed under the condition of high hydrogen sulfide, and the dechlorinating precision can reach 0.5 ppm or below.

Owner:SHENYANG SANJUKAITE CATALYST

Stabilized aqueous suspension for initiating setting and hardening of aluminous cement compositions

ActiveUS10822284B2Solid waste managementBuilding constructionsAlkaline earth metalCitric Acid / tartaric acid

A long-term stabilized aqueous initiator composition, which includes components for curing of a two-component mortar system composition. The long-term stabilized aqueous initiator composition includes an activator component that has an alkali and / or alkaline earth metal salt, an accelerator component that has a water-soluble alkali and / or alkaline earth metal salt, a retarder selected from citric acid, tartaric acid, lactic acid, salicylic, gluconic acid, and a mixture of these components, a mineral filler selected from a limestone filler, corundum, dolomite, alkaline-resistant glass, crushed stone, gravel, pebble, and a mixture of these components, a thickening agent, and water.

Owner:HILTI AG

Catalyst for the production of mtbe from a refinery carbon four fraction

ActiveCN104923286BHigh load rateExcellent selective catalyticMolecular sieve catalystsEther preparation by compound additionOXALIC ACID DIHYDRATEPtru catalyst

The invention discloses a catalyst for producing MTBE (Methyl Tert-Butyl Ether) by virtue of C4 fractions in a refinery plant, and relates to the technical field of catalyst synthesis. A ZSM-5 zeolite molecular sieve serves as a carrier, platinum or nickel serves as an active ingredient, alumina, titanium dioxide, zinc oxide or zirconia serves as an adhesive, citric acid, tartaric acid, hydrochloric acid, oxalic acid, lactic acid or trichloroacetic acid serves as a competitive adsorbent, and the catalyst is prepared by an ultrasonic-microwave impregnation method. According to the catalyst, by the microporous structure of the ZSM-5 zeolite molecular sieve, the load ratio of the active ingredient can be increased, and the obtained catalyst has high selective catalytic performance; the ultrasonic-microwave impregnation method is used, so that the load ratio of the active ingredient can be increased, and time for preparing the catalyst is shortened.

Owner:ANHUI HAIDE PETROCHEM

Electrochemical decontamination electrolyte and preparation method and application thereof

ActiveCN112176393AEasy to handleReduce radioactive contaminationRadioactive decontaminationOXALIC ACID DIHYDRATEElectrolytic agent

The invention relates to the technical field of radioactive waste treatment, and provides an electrochemical decontamination electrolyte and a preparation method and application thereof. The electrochemical decontamination electrolyte is an aqueous solution, and solutes are prepared from phosphoric acid, oxalic acid, citric acid, tartaric acid, hydrogen peroxide and glacial acetic acid. Accordingto the electrochemical decontamination electrolyte and the preparation method and application thereof, the types of solutes of the electrochemical decontamination electrolyte are reasonably matched, and the dosage of the solutes is reasonably controlled, so that the electrochemical decontamination electrolyte which is good in decontamination effect, high in decontamination speed and capable of easily treating generated secondary waste liquid and residues is obtained; and the electrochemical decontamination electrolyte is suitable for overall or local electrochemical decontamination of radioactive contaminated waste stainless steel. In addition, in the electrochemical decontamination electrolyte, oxalic acid, citric acid, tartaric acid and glacial acetic acid are all organic acids and do not contain N and Cl ions, the electrochemical decontamination electrolyte is very beneficial to a glass solidification treatment system of decontamination waste liquid, and thus the generated waste liquid is easy to treat through the glass solidification system.

Owner:SICHUAN ENVIRONMENTAL PROTECTION ENG CO LTD CNNC

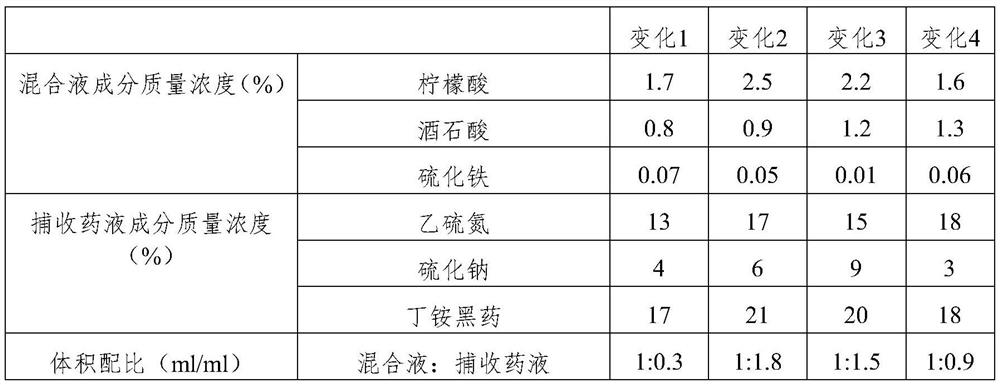

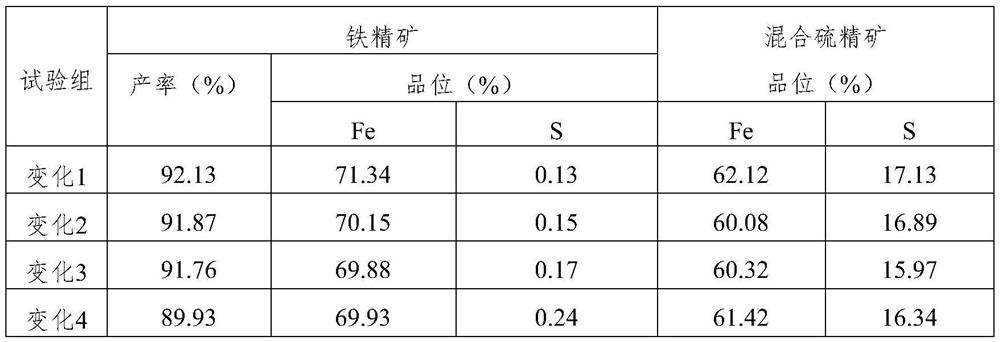

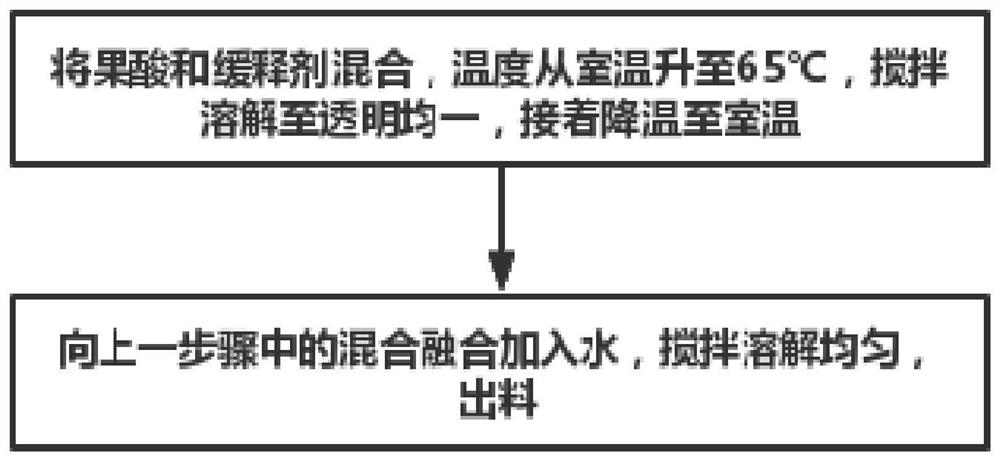

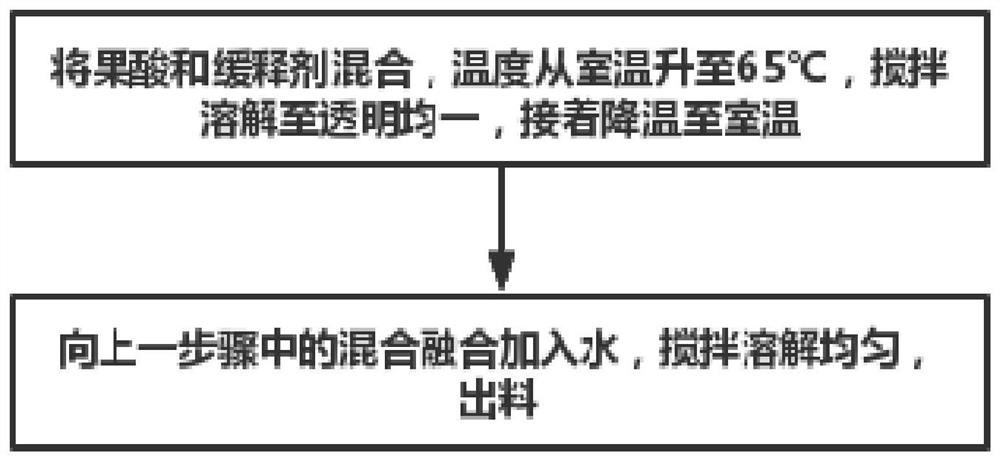

A kind of chemical agent for beneficiation of high-sulfur magnetite ore and its application method

InactiveCN109604070BAchieve activationGuaranteed separation effectFlotationDibutyl dithiophosphateCitric Acid / tartaric acid

The invention relates to the technical field of mineral processing chemicals, in particular to a high-sulfur magnetite processing agent and an application method thereof. The high-sulfur magnetite processing agent is prepared by the following steps: using citric acid, tartaric acid, iron sulfide and water to prepare a mixed solution; using sodium diethyldithiocarbamate, sodium sulfide, ammonium dibutyl dithiophosphate and water to prepare a collecting agent liquid; and mixing the mixed solution and the collecting agent liquid according to a volume ratio of 1:(0.3-1.8) to form the high-sulfur magnetite processing agent. Therefore, activation of pyrrhotite is realized, separation between the pyrrhotite and magnetite is ensured, and the purpose of enhancing the desulfurization effect is achieved. The high-sulfur magnetite processing agent can be applied to desulfurization treatment of high-sulfur magnetites with different sulfur contents, and enables the sulfur content of iron concentrateafter flotation treatment to be reduced 0.15% or less, and the iron concentrate yield to be 91% or more.

Owner:遵义市博莱金矿业有限责任公司

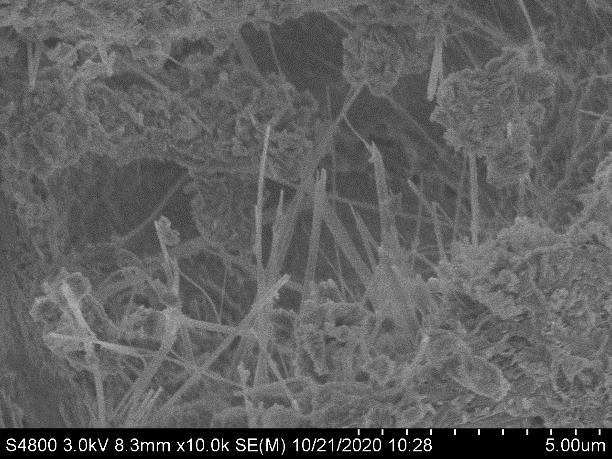

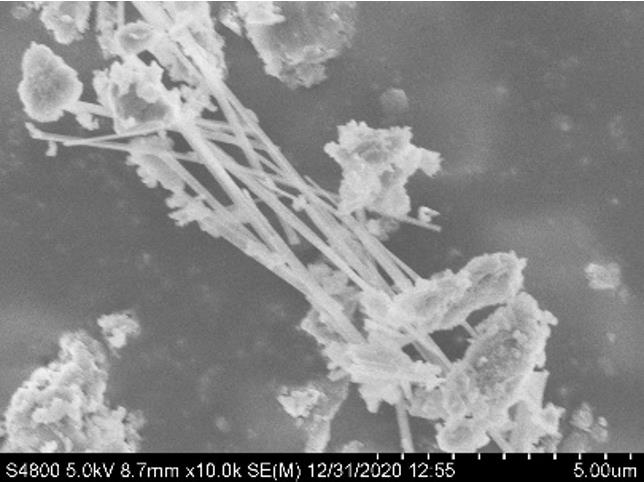

A method for preparing organic intercalated chromium-containing hydrotalcite nano-tanning agent by utilizing chrome tanning waste liquor

ActiveCN113073158BEasy to handleReduce processing burdenTanning treatmentItaconic acidCitric Acid / tartaric acid

The invention discloses a method for preparing an organic intercalated chromium-containing hydrotalcite nano-tanning agent by using chrome tanning waste liquid, which solves the disadvantages of high cost, complicated operation, secondary pollution and the like in the existing chromium reuse method. The technical scheme of the present invention is as follows: a method for preparing an organic intercalated chromium-containing hydrotalcite nano-tanning agent using chrome tanning waste liquid, using organic anions such as citric acid, tartaric acid or itaconic acid as an intercalation agent, using chrome tanning waste liquid Preparation of organic intercalated chromium-containing hydrotalcite nano-tanning agent. The present invention uses the chrome tanning waste liquid which is the most polluted in the tanneries as the raw material to prepare the material for tanning leather, which can effectively treat the chrome tanning waste liquid so that it can be effectively recycled, save chemical raw materials, and reduce the waste water of chrome tanning comprehensive waste water. The processing burden, the tanning performance of the organic intercalated chromium-containing hydrotalcite nano-tanning agent prepared by the present invention meets the standard requirements, and has practical application value.

Owner:SHAANXI UNIV OF SCI & TECH

Tartaric acid sustained-release composition as well as preparation method and application thereof

PendingCN113952254AEasy to useBrighten the skinCosmetic preparationsToilet preparationsGlycolic acidSalicylic acid

The invention discloses a tartaric acid sustained-release composition, and belongs to the technical field of cosmetics. The tartaric acid sustained-release composition comprises the following components in percentage by weight: 2-30% of tartaric acid, 5-55% of a sustained-release agent and 15-93% of water. Wherein the tartaric acid is one or more of glycolic acid, lactic acid, citric acid, tartaric acid, malic acid, salicylic acid, lactobionic acid, gluconic acid and amygdalic acid; the sustained-release agent is a PEG and PPG polyether copolymer. The invention also provides a preparation method and application of the tartaric acid sustained-release composition. Compared with the prior art, the tartaric acid sustained-release composition disclosed by the invention has the beneficial effects that the tartaric acid sustained-release composition has the characteristics of safety and no pain to user experience; meanwhile, the tartaric acid sustained-release composition is convenient to use, and can be freely used by a user at home without being operated and used by professionals. In addition, the tartaric acid sustained-release composition can significantly whiten and brighten the skin, remove dull yellow and fade stains, and has a good use effect.

Owner:濡美(广州)生物工程有限公司

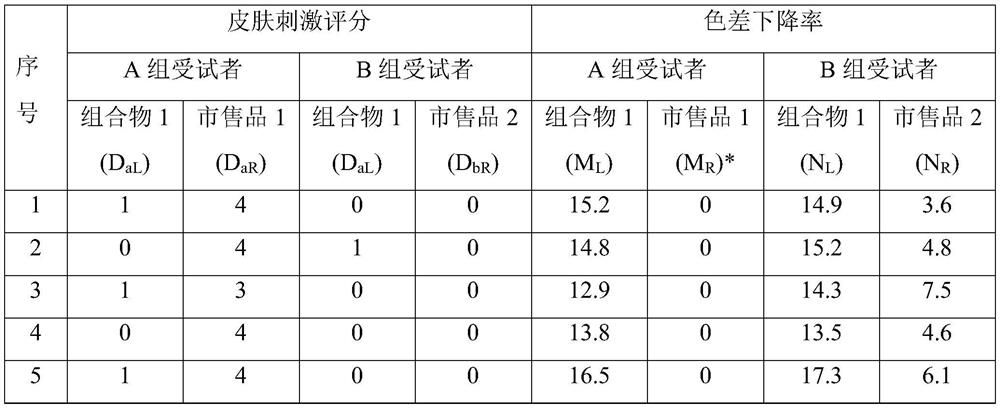

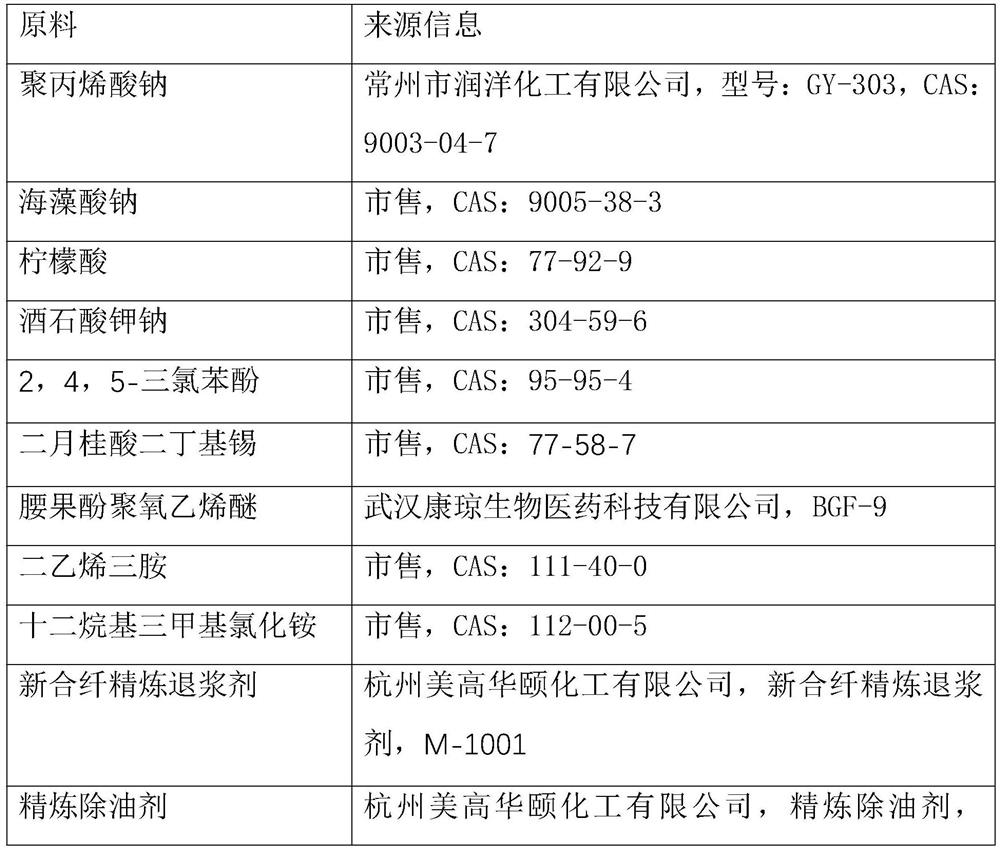

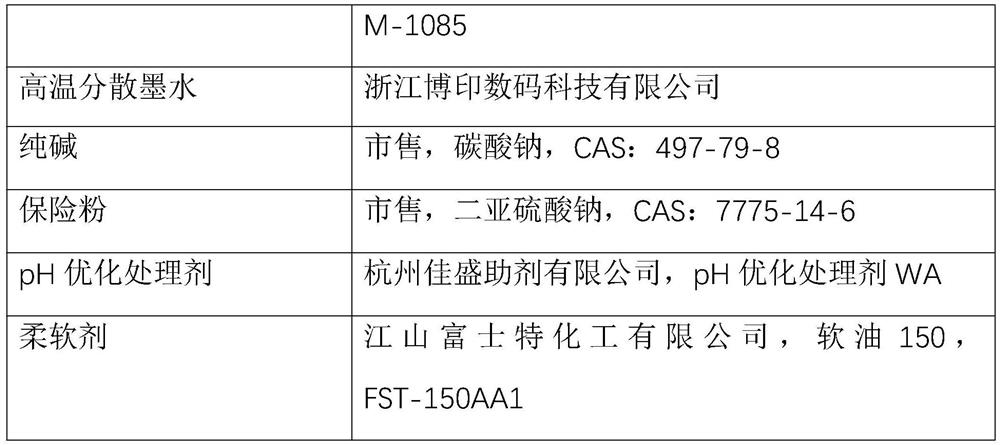

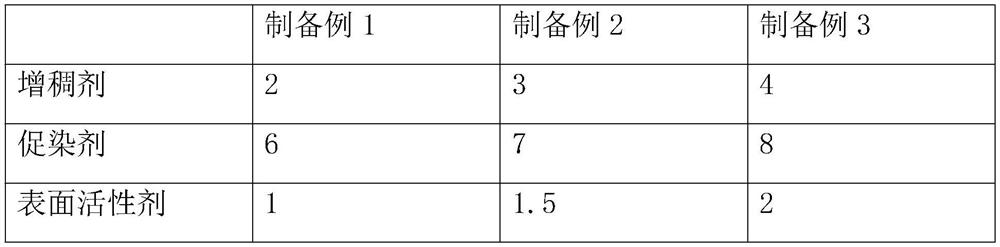

Digital printing method for tatting acetic acid printing

The invention relates to the field of digital printing, and particularly discloses a digital printing method for tatting acetic acid printing. A digital printing method for tatting acetic acid printing at least comprises the steps of sizing and printing. The sizing step specifically comprises the following steps: applying sizing slurry on the cloth; the sizing slurry comprises the following components in parts by mass: 2-4 parts of a thickening agent; 6-8 parts of an accelerating agent; 1-2 parts of a surfactant; 60 to 70 parts of water; the accelerating agent is a compound of citric acid, sodium potassium tartrate tetrahydrate, 2, 4, 5-trichlorophenol, dibutyltin dilaurate and cardanol polyoxyethylene ether; the printing step specifically comprises the following steps: jet-printing high-temperature dispersed ink on the cloth, and then ageing at 120-130 DEG C for 35-45 minutes. The artificial leather has the effects of keeping a relatively good color development effect and relatively good hand feeling.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

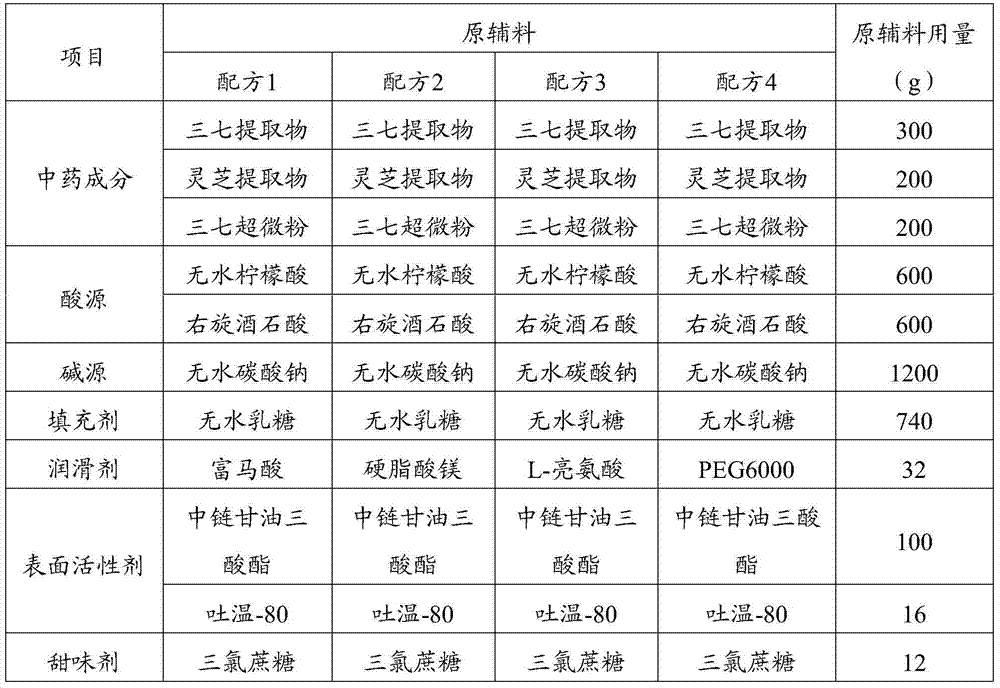

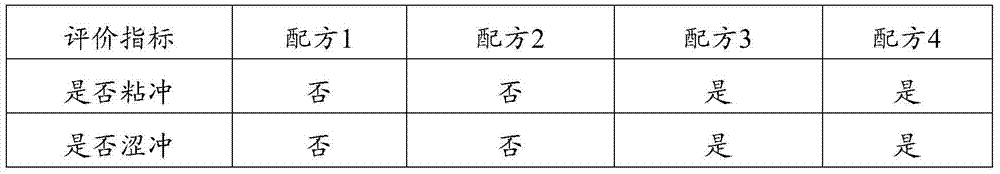

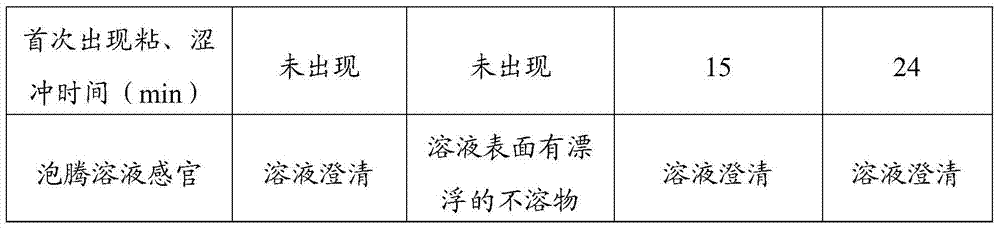

A kind of effervescent tablet of traditional Chinese medicine

ActiveCN104623672BRelaxed temperature and humidity requirementsSave energyPharmaceutical delivery mechanismUnknown materialsCitric Acid / tartaric acidBULK ACTIVE INGREDIENT

The invention relates to the technical field of preparations, in particular to a traditional Chinese medicine effervescent tablet. The traditional Chinese medicine effervescent tablet comprises an active ingredient, an acid source, an alkali source, a lubricant and a surfactant; the lubricant is fumaric acid; and the acid source is a mixture of citric acid and tartaric acid. The Chinese medicine effervescent tablet formula provided by the present invention solves the ubiquitous problems of stickiness and astringency in Chinese medicine effervescent tablets, and relaxes the requirements for environmental temperature and humidity during production. The hardness and friability meet the tablet requirements, and at the same time It has the advantages of rapid disintegration, no effect on the clarity of the solution, and good effervescent effect.

Owner:BY HEALTH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com