Radioactive waste metal recovery method

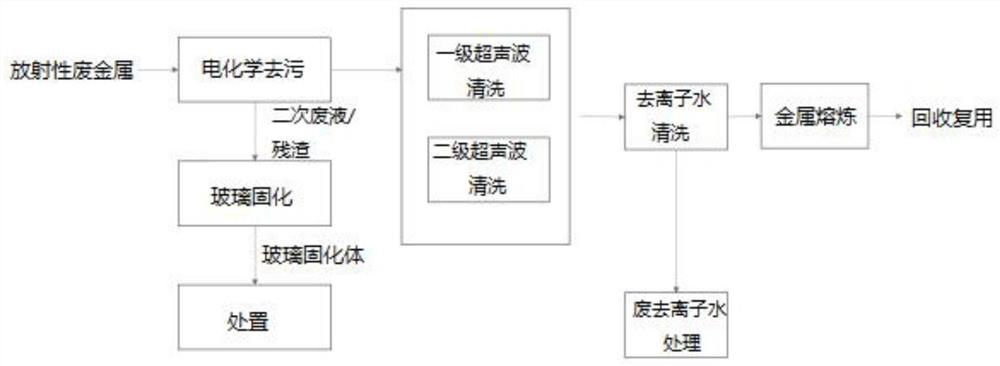

A recycling method and technology for radioactive waste, applied in the field of radioactive waste metal recycling, can solve the problems of difficult recycling of radioactive waste metal, poor decontamination effect, etc., and achieve the effect of good decontamination effect, easy operation, and easy collection and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Prepare electrolytic solution for electrochemical decontamination, wherein: phosphoric acid: 75wt%, oxalic acid: 5g / L, citric acid: 5g / L, tartaric acid: 1g / L, hydrogen peroxide: 3g / L, glacial acetic acid: 6g / L, the solvent is water.

[0042] (2) Put 1L of electrolyte in the electrochemical decontamination device, and soak the radioactively contaminated waste stainless steel parts (called parts to be decontaminated) in the electrolyte, connect the parts to be decontaminated to the anode of the power supply, and turn on the power, Adjust the voltage to 12V, electrochemically treat the parts to be decontaminated, and the current density is 0.4A / cm 2 , the processing time is 20min. After the electrochemical decontamination is completed, the decontaminated parts are transferred to a two-stage ultrasonic decontamination device for ultrasonic cleaning, the ultrasonic frequency is 28KHz, and the single-stage ultrasonic cleaning time is 20min.

[0043] (3) Take out the pa...

Embodiment 2

[0048] (1) Electrolyte for preparing electrochemical decontamination, wherein: phosphoric acid: 60wt%, oxalic acid: 5g / L, citric acid: 5g / L, tartaric acid: 1g / L, hydrogen peroxide: 3.75g / L, glacial acetic acid: 6g / L, the solvent is water.

[0049] (2) Put 1L of electrolyte in the electrochemical decontamination device, and soak the radioactively contaminated waste stainless steel parts (called parts to be decontaminated) in the electrolyte, connect the parts to be decontaminated to the anode of the power supply, and turn on the power, Adjust the voltage to 12V, electrochemically treat the parts to be decontaminated, and the current density is 0.4A / cm 2 , the processing time is 20min. After the electrochemical decontamination is completed, the decontaminated parts are transferred to a two-stage ultrasonic decontamination device for ultrasonic cleaning, the ultrasonic frequency is 28KHz, and the single-stage ultrasonic cleaning time is 20min.

[0050] (3) Take out the parts af...

Embodiment 3

[0055] (1) Electrolyte for preparing electrochemical decontamination, wherein: phosphoric acid: 65wt%, oxalic acid: 5g / L, citric acid: 6g / L, tartaric acid: 1g / L, hydrogen peroxide: 3.75g / L, glacial acetic acid: 8g / L, the solvent is water.

[0056] (2) Put 1L of electrolyte in the electrochemical decontamination device, and soak the radioactively contaminated waste stainless steel parts (called parts to be decontaminated) in the electrolyte, connect the workpiece to be decontaminated to the anode of the power supply, and turn on the power supply, Adjust the voltage to 24V, electrochemically treat the parts to be decontaminated, and the current density is 0.3A / cm 2 , the temperature treatment time is 15min. After the electrochemical decontamination is completed, the decontaminated parts are transferred to a two-stage ultrasonic decontamination device for ultrasonic cleaning, the ultrasonic frequency is 40KHz, and the single-stage ultrasonic cleaning time is 20min.

[0057] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com