Preparation method of magnesium oxysulfate cementing material adopting silicon dioxide aerogel and building component

A technology of magnesium oxysulfide gelling material and silicon dioxide, which is applied in the field of building materials, can solve the problems of lack of adding airgel, heat insulation, insufficient formation of heat preservation, weakening of material mechanical properties, etc., and achieve good economic and social significance , excellent mechanical properties and thermal insulation properties, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment relates to a magnesium oxysulfide gelling material using silica airgel, which helps to improve the mechanical properties and thermal insulation properties of magnesium oxysulfide gelling building materials. The magnesium oxysulfate gel using silica airgel includes A component and B component, wherein:

[0038] Component A is proportioned by molar ratio, including 1 part of magnesium sulfate heptahydrate, 8-12 parts of light-burned magnesia and 15-22 parts of water; and the content of active magnesia in light-burned magnesia is 55%-65% .

[0039] The B component includes modifiers and aerogels. Among them, the modifier is one of citric acid, tartaric acid and sodium malate, or a mixture of citric acid and tartaric acid; the amount of various modifiers is: citric acid is 0.7%~0.8% of the mass of light-burned magnesium oxide , tartaric acid and sodium malate are 1.3% to 1.8% of the mass of light-burned magnesia. The amount of airgel is less than 6% of th...

Embodiment 2

[0048] This embodiment relates to a preparation method of magnesium oxysulfate gelling material using silica airgel and building components, which is convenient for operation and implementation in construction, and can generate sulfur oxide with excellent mechanical properties and thermal insulation properties. Magnesium gelling material.

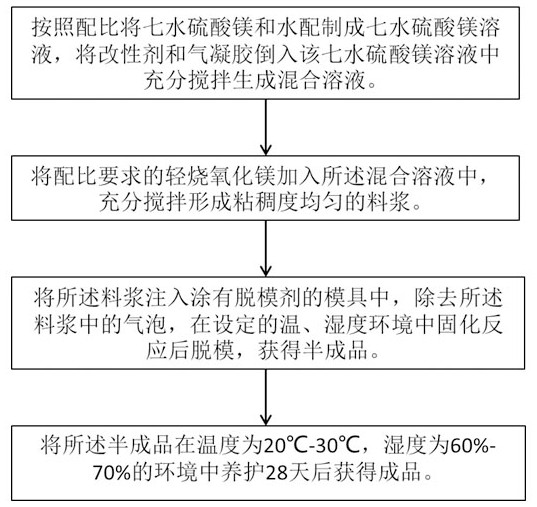

[0049] This method is used in the preparation of the magnesium oxysulfate gelled material that adopts silica aerogel provided in Example 1, and comprises the following steps:

[0050] s1. According to the proportioning, magnesium sulfate heptahydrate and water are formulated into a magnesium sulfate heptahydrate solution, and the modifier and aerogel are poured into the magnesium sulfate heptahydrate solution and fully stirred to form a mixed solution;

[0051] s2. Add the light-burned magnesia required by the proportioning ratio into the mixed solution, and fully stir to form a slurry with uniform viscosity;

[0052] s3. Inject the slurry...

Embodiment 21

[0067] The magnesium oxysulfate gelling material of the present embodiment adopts the following ratio: wherein the molar ratio of light-burned magnesium oxide powder, magnesium sulfate heptahydrate, and water is 10:1:18, and the active magnesium oxide in the light-burned magnesium oxide powder The content is 57.8%. Modifier adopts citric acid, tartaric acid and sodium malate to carry out respectively, and form three groups of embodiment products; Wherein, the content of citric acid is 0.75% of the quality of light-burned magnesium oxide powder, forms grouping 1 product; The content of tartaric acid is light The content of sodium malate is 1.5% of the mass of lightly burned magnesia powder, forming the product of group 2.

[0068] In this embodiment, the corrugated tile and ridge tile (JC / T747-2002) of glass fiber magnesium cementitious materials can be referred to as the detection standard, and the flexural strength, compressive strength, and thermal conductivity are measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com