A method of supplementing an edible aqueous liquid composition with two or more mineral salts

A liquid composition, water liquid technology, applied in the fields of food science, application, pharmaceutical formulation, etc., can solve problems such as being unsuitable for the production of transparent metastable solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

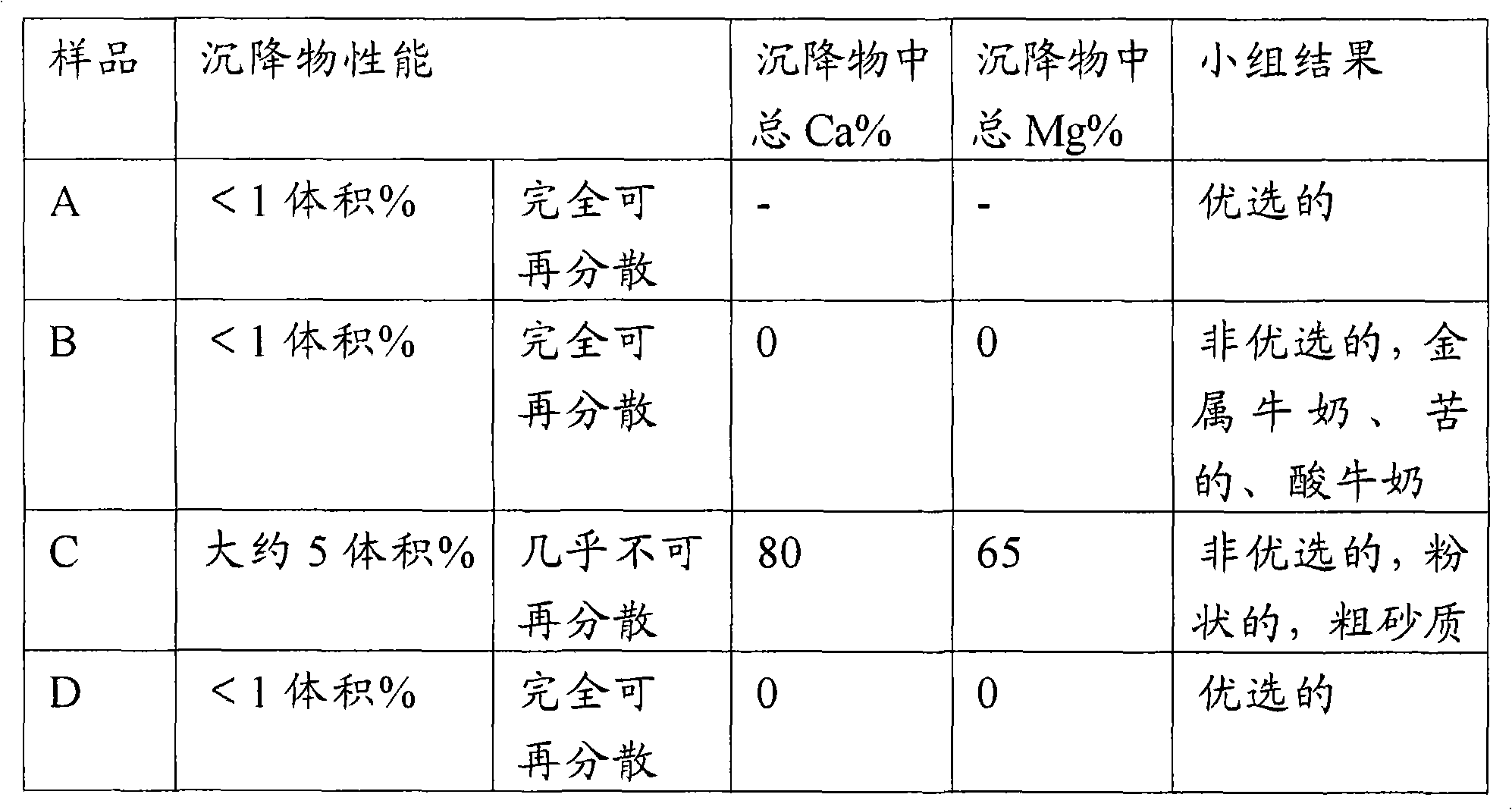

[0077] Soy-based beverages are produced based on the recipes described in the table below:

[0078] Composition (wt%)

[0079] Element

A

B

C

D

Soy Protein Isolate 1

1.27

1.27

1.27

1.27

3

3

3

3

HM pectin

0.35

0.35

0.35

0.35

0.01

0.01

0.01

0.01

Fruit Concentrate (65°Brix)

3.7

3.7

3.7

3.7

0.20

0.20

0.25

0.75

0

0

0.27

0.27

magnesium carbonate 3

0

0

0.18

0.18

calcium lactate 4

0

0.84

0

0

magnesium lactate 4

0

0.63

0

0

to 100%

to 100%

to 100%

to 100%

[0080] 1 From Solae (FXP 219)

[0081] 2 From Scora S.A., France (Particle size: 98.5% t...

Embodiment 2

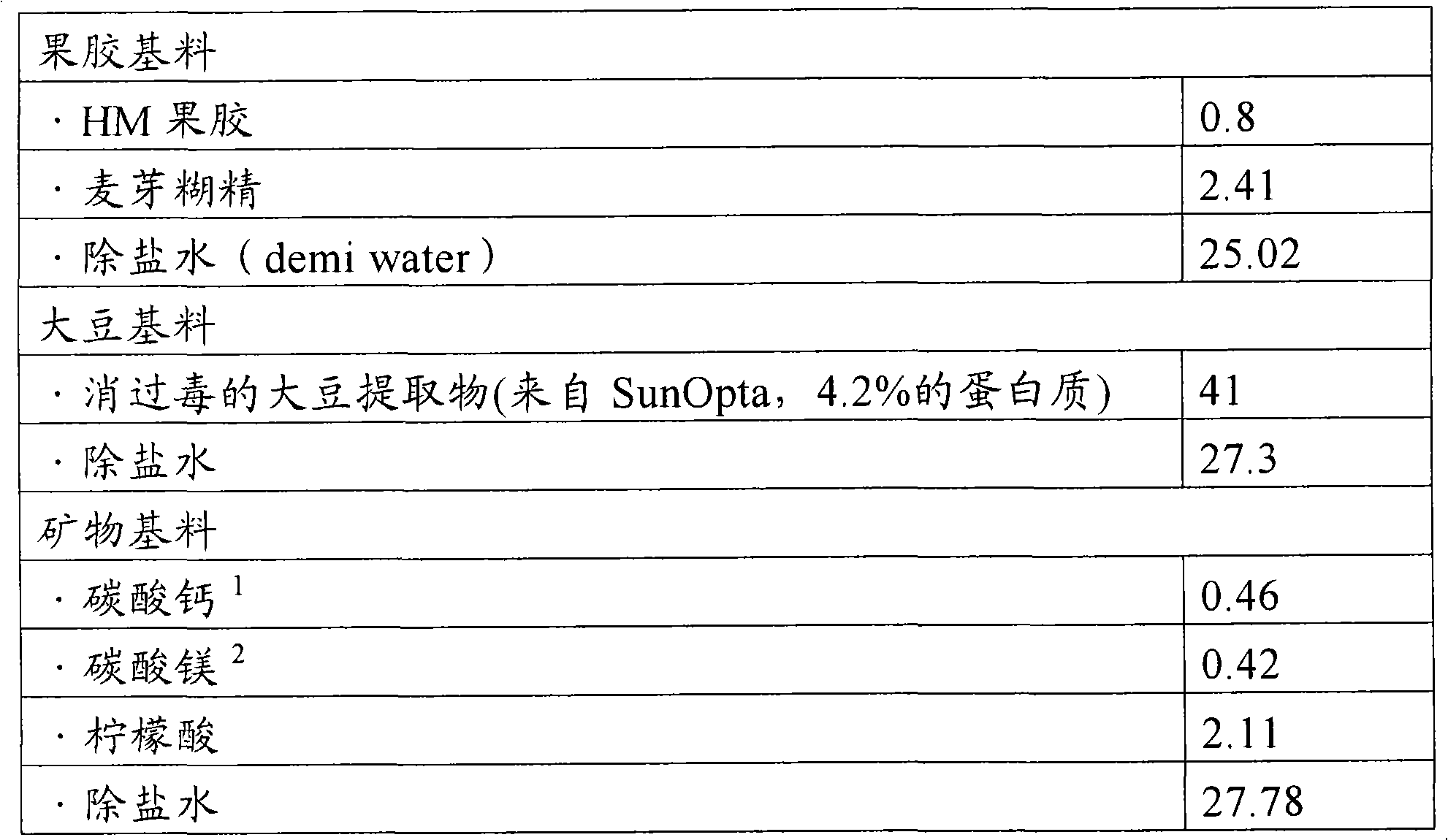

[0102] A reconstitutable powder containing soy protein, citric acid, calcium and magnesium was produced starting with the premix described in Table 3:

[0103] Table 1: Composition of the premix (wt %)

[0104]

[0105] 1 From Scora S.A., France (Particle size: 98.5% through 325 mesh / 45 μm (wet sieve))

[0106] 2 From Lohmann, Germany (approx. 90% particle size < 0.1 mm).

[0107] The pectin base was stirred at 80 °C for 20 min under high shear. Thereafter, it was cooled to below 40°C. The soy base was homogenized at 150 bar. Thereafter, the soy base was slowly added to the pectin base while stirring. After all of the soy base had been added, the resulting mixture was stirred under high shear for 30 min.

[0108] In parallel, the following method was used to prepare the mineral base: citric acid was added to all water at a temperature of 10°C. Magnesium carbonate was added with gentle stirring. After about half an hour, the formation of carbon dioxide ceased and th...

Embodiment 3

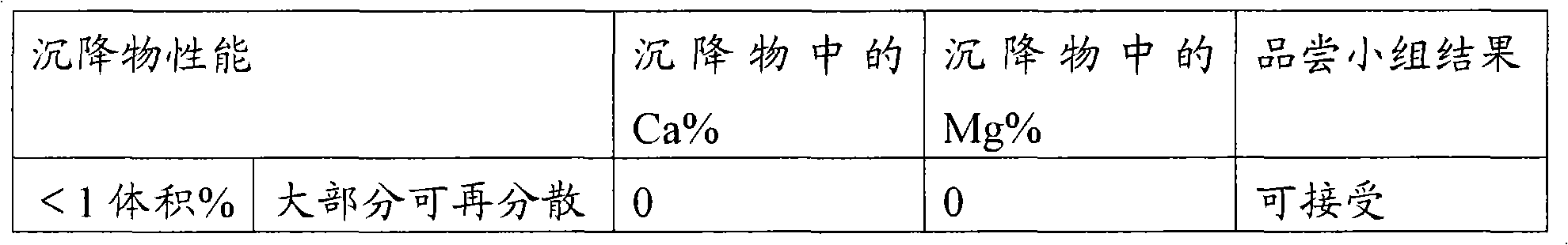

[0113] The powder of Example 2 was made into a soybean / fruit drink using the recipe in Table 3:

[0114] Table 3: Composition of soy / fruit drinks

[0115]

Wt%

Powder of Example 2

3.6

3

0.01

Fruit Concentrate (65°Brix)

3.7

additional citric acid

bring the pH to 4.1

to 100%

[0116] The soybean beverage was prepared by heating water to 80°C. The powder from example 2 was dispersed into this water with the help of a turrax mixer, after which the solution was kept for 10 minutes. Next, the dry blend of sugar and sucralose is dispersed into this aqueous solution with the help of a turrax mixer. Next, add the fruit concentrate and citric acid. The final pH of the beverage was 4.1.

[0117] Subsequently, the product was pasteurized using an indirect heating system at 72° C. for 40 seconds (laminar flow). The pasteurized product was homogenized using a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com