Dechlorinating agent as well as preparation method and application thereof

A dechlorination agent and modifier technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problem of inability to specifically remove hydrogen chloride, achieve good dechlorination effect, promote interaction, and improve fragmentation. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

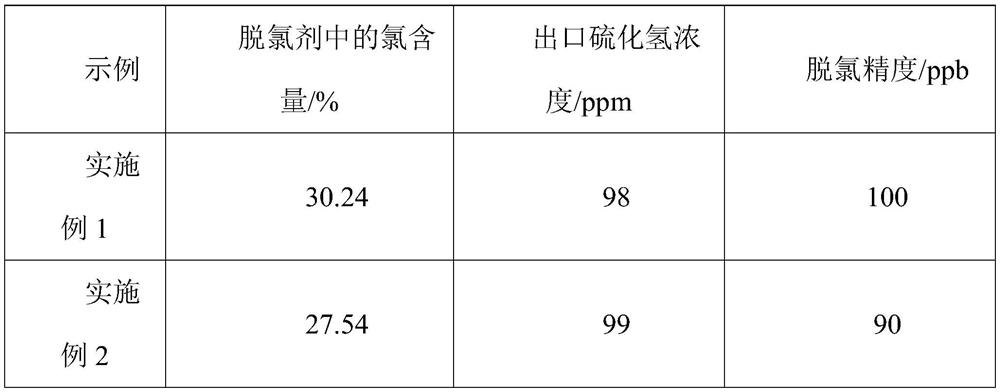

Examples

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of dechlorination agent, comprises the following steps,

[0036] The specific surface area of 50g is 650m 2 / g, X-type molecular sieve with a pore size of 0.7nm, 10g of potassium carbonate, 30g of magnesium hydroxide, 5g of turnip powder, 35g of silica sol, 10g of kaolin and 5g of oxalic acid were mixed evenly, and dried at 100°C for 2 hours after extruding. Roast at 480°C for 3 hours to obtain a gas-phase dechlorination agent.

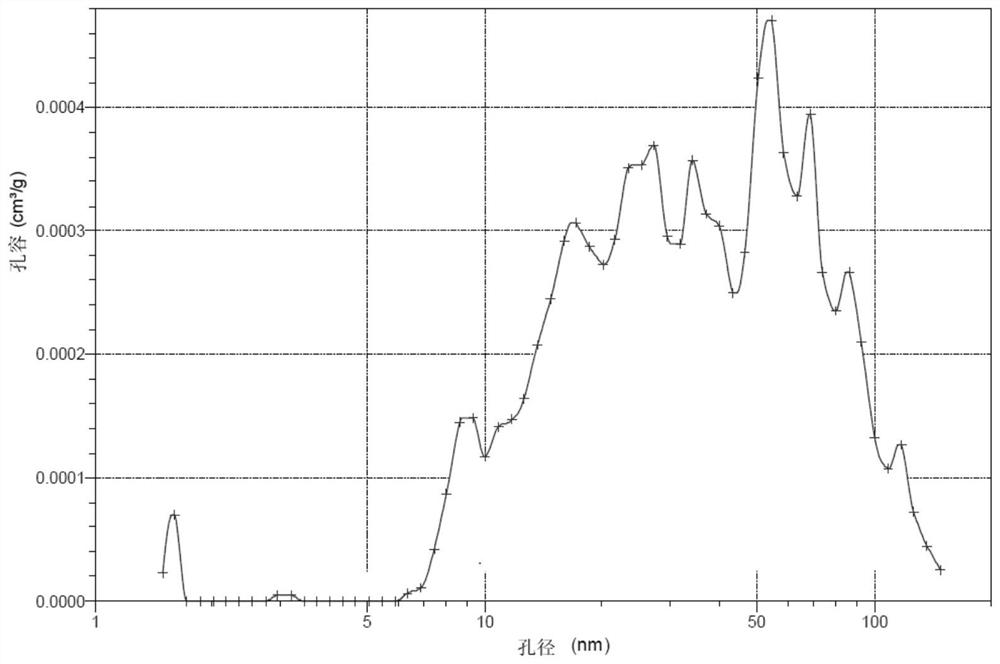

[0037] The pore size distribution figure of gained dechlorination agent is as follows figure 1 As shown, as can be seen from the figure, its mesopore diameter is mainly distributed in 3-4nm and 6-50nm, meanwhile, there are also pore distributions above 50nm, and the overall pore size distribution is diversified; other embodiments and comparative examples are attached The figure is no longer provided, only the pore size distribution of the mesopores is given.

Embodiment 2

[0039] The present embodiment provides a kind of preparation method of dechlorination agent, comprises the following steps,

[0040] The specific surface area of 50g is 900m 2 / g, X-type molecular sieve molecular sieve with a pore size of 1.0nm, 20g sodium carbonate, 10g sodium carbonate, 20g attapulgite and 5g tartaric acid, mix evenly, add 25g silica sol rolling balls, dry at 110°C for 3h, and then dry at 350°C Under roasting for 6h to obtain a gas phase dechlorination agent.

Embodiment 3

[0042] The present embodiment provides a kind of preparation method of dechlorination agent, comprises the following steps,

[0043] The specific surface area of 50g is 400m 2 / g, X-type molecular sieve molecular sieve with a pore size of 1.2nm, 5g sodium hydroxide, 35g calcium hydroxide, 3g sodium carboxymethylcellulose and 10g disodium ethylenediaminetetraacetic acid are mixed evenly, and 35g silica sol is added to form a rolling ball , dried at 120°C for 4h, and then roasted at 550°C for 4h to obtain a gas-phase dechlorination agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com