Patents

Literature

65 results about "Dibutyl dithiophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flotation method for lead and zinc ore difficult to select

InactiveCN103639061AThe process is simple and reliableEasy to operateFlotationDibutyl dithiophosphateSulfite salt

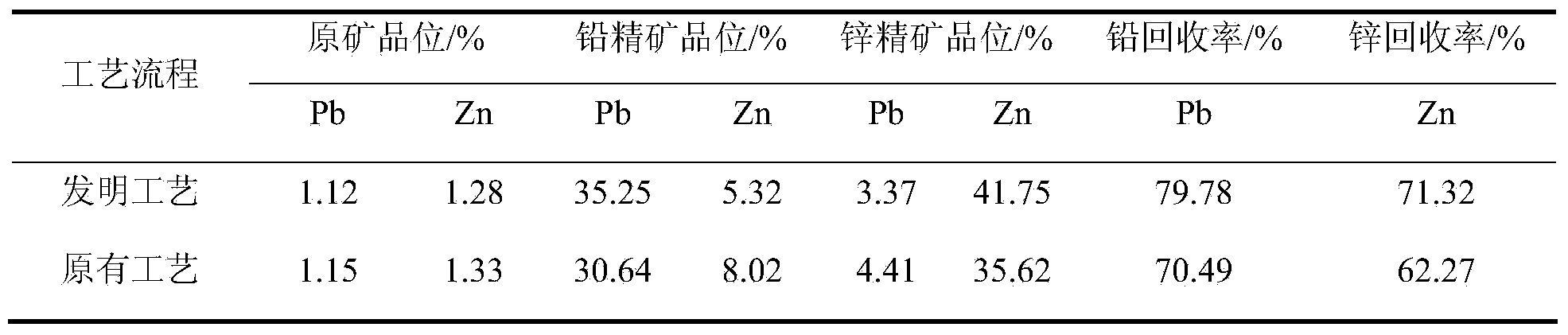

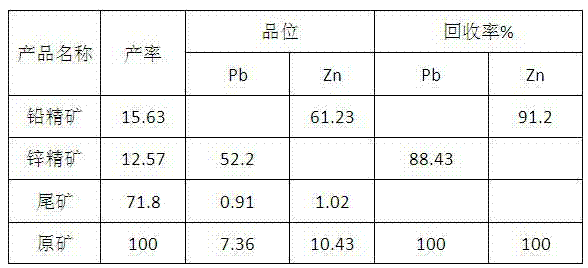

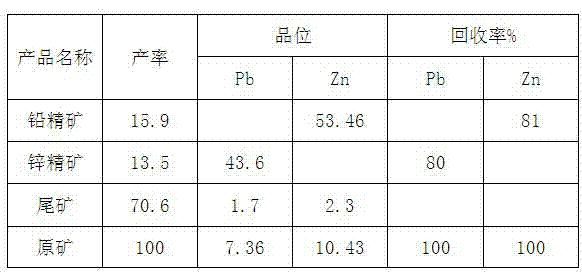

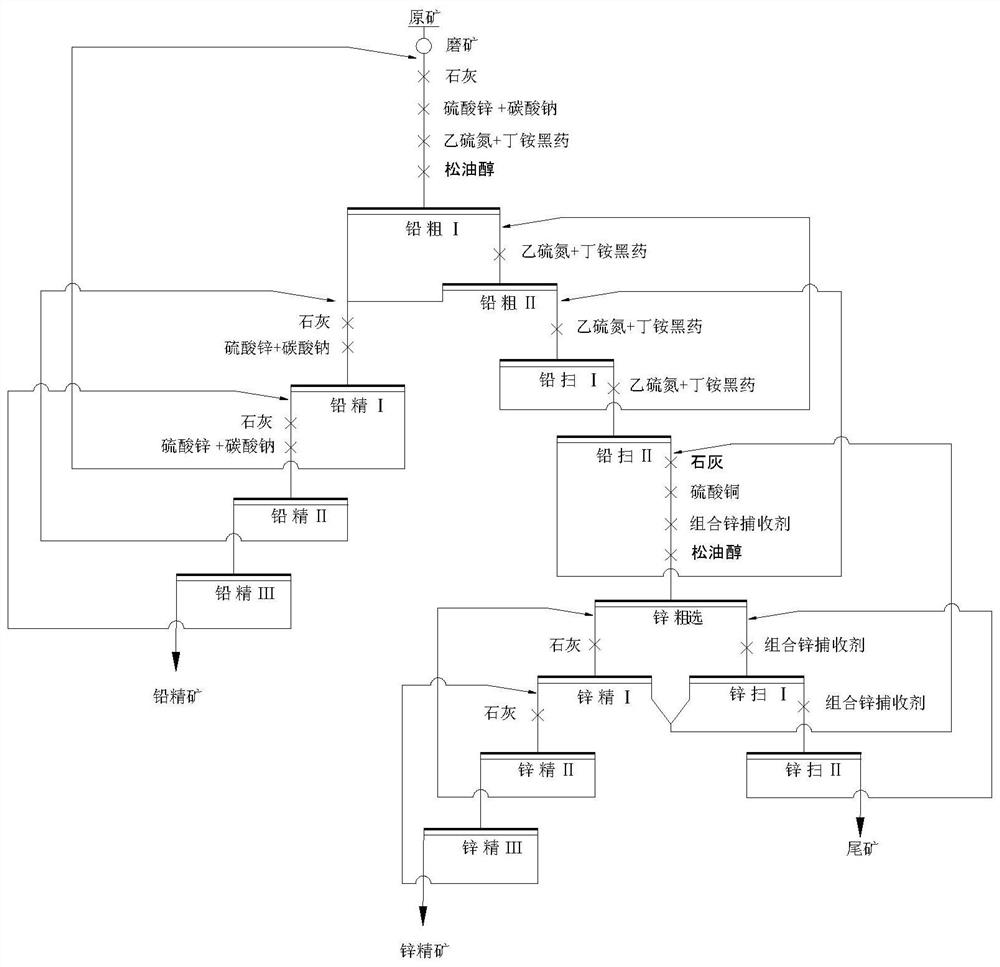

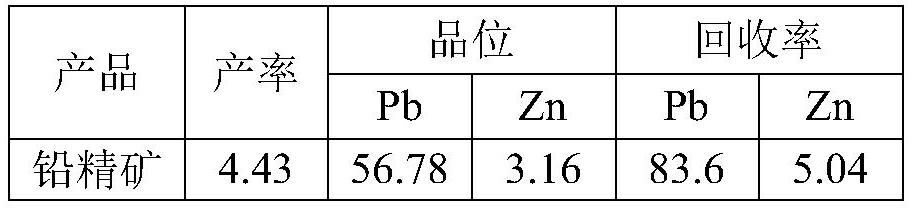

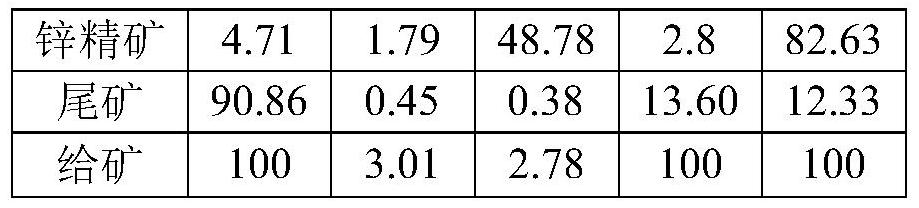

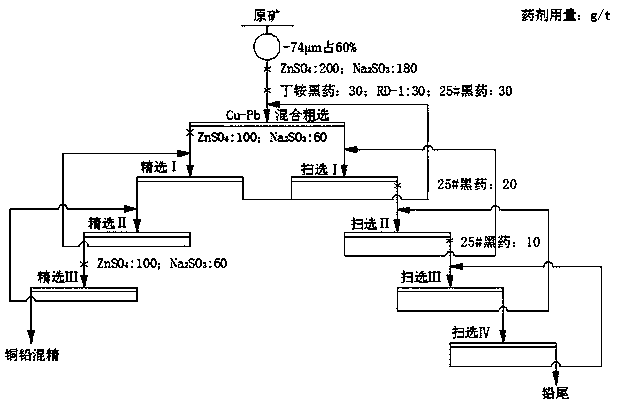

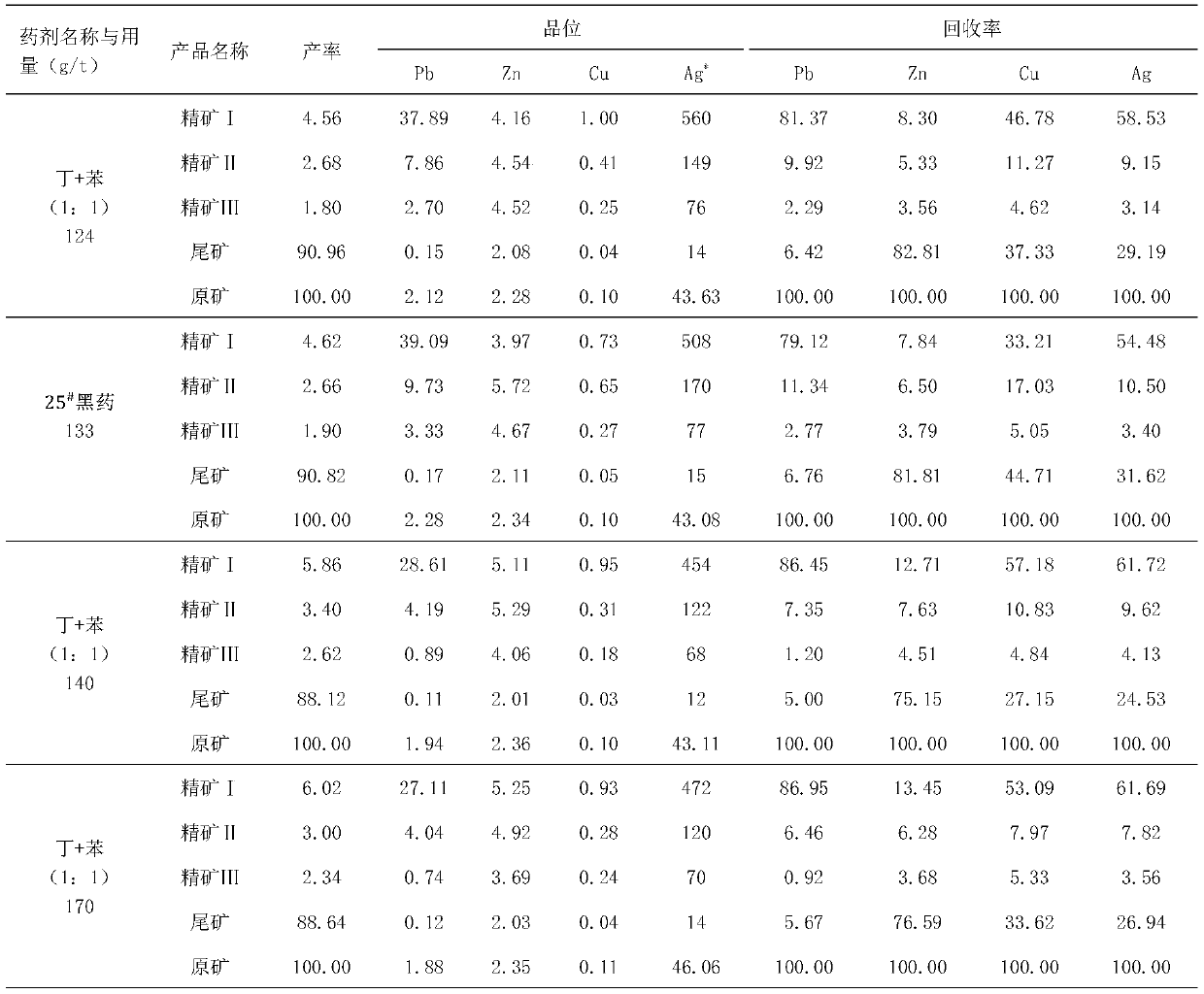

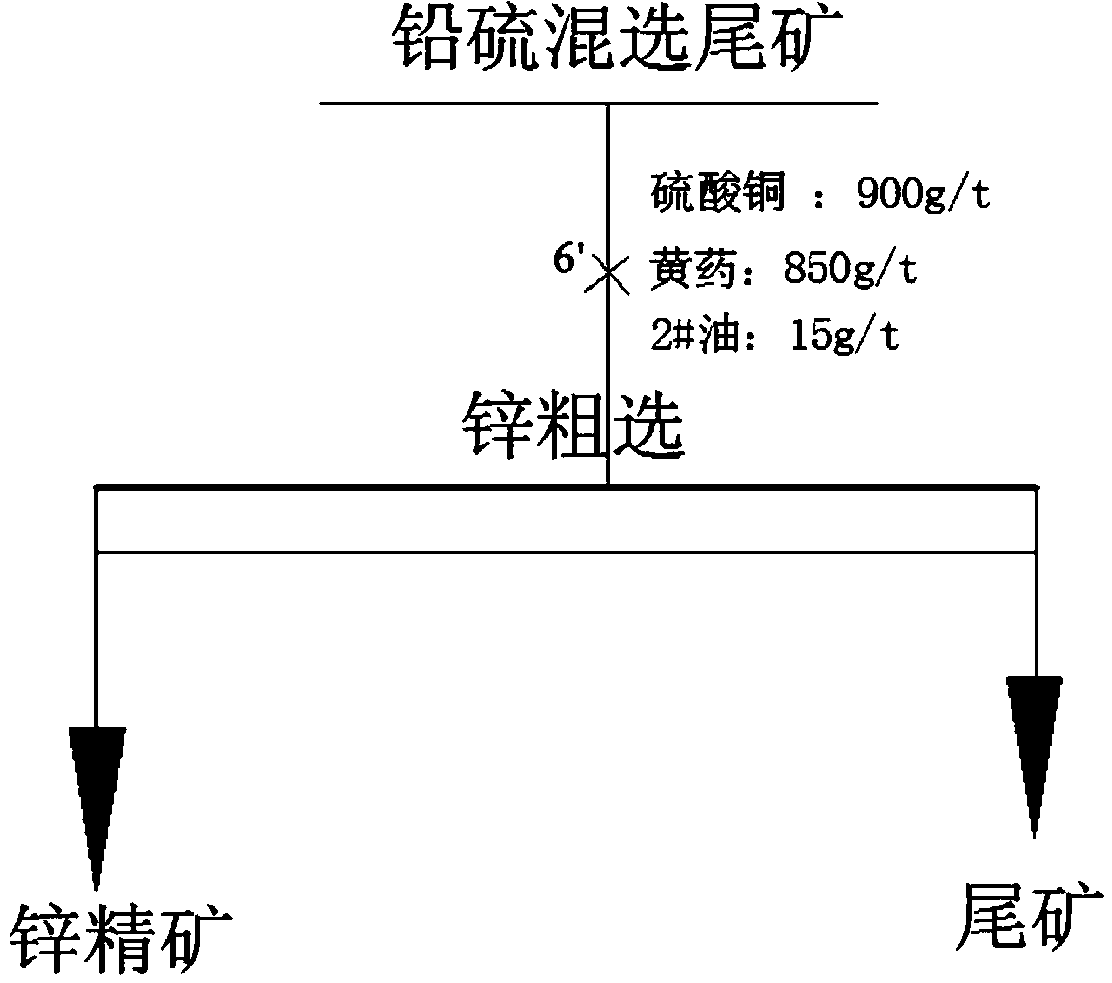

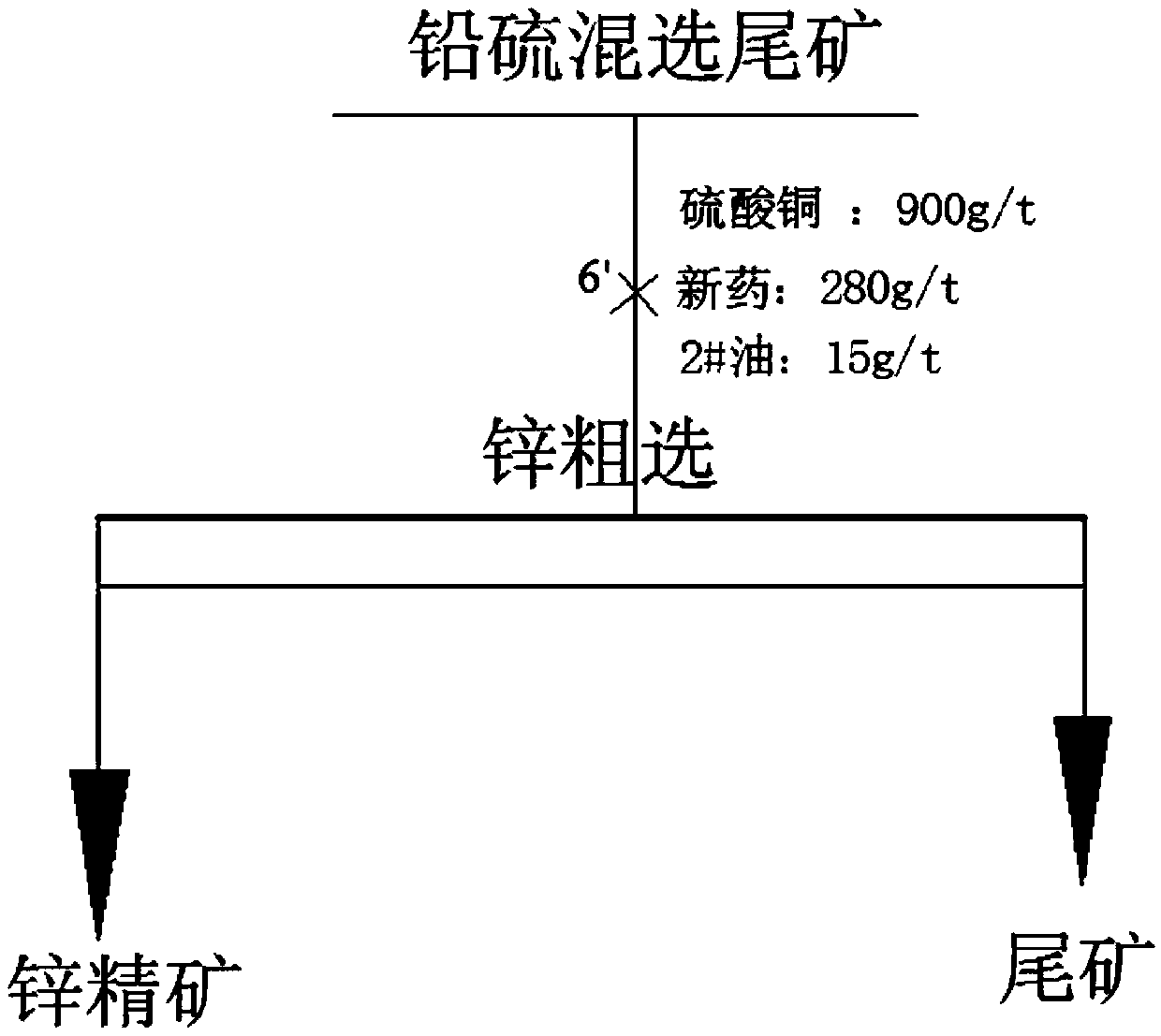

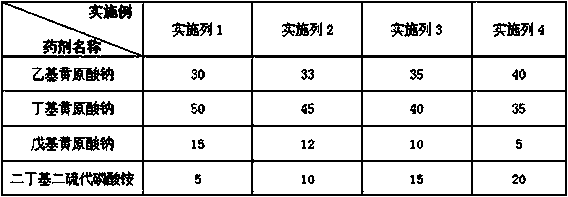

The invention relates to a flotation method for lead and zinc ore difficult to select. The method includes the following steps of lead roughing, two-time lead scavenging, three-time lead fine selection, zinc roughing, two-time zinc scavenging and three-time fine selection. Lime serves as regulators, zinc sulfate and sodium sulfite serve as zinc inhibitor, diethyl dithiocarbamate and ethyl xanthogenate serve as lead collecting agents, copper sulfate serves as zinc activating agents, ammonium dibutyl dithiophosphate serves as zinc collecting agents, and terpenic oil serves as foaming agents. The lead and zinc ore difficult to select is processed by the adoption of lead differential flotation and zinc selection technological processes, and the practical problems that in original technological processes, zinc contains a high content of lead which contains a high content of the zinc, and the lead recovery rate and the zinc recover rate are low are solved. The technological processes are simple, reliable, easy to operate, and good in sorting index. Compared with the original technological processes, the method has the advantages that under the circumstance that raw ore contains the same lead and zinc, mutual containing of the lead and zinc is reduced, and the lead recovery rate and the zinc recovery rate are greatly increased and increased by 9.29% and 9.05% respectively.

Owner:GUANGXI UNIV

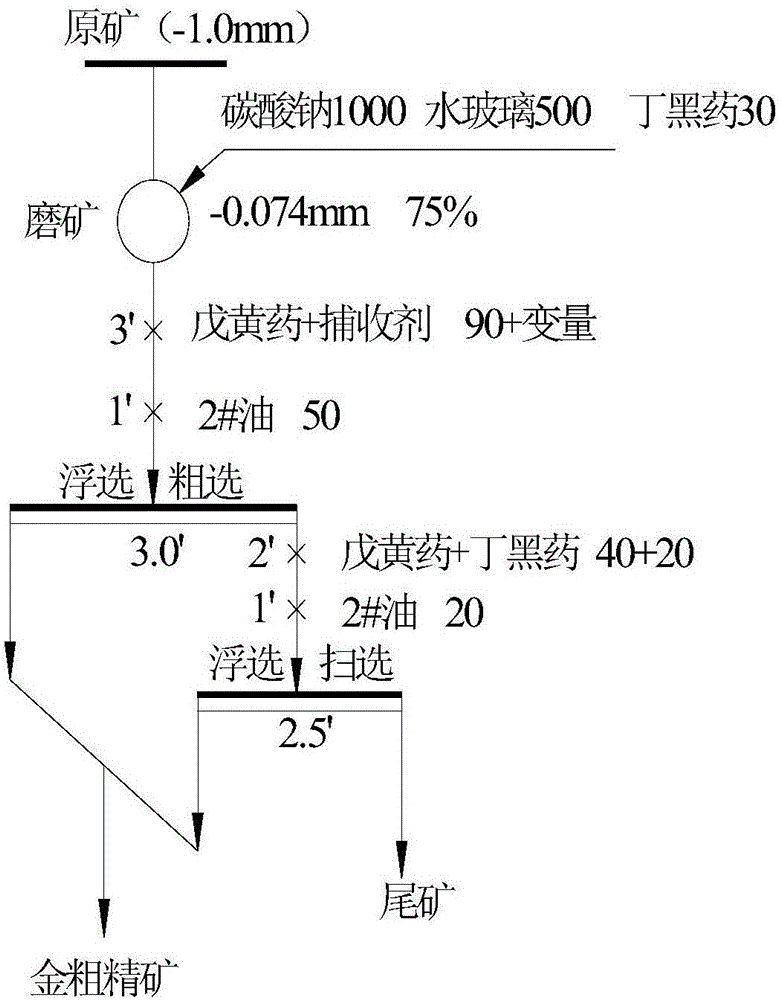

Collecting agent for low-grade refractory gold ores

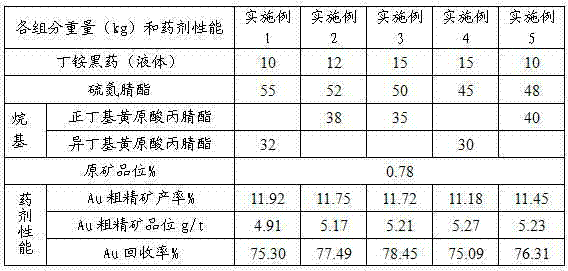

The invention discloses a collecting agent for low-grade refractory gold ores. The collecting agent comprises the following materials by weight: 45-55 parts of cyanoethyl diethyl dithionocarbamate, 30-40 parts of allyl alkyl xanthate, and 10-15 parts of liquid ammonium dibutyl dithiophosphate. The collecting agent has dual attributes, such as collecting and bubbling, the selectivity is good, the collecting capacity is strong, and the concentrate grade and the recovery rate can be effectively improved in a pH value range of from 8 to 8.5, thereby being the high-efficiency collecting agent for low-grade refractory gold ores.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

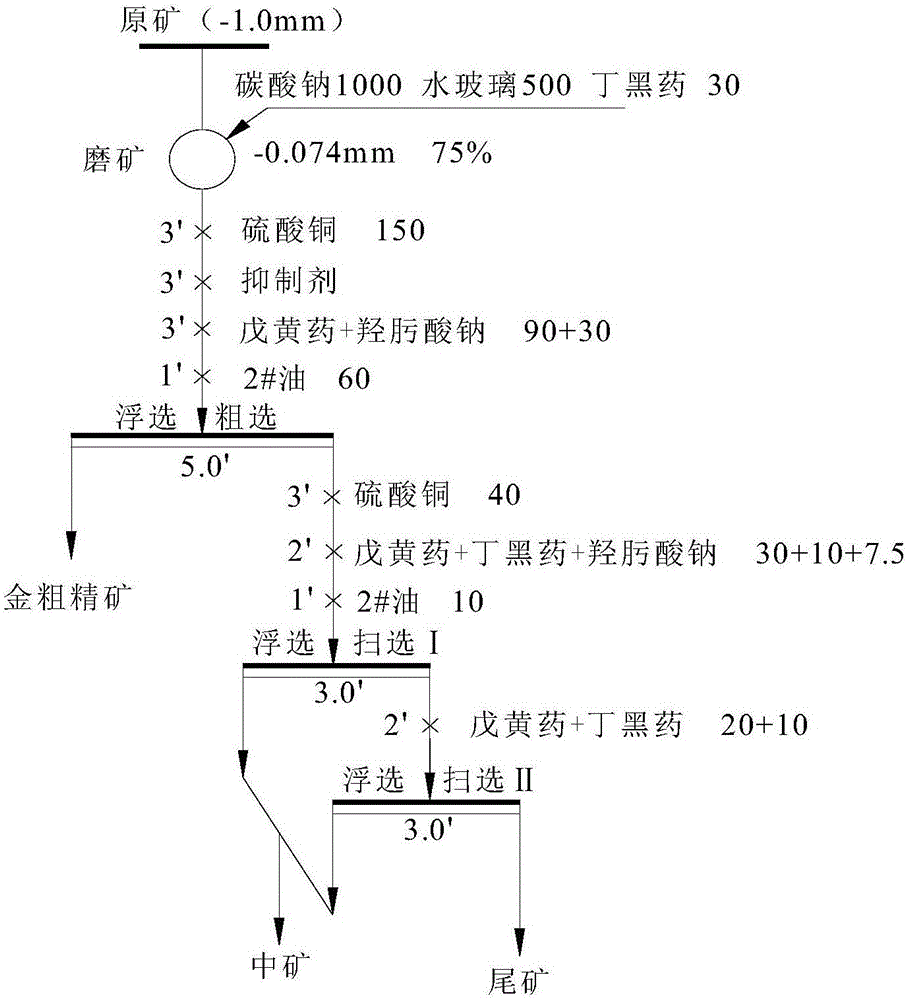

Collecting agent for refractory gold ores

The invention provides a collecting agent for refractory gold ores. The collecting agent comprises components in parts by weight as follows: 20-40 parts of cyanoethyl diethyl dithionocarbamate, 10-20 parts of a 25# black catching agent, 30-60 parts of liquid ammonium dibutyl dithiophosphate and 5-15 parts of a black catching agent acid. The collecting agent has dual attributes of collecting and bubbling, the selectivity is good, the collecting capability is high, the flotation froth is stable, the mineral floating speed is high, and the concentrate grade and the recovery rate can be effectively increased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

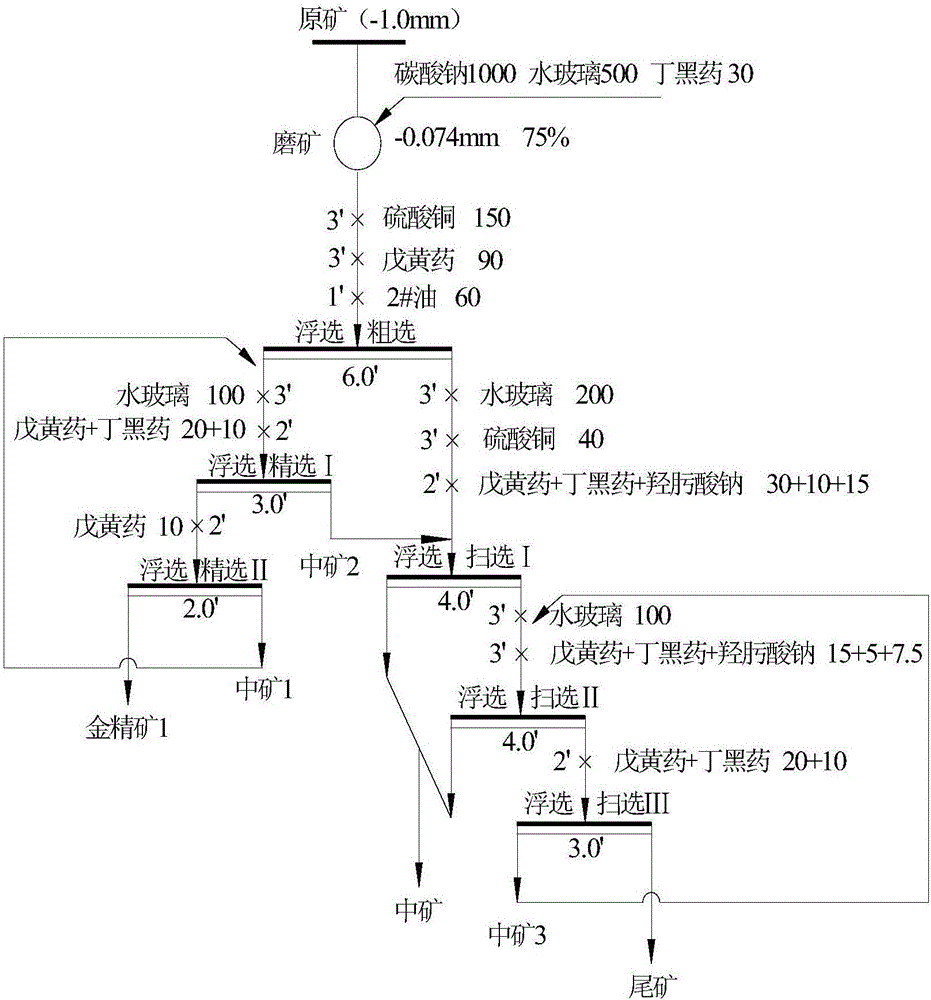

Beneficiation process for gold ores containing high arsenic and antimony content easily argillized minerals

InactiveCN106179722AHigh recovery rateFew influencing factorsFlotationWet separationDibutyl dithiophosphateFoaming agent

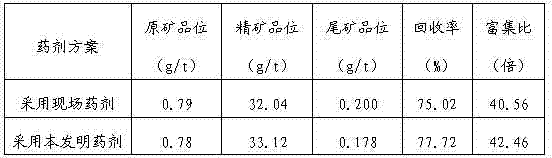

The invention relates to a beneficiation process for gold ores containing high arsenic and antimony content easily argillized minerals. By taking sodium carbonate as a flotation pulp regulator, water glass and sodium hexametaphosphate as an inhibitor and a dispersant for argillized minerals, copper sulfate as an activator for gold ores, pentyl xanthate and ammonium dibutyl dithiophosphate as a collecting agent for gold-bearing vulcanized minerals, sodium hydroxamate as a collecting agent for gold-bearing oxide minerals, and oil #2as a foaming agent, the process comprises the following steps: performing one stage grinding on raw ores; performing fast grading of one-stage roughing and one-stage concentrating on the ground minerals to obtain gold concentrate 1, and performing scavenging three times on the roughed tailings to obtain middlings; desliming the obtained middlings, and performing two-stage re-grinding on the deslimed pulp; and performing a strengthened collecting process of roughing at two times and concentrating at one time on the reground pulp to obtain gold concentrate 2. The process provided by the invention is high in recovery rate of the obtained gold concentrate, the affecting factors of the argillized minerals on gold grading are reduced, and through flow grading, the gold grade of obtained mixed gold concentrate is 52.84g / t and the gold recovery rate is 71.01%.

Owner:青海省地质矿产测试应用中心

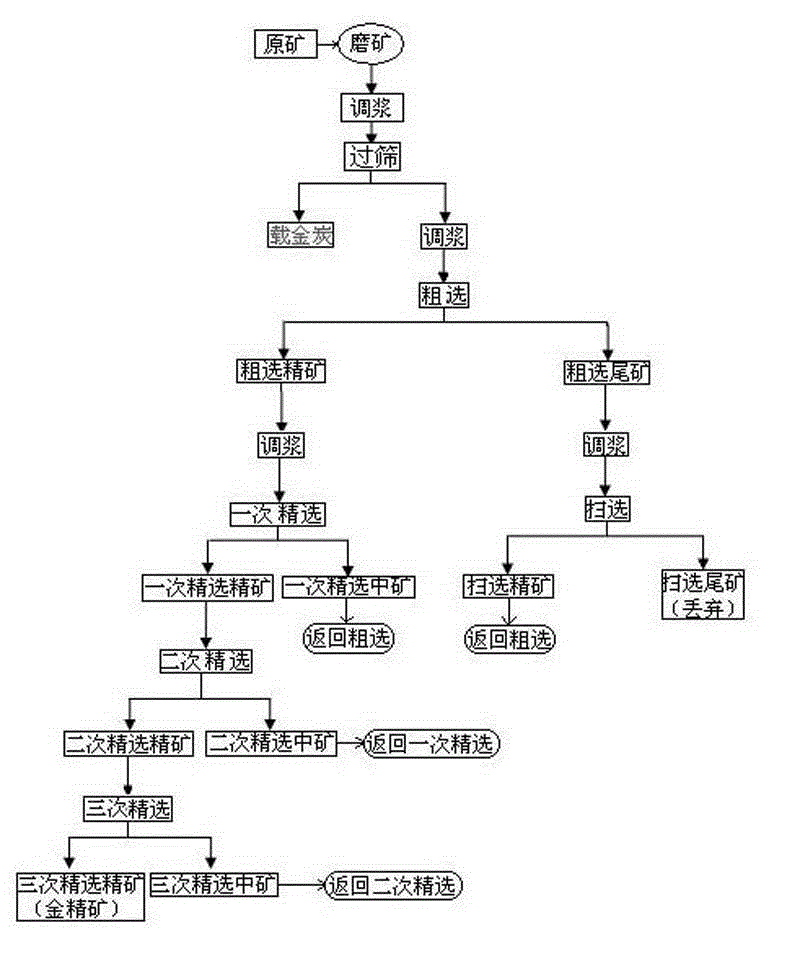

Method for selecting gold from gold ore leaching residue

ActiveCN103977881AAchieve recyclingProcess results are simpleFlotationWet separationDibutyl dithiophosphateFoaming agent

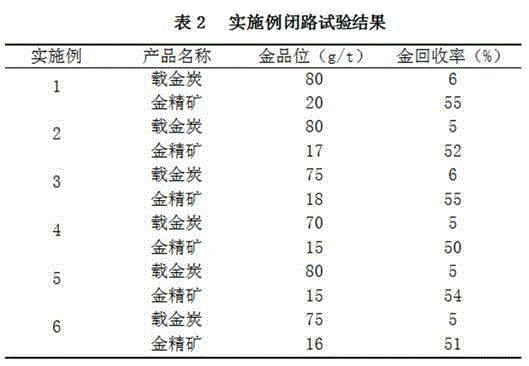

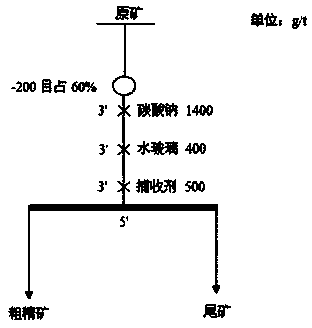

The method discloses a method for selecting gold from gold ore leaching residue. The method comprises the following steps: ore grinding, grid screening, roughing, scavenging, first selection, second selection and third selection. Active carbon is added during ore grinding, gold loaded carbon with higher gold content is firstly screened by adopting a 40-mesh grid screen at a ball-milling ore discharge port, then an inhibitor, a collecting agent and a foaming agent are added during the floatation process, and finally size mixing and stirring are carried out for roughing floatation work. The inhibitor is sodium fluosilicate, the collecting agent is Ammonium dibutyl dithiophosphate, and the foaming agent is terpenic oil. According to the method, through reasonable allocation of ore grinding and grid screening, the gold grade of the gold loaded carbon reaches to 70-80 g / T, the gold grade of floatation gold concentrate reaches to 15-20 g / T, the recovery rate of the gold loaded carbon reaches to 5-6%, the recovery rate of floatation gold reaches to 50-55%, and the total recovery rate of gold reaches to 55-61%. The ore dressing method is simple in technology and easy to operate on site.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Mineral flotation collecting agent for oxidized ores

The invention provides a collecting agent for collecting minerals of oxidized ores such as ilmenite and a preparation method thereof, and belongs to the technical field of mineral flotation collectingagents. The mineral flotation collecting agent for the oxidized ores such as ilmenite is used after ammonium dibutyl dithiophosphate, ethylenediaminetetraacetic acid salt, maleate, sodium oleate andthe like are mixed; and the mineral flotation collecting agent has the characteristics of good water solubility, good dispersion and high selective adsorption ability to objective minerals, and is mainly used for flotation separation of valuable minerals in the oxidized ores such as the ilmenite, scheelite and wolframite. The preparation method of the mineral flotation collecting agent for the oxidized ores is simple in process, operation is easy to control, the prepared collecting agent has the advantages of high selectivity, good dispersion, low agent dosage and high mineral separation comprehensive efficiency, and quite important significance for promoting mineral separation of the minerals such as the oxidized ores is achieved.

Owner:河南天鸿新材料科技有限公司

Flotation method for micro-fine particle complicated jamesonite

ActiveCN103433142AThe flotation process is simple and practicalReduce joinFlotationDibutyl dithiophosphateSulfite salt

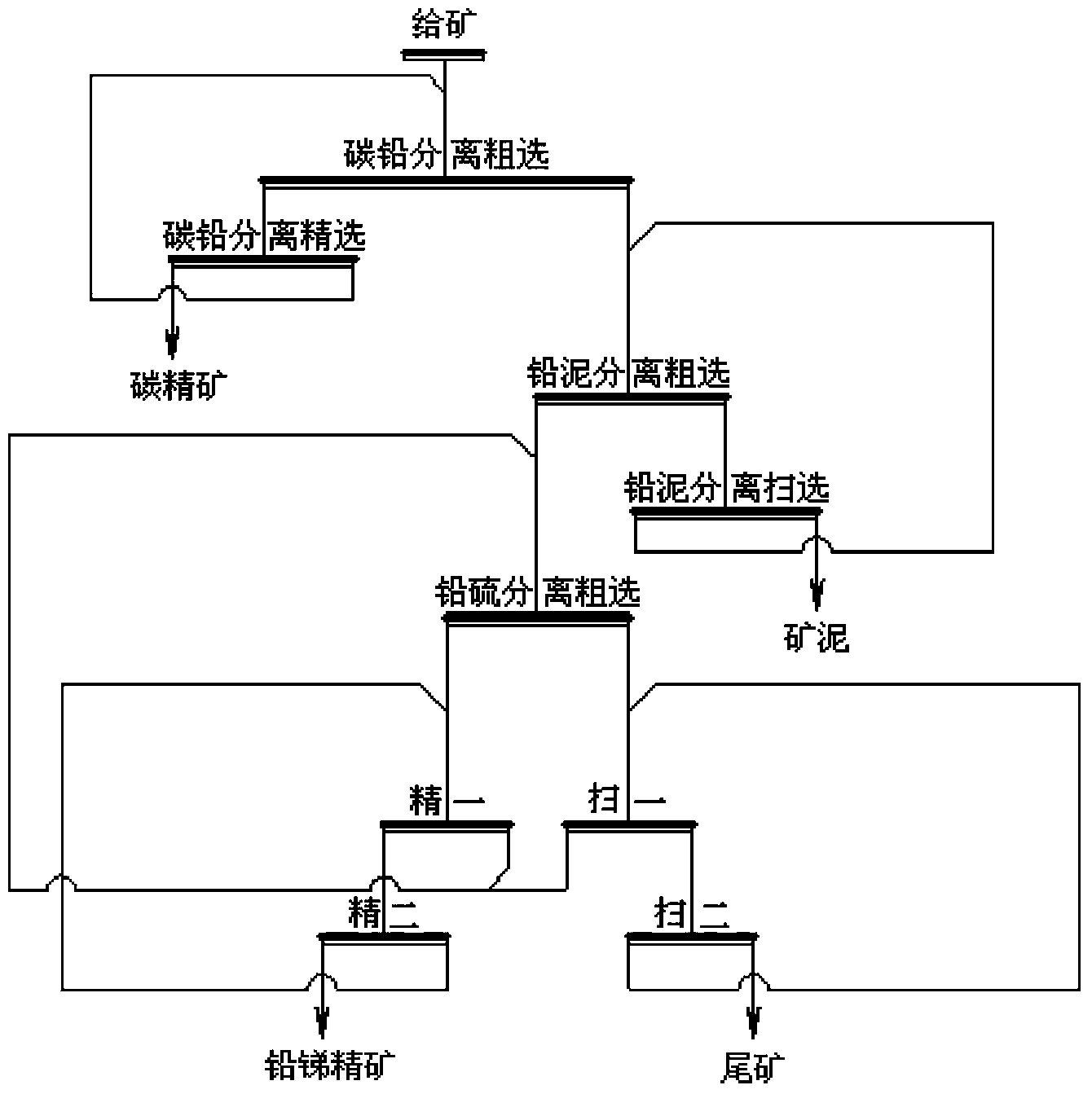

The invention discloses a flotation method for micro-fine particle complicated jamesonite. The flotation method comprises the steps of carbon-lead separation, lead-mud separation, lead-sulfur separation and the like; sulfuric acid is used as a pH regulator; a mixture of sodium carbonate, zinc sulfate and sodium sulfite is used as a zinc inhibitor; a mixture of ammonium dibutyl dithiophosphate and sodium butyl xanthogenate is used as a collector. The flotation method has simple and practical technology, and a small amount of medicament is used; the production is performed under weak-acid condition, and the recovery rate and concentrate grade of the jamesonite are improved.

Owner:广西华锡矿业有限公司铜坑矿业分公司 +1

Ore dressing method for lead, zinc and antimony ore containing carbon

InactiveCN103623919AReduce adverse effectsReduce dosageWet separationDibutyl dithiophosphateSulfite salt

The invention provides an ore dressing method for lead, zinc and antimony ore containing carbon. The method comprises the following steps of decarburization in advance, lead and antimony coarse separation, twice lead antimony scavenging, three-time lead and antimony fine separation, zinc coarse separation, twice zinc scavenging and three-time zinc fine separation. Kerosene is used as carbon substance collecting agents, lime is used as regulating agents, zinc sulfate and sodium sulfite are used as zinc inhibiting agents, lead nitrate is used as antimony activating agents, ammonium dibutyl dithiophosphate and diethyldithiocarbamate are used as lead and antimony collecting agents, copper sulfate is used as zinc activing agents, butyl xanthate is used as zinc collecting agents, and terpenic oil is used as foaming agents. The ore dressing method has the advantages that the technical flow processes of decarburization in advance, preferential lead and antimony flotation and zinc re-separation are adopted for processing lead, zinc and antimony ore containing carbon, and the actual problems of great separation index fluctuation, great medicine consumption and high production cost of the existing technical flow process are solved.

Owner:GUANGXI UNIV

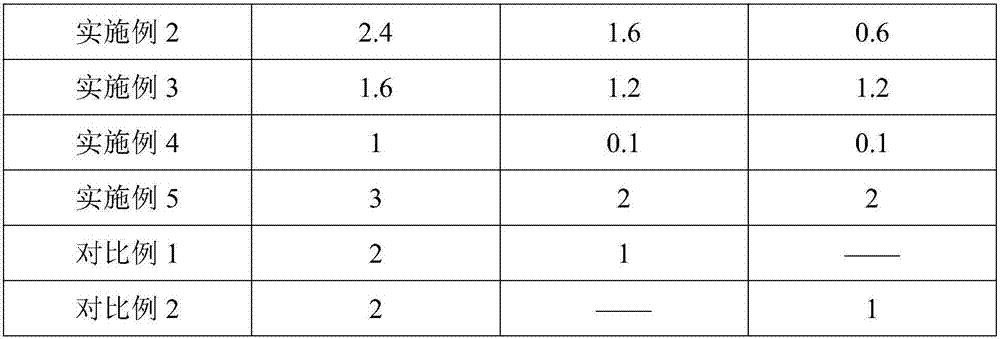

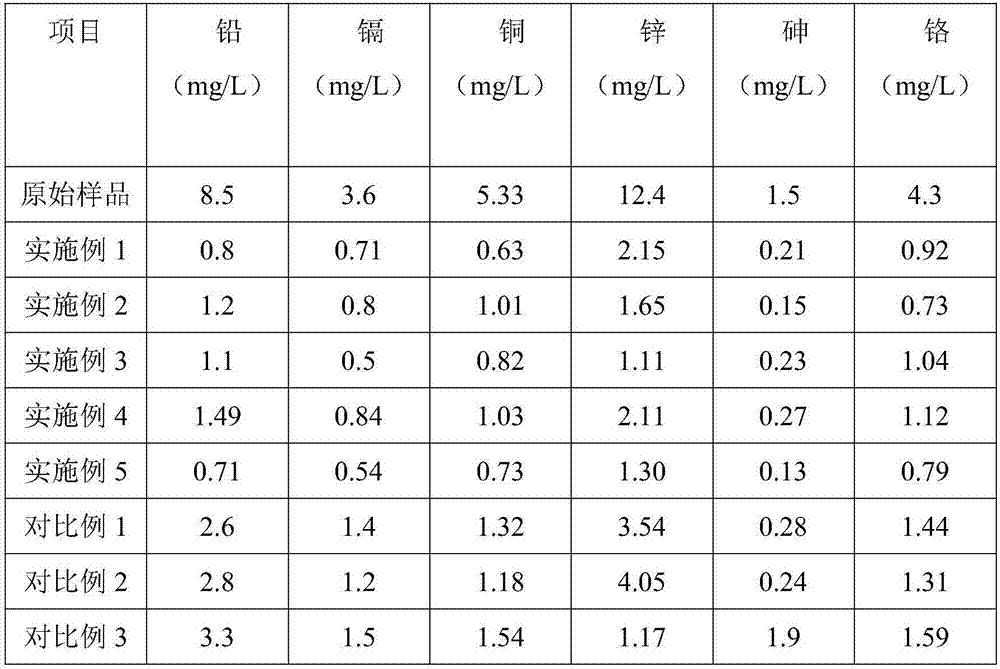

Preparation method and application of heavy metal contaminated soil/bottom mud stabilizer

ActiveCN107446587AImprove stabilityLimited ratioContaminated soil reclamationOrganic fertilisersDibutyl dithiophosphateSolubility

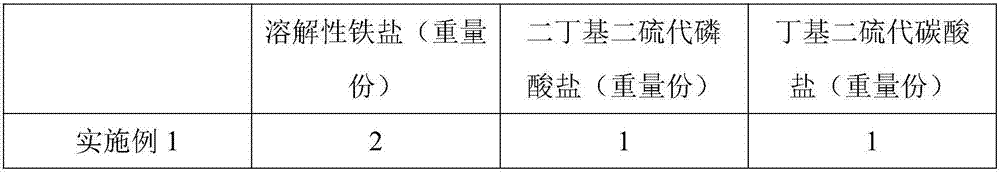

The invention relates to the technical fields of soil remediation and environmental protection, in particular to a heavy metal contaminated soil / bottom mud stabilizer. The heavy metal contaminated soil / bottom mud stabilizer is prepared from soluble ferric salt, dibutyl dithiophosphate and butyl dithiocarbonate in proportion. A heavy metal repair agent is low in cost, can effectively eliminate harm of heavy metal ions in soil, and has relatively good stabilizing effect on arsenic and other heavy metals in arsenic-containing composite heavy metal contaminated bottom mud under an acid condition, so that the defect that an existing product is poor in stabilizing effect on the arsenic-containing composite heavy metal contaminated bottom mud is overcome. The heavy metal contaminated soil / bottom mud stabilizer can be applied to stabilizing treatment of heavy metal contaminated muddy bottom of arsenic, lead, cadmium, copper, zinc and chromium. The heavy metal contaminated soil / bottom mud treated by the stabilizer can be used for roadbed building filler. The heavy metal contaminated soil / bottom mud stabilizer has the effects of protecting the environment, changing waste into things of value and increasing a waste utilization rate, and has a considerable economic value.

Owner:湖南新九方科技有限公司

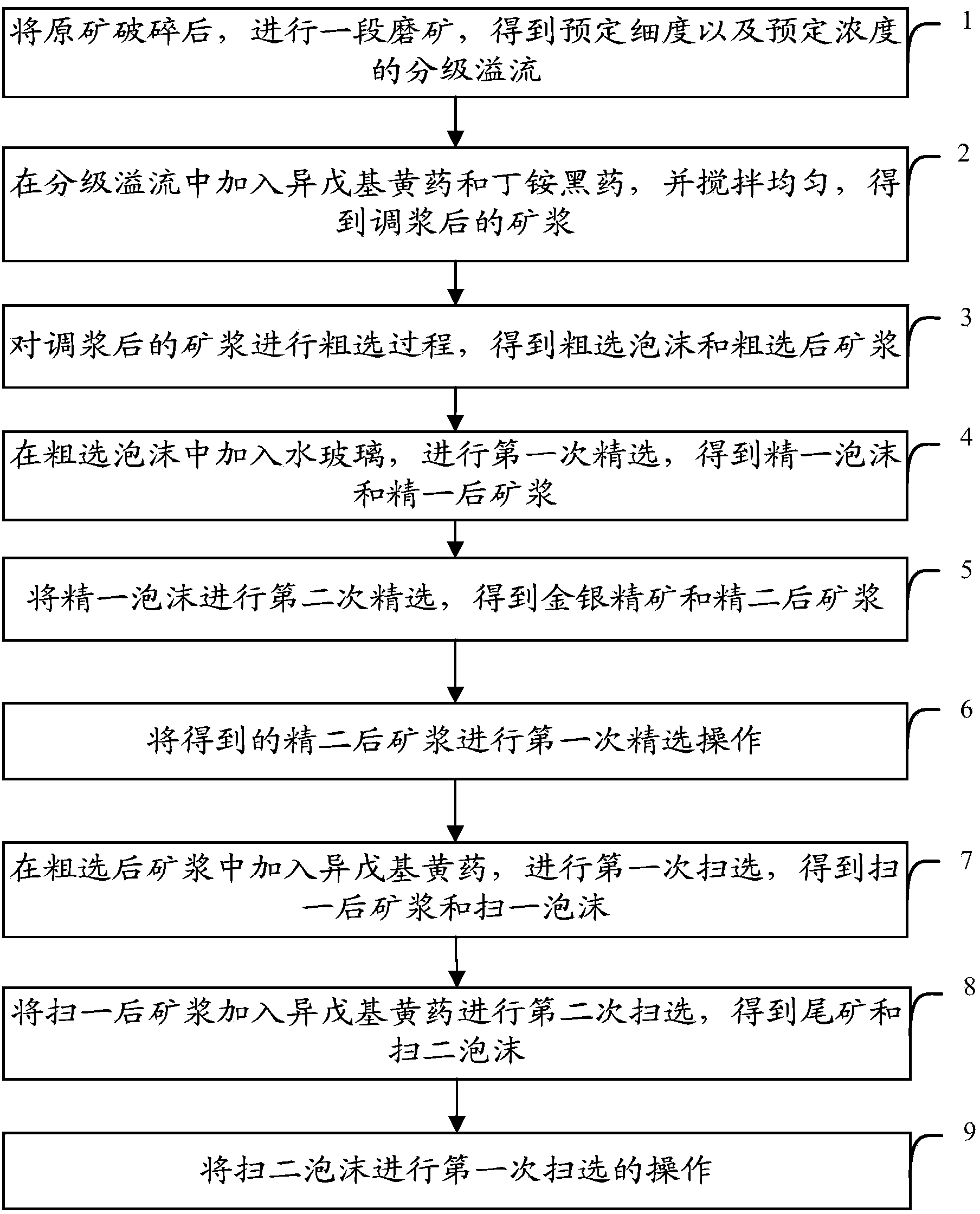

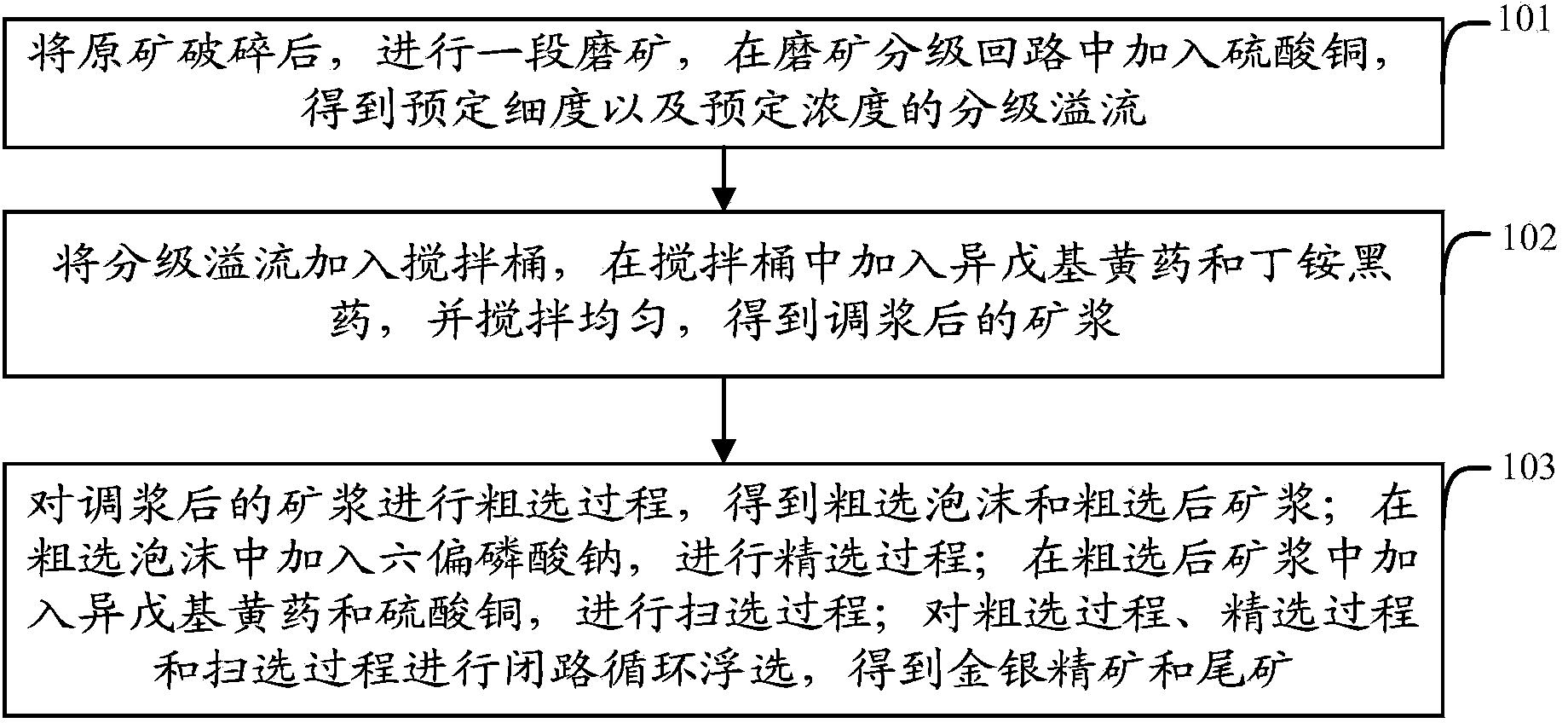

Flotation agent for flotation of kustelite and flotation method

ActiveCN103433144APlay a role in purificationImprove stabilityFlotationDibutyl dithiophosphateEngineering

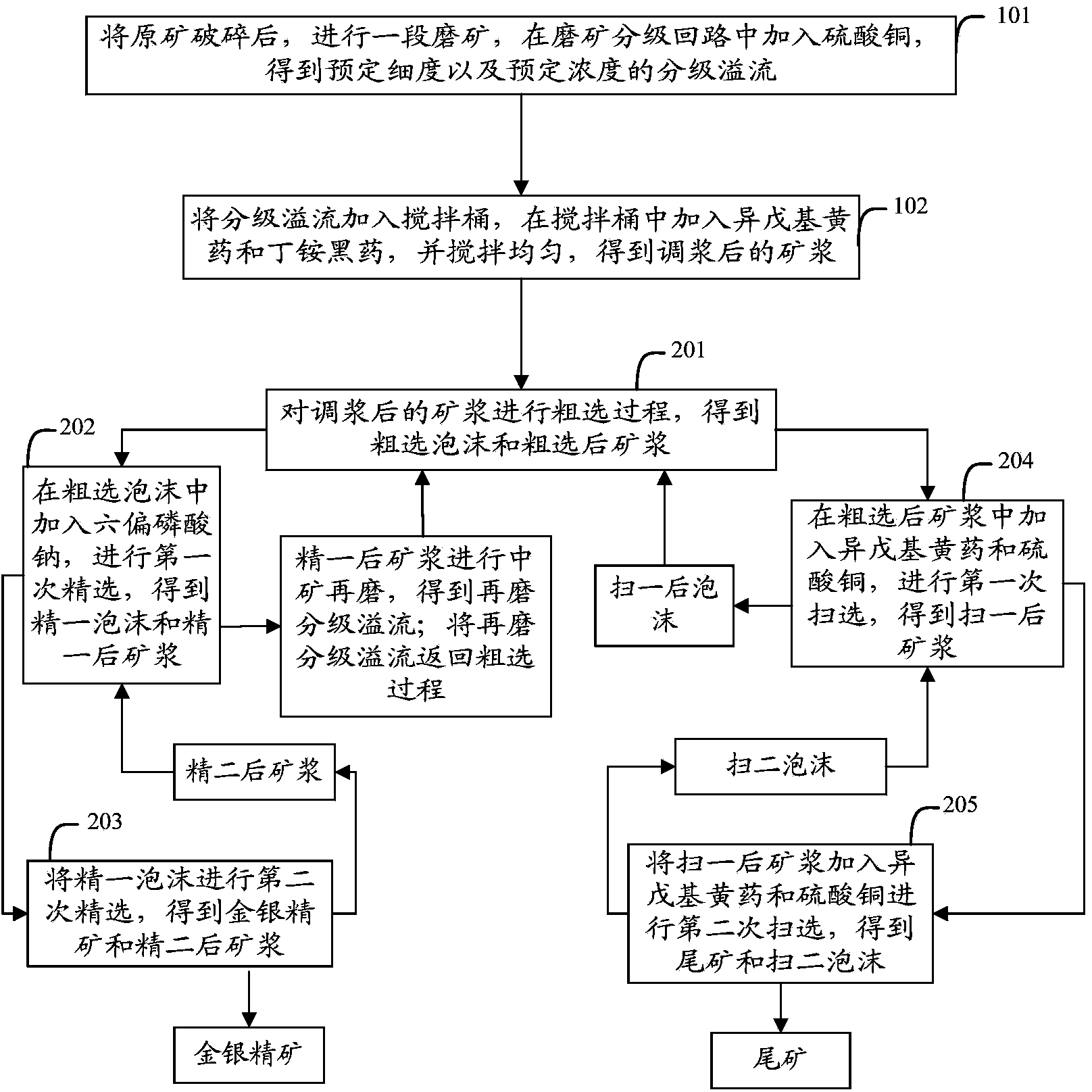

The invention relates to the field of mineral mining, and specifically relates to a flotation agent for flotation of kustelite and a flotation method. The flotation agent for flotation of the kustelite comprises copper sulfate, iso-amyl xanthate, ammonium dibutyl dithiophosphate and sodium hexametahposphate; in measurement by weight, the flotation agent for flotation of each ton of a raw ore comprises 50-170 grams of copper sulfate, 250-290 grams of iso-amyl xanthate, 50-90 grams of ammonium dibutyl dithiophosphate and 1-3 grams of sodium hexametahposphate. The flotation method for flotation of the kustelite by using the flotation agent comprises the following steps in the process of obtaining graded overflows: crushing the raw ore, and then performing one section of ore grinding; and adding copper sulfate into a loop for grading ore grinding to obtain graded overflows with prescheduled fineness and concentration, wherein in measurement by weight, 40-160 grams of copper sulfate is added into each ton of the raw ore. The flotation agent and flotation method provided by the invention ensure that tailing water generated during flotation is purified, and an effect of recycling can be realized.

Owner:FUJIAN PROVINCE ZHENGHE COUNTY YUANXIN MINING IND

Low-grade chalcopyrite flotation agent and preparation method thereof

The invention discloses a low-grade chalcopyrite flotation agent which is prepared from the following raw materials in parts by weight: 23-27 parts of ammonium dibutyl dithiophosphate, 3-4 parts of sulfonated tall oil, 3-5 parts of pyrophosphoric acid, 2-3 parts of nanometer titania, 6-8 parts of dipolyethylene glycol methyl ether, 5-7 parts of silicone polyether emulsion, 10-15 parts of diesel oil, 16-19 parts of sodium thiosulfate, 20-24 parts of butyl xanthate nitrile ester and 4-5 parts of activating agent. Since the nanometer titania is added, the flotation agent is good in dispersion and flocculation effect, the foam is stable and the collecting effect is enhanced; in addition, the low-grade chalcopyrite flotation agent has the advantages of good collecting effect, high copper yield, good medicine selecting property, good inhibiting property for other ores and high copper grade. The activating agent in the low-grade chalcopyrite flotation agent has the advantages of stable dispersion, good permeation, good activating property and long activating effect duration; the yield and the grade of copper can be improved.

Owner:ANHUI AODE MINING MACHINERY & EQUIP LTD

Lead-zinc oxide ore flotation agent

The invention discloses a lead-zinc oxide ore flotation agent. The lead-zinc oxide ore flotation agent comprises, by weight, 11-18 parts of dithiophosphate 25, 7.8-14 parts of ammonium dibutyl dithiophosphate, 20-25 parts of sodiumn-butylxanthate, 35.7-50 parts of diethyldithiocarbamate, 4.5-8 parts of kerosene, 150-200 parts of sodium silicate, 30-50 parts of ammonium bicarbonate and 10-20 parts of terpenic oil. The lead-zinc oxide ore flotation agent has the advantages of being good in flotation effect, easy to prepare, low in cost and high in recovery rate, thereby being worthy of intensive study and popularization and application in flotation of lead-zinc ore difficult to separate. During flotation of the lead-zinc oxide ore difficult to separate, it is only required that the eight materials are proportionally mixed to form the new flotation agent, the recovery rate of lead-zinc concentrate can be substantially improved, and operating difficulty is reduced for flotation workers and agentia workers as well.

Owner:玉门大昌矿业有限公司

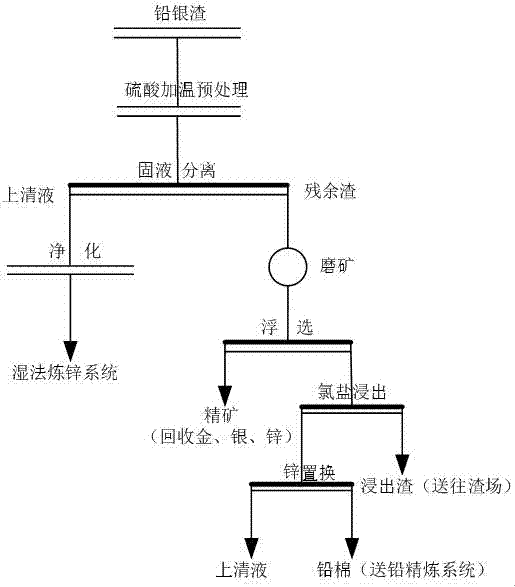

Lead silver residue flotation combined collector and application technology

The invention discloses a lead silver residue flotation combined collector and belongs to the technical field of mineral processing and wet metallurgy. The lead silver residue flotation combined collector is formed by the following parts, 4 to 8 parts of ammonium dibutyl dithiophosphate, 0.5 to 1 part of 25# black powder and 0.5 to 1 part of 2# oil. An application technology comprises the following steps of enabling electrolyte generated from clean water or zinc hydrometallurgy to serve as solvent and warming and pre-processing lead silver residues after sulfuric acid is added; returning to a zinc hydrometallurgy system to recycle zinc after supernate is purified, recycling silver through flotation after the residues are performed on ore grinding and meanwhile enabling gold and zinc to be collected in solver concentrate. The lead silver residue flotation combined collector is simple in composition, low in cost and has a collecting and foaming function and an advanced concentrated effect, achieves cyclic utilization due to the fact that the waste electrolyte serves as the solvent, is low in production cost, high in recovery rate, strong in adaptability, wide in application range and friendly to the environment and achieves recycle of various valuable elements.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

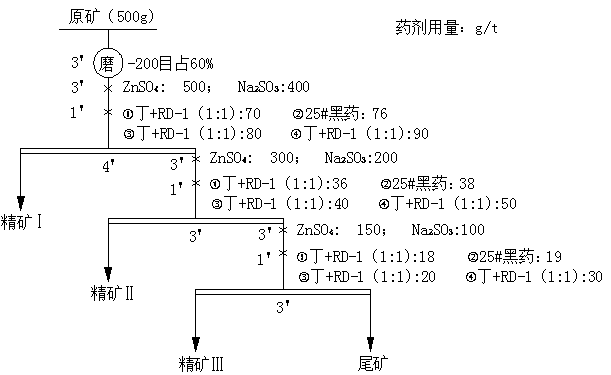

Combined zinc collecting agent for flotation of lead-zinc sulfide ore and application thereof

The invention discloses a combined zinc collecting agent for flotation of lead-zinc sulfide ore and application thereof. The combined zinc collecting agent comprises the following active components inparts by weight: 10-30 parts of ammonium dibutyl dithiophosphate, 30-50 parts of ethyl thiocarbamate and 30-50 parts of 2-aminothiophenol. According to the efficient combined collecting agent for sphalerite flotation, the combined collecting agent is composed of ammonium dibutyl dithiophosphate, ethyl thiocarbamate and 2-aminothiophenol and is easy to obtain, low in price, small in dosage and free of pollution. The ammonium dibutyl dithiophosphate is weak in collecting capacity, but has foamability, high sulfur and nitrogen collecting capacity and certain lead sulfide ore and zinc sulfide orecollecting capacity; compared with a conventional collecting agent butyl xanthate, 2-aminothiophenol has good flotation effect of on marmatite even under the condition that copper ion activation is not used, and has poor lead sulfide ore flotation effect; however, 2-aminothiophenol is a weakly acidic compound, and cannot fully react with zinc sulfide ore when a pH value is relatively low; and therefore, the components of the combined collecting agent can supplement each other.

Owner:CENT SOUTH UNIV

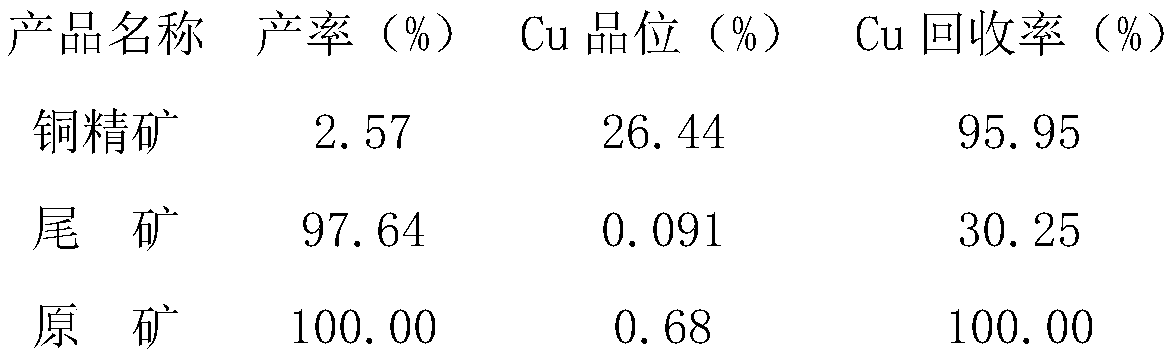

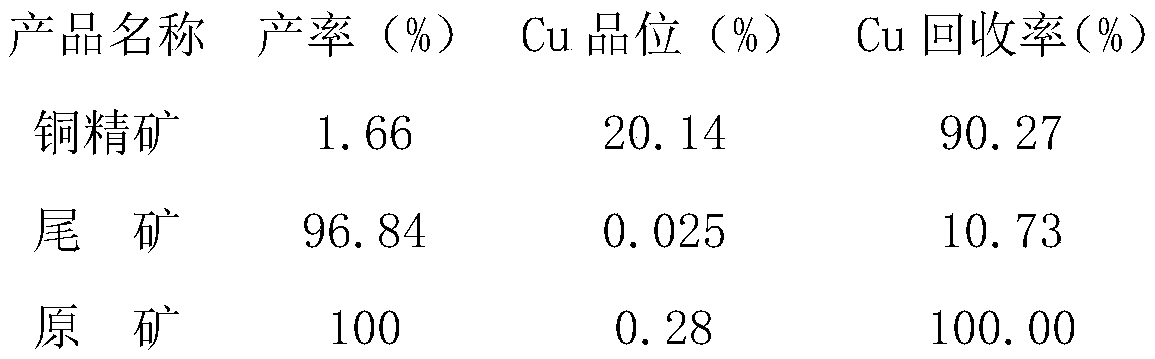

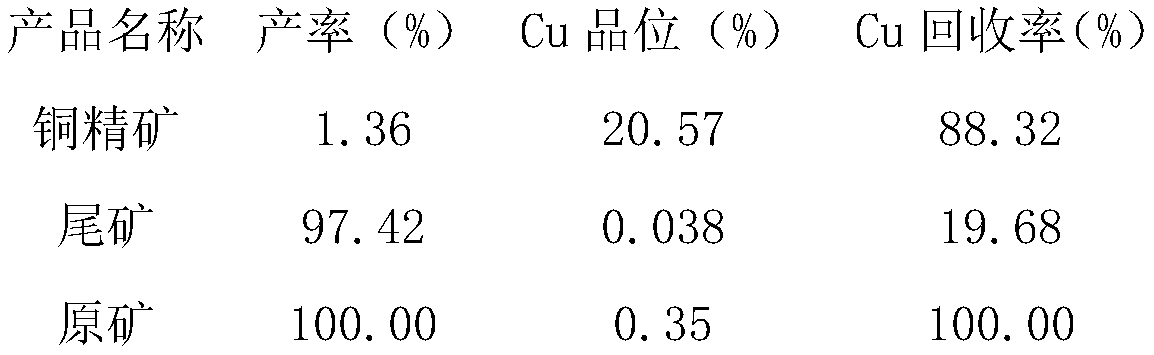

Beneficiation collecting agent for recycling copper and silver associated with multi-metal vulcanization lead zinc ores and beneficiation method of beneficiation collecting agent

InactiveCN109746123AReduce dosageReduce manufacturing costFlotationWet separationSocial benefitsDibutyl dithiophosphate

The invention relates to a beneficiation collecting agent for recycling copper and silver associated with multi-metal vulcanization lead zinc ores and a beneficiation method of the beneficiation collecting agent and belongs to the field of metal ore processing. The beneficiation collecting agent and the beneficiation method have the advantages that the mixed chemical of ammonium dibutyl dithiophosphate and dianilinodithiophosphoric acid and No. 25 aerofloat are used in a mixed manner in the beneficiation of the multi-metal vulcanization ores, adverse effects on lead-zinc indexes are avoided, copper and silver recycling rate is increased greatly, and copper concentrate grade is stable (above 20%); low cost and quick action are achieved, good economic and social benefits can be generated, and promising application prospect is achieved.

Owner:XINBARHU YOU BANNER RONG DA MINING LLC

High-sulfur magnetite processing agent and application method thereof

InactiveCN109604070AAchieve activationGuaranteed separation effectFlotationDibutyl dithiophosphateMagnetite

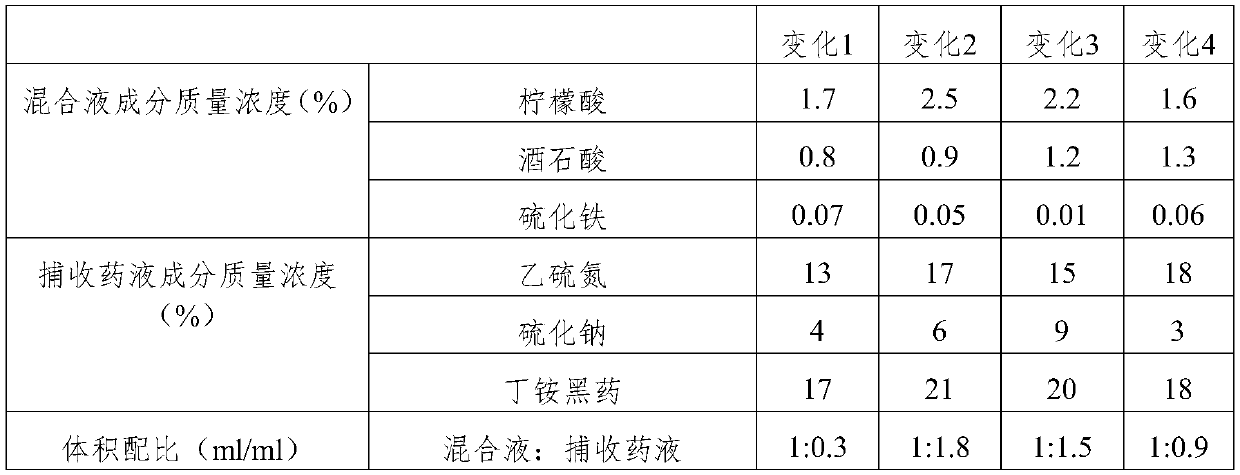

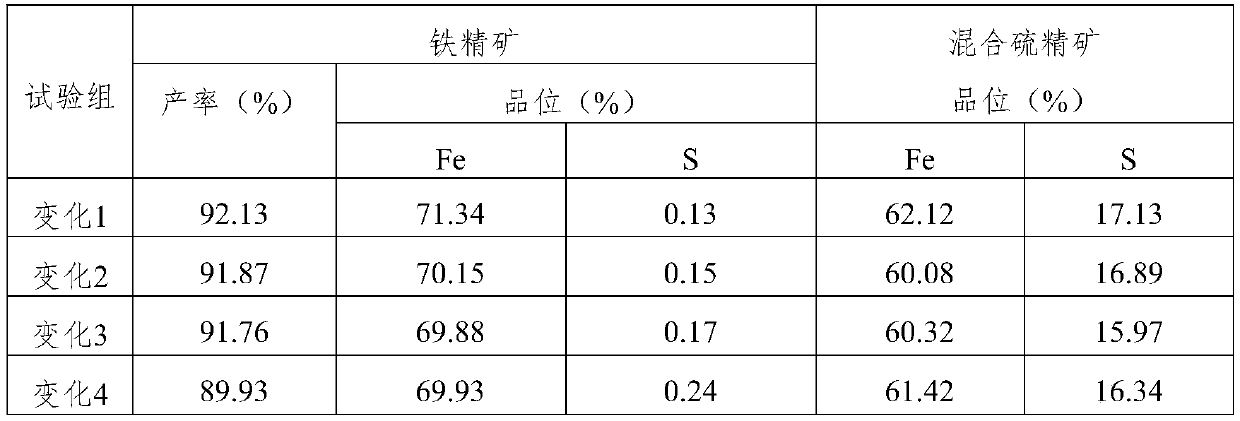

The invention relates to the technical field of mineral processing chemicals, in particular to a high-sulfur magnetite processing agent and an application method thereof. The high-sulfur magnetite processing agent is prepared by the following steps: using citric acid, tartaric acid, iron sulfide and water to prepare a mixed solution; using sodium diethyldithiocarbamate, sodium sulfide, ammonium dibutyl dithiophosphate and water to prepare a collecting agent liquid; and mixing the mixed solution and the collecting agent liquid according to a volume ratio of 1:(0.3-1.8) to form the high-sulfur magnetite processing agent. Therefore, activation of pyrrhotite is realized, separation between the pyrrhotite and magnetite is ensured, and the purpose of enhancing the desulfurization effect is achieved. The high-sulfur magnetite processing agent can be applied to desulfurization treatment of high-sulfur magnetites with different sulfur contents, and enables the sulfur content of iron concentrateafter flotation treatment to be reduced 0.15% or less, and the iron concentrate yield to be 91% or more.

Owner:遵义市博莱金矿业有限责任公司

Low-grade copper mine flotation agent and preparation method thereof

The invention relates to a low-grade copper mine flotation agent, which is prepared with the following materials in part by weight: 25 to 30 parts of 208 dithiophosphate, 12 to 14 parts of ethyl isopropylxanthogenic formate, 9 to 12 parts of ammonium dibutyl dithiophosphate, 2 to 3 parts of dihenylethyl phenol polyoxyethylene ether, 1 to 2 parts of polyethyleneglycol monooleate, 3 to 4 parts of triethylene tetramine, 5 to 7 parts of menthol, 5 to 8 parts of phytic acid, 2 to 3 parts of calcium oxide, 2 to 4 parts of soda and 4 to 5 parts of activator. The foam of the flotation agent is stable, the flocculation effect is good, the flotation agent has good collecting capability within the pH range between 7 and 10, the capability of copper collection is high, yield is high, the selectivity of the agent is good, and the grade of copper is high; becauase the activator contains components such as fumed silica, dispersion is stable, moreover, permeability is good, activation is good, the duration of the activation effect is long, and the yield and grade of copper can be increased.

Owner:ANHUI AODE MINING MACHINERY & EQUIP LTD

Efficient flotation separation method of copper sulfide ores

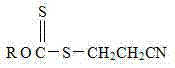

InactiveCN109731692ALow costNo pollution in the processFlotationDibutyl dithiophosphateAcrylonitrile

The invention discloses an efficient flotation separation method of copper sulfide ores. The method includes the steps: taking the copper sulfide ores to perform ore grinding, and adjusting the mass percentage concentration of ore pulp to reach 40%; adding calcium oxide into the ore pulp according to the proportion of 800g / t-1500g / t, adding combination regulators into the ore pulp according to theproportion of 150g / t-260g / t, and adding combination collectors into the ore pulp according to the proportion of 80g / t-120g / t. The combination regulators comprise, by weight, 10-20 parts of sodium sulfide, 10-30 parts of sodium hexametaphosphate and 5-10 parts of sodium humate. The combination collectors comprise, by weight, 1-3 parts of acrylonitrile alkyl xanthate, 0.5-2 parts of Xanthate diester, 0.5-1 part of ammonium dibutyl dithiophosphate, 1-2 parts of methyl benzyl thiazide and 1-2 parts of terpene alcohol. According to the method, efficient flotation separation of copper sulfide and gangue minerals is achieved, concentrate quality is high, and environmental pollution is omitted.

Owner:KUNMING UNIV OF SCI & TECH

Novel combined collecting foaming agent for copper ore grading in high and cold area and application of novel combined collecting foaming agent

ActiveCN109482354ALow melting pointGood solubility and dispersibilityFlotationDibutyl dithiophosphateAlcohol

The invention discloses a novel combined collecting foaming agent for copper ore grading in a high and cold area and application of the novel combined collecting foaming agent. The novel combined collecting foaming agent is characterized by being prepared from the following components in parts by weight: 2-5 parts of cyanoethyl diethyl dithionocarbamate, 1-2 parts of ammonium dibutyl dithiophosphate, 0.25-0.5 part of diesel oil, 0.5-0.75 part of ethyl alcohol, and 1-2 parts of 43# yellow hydrocyanic ester. The problems that in the production process of a copper mine in the high and cold area in winter, the outdoor air temperature reaches minus 20-minus 30 DEG C or below, an ester collecting agent used currently is prone to being crystallized due to the high melting point, thus inconvenience is brought to production, and the production index is influenced are solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Collecting agent for copper and gold ores and method for manufacturing collecting agent

The invention discloses a collecting agent for copper and gold ores. The collecting agent comprises, by weight, 20-23 parts of diltiazem nitrile ester, 20-23 parts of ammonium dibutyl dithiophosphate, 3-5 parts of naphthenic acid, 2-3 parts of oxidized paraffin soap, 3-4 parts of sodium dodecyl benzene sulfonate, 1-2 parts of sodium napthionate, 3-4 parts of sodium oleate, 3-4 parts of sodium fluoride, 7-9 parts of O-alkyl-N-alkyl sulfide thionic carbamate, 6-9 parts of dimethylglyoxime and 10-12 parts of activator. The collecting agent has the advantages that collecting and foaming effects can be realized by the collecting agent, foams are stable, the collecting agent is high in collecting capacity, gold ores are high in recovery rate, selectivity and grade, a copper suppressing effect can be realized, and copper can be prevented from being collected; owing to the activator, surface hydrophobic properties of the gold ores can be changed, internal structures of the gold ores can be activated, the gold collection performance of the collecting agent can be improved, and gold is high in recovery rate and grade.

Owner:ANHUI CHAOSHAN NEW MATERIAL

Flotation reagent for improving flotation indexes of sphalerite

The invention relates to a flotation reagent for improving flotation indexes of sphalerite and belongs to the field of metal mineral beneficiation. The special flotation reagent is prepared by mixing the following solutions by volume percent: 5-20% of a 1-1.5 wt% ammonium dibutyl dithiophosphate solution, 5-15% of a 8-10 wt% sodium(potassium)amyl xanthate solution, 30-40% of a 8-10 wt% sodium O-ethyl dithiocarbonate solution and the balance of a 8-10 wt% sodium n-butyl-xanthate solution. The flotation reagent is high in zinc recovery rate and low in consumption and cost, and has an obvious beneficiation effect on fine sphalerite.

Owner:YILIANG CHIHONG MINING IND

Improved type flotation agent

The invention provides an improved type flotation agent. The improved type flotation agent is composed of butyl xanthate, ammonium dibutyl dithiophosphate, ethionine ester, erucic acid, maleic acid, polyethylene, alkylphenol polyglycol ether, ethyl alcohol, sodium dodecyl benzene sulfonate, coupling agent KH550 and water. The dispersion and collecting effects of the improved type flotation agent are quite good, the selectivity of the improved type flotation agent is good, and efficient flotation of copper in a low-grade chalcopyrite can be achieved.

Owner:廖继华

Collecting agent for low-grade gold ores and method for manufacturing collecting agent

The invention discloses a collecting agent for low-grade gold ores. The collecting agent comprises, by weight, 30-34 parts of diltiazem nitrile ester, 10-12 parts of alkyl xanthate acrylonitrile ester, 10-12 parts of ammonium dibutyl dithiophosphate, 1-2 parts of sodium hydroxide, 17-19 parts of styrene phosphoric acid, 3-4 parts of 4-butanediol vinyl ether, 1-2 parts of potassium dichromate, 2-3 parts of sodium metasilicate, 2-3 parts of diphenyl ethyl phenol-compounded polyoxyethylene ether, 1-2 parts of oleic acid polyoxyethylene ester, 5-7 parts of 2-peracetic acid-group butyric acid and 10-20 parts of activator. The collecting agent has the advantages that the collecting agent can realize capturing and foaming effects, foams are stable, and the collecting agent is high in collection capacity, so that the gold ores are high in recovery rate, selectivity and grade; owing to the activator, surface hydrophobic properties of the gold ores can be changed, internal structures of the gold ores can be activated, accordingly, the gold ore collection performance of the collecting agent can be improved, characteristics of the collecting agents can be played for the low-grade gold ores, the gold ores are high in recovery rate, and gold is high in grade.

Owner:ANHUI CHAOSHAN NEW MATERIAL

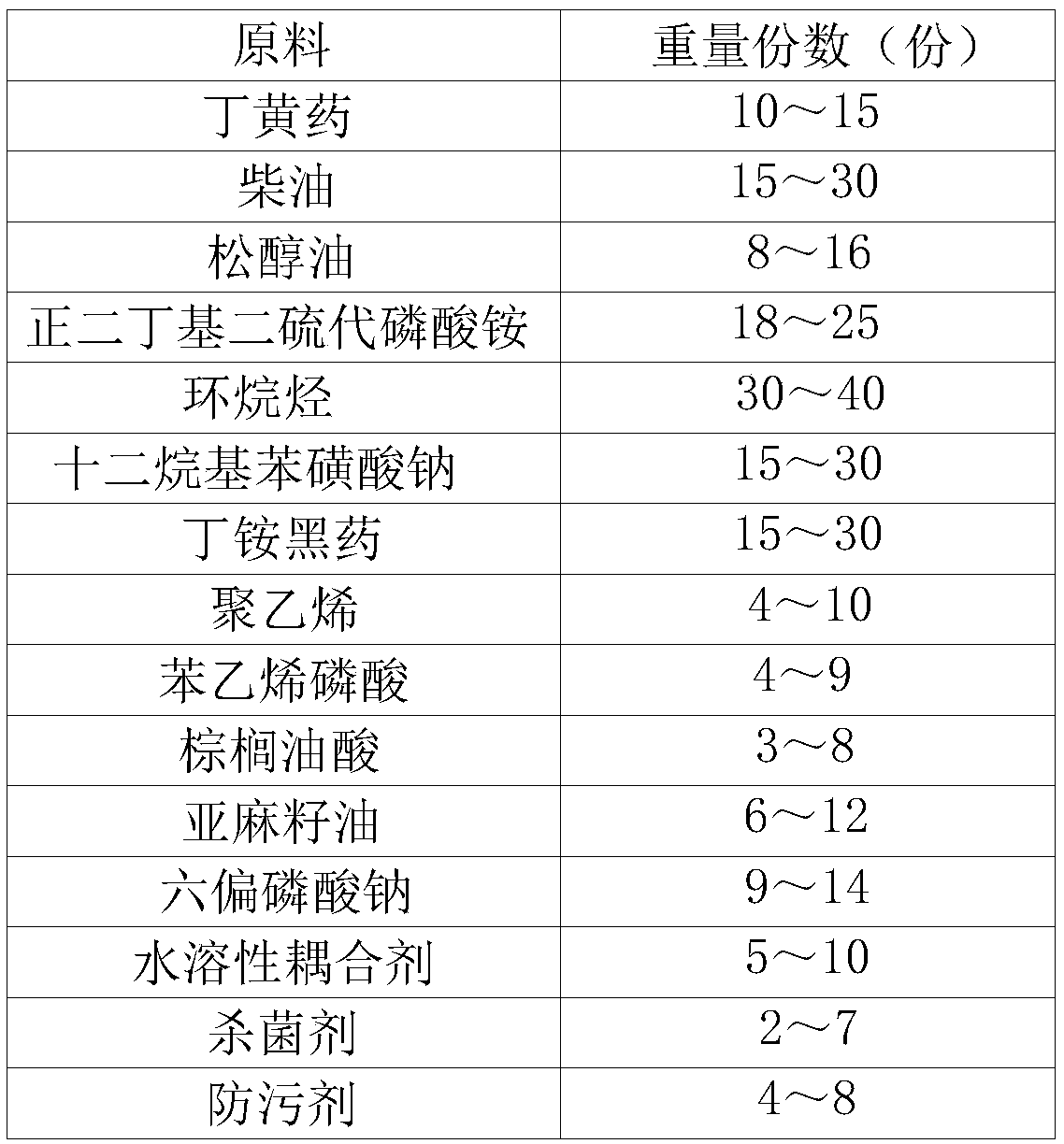

Environment-friendly high-performance mining flotation agent

InactiveCN111346739AReduce manufacturing costFast flotationFlotationDibutyl dithiophosphateO-Phosphoric Acid

The invention discloses an environment-friendly high-performance mining flotation agent. The flotation agent is prepared from the following components in parts by weight: 10-15 parts of butyl xanthate, 15-30 parts of diesel oil, 8-16 parts of terpenic oil, n-dibutyl ammonium dithiophosphate, a naphthenic hydrocarbon, sodium dodecylbenzene sulfonate, ammonium dibutyl dithiophosphate, polyethylene,styrene phosphoric acid, palmitoleic acid, linseed oil, sodium hexametaphosphate, a water-soluble coupling agent , a bactericide, and an anti-fouling composition. Due to the fact that the raw materials are cheap and easy to obtain, the production cost of the flotation agent is reduced, and meanwhile the flotation agent has the advantages of being high in flotation speed, high in foaming capacity,free of toxicity and pungent smells and high in environmental friendliness.

Owner:PINGDINGSHAN TEXT HIGH GRADE OIL CO LTD

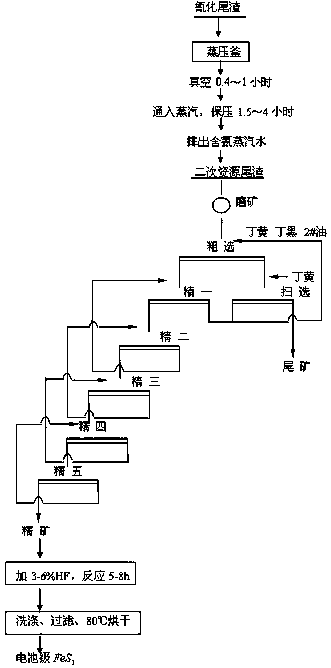

Technology for extracting ferrous sulfide from gold-bearing cyanide tailings

InactiveCN108043587AImprove qualityGood cyanide removal effectSolid waste disposalFlotationDibutyl dithiophosphateGold content

The invention relates to a technology for extracting ferrous sulfide from gold-bearing cyanide tailings. The technology comprises the steps that firstly, cyanide in the gold-bearing cyanide tailings is hydrolyzed by an autoclaving process, obtained secondary tailings are ground till a material in the secondary tailings, of which the fineness reaches 400 meshes, accounts for 95-98% of the secondarytailings; then, slurry blending is carried out to allow a liquid-solid mass ratio to be (3-4):1; and beneficiation reagents, namely, 60-120 g / t sodium n-butylxanthate and 15-35 g / t ammonium dibutyl dithiophosphate are added, a system pH value is adjusted to be between 6 and 9, and after one time of roughing, one time of scavenging and five times of cleaning are carried out, high-grade pyrites with the sulfur content being 52.87%, the gold content being 5.8 g / t, and the purity reaching 99.19% is obtained. With the adoption of the technology, the gold-bearing cyanide tailings in a smelting plant are recycled, secondary utilization of resources and the high value purpose are realized, and the amount of discharged pollutants is reduced substantially.

Owner:FUJIAN SHUANGQISHAN MINING +1

Collecting agent for flotation of copper sulfide from copper oxide ore and application

ActiveCN112337652AGood choiceImprove adsorption capacityFlotationProcess efficiency improvementDibutyl dithiophosphateCarbonyl sulfide

The invention belongs to the field of flotation reagents in the mineral processing discipline, and relates to a beneficiation reagent, in particular to a collecting agent for the flotation of copper sulfide from copper oxide ore and application. The collecting agent for the flotation of the copper sulfide from the copper oxide ore. The collecting agent is composed of isobutyl butyloxycarboryl thionocarbamate, xanthic acid methyl formate, ammonium dibutyl dithiophosphate, diesel oil, terpenic oil and 3# solvent oil. The flotation method for the flotation of the copper sulfide from the copper oxide ore adopts the collecting agent for the flotation of the copper sulfide from the copper oxide ore. According to the novel collecting agent for sorting copper sulfide, copper oxide and gangue minerals, the collecting agent has good selectivity and extremely high collecting capacity on the copper sulfide, can increase the recovery rate of the copper sulfide, meanwhile,and greatly reduce the content of gangue and copper oxide in copper concentrate, and therefore, the quality and the recovery rate of the copper concentrate and the hydrometallurgy cathode copper yield in subsequent steps are improved.

Owner:SHENYANG RES INST OF NONFERROUS METALS

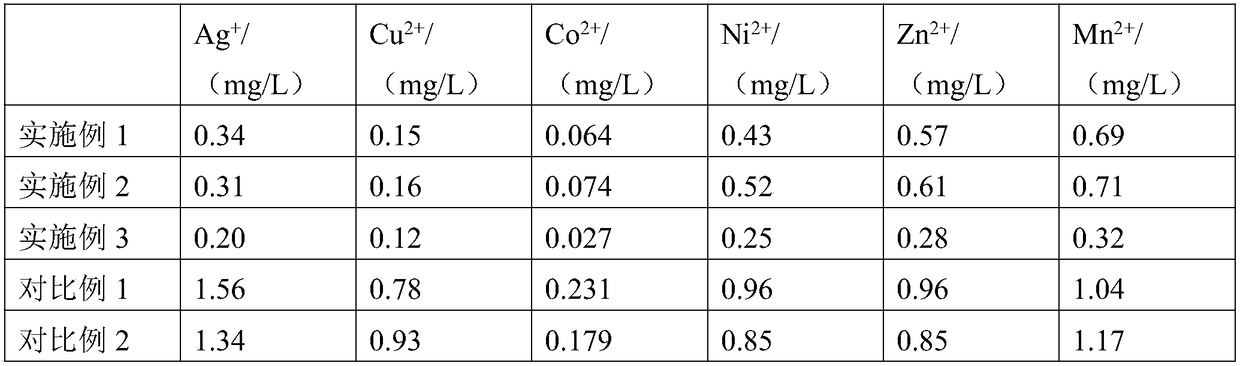

Preparation method and application of composite magnetic nanomaterial based on nanoscale zero-valent iron

InactiveCN108585162AGood removal effectEasy to prepareWater contaminantsWater/sewage treatment by reductionDibutyl dithiophosphateMaterials science

The invention relates to a preparation method and application of a composite magnetic nanomaterial based on nanoscale zero-valent iron, and belongs to the technical field of composite magnetic nanomaterials. The preparation method particularly comprises the following steps that the nanoscale zero-valent iron is added into a reaction vessel loaded with absolute ethyl alcohol and acetonitrile, thencetyl trimethyl ammonium bromide, lecithin and ammonium hydroxide are added, ultrasonic treatment is conducted, and suspension liquid is obtained; under the condition of stirring, an ethanol solutioninto which sodium oleate is dissolved is dropwise added in the suspension liquid, and stirring is conducted at room temperature; tetrabutyl titanate is added in the mixture, after ultrasonic treatmentis conducted at room temperature, reaction liquid is transferred into a high pressure kettle, and a high-temperature reaction is conducted; after the reaction liquid is cooled to the room temperature, zeolite is added in the mixed liquid, and stirring is conducted; ammonium dibutyl dithiophosphate is added in the mixed liquid obtained after stirring is conducted, and stirring is conducted. The preparation method is simple, the problem that the surface of the nanoscale zero-valent iron is likely to be oxidized to be Fe<2+> or Fe<3+>, and reducibility is poor can be solved, and the removal effect of the nanoscale zero-valent iron on heavy metal ions in a water body is greatly increased.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

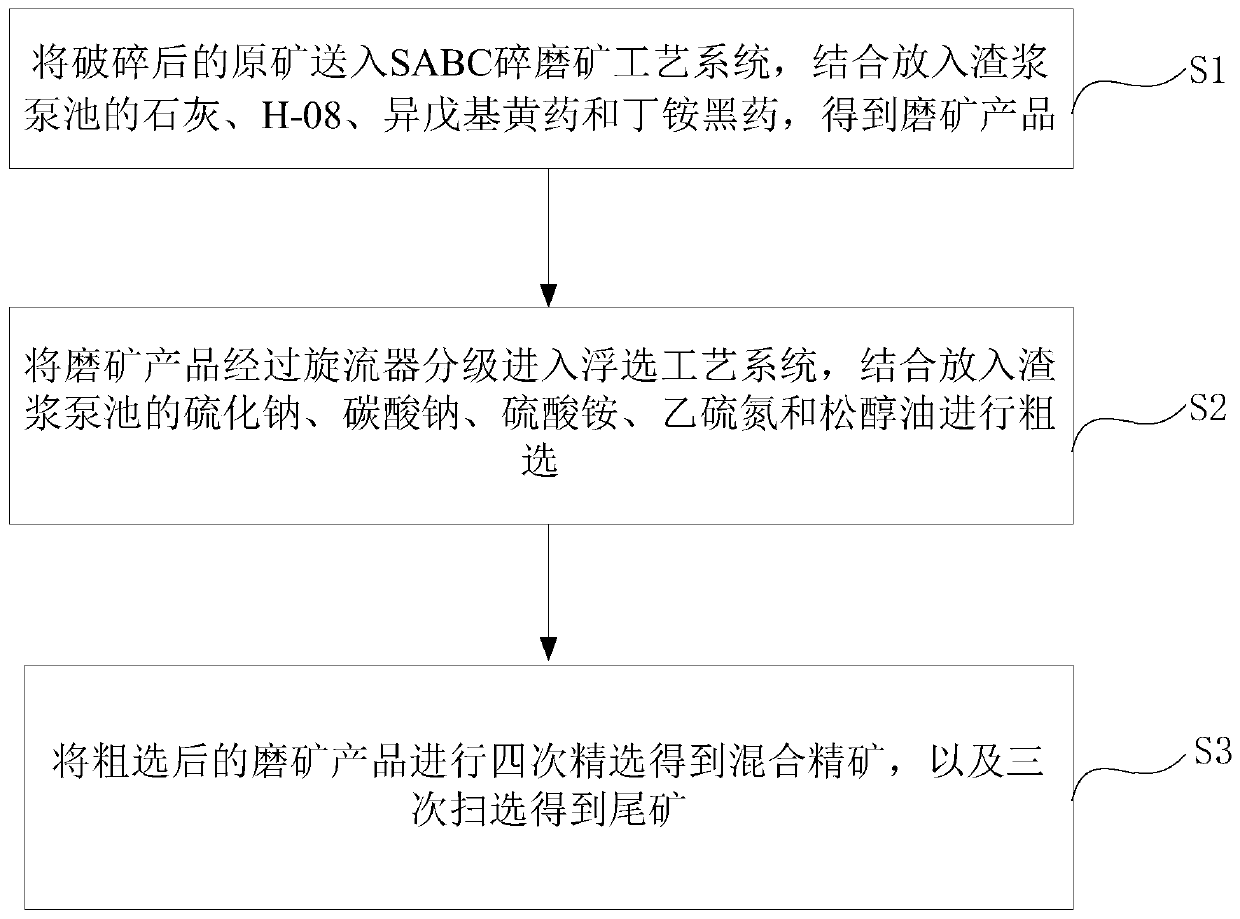

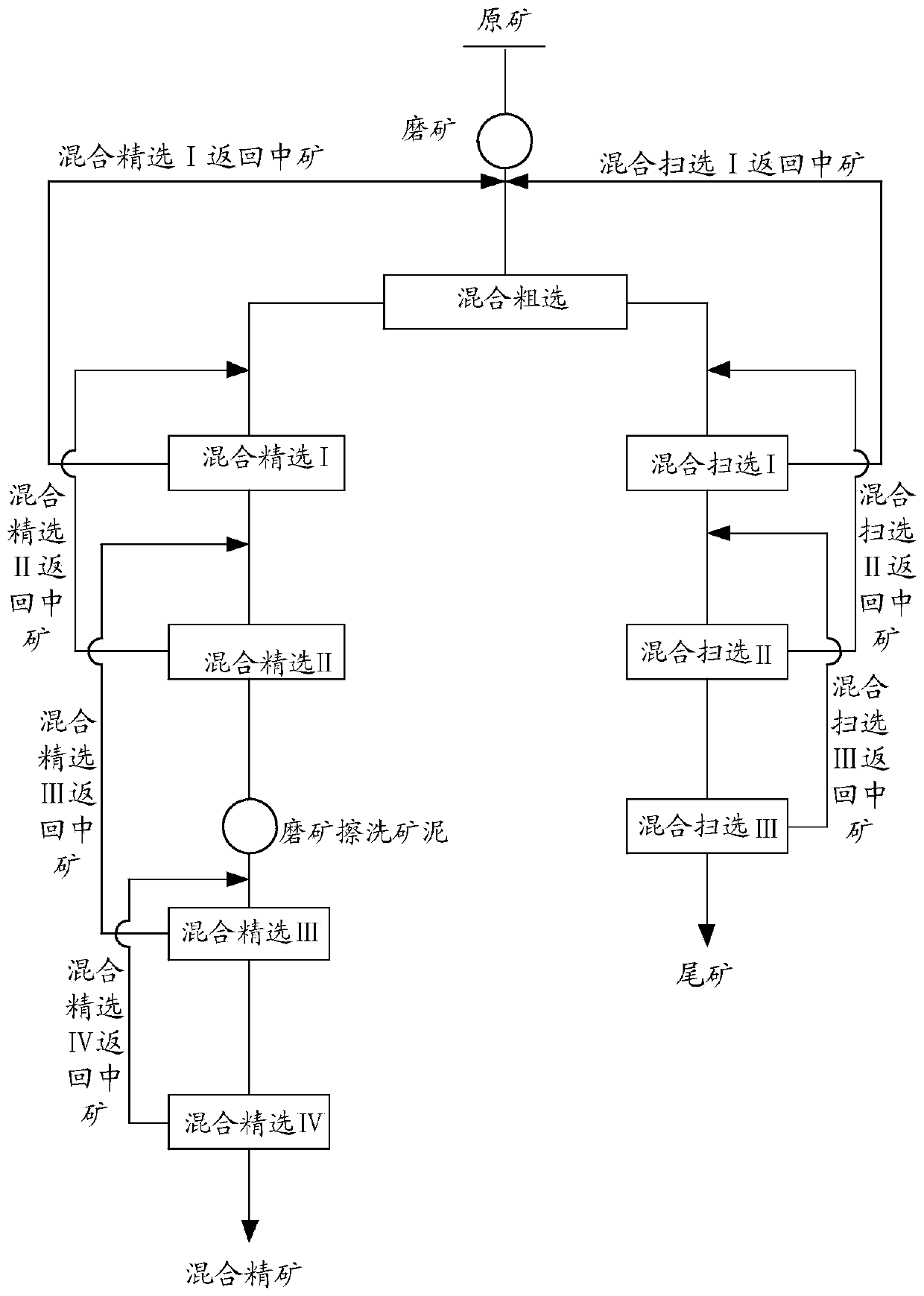

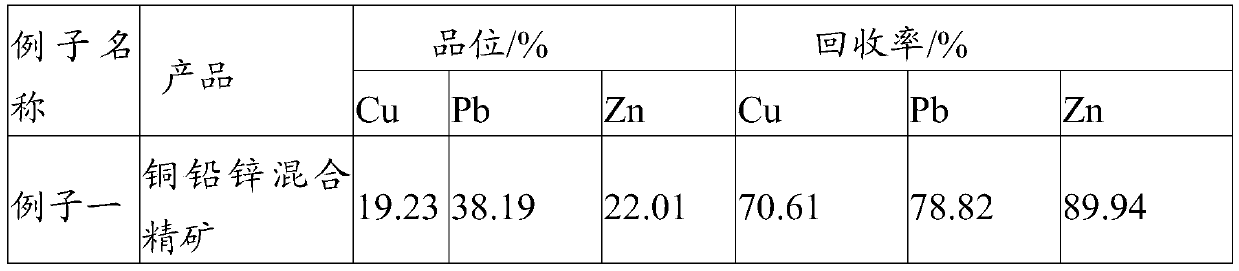

Beneficiation method for recycling copper oxide lead-zinc ore with high mud content, high oxidation rate and high sulfur content

InactiveCN111013827AAvoid inhibitionHigh recovery rateFlotationWet separationDibutyl dithiophosphateCarbamate

The invention discloses a beneficiation method for recycling copper oxide lead-zinc ore with high mud content, high oxidation rate and high sulfur content. The beneficiation method comprises the following steps: sending crushed raw ore into an SABC crushing and grinding process system, and obtaining an ore grinding product by combining lime, H-08, isoamyl xanthate and ammonium dibutyl dithiophosphate which are put into a slurry pump pool; grading the ore grinding product through a cyclone, feeding the ore grinding product into a flotation process system, and roughing by combining sodium sulfide, sodium carbonate, ammonium sulfate, ethyl thio carbamate and terpenic oil which are put into the slurry pump pool; and carrying out four times of concentration on the roughed ore grinding product to obtain a bulk concentrate, and carrying out three times of scavenging to obtain tailings. According to the beneficiation method for recycling copper oxide lead-zinc ore with high mud content, high oxidation rate and high sulfur content, comprehensive recycling and utilization of the ore of the type can be achieved, and adverse effects on the environment are avoided.

Owner:TIBET HUATAILONG MINING DEV

Efficient flotation reagent for fine-grained sphalerite separation, preparation method and application thereof

InactiveCN110665645AImprove sorting effectHigh recovery rateFlotationDibutyl dithiophosphateSodium ethylxanthate

The invention discloses an efficient flotation reagent for fine-grained sphalerite separation, a preparation method and application thereof. The efficient flotation reagent for fine-grained sphaleriteseparation is composed of a sodium ethyl-xanthate solution, a sodium butyl xanthate solution, a sodium amyl xanthate solution and an ammonium dibutyl dithiophosphate solution. The preparation methodincludes: mixing the raw materials according to the formula ratio uniformly to obtain the target object efficient flotation reagent for fine-grained sphalerite separation. The efficient flotation reagent for fine-grained sphalerite separation can be applied to a complex sulfide ore separation process. The prepared reagent can be directly added for roughing operation in sphalerite flotation. The method and the collecting agent provided by the invention have obvious technical index advantages, economic benefit advantages and environmental advantages when applied to flotation process.

Owner:YILIANG CHIHONG MINING IND

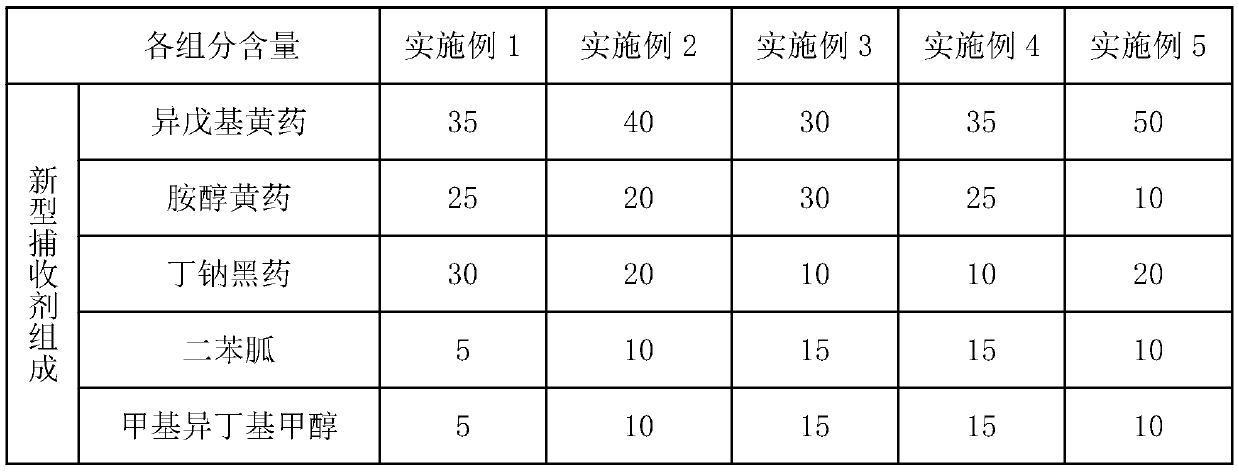

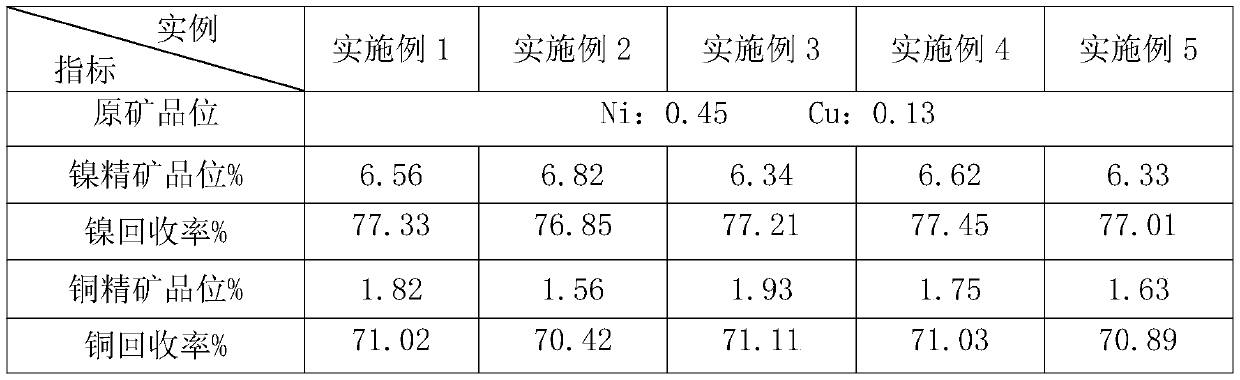

Efficient collecting agent applied to low-grade copper-nickel sulfide ore and preparation method of efficient collecting agent

InactiveCN109701751AAvoid the disadvantages of poor sorting effectImprove sorting effectFlotationDibutyl dithiophosphateNickel sulfide

The invention discloses an efficient collecting agent applied to low-grade copper-nickel sulfide ore and a preparation method of the efficient collecting agent. The collecting agent is prepared from the following raw materials in parts by weight: 30-50 parts of sodium isoamylxanthate, 10-30 parts of amine-alcohol xanthate, 10-30 parts of sodium dibutyl dithiophosphate,5-15 parts of diphenyl guanidine and 5-15 parts of methyl isobutyl carbinol, and the collecting agent is prepared by fully mixing the raw materials and uniformly carrying out stirring. The collecting agent has the characteristicsof collecting and foaming, and has good selectivity and obvious collecting effect on magnesium-rich low-grade copper-nickel sulfide ore; the size, color, luster and strength of flotation froth are stable, the mineralization degree of the froth is good, the floating speed of the ore is high, the concentrate grade and the copper-nickel recovery rate can be effectively improved, and the collecting agent is an ideal selective collecting agent for the low-grade copper-nickel ore.

Owner:WESTERN MINING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com