Beneficiation collecting agent for recycling copper and silver associated with multi-metal vulcanization lead zinc ores and beneficiation method of beneficiation collecting agent

A technology of lead-zinc sulfide and mineral processing method, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of retention of copper and silver recovery rate, and achieve improved recovery rate, less chemical dosage, and great promotion The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below, so as to facilitate the understanding of the skilled person.

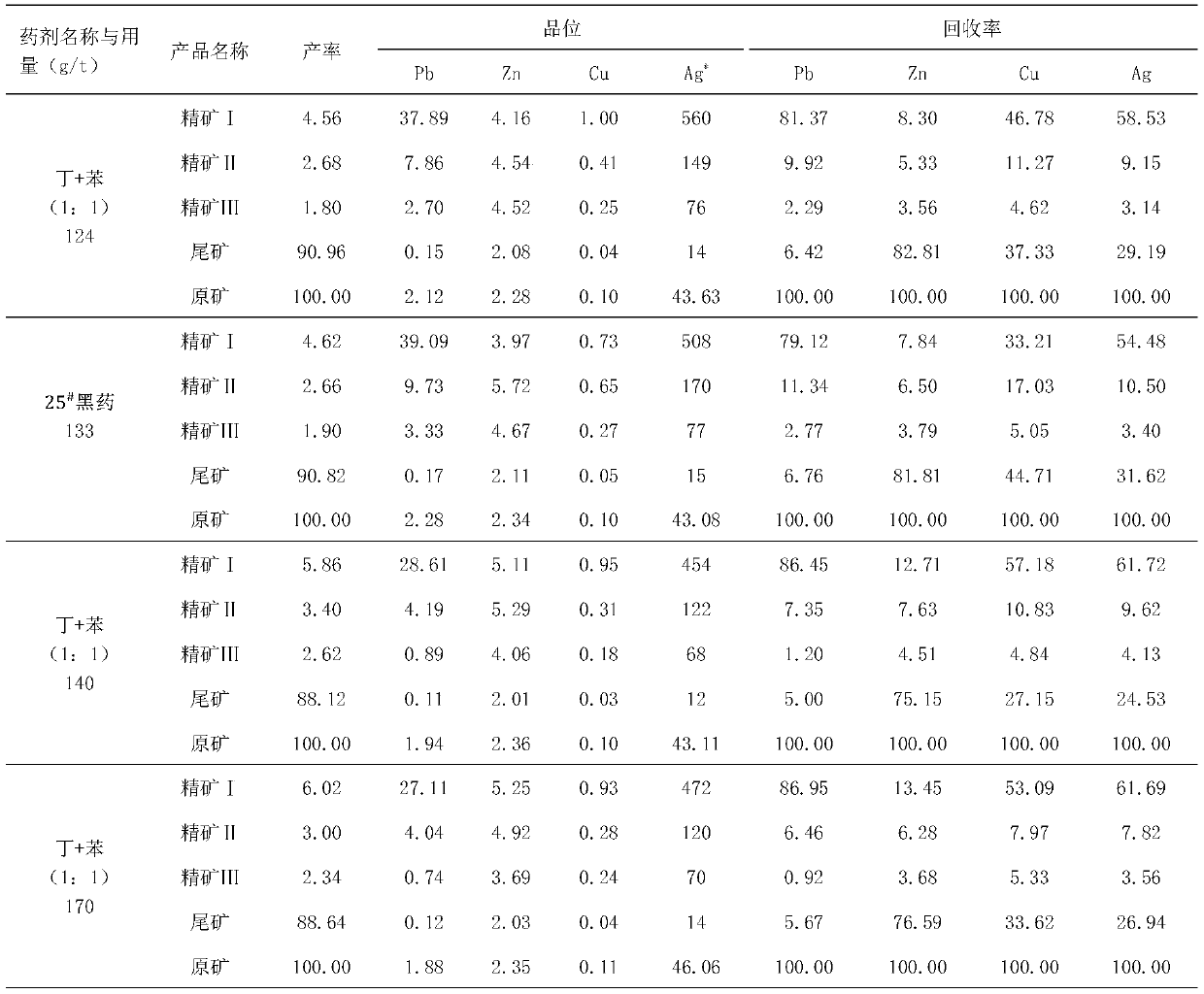

[0028] 1 laboratory test

[0029] 1.1 Test ore preparation

[0030] The test ore is collected from the production ore, that is, the ratio of Jiawula: 10#: 40#: 48#: 3-1#: 76# = 1:1:1:1:1:1, and 150 kg is collected. Crushed to less than 2mm by a laboratory crusher, stirred evenly, and divided into one bag for every 500g ore sample.

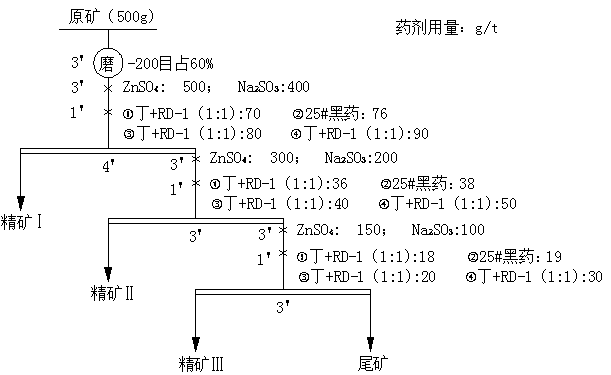

[0031] 1.2 Grinding fineness and time

[0032] The test grinding fineness directly determines the production fineness -200 mesh accounts for 60%. Determine the test grinding time required for fineness to -200 mesh accounting for 55% by 4 test grindings. The test grinding was 47% at 2 minutes and 10 seconds, 55% at 2 minutes and 40 seconds, 60% at 3 minutes and 00 seconds, and 65% at 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com