Beneficiation process for gold ores containing high arsenic and antimony content easily argillized minerals

A technology of mudification and mineralization, which is applied in the field of gold ore beneficiation technology, can solve the problems such as unfavorable gold recovery, achieve the effect of improving recovery rate, high recovery rate and reducing influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

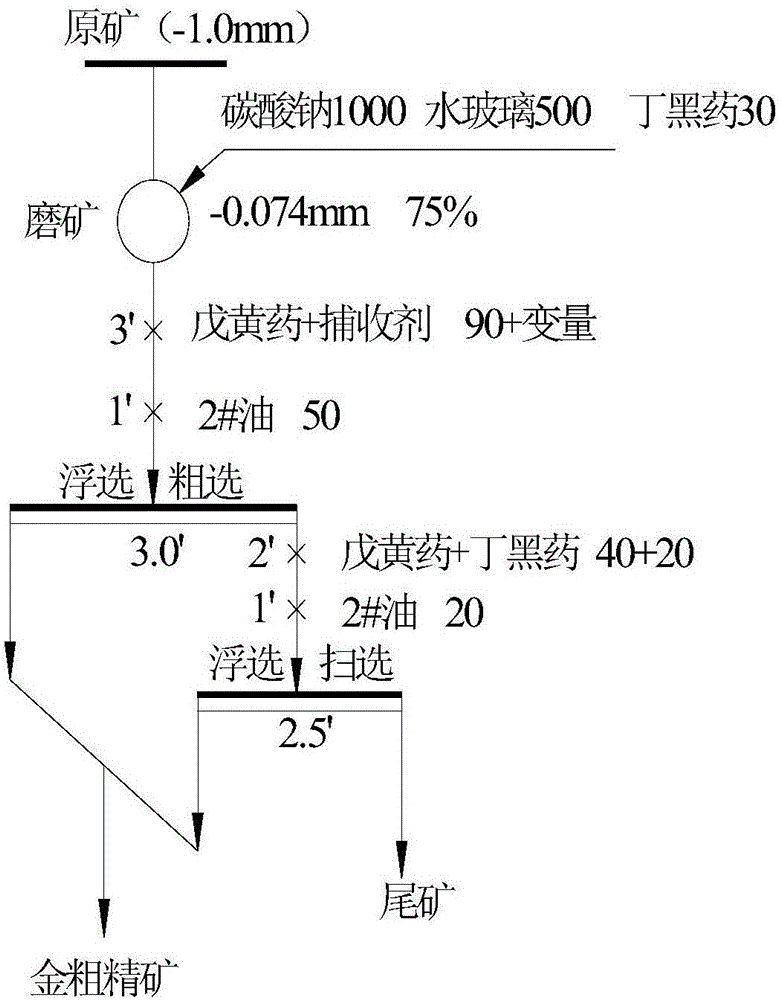

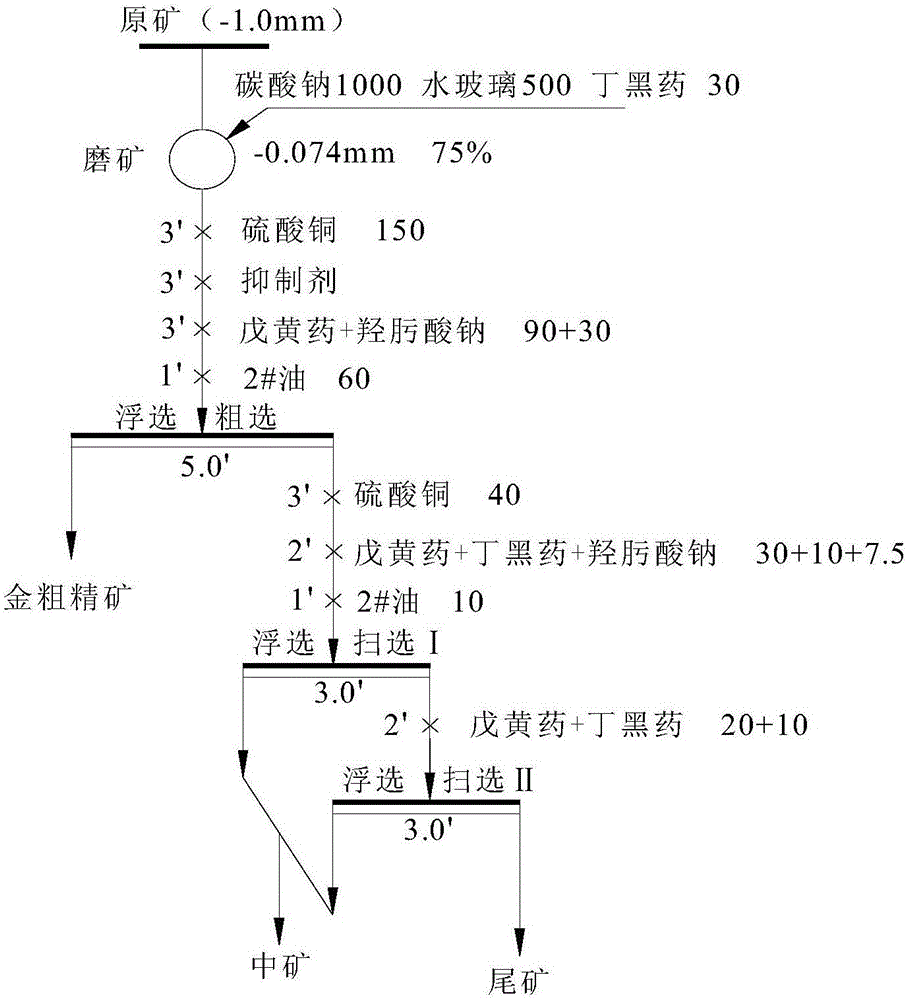

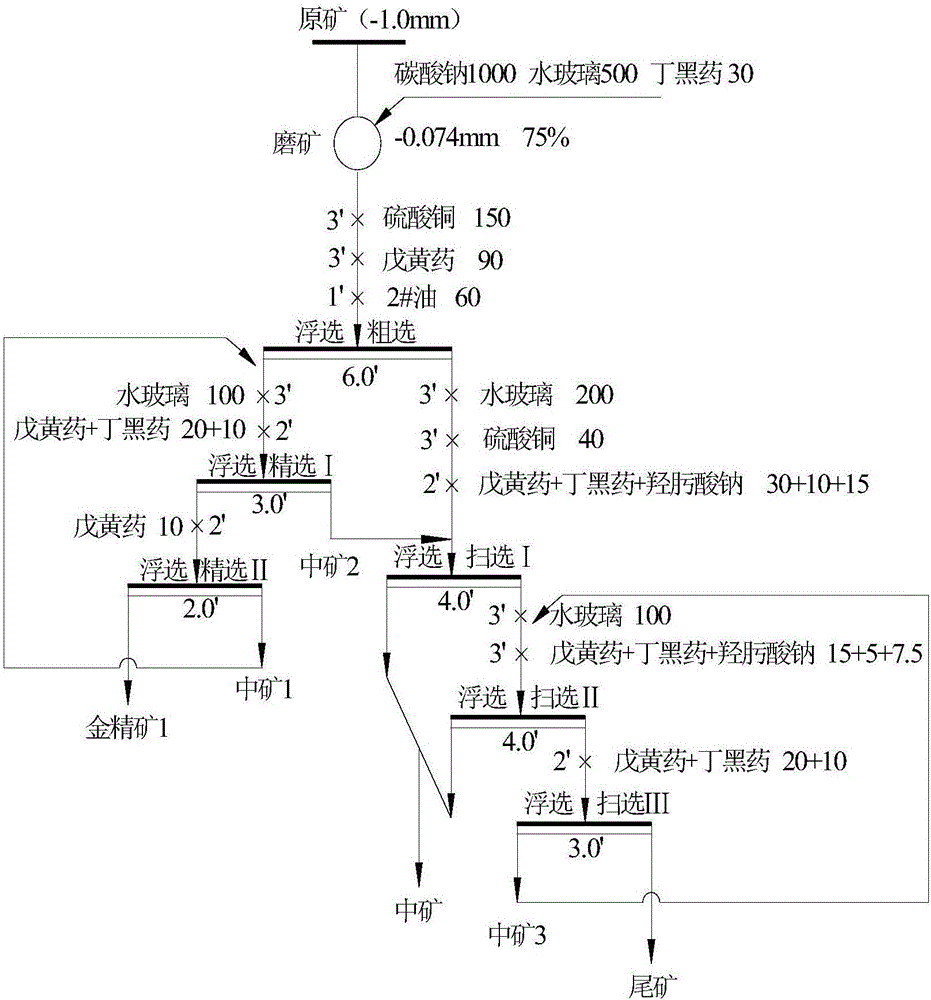

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0028] The raw ore sample was crushed and mixed, and then chemical samples were taken for analysis. The gold grade of the raw ore was 4.38g / t. The chemical composition of the ore is shown in Table 1.

[0029] Table 1 Analysis results of chemical composition of ore

[0030] Element

Au / g / t

Ag / g / t

S

As

Sb

Cu

Pb

Zn

content / %

4.38

0.20

0.97

0.42

0.49

0.0042

0.0070

0.014

Element

Fe 2 o 3

Al 2 o 3

SiO 2

K 2 o

Na 2 o

CaO

MgO

mn

content / %

4.58

15.25

57.21

2.71

0.36

6.63

2.13

0.056

Element

Ti

P

co

Cr

V

Rb

Sr

Ba

content / %

0.32

0.050

0.0013

0.0054

0.0066

0.016

0.038

0.030

[0031] It can be seen from Table 1 that the main recovery elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com