Flotation method for micro-fine particle complicated jamesonite

A brittle sulphur antimony lead ore and fine particle technology is applied in the flotation field of lead antimony ore, which can solve the problems of easy adsorption of chemicals, influence on the recovery of brittle sulphur antimony lead ore, low lead and antimony lead ore recovery rate, etc. Concentrate grade, flotation process is simple and practical, and the effect of improving concentrate grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

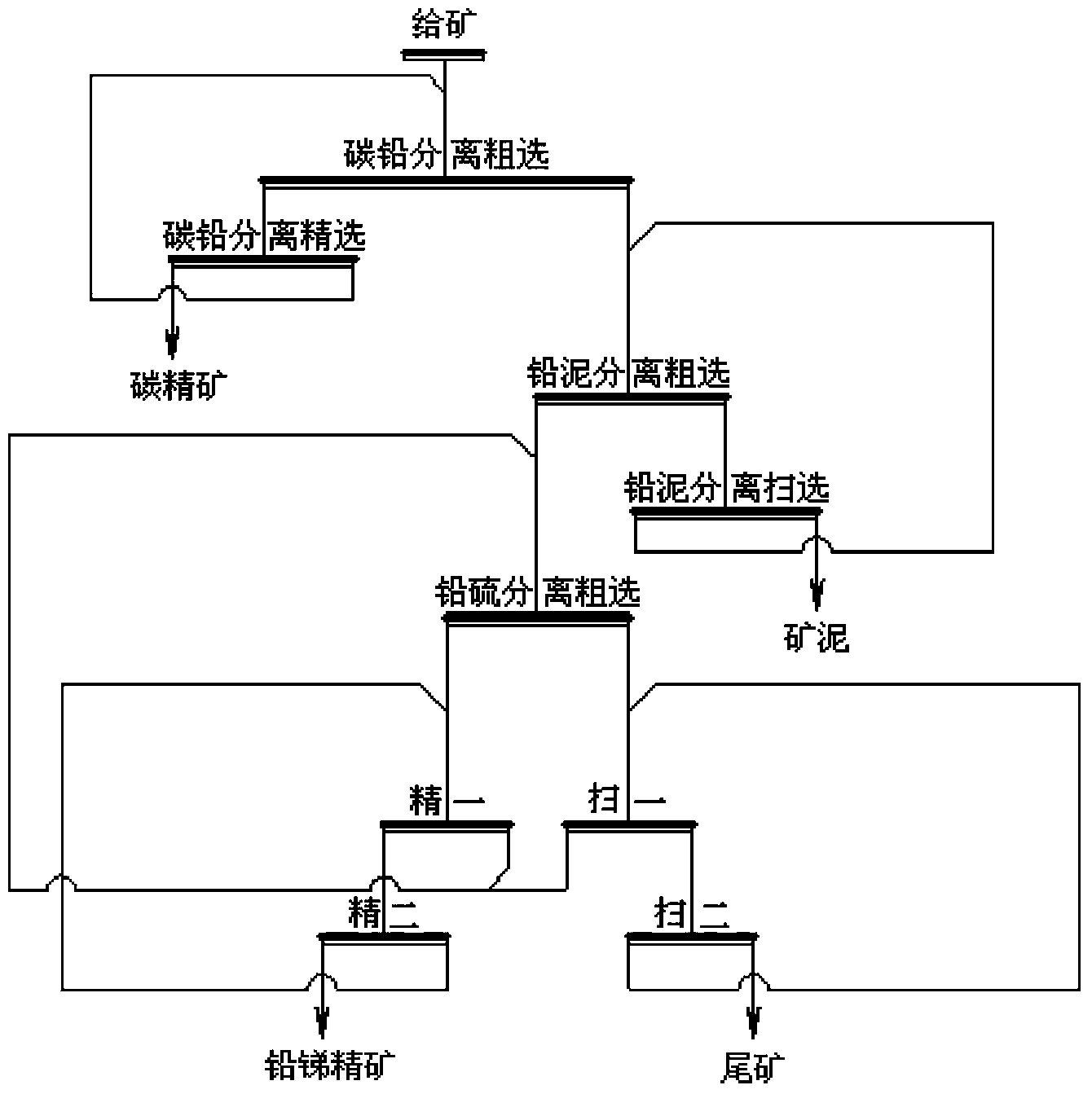

[0041] Such as figure 1As shown, a kind of flotation method of fine-grained and complex brittle pyrostibite includes carbon-lead separation, lead slime separation, and lead-sulfur separation; it is characterized in that: the recovery process of the method includes the following steps:

[0042] (1) Add 2# oil to the carbon-lead separation roughing tank to carry out carbon-lead separation and roughing for the raw ore liquid, and then the ore liquid flows out in two ways, and the ore liquid with high carbon concentrate content flows into the carbon-lead separation and concentration pool, and the other All the way, the ore liquid with high lead ore content flows into the lead slime separation rougher;

[0043] (2) Sodium carbonate and collectors are added to the lead slime separation roughing tank to conduct lead slime separation and roughing for the ore liquid with high lead ore content, and then the ore liquid flows out in two ways, and the ore liquid with high lead and sulfur c...

Embodiment 2

[0054] The difference between this embodiment and Example 1 is: the addition of 2# oil in the step (1) is 13g / t; the addition of sodium carbonate in the step (2) is 40g / t, and the amount of collector The addition amount is 70g / t; the addition amount of the pH regulator in the step (3) is 450g / t, the addition amount of the zinc inhibitor is 300g / t, and the addition amount of the collector is 50g / t; The amount of collector added to the separation and scavenging pool is 15g / t; in the step (4), the amount of collector added to the first-stage purification pool is 40g / t, and zinc is added to the first-stage scavenging pool The amount of inhibitor is 40g / t, and the amount of collector added in the primary sweep pool is 15g / t; the amount of zinc inhibitor added in the secondary sweep pool in the step (5) is 40g / t t, the amount of collector added in the secondary sweep pool is 15g / t.

Embodiment 3

[0056] The difference between this embodiment and Example 1 is: the addition of 2# oil in the step (1) is 18g / t; the addition of sodium carbonate in the step (2) is 60g / t, and the amount of collector The addition amount is 90g / t; the addition amount of the pH regulator in the step (3) is 550g / t, the addition amount of the zinc inhibitor is 400g / t, and the addition amount of the collector is 70g / t; The amount of collector added to the separation and scavenging pool is 25g / t; in the step (4), the amount of collector added to the first-stage purification pool is 60g / t, and zinc is added to the first-stage scavenging pool The amount of inhibitor is 60g / t, and the amount of collector added in the primary sweep pool is 25g / t; the amount of zinc inhibitor added in the secondary sweep pool in the step (5) is 60g / t t, the amount of collector added to the secondary sweep pool is 25g / t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com