Patents

Literature

199results about How to "Improve concentrate grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

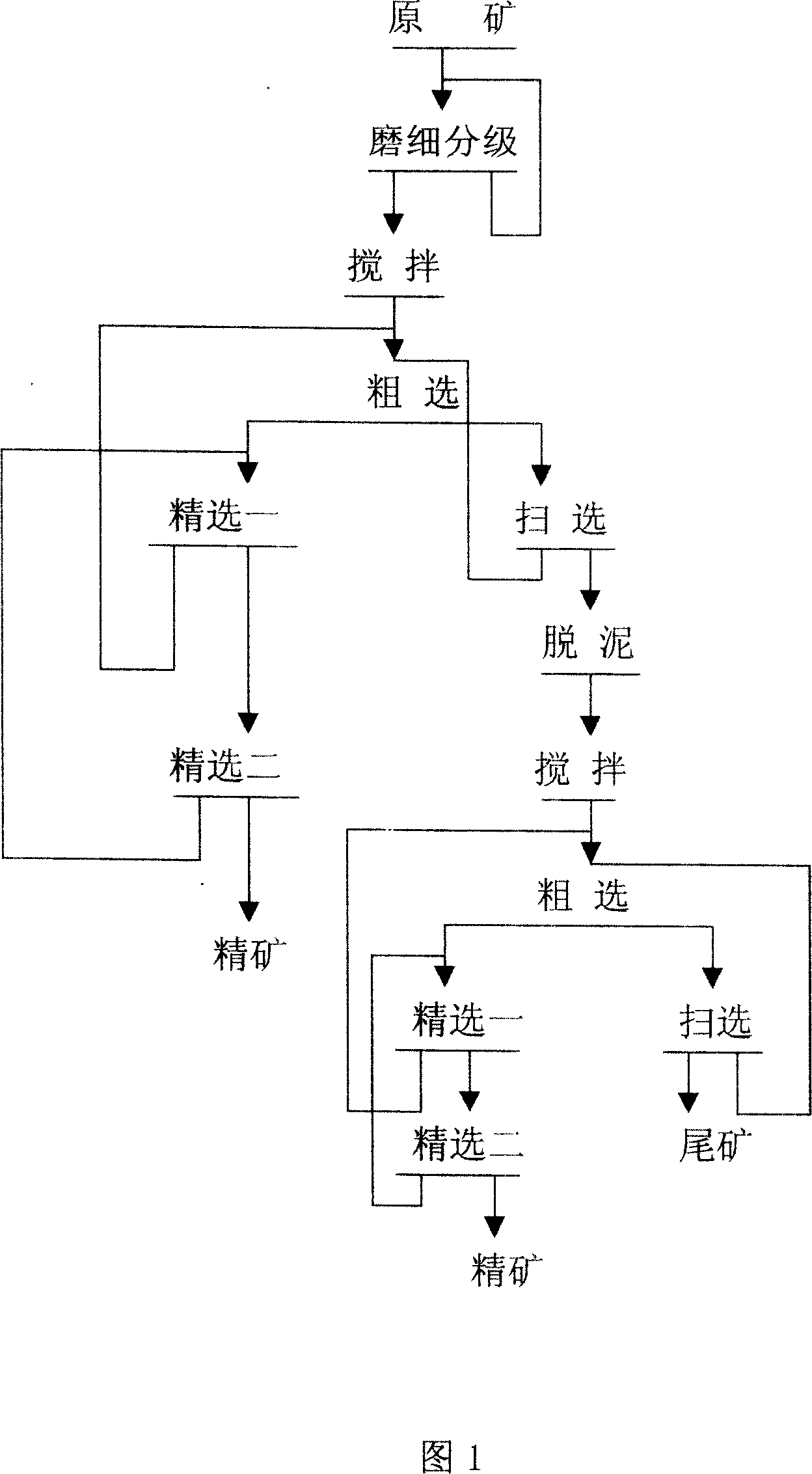

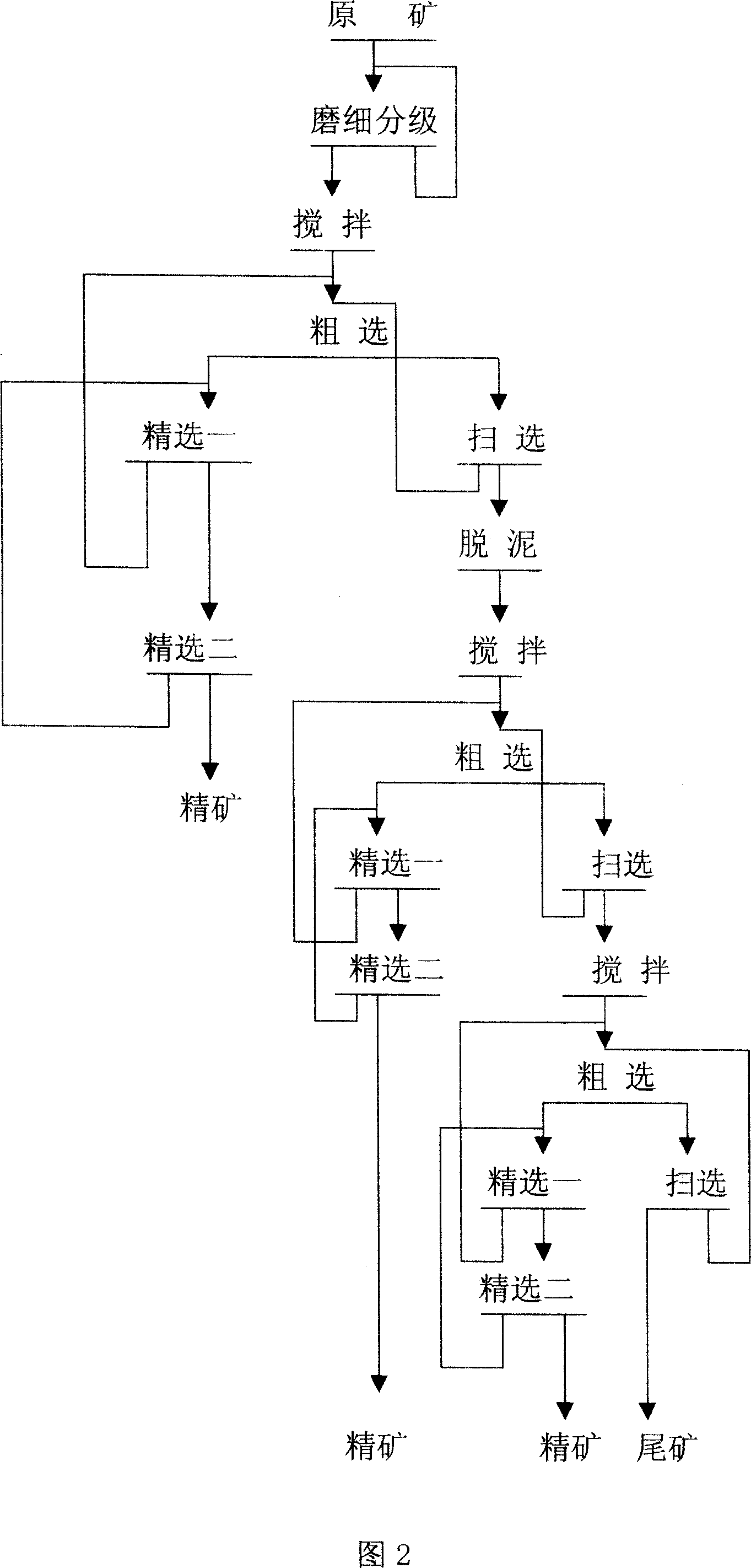

Beneficiation method of complex copper oxide ore

InactiveCN100998963AHigh recovery rateImprove concentrate gradeFlotationWet separationMaceralBeneficiation

A method for dressing the complex copper oxide ore consisting of the copper oxide ore easy to dress and the copper oxide ore difficult to dress includes such steps as preparing multiple kinds of composite dressing chemical, floatation for the fine-particle copper oxide ore easy to dress, removing mud, forced floatation for the coarse-particle copper oxide ore difficult to dress, grinding the specially complex copper oxide ore, and forced floatation.

Owner:陈铁

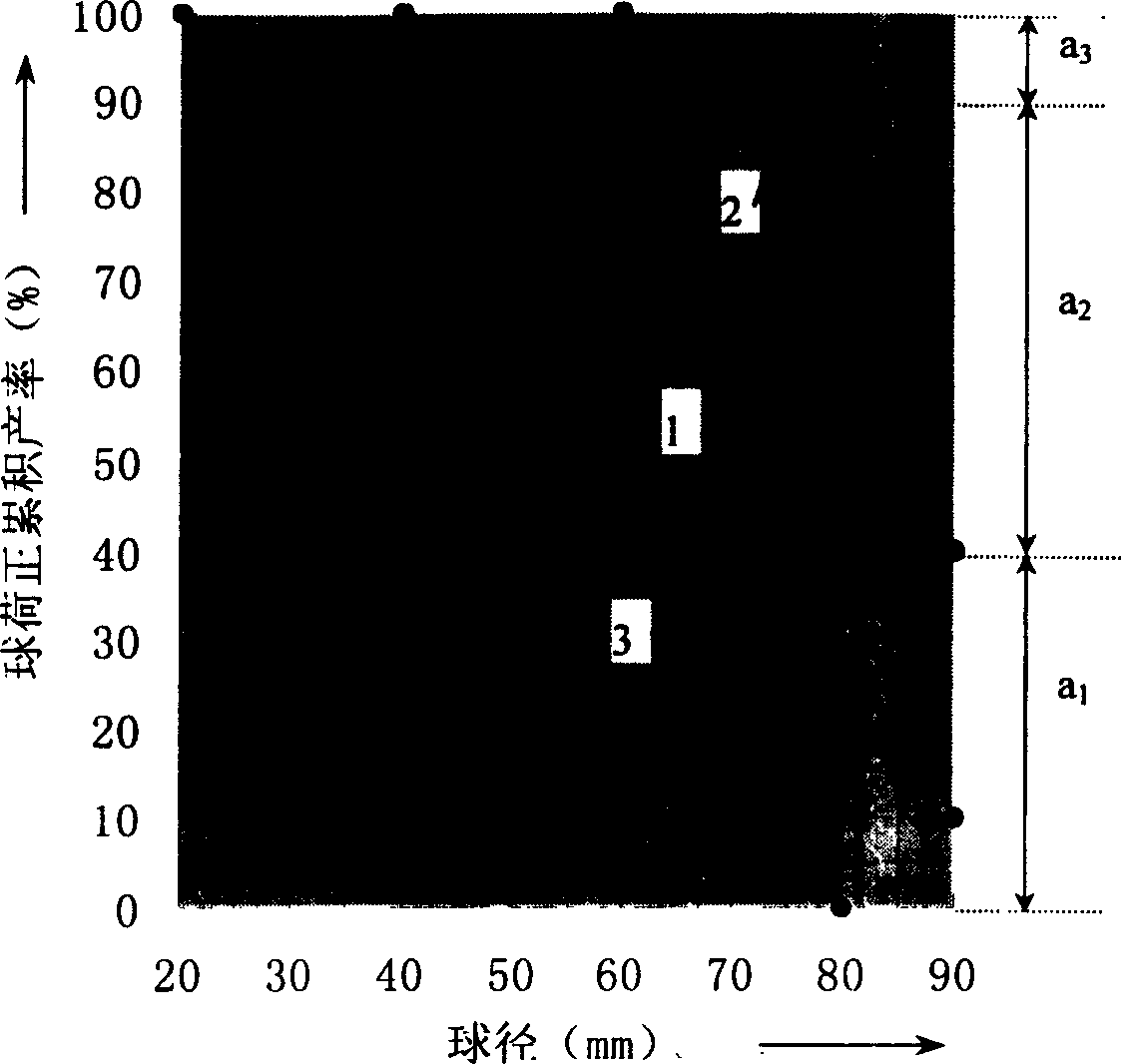

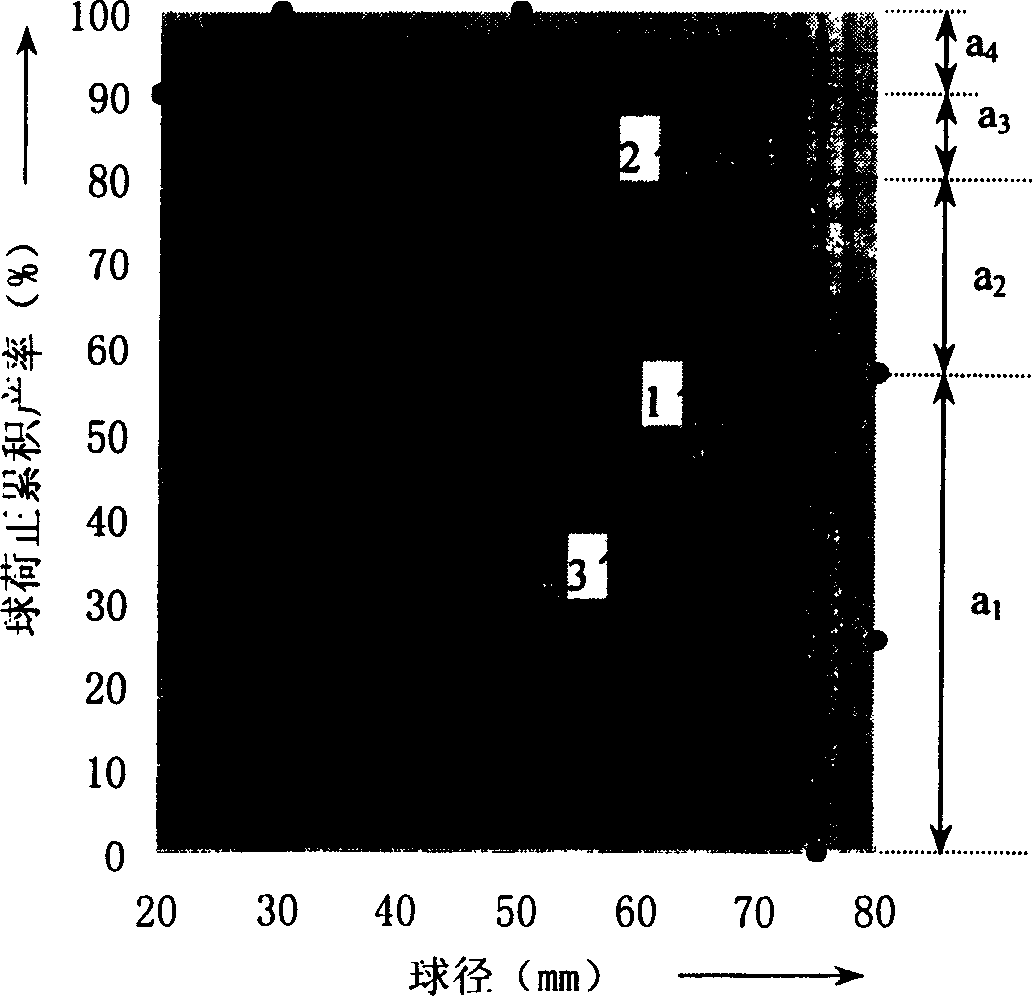

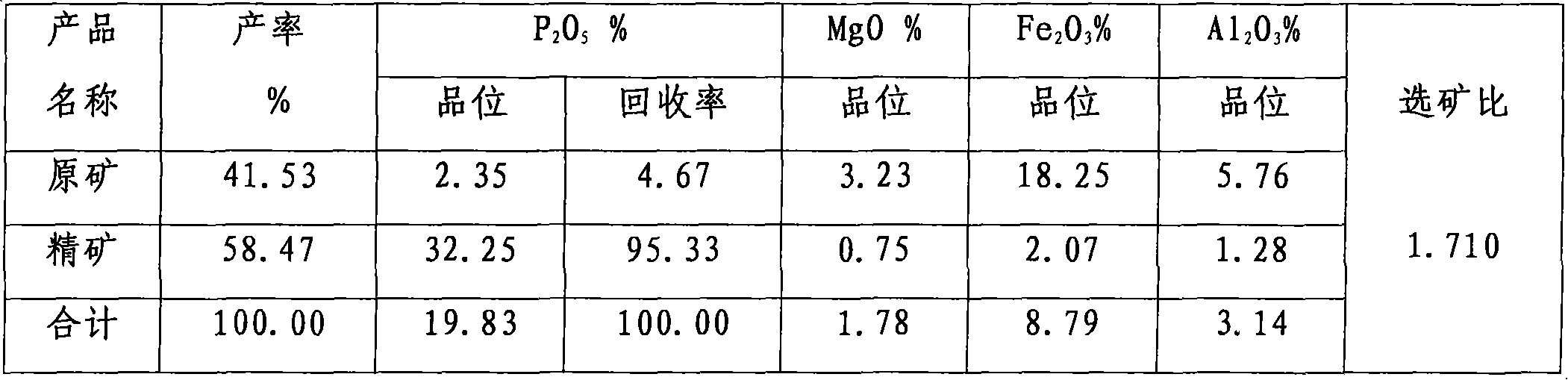

Ball grinder accurate ball loading method

The invention is a method for ball mill to recuperate balls precisely, which belongs to ore pulverizing, grinding technology field. The method includes: measures the mechanical parameter of ore; sifts and analyzes the mill ore and back sands, calculates the ore particle components and groups them; calculates the particle radius value according to ball radius haft theory formula; determines the ball ratio of the mill according to the ore particle and the needed ball radius; paints the ball particle accumulating curve, thus acquires the radius and recuperating ratio precisely. The proportion is reasonable, the method is simple, the productivity is upgraded greatly, and the quality is improved.

Owner:KUNMING UNIV OF SCI & TECH +2

Mineral separation process of magnetic iron ore

ActiveCN101480632AReduce energy consumptionFine Concentrate SizeSievingScreeningMagnetiteMaterials science

The invention discloses a beneficiation method for a pure magnetic iron ore. A crude ore is sequentially treated according to the steps such as first crushing, first-stage dry-type magnetic dressing, medium crushing, second-stage dry-type magnetic dressing, fine crushing and third-stage dry-type magnetic dressing, fine ore is obtained after a great amount of gangues are thrown by the third-stage dry-type magnetic dressing and sent to a grinding head sieve to be griddled and separated, granules griddled by the grinding head sieve are treated in a first-section magnetic dressing process, rough ore griddled by the grinding head sieve is treated in a first-section ball grinding and then enters the first-section magnetic dressing process; ore aggregates obtained from the first-section magnetic dressing process are treated in a second-section ball grinding after discharging gangue sands till the granularity of ore powder is -200meshes being more than or equal to 60 percent, ore powder generated from the second-section ball grinder are treated in second-section magnetic dressing, ore aggregates generated from the second-section magnetic dressing are treated in a high-frequency sieve after discharging gangue sands, products positioned on the high-frequency sieve are filtered to obtain ore concentrate, and products positioned below the high-frequency sieve are treated with desliming and then treated with floatation. The invention adopts two sections of grinding ore open-way processes and distinguishes the ore aggregates during the ore dressing process, thereby greatly reducing the energy consumption of a system, lowering the production cost and enhancing the utility ratio of equipment.

Owner:安徽大昌矿业集团有限公司

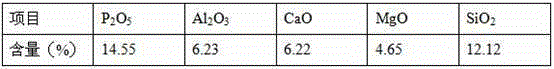

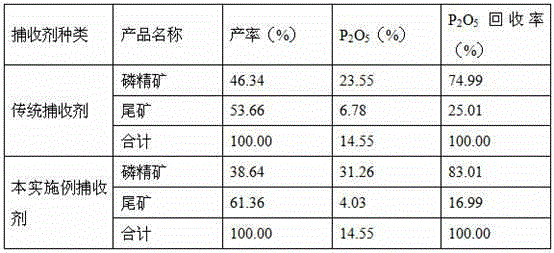

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

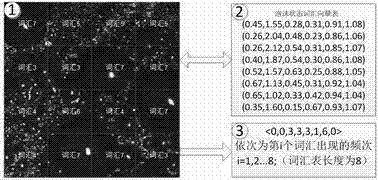

Classification method based on mineral flotation foam image

ActiveCN102855492AHigh recovery rateReduce dosageCharacter and pattern recognitionText categorizationClassification methods

The invention discloses a classification method based on a mineral flotation foam image. A real-time acquired foam image is classified in different known working conditions. The classification method comprises the following steps of: introducing a vocabulary in text classification into a flotation foam image, blocking the foam image acquired by an industrial camera and extracting the characteristic parameters, clustering the color and texture characteristic parameters of the extracted foam image by employing a K-mean clustering method, obtaining a plurality of clustering centers, and constructing a foam state vocabulary; describing the real-time foam image through a word bag method by utilizing the obtained foam state vocabulary, and forming a vector representation of the foam image; and finally, classifying the foam image through the similarity between measuring vectors by employing a vector space model. Because different types correspond to different working conditions, the flotation working condition recognition can be performed according to the classification result of the foam image; and therefore, the operation guide is given, the production is optimized, and the production efficiency is improved.

Owner:CENT SOUTH UNIV

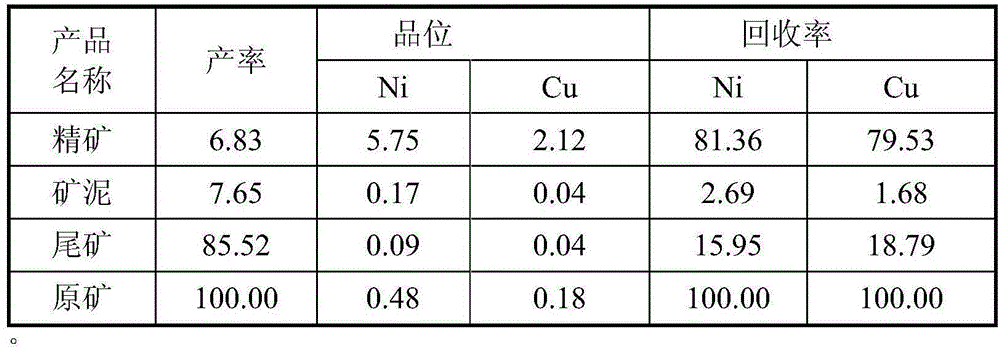

Mineral processing method for talc-containing copper-nickel sulphide

The invention relates to a mineral processing method for talc-containing copper-nickel sulphide. The method comprises the following steps: grinding raw ore; adding a regulator into ore pulp obtained through grinding, and after stirring for regulating the ore pulp, adding a foaming agent so as to remove partial easy-floating slime through floating; after adding a copper-nickel sulphide collecting agent xanthate into ore pulp subjected to desliming for regulating the ore pulp, adding a talc inhibitor hydroxyethyl cellulose and salinized water glass for inhibiting easy-floating talc, so as to realize separation of talc and sulphide copper-nickel minerals. The inhibitor hydroxyethyl cellulose and salinized water glass have a relatively high inhibiting effect on gangue, and the collecting agent added in advance selectively adsorbs on the surface of sulfide minerals and nickel / copper minerals, so that the inhibition of the inhibitor on sulfide minerals is reduced, and the concentrate recovery rate is increased greatly while gangue minerals are effectively inhibited. The used flotation reagents are low-toxic or non-toxic and have the characteristic of less dosage and excellent effects; and the mineral processing method is an efficient mineral processing method for talc-containing copper-nickel sulphide.

Owner:JIANGXI UNIV OF SCI & TECH

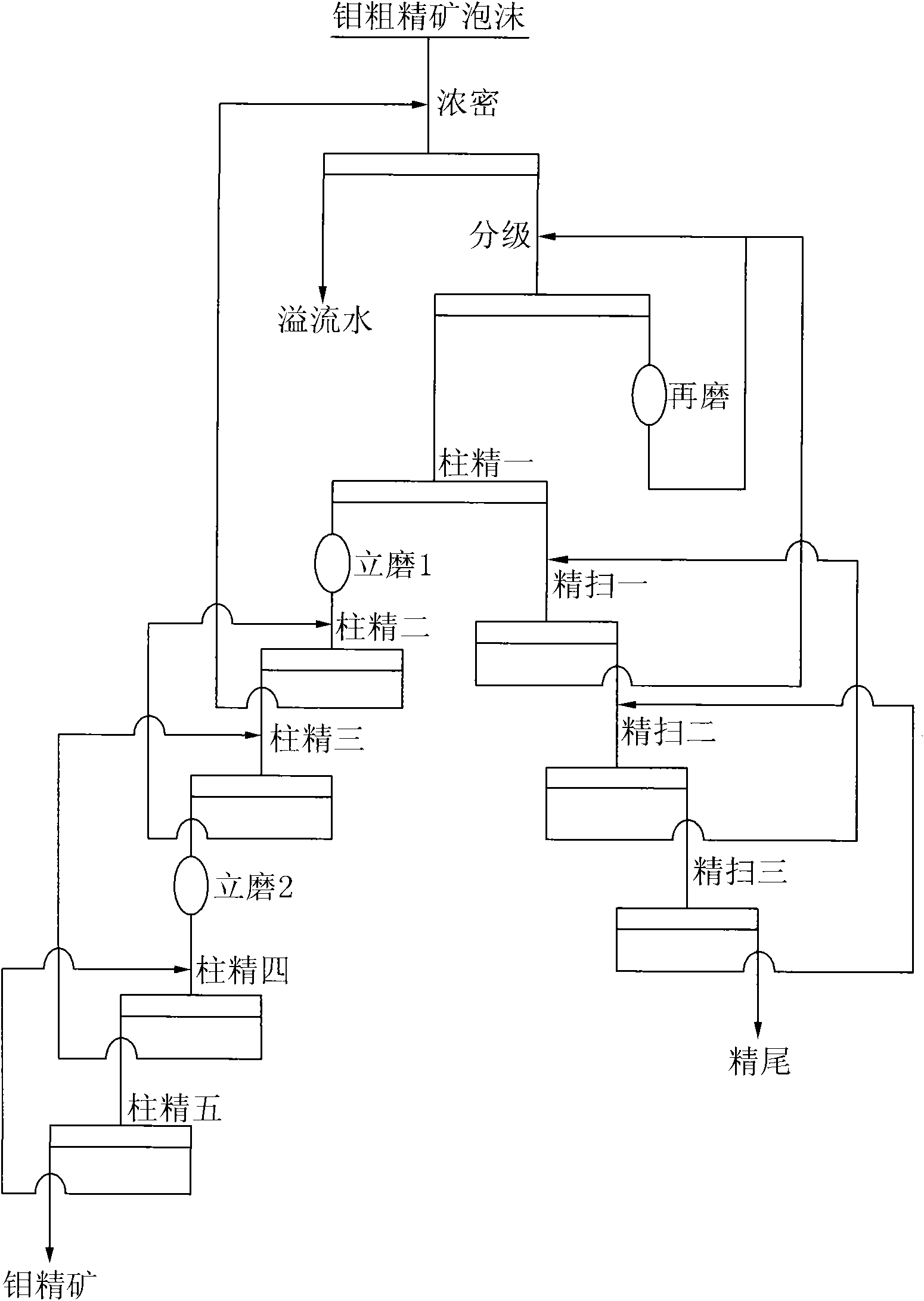

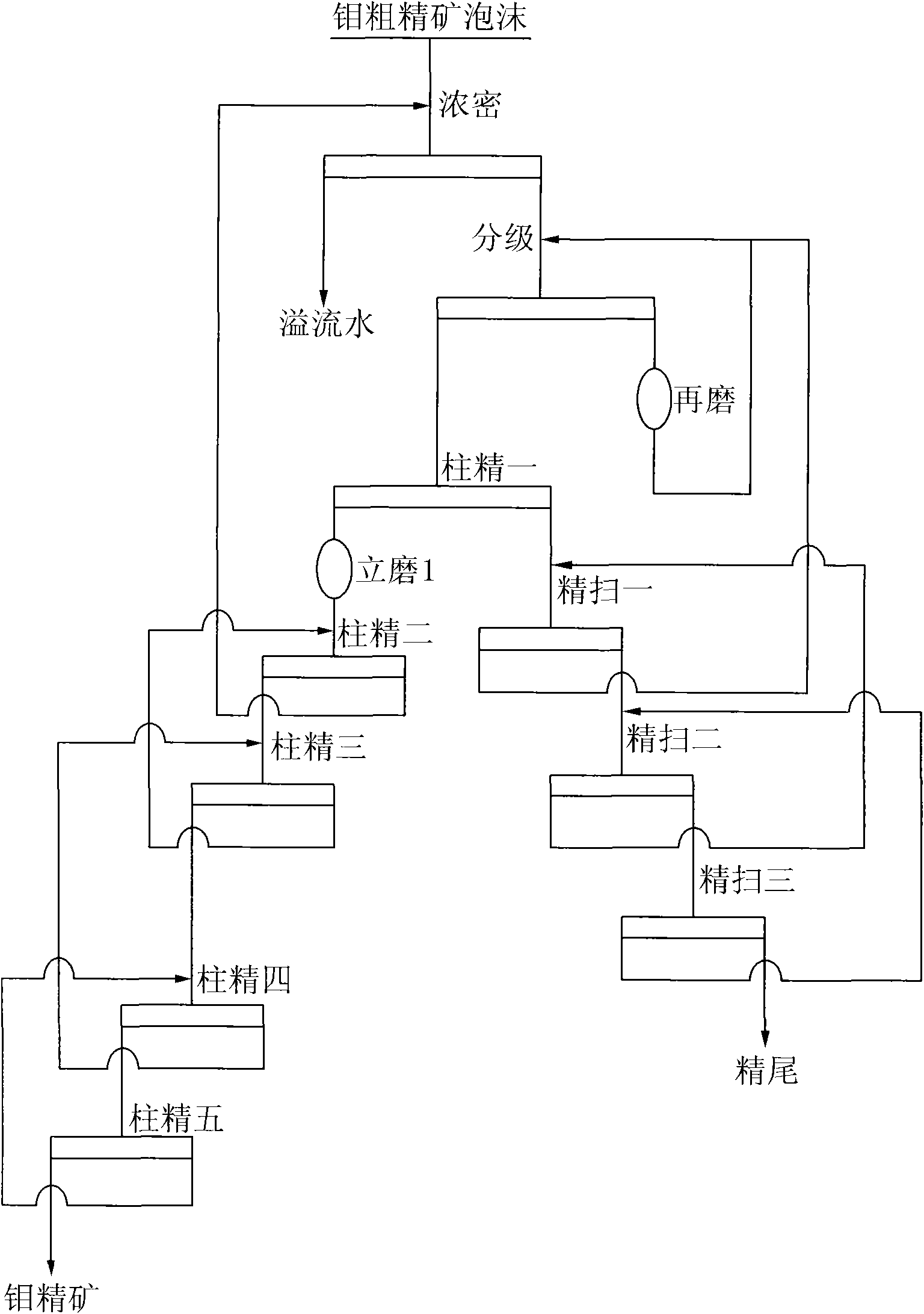

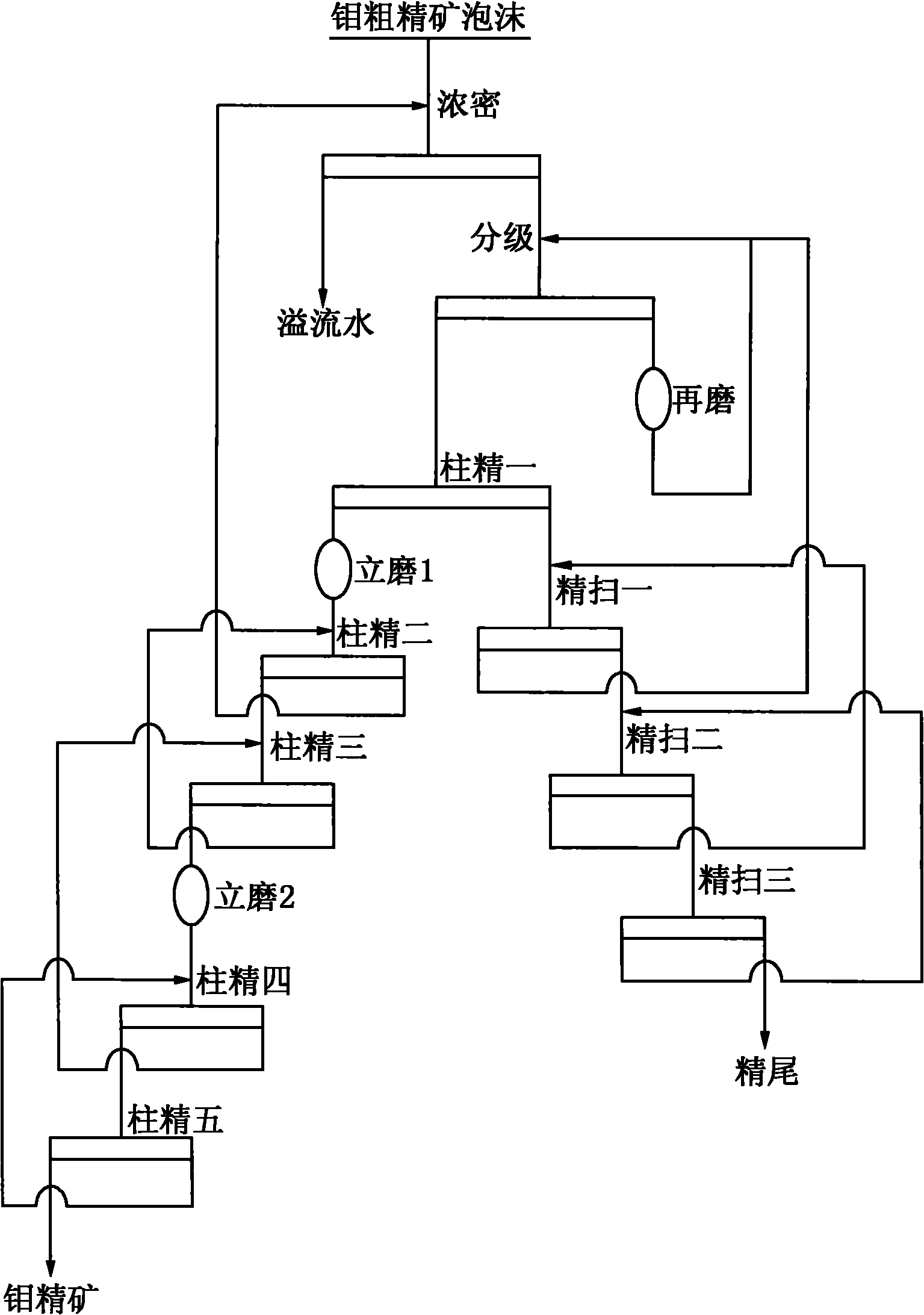

Production technology of high-grade molybdenum concentrate

ActiveCN101773871AReduce pollutionIncrease feed concentrationFlotationWet separationBall millReagent

The invention discloses a production technology of high-grade molybdenum concentrate, which comprises the following steps: rough molybdenum concentrate is obtained by roughing crude molybdenum ore, the rough molybdenum concentrate is concentrated and removed reagent through a thickener, underflow enters a hydraulic swirler to be graded previously, overflow after the grading enters a primary flotation column to be selected, the underflow after the grading enters a horizontal ball grinding mill to be reground, and after the regrinding, the ore discharge enters the hydraulic swirler to be regraded; selected concentrate from the primary flotation column is cleaned by a vertical ore mill to enter a secondary and a tertiary flotation columns to be selected, and the selected concentrate from thetertiary flotation column directly enters or enters a quartic or a quintic flotation columns to be selected after being cleaned by a second section of the vertical ore mill to obtain the high-grade molybdenum concentrate; the selected tailings from the primary flotation column is tertiary scavenged by a flotation machine, and the scavenged concentrate tailings from the tertiary scavenging enters the next procedure. The technology adopts the flotation columns and the flotation machine, so the flow is short, the agent system is simple, the adaptability of the crude ore is strong, and the molybdenum concentration ratio is high, the molybdenum concentrate has high grade, large yield and high recycling rate so as to provide excellent raw material to the following molybdenum chemical engineering and further processing.

Owner:JINDUICHENG MOLYBDENUM CO LTD

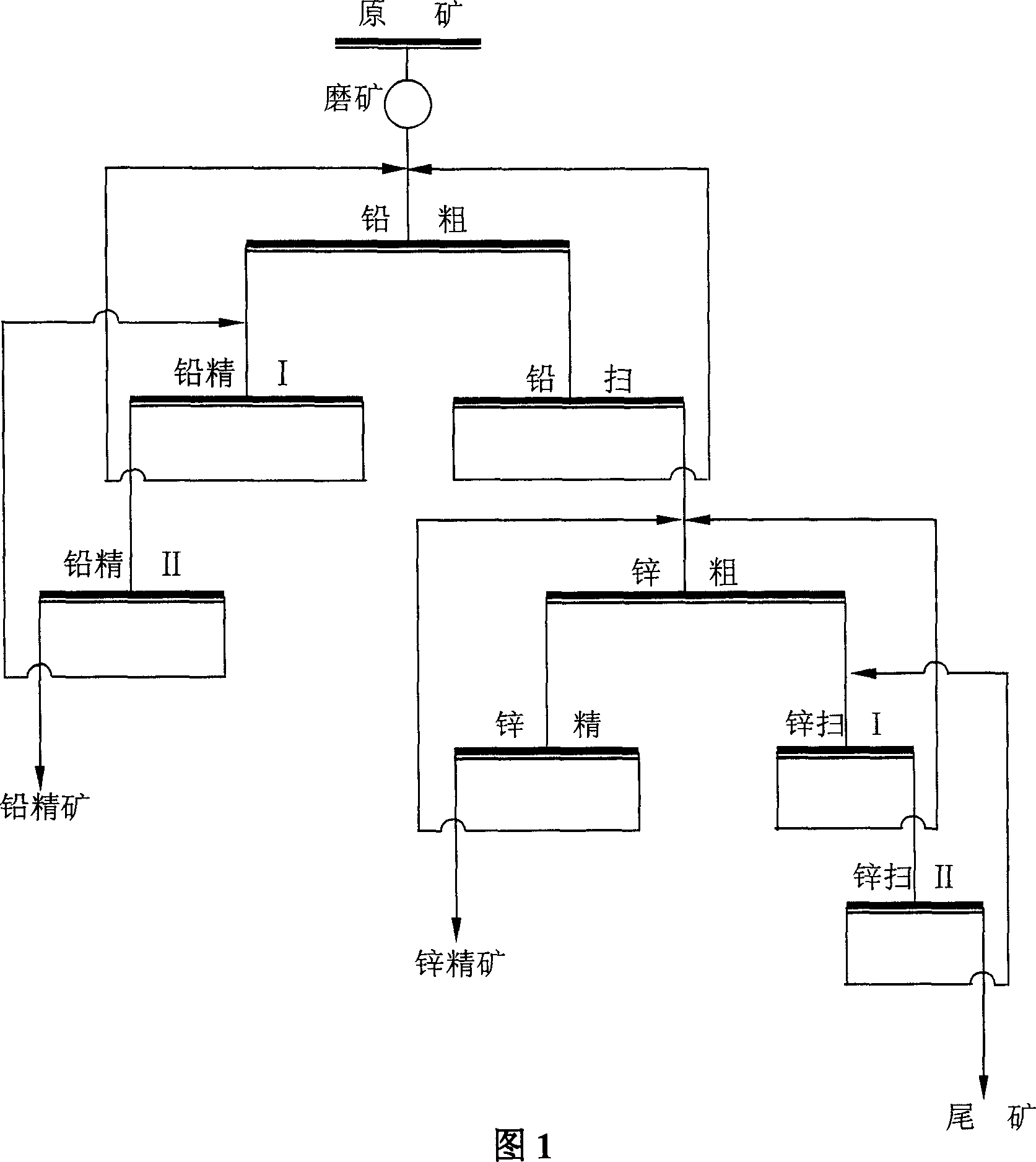

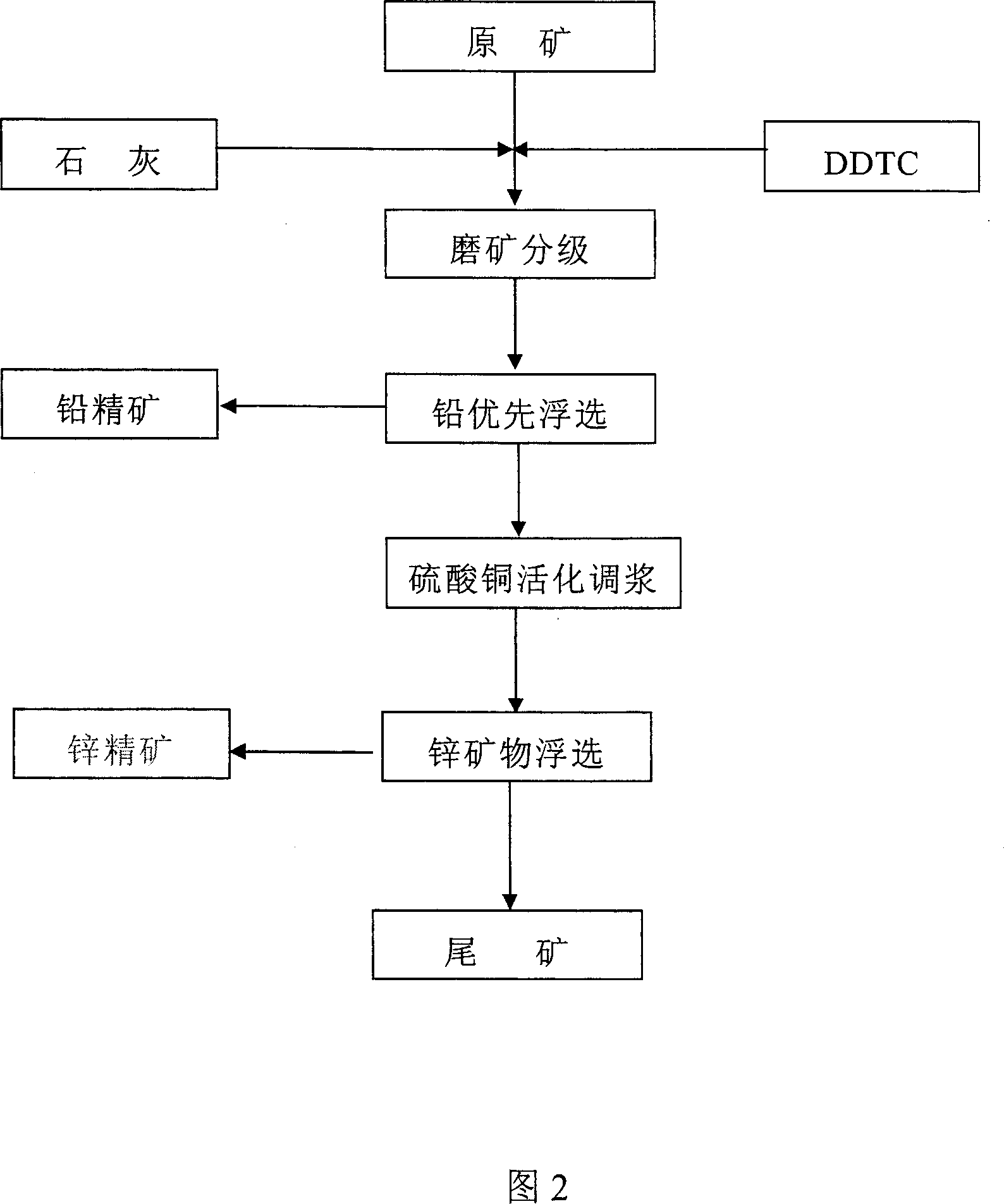

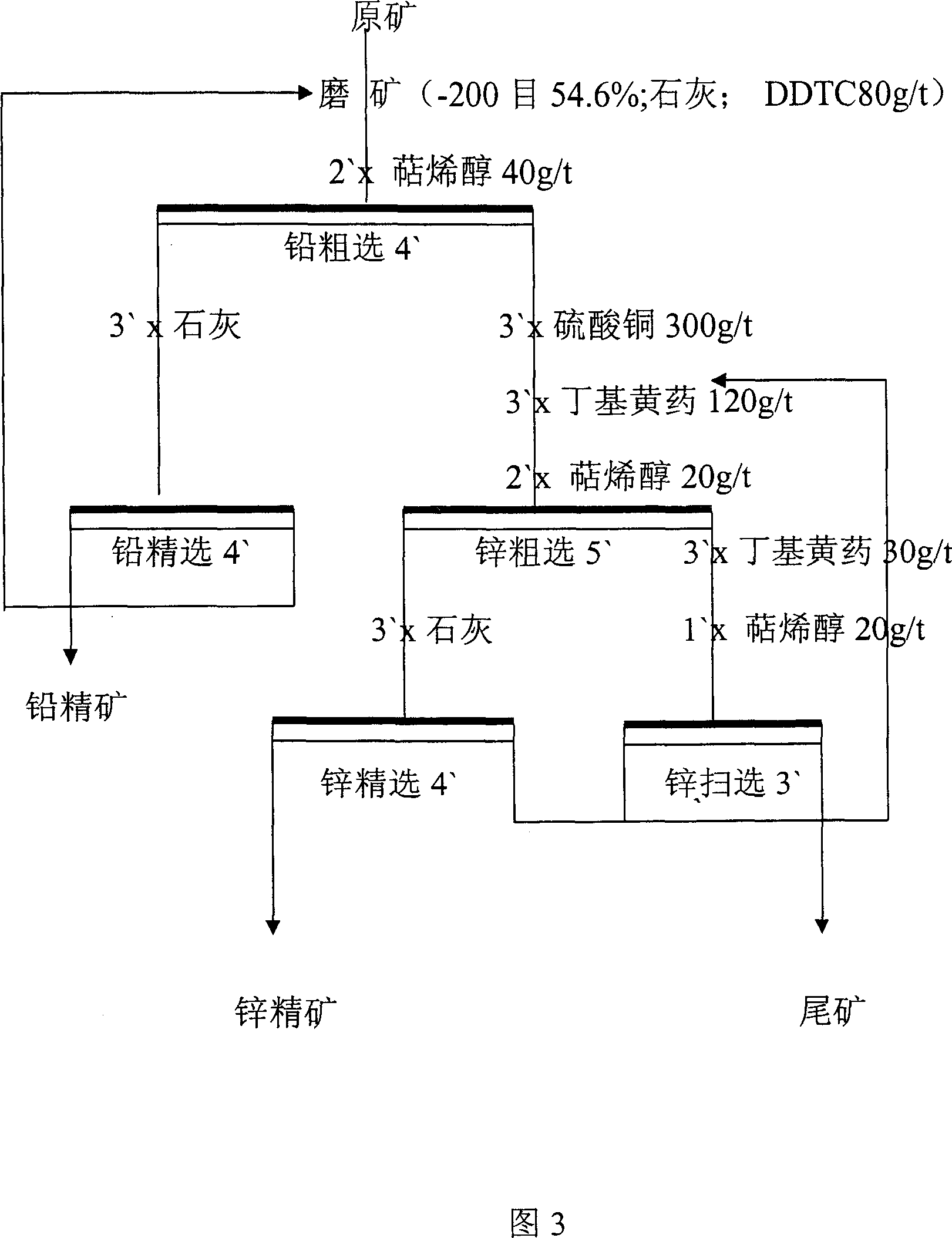

Process for increasing complicated sulfurized-lead-zinc ore dressing recovery rate

The present invention is green process of recovering complicated lead-zinc sulfide ore in high recovering rate. The technological process adopts lime to form high alkalinity and maintain the original potential of lead-zinc sulfide slurry during ore grinding floatation, sodium diethyl dithioamino formate as the selective lead mineral collecting agent, copper sulfate as the sphalerite activating agent and butyl xanthate as the zinc mineral collecting agent for optimized successive fast floatation. The present invention has raised recovering rate, low chemical consumption, simple technological process and low production cost.

Owner:青海西部矿业科技有限公司

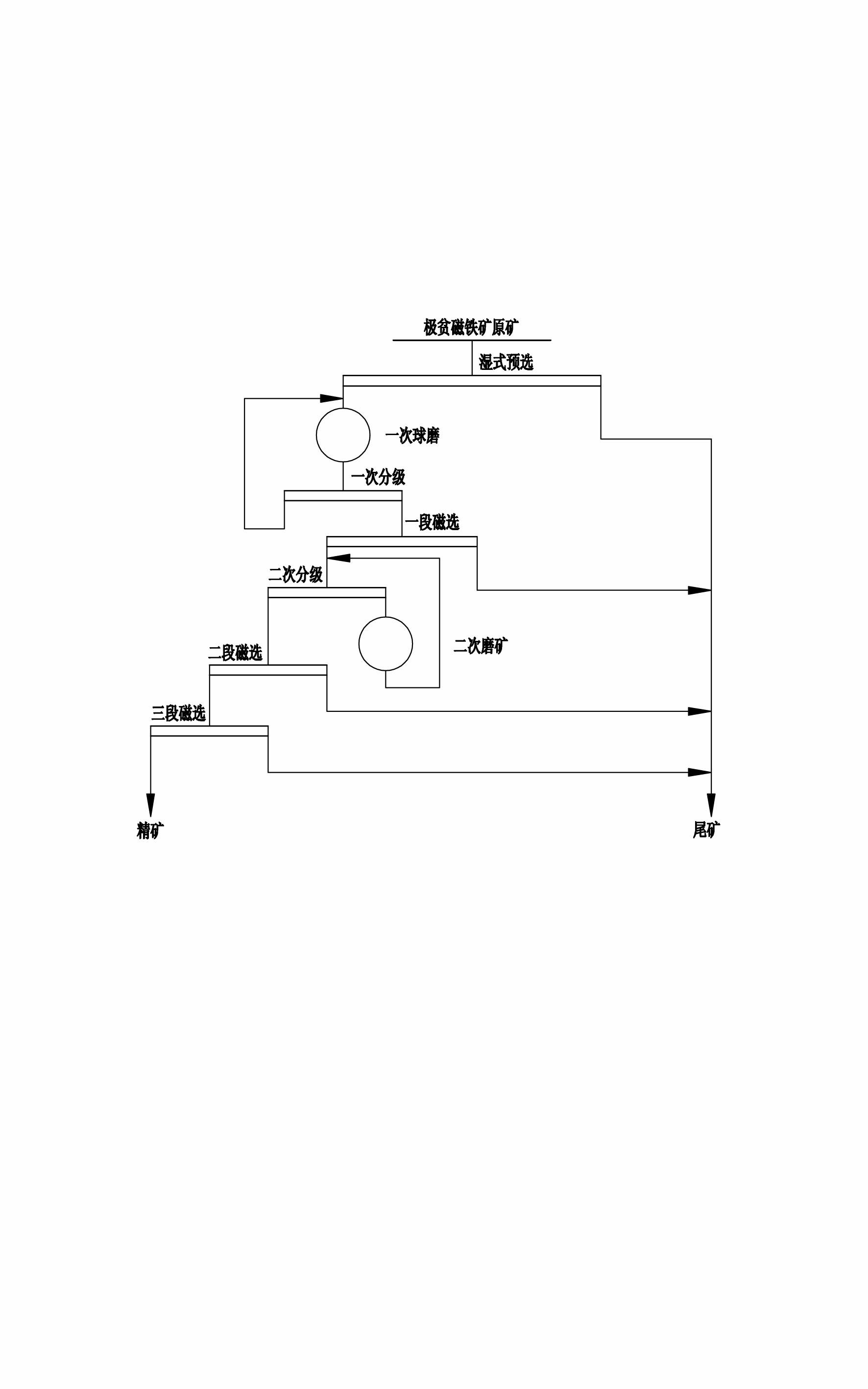

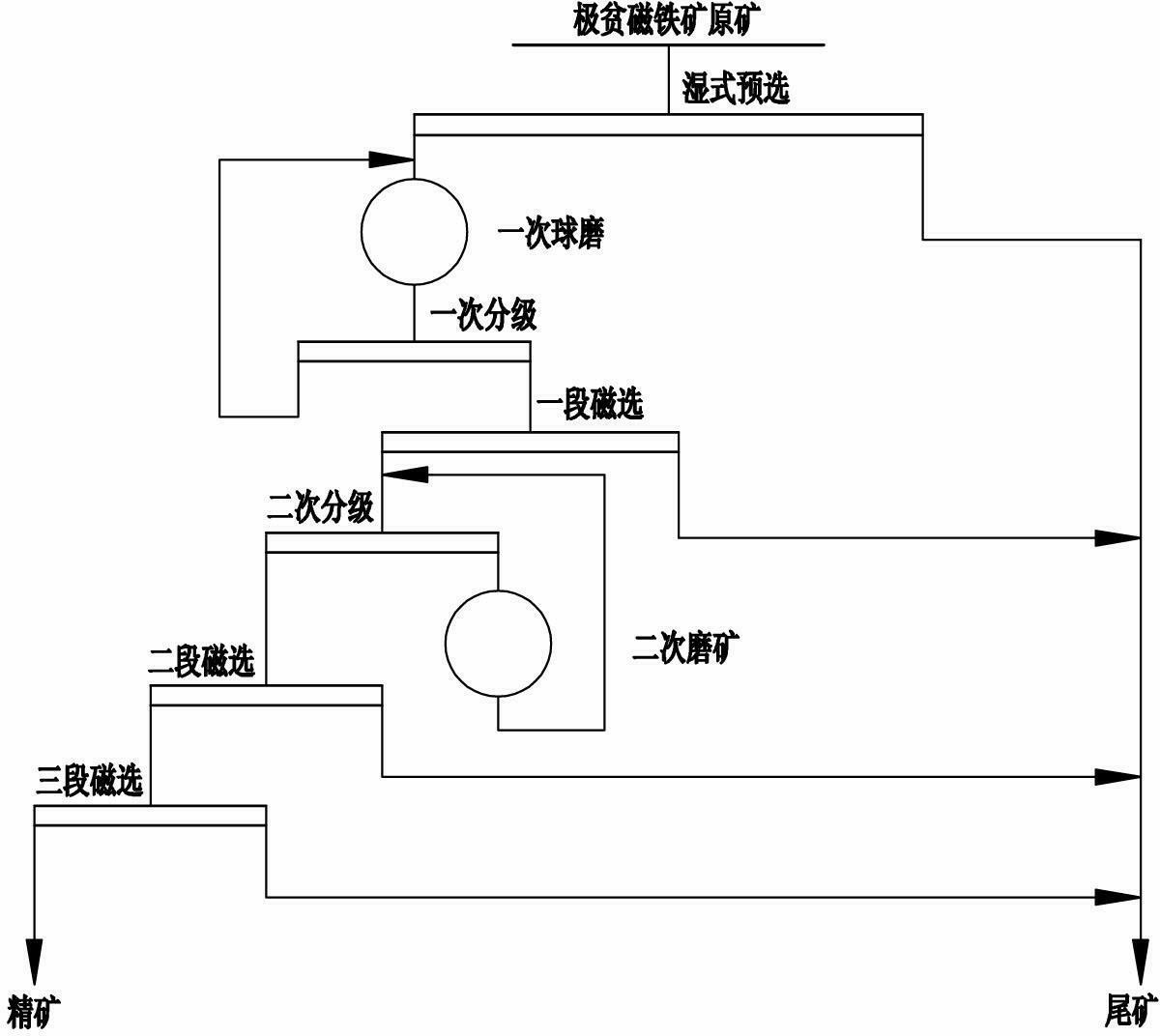

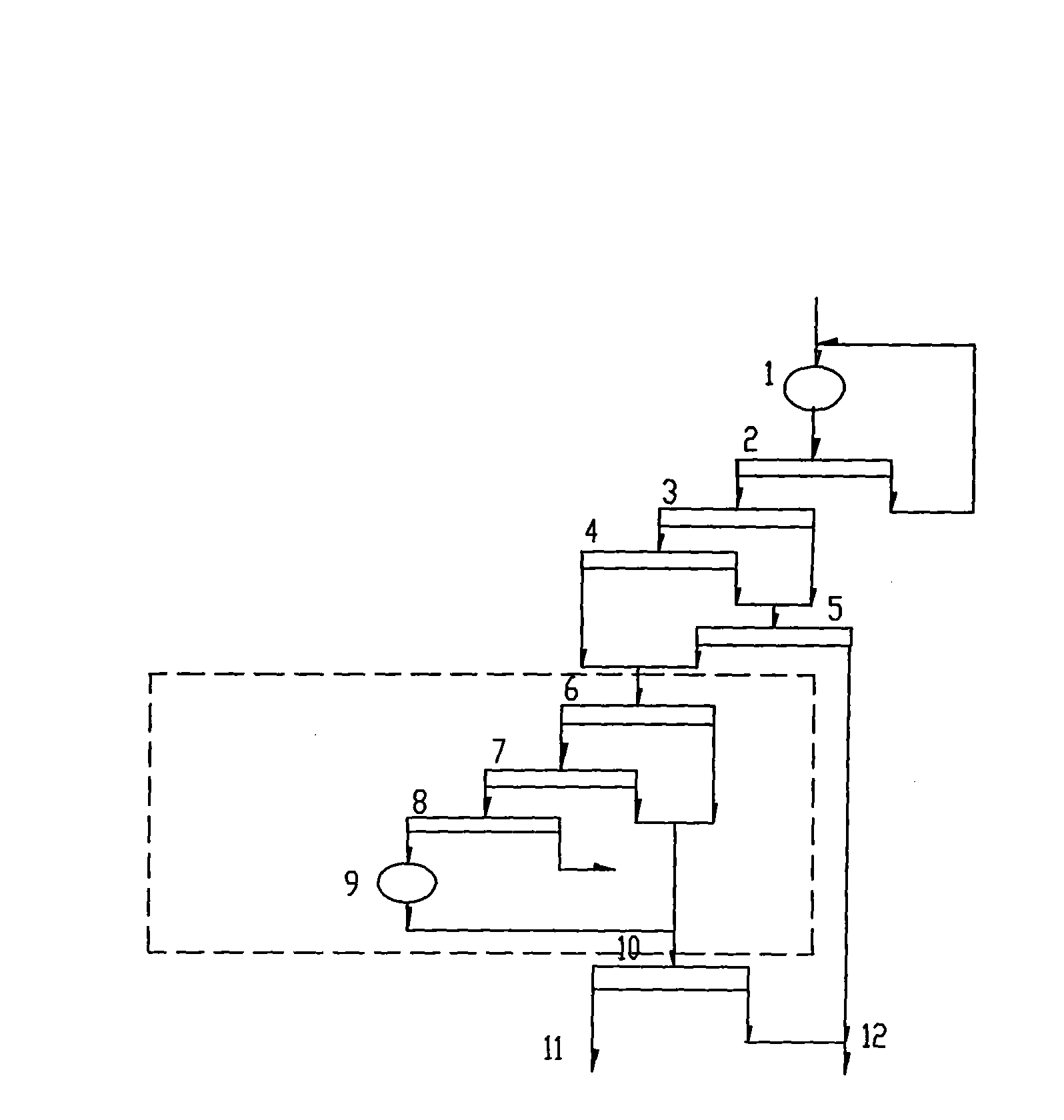

Extremely lean magnetite beneficiating process

InactiveCN102489387AReduce the cost of beneficiationEnergy savingWet separationOre concentrateBall mill

The invention relates to the technical field of ore beneficiation, and in particular relates to an extremely lean magnetite beneficiating process. The process is characterized by comprising the following steps of: 1) carrying out wet pre-beneficiation on raw ores with grain sizes being 0-5mm and concentration being 35-45%; 2) processing the concentrates obtained through wet pre-beneficiation with a primary closed-circuit milling system formed by primary ball milling and primary classifying and discarding the tailings obtained through wet pre-beneficiation; 3) carrying out first-stage magnetic separation on overflow obtained through primary classifying; 4) processing the concentrates obtained through first-stage magnetic separation with a secondary closed-circuit milling system formed by secondary ball milling and secondary classifying; 5) carrying out second-stage magnetic separation on overflow obtained through secondary classifying; 6) carrying out third-stage magnetic separation on concentrates obtained through second-stage magnetic separation; 7) taking the concentrates obtained through third-stage magnetic separation as the final concentrates with grades being 63-64%; and 8) discarding the final tailings formed by the tailings obtained through first-stage magnetic separation, second-stage magnetic separation and third-stage magnetic separation. The process has the following characteristics that: 30% of tailings are discarded by adopting the pre-beneficiation method, thus improving the beneficiation feed grade of the ores to 16-18%, reducing the quantity of the ores entering the ball mill by 30% and obviously lowering the ore beneficiation cost; and the energy is saved and the economic benefits are obvious.

Owner:鞍钢集团矿业设计研究院有限公司

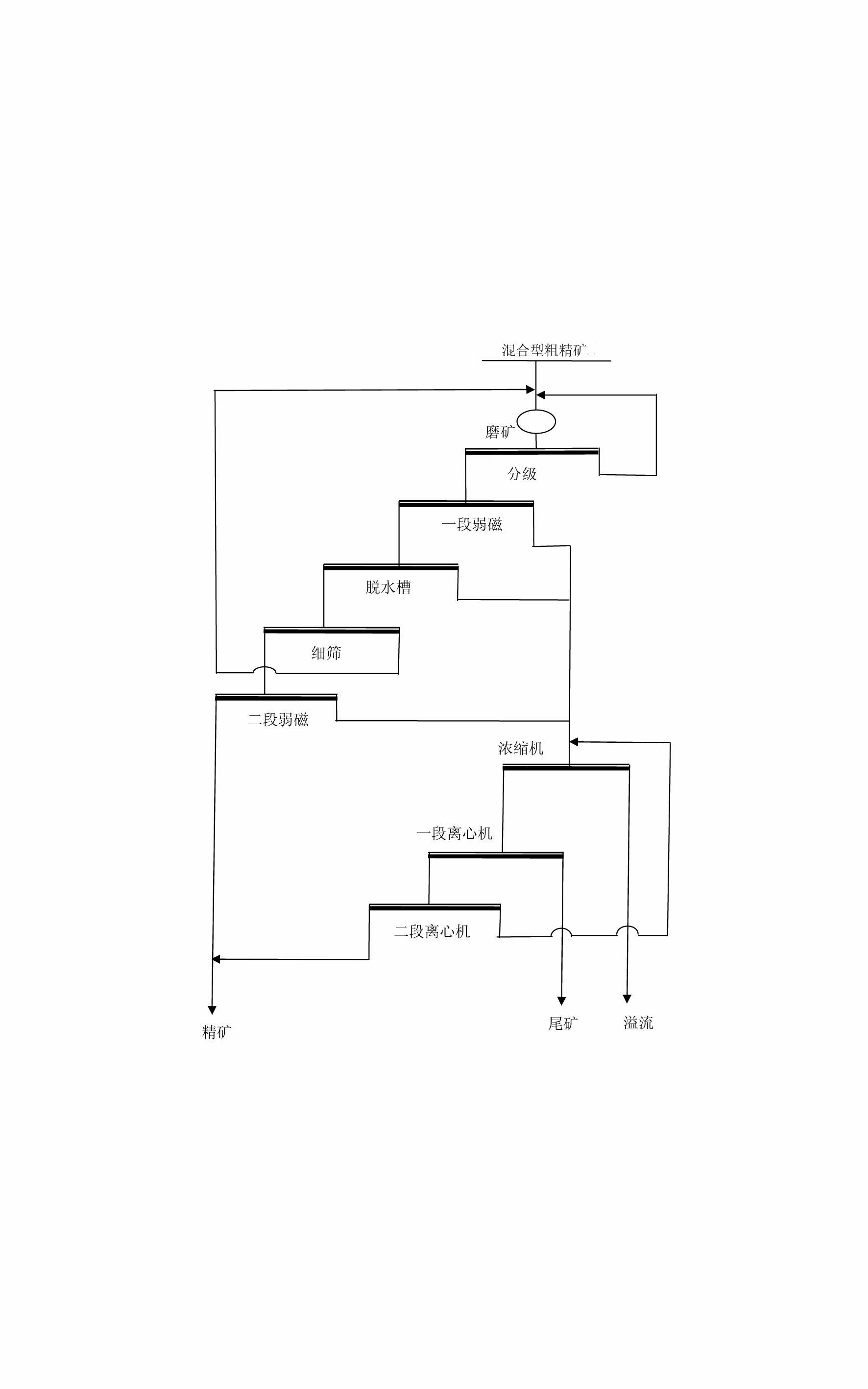

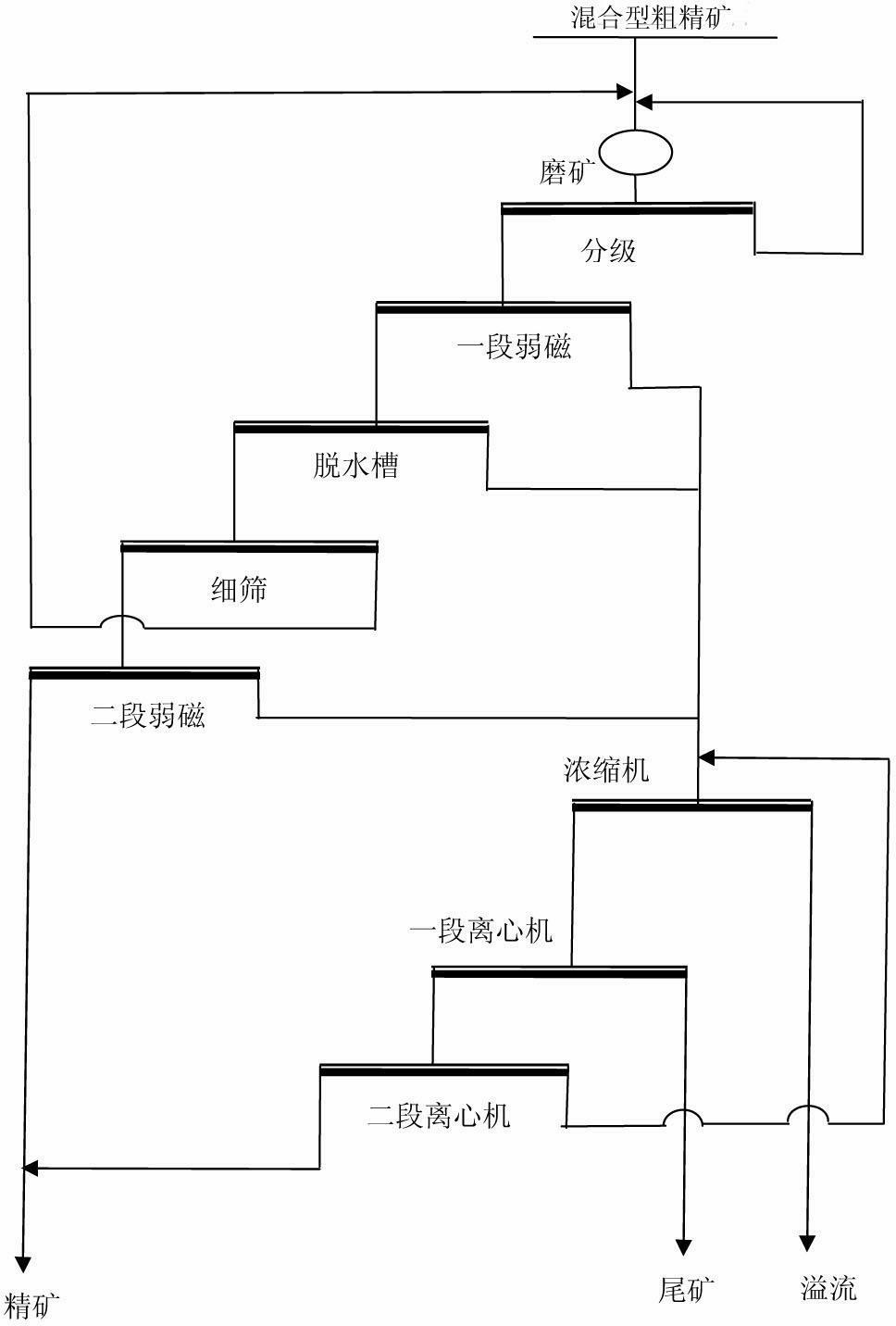

Magnetism-gravity combined separation technology for magnetic hematite mixed type rough concentrate

ActiveCN102430468AEmbodies the depth of selectionRealize the purpose of improving quality and removing impuritiesSievingScreeningHybrid typeSeparation technology

The invention relates to a magnetism-gravity combined separation technology for magnetic hematite mixed type rough concentration. The technology is characterized by comprising the following steps of: feeding the magnetic hematite mixed type rough concentration into a closed-circuit grinding system; feeding first-section weak magnetism through primary classification overflow; feeding the concentrate of the first-section weak magnetism into a dehydration tank; feeding the concentrate of the dehydration tank into a fine sieve; returning the coarse-grain product on the sieve to the grinding system; feeding the fine-grain product below the sieve to second-section weak magnetism; mixing the tailings of the second-section weak magnetism with the tailings of the first-section weak magnetism and the tailings of the dehydration tank to obtain weak-magnetic separation tailings; concentrating the weak-magnetic separation tailings by a concentrator, and feeding into a first-section centrifugal machine for roughing; feeding the concentrate of the first-section centrifugal machine into a second-section centrifugal machine for selection; discarding the tailings of the first-section centrifugal machine; mixing the concentrate of the second-section centrifugal machine with the second-section weak-magnetism concentrate to obtain the final concentrate; and returning the tailings of the second-section centrifugal machine to the concentrator. The technology provided by the invention is simple and efficient, has low separation cost, a good effect and high concentrate grade and metal recovery rate, and realizes efficient utilization of resources.

Owner:ANSTEEL GRP MINING CO LTD

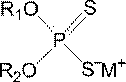

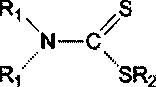

Flotation reagent for copper-nickel sulfide ores

The invention discloses a flotation reagent for copper-nickel sulfide ores. The flotation reagent comprises, by weight, 35-65 parts of alkyl-dithiocarbamate, 5-25 parts of second oil, 5-10 parts of terpilenol, 15-20 parts of hydrazide-group-dithio-formic ether and 5-15 parts of dialkyl-dithiophosphate. The flotation reagent is good in selection, strong in collecting capacity and good in bubble stability, especially has a stronger collecting effect on the copper-nickel sulfide ores, can achieve separation of valuable minerals from gangue minerals such as serpentine and olivine within the pH value of 7-10, and can effectively improve concentrate grade and the recovery rate.

Owner:LANZHOU UNIVERSITY

Process for processing hematite ore containing iron carbonate

InactiveCN101632957AImprove technical indicatorsEfficient recyclingFlotationMagnetic separationMonomerMaterials science

The invention relates to a process for processing hematite ore containing iron carbonate. The process comprises the following steps that: ore is subjected to ore grinding to achieve monomer separation; concentrated ore obtained through magnetic separation of a weak magnetic separator, a medium magnetic separator and a strong magnetic separator are converged; the converged concentrated ore is subjected to coarse separation and fine separation sequentially by a floatation medicament with strong selective collection capacity on the iron carbonate to obtain iron carbonate concentrated ore; the obtained iron carbonate concentrated ore enters a thermal decomposition process; the decomposed ore enters a water-addition stirring tank to prepare ore pulp with appropriate concentration; the ore pulp and tailings after being subjected to floatation by the iron carbonate are mixed together for reverse floatation of the hematite; and after the reverse flotation, final concentrated ore and final tailings are obtained. The thermal decomposition process utilizes a rotary kiln to carry out thermal decomposition on the iron carbonate concentrated ore. The weight percentage of the appropriate concentration of the ore pulp is between 42 and 48 percent. The process can effectively reclaim the iron carbonate lost in the tailings, improves the grade of the final concentrated ore, provides referential significance for domestic similar ore separation and has remarkable economic and social benefits.

Owner:ANSTEEL GRP MINING CO LTD

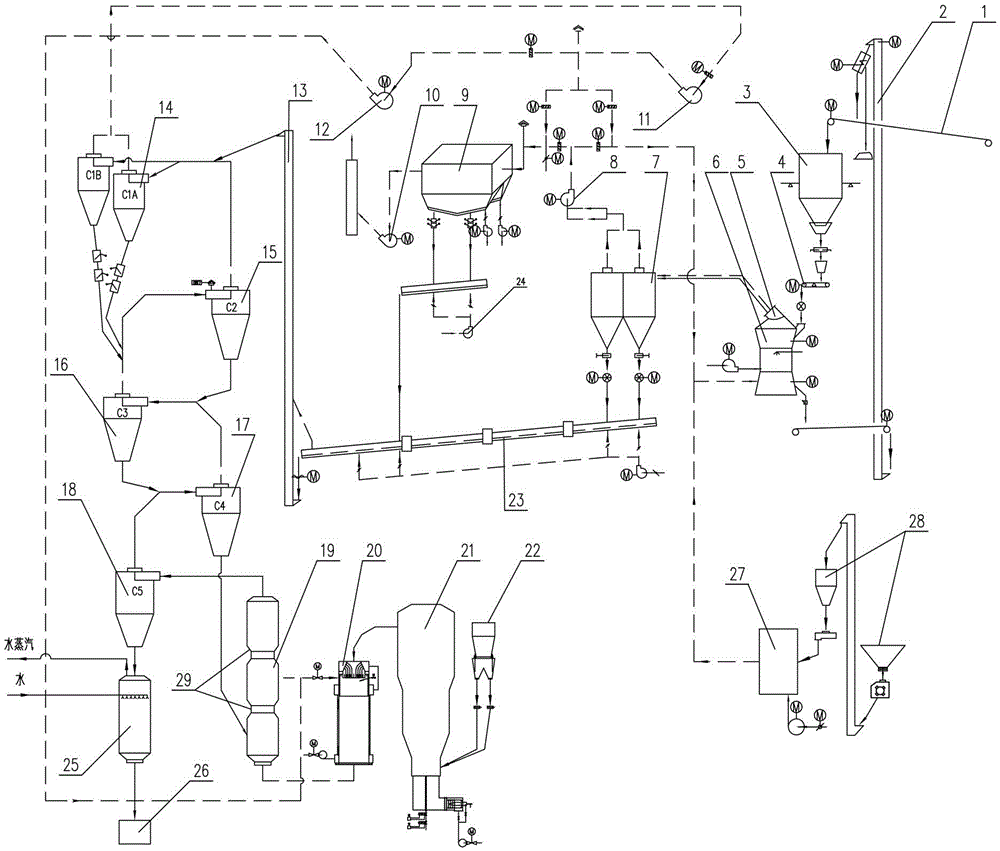

Preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore

The invention relates to the production techniques of iron ore concentrate of refractory ore, in particular to a preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore. The method comprises the following steps that firstly, the crushed iron ore is ground into fine ore; then the fine ore is subjected to low-temperature roasting, and during the low-temperature roasting, the fine ore is made to be in a roasting system to be preheated and roasted; the roasted ore enters a cooling system to be cooled; and then the cooled roasted ore is subjected to size mixing and sent to a magnetic separation system to be separated, and high-grade iron ore concentrate is obtained through separation. According to the method, the process is simple, the temperature and air flow are distributed uniformly, control is easy, the automation degree is high, the number of operation components of equipment is small, refractory siderite and limonite can be treated, the magnetizing roast efficiency of the refractory iron ore is high, heat is substantially recycled during roasting, the roasted ore is stable in quality and high in magnetic separation efficiency, and the technical indexes that the grade of the iron ore concentrate is larger than 60%, and the iron recycling rate is larger than 85% can be achieved.

Owner:湖北华方装备有限公司

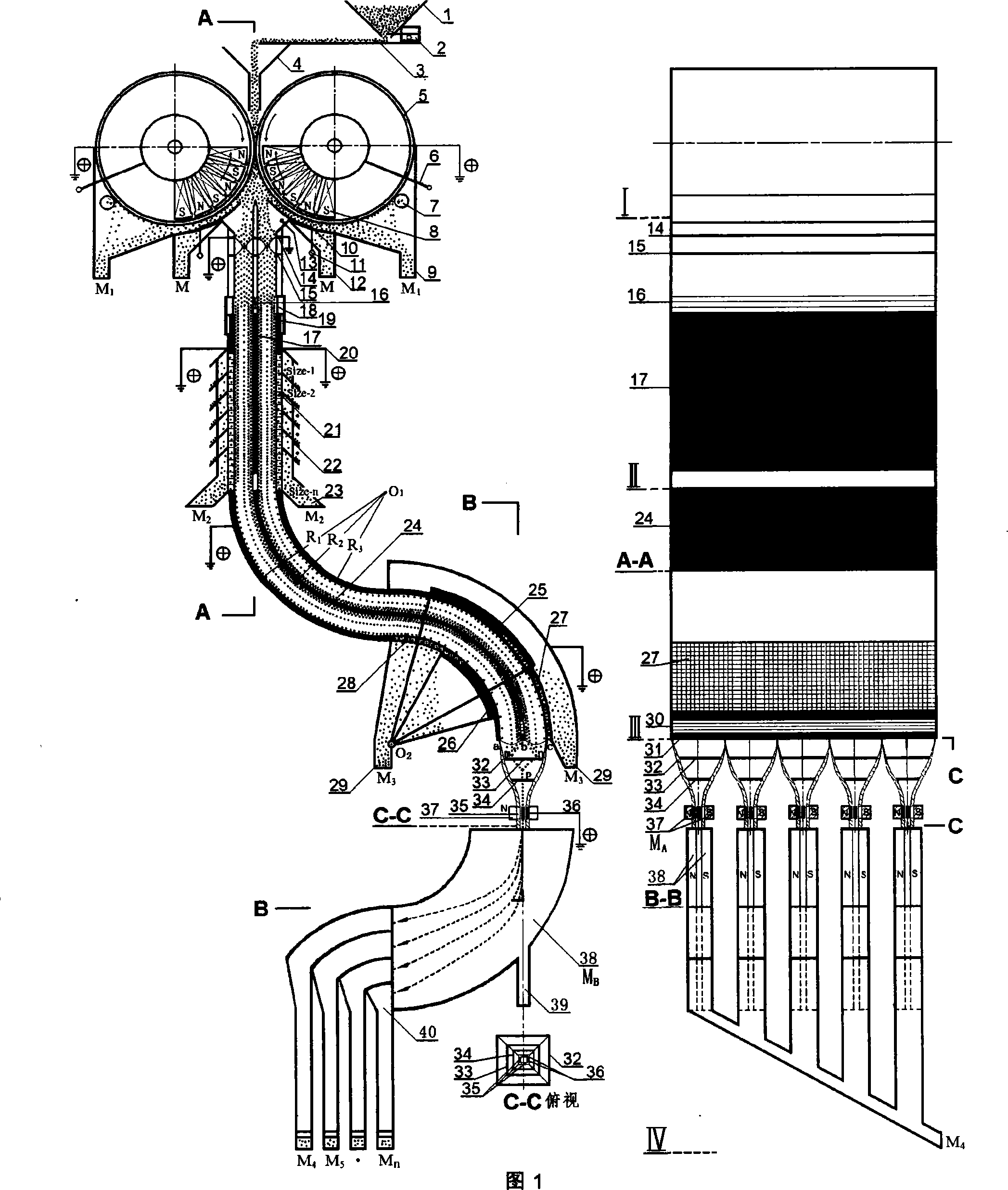

Magnetoelectricity sorting method and equipment of multiple element mineral

InactiveCN101229528ASimple processImprove sorting efficiencyElectrostatic separationMagnetic separationNatural mineralImpurity

The invention relates to a magnetoelectric combined separation method for a plurality of element minerals and equipment thereof, which belongs to a field of mineral processing technology, mineral processing equipment and comprehensive utilization of mineral resources in mineral processing industry. Through comprehensive utilizing modern technologies such as a magnetic separation method, an electric separation method, a reverse rotating magnetic field, corona and an electrostatic composite electric field and a new electrode structure, isotopic ion excitation source, an electrostatic focusing quality analyzer, a particle speed selector, a magnetic field quality analyzer, etc., no water and chemicals are demanded; comprehensive treatment of the plurality of elements minerals with complex components and separation of minerals of fine particles which are difficult to be treated realize comprehensive separation operation of the plurality of mineral elements in the minerals and solve the difficult problems that the plurality of the element minerals in natural minerals or tail minerals can not be separated by current mineral processing technology and mineral processing equipment and content of harmful substances such as sulfur and phosphorus in iron concentrate in steel smelting industry is too high. The invention has the advantages of simple mineral processing technology, high equipment efficiency, high grade concentrate, low mineral processing cost, energy saving, environment protection and high-efficiency development and comprehensive utilization of national mineral resources.

Owner:赵平

Spodumene ore heavy medium-strong-magnetic ore-dressing technology method

InactiveCN101147888ALess investmentRaise the gradeMagnetic separationWet separationEngineeringMaceral

The present invention relates to an ore separation method, in particular, it relates to a spodumene ore-heavy medium-strong magnetic separation process. Said separation process includes the following steps: (1), crushing spodumene ore; (2), washing the crushed spodumene ore to remove mire; and (3), separation: mixing spodumene ore and heaving medium, applying pressure with 0.05-0.20MPa into heavy medium cyclone separator to make separation so as to obtain concentrate spodumene.

Owner:陶家荣

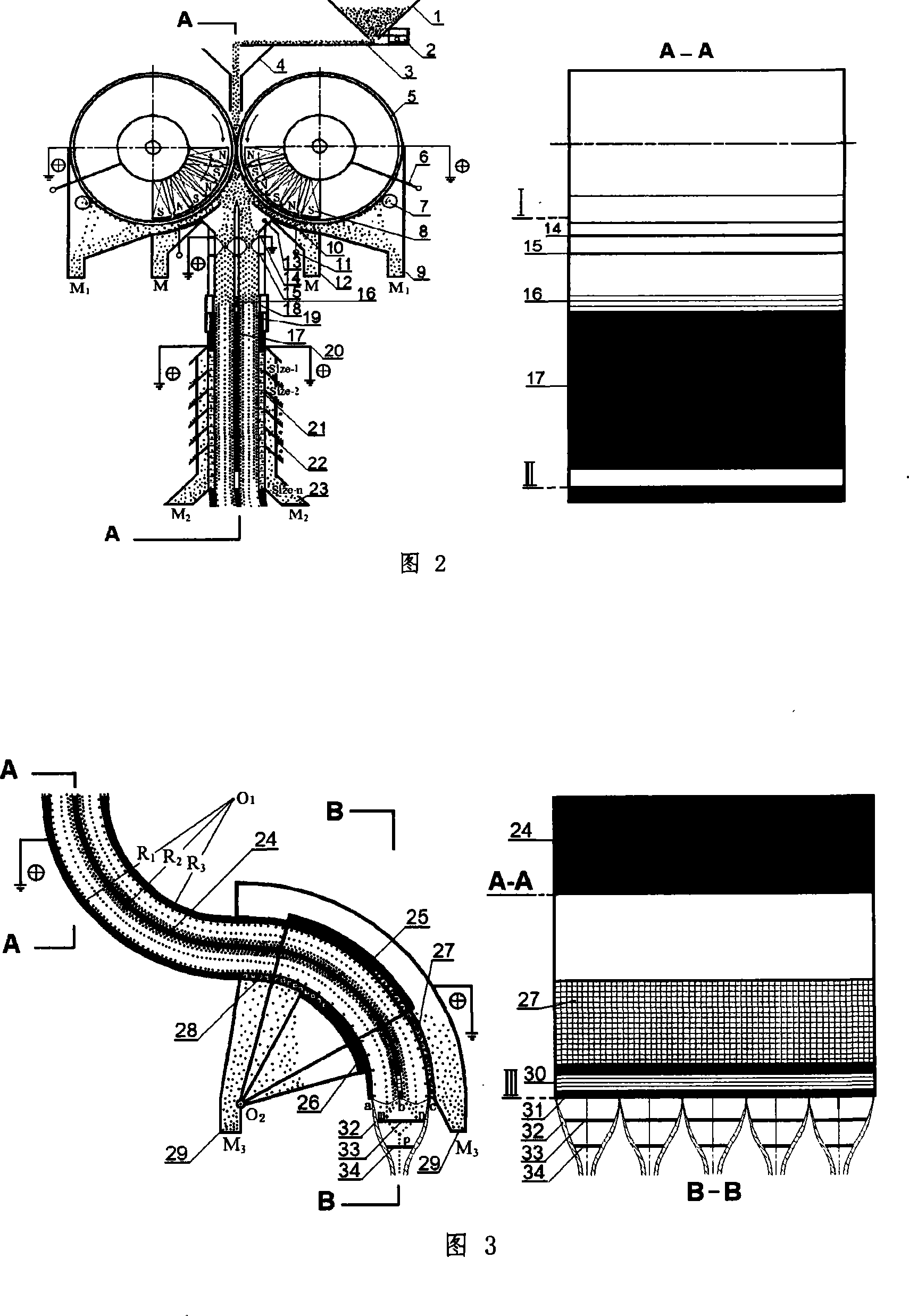

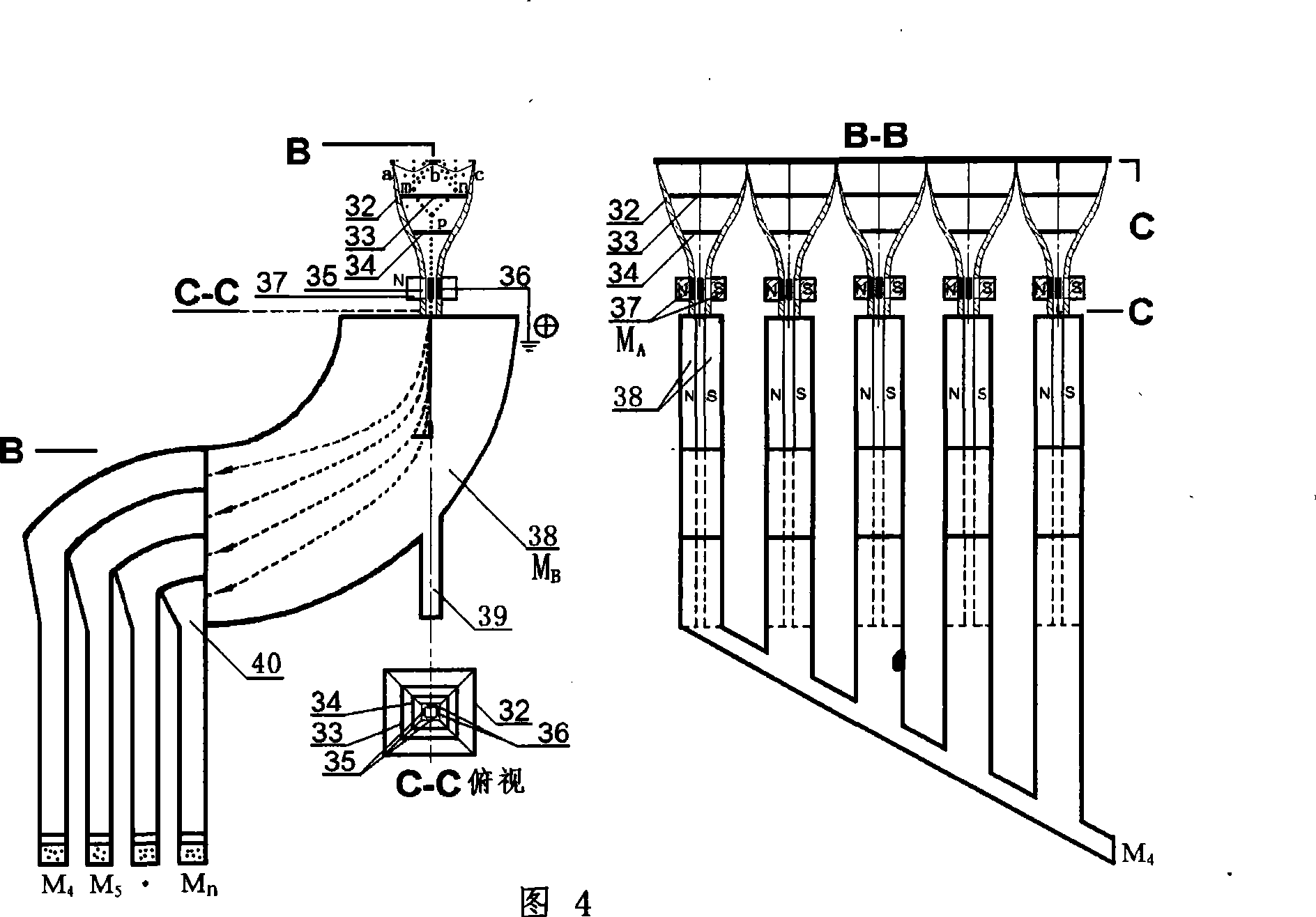

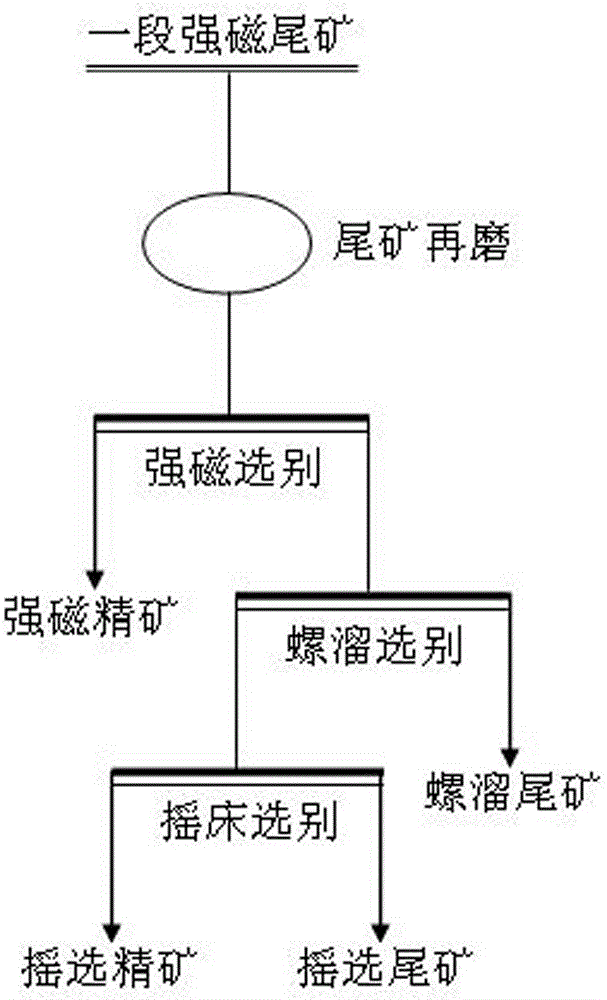

Recleaning process for section of strong magnetic tailings in mixed lean iron ores

ActiveCN102909125AIncrease monomer dissociation rateEfficient sorting processSolid separationMechanical material recoveryHybrid typeMagnetic separator

The invention discloses a recleaning process for a section of strong magnetic tailings in mixed lean iron ores, comprising the following steps of: tailing regrinding: adding water into a section of tailings subjected to strong magnetic separation, grinding the tailings into regrinding ore pulp with mineral aggregate proportion of 60-95% and fineness of -0.045mm, and controlling the concentration of the ore pulp at 65-75%; strong magnetic separation: adding water into the regrinding ore pulp and desliming in an ore separation box to obtain bottom ores with the ore pulp concentration of 25-35% and overflow tailings, and feeding the bottom ores into a strong magnetic separator with the magnetic field strength of 5000-20000 oersteds to obtain strong magnetic concentrates and magnetic separation tailings; spiral chute separation: screening the magnetic separation tailings through a spiral chute to obtain spiral chute concentrates with the concentration of 15-25% and spiral chute tailings; and table separation: separating the spiral chute concentrates by a table with the stroke of 8-10mm and the stroke times of 250-300 times / min to obtain table concentrates and table tailings. A regrinding, magnetic separation and recleaning process is adopted for respectively recovering large-grain and fine-grain recovering magnetic iron ores and weakly magnetic iron ores in the section of strong magnetic tailings, and therefore, the recovery rate and the concentrate grade are high. The process provided by the invention is simple and convenient, high in production efficiency, low in production cost, high in concentrate grade and recovery rate and low in tailing grade lower than 10%.

Owner:YUXI DAHONGSHAN MINING

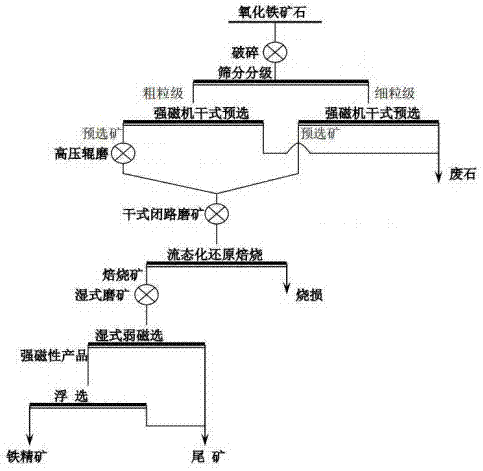

Combined mineral separation technology for ferric oxide mineral

InactiveCN107185686AThrow out earlyReduce transportationMagnetic separationGrain treatmentsIronstoneOxide minerals

The invention discloses an iron oxide ore joint beneficiation process, which comprises the following steps: (1) dry selection and discarding of iron oxide ore to obtain pre-selected coarse-grained ore, pre-selected fine-grained ore and waste rock; (2) high-pressure Roller mill crushing: the pre-selected coarse-grained ore obtained in step (1) is fed into a high-pressure roller mill for crushing; (3) dry grinding: the crushed product in step (2) and the pre-selected fine-grained ore in step (1) Combined for dry closed-circuit grinding; (4) Fluidized reduction roasting: a. Put the ground product obtained in step (3) into the fluidized reduction roaster; b. Preheating; c. Heating; d. Magnetization roasting; e . Cool to below 200°C to obtain roasted ore with a magnetite content greater than 90%; (5) beneficiation of roasted ore to obtain iron concentrate products with a grade of 57%-65%. The present invention can effectively solve the current iron oxide ore beneficiation There are technical problems such as low resource utilization rate, poor concentrate quality and high energy consumption in the process.

Owner:JIUQUAN IRON & STEEL GRP

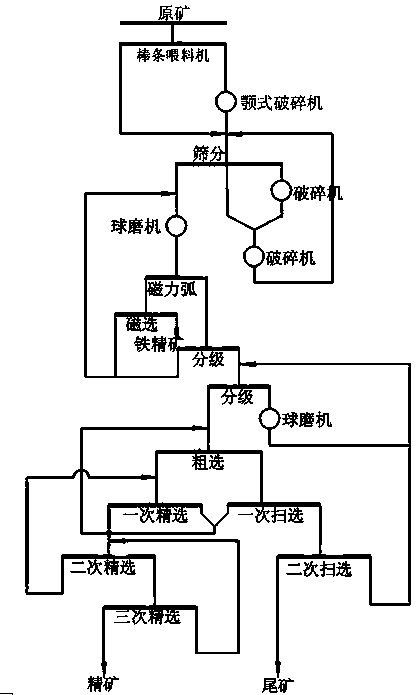

Novel separation process of multi-metal lean hematite

ActiveCN102228863AEfficient separationImprove concentrate gradeFlotationWet separationMetalMetallurgical industry

The invention belongs to the technical field of mineral separation in the metallurgical industry, and in particular relates to a novel separation process of multi-metal lean hematite, which is characterized in that a separation method of two sections of continuous ore grinding, magnetic separation, reverse floatation, regrinding and centrifuging through a centrifugal machine is adopted so that iron minerals and other metal minerals are separated. The novel separation process comprises the following steps of: subjecting primary ball grinding, primary grading, secondary grading, secondary ball grinding, one-section weak magnetic separation, one-section strong magnetic separation, one-section strong magnetic fine separation, reverse floatation operation separation, two-section magnetic separation and regrinding to multi-metal symbiotic lean hematite ores; carrying out one-section rough separation, one-section fine separation, one-section scavenging and two-section scavenging; merging weak magnetic concentrate and secondary reverse floatation concentrate to form final concentrate; and merging two-section strong magnetic tailings and reverse floatation tailings to form final tailings. After the novel separation process is adopted for separation, raw ore grade is 30.505 percent, the concentrate obtained after the separation has better selection indexes such as a grade of 64.14 percent, a yield of 28.59 percent, a metal recovering rate of 60.13 percent, and a tailing grade of 17.03 percent. The grade of the concentrate can be improved from about 58 percent to 64.14 percent.

Owner:ANSTEEL GRP MINING CO LTD

Preparation method and application of dolomite inhibitor

A preparation method of a dolomite inhibitor comprises the following steps of firstly mixing sulfuric acid, hydrochloric acid and water by the mass ratio of the sulfuric acid to the hydrochloric acid to the water = 2-7:1-2:8-13 to obtain a solution 1, then adding benzoic acid or nitrobenzene into the solution 1 by the mass ratio of 1-3:3-10, and obtaining a solution 2 through stirring and solution; adding water-soluble sulfate or sulfite into the solution 2 by the mass ratio of 1-2:3-7, controlling the temperature of the solution 2 to be 40-50 DEG C, performing stirring reaction for 6-7h to obtain a solution 3, performing suction filtration on the solution 3 to obtain crystallized slime and finally drying the crystallized slime under the condition of 60-75 DEG C to obtain the dolomite inhibitor. By adopting the dolomite inhibitor, dolomites can be inhibited, and the fluorite concentrate grade is improved.

Owner:GUANGXI UNIV

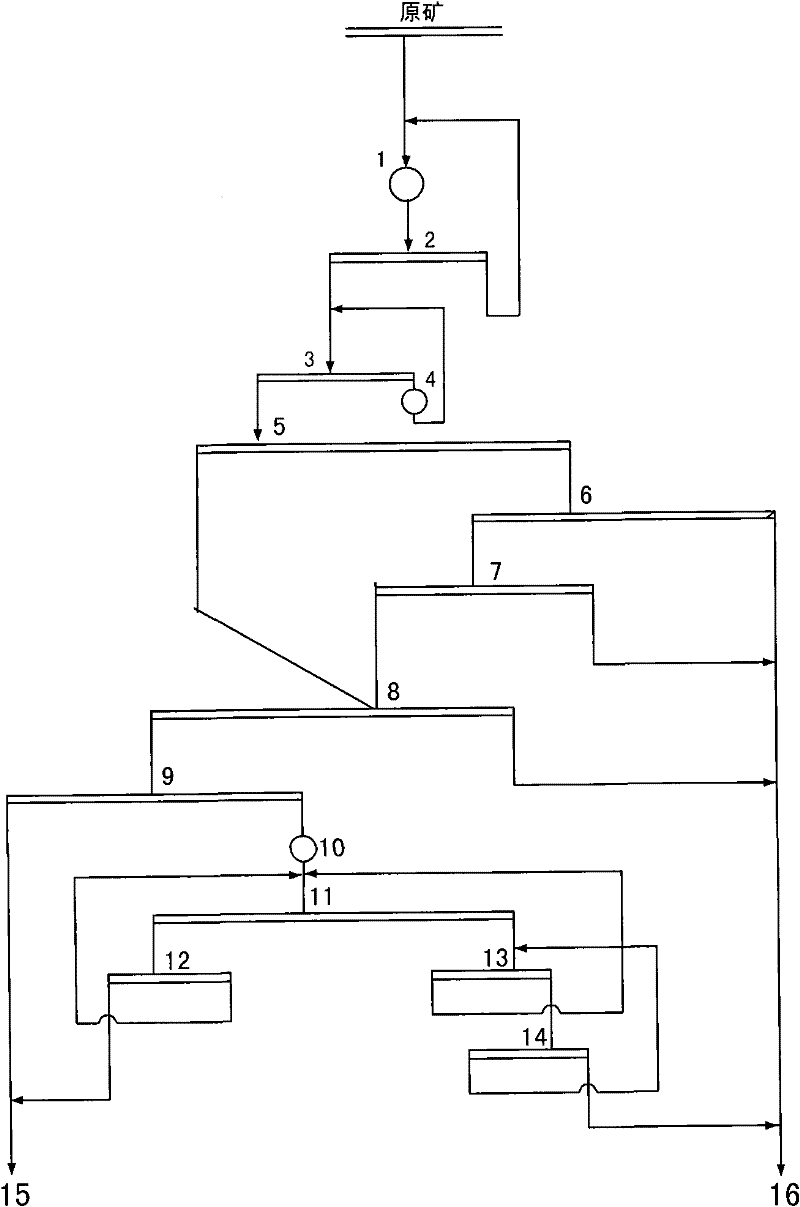

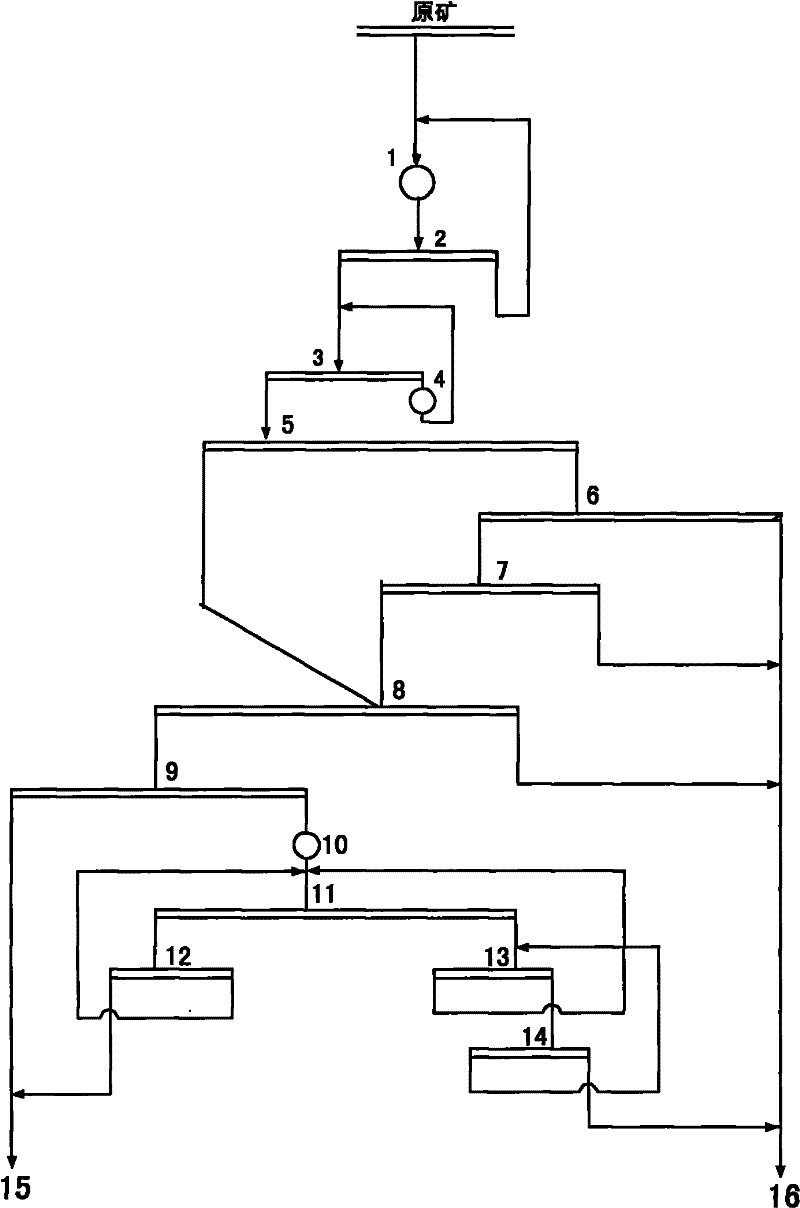

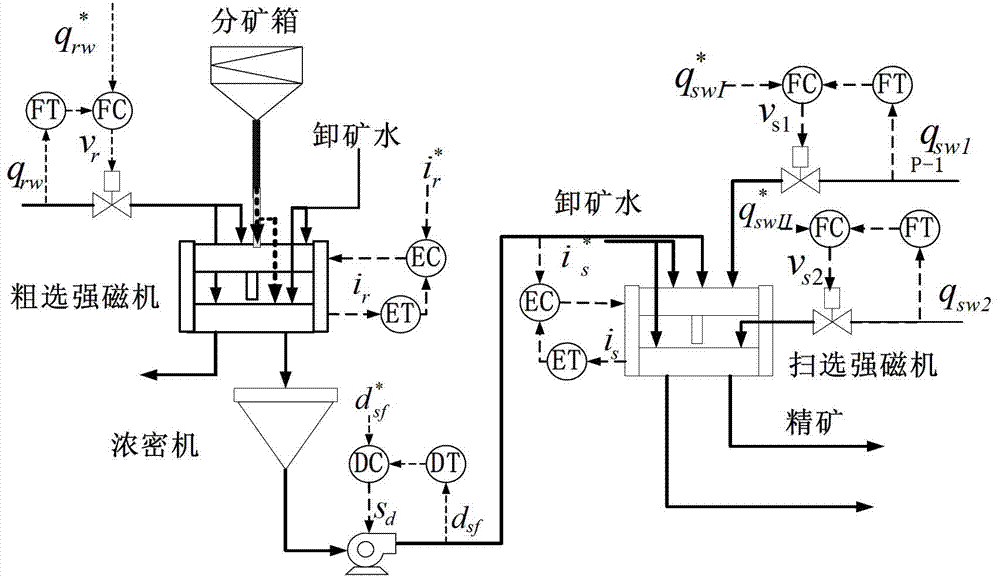

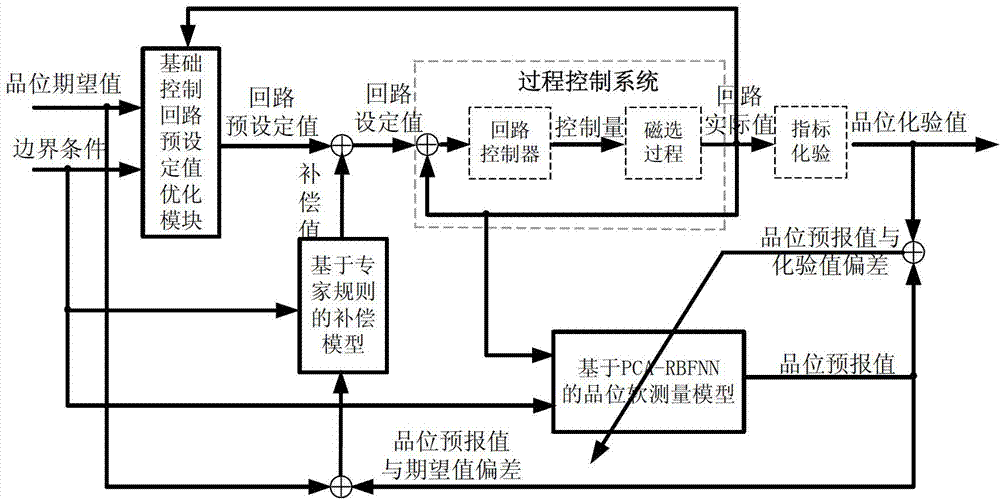

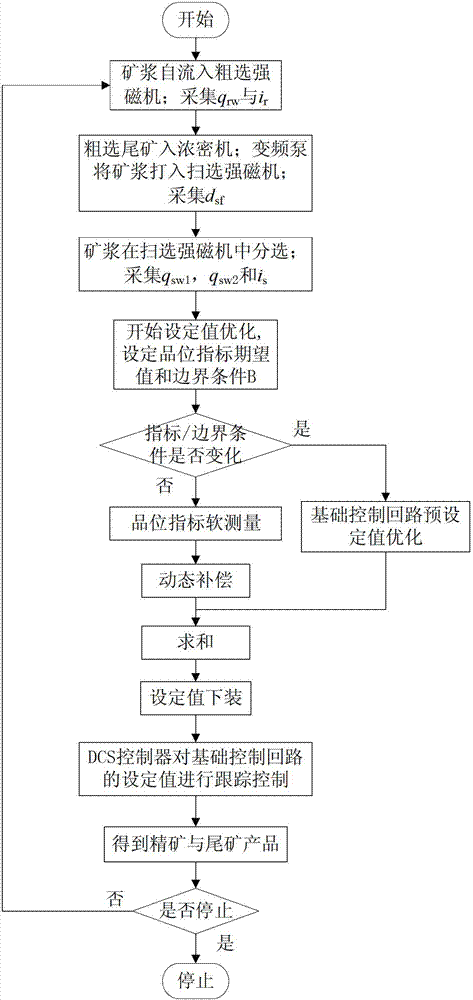

Operation control method of high magnetic grading process

ActiveCN102778843AHigh metal recovery rateMeet needsMagnetic separationAdaptive controlSystems designAutomatic control

An operation control method of a high magnetic grading process belongs to the technical field of automatic control and comprises the following steps of: performing optimal control on a set value of a basic control loop of the high magnetic grading process according to an expected value of a high magnetic grading index and an actual value of the basic control loop to improve the concentrate grade and lowering the tailing grade. With the adoption of the method, a system is ensured to run on working points corresponding to the expected value of concentrate grade and the expected value of the tailing grade, the concentrate grade and the tailing grade which cannot be measured on line are predicated in real time by a neural network, the poor effect to the grading process, caused by each unknown interference, is inhibited effectively by using a dynamic compensation method, in this way, the concrete grade is improved, meanwhile, the tailing grade is lowered, and thus the metal recovering rate of a final grading product is increased. The method can be realized by a software system; with the adoption of the software system, the separation of a software functional module and an algorithm is realized, the de-coupling degree is low, the algorithm is easy to expand and maintain, and a technical support and a running platform are provided to the research and the system design of the operation control method of the high magnetic grading process.

Owner:NORTHEASTERN UNIV

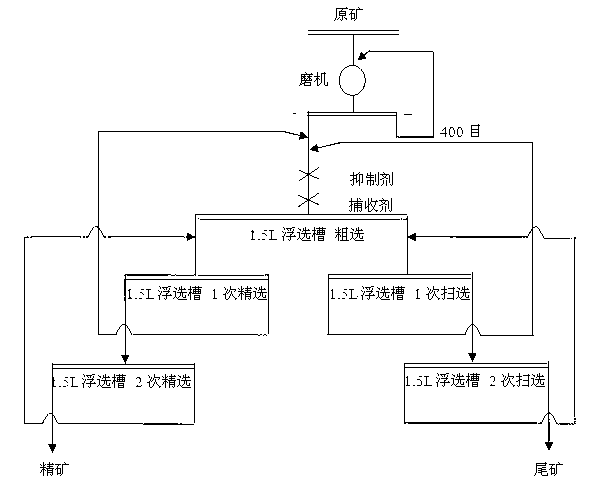

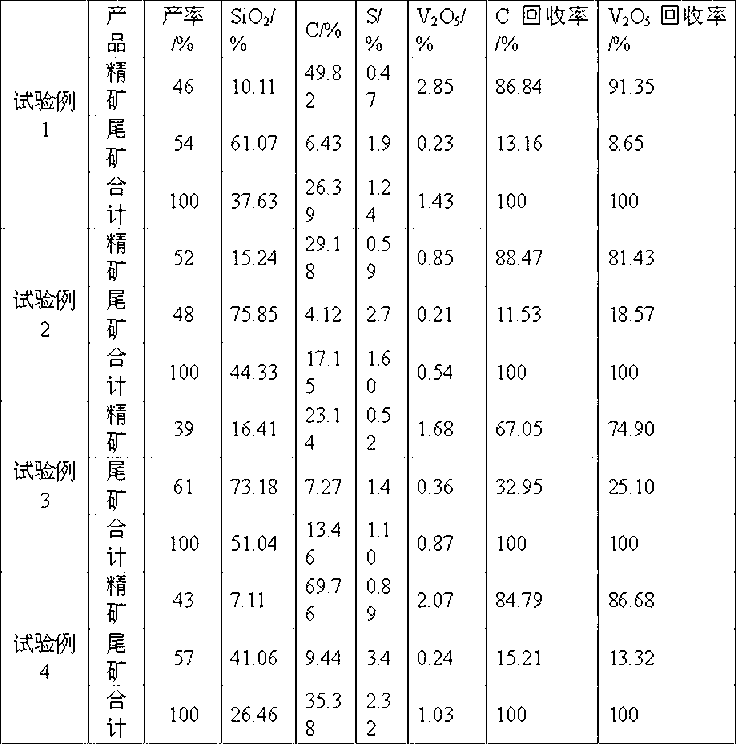

Composite beneficiation reagent for extracting vanadium from stone coal

The invention relates to a composite beneficiation reagent for extracting vanadium from stone coal. The composite beneficiation reagent for extracting the vanadium from the stone coal is characterized in that the composite beneficiation reagent is composed of a component A, a component B, a component C, a component D and water, the component A is kerosene and / or diesel oil, the component B is quaternary ammonium salt class matter and / or aliphatic amine hydrochloride class matter, the component C is any one or more of alcohol ranging from C4 to C8, 4-methyl-cyclohexyl-methanol, MIBC, terpenic oil, methyl triisopropoxy silane, and the component D is any one or more of alkyl-sulfonate ranging from C8 to C12, OP-10 and Tween-60. The composite beneficiation reagent for extracting the vanadium from the stone coal is prepared by a plurality of components according to a certain proportion and a rule, combination of the components of the reagent can be adjusted according to different mineral properties so that a series of flotation reagents can be prepared, and thebest use effect is achieved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Floatation method of pyrites

InactiveCN101658818AImprove surface propertiesHigh recovery rateFlotationFoaming agentNonferrous metal

The invention provides a floatation method of pyrites, belonging to the field of floatation technologies. The floatation method is characterized by comprising the following steps: adding ammonium saltand sulfide as activating agents under the condition of alkaline ore pulp after the floatation of nonferrous metal sulphide ore, then adding collector xanthate and foaming agent pine oil, and stirring to float the pyrites. In the floatation process, the addition amount of the activating agent is 6-120mol / t raw ore, the addition amount of the activating agent sulfide is 6-36mol / t raw ore, the addition amount of the collector xanthate is 500g / t raw ore, and the addition amount of the foaming agent pine oil is 50g / t raw ore. The method can improve the surface properties and the floatation conditions of the pyrites, accelerate the upward-floating speed of the pyrites, improve the recovery rate and the concentrate grade of the pyrites and reduce the flotation agent consumption and the production cost.

Owner:浙江巨化化工矿业有限公司 +1

Benefication of magnetite-haematite acid mixed mine

InactiveCN1778471ATake advantage ofEfficient use ofMagnetic separationWet separationMagnetiteMaterials science

A magnetic separation method for preparing the ore concentrate from the acidic mixture of magnetite and hematitie includes such steps as strong magnetic separating twice, separating by spiral chute for the separated concentrate, and separating by sorting table for the intermediate ore and tailings. Its advantages are high quality of ore concentrate and high recovery rate.

Owner:KUNMING IRON & STEEL GRP CO LTD +1

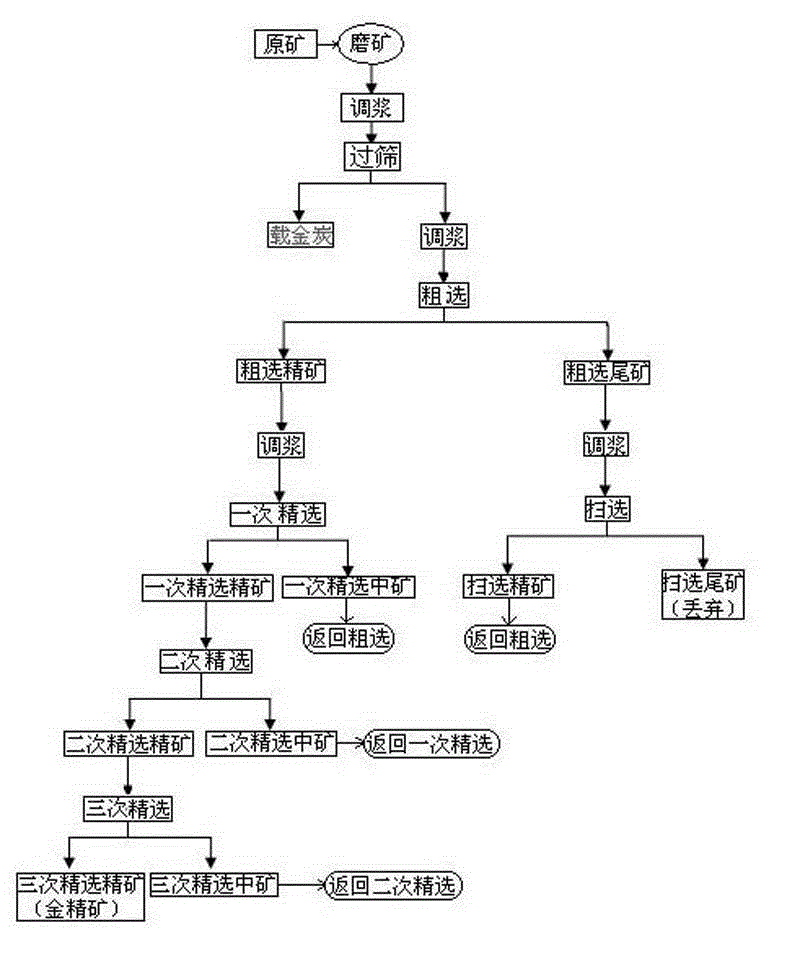

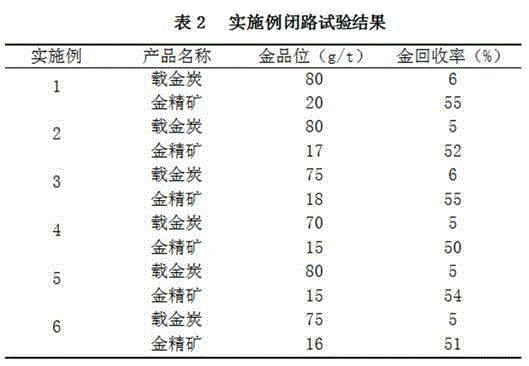

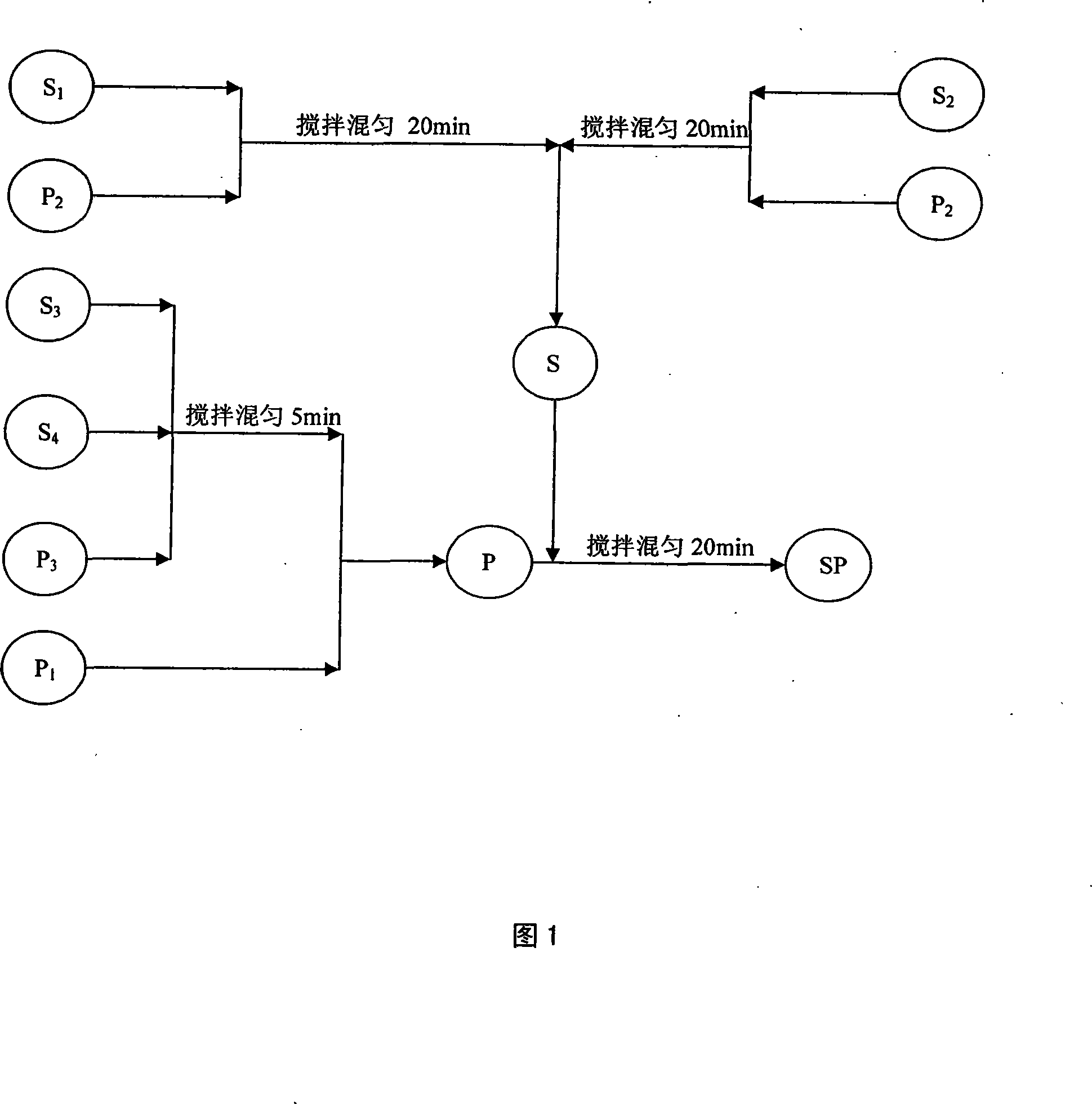

Method for selecting gold from gold ore leaching residue

ActiveCN103977881AAchieve recyclingProcess results are simpleFlotationWet separationDibutyl dithiophosphateFoaming agent

The method discloses a method for selecting gold from gold ore leaching residue. The method comprises the following steps: ore grinding, grid screening, roughing, scavenging, first selection, second selection and third selection. Active carbon is added during ore grinding, gold loaded carbon with higher gold content is firstly screened by adopting a 40-mesh grid screen at a ball-milling ore discharge port, then an inhibitor, a collecting agent and a foaming agent are added during the floatation process, and finally size mixing and stirring are carried out for roughing floatation work. The inhibitor is sodium fluosilicate, the collecting agent is Ammonium dibutyl dithiophosphate, and the foaming agent is terpenic oil. According to the method, through reasonable allocation of ore grinding and grid screening, the gold grade of the gold loaded carbon reaches to 70-80 g / T, the gold grade of floatation gold concentrate reaches to 15-20 g / T, the recovery rate of the gold loaded carbon reaches to 5-6%, the recovery rate of floatation gold reaches to 50-55%, and the total recovery rate of gold reaches to 55-61%. The ore dressing method is simple in technology and easy to operate on site.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

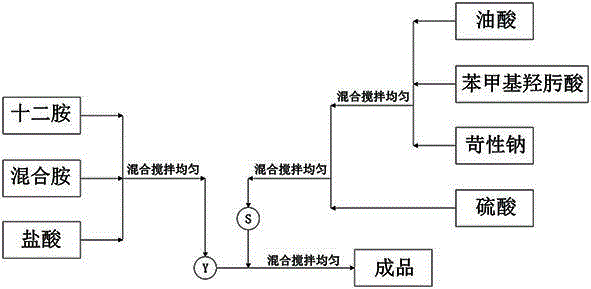

Siderite floatation collector and preparation thereof

InactiveCN101234367AStrong selective collection abilityShort flotation timeFlotationEconomic benefitsSlurry

The invention relates to a siderite flotation collecting agent and a preparation method thereof. The collecting agent takes lauryl amine, mixed amine, polyether amine, naphthenic acid, sulphuric acid, hydrochloric acid and caustic soda as raw materials and after adding accessory materials to prepare a complex collecting agent. Adopting the collecting agent for siderite flotation and collection not only raises the grade of siderite ore concentrate but also raises the coefficient of iron recovery over 80 percent. The invention also has good performance in collecting complicated and polymetallic ore mineral which mainly contains siderite. The siderite flotation collecting agent preparation method has the advantages of good selectivity, little interference by other ions in ore slurry, strong collecting property, thus realizing the effective separation of siderite form other ores during flotation; the collecting agent has certain foaming tendency, which can reduce the usage of 2oil which is often used in flotation technique, can reduce ore choosing cost, thereby raising the economic benefit correspondingly.

Owner:昆明晶石矿冶有限公司

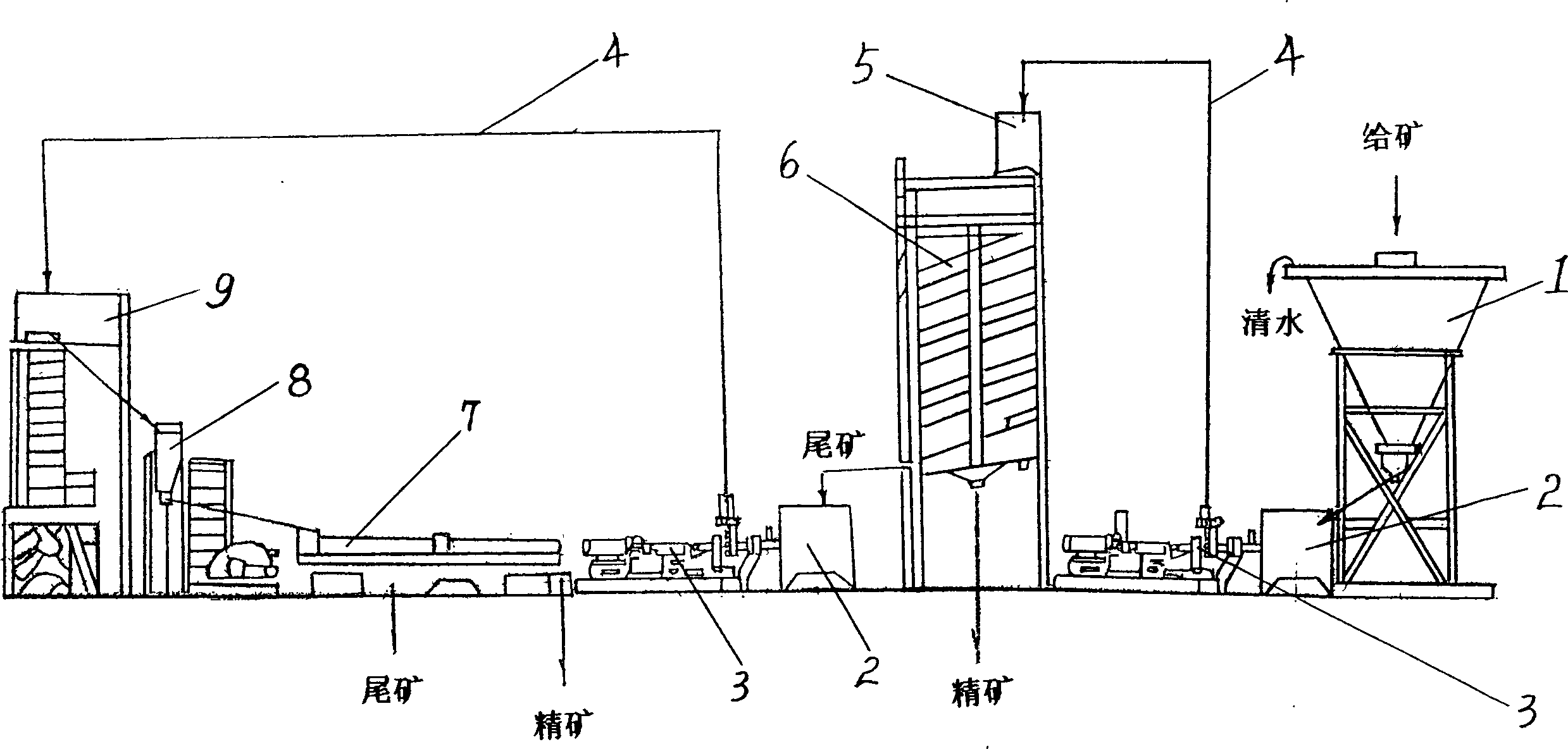

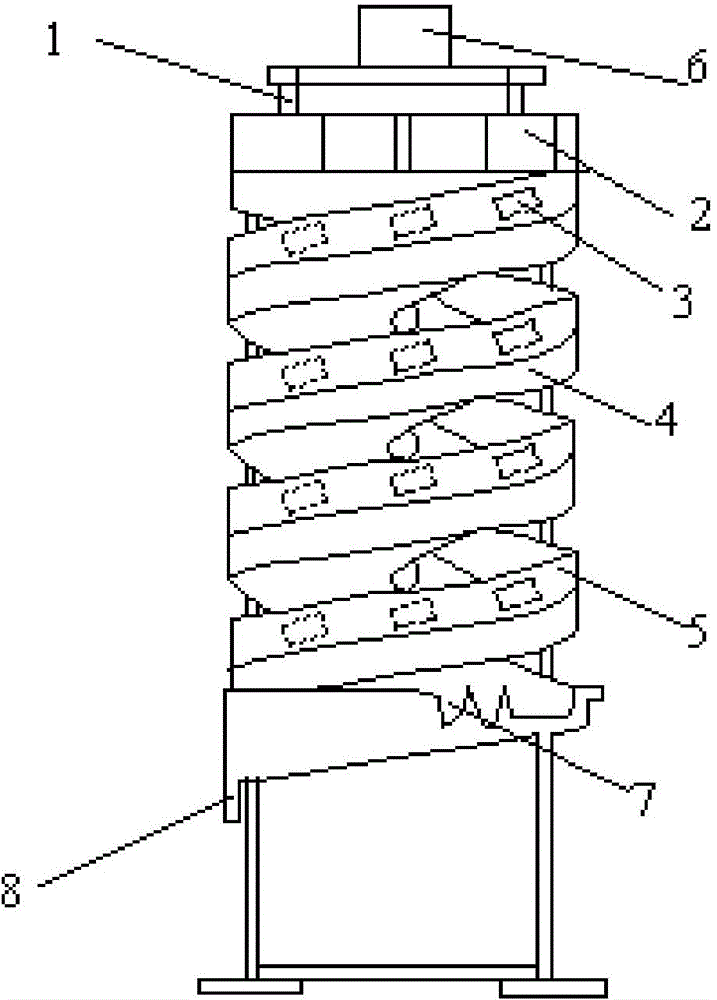

Complex force field spiral chute for ore dressing

The present invention discloses a complex force field spiral chute for ore dressing, and fine particles can be effectively prevented from entering into a tailing zone. The spiral chute comprises a channel steel support, an ore-feeding device, magnetic poles, a pulsating pressure water tank, a spiral blade, an ore dividing bucket, an ore intercepting bucket and an ore receiving bucket. The permanent magnetic fixed magnetic poles are installed at an external portion of a spiral blade of an existing spiral chute, so that magnetic fine particles in magnetic mineral can be forced by an inward-radial magnetic retentive force to enter into a concentrate zone under the function of an applied magnetic field. The pulsating water tank is installed at the bottom of a spiral surface, ore particles are prevented from rubbing with the spiral surface, so that the ore particles can be well layered and separated conveniently, and equipment abrasion can be eliminated conveniently. Concentrate grades can be improved, concentration ratio can be increased, mineral recovery rates can be improved, an existing spiral ore dressing technology can be simplified, and equipment maintenance rates and equipment power consumption can be reduced.

Owner:UNIV OF SCI & TECH LIAONING

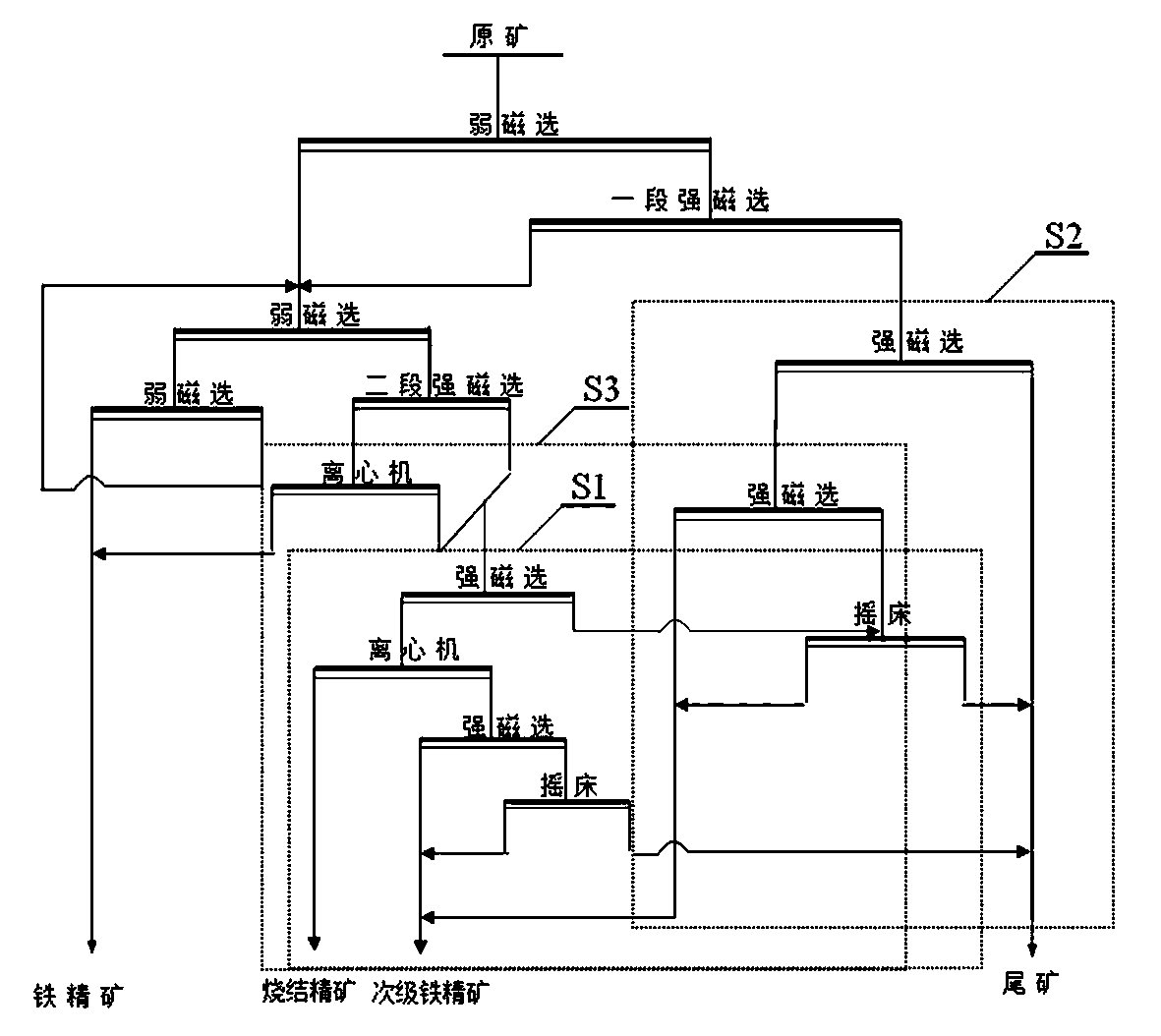

Separation process of ferrous high silicate type iron ore

ActiveCN103894283AOvercome the disadvantages of independent processingReduce secondary selectionWet separationResource utilizationFinings

The invention discloses a separation process of ferrous high silicate type iron ore. The process includes classifying, degrading tailings and upgrading. Tailing degrading includes S1 tailing degrading and S2 tailing degrading. The separation process has the advantages that the process is free of calcination and reverse floatation, short is process flow, low in process management requirement, low in operation cost, low in environmental pollution and suitable for industrial production; the iron grade of fine ferrous silicate type iron concentrate is increased, silicon content is lowered, the grade of fine high silicate type iron tailings is lowered, the grade of the iron concentrate is increased by about 10%, and the silicon content is lowered by about 10%; the iron ore in the tailings can be recycled effectively, the comprehensive grade of total tailings is lowered from 16.2% to about 10.53%; the separation process is environmental friendly, low in energy consumption, low in cost, high in fining and concentration degree, and capable of effectively increasing comprehensive resource utilization rate, increasing benefits, saving energy and reducing emission.

Owner:KUNMING UNIV OF SCI & TECH +1

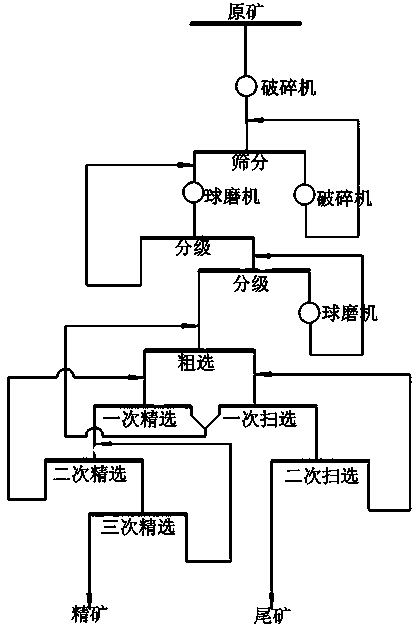

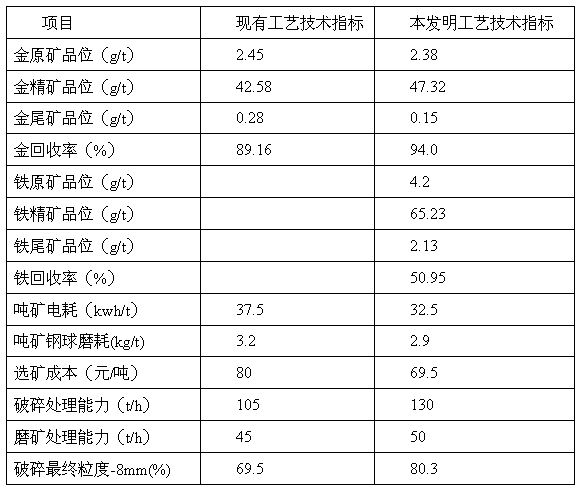

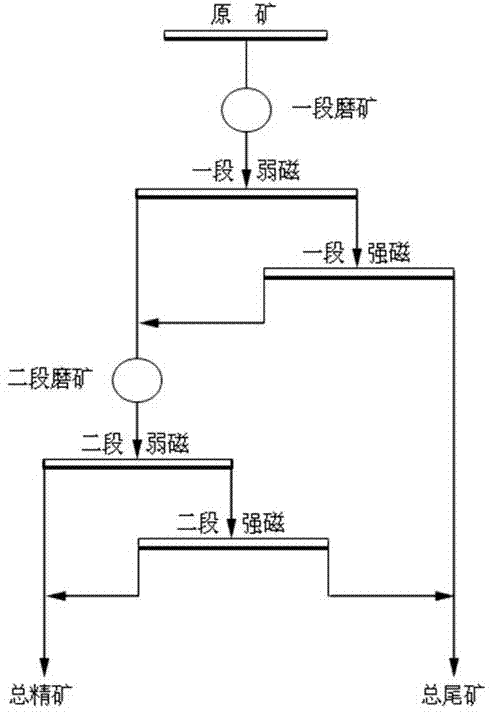

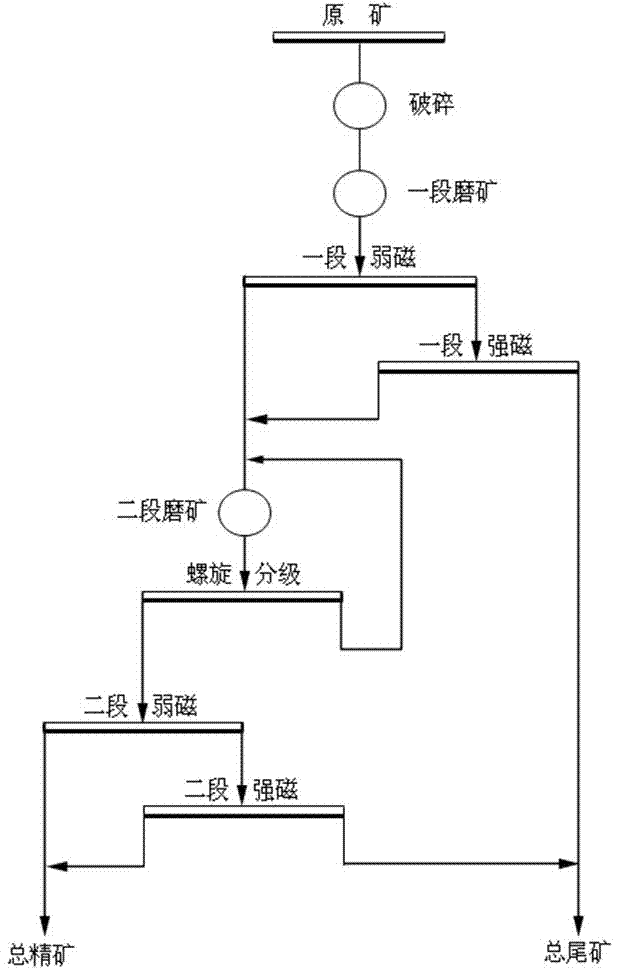

Beneficiation method and device for quartz vein type gold deposit

ActiveCN103464275AReduce wearIncreased crushing capacity efficiencyWet separationSteel ballNon magnetic

The invention discloses a beneficiation method for quartz vein type gold deposit. The beneficiation method for the quartz vein type gold deposit includes the steps of using a jaw crusher to crush raw ore, sending crushed mineral material into a double layer circular vibrating screen to be sieved, putting sieved and qualified mineral material into a grid type ball mill for single stage grinding, returning unqualified mineral material after two stage crushing back to the double layer circular vibrating screen, separating magnetic and non-magnetic minerals after discharging material from single stage grinding passing a magnetic arc, making magnetic minerals for magnetic separation to obtain iron ore concentrate and putting the non-magnetic minerals separated through the magnetic arc into a sorting system after twice classification. Compared with the prior art, with beneficiation method for quartz vein type gold deposit, the content of fine particles of a crushed final product is mostly of 80.3%, crushing efficiency is improved, wear rate of a steel ball is decreased by 9%, ferrous metals can be recycled, synchronous improvement of ore dressing recovery percentage and concentrate grade is realized with the recovery percentage increased by 4.2% and the concentrate grade increased by 3.5 grams per ton, power consumption rate is reduced by 13.86%, and cost is reduced by 15.0%.

Owner:阿勒泰正元国际矿业有限公司

Beneficiation method of efficiently recovering fine-grain low-grade magnetite

The invention discloses a mineral processing method for efficiently recovering fine-grained low-grade magnetite. Iron concentrate I and tailings I can be obtained by weak magnetic separation with a magnetic induction intensity of 1100-1300Oe; iron concentrate II and tailings II can be obtained from tailings I by strong magnetic separation with a magnetic induction intensity of 0.9-1T; iron concentrate I and iron Concentrate II is combined and ground to -0.045mm, accounting for 75-85% to obtain fine-grained ore II; fine-grained ore II is subjected to weak magnetic separation with a magnetic induction intensity of 1000-1200Oe to obtain iron concentrate III and tailings III; Iron concentrate IV and tailings IV are obtained by strong magnetic separation with a magnetic induction intensity of 0.560-0.783T, and iron concentrate III and iron concentrate IV are combined to obtain a total concentrate, and tailings II and tailings IV are combined to throw tailings. The invention has the characteristics of short process flow, less grinding amount, high beneficiation efficiency, iron recovery rate and high concentrate grade.

Owner:YUXI DAHONGSHAN MINING

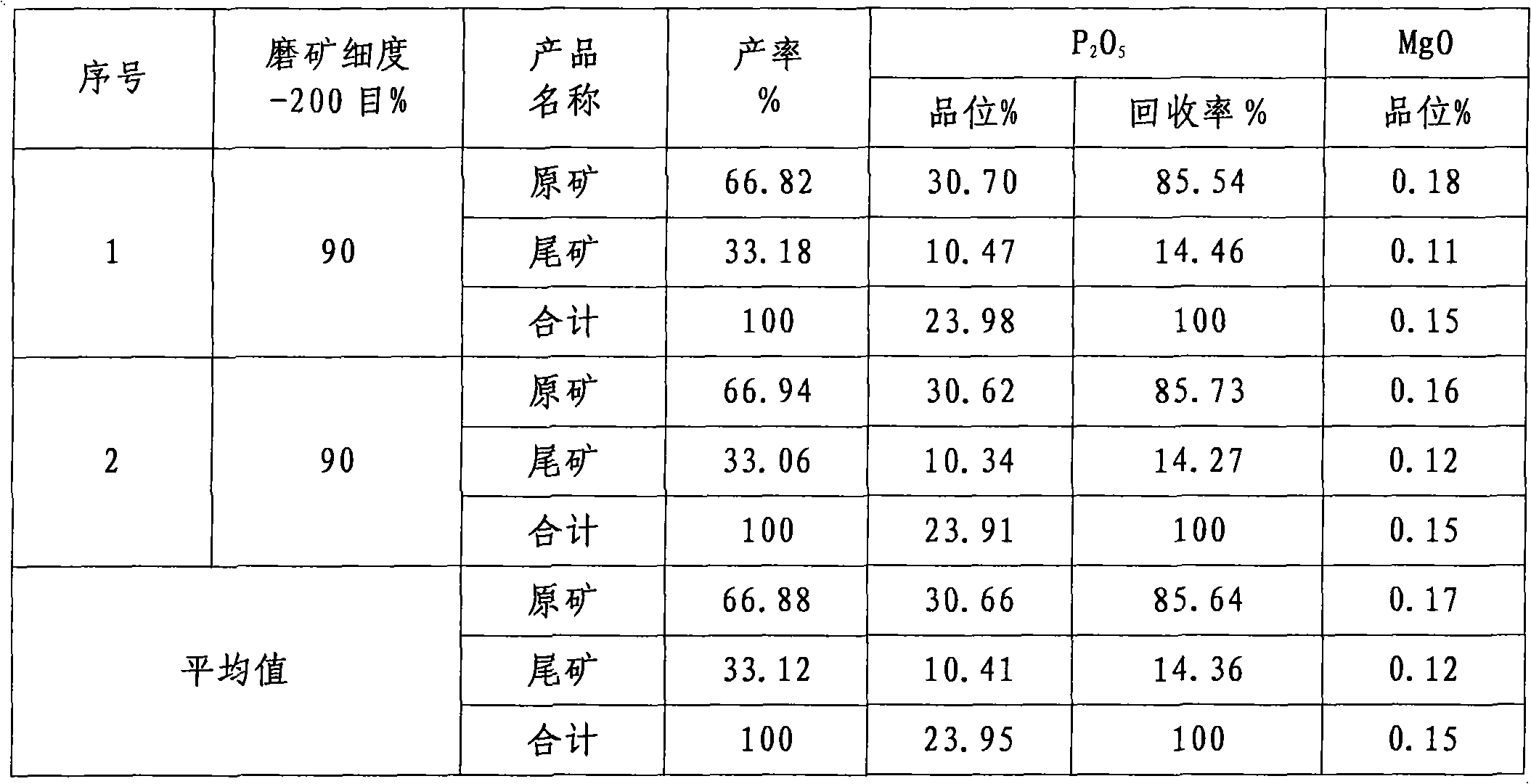

Phosphate rock flotation collector and preparation method thereof

InactiveCN105013619AReduce distractionsImprove concentrate gradeFlotationPhosphatePhysical chemistry

The invention discloses a phosphate rock flotation collector. The phosphate rock flotation collector comprises, by weight ratio, 20-70 parts of Y and 30-80 parts of S; the Y comprises, by weight ratio, 60-30 parts of lauryl amine, 20-40 parts of mixed amine and 20-30 parts of hydrochloric acid; the S comprises, by weight ratio, 20-40 parts of oleic acid, 20-40 parts of phenmethyl hydroximic acid, 20-30 parts of caustic soda and 10-20 parts of sulfuric acid. The invention further discloses a preparation method of the phosphate rock flotation collector. The phosphate rock flotation collector and the preparation method have the beneficial effects that the selectivity and the collecting property are strong, the flotation time is short, the interference caused by other ions in pulp is small, the technological operation is simple, and the economic benefit is remarkable; the grade of P2O5 can be improved by about 5%, and the phosphorus comprehensive recovery rate can be improved by about 10%; poisonous and side effects do not exist, pollution to the environment can be avoided; and the raw material source channels are convenient, and the preparation method is simple.

Owner:四川有色金砂选矿药剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com