Combined mineral separation technology for ferric oxide mineral

A technology for iron oxide and ore, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of low iron grade in concentrate, low process efficiency, and less output of concentrate, so as to achieve concentrate grade and recovery Increased efficiency, high resource utilization, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take the beneficiation of an iron oxide ore with an iron grade of 34% in China as an example.

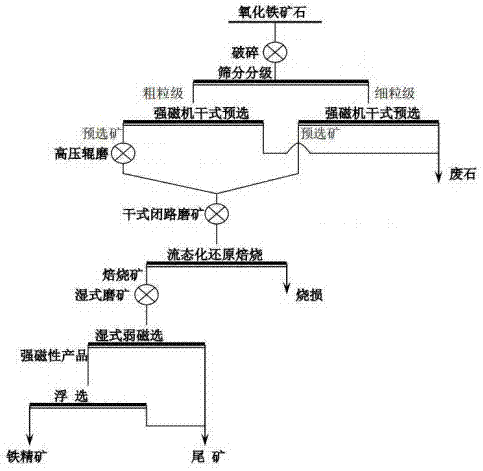

[0041] use as figure 1 Shown a kind of iron oxide ore joint mineral processing technology of the present invention, its processing step is as follows:

[0042] (1) Iron oxide ore dry selection and discarding: crush the mined iron oxide ore to a particle size of less than 30mm, screen into two products of 30-5mm coarse-grained grade and less than 5mm fine-grained grade, and enter the magnetic field strength 1.1 respectively T, the dry-type strong magnetic separator with a drum line speed of 1.2m / s performs dry separation and removal of waste rocks composed of surrounding rocks and intercalated rocks, and obtains pre-selected coarse-grained ores, pre-selected fine-grained ores and waste rocks;

[0043] (2) High-pressure roller mill crushing: feed the pre-selected coarse-grained ore obtained in step (1) into a high-pressure roller mill for closed-circuit crushing until the part...

Embodiment 2

[0056] Take the beneficiation of an iron oxide ore with an iron grade of 31% in China as an example.

[0057] use as figure 1 Shown a kind of iron oxide ore joint mineral processing technology of the present invention, its processing step is as follows:

[0058] (1) Iron oxide ore dry selection and discarding: crush the mined iron oxide ore to a particle size of less than 30mm, screen into two products of 30-5mm coarse-grained grade and less than 5mm fine-grained grade, and enter the magnetic field strength 0.9 T, the dry-type strong magnetic separator with a drum line speed of 1.5m / s performs dry separation and removal of waste rocks composed of surrounding rocks and intercalated rocks, and obtains pre-selected coarse-grained ores, pre-selected fine-grained ores and waste rocks;

[0059] (2) High-pressure roller mill crushing: feed the pre-selected coarse-grained ore obtained in step (1) into a high-pressure roller mill for open-circuit crushing until the particle size is le...

Embodiment 3

[0072] Take the beneficiation of an iron oxide ore with an iron grade of 30-48% in China as an example.

[0073] use as figure 1 Shown a kind of iron oxide ore joint mineral processing technology of the present invention, its processing step is as follows:

[0074] (1) Iron oxide ore dry selection and discarding: crush the mined iron oxide ore to a particle size of less than 30mm, sieve into two products of 30-5mm coarse-grained grade and less than 5mm fine-grained grade, and enter the magnetic field strength 0.8 T, the dry-type strong magnetic separator with a drum line speed of 1.8m / s performs dry separation and removal of waste rocks composed of surrounding rocks and intercalated rocks, and obtains pre-selected coarse-grained ores, pre-selected fine-grained ores and waste rocks;

[0075] (2) High-pressure roller mill crushing: feed the pre-selected coarse-grained ore obtained in step (1) into a high-pressure roller mill for closed-circuit crushing until the particle size i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com