Patents

Literature

364results about How to "Reduce filter effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

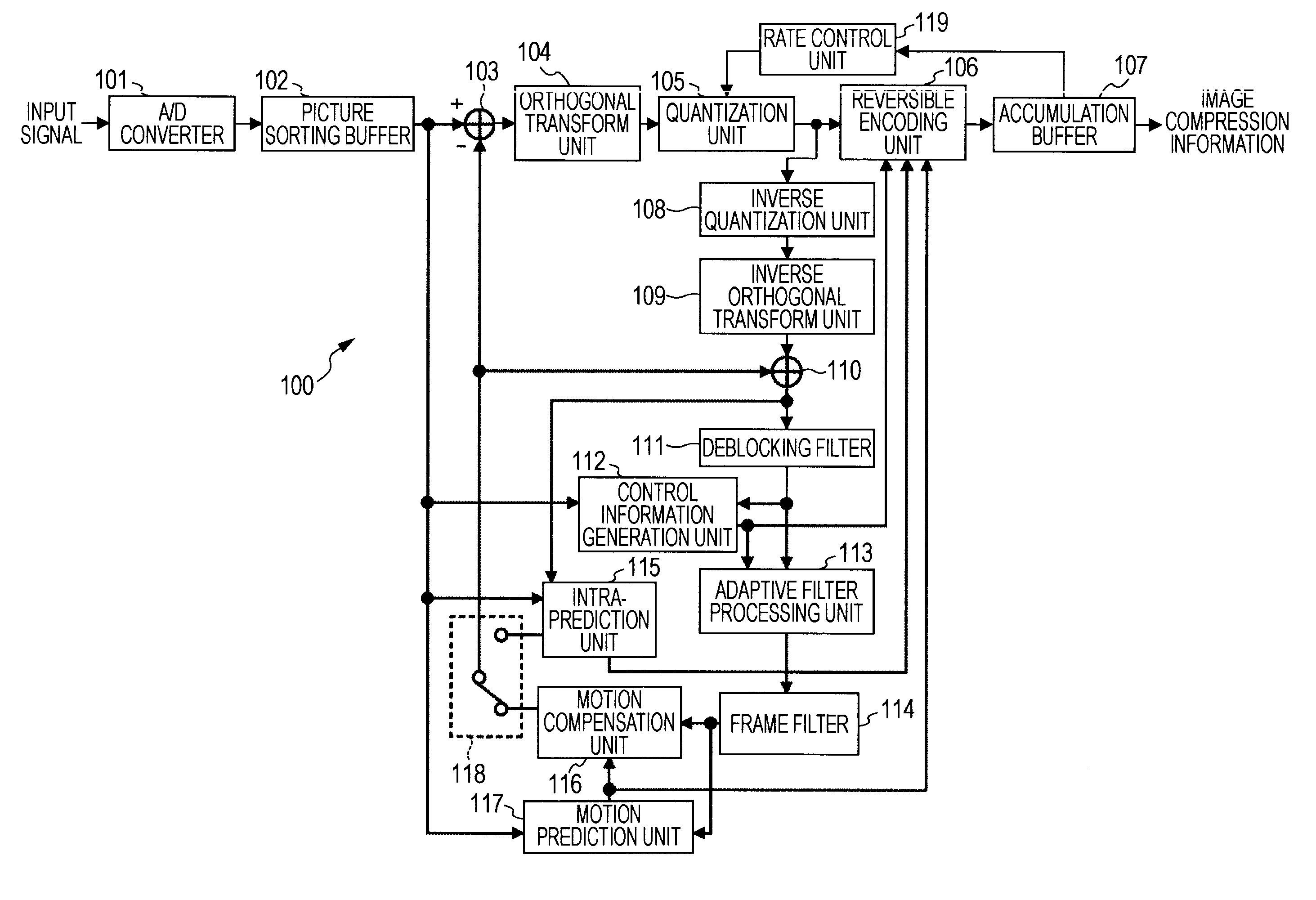

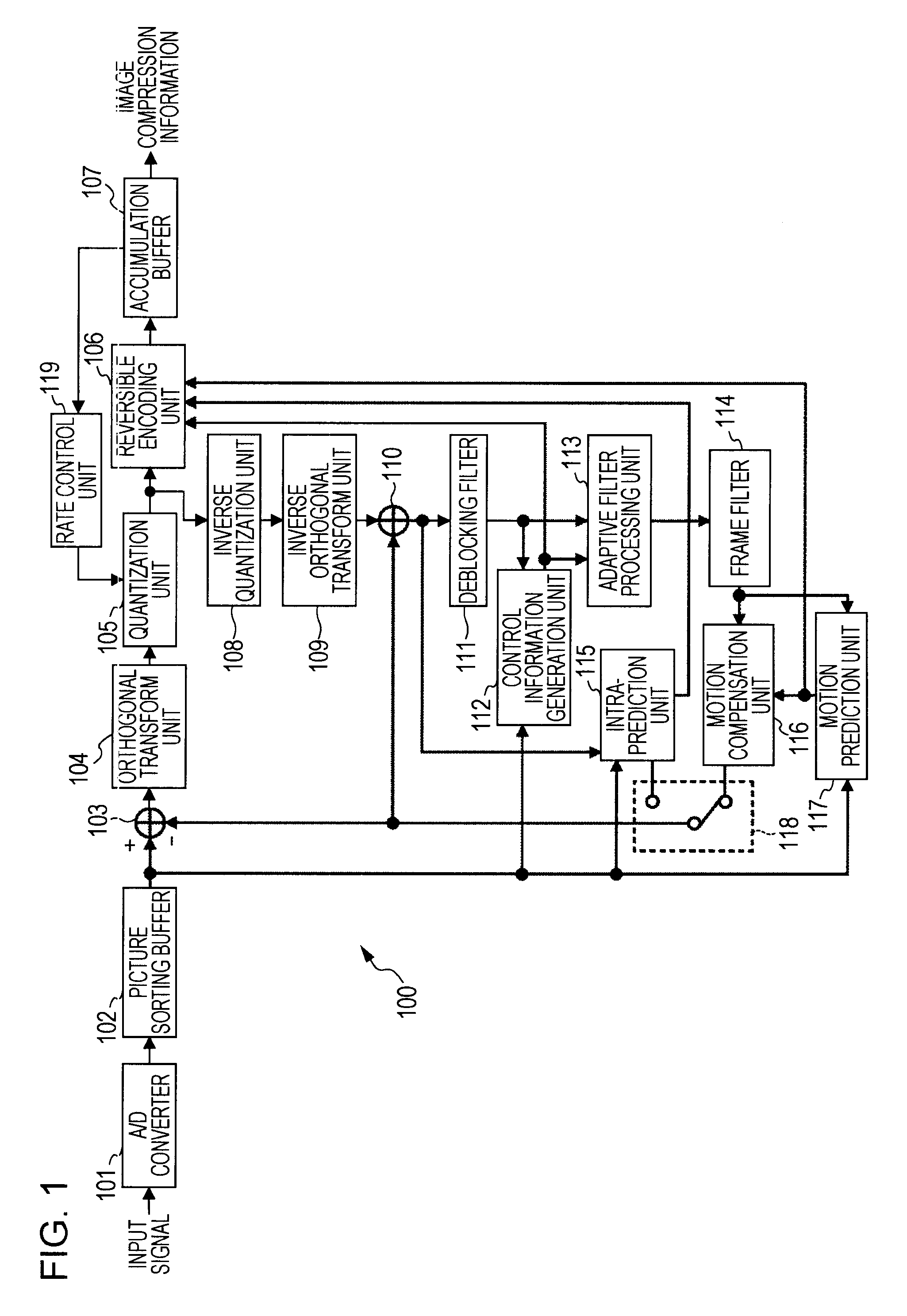

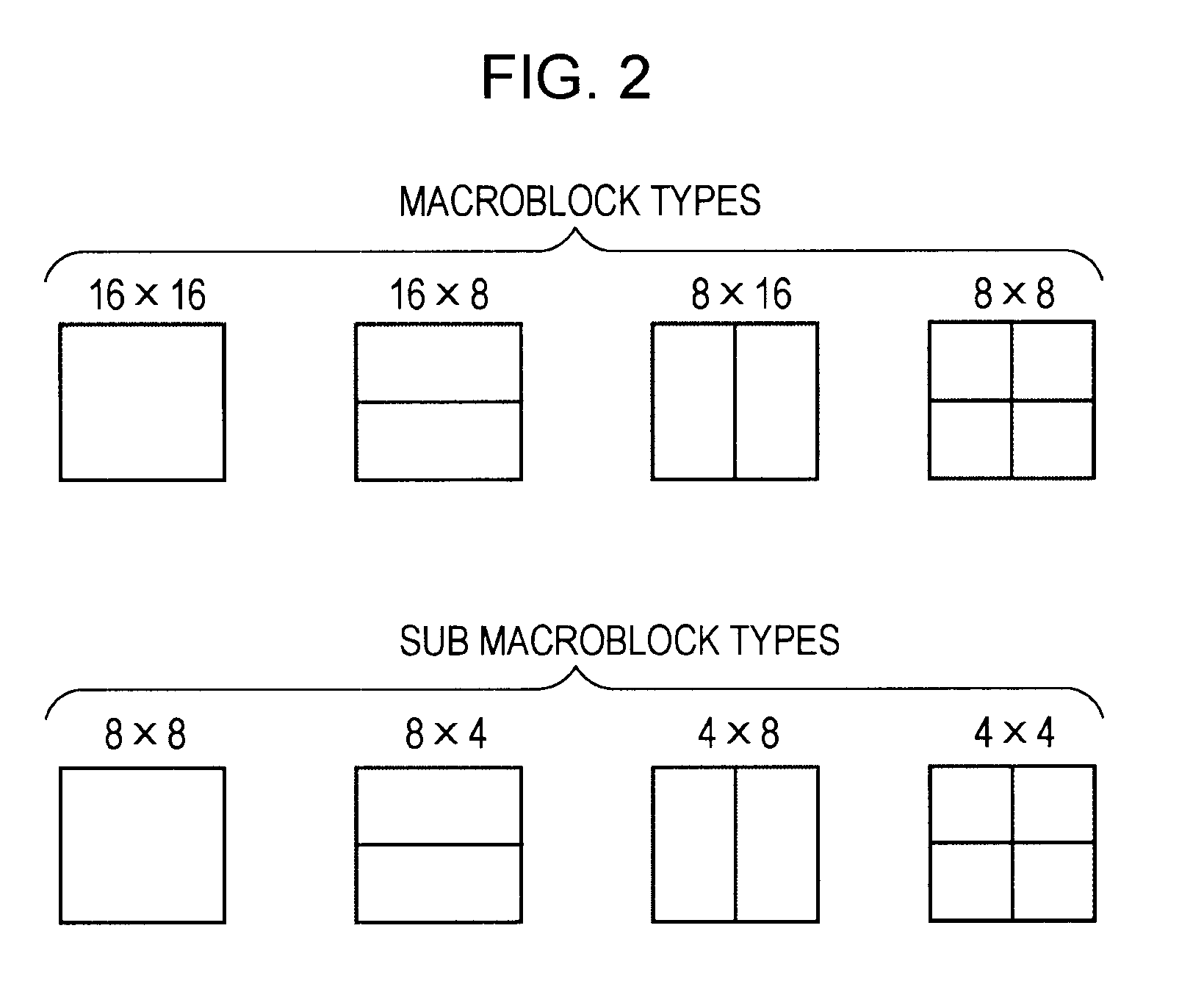

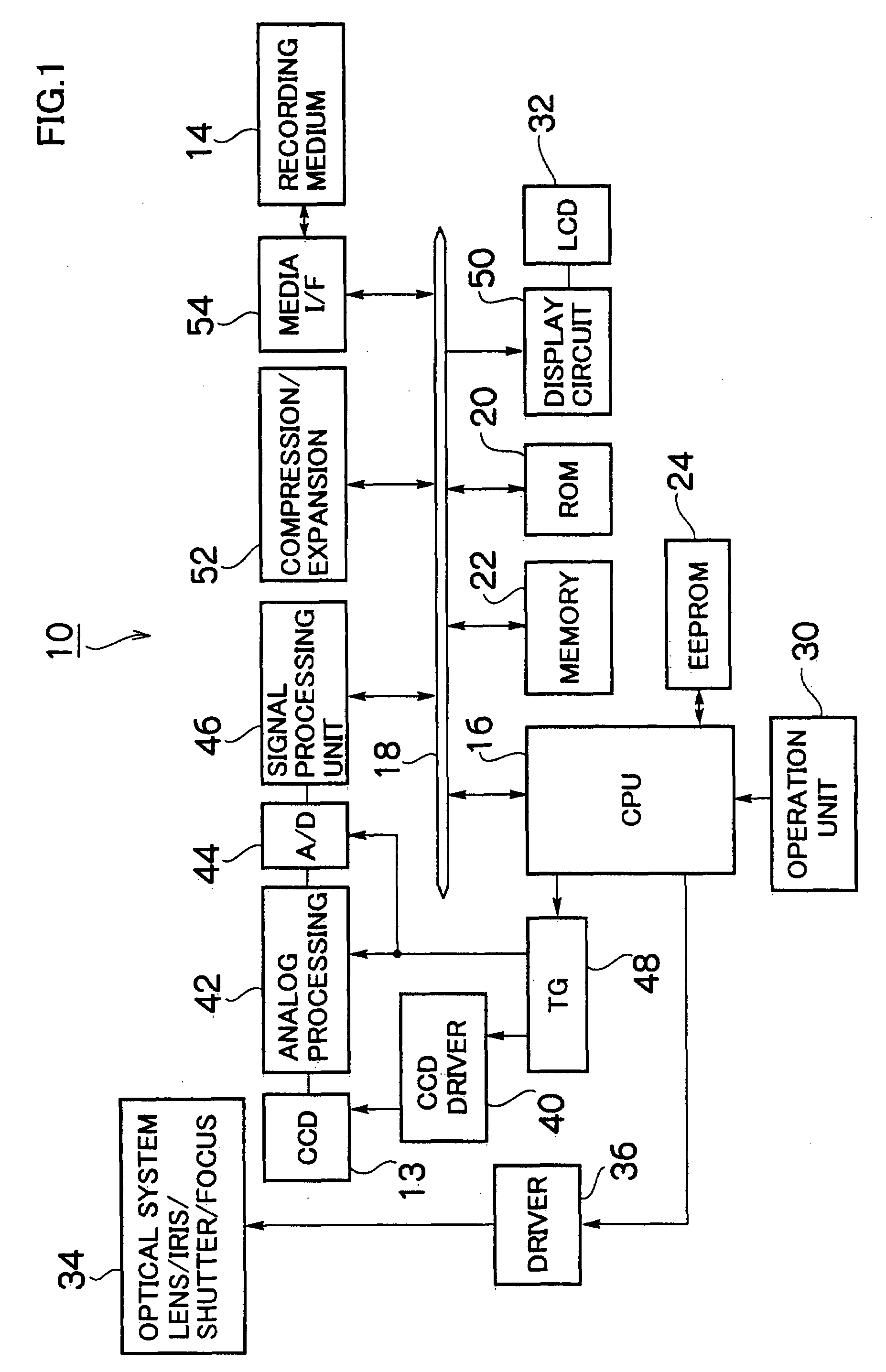

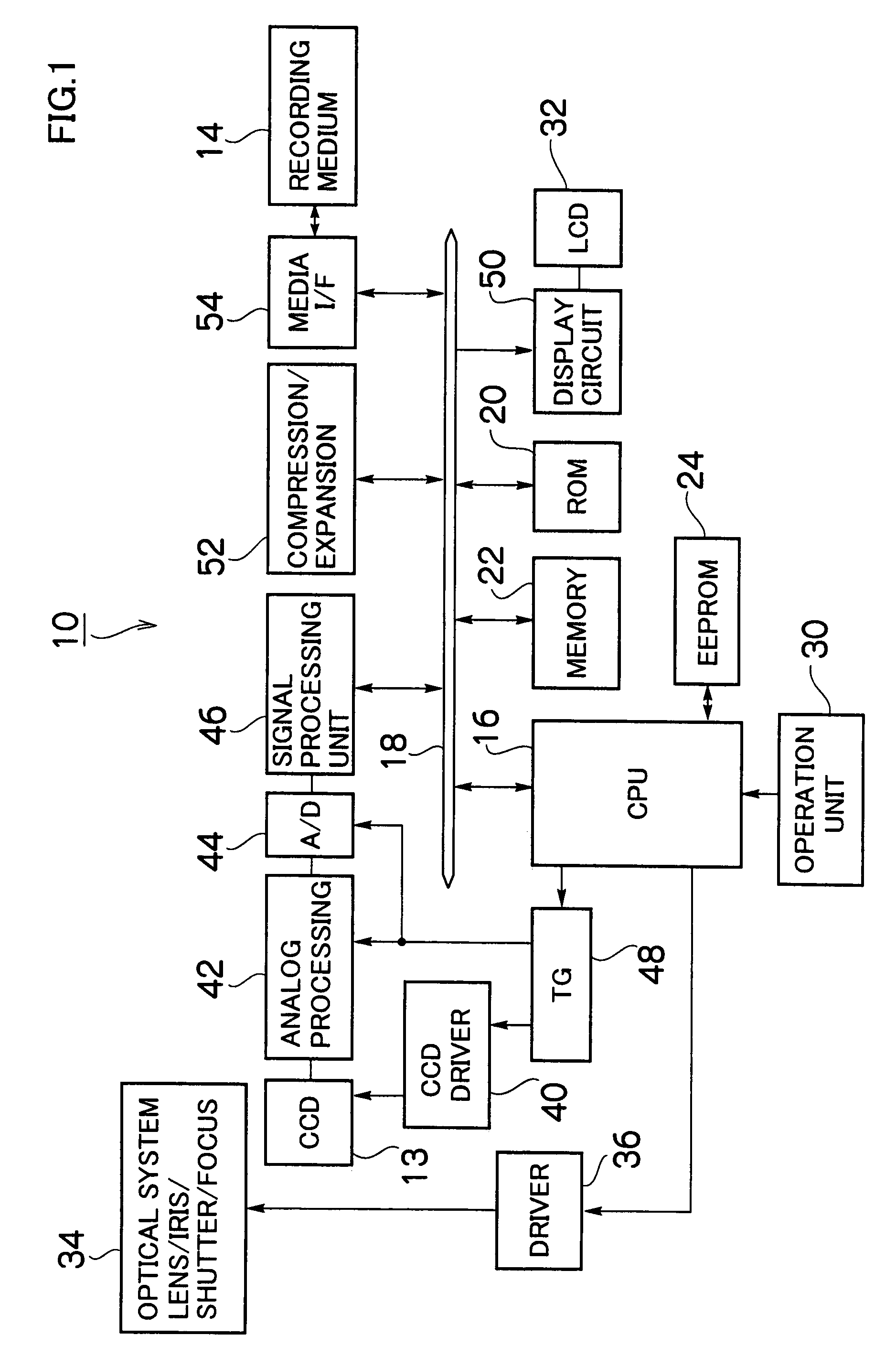

Image processing apparatus and method

ActiveUS20110026600A1Appropriate performanceReduce filter effectColor television with pulse code modulationColor television with bandwidth reductionImaging processingControl unit

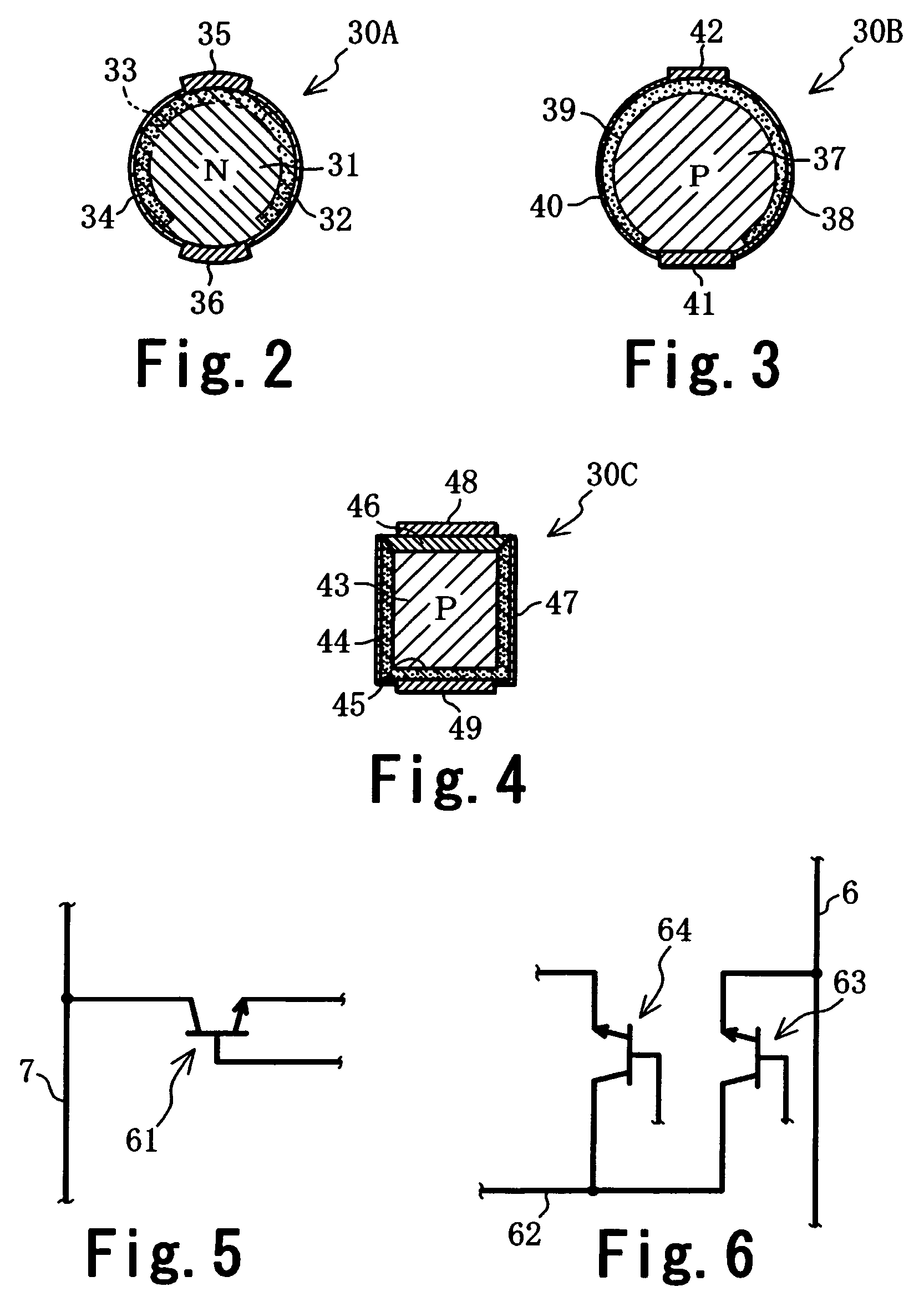

Provided is an image processing apparatus which includes a setting unit assigning a control block, which is a control unit of a filter process that is locally performed with respect to an image, to an initial position of the image determined based on a predetermined reference point; a movement unit moving the control block, which has been assigned to the initial position of the image by the setting unit, a to a position in which the result of the filter process is improved; and a filter processing unit performing the filter process for the respective control blocks which has been moved by the movement unit.

Owner:SONY CORP

Method for preparing flame-proof viscose fiber

InactiveCN101215726ASimple and convenient filteringFilter is not easy to clogFlame-proof filament manufactureMonocomponent cellulose artificial filamentPolymer scienceEmulsion

The invention discloses a process for preparing flame retarding cellulose viscose, which adopts pyrophosphate exchange reaction flame retardant particle whose mean particle diameter is <= 1.0um, non-ionic surface active agent, dispersing agent and solvent water to mix and obtain flame retardant emulsion, each percentage by weight is pyrophosphate exchange reaction flame retardant 20-45 wt%, non-ionic surface active agent 5-10 wt% and dispersing agent 0.5-1.0 wt%, and residue is solvent water. The process for preparation comprises adding pyrophosphate exchange reaction flame retardant of flame retardant emulsion which is corresponded to alpha cellulose 15-30 % into spinning original liquid which is filtered to mix, shaping spinning by adopting spinning bath which is low acid, low salt, low temperature and high zinc. The spinning original liquid of the invention has simple and convenient preparation, fiber does not contain halogen elements, which avoids environmental pollution, when in burning, the invention is not melted, while charring only happens to keep the original shape of fiber, the invention prevents dripping which is melted in high temperature from scalding human body, and flame retardant is distributed evenly in adhesive, which can not smolder after leaving fire and easy to be self-extinguished.

Owner:CHTC HELON

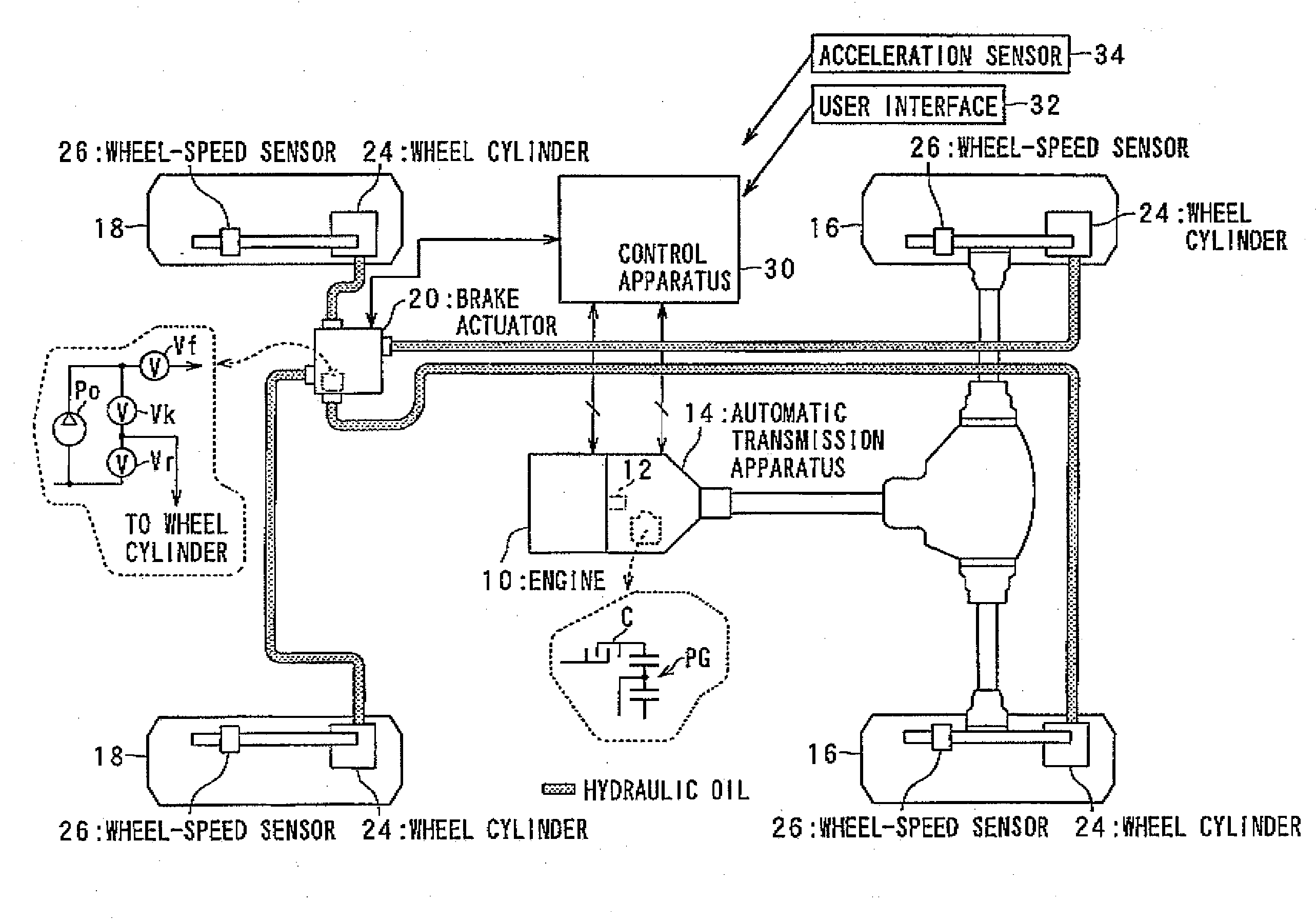

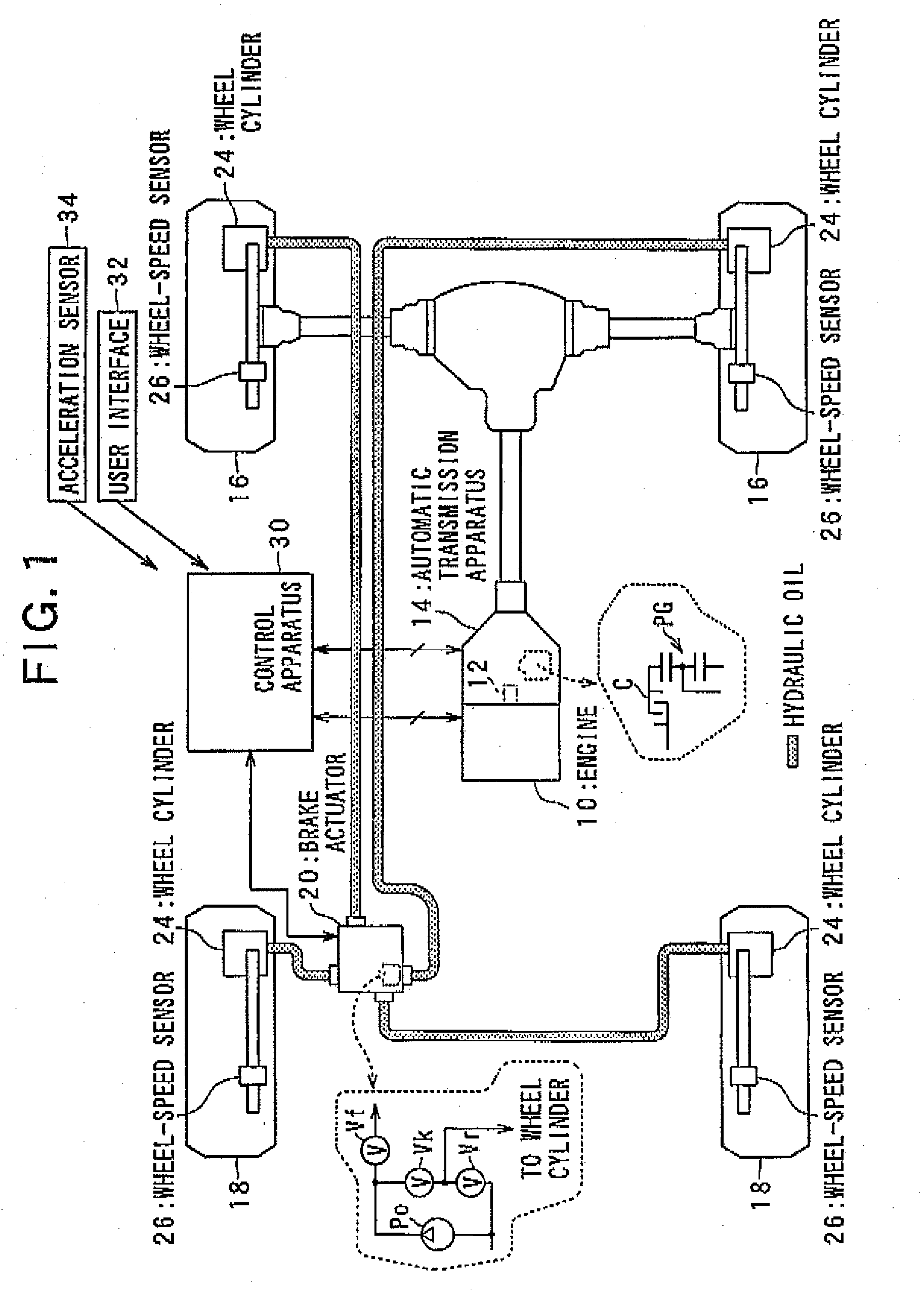

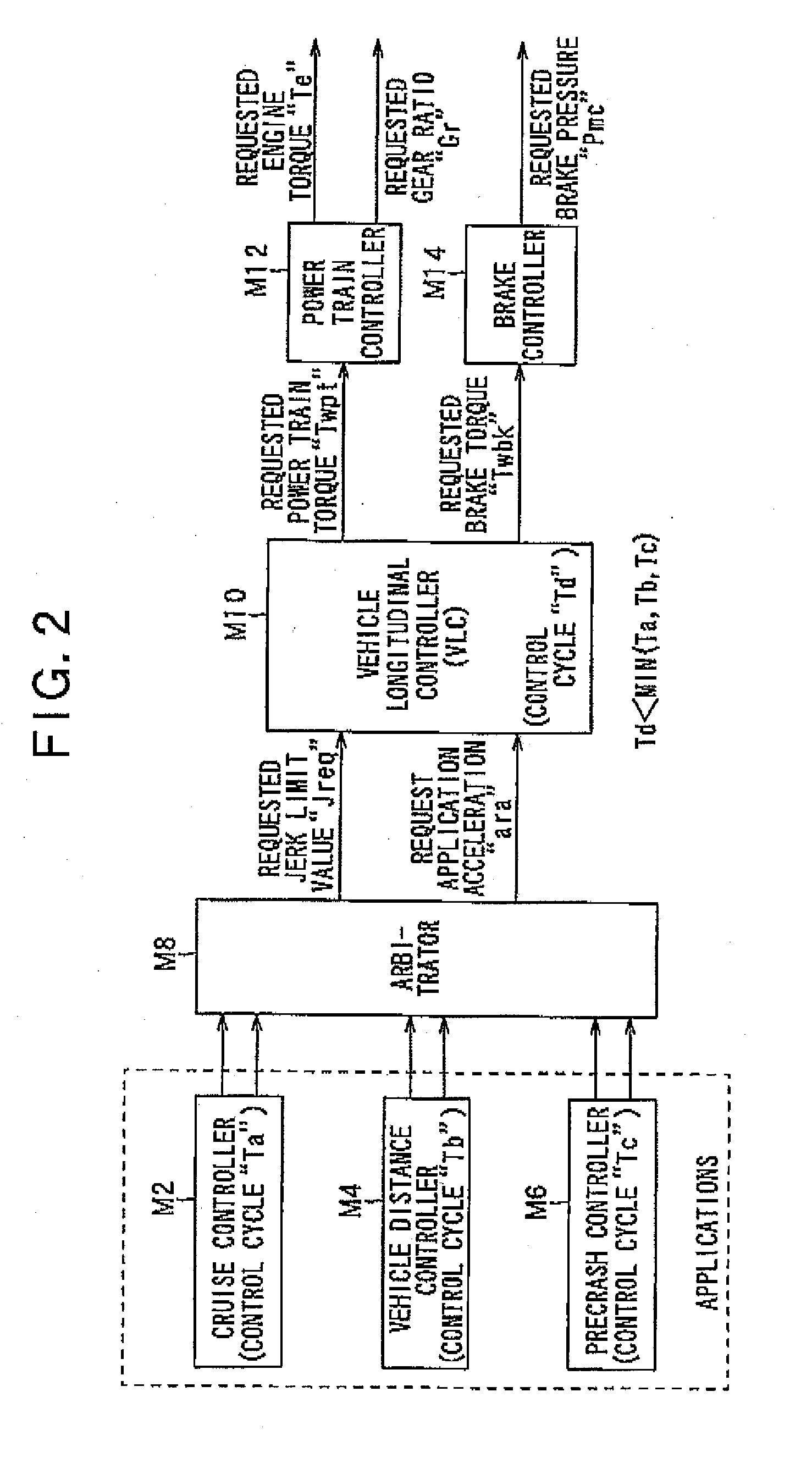

Apparatus for estimating road surface gradient and vehicular control apparatus using the same

InactiveUS20090043473A1Improve travel conditionsImprove ride qualityAnalogue computers for trafficExternal condition input parametersEngineeringRoad surface

An apparatus is provided to estimate a gradient of a road surface on which a vehicle travels. The apparatus comprises acquisition, estimation, and compensation members. The acquisition member acquires at least one of acceleration of the vehicle calculated on changes in a travel speed of the vehicle and acceleration sensed from a force applied to the vehicle. The estimation means estimates the gradient of the road surface based on the acquired acceleration. The compensation member compensates the acquired acceleration in terms of influence of noise superposed on the acceleration, depending on an operational condition of the vehicle. The compensated acceleration is used by the estimation. The compensation is carried out by cutting off the noise by a filter, for example.

Owner:DENSO CORP

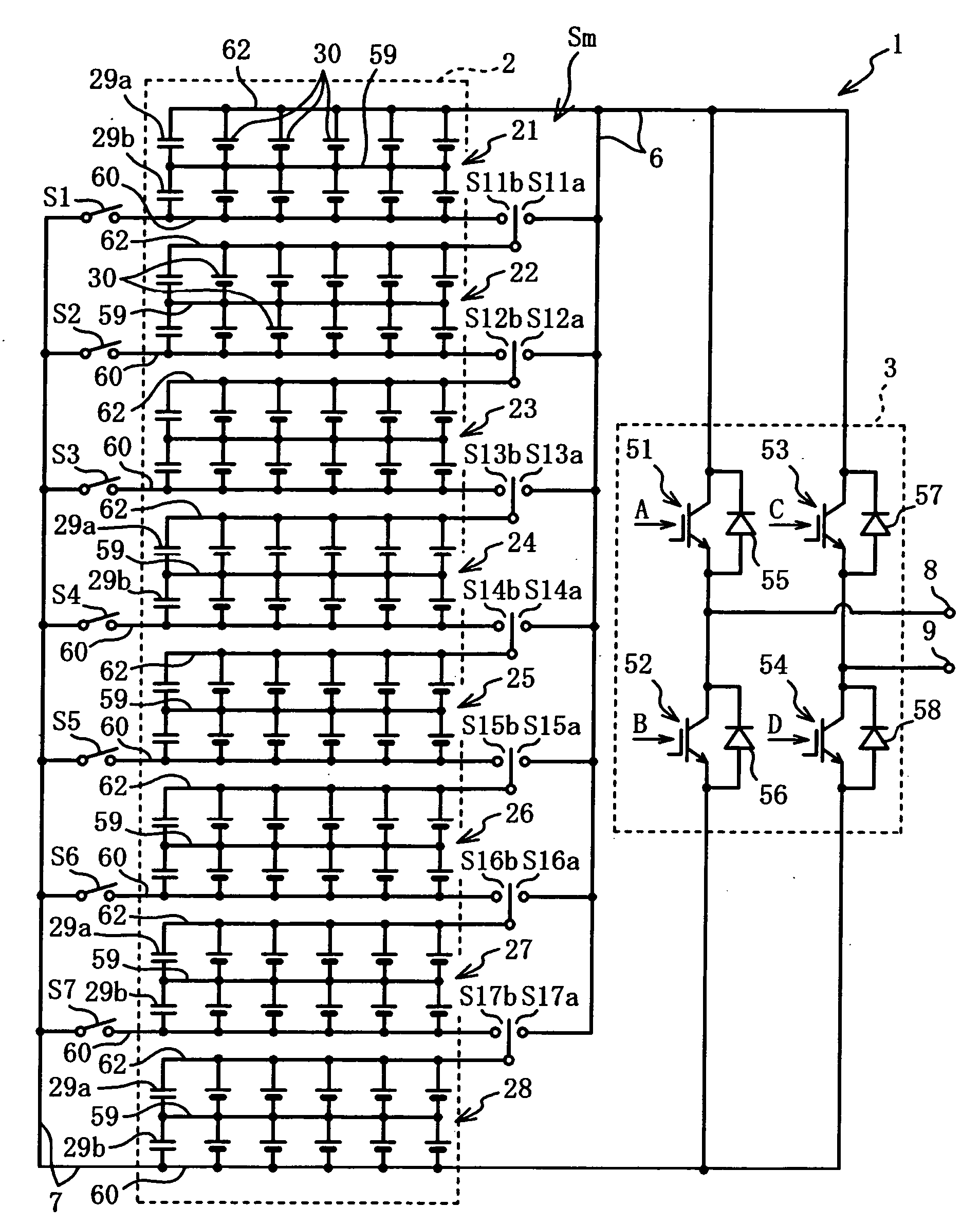

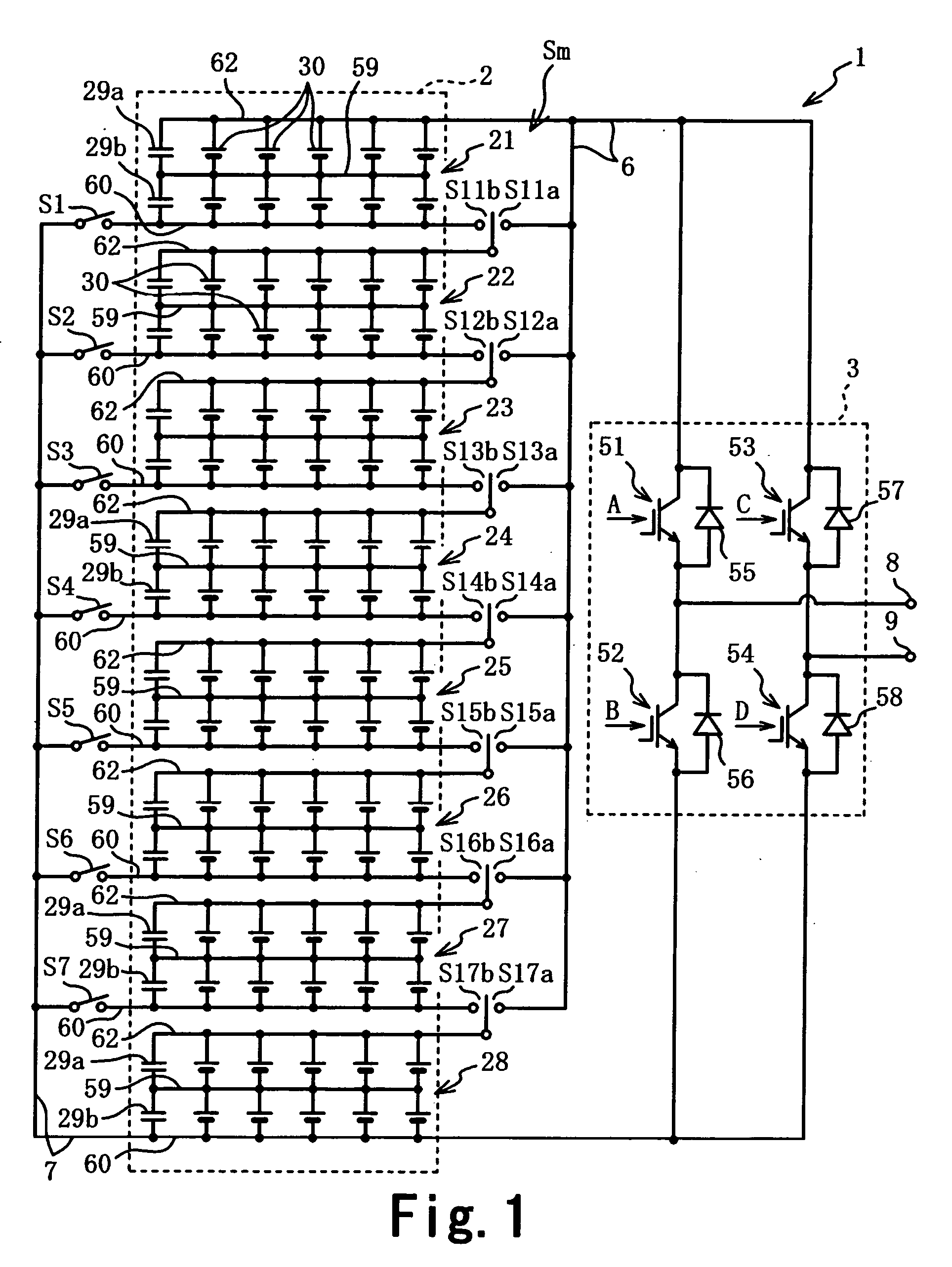

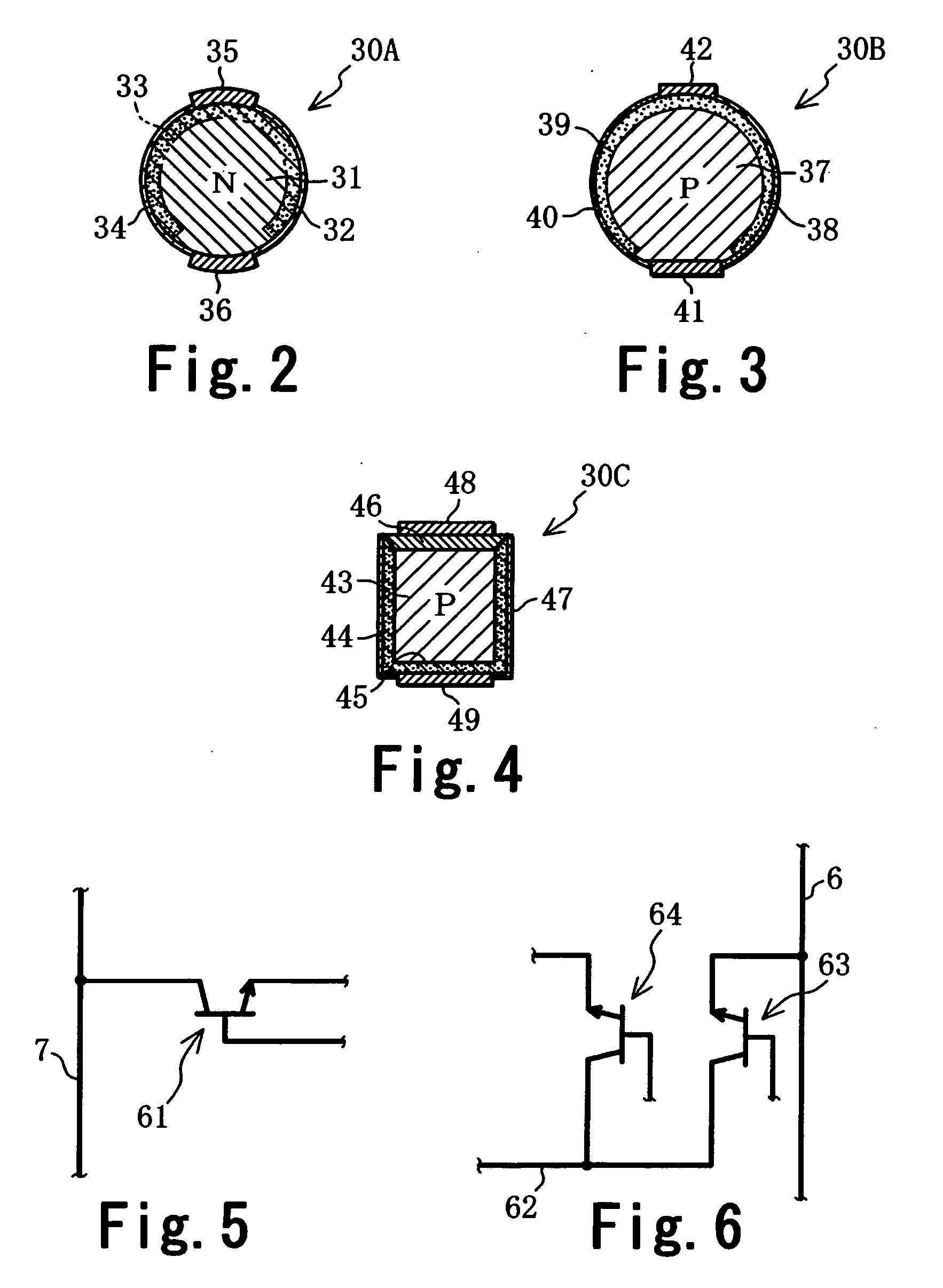

Power generation system

InactiveUS20070034246A1Efficient outputIncrease profitBatteries circuit arrangementsFuel cells groupingEngineeringAC power

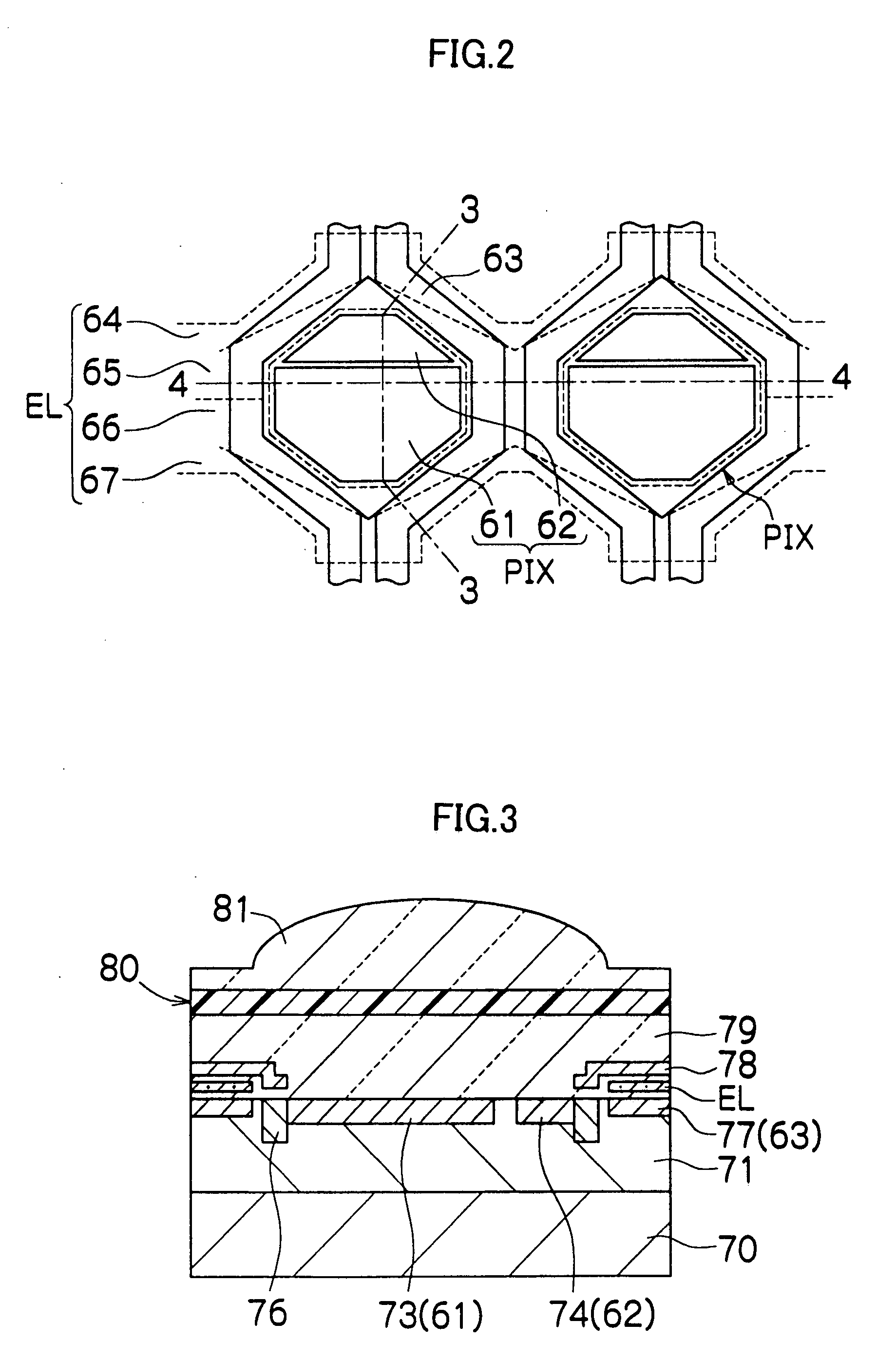

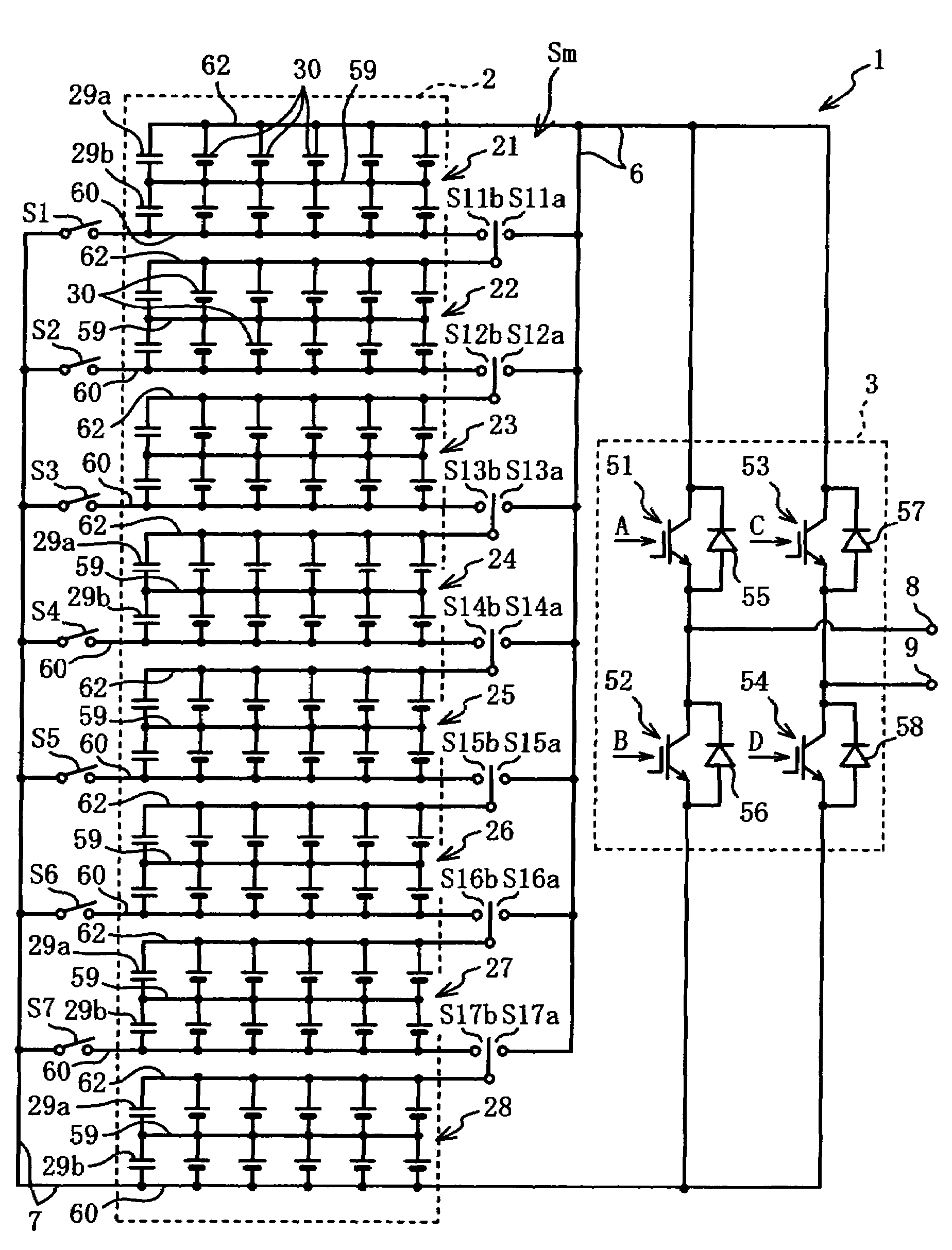

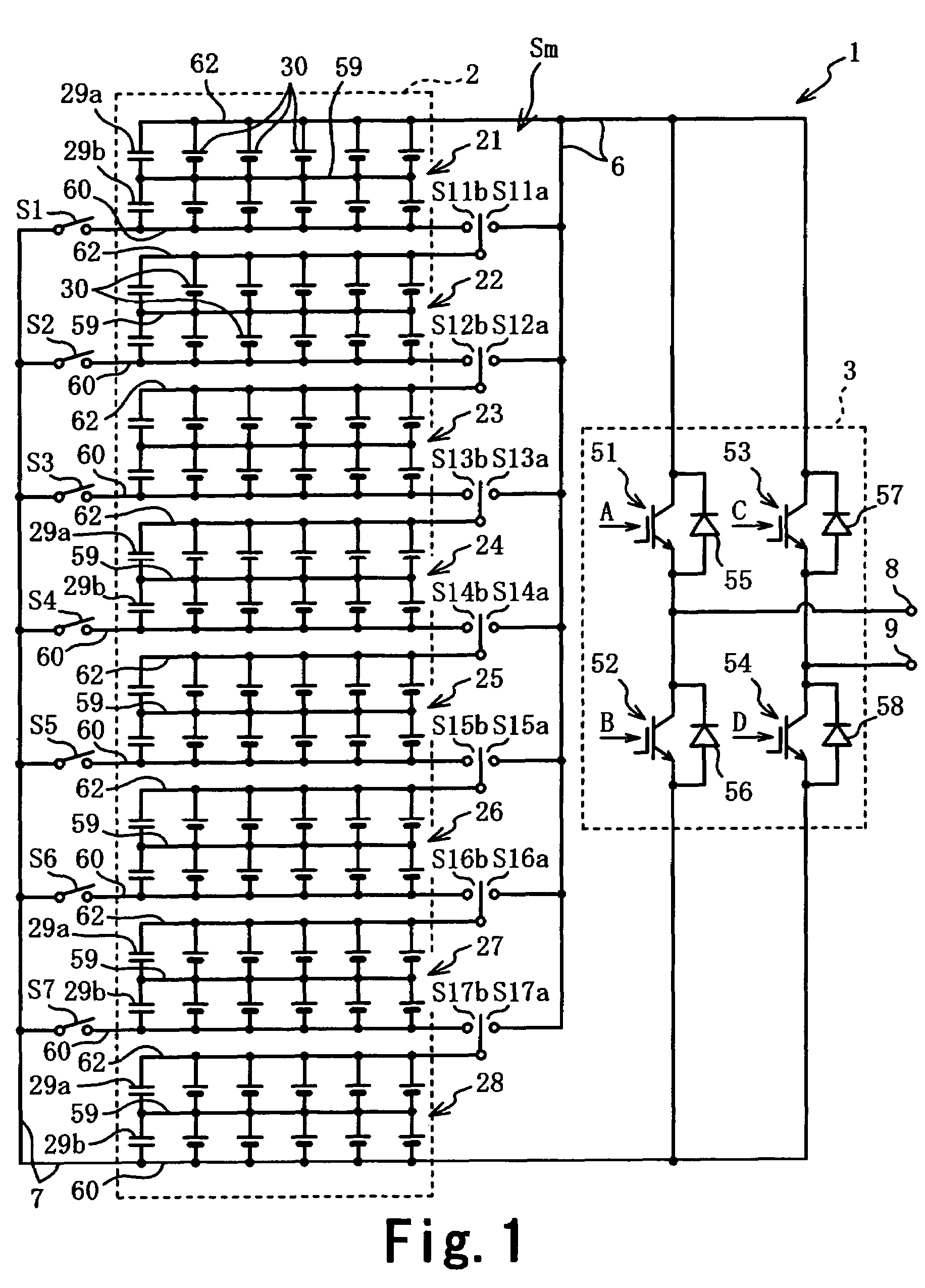

A power generating system 1 comprises a power generator 2 generating DC power, and an inverter circuit 3 for converting DC power into AC power; the power generator 2 comprises a plurality of power generating modules 21-28 each comprising a plurality of power generating units 30 and at least one electric storage means connected to each of the plurality of power generating modules 21-28. A plurality of first switch means S11a-17a connect / disconnect each of the positive electrodes 62 of the plurality of power generating modules 22-28 to / from a positive bus 6, a plurality of second switch means S11b-17b connect / disconnect each of the positive electrodes 62 of the plurality of power generating modules 22-28 to / from the negative electrodes 60 of the power generating modules 21-27 contiguous to the one side, a plurality of third switch means S1-S7 connect / disconnect each of the negative electrodes 60 of the plurality of power generating modules 21-27 to / from a negative bus 7, and the DC output voltage can be increased / decreased stepwise by switching the switch means S1-S7, S11a-17a and S11b-S17b.

Owner:SPHELAR POWER

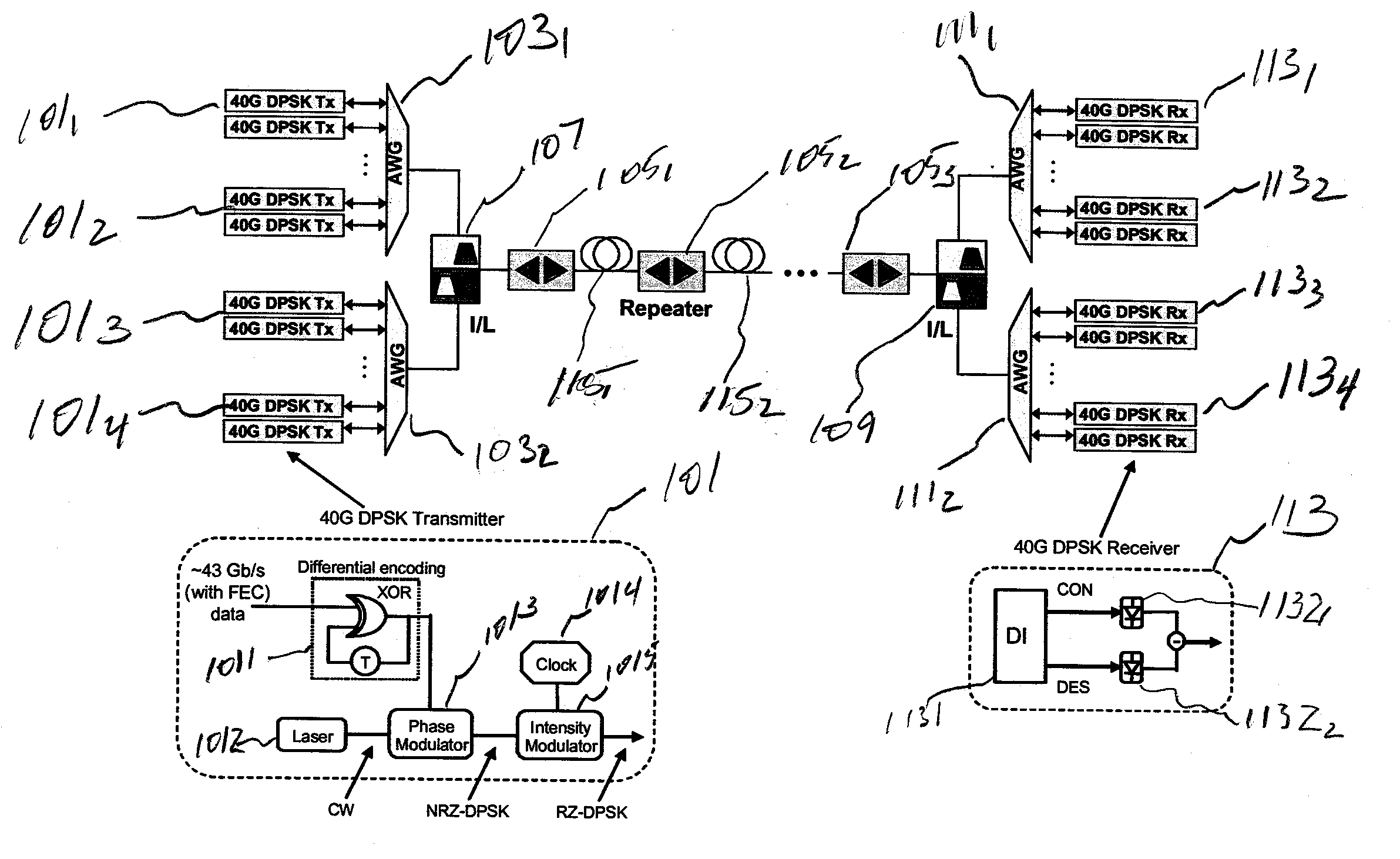

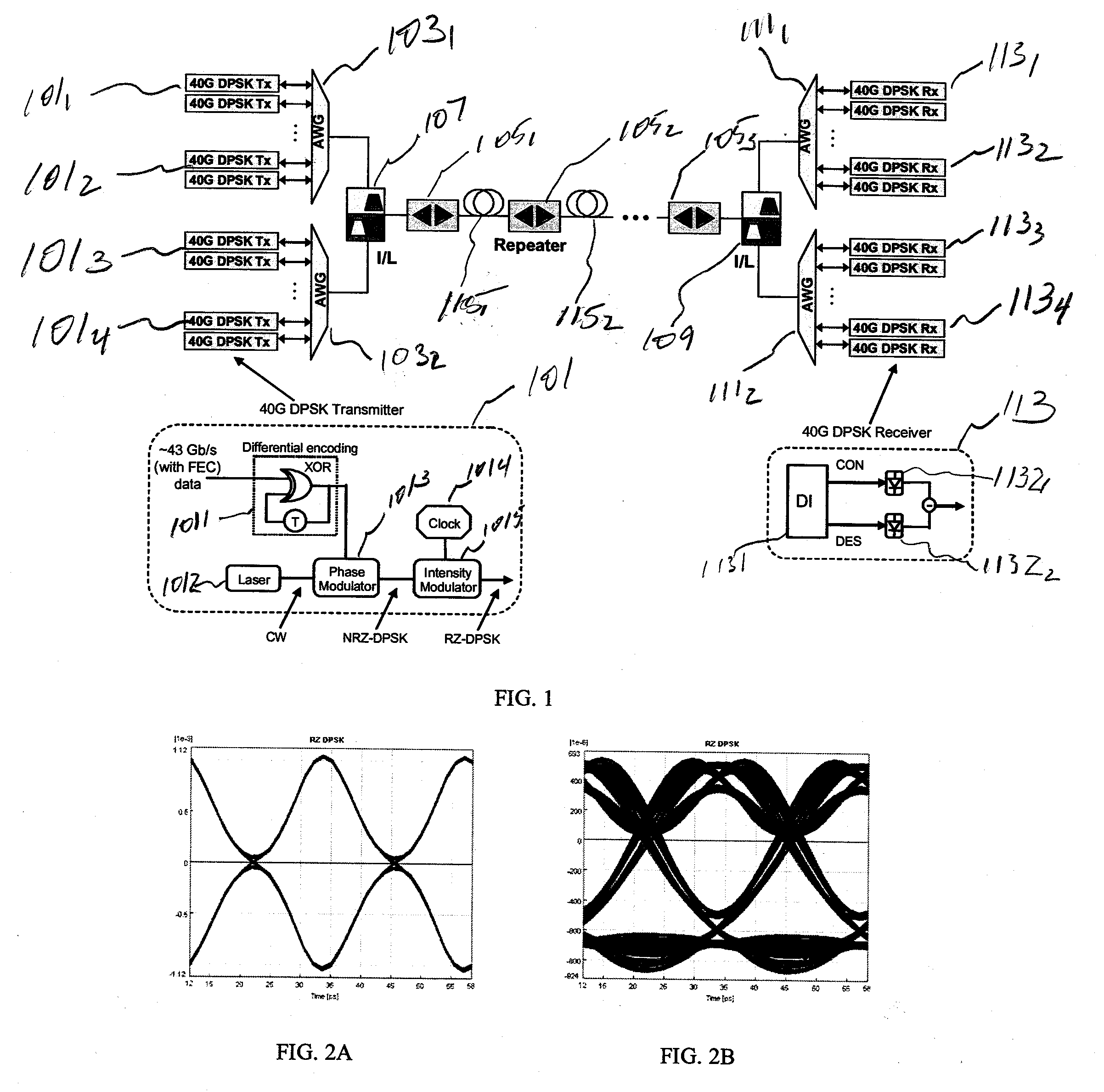

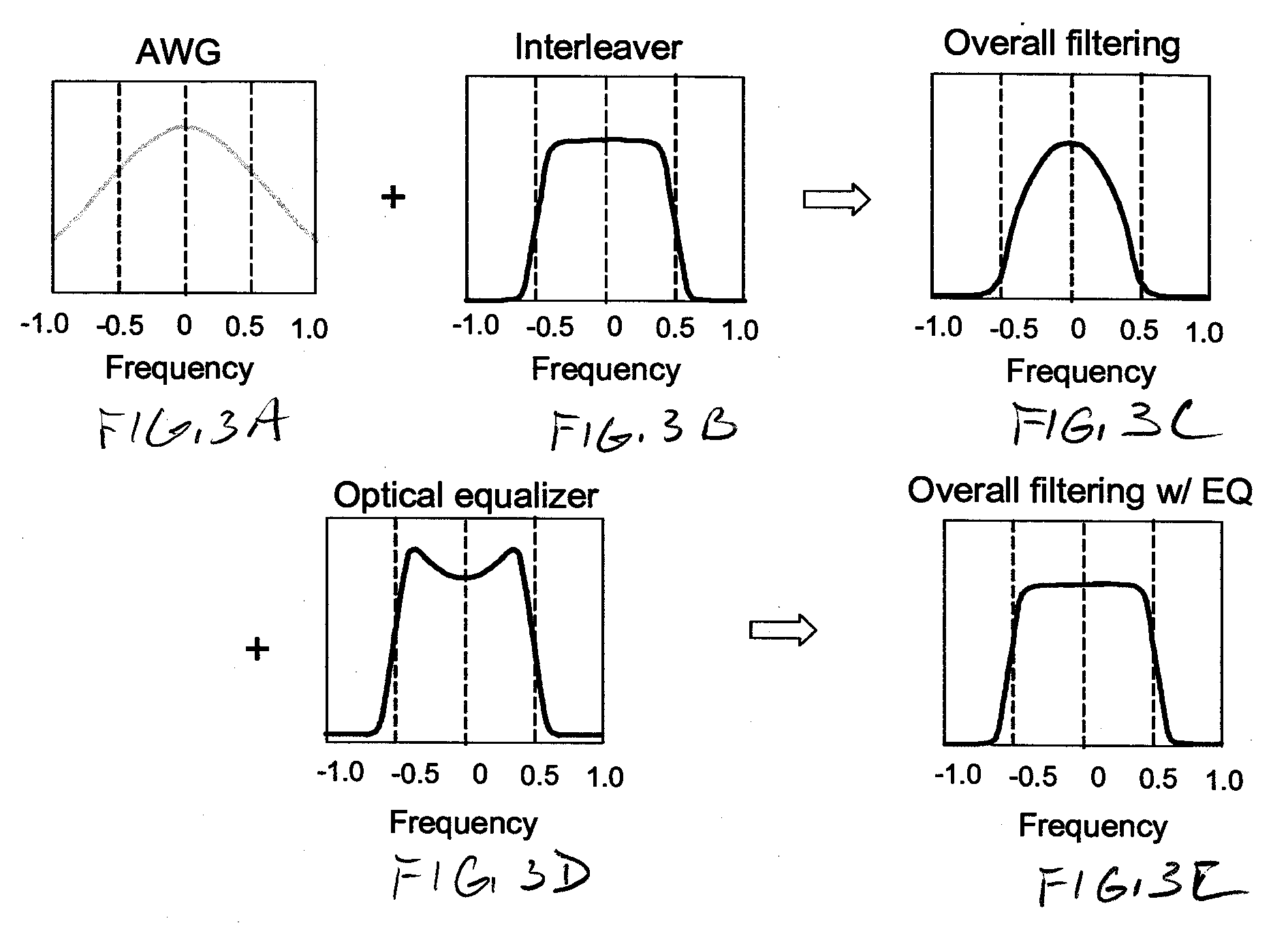

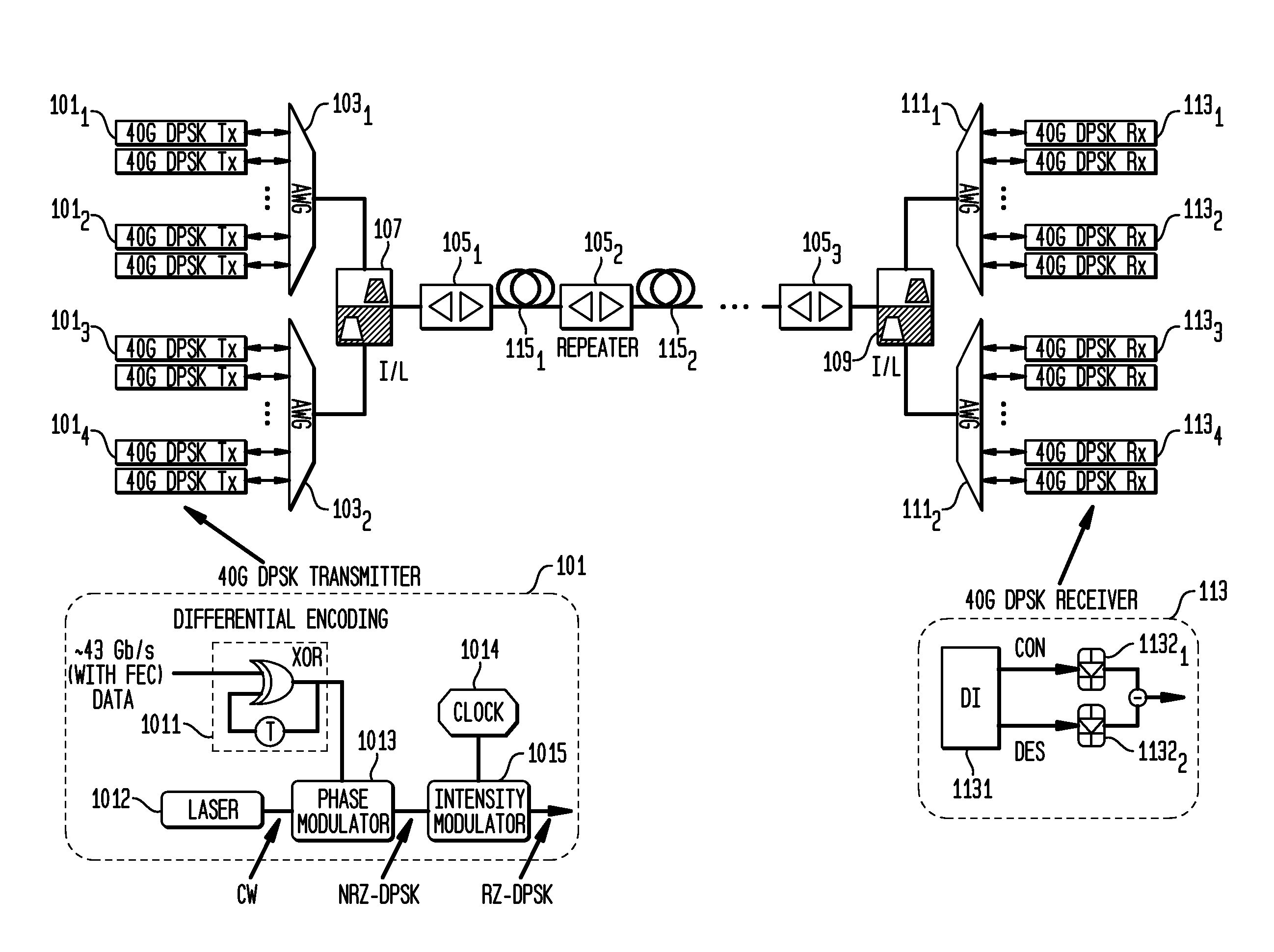

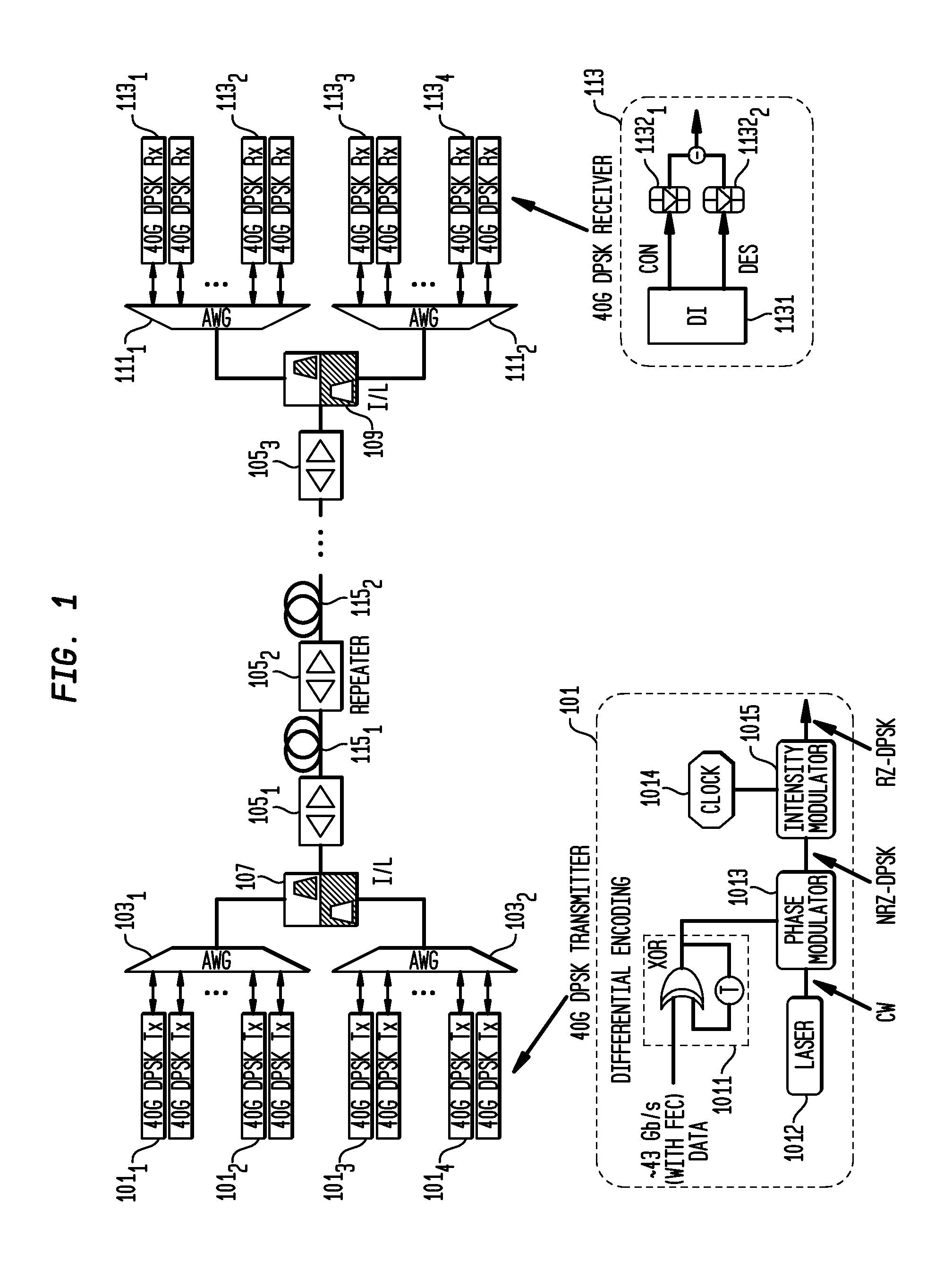

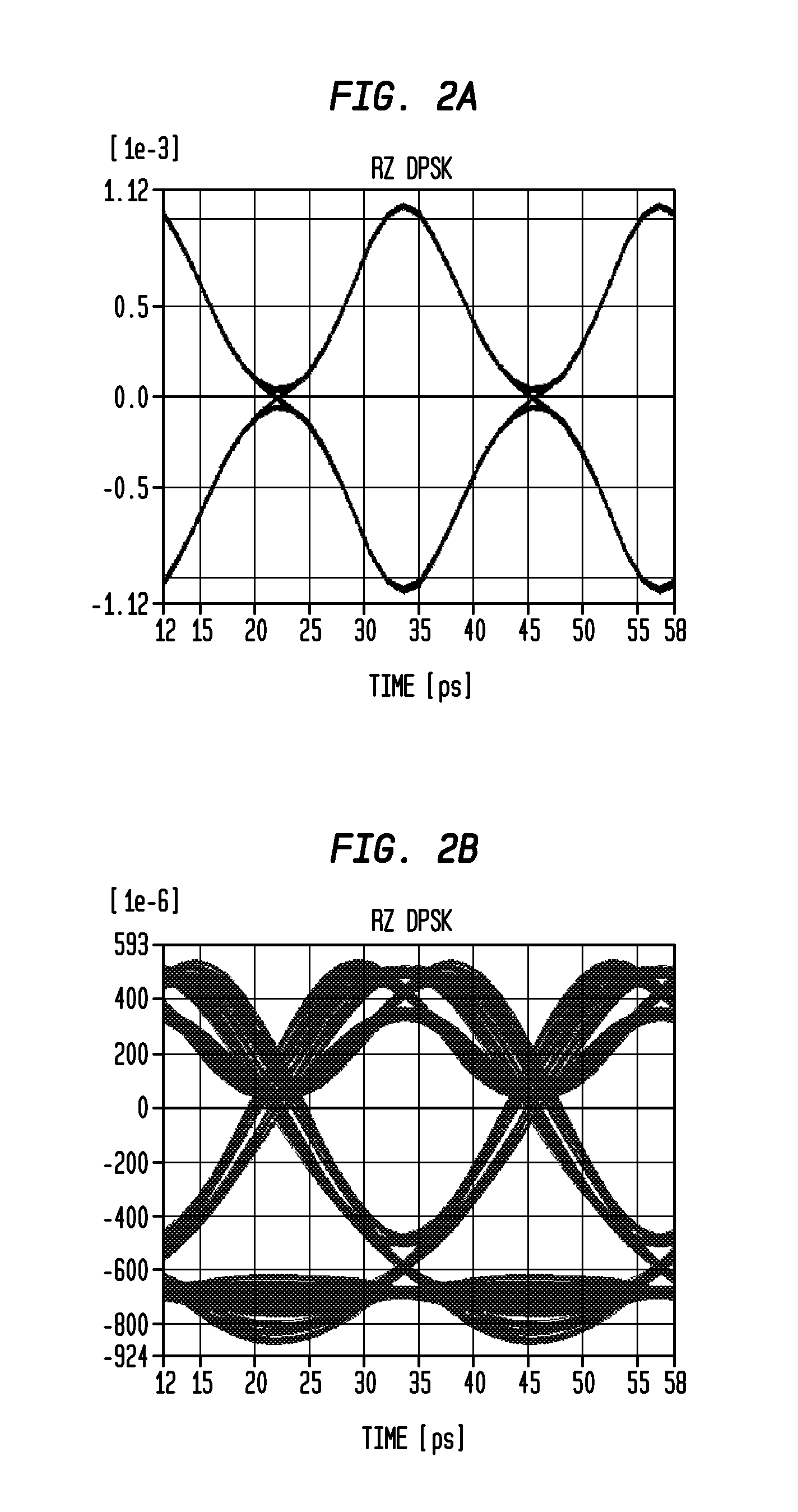

Inter-Symbol Interference-Suppressed Colorless DPSK Demodulation

An optical device includes an interferometer for a received optical differential phase shift keying DPSK signal, and an equalizer integrated with the interferometer in a manner for reducing from optical filtering effects an interference by signal bits of the DPSK signal with signal bits of a contiguous DPSK signal. The interferometer is a Michelson delay interferometer type, but can also be a Mach-Zehnder delay interferometer type on fiber, waveguide or other optical structure. The equalizer is a Fabry-Perot type equalizer, but can be a ring resonator type or a fiber based equalizer.

Owner:NEC CORP +1

Method for preventing disease of konjac

InactiveCN102630401APrevent diseaseImprove disease resistancePlant protectionSeed immunisationDiseaseSoil treatment

The invention relates to a method for preventing disease of konjac, and the method comprises the following five aspects of: konjac seed treatment, soil treatment, sowing pre-treatment, a sowing method and field management. The method disclosed by the invention has the beneficial effects that the konjac seed treatment is carried out, thus diseased konjac seeds can be avoided from being mixed and the konjac seeds can be prevented from being infected with a disease; the soil treatment is carried out, thus harmful bacteria can be avoided from being carried in soil, the harmful bacteria in the soil can be killed, and meanwhile the living environment of the harmful bacteria can be destroyed; the sowing pre-treatment is carried out, thus the diseased konjac seeds can be avoided from being mixed, the disease resistance of the konjac seeds can be enhanced, and sprouting and sowing can be used for reducing the opportunity that the harmful bacteria are immersed into the konjac seeds; interplanting can be used for reducing the survival chance of the harmful bacteria and filtering part of sunlight, and a base fertilizer is applied well, thus top dressing can be reduced, and the influence on a konjac plant can be reduced; the filed management can be used for preventing the harmful bacteria from intruding in the whole journey; and a series of comprehensive methods can be used for preventing the disease of the konjac in every aspect.

Owner:重庆天娇农业开发有限公司

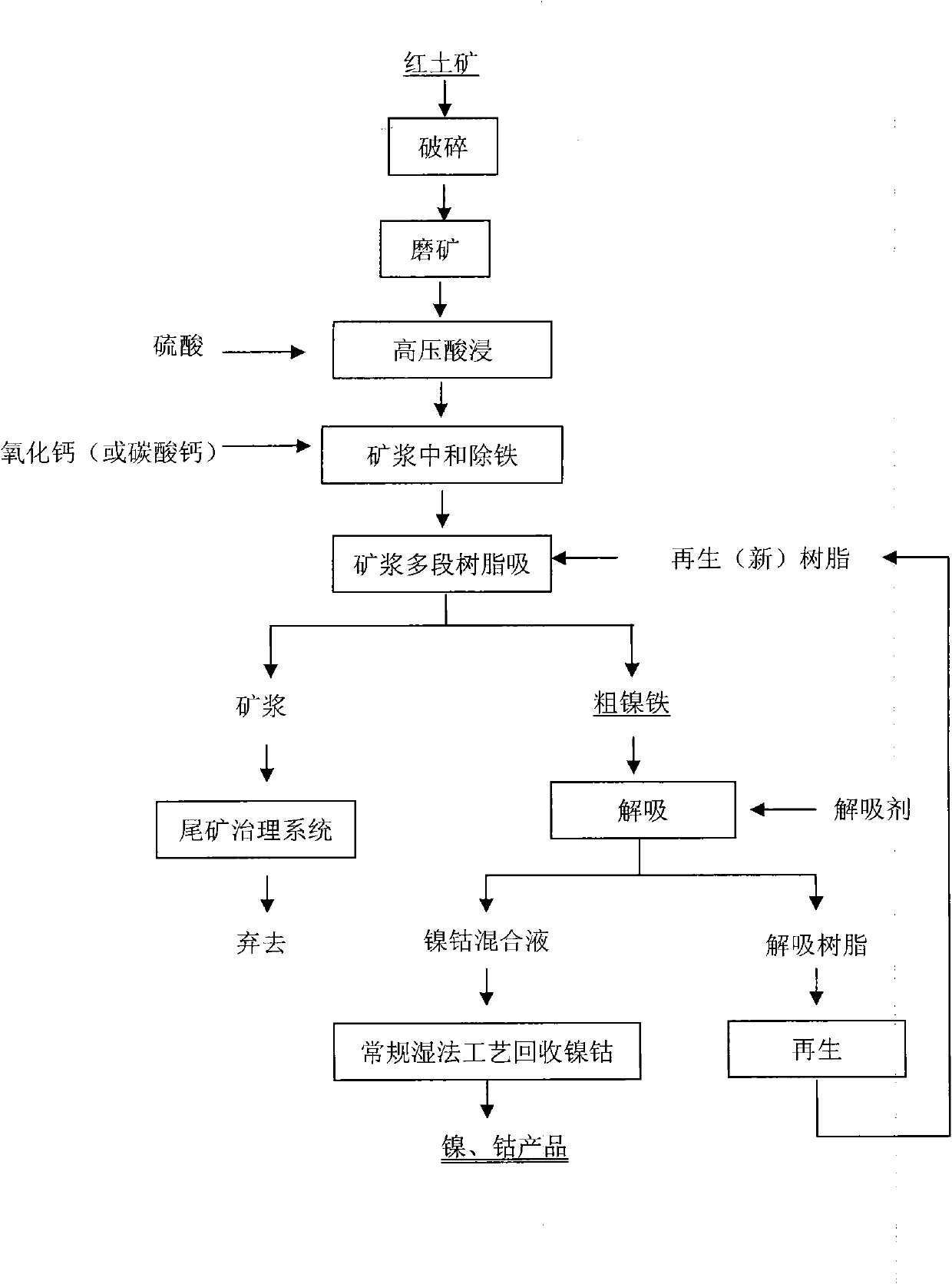

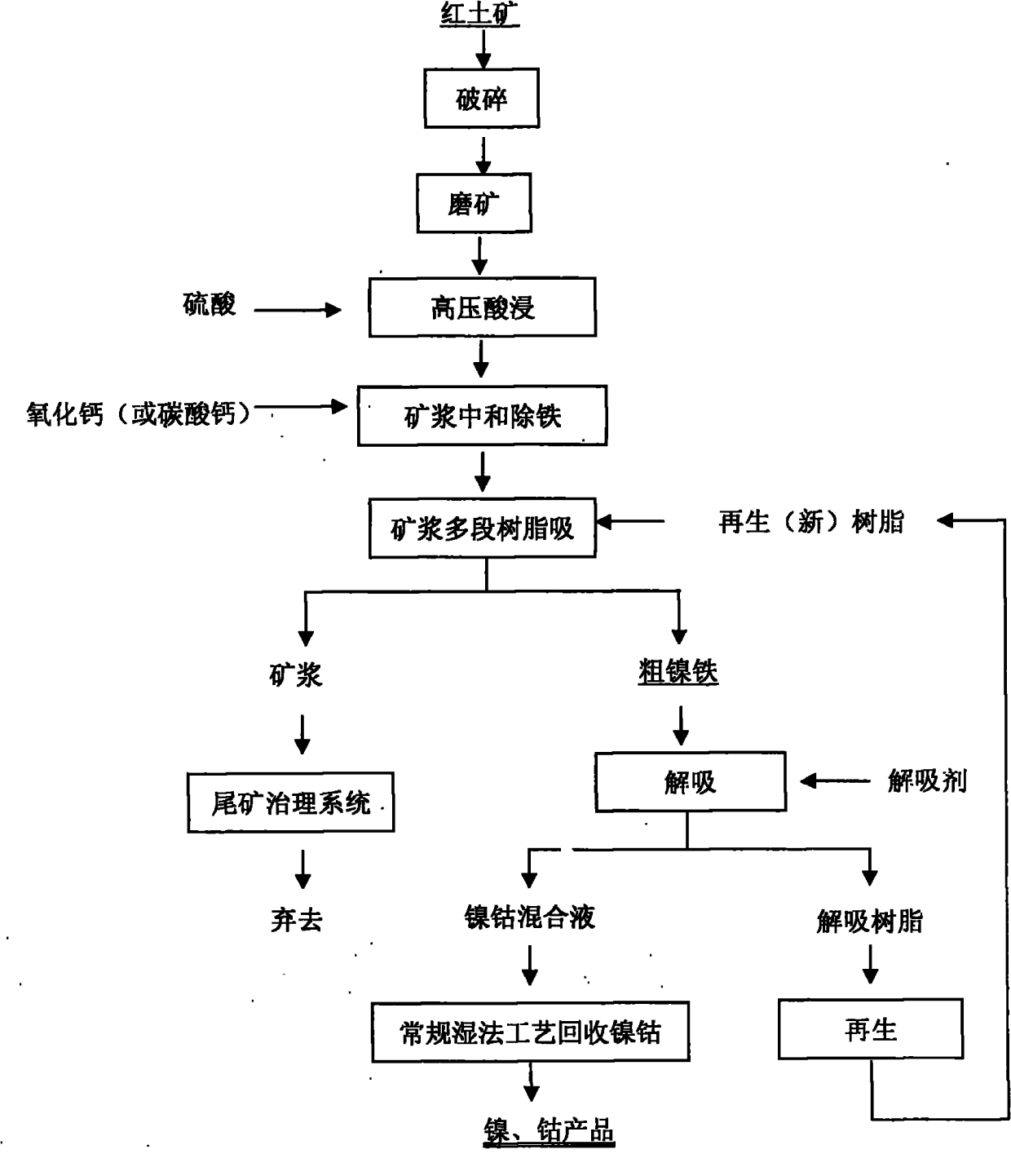

Process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology

ActiveCN101974685AReduce governance costsReduce the burden of separationProcess efficiency improvementDesorptionLaterite

The invention relates to a process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology. The process comprises the following steps of: milling the laterite, and adding sulfuric acid into the milled laterite to perform high-pressure leaching; pouring the ore pulp after the leaching into a reaction kettle for neutral impurity removal; directly pouring the ore pulpafter the impurity removal into an adsorption tank to perform resin adsorption; adopting multilevel counter current absorption to perform desorption on the loaded resin so as to obtain pure nickel and cobalt mixed solution; and performing extraction separation to obtain a nickel-cobalt product. The resin can be used repeatedly after regeneration, the damaged resin is less, the service life of theresin is long, the desorption of the loaded resin and the regeneration of a poor resin are performed at normal temperature and normal pressure and are simple and easy to operate without a pressure vessel and heat regeneration device, thereby saving energy resources and reducing equipment investment. The ore pulp after adsorption is uniformly neutralized to reduce the tailings treating cost. The process shortens the technological process, reduces the liquid-solid separation burden, and reduces a great number of washing and filtering process steps, thereby reducing the production energy consumption and reducing the production cost. The process is simple, and the recovery rate of nickel and cobalt is over 90 percent.

Owner:JILIN JIEN NICKEL IND +1

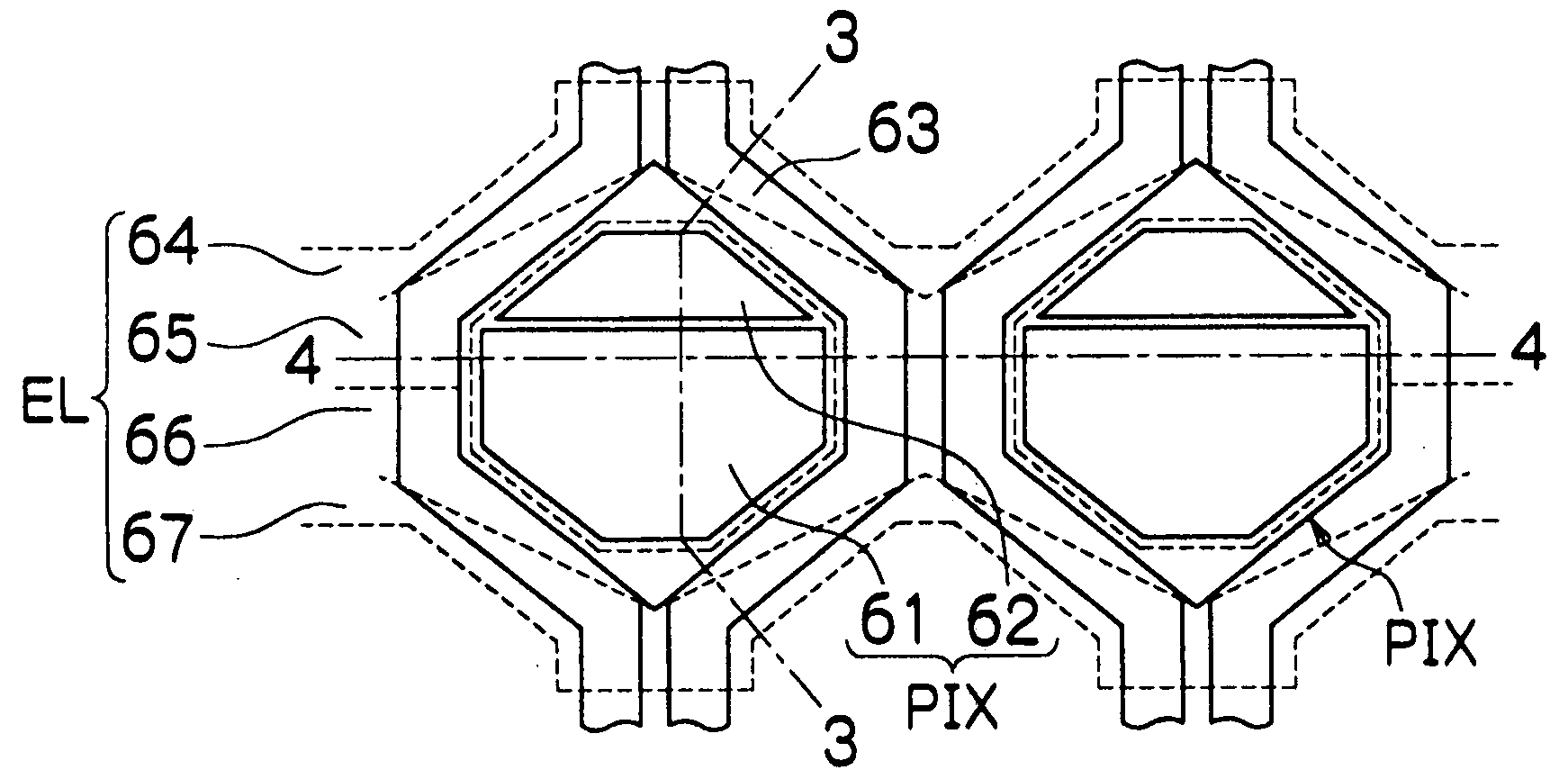

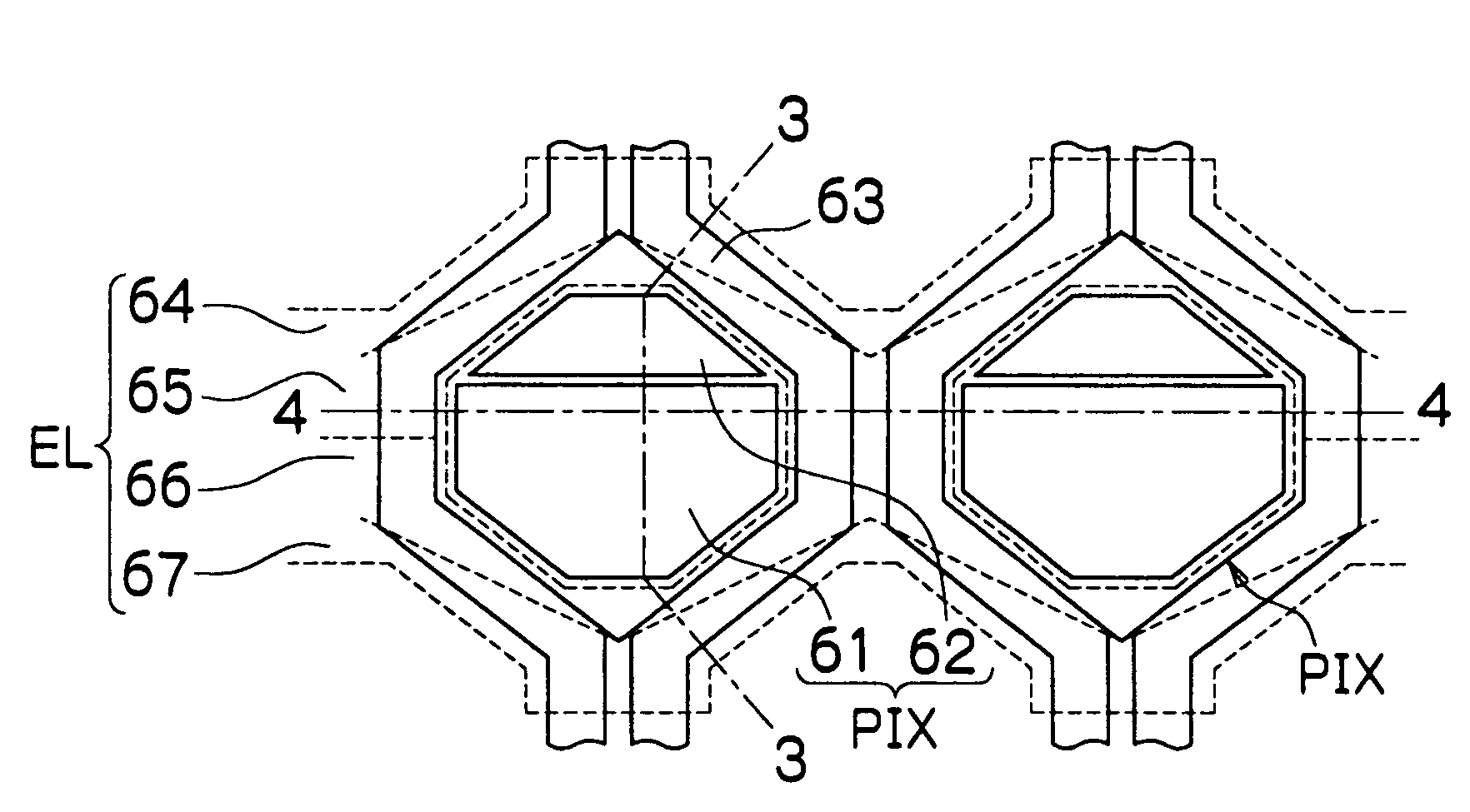

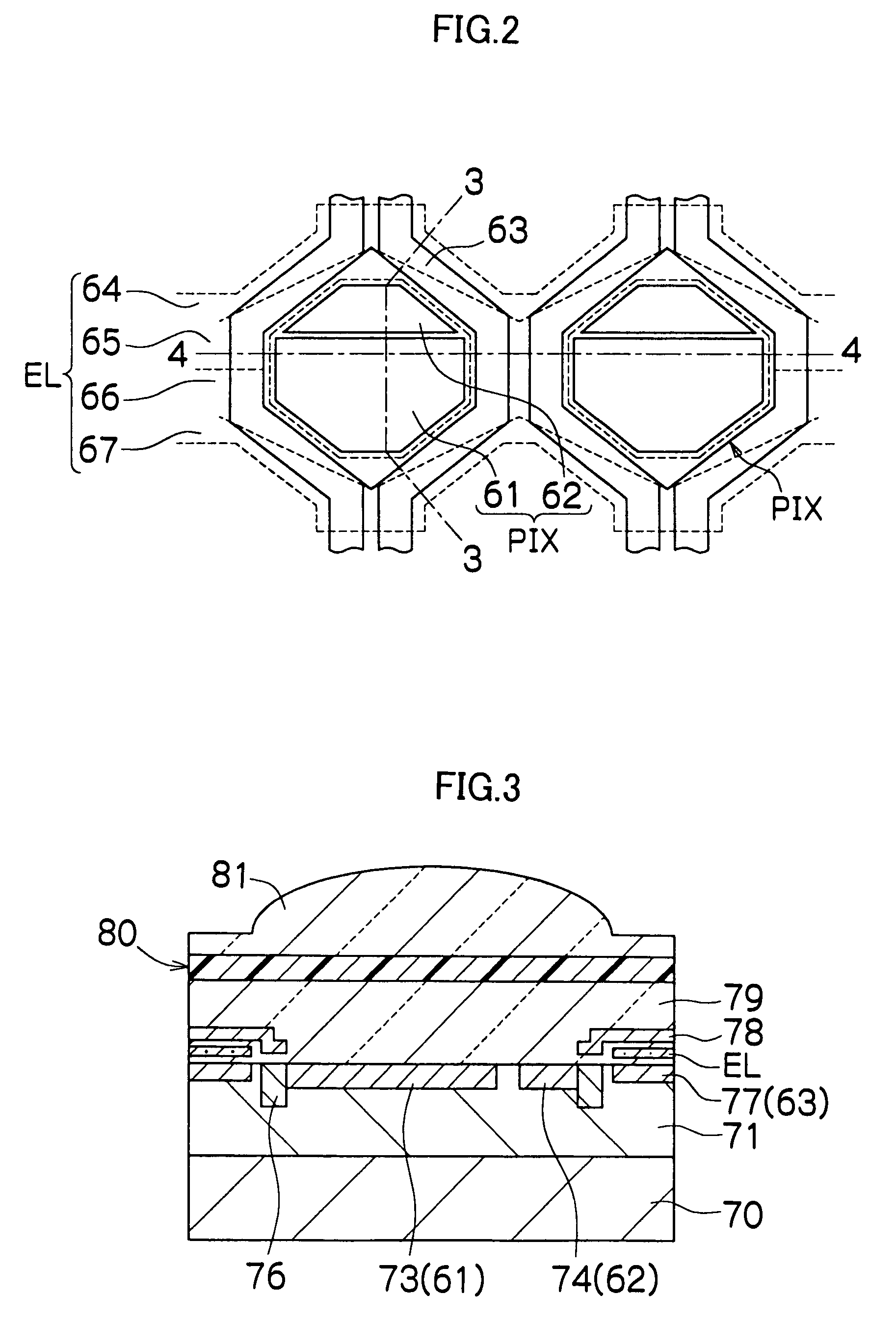

Method and imaging apparatus for correcting defective pixel of solid-state image sensor, and method for creating pixel information

InactiveUS20080180554A1Accurate valueReduce sensitivityTelevision system detailsColor signal processing circuitsImage resolutionImaging equipment

In a solid-state image sensor in which a large number of pixel cells each comprised of a combination of a main photosensitive pixel having a relatively large area and a subsidiary photosensitive pixel having a relatively small area are arranged, if the subsidiary photosensitive pixel has a defect for any pixel cell, division photometry data during AE processing is read, and the defective pixel is replaced with a value obtained by dividing the output value of the main photosensitive pixel at the same position by a sensitivity ratio only for a section for which it is determined that the main photosensitive pixel is not saturated. Thus, the pixel value of a defective pixel can be accurately corrected without causing a reduction in resolution sensitivity compared to a conventional method of correcting a defective pixel using surrounding pixel information.

Owner:FUJIFILM CORP

Power generation system

InactiveUS7378757B2Efficient outputIncrease profitDc network circuit arrangementsBatteries circuit arrangementsAC powerElectric power

A power generating system includes a power generator generating DC power, and an inverter circuit for converting DC power into AC power. The power generator has a plurality of power generating modules each including a plurality of power generating units and at least one electric storage device connected to each of the plurality of power generating modules. A plurality of first switch devices connect / disconnect each of positive electrodes of the plurality of power generating modules to / from a positive bus, a plurality of second switch devices connect / disconnect each of the positive electrodes of the plurality of power generating modules to / from negative electrodes of the power generating modules which are contiguous to one side, a plurality of third switch devices connect / disconnect each of the negative electrodes to / from a negative bus, and the DC output voltage can be increased / decreased stepwise by switching the switch devices.

Owner:SPHELAR POWER

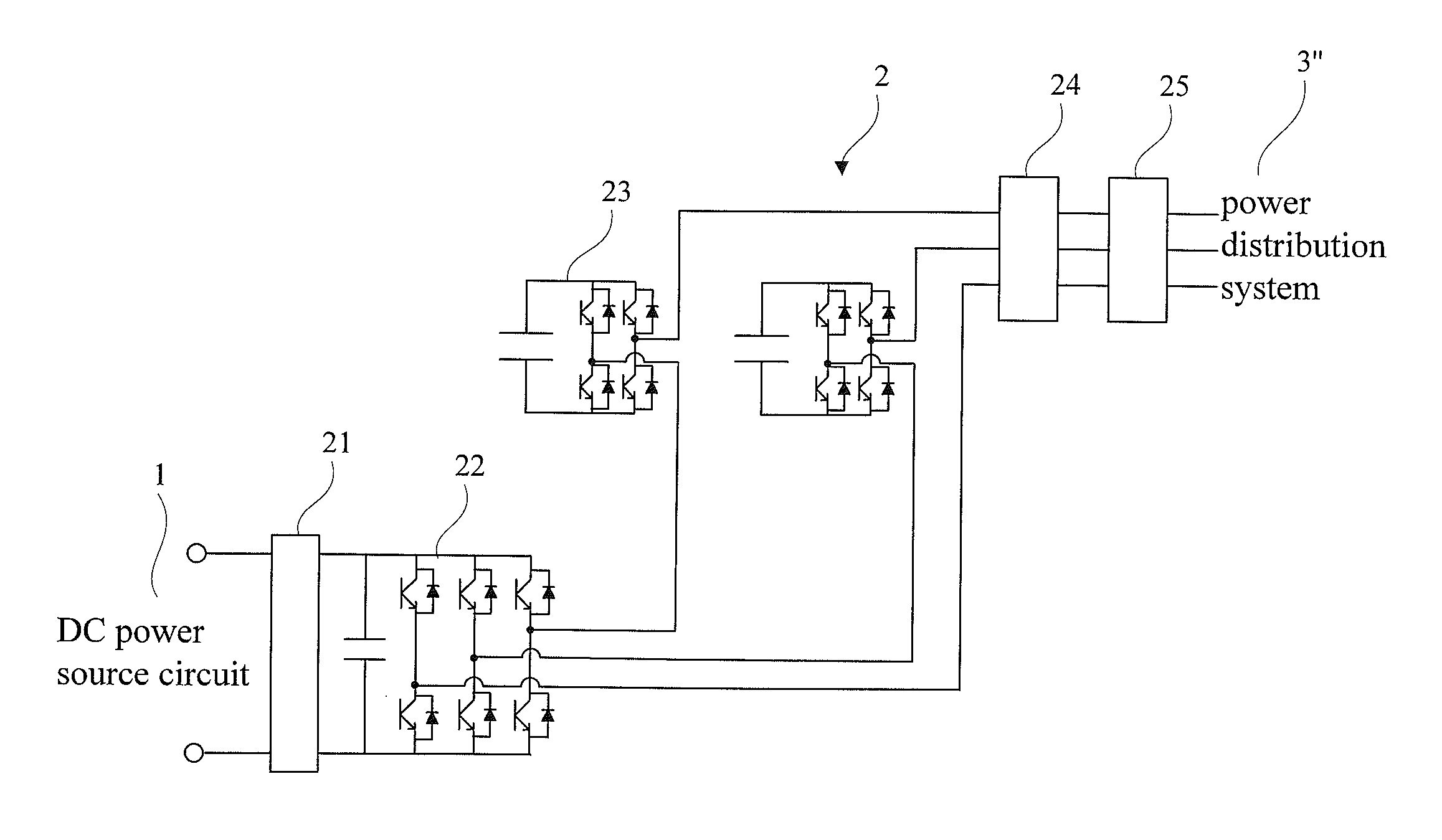

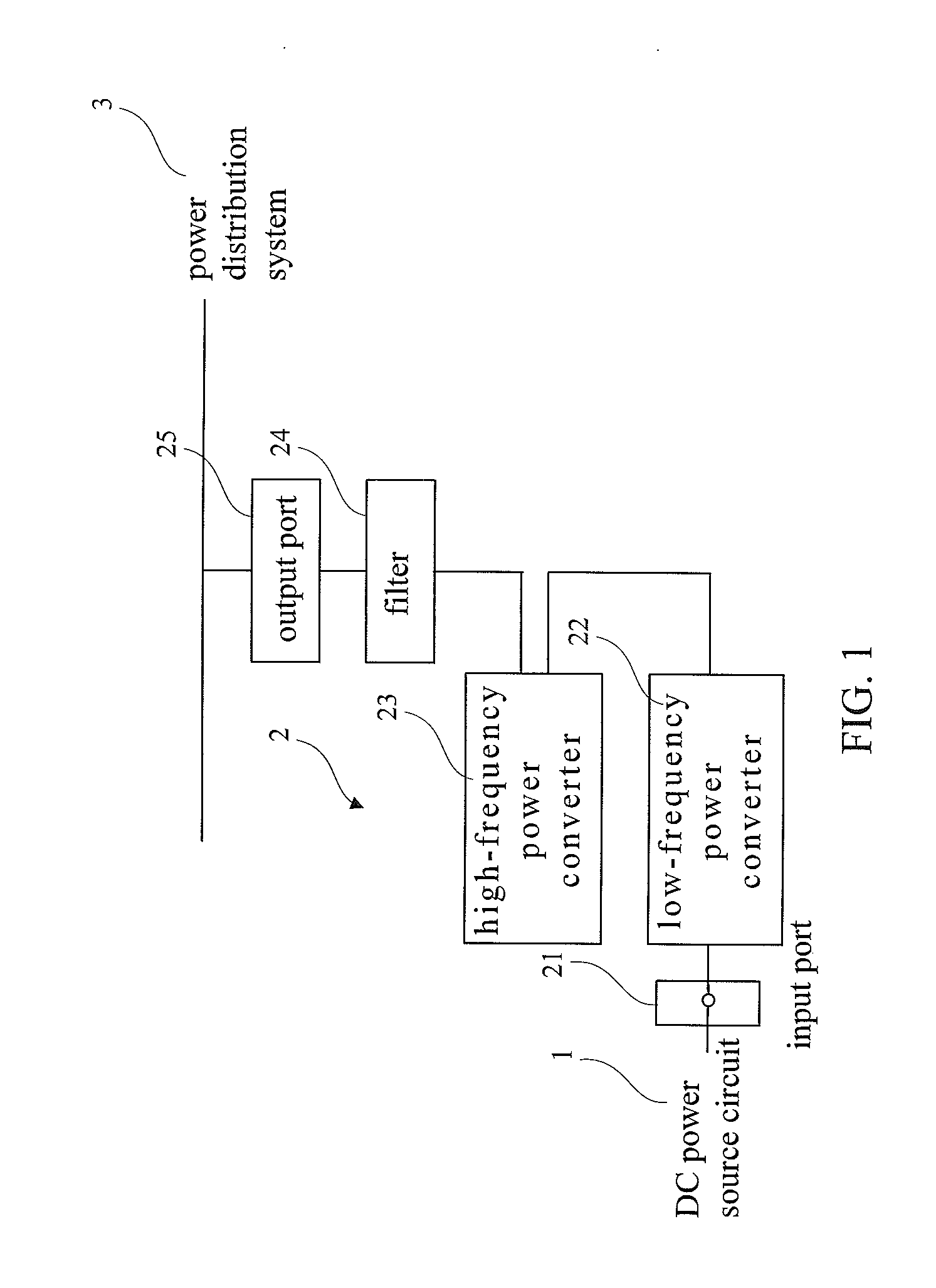

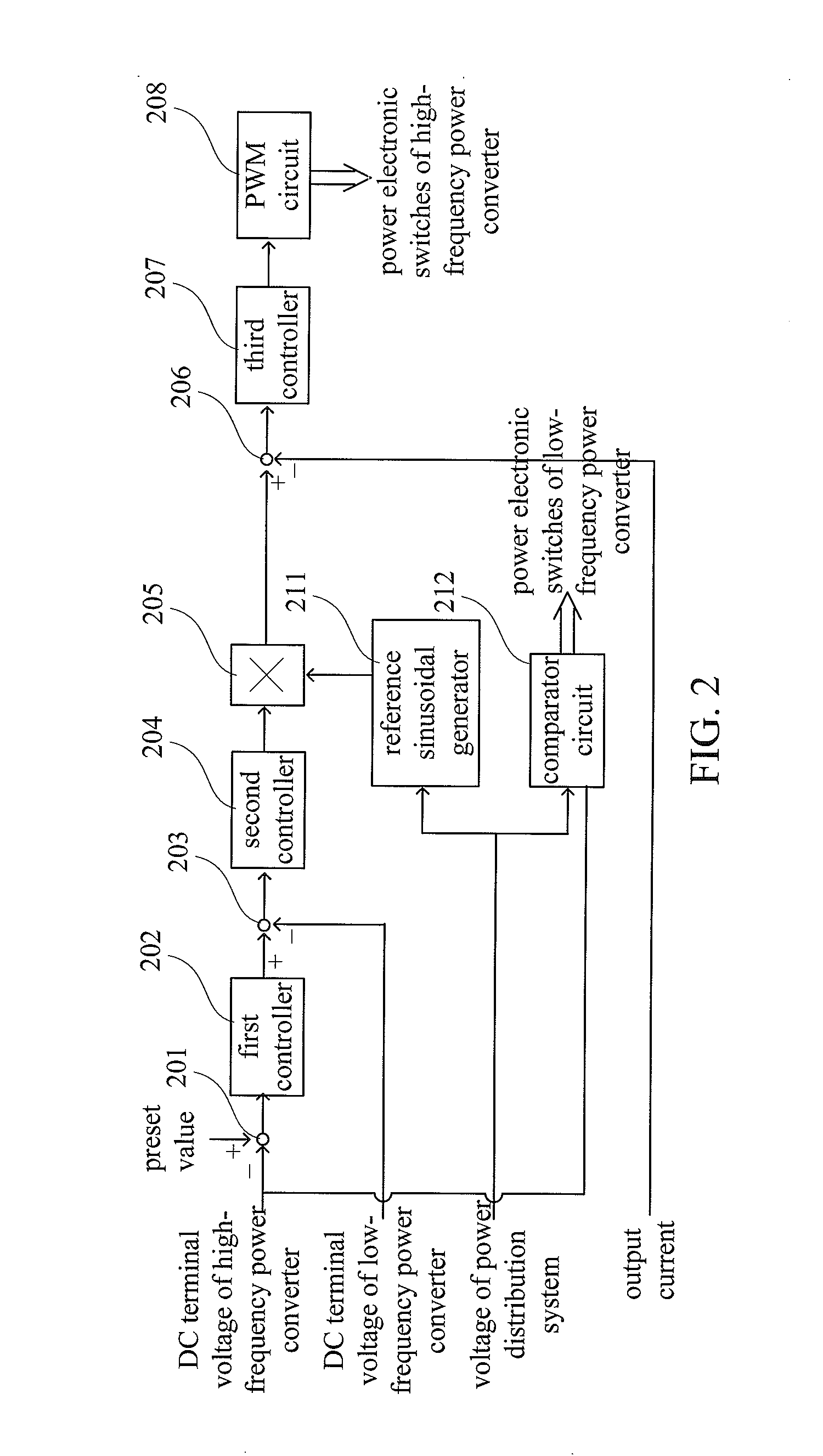

Cascade Bridge-type DC-AC Power Conversion Method and Converter Device Thereof

ActiveUS20140301124A1Reduce power lossImprove efficiencyConversion without intermediate conversion to dcDc-ac conversion without reversalBridge typeAC power

A cascade bridge-type DC-AC power converter device includes a low-frequency bridge-type power converter including an AC terminal and a DC bus and a high-frequency bridge-type power converter including an AC terminal. A power conversion method includes: serially connecting the AC terminal of the high-frequency bridge-type power converter and the AC terminal of the low-frequency bridge-type power converter; operating frequency of the low-frequency bridge-type power converter synchronized with frequency of an AC source and operating the high-frequency bridge-type power converter with high-frequency PWM to generate a multilevel AC voltage. A DC power source connects to the DC bus of the low-frequency bridge-type power converter. No additional power supply circuit will be required for power supply to a DC bus of the high-frequency bridge-type power converter. Accordingly, the power circuit is simplified and the manufacturing cost is reduced.

Owner:ABLEREX ELECTRONICS CO LTD

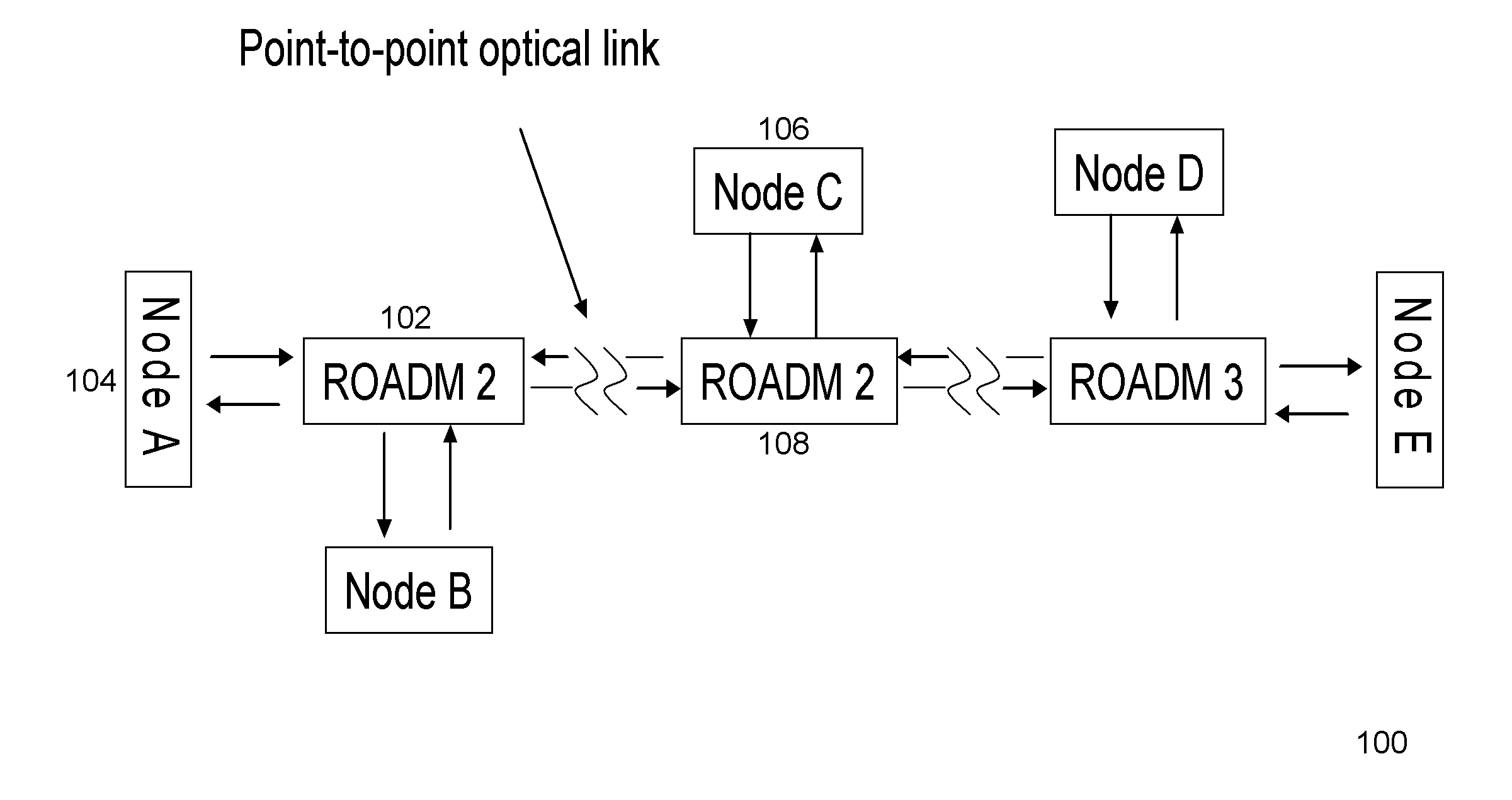

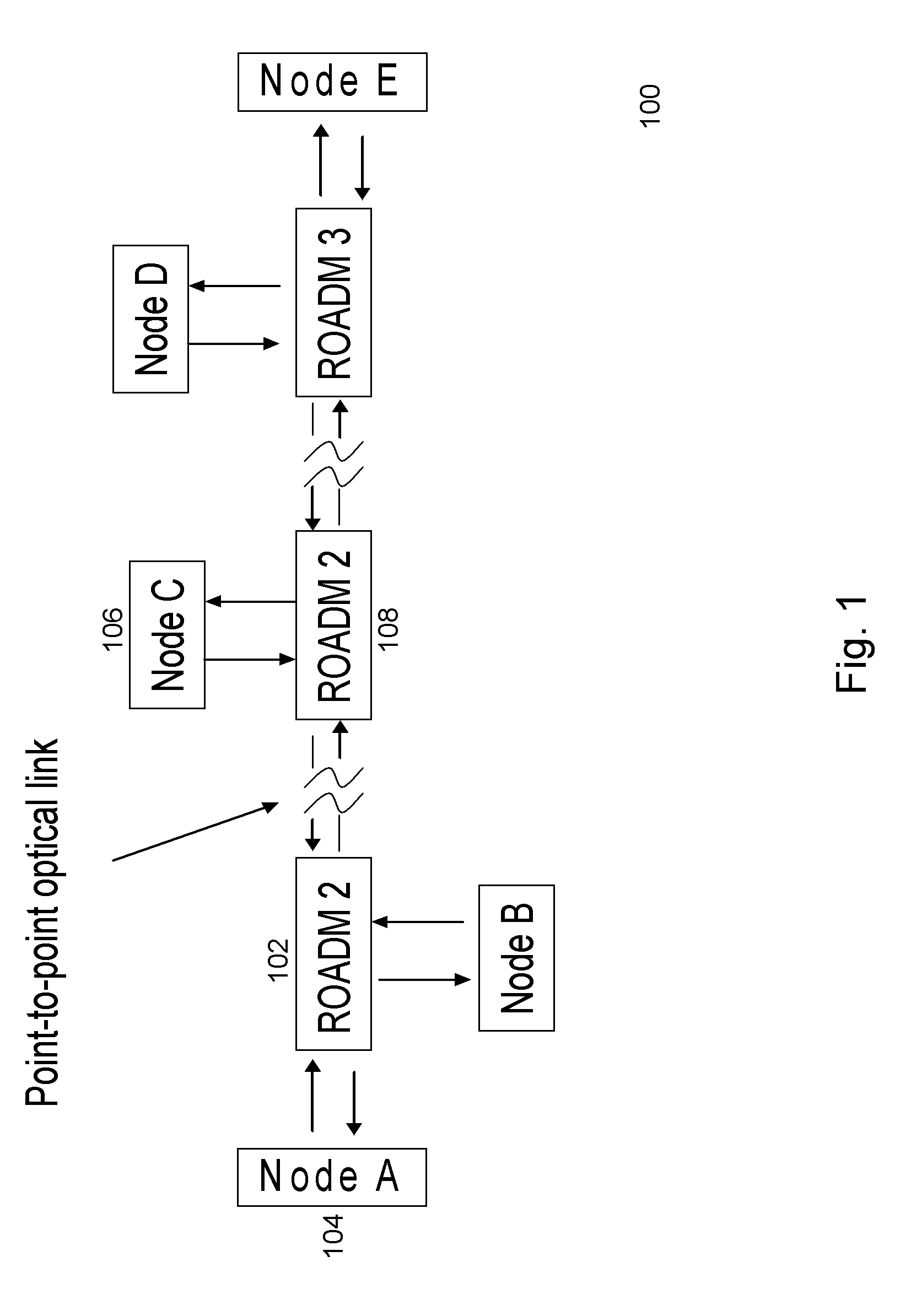

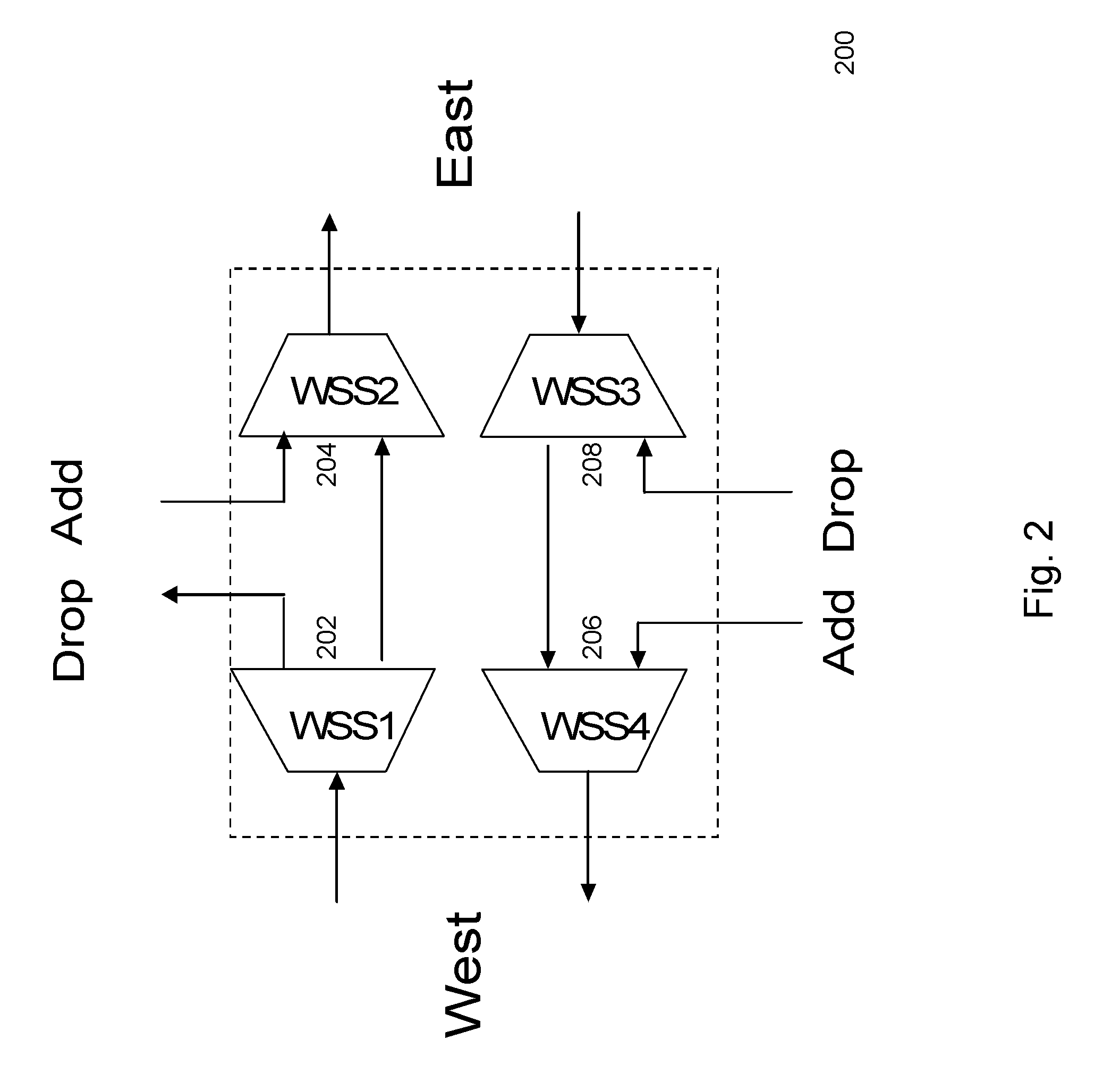

Apparatus and method for distributed compensation of narrow optical filtering effects in an optical network

ActiveUS20130142516A1Mitigate optical filtering effectReduce filter effectWavelength-division multiplex systemsWavelengthReconfigurable optical add-drop multiplexer

The present disclosure describes a reconfigurable optical add-drop multiplexer including a wavelength selective switch configured to filter wavelengths of an optical signal; and an optical equalizer, coupled to the wavelength selective switch, configured to equalize the optical signal to mitigate optical filtering effects caused by the wavelength selective switch.

Owner:AT&T INTPROP I L P

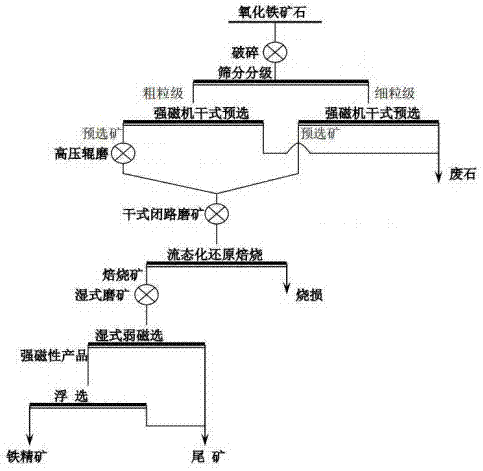

Combined mineral separation technology for ferric oxide mineral

InactiveCN107185686AThrow out earlyReduce transportationMagnetic separationGrain treatmentsIronstoneOxide minerals

The invention discloses an iron oxide ore joint beneficiation process, which comprises the following steps: (1) dry selection and discarding of iron oxide ore to obtain pre-selected coarse-grained ore, pre-selected fine-grained ore and waste rock; (2) high-pressure Roller mill crushing: the pre-selected coarse-grained ore obtained in step (1) is fed into a high-pressure roller mill for crushing; (3) dry grinding: the crushed product in step (2) and the pre-selected fine-grained ore in step (1) Combined for dry closed-circuit grinding; (4) Fluidized reduction roasting: a. Put the ground product obtained in step (3) into the fluidized reduction roaster; b. Preheating; c. Heating; d. Magnetization roasting; e . Cool to below 200°C to obtain roasted ore with a magnetite content greater than 90%; (5) beneficiation of roasted ore to obtain iron concentrate products with a grade of 57%-65%. The present invention can effectively solve the current iron oxide ore beneficiation There are technical problems such as low resource utilization rate, poor concentrate quality and high energy consumption in the process.

Owner:JIUQUAN IRON & STEEL GRP

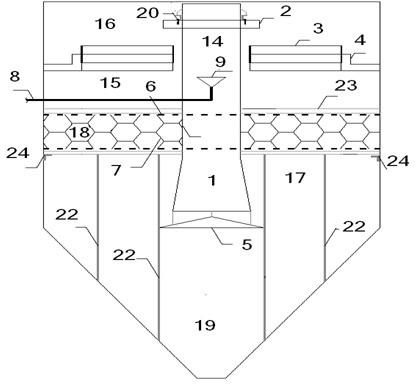

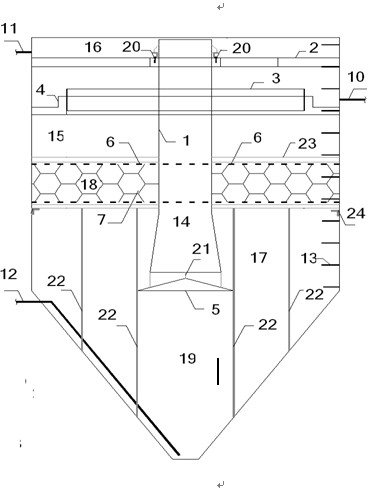

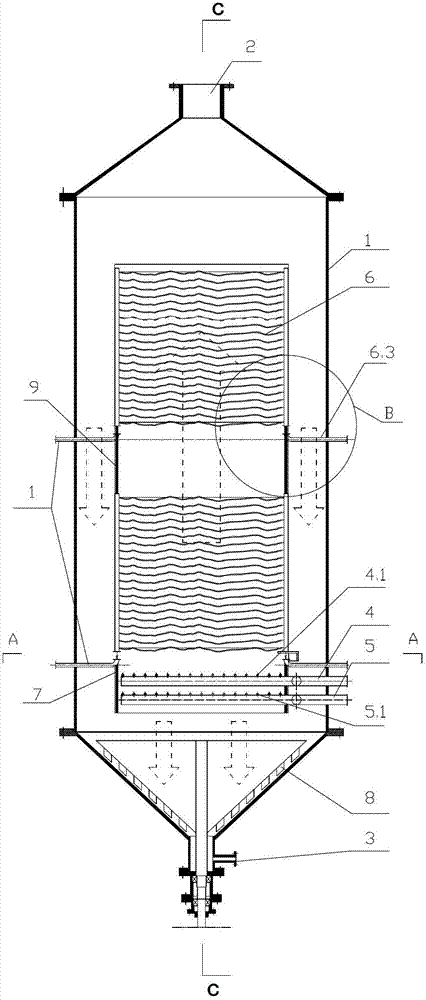

Vertical-flow type settling pond

InactiveCN102180570AExtended backwash cycleGood biological treatment effectMultistage water/sewage treatmentWater dischargeSludge

The invention relates to a vertical-flow type settling pond for sewage treatment, comprising a water feeding area, a water feeding pipe, an overhaul area, a water collecting area, a filtering area, a settling area, a sludge collecting area and a water discharging pipe. The water feeding area extends from the top of the settling pond into the lower part of the settling pond, the water feeding area is provided with the water feeding pipe, the overhaul area, the water collecting area, the filtering area and the settling area are sequentially arranged around the water feeding area from the top down, the sludge collecting area is communicated with the lower part of the settling area, a water collector which can be regulated according to the water level is arranged in the water collecting area, and the water collector is communicated with the water discharging pipe; and the water collecting area further comprises a filtering water buffering section arranged at the lower part of the water collector. Due to the existence of the filtering water buffering section, water after filtered in the filtering area firstly enters into the filtering water buffering section to be buffered and then enters into the water collector, thus the uniform water discharge at an water discharge part still can be ensured due to the action of the filtering water buffering section even though filtering materials or biological fillers are aggregated.

Owner:BEIJING MUNICIPAL ENG PROFESSIONAL DESIGNINST

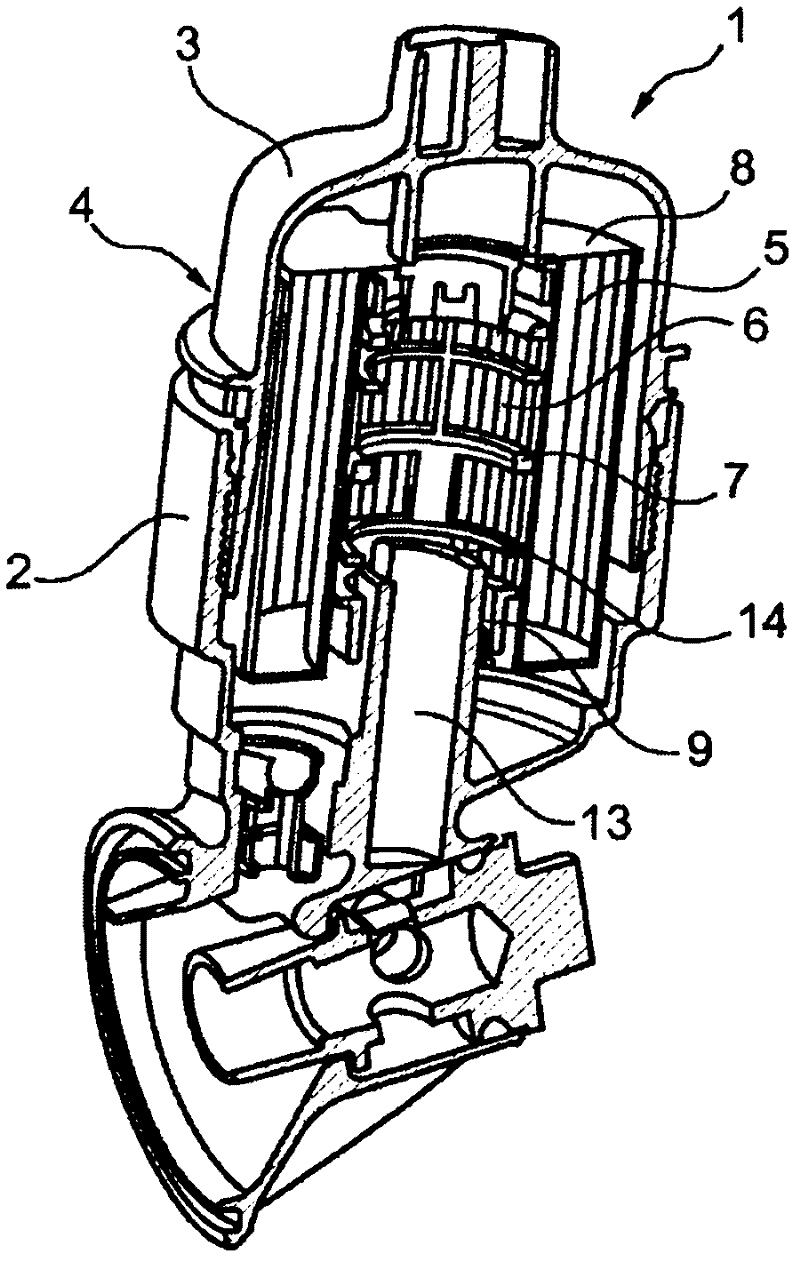

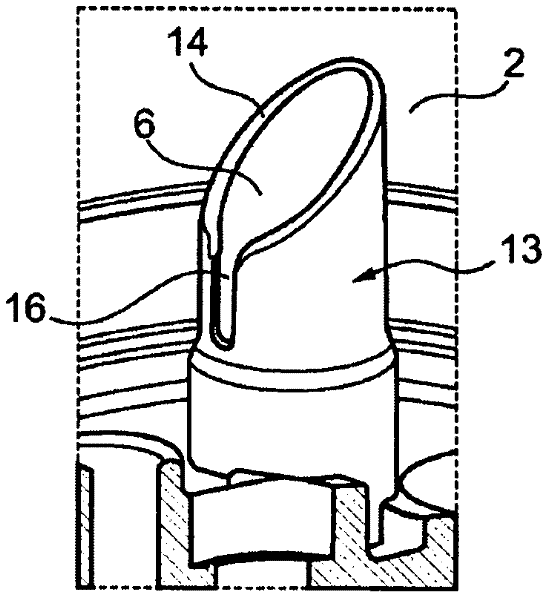

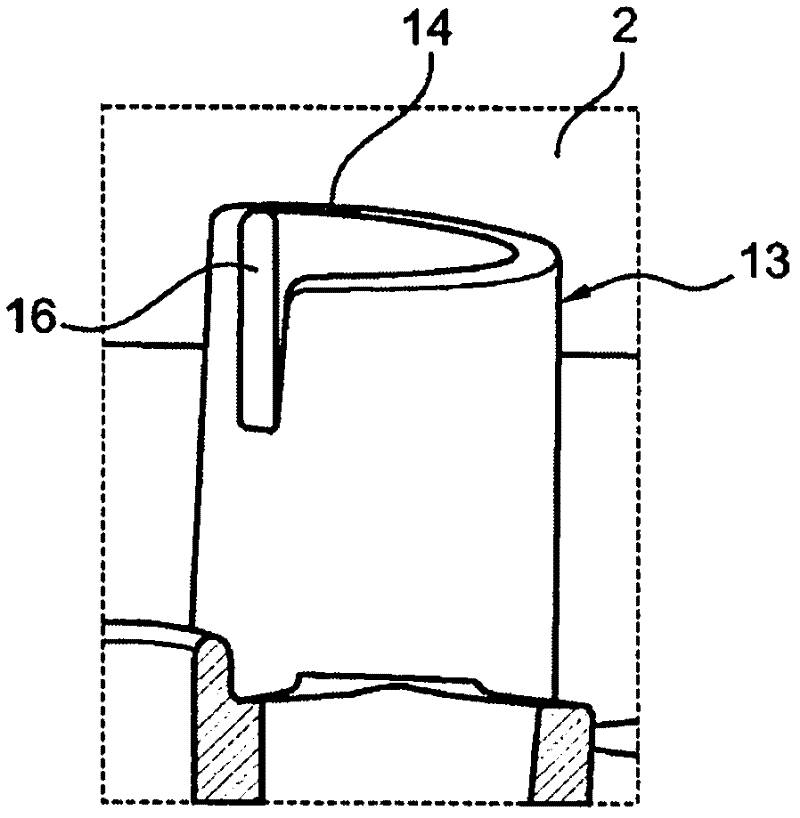

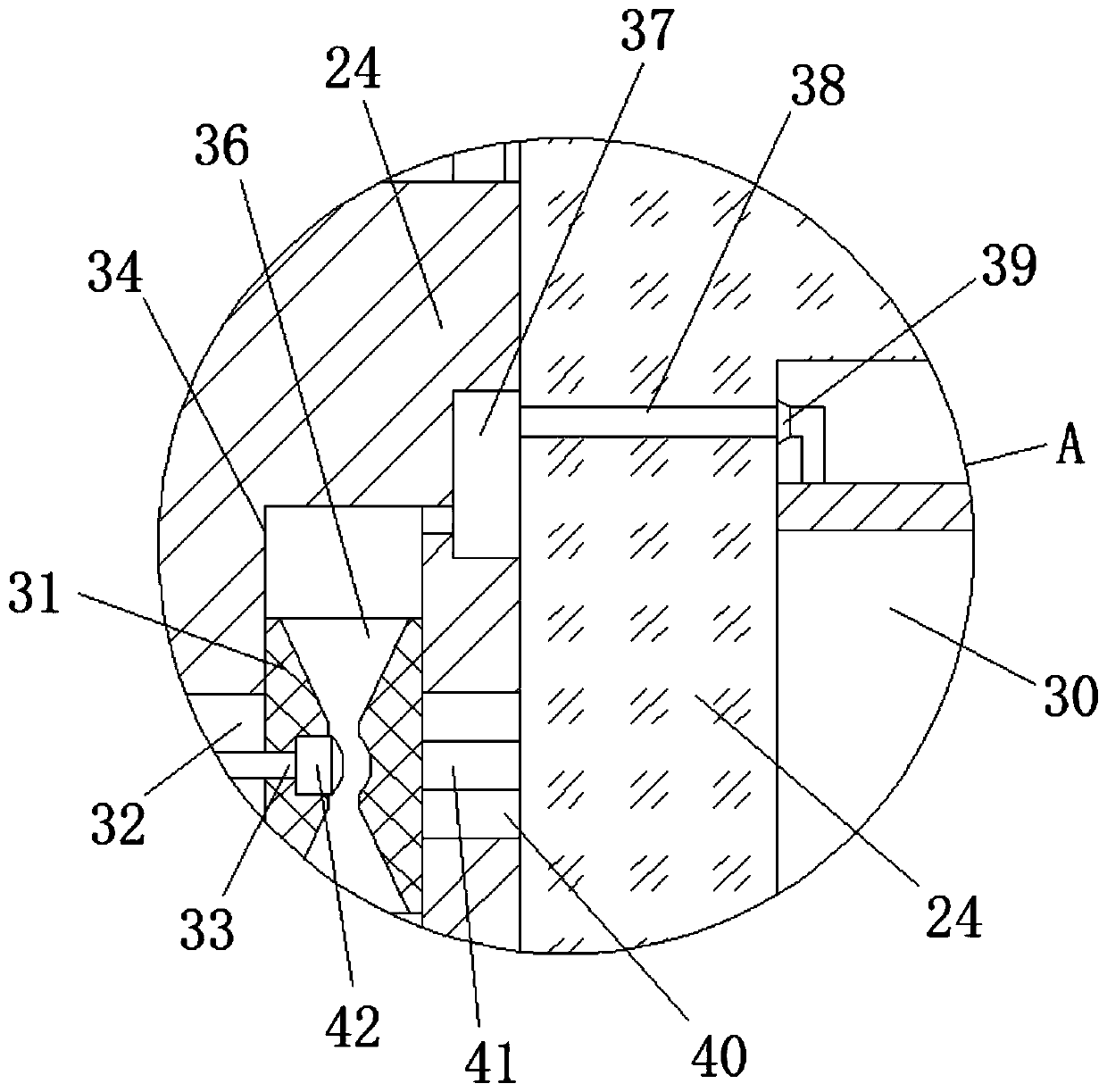

Filter device

ActiveCN102648036ASimple designSimple and precise designMembrane filtersCartridge filtersFuel filterFilter element

The invention relates to a filter device (1), in particular an oil or fuel filter, comprising a filter housing (4) having a filter housing crucible (2) and a filter housing cover (3), a ring filter element (5) being arranged in the filter housing, the filter element having an axially projecting pin (10) on a lower end disc (9), by means of which pin the element engages with a channel (11) on the filter housing crucible side when the filter device (1) is assembled. According to the invention, it is essential that a tube-shaped dome (13) is provided on the filter housing crucible (2), the dome engaging with an inner chamber (6) of the ring filter element (5) when the filter device (1) is assembled, and that a guide contour (14) is provided at a free end of the tube-shaped dome (13), the contour cooperating with a guide element (15) arranged on the ring filter element (5). Thus, assembly can be facilitated.

Owner:MAHLE INT GMBH

Air purifier

InactiveCN105169826AThere will be no phenomenon that is not filteredImprove filtration efficiencyDispersed particle filtrationFire rescueAir purifiersEnvironmental engineering

The invention relates to an air purifier, which comprises a purifying main body, one side of the purifying main body is provided with an air inlet, a filter and a fan are arranged sequentially along an air flow path in the purifying main body, and the entire purifying main body is covered by the filter; the purifying main body is provided with an air passage at a position corresponding to the fan; the air passage is communicated with an air outlet formed in one side of the purifying main body; a flow guide plate for air flow is arranged at one side of the fan, the flow guide plate is divided by ribs, and the ribs are in contact with the filter. The air purifier is small in size and lightweight, and therefore is convenient to carry, the air supply and filtering power is high, active air supply is adopted, breathing resistance is low, and the air purifier is comfortable.

Owner:BROAD A Q TECH

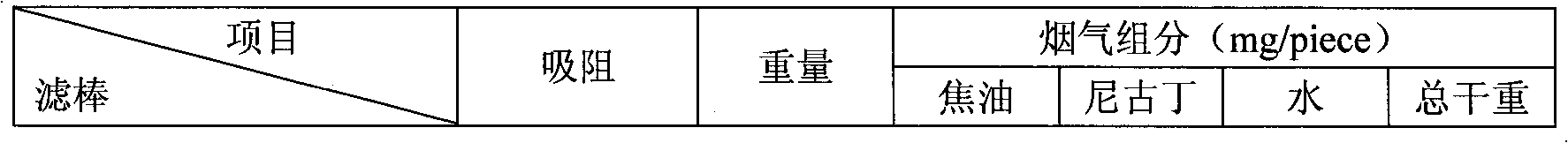

Method for preparing tows for modified cigarettes

ActiveCN102134758ALight weightSimple spinning processArtificial filament physical treatmentMelt spinning methodsFiberPolymer science

The invention relates to a method for preparing tows for blended modified polylactic acid cigarettes. Fiber grade polypropylene particles, functional master batches and polylactic acid particles are uniformly mixed according to a certain ratio, and the tows for polylactic acid cigarettes are prepared through the working procedures of spinning, oiling, drafting, wrapping and drying. The method has a simple process and high speed to form, the produced product can reduce the specific weight of polylactic acid fiber, the operational performance is increased, the surface area of the fiber is increased, grain phase particles in smoke can be effectively absorbed, and a good filtering effect is generated.

Owner:JIANGSU DAYA CIGARETTE FILTER MATERIAL CO LTD

Integrated Equalizer and Michelson Interferometer Structure for Inter-Symbol Interference-Suppressed colorless DPSK demodulation

ActiveUS20100232803A1Reduce filter effectElectromagnetic receiversDifferential phaseMichelson interferometer

Owner:NEC CORP

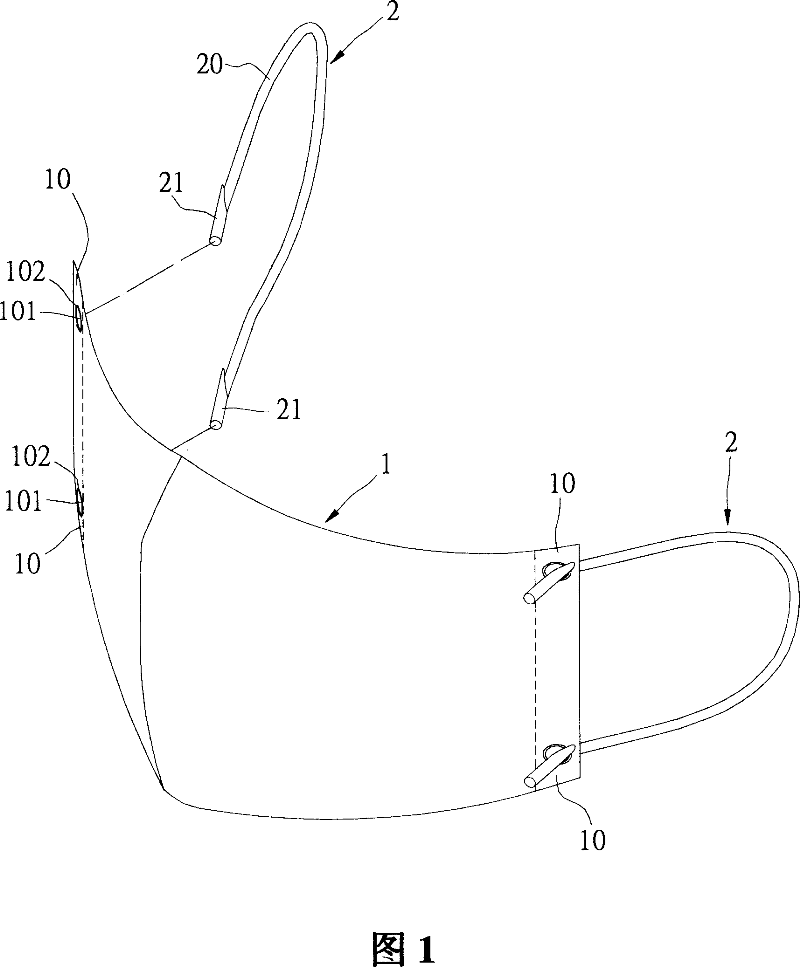

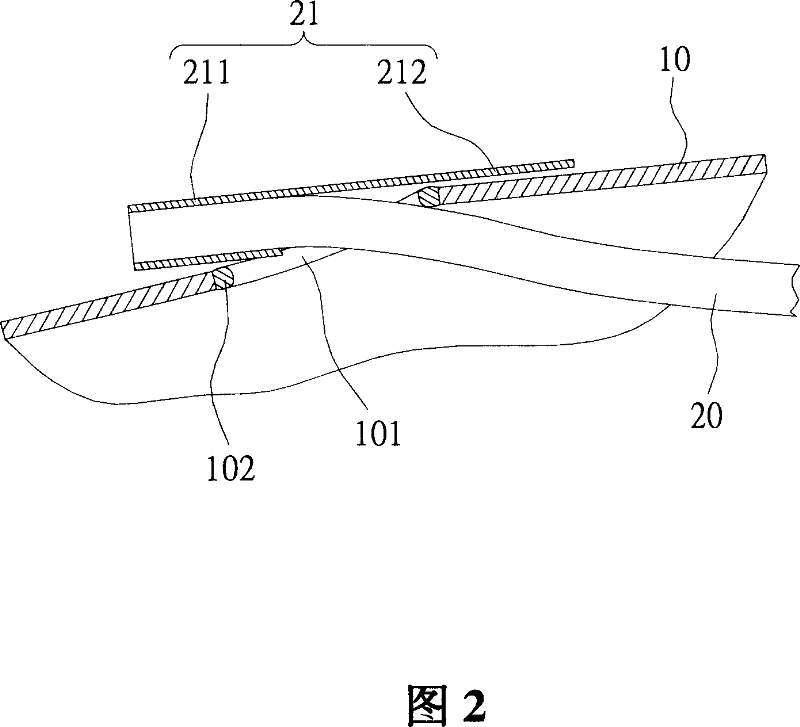

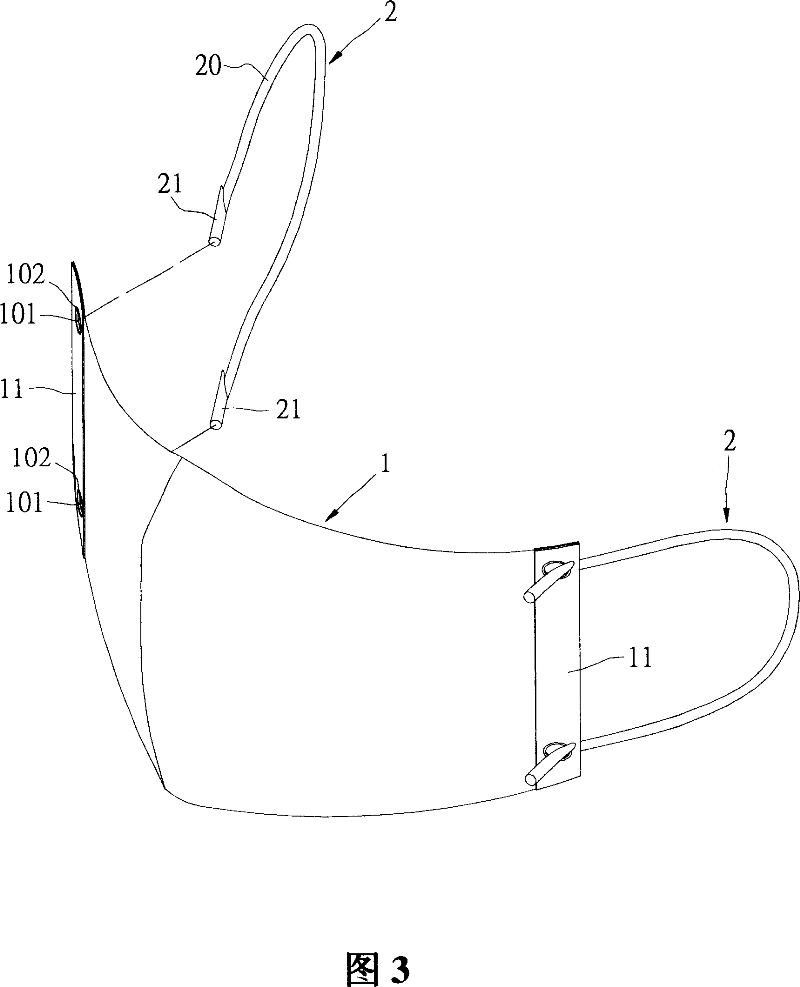

Detachable and portable respirator and the portable respirator noumenon

InactiveCN101040731AReduce filter effectReduce Burdened Purchasing CostsBreathing filtersBreathing masksPolyolefinRespirator

The invention discloses a detachable throw-type mouthpiece and relative body, wherein the detachable throw-type mouthpiece comprises a body and two straps, the body comprises a thermal plastic filter sheet containing polyolefin material, each strap is provided with two connectors at two ends of the strap, the connectors are detachably connected with the body. When the detachable throw-type mouthpiece is used some time, the filter effect of the body is reduced and needed to be thrown out, and since the connectors of straps are detachably connected with the body, the strap will be kept from the body, therefore, the inventive mouthpiece can avoid waste straps, reduce cost and protect environment.

Owner:邱俊亮

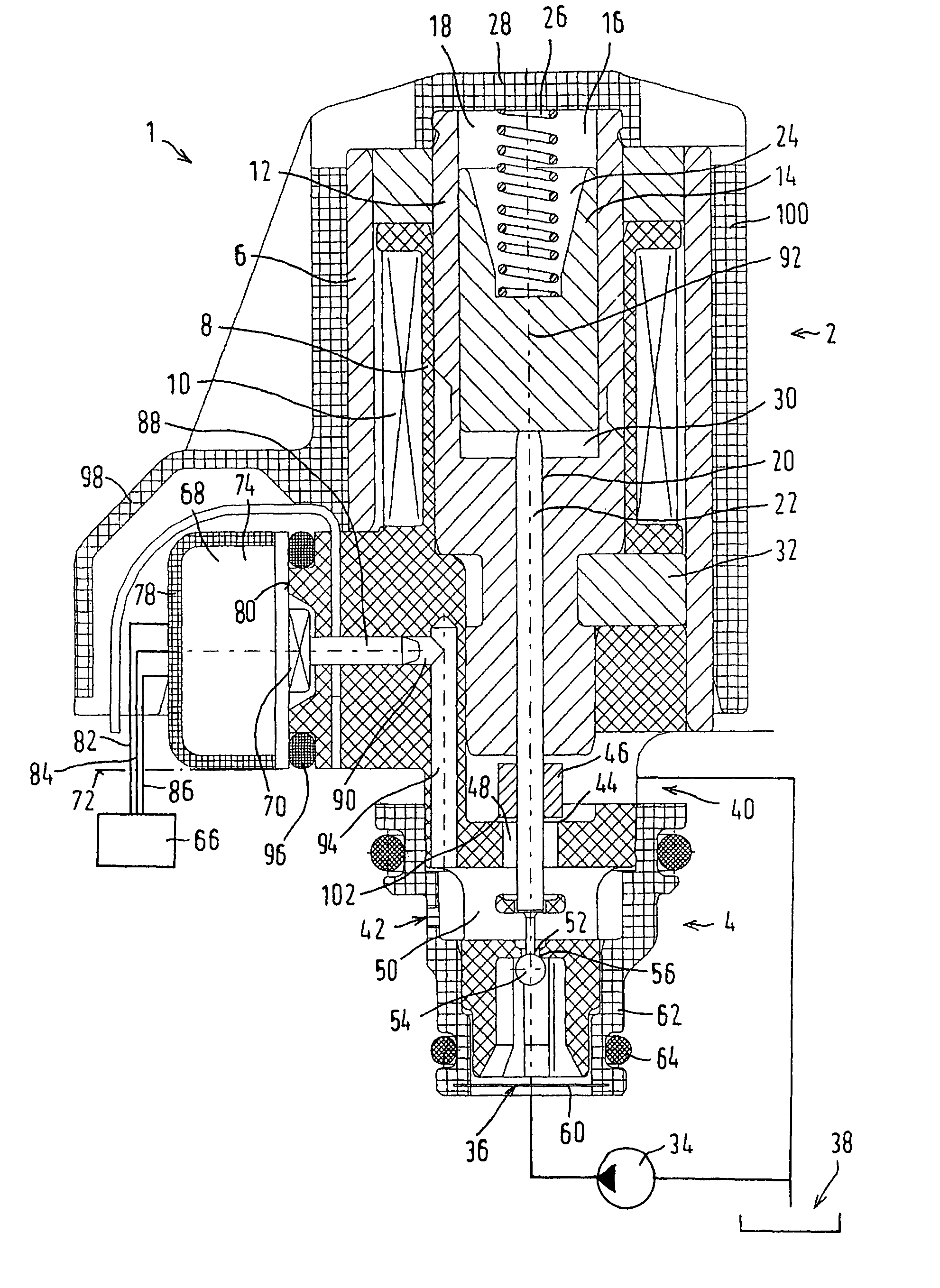

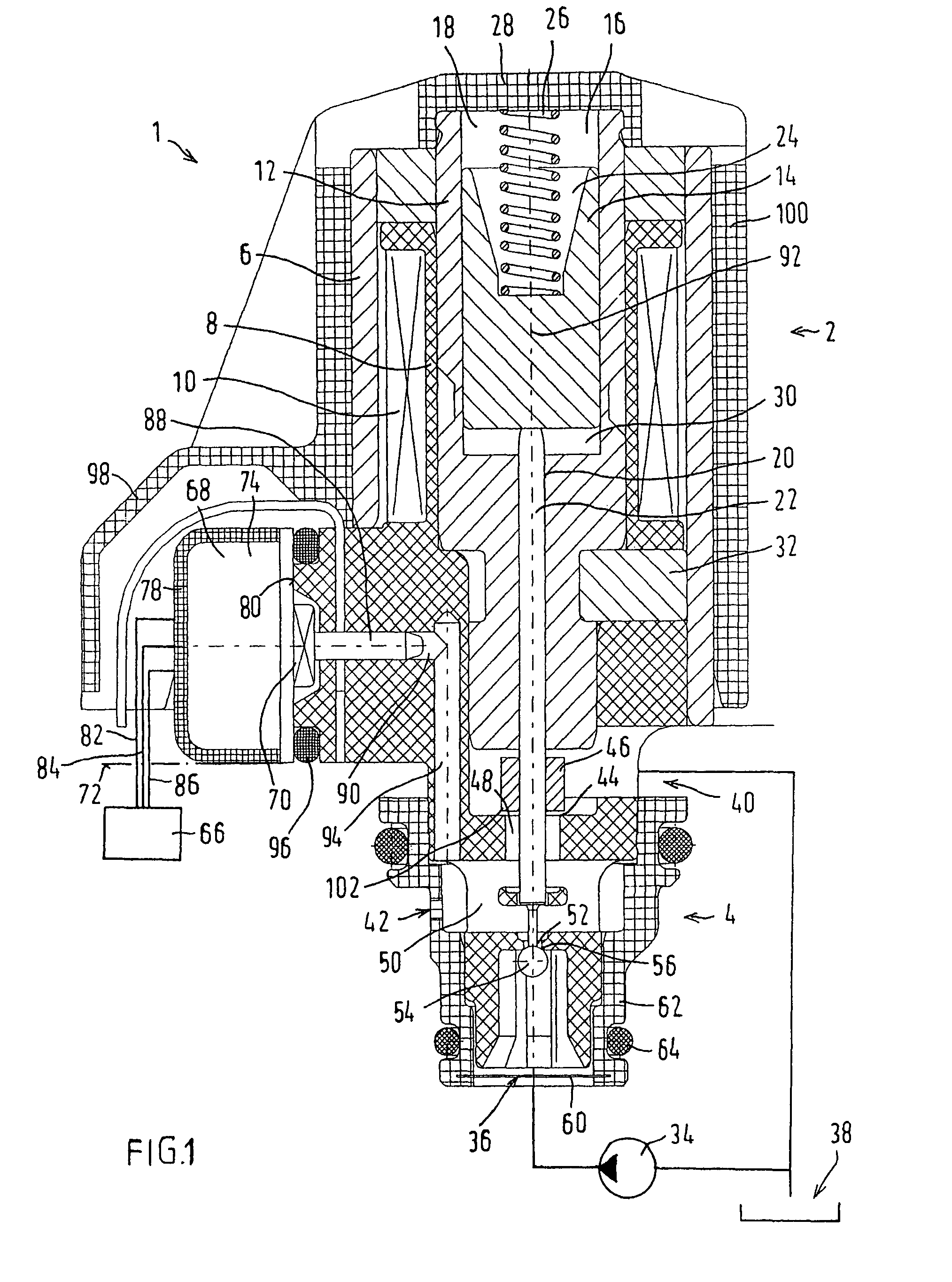

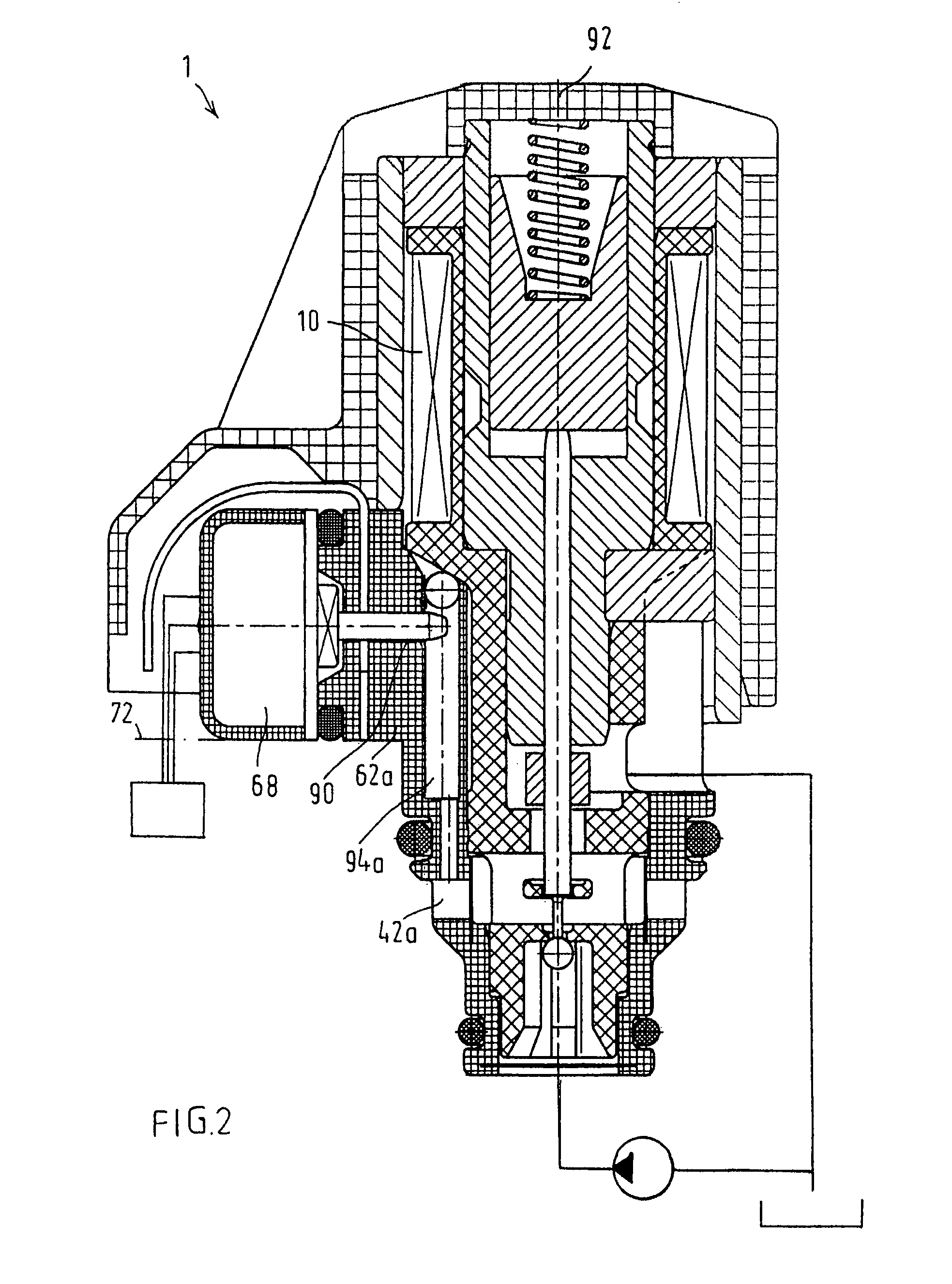

Electromagnetic pressure regulating valve device having an integrated pressure sensor

InactiveUS7950413B2Reduce filter effectHigh measurement accuracyOperating means/releasing devices for valvesFluid pressure control using electric meansElectricityBobbin

An electromagnetic pressure regulating valve device for regulating a hydraulic pressure including at least one pressure regulating valve which includes a solenoid part having at least one bobbin holding an electric coil, a coil core and a movably guided armature; a valve part having at least one supply connection, one return connection, one load connection and one actuating element operated by the armature and cooperating with a valve seat; and an electronic part having at least one pressure sensor for measuring the hydraulic pressure present at the load connection. At least the pressure sensor is situated on an end of the solenoid part facing the valve part upstream from the electronic part. Positioning the pressure sensor close to the valve part may substantially reduce the filter effect of the transmission link, and the hydraulic pressure to be measured is therefore transmittable free of errors up to a much higher cutoff frequency. This may result in a higher measurement accuracy, and therefore also a higher regulation accuracy, of the pressure regulating valve.

Owner:ROBERT BOSCH GMBH

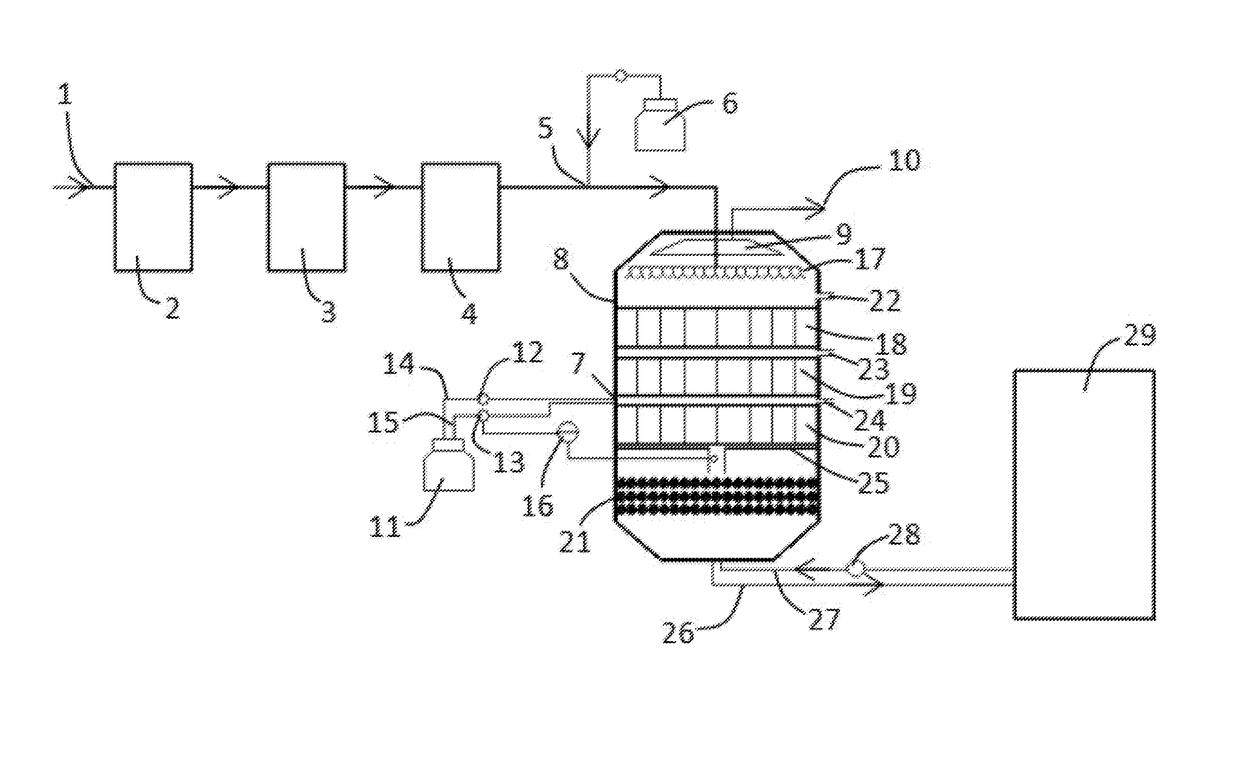

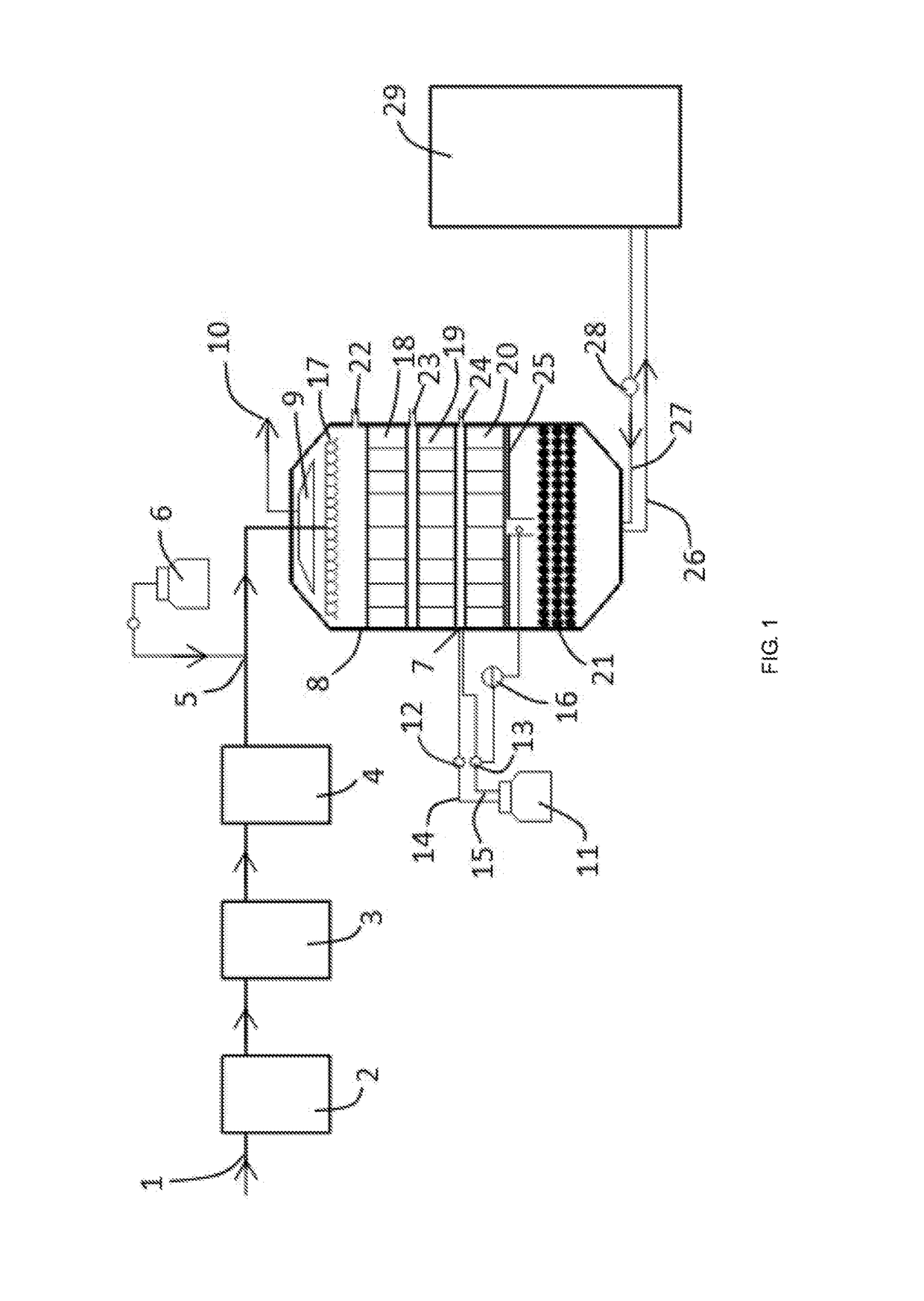

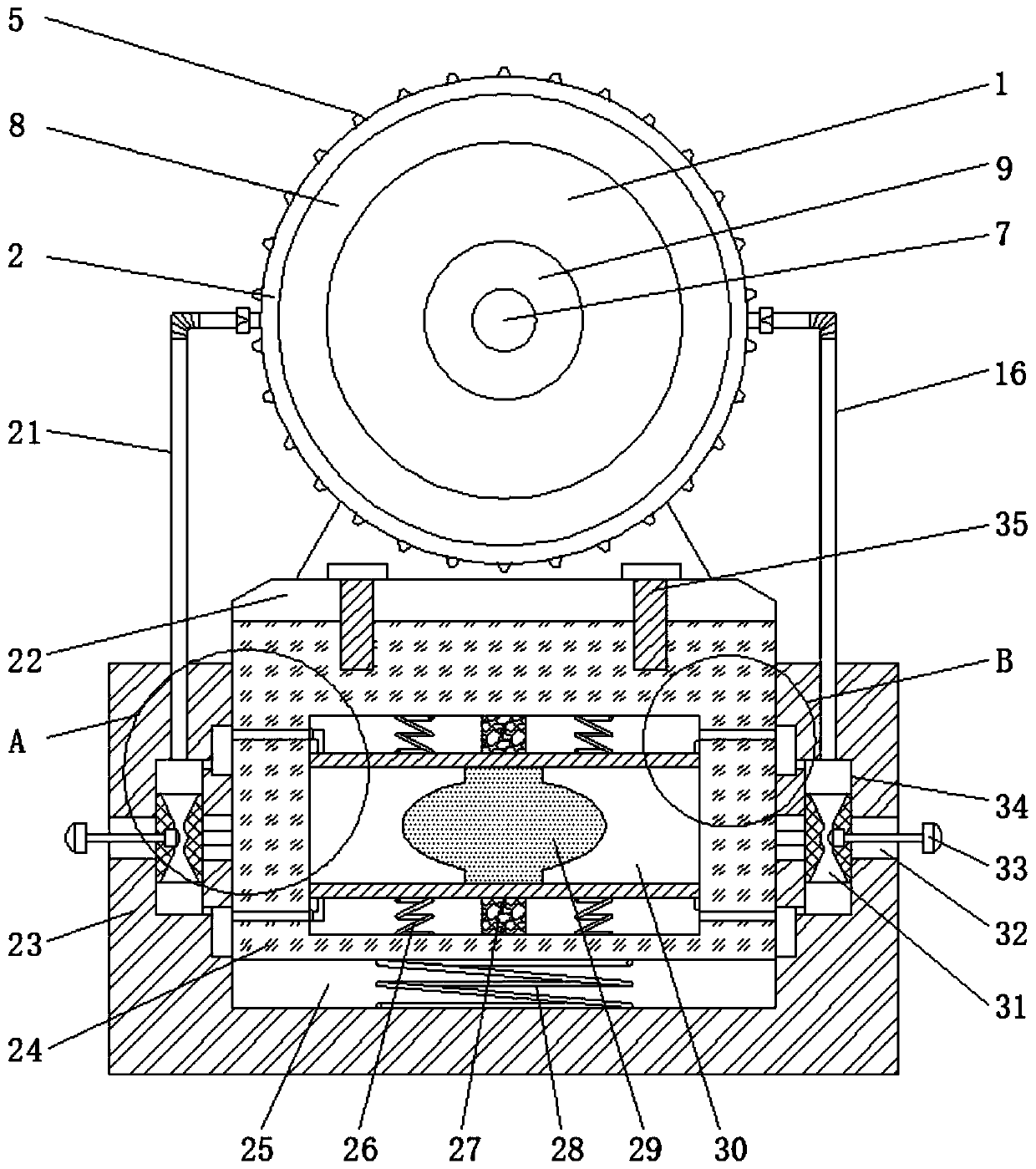

Apparatus for sewage deep denitrification with high pollutant carrying capacity and low energy consumption, and method for running the same

ActiveUS20180099885A1Reduce backwash timesStable water-bearing layerWater treatment parameter controlTreatment using aerobic processesChemical storageBiological filter

The invention discloses an apparatus for sewage deep denitrification with high pollutant carrying capacity and low energy consumption and a method for running the same, characterized in that: the apparatus mainly includes a settling tank, an electrodialysis device, a pH adjusting tank, a first chemical storage tank, a biofilters a second chemical storage tank, a redox potential measuring device, a backwash pump, and a clean water tank, wherein the biofilter is provided with, a gas collecting device, an uniform water distributor, a first filter bed, a second filter bed, a third filter bed, and a fourth filter bed sequentially from up to down, a second dosing port is arranged underneath the second filter bed, and the second chemical storage tank is communicated to the second dosing port respectively through a first flow path and a second flow path.

Owner:NANJING UNIV

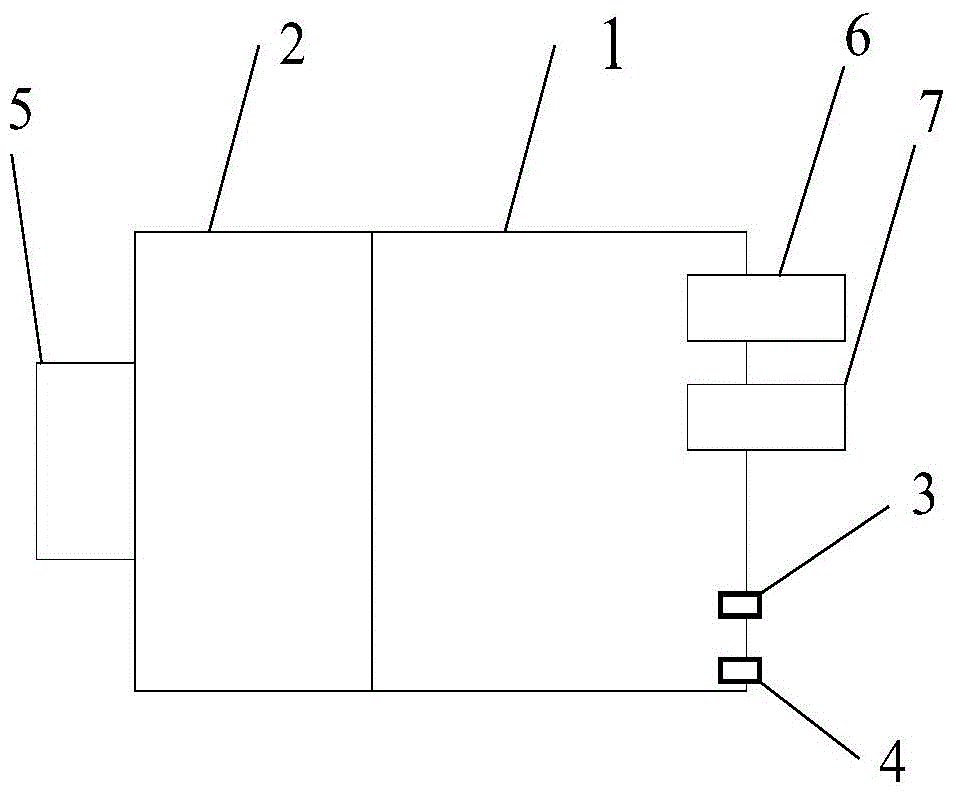

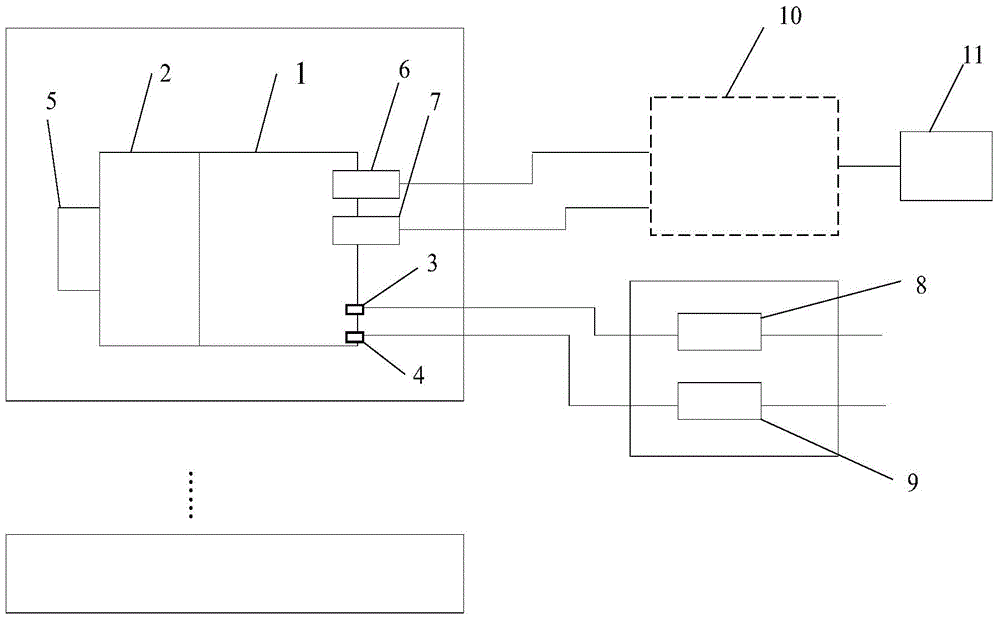

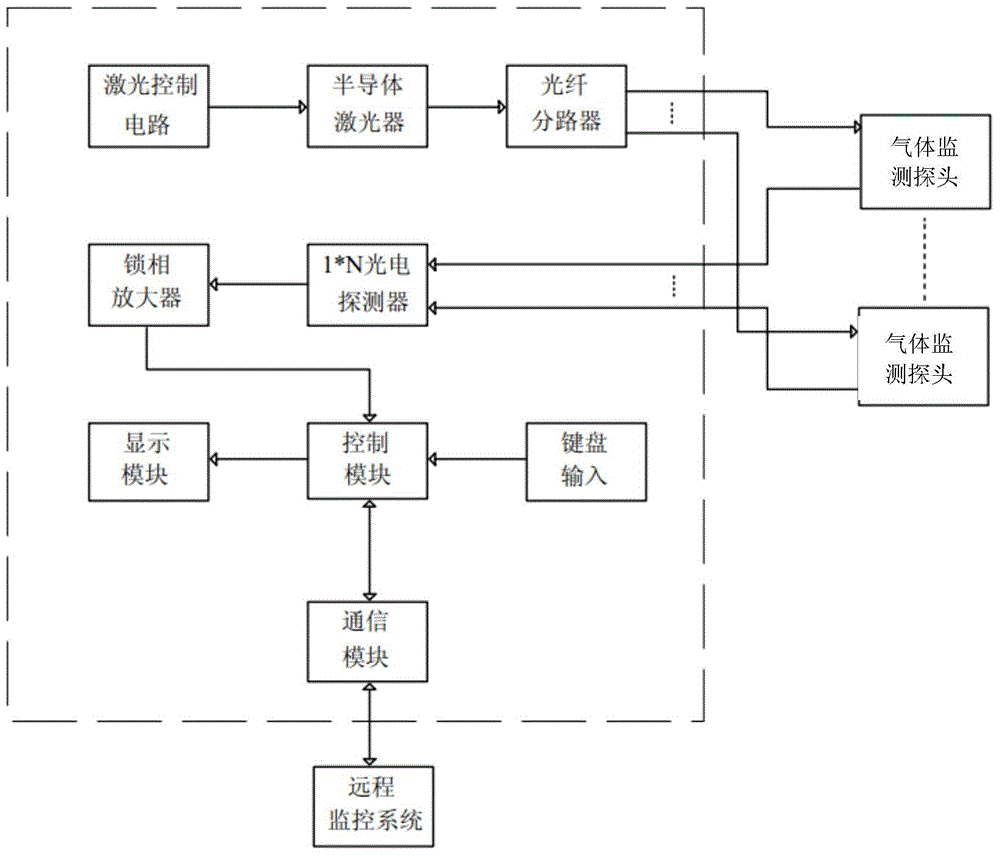

Gas monitoring probe and gas monitoring system

InactiveCN104535515AGuaranteed cleanlinessEasy to cleanWithdrawing sample devicesColor/spectral properties measurementsEngineeringImpurity

The invention relates to a gas monitoring probe and a gas monitoring system. The gas monitoring probe comprises a sampling inner cavity, the sampling inner cavity is provided with a purging air inlet and an exhaust air outlet, the purging air inlet is used for conducting purging cleaning on the sampling inner cavity, and the exhaust air outlet is used for exhausting gas in the sampling inner cavity. The gas monitoring system comprises the gas monitoring probe, the purging air inlet is connected with a purging pipeline, and the exhaust air outlet is connected with an exhaust pipeline. The sampling inner cavity is subjected to purging cleaning through the purging air inlet, then the gas in the sampling inner cavity can be exhausted in time through the exhaust air outlet, dust and impurities generated in the sampling inner cavity due to accumulation for a long time are effectively cleaned, the dust and impurities can be discharged thoroughly, the cleanliness of the sampling inner cavity is guaranteed, and the influence on testing results and errors are avoided.

Owner:GL TECH CO LTD

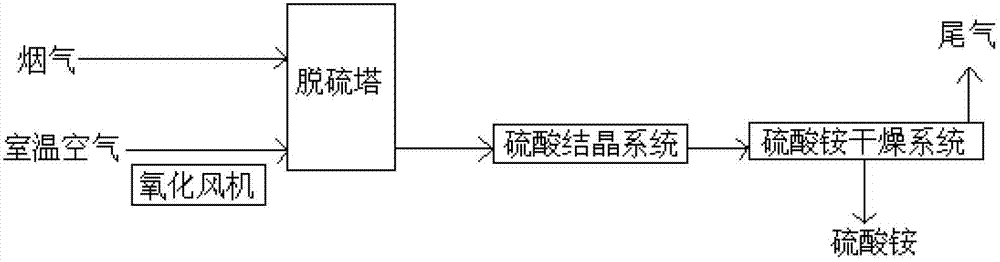

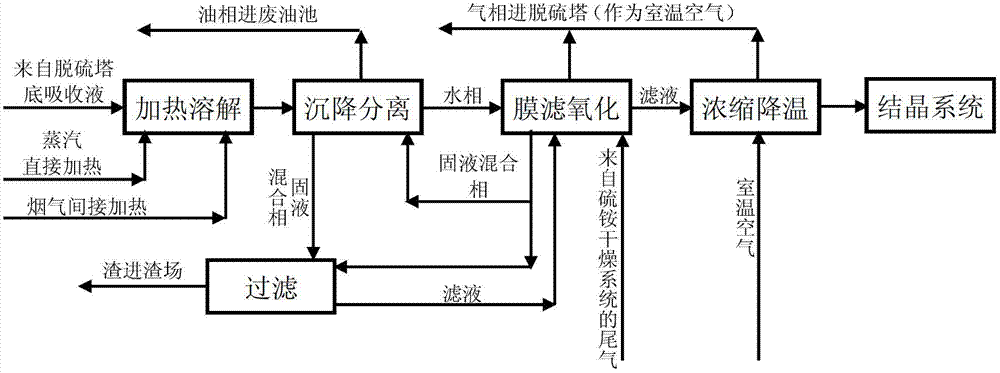

Purification technology for side product of flue gas ammonia-desulphurization

InactiveCN102826572AImprove mixing efficiencyImprove filtering effectDispersed particle separationAmmonium sulfatesGas phaseRoom temperature

The invention discloses a purification technology for a side product of flue gas ammonia-desulphurization, by the purification technology, the problem of influence on product quality caused by that the dust cannot be removed in the existing purification technology is solved. The technical scheme comprises the following steps of: 1, solid liquid separation: heating an absorption solution to be 75 DEG C to 90 DEG C, standing, settling and separating, so as to obtain an oil phase of the uppermost layer, a water phase of the intermediate layer, and a solid-liquid mixed phase of the lower layer; 2, film filter oxidization: introducing the water phase in a film filter oxidization device, bubbling while filtering, introducing hot air, keeping the hot air at the temperature of 75 DEG C to 90 DEG C, carrying out oxidization of ammonium sulfate and ammonium nitrite, and film filter treatment of dust, so as to obtain a gas phase, a filtrate and a solid-liquid mixed phase; 3, concentrating cooling: introducing bubbles in the filtrate in room-temperature air, or spraying the filtrate to contact room-temperature air, concentrating and cooling to 55 DEG C to 60 DEG C, so as to obtain a gas phase and a cooled solution, and introducing the cooled solution in an ammonium sulfate crystallizing system to carry out the ammonium sulfate crystallization treatment. The technology disclosed by the invention is simple in process, low in operation cost, is doubled as oxidization and dust removing, and high-quality ammonium sulfate products can be obtained.

Owner:武汉钢铁有限公司 +1

Method and imaging apparatus for correcting defective pixel of solid-state image sensor, and method for creating pixel information

InactiveUS7301571B2Accurate valueReduce sensitivityTelevision system detailsColor signal processing circuitsImage resolutionImaging equipment

In a solid-state image sensor in which a large number of pixel cells each comprised of a combination of a main photosensitive pixel having a relatively large area and a subsidiary photosensitive pixel having a relatively small area are arranged, if the subsidiary photosensitive pixel has a defect for any pixel cell, division photometry data during AE processing is read, and the defective pixel is replaced with a value obtained by dividing the output value of the main photosensitive pixel at the same position by a sensitivity ratio only for a section for which it is determined that the main photosensitive pixel is not saturated. Thus, the pixel value of a defective pixel can be accurately corrected without causing a reduction in resolution sensitivity compared to a conventional method of correcting a defective pixel using surrounding pixel information.

Owner:FUJIFILM CORP

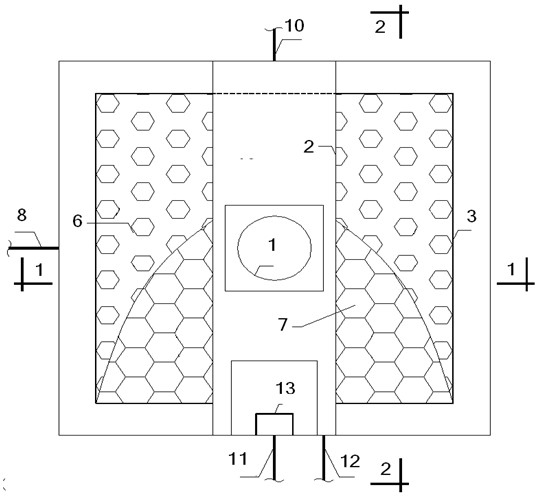

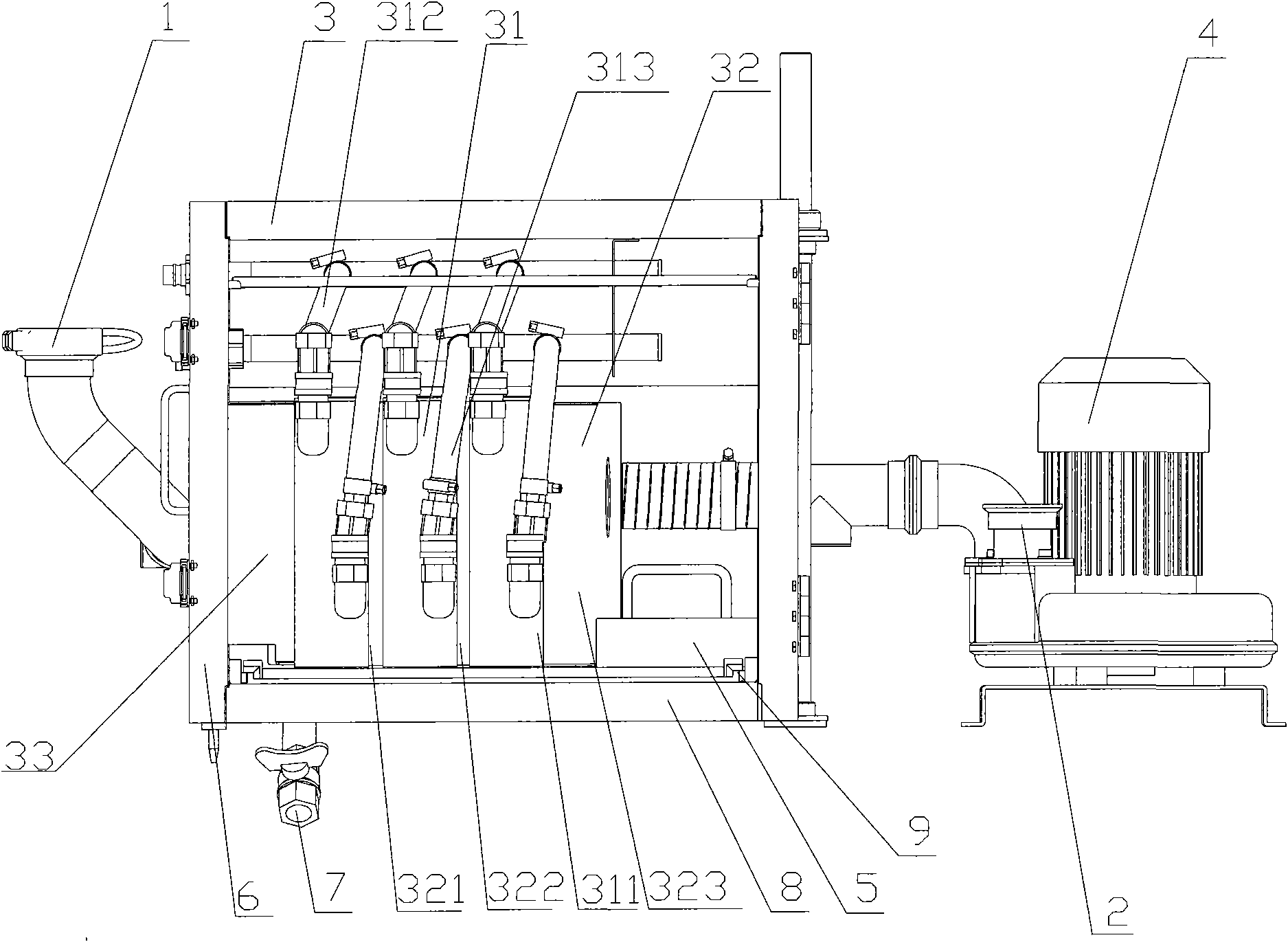

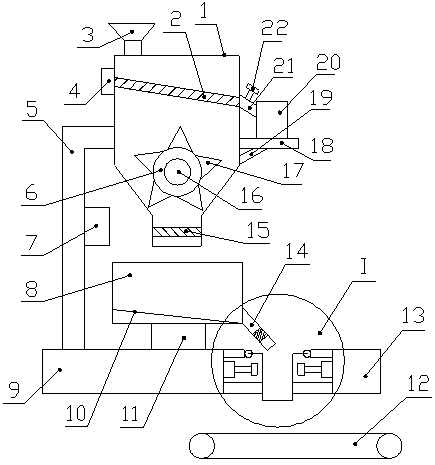

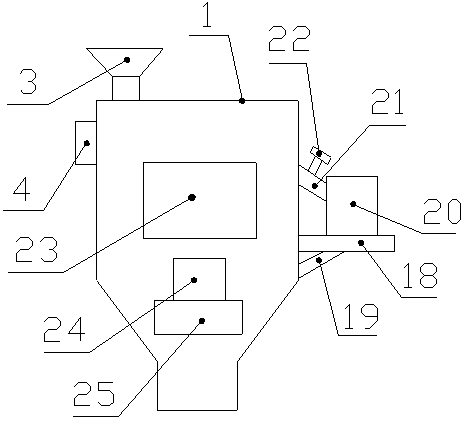

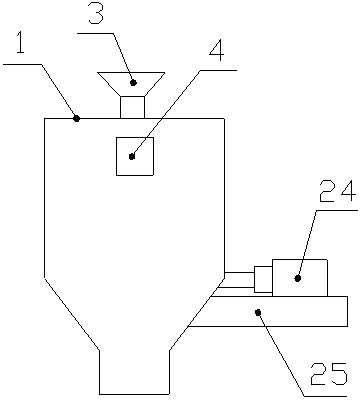

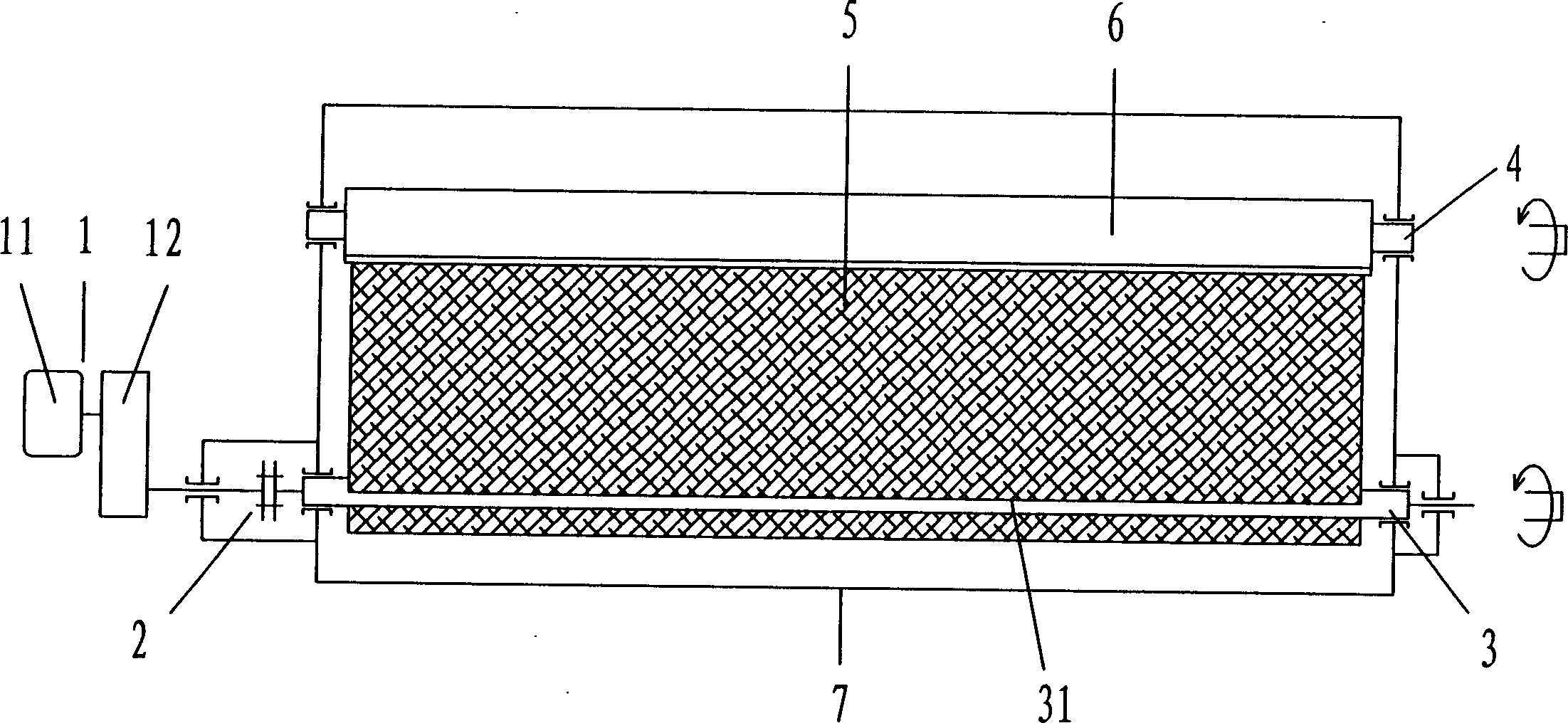

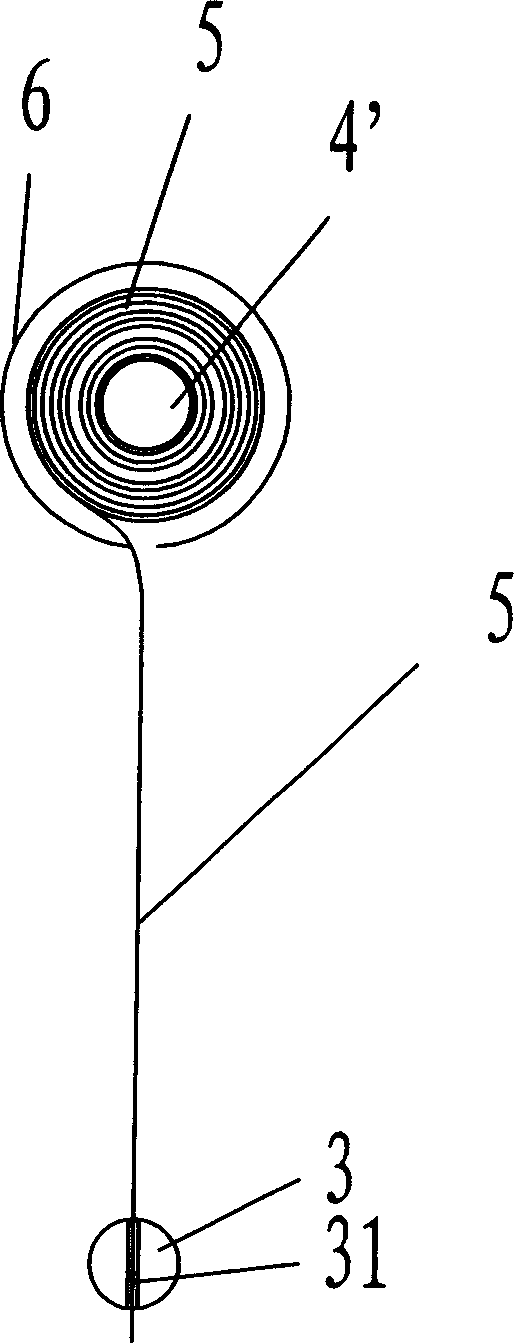

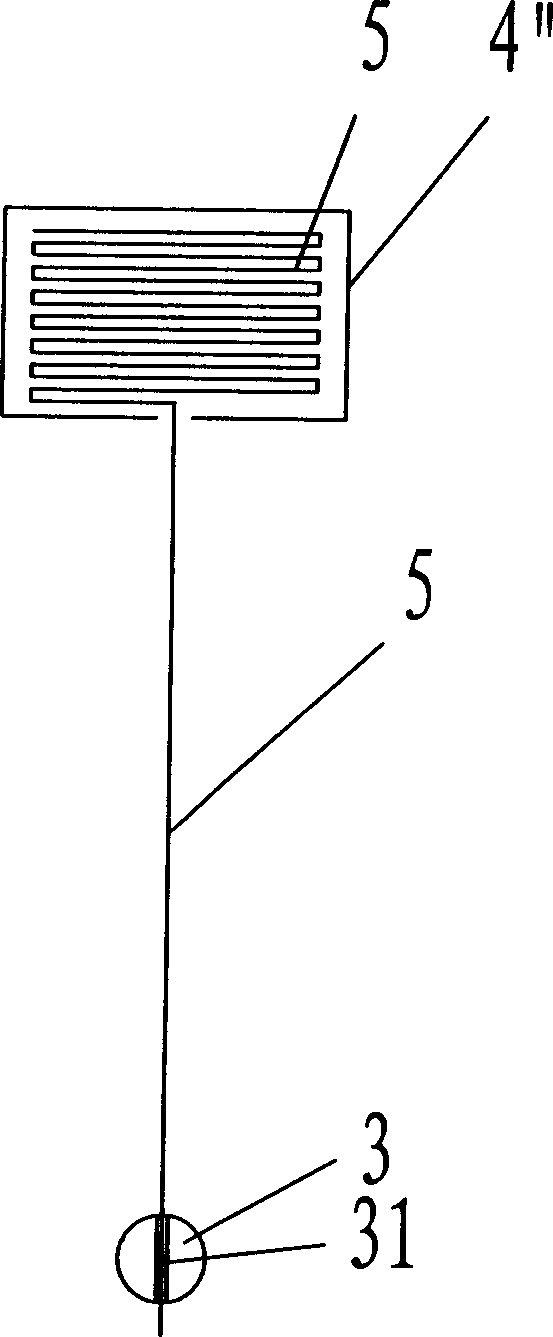

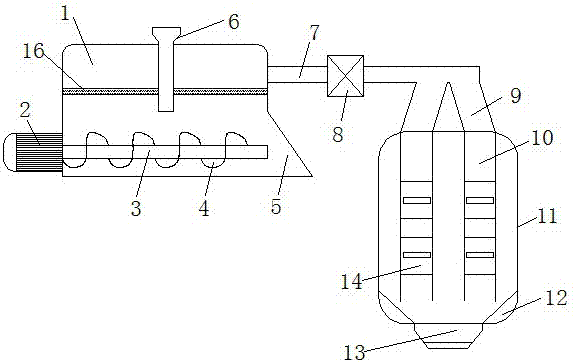

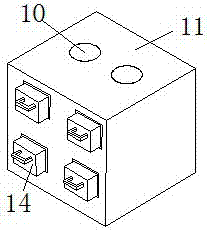

Nitrogen filtering recovery system of reflow oven

InactiveCN101612506AReduce the chance of damageReduce volumeCombination devicesPrinted circuit assemblingNitrogenProcess engineering

The invention discloses a nitrogen filtering recovery system of a reflow oven, comprising a gas inlet (1) and a gas outlet (2), wherein a gas filtration device (3) and a negative pressure power device (4) are sequentially connected between the gas inlet and the gas outlet; the nitrogen filtering recovery system is characterized in that the gas filtration device (3) is arranged in a sealing way, the negative pressure power device (4) is independently arranged outside the gas filtration device (3), and the gas filtration device (3) is communicated with the negative pressure power by a pipeline. The system has obviously excellent filtering effect, reliable sealing performance and convenient assembly and disassembly, can be used for recovering scaling powder in a centralized way, and is applied to the field of gas circulating purification technology of the reflow oven.

Owner:依工电子设备(苏州)有限公司

Traditional Chinese medicine weighing and packaging device for pharmacists of traditional Chinese medicine

InactiveCN109335051APrevent drug efficacy from decreasingReduce filter effectWrapper twisting/gatheringSolid materialDrive motorChinese herbology

Owner:孙菁

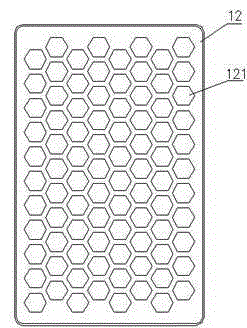

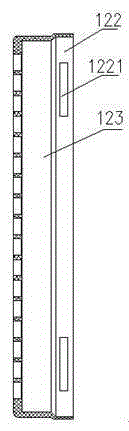

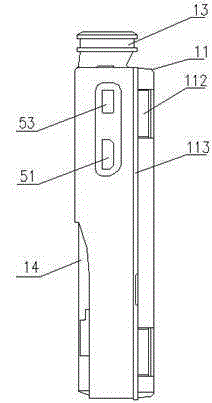

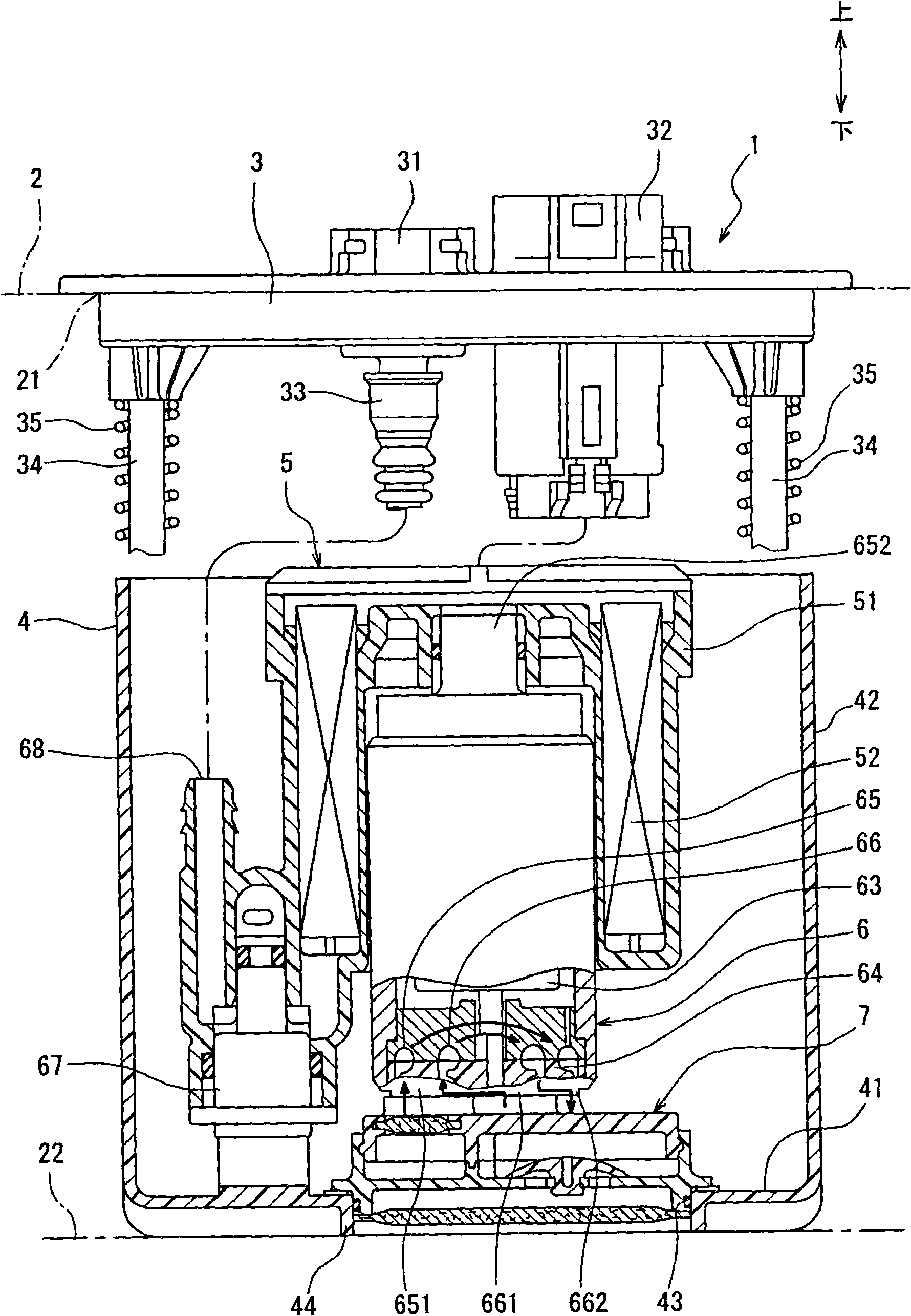

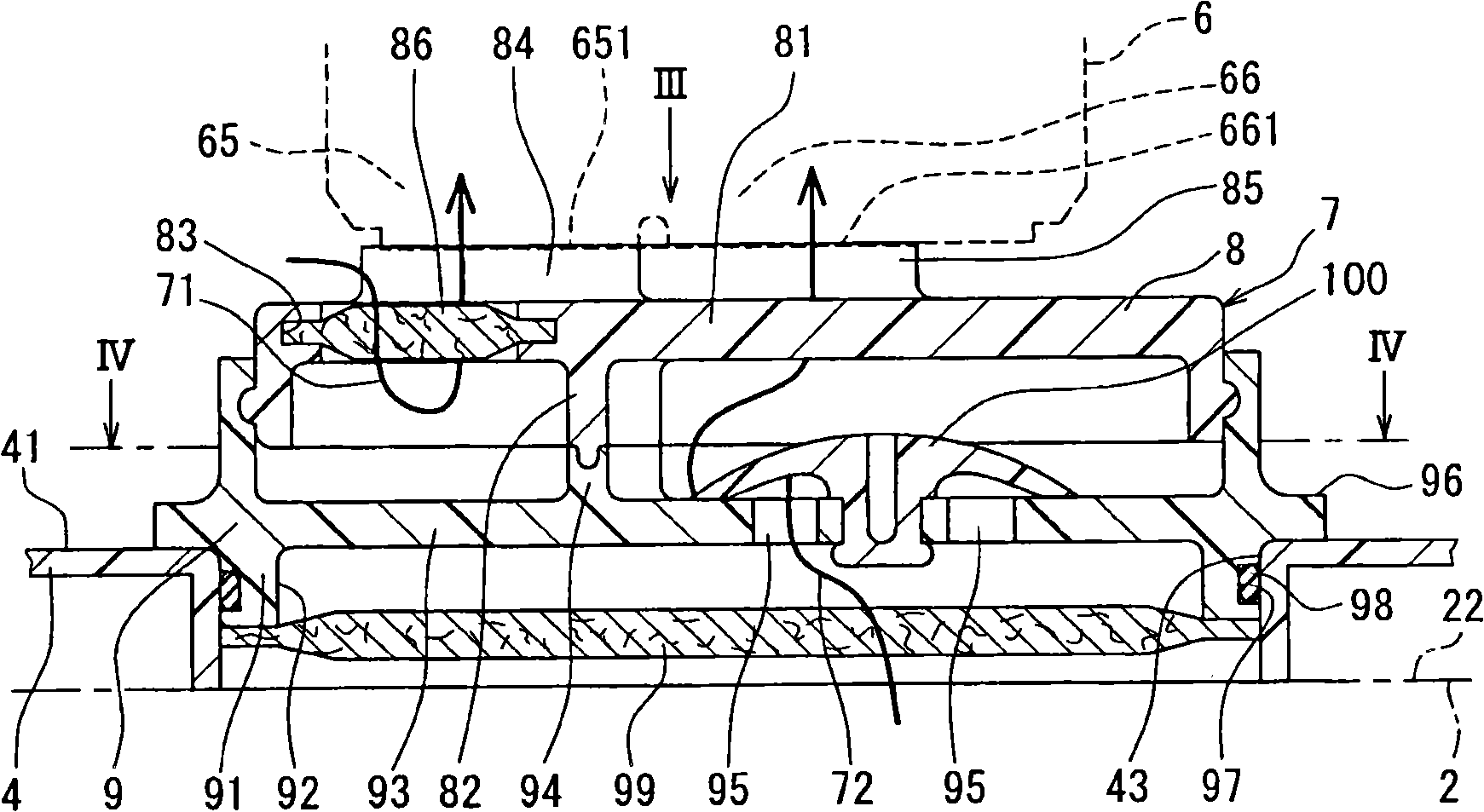

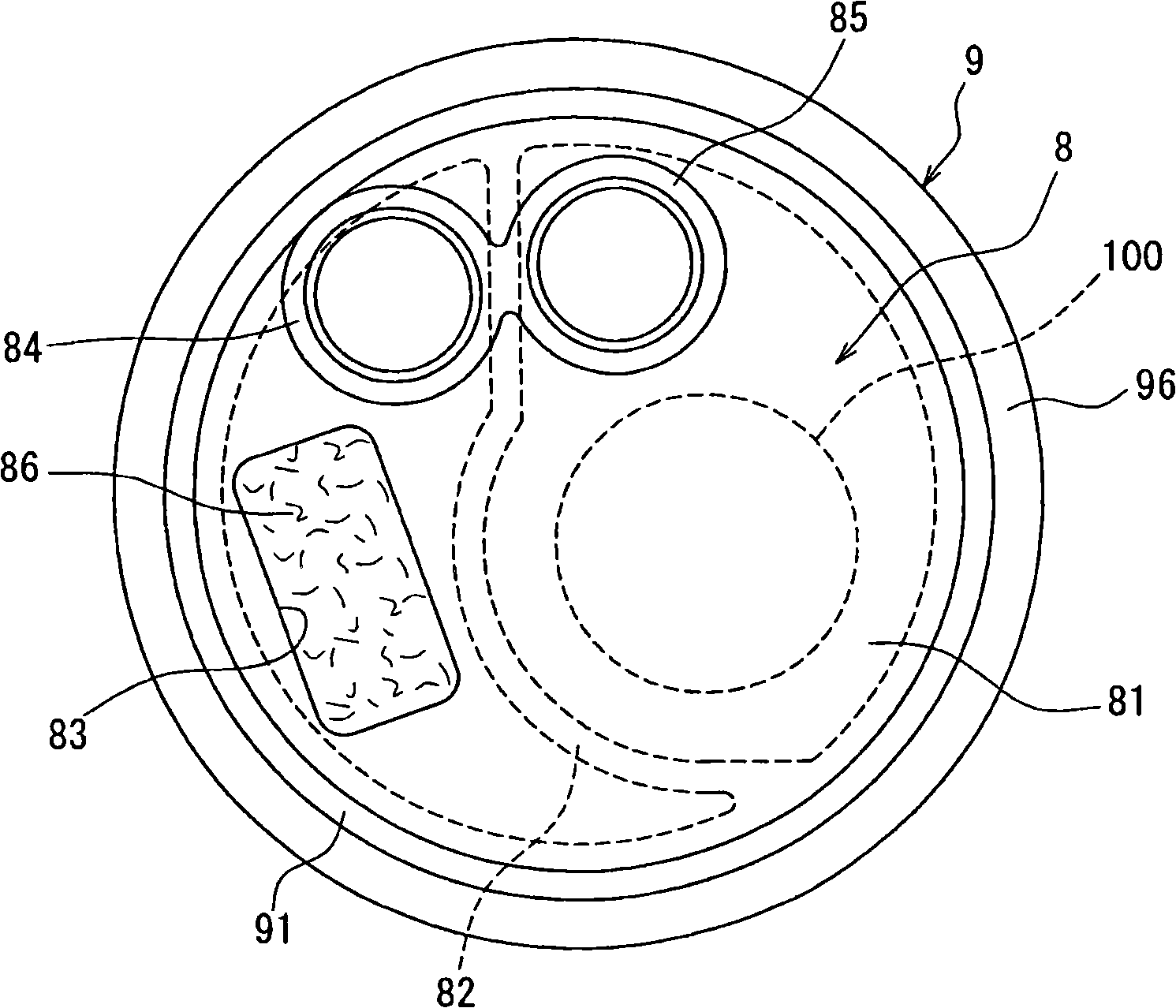

Fuel supply device

A fuel supply device includes a subtank in a fuel tank, a fuel pump in the subtank having a first pump unit suctioning fuel in the subtank to supply fuel to an external equipment and a second pump unit suctioning fuel outside the subtank to pump fuel into the subtank, and a filter connected to a first suction port of the first unit and a second suction port of the second unit and filtering supply fuel supplied to the equipment and pump fuel pumped into the subtank. The filter includes a case, a first filter, and a second filter. The first filter in a first passage of the case directing fuel in the subtank into the first port filters the supply fuel. The second filter in a second passage of the case directing fuel outside the subtank into the second port filters the pump fuel.

Owner:DENSO CORP

Filtering apparatus utilizing wetting filtering net for air sterilization and filtering

InactiveCN1548829AImprove adsorption capacityReduce filter effectLighting and heating apparatusAir conditioning systemsDrive shaftDisinfectant

The present invention is one filter with wet filtering net to disinfect and filter air. The filter includes one filtering net and one rack, and the wet filtering net is disinfectant liquid or water soaked and wound or folded onto some net holding part. One driving shaft with wound wet filtering net is driven by some driver. The filtering net holding part and the driving shaft are installed onto the rack and are detachable. The present invention has excellent filtering, dedusting and disinfecting effects. The filter of the present invention may be used alone or combined with other air purifying device or used in air conditioner or air exchange apparatus to raise disinfecting effect.

Owner:王彦

Sewage treatment system and treatment method thereof

ActiveCN106984077AReduce filter effectEasy to installSettling tanks feed/dischargeSedimentation settling tanksHelical bladeWater diversion

The invention discloses a sewage treatment system which comprises a precipitation tank, wherein a motor is mounted at the lower part of the left side of the precipitation tank, a rotating shaft is arranged at the output end of the motor in a manner of penetrating through the left sidewall of the precipitation tank, a discharge outlet is formed in the lower part of the right side of the precipitation tank, a two-way pipe is connected to the upper part of the right side of the precipitation tank through a water diversion pipe on which a water pump is mounted, a filtering tank is connected to the lower end of the two-way pipe, water guide cavities are arranged on the two sides of an inner cavity of the filtering tank, sewage filtering devices are mounted in the water guide cavities, and a water outlet is formed in the bottom of the filtering tank. According to the sewage treatment system, clamping plates are arranged, so that filter screens can be mounted and dismounted conveniently and fixed firmly and stably, and reduction in the filtering effects of the sewage filtering devices caused by the fact that the filter screens are impacted and separated by sewage falling off the water guide cavities is avoided; the rotating shaft is driven by the motor to rotate, and then sewage precipitates at the bottom of the inner cavity of the precipitation tank are discharged from the discharge outlet by a helical blade, so that a good discharge effect is achieved. The invention further provides a sewage treatment method.

Owner:工大环境股份有限公司

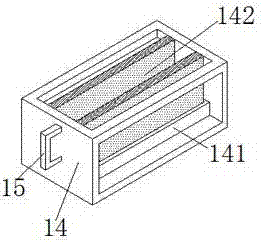

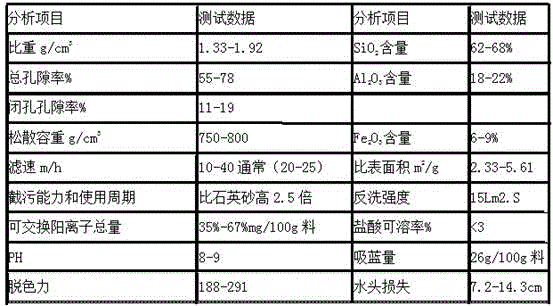

An attapulgite ceramic filter material for water treatment

InactiveCN105461342ADoes not destroy crystal formLarge specific surface areaCeramicwareClaywaresClay mineralsAdhesive

The invention relates to ceramic filter materials and particularly relates to an attapulgite ceramic filter material for water treatment. The specific surface area of attapulgite is increased by adding an agglomerant and an adhesive and calcinating, so that the attapulgite is high in adsorption capability and is increasingly taken seriously in waste water treatment and the modified attapulgite has wide uses in waste water treatment. The attapulgite is a water-containing magnesium-rich aluminosilicate clay mineral having a layered chain structure. By addition of the agglomerant and the adhesive and calcination, attapulgite crystals are hairy or fibrous, are rod-like or needle like under an electron microscope, are white, grey, light green or light brown, and are fibrous under an atomic force microscope. The inside of the attapulgite is provided with a plurality of porous channels and the cross section of the porous channels is about 0.38 nm*0.63 nm. The attapulgite ceramic filter material is particularly suitable for water treatment.

Owner:LANZHOU JIAOTONG UNIV

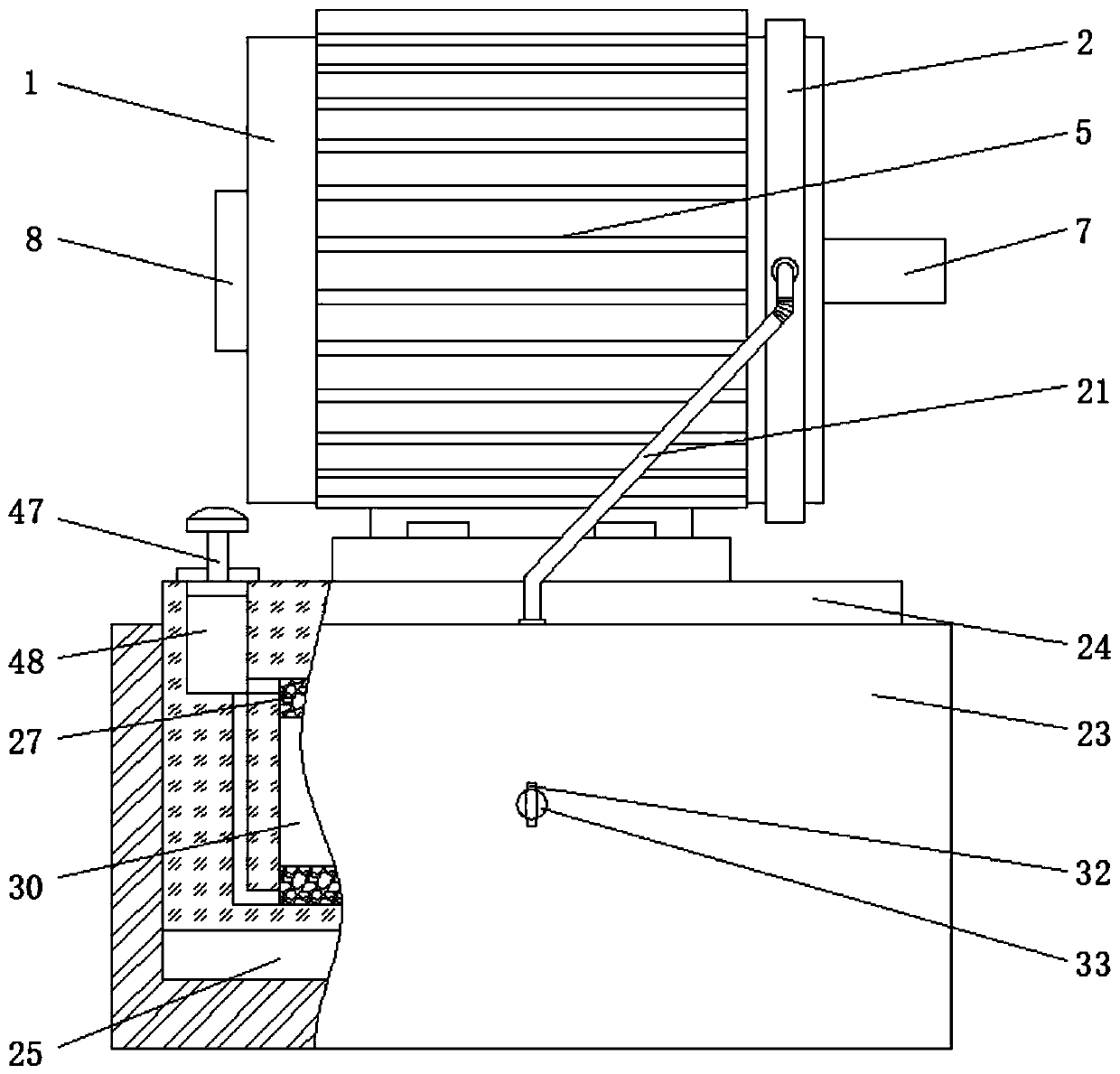

Motor with shock absorption and heat dissipation functions

ActiveCN110868011ARealize the shock absorption effectImprove stabilityCooling/ventillation arrangementSupports/enclosures/casingsOil canEngineering

The invention discloses a motor with shock absorption and heat dissipation functions. The motor comprises a motor body, a heat dissipation mechanism and a shock absorption seat; a cavity is formed inthe top of the shock absorption seat, a shock absorption block is slidably connected to the interior of the cavity, an oil filtering cavity is formed in the center of the interior of the shock absorption block, an oil pressing seat is slidably arranged in the oil filtering cavity, the motor body is arranged above the shock absorption seat, and the heat dissipation mechanism is arranged in the motor body; the motor body comprises a casing, a stator, a rotor, a rotating shaft and a bearing; the heat dissipation mechanism comprises a first oil guide base, a heat conduction pipe and a second oil guide base. Oil can be effectively pushed into a machine body through vibration generated by working of the motor body; heat exchange cooling is conducted on the interior of the machine body through flowing of oil, lubrication on bearings is achieved, mechanical loss is reduced, the service life of the motor body is prolonged, oil pressure of backflow oil can be effectively used as buffering forceto reduce device vibration, the operation stability of the motor body is improved, overall energy consumption is low, linkage performance is high, and the motor is suitable for popularization.

Owner:WUXI NEW GREAT POWER ELECTRICAL MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com