Gas monitoring probe and gas monitoring system

A gas monitoring and gas technology, applied in the direction of color/spectral characteristic measurement, sampling device, etc., can solve the problems of untimely cleaning of dust impurities, detection result errors, etc., to achieve the effect of ensuring cleaning, eliminating errors, and avoiding detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

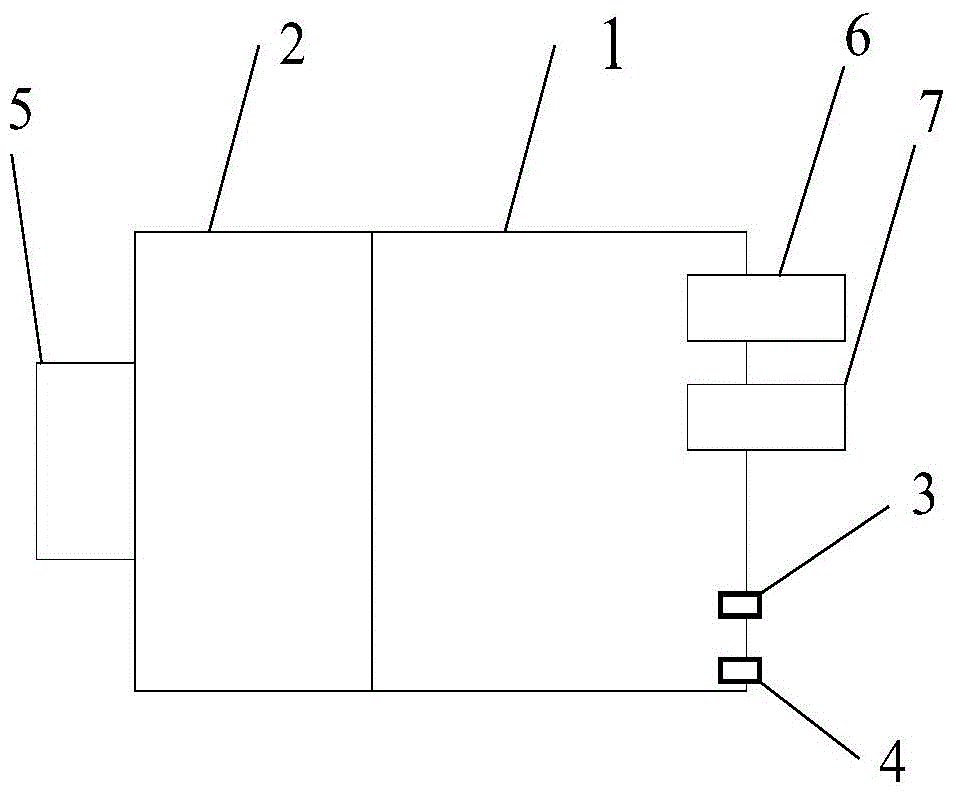

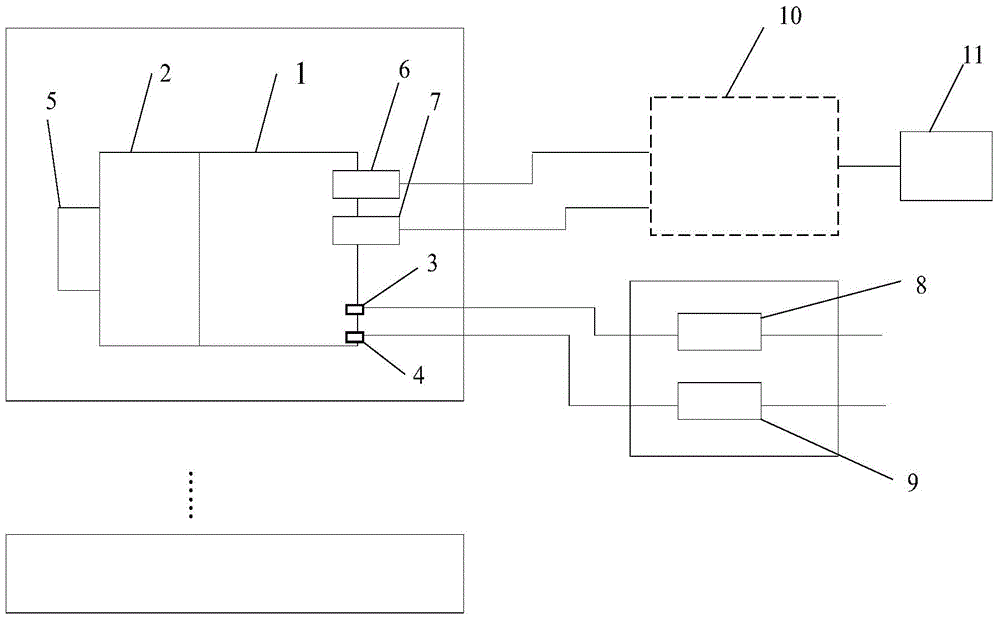

[0025] Such as figure 1 Shown is a schematic diagram of the structure of the gas monitoring probe. The gas monitoring probe includes a sampling inner cavity 1, the sampling inner cavity 1 communicates with the filter device 2 through a communication airway, and the filter device 2 has an air inlet 5; The gas to be tested is filtered to prevent dust and impurities from being sampled in the inner chamber 1, causing errors in the test results.

[0026] The sampling inner cavity 1 has a purge inlet 3 and an air extraction outlet 4 .

[0027] After a long period of detection, it is inevitable that a certain amount of tiny dust and impurities will accumulate in the sampling inner cavity 1. When the sampling inner cavity 1 is purged and cleaned, the purge air inlet 3 blows the cleaning gas into the sampling inner cavity 1, and the cleaning gas The dust and impurities in the sampling inner cavity 1 are blown up, and the cleaning gas blown into the sampling inner cavity 1 by the purg...

Embodiment 2

[0030] Such as figure 1 Shown is a schematic diagram of the structure of the gas monitoring probe. The gas monitoring probe includes a sampling inner cavity 1, the sampling inner cavity 1 communicates with the filter device 2 through a communication airway, and the filter device 2 has an air inlet 5; The gas to be tested is filtered to prevent dust and impurities from being sampled in the inner chamber 1, causing errors in the test results.

[0031] The sampling inner cavity 1 has a purge inlet 3 and an air extraction outlet 4 .

[0032] After a long period of detection, it is inevitable that a certain amount of tiny dust and impurities will accumulate in the sampling inner cavity 1. When the sampling inner cavity 1 is purged and cleaned, the purge air inlet 3 blows the cleaning gas into the sampling inner cavity 1, and the cleaning gas The dust and impurities in the sampling inner cavity 1 are blown up, and the cleaning gas blown into the sampling inner cavity 1 by the purg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com