Method for preparing tows for modified cigarettes

A technology for tow and cigarettes, which is applied in the field of preparation of blended modified polylactic acid tow for cigarettes, can solve problems such as poor mechanical properties, high preparation process, and high specific weight, and achieve improved melt flow performance and good filtration effect, the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mix fiber-grade polypropylene particles, functional masterbatches and polylactic acid particles, and stir evenly. The proportions of the components are: functional masterbatch: no more than 5%; polylactic acid: no more than 10%; the rest is fiber-grade poly Propylene particles; fiber-grade polypropylene particles have a viscosity average molecular weight of 180,000 to 200,000, and a molecular weight distribution of less than 6. The functional masterbatch is a mixture of molecular weight adjusting masterbatch, fiber strength adjusting masterbatch and whitening masterbatch according to the weight component ratio of 2:1:2. The weight average molecular weight M of polylactic acid particles wBetween 80,000 and 160,000. The mixed particles are extruded into a spinning melt through a screw extruder, and the spinning melting temperature in the screw extruder is 170-240°C. Then spinning, the number of holes in the spinning spinneret is 5500 to 11500 holes; the spinning melt af...

Embodiment 2

[0034] Take 75kg of polylactic acid slices with a molecular weight of 100,000 and MI=15-30g / 10min, take 2,000g of polypropylene slices with a molecular weight of about 180,000 and MT=15-30g / 10min, and 1,000g of functional masterbatches, which are molecular weight adjustments The masterbatch, the fiber strength adjusting masterbatch and the whitening masterbatch are mixed according to the weight component ratio of 2:1:2. Put it into the screw extruder, the temperature of the spinning equipment is controlled at 170-250°C, and it is melted under the action of the screw extruder. The spinneret hole is 9100 three-lobed special-shaped, and the air temperature of the tow cold blower is controlled at 12-30°C , the wind speed is 0.2-0.5m / s, and the tow is drawn again through the slow drawing roller, water bath, and fast drawing roller. The drafting ratio is 2 to 4 times that of the initial drawing, and the temperature of the water bath is controlled at 50-70°C , the drawing speed of th...

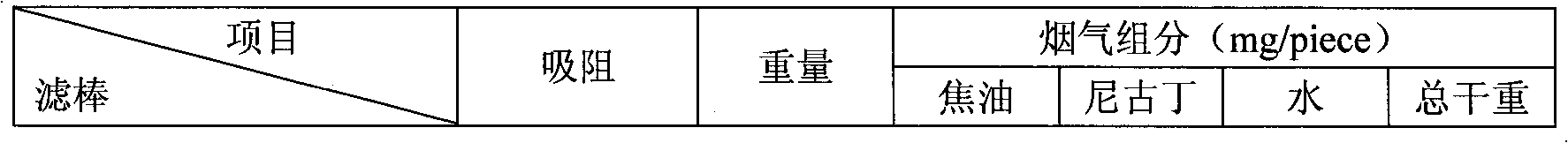

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com