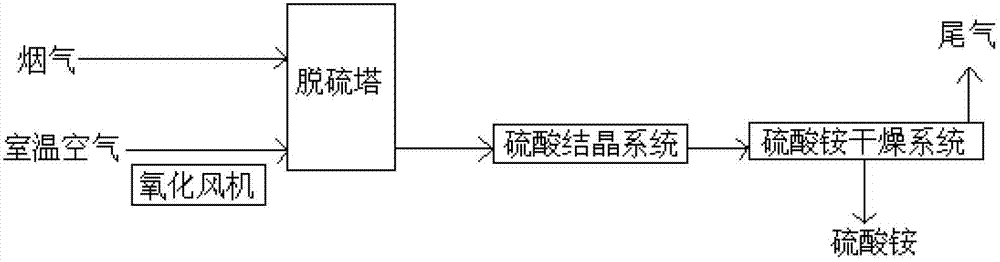

Purification technology for side product of flue gas ammonia-desulphurization

A technology of ammonia desulfurization and by-products, which is applied in the field of flue gas ammonia method, can solve the problems affecting the quality of by-products, achieve the effects of improving gas mixing efficiency, prolonging the cycle of backwashing, and improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

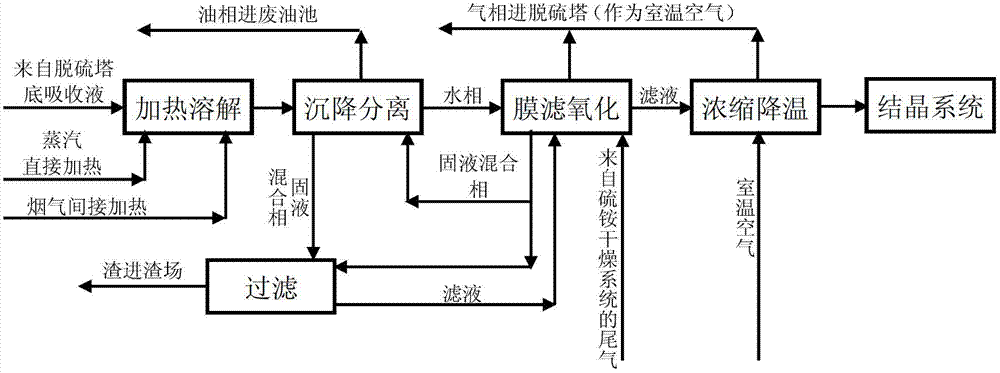

Embodiment 1

[0044] 1. Solid-liquid separation: 20-50% of the total amount of room temperature air from the bottom of the desulfurization tower (the total volume percentage of room temperature air required to fully oxidize ammonium sulfite and ammonium nitrite in the absorption liquid is 100%), combined with the absorption liquid The ammonium sulfite and ammonium nitrite in the solution are partially oxidized, and then the absorption liquid (solid phase content 5-10% by mass) is transported to the heating and dissolving tank by the delivery pump, and part of the flue gas (such as the low-sulfur section flue gas temperature (Generally 180-200°C) Indirectly heated to 75-90°C, the flue gas after heat exchange is sent back to the desulfurization tower; the heated absorption liquid is sent to the oil and slag removal tank for standing, and then settles and stratifies to form an oil phase and dissolve The water phase and solid-liquid mixed phase with ammonium sulfate and ammonium sulfite, skim o...

Embodiment 2

[0048] In step 1, steam is used to directly heat the absorption liquid; in step 2, the solid-liquid mixture filtered by the filter membrane is returned to the oil and slag removal tank for standing and then settled for separation, and the gas phase obtained in steps 2 and 3 is directly discharged, and the rest With embodiment 1.

Embodiment 3

[0050] In step 2, the solid-liquid mixture part (50% by weight) filtered by the filter membrane is returned to the oil and slag removal tank for standing and then settled for separation, and part is sent to the filtration system for filtration. All the other are with embodiment 1.

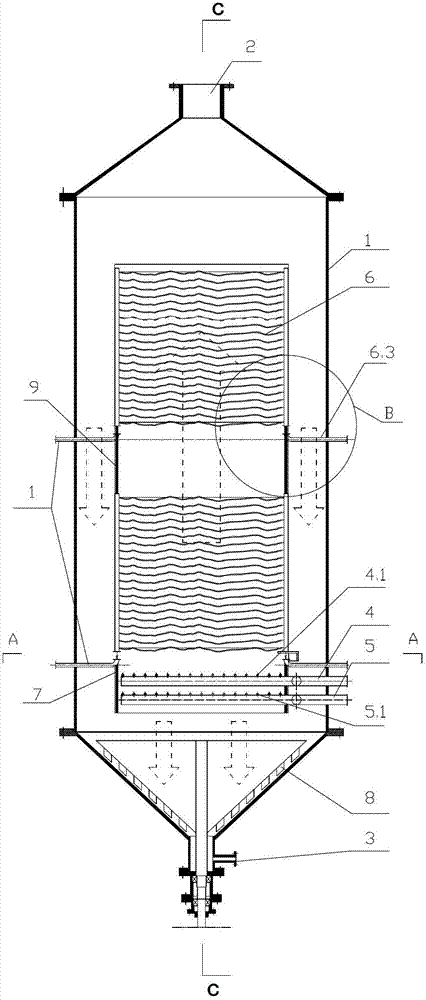

[0051] Reactor Example:

[0052] refer to image 3 and Figure 4 , the top of the cylinder 1 is provided with an exhaust port 2, and the bottom is provided with a sewage outlet 3, and the cylinder 1 is provided with a filter membrane assembly 6 along the center of the axis, referring to Figure 5 , the filter membrane assembly 6 is composed of multilayer membrane tubes 6.1, membrane tube drain frame 6.2 and clear liquid outlet 6.3 which are connected to each other. The membrane tubes in the multilayer membrane tubes are hollow fiber membranes, and the membrane aperture range is 0.05- 0.5 μm. In this embodiment, the filter membrane assembly 6 includes two groups arranged vertically along the axi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com