Nitrogen filtering recovery system of reflow oven

A technology of reflow soldering furnace and recovery system, which is applied in the direction of dispersed particle filtration, steam condensation, nitrogen purification/separation, etc., which can solve problems such as difficult sealing performance, difficult maintenance and cleaning, damage to negative pressure power devices, etc., to increase service life, Effect of reducing volume and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

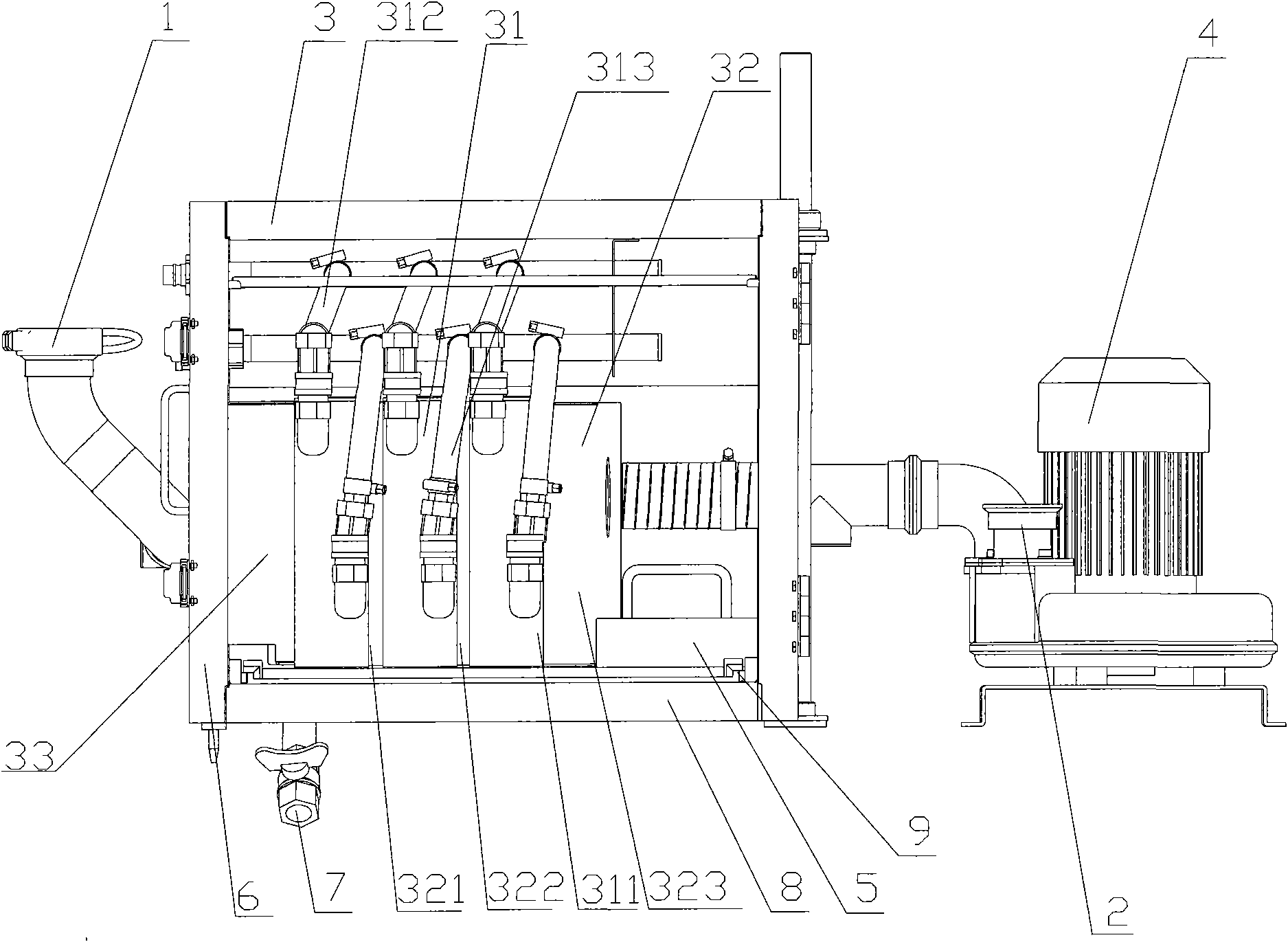

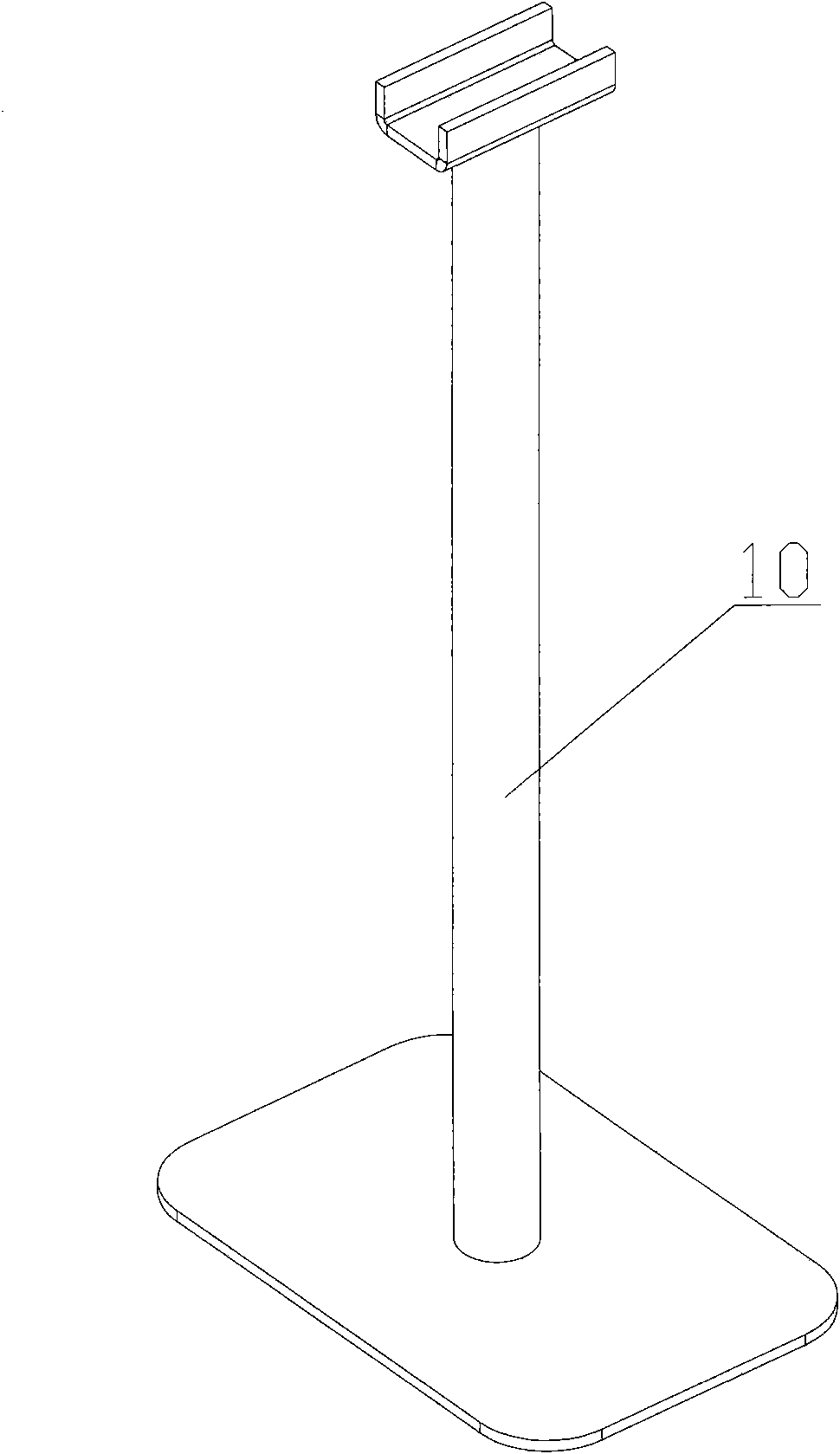

[0032] Example Figure 1~2 The nitrogen filtration recovery system of the reflow oven includes a gas inlet 1 and a gas outlet 2, and a gas filtration device 3 and a negative pressure power device 4 are sequentially connected between the gas inlet and the gas outlet. The gas filter device 3 is arranged in a sealed manner, and the negative pressure power device 4 is independently arranged outside the gas filter device 3 , and the gas filter device 3 communicates with the negative pressure power device through a pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com