Patents

Literature

142results about How to "Reduced drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fresh dendrobium officinale American ginseng particle and preparation method thereof

ActiveCN103230538AReduced drying processAvoid breakingNervous disorderMetabolism disorderFiltrationAdditive ingredient

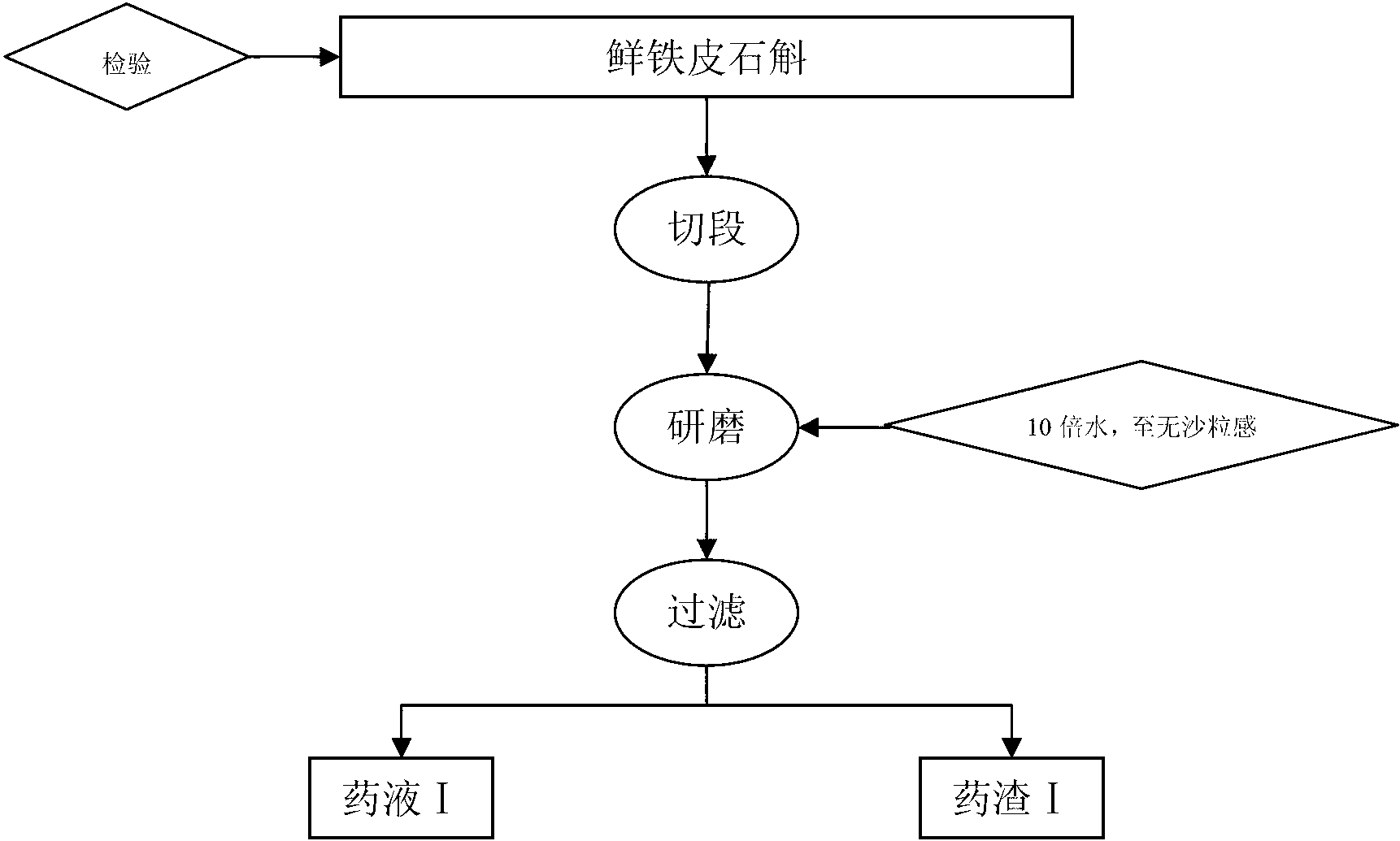

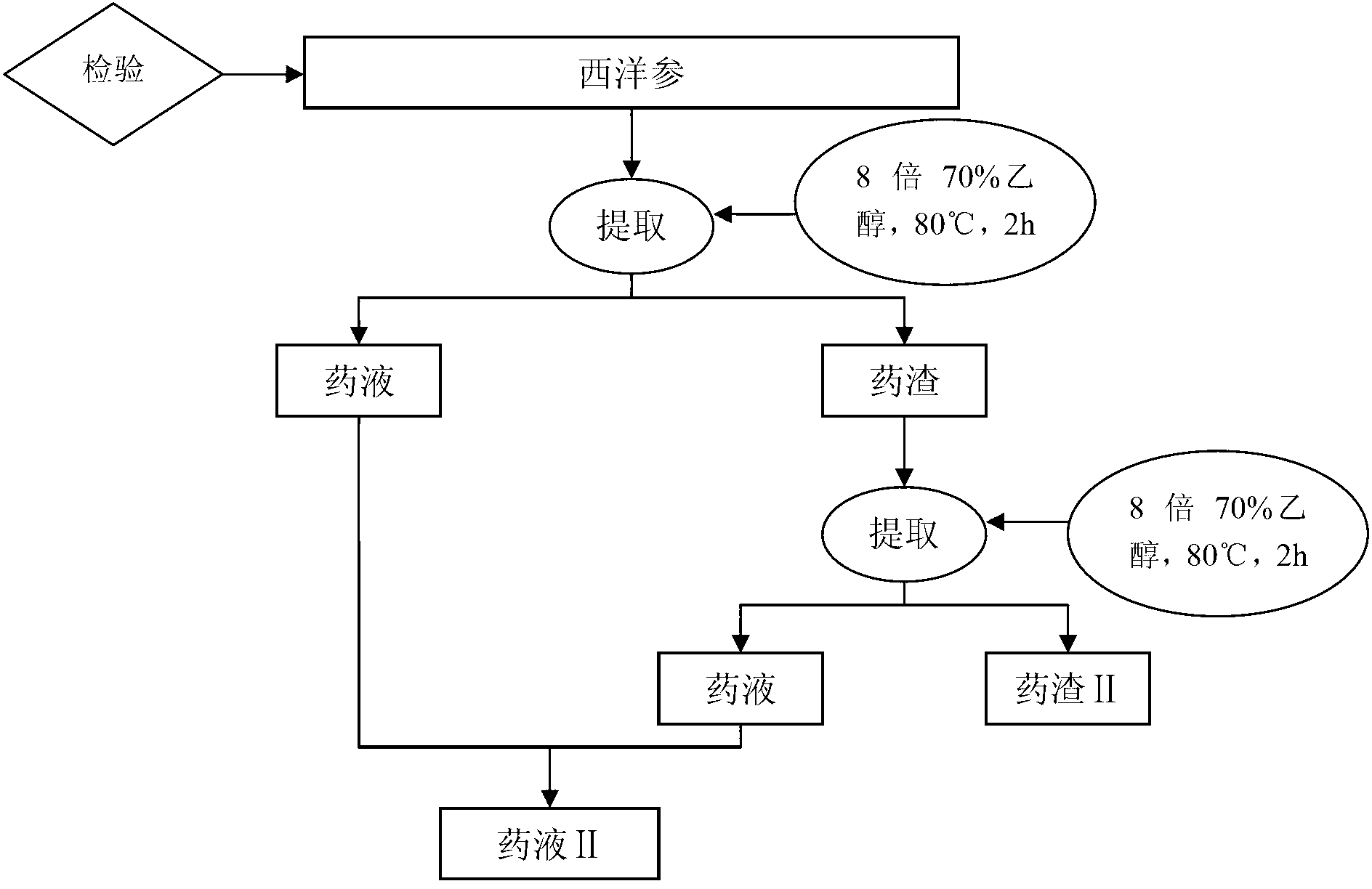

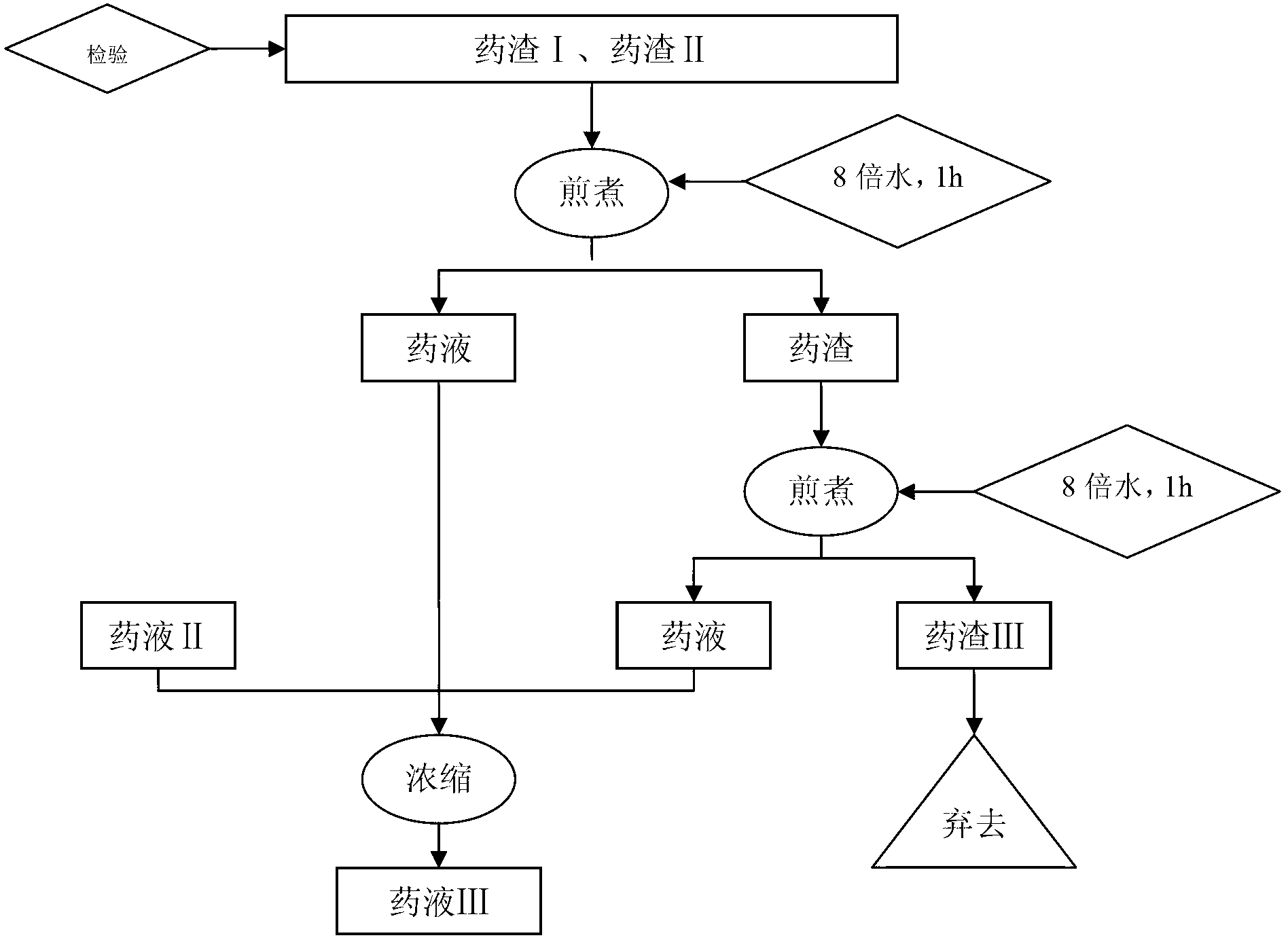

The invention discloses a fresh dendrobium officinale American ginseng particle and a preparation method thereof. The weight proportion of dendrobium officinale to American ginseng is (1.5-3.0): (0.8-2.0), wherein the dendrobium officinale is fresh and the American ginseng is dry. The method comprises the following steps of: grinding, filtration, extraction, drying and granulation. The fresh dendrobium officinale American ginseng particle has the beneficial effect that fresh dendrobium officinale is used as raw materials for direct processing, so that the traditional drying process of the dendrobium officinale is saved and the effective constituents are not easy to be destroyed; the obtained product has high polysaccharide content and the yield is higher than that of the traditional process, so that the advantage of the fresh dendrobium officinale American ginseng particle is more obvious. Moreover, as being rich in dendrobium officinale chlorophyll, the product has light green color after brewing; and chlorophyll is taken as a mark to indicate whether the nutritional ingredients are destroyed or not in the product processing process, the product follows the principle of low temperature and quick speed in the whole processing process and then the nutritional ingredients including the dendrobium officinale chlorophyll are completely retained, so that the product has light green color and natural smell after brewing, and to the point, the similar products on the market cannot achieve the effect.

Owner:浙江亚林生物科技股份有限公司

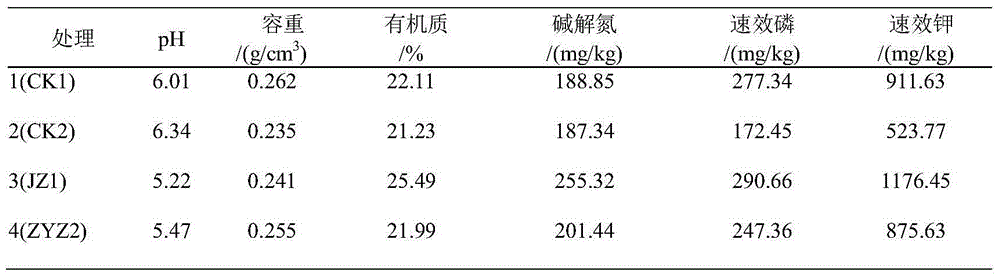

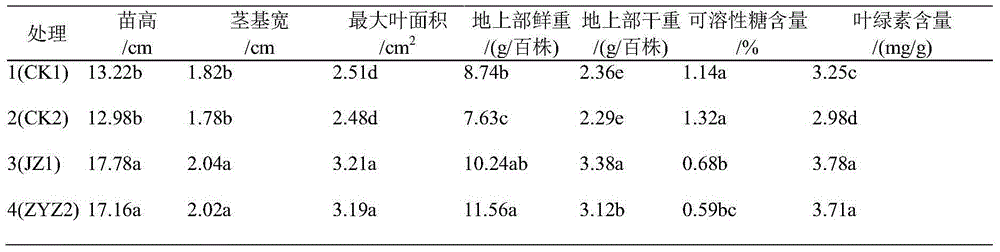

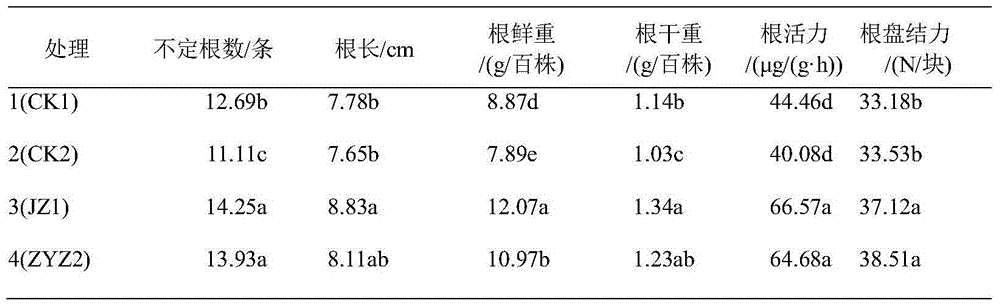

Organic ecological substrate for rice industrialized seedling production and preparation method of organic ecological substrate

InactiveCN104909909AGood qualityReduce pollutionBio-organic fraction processingOrganic fertiliser preparationMicrobial agentHusk

The invention belongs to the technical field of rice matrix seedling and discloses an organic ecological substrate for rice industrialized seedling production. The organic ecological substrate for rice industrialized seedling production comprises the following components in parts by mass: 20 to 40 parts of animal dung, 30 to 50 parts of organic waste, 15 to 30 parts of a conditioner, 20 to 40 parts of carbonized rice husk and 0.01 to 0.03 part of a microbial agent. The organic ecological substrate has high nutrient content and good seedling strengthening effect. The invention also provides a preparation method of the organic ecological substrate for rice industrialized seedling production.

Owner:ZUNYI NORMAL COLLEGE

Method for extracting vanadic anhydride from stone coal vanadium ore

InactiveCN101182596AReduced drying processFew ingredientsVanadium oxidesProcess efficiency improvementCelsius DegreeDesorption

The invention relates to a method for extracting vanadic oxide from bone coal vanadium mine; the method comprises the following steps that the bone coal vanadium mine is selected to be delivered into a kiln for baking and the kiln temperature is controlled between 750 to 1100 Celsius degrees and the discharge temperature of the baked material is 750 to 1000 Celsius degrees; and then the materials are delivered into a heat-preservation warehouse to be kept still for 24 to 120 hours; and then the material is extracted and the pH value of the obtained extraction liquid is adjusted to be 2.5; the liquid is absorbed and desorbed to obtain the desorption liquid and then the desorption liquid is purified and the silicon and phosphor in the desorption liquid is removed; ammonium chloride is added to precipitate vanadium and obtain ammonium meta-vanadate; the ammonium meta-vanadate is implemented with the process of pyrolysis to obtain the vanadic oxide. The beneficial effect of the invention is that the bone coal vanadium mine is directly baked which reduces the working procedures of baking, proportioning, ball grinding and balling; the invention adopts the heat-preserving warehouse for preserving heat and the extraction rate can reach more than 90 percent if the temperature is kept between 750 to 1100 Celsius degrees for more than 72 hours; the extraction rate is higher if the heat-preserving time is longer; moreover, the mechanization degree is high and no dust pollution exists.

Owner:杨秋良

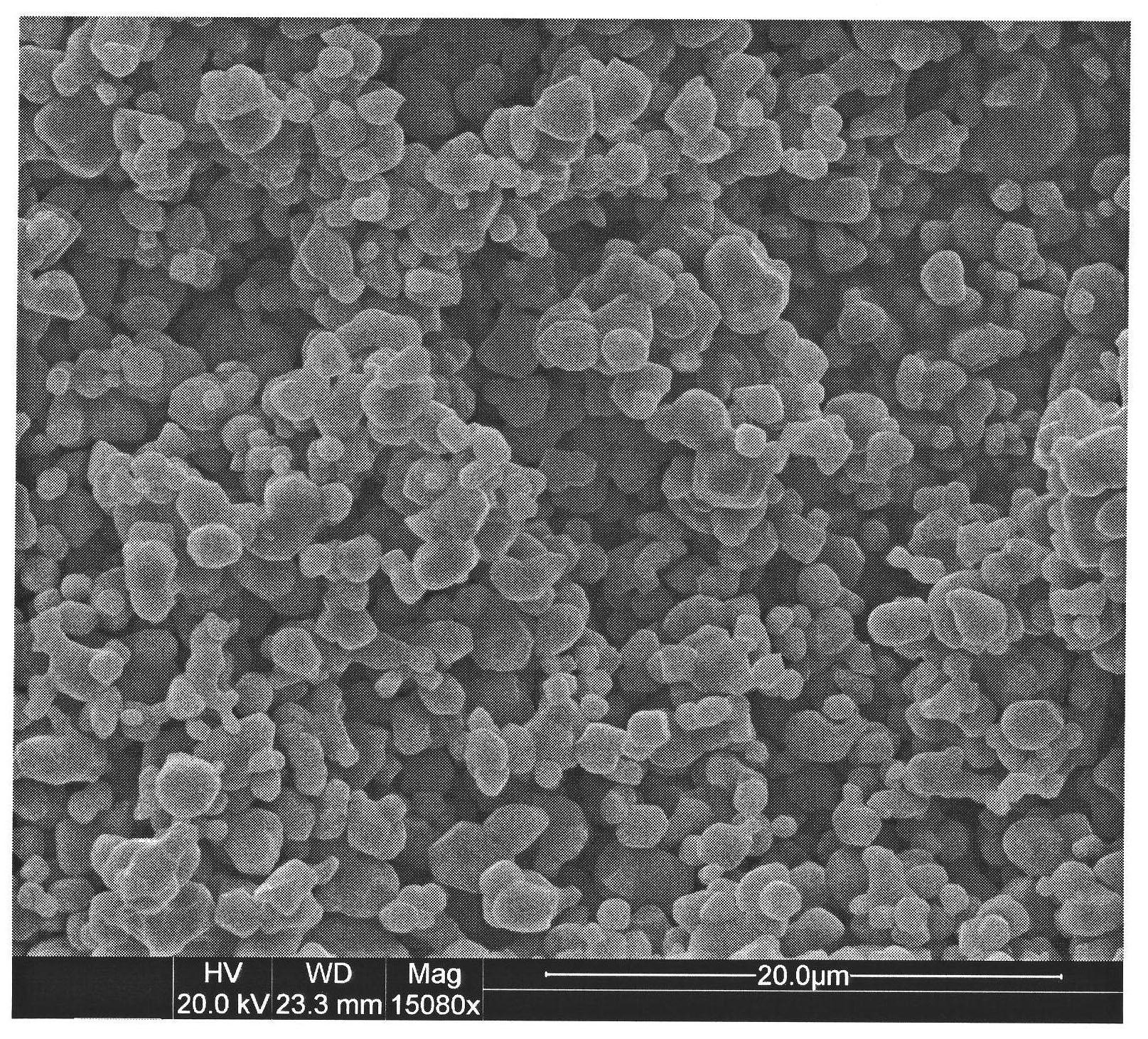

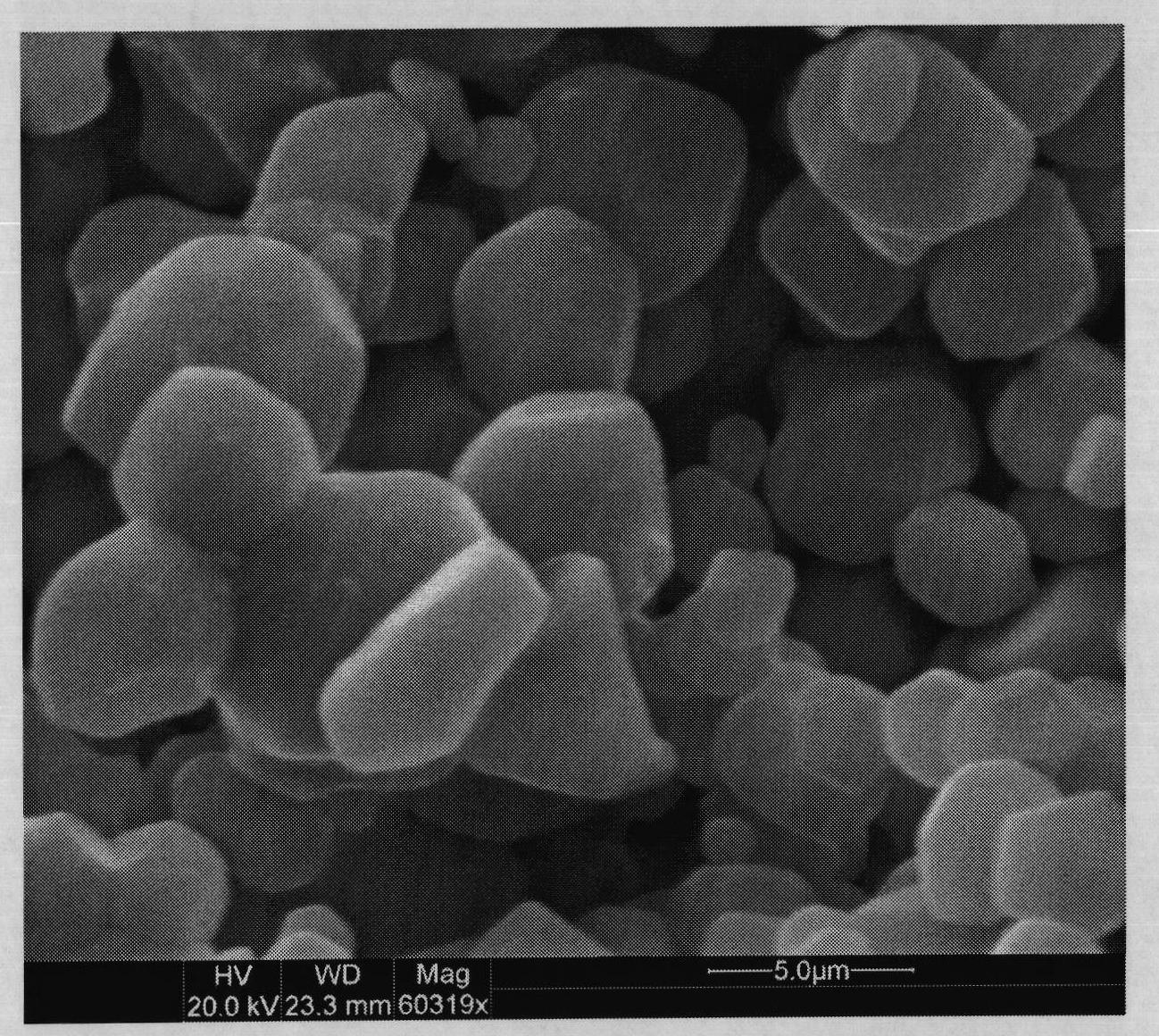

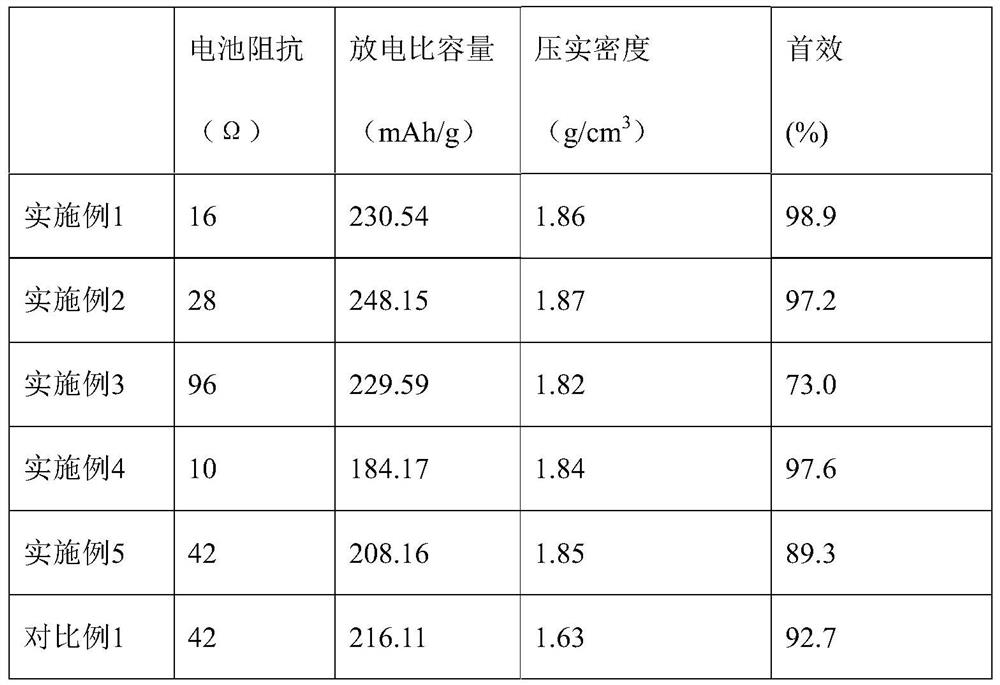

Battery-grade cobaltosic oxide preparation method

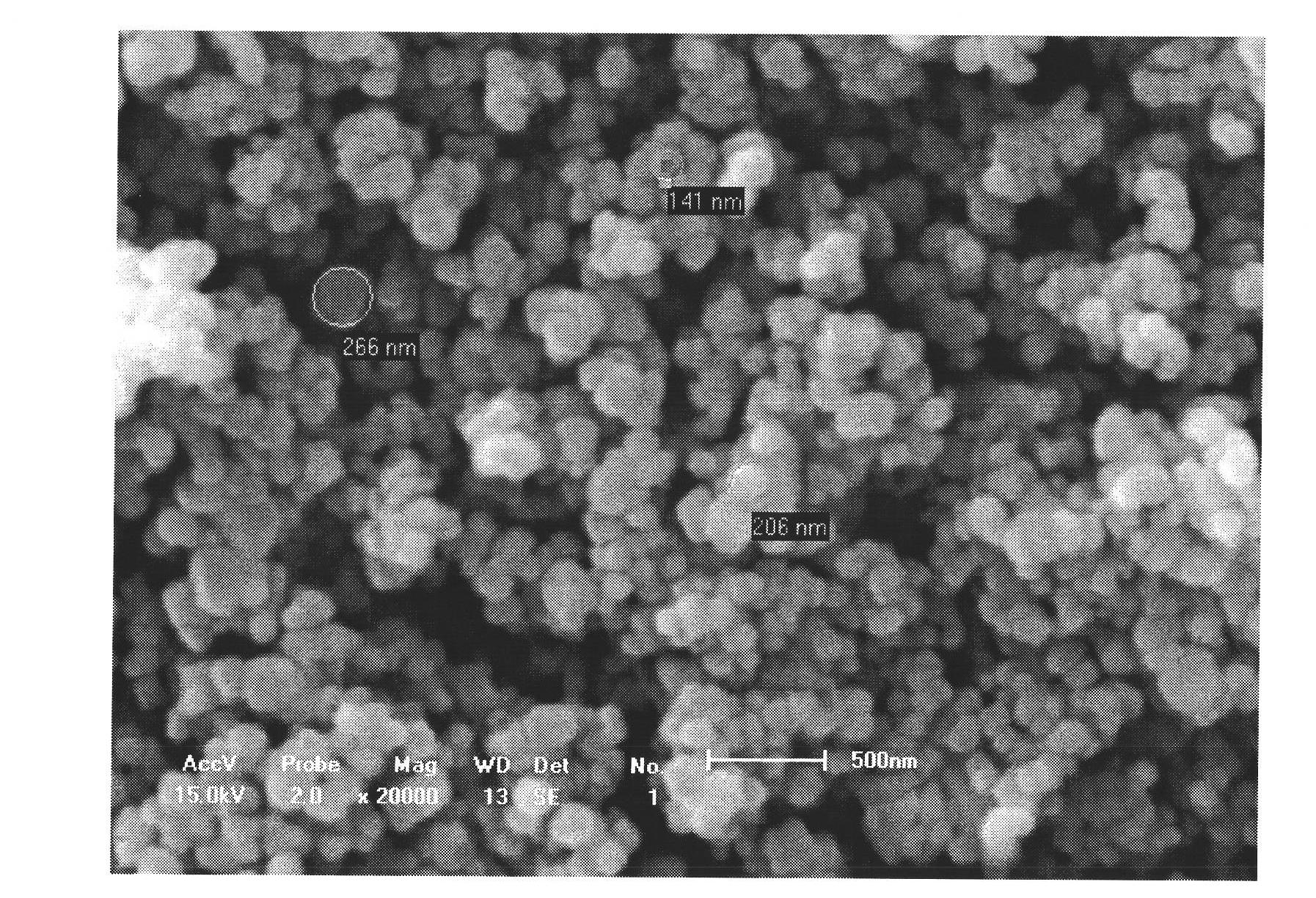

InactiveCN101913659AHigh densityHigh chemical purityCobalt oxides/hydroxidesReaction temperatureSpherical shaped

The invention relates to a battery-grade cobaltosic oxide preparation method, which comprises the following steps of: preparing solution of cobalt and solution of precipitator from a cobalt raw material and a precipitator by using de-ionized water respectively; preparing a precursor by using a homogeneous crystallization precipitation method, wherein the precipitate precursor is synthesized by adding the prepared solution of cobalt at a certain concentration and the solution of precipitator at a certain concentration into a reactor according to a certain molar ratio by using a cocurrent-flow feeding method, and effectively controlling chemical impurities, crystallinity of crystals, granularity, density and the like of the precursor by controlling parameters such as reaction temperature, feeding speed, pH value and stirring speed; directly filling a water-containing filter cake into a pot after washing and dewatering, and controlling grain size and crystal shape by using low-temperature dehydration phase-change calcination and high-temperature nodulizing sintering; crushing by using a machine and performing classified activation treatment; and finally, removing magnetic metal foreign bodies to obtain the battery-grade cobaltosic oxide similar to spheres. The battery-grade cobaltosic oxide has high density and high chemical purity, the grain size is easy to control, grain composition is uniform and narrow in distribution, and the magnetic metal foreign body content is low.

Owner:JIANGSU DONGXIN ENERGY TECH

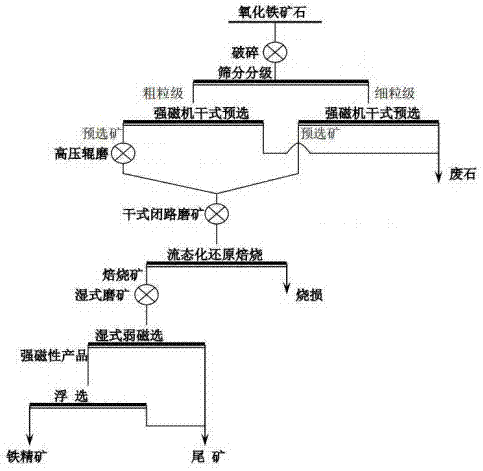

Combined mineral separation technology for ferric oxide mineral

InactiveCN107185686AThrow out earlyReduce transportationMagnetic separationGrain treatmentsIronstoneOxide minerals

The invention discloses an iron oxide ore joint beneficiation process, which comprises the following steps: (1) dry selection and discarding of iron oxide ore to obtain pre-selected coarse-grained ore, pre-selected fine-grained ore and waste rock; (2) high-pressure Roller mill crushing: the pre-selected coarse-grained ore obtained in step (1) is fed into a high-pressure roller mill for crushing; (3) dry grinding: the crushed product in step (2) and the pre-selected fine-grained ore in step (1) Combined for dry closed-circuit grinding; (4) Fluidized reduction roasting: a. Put the ground product obtained in step (3) into the fluidized reduction roaster; b. Preheating; c. Heating; d. Magnetization roasting; e . Cool to below 200°C to obtain roasted ore with a magnetite content greater than 90%; (5) beneficiation of roasted ore to obtain iron concentrate products with a grade of 57%-65%. The present invention can effectively solve the current iron oxide ore beneficiation There are technical problems such as low resource utilization rate, poor concentrate quality and high energy consumption in the process.

Owner:JIUQUAN IRON & STEEL GRP

Agglomeration-wrapping dry-proof pelleting method for organic inorganic mixed fertilizer

InactiveCN1951881AReduce moisture contentReduce pollutionSuperphosphatesAlkali orthophosphate fertiliserWater contentFree water

The invention discloses an agglomeration-parcel non-drying graining method of organic inorganic composite fertilizer in the fertilizer preparing domain, which comprises the following steps: allocating raw material; grinding; blending; graining through disc machine; parceling; shaping; sieving; detecting; packing. The invention transmits partial free water in the particle fertilizer into crystallized water without drying, which satisfies the request of GB18877-2002.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

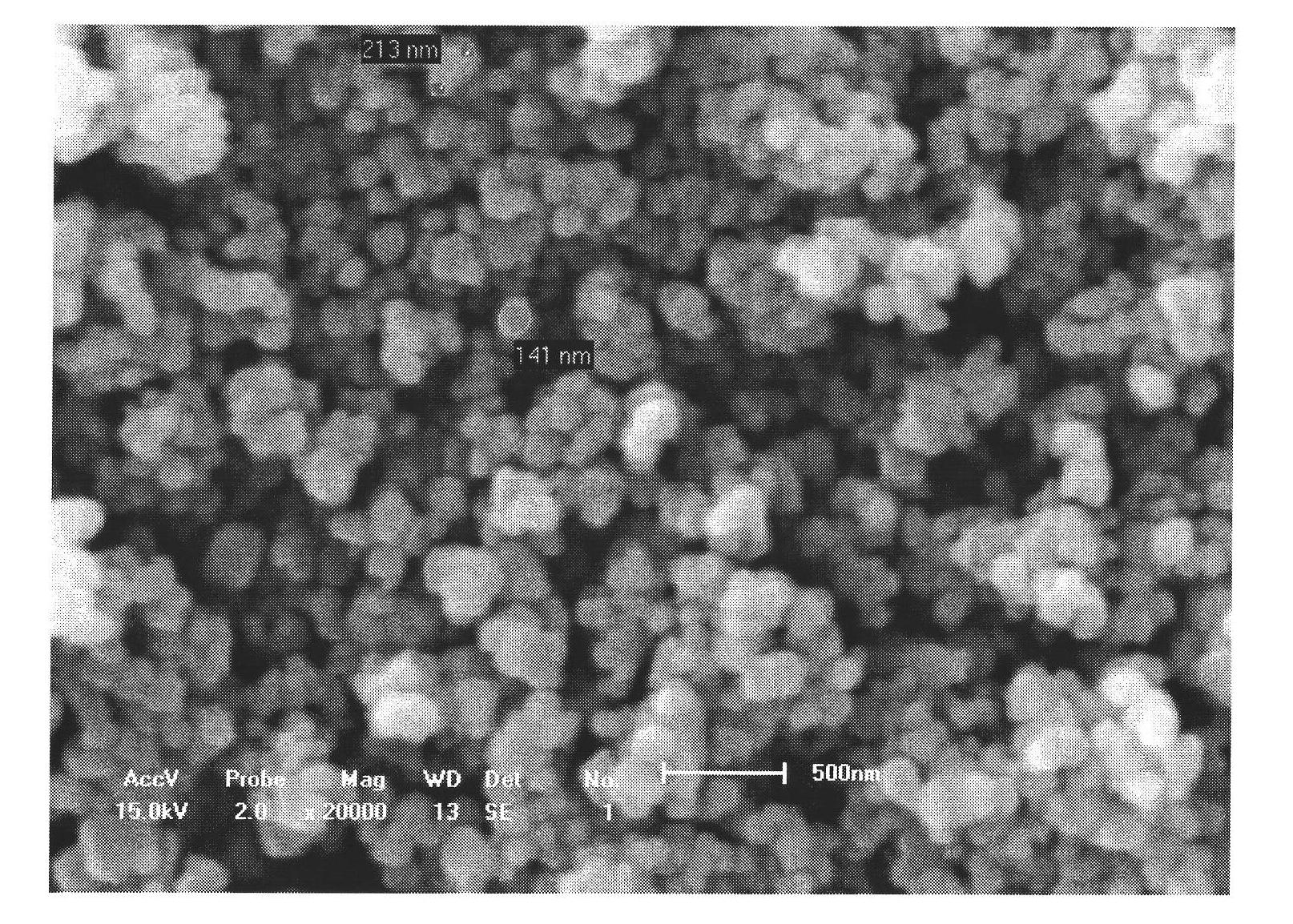

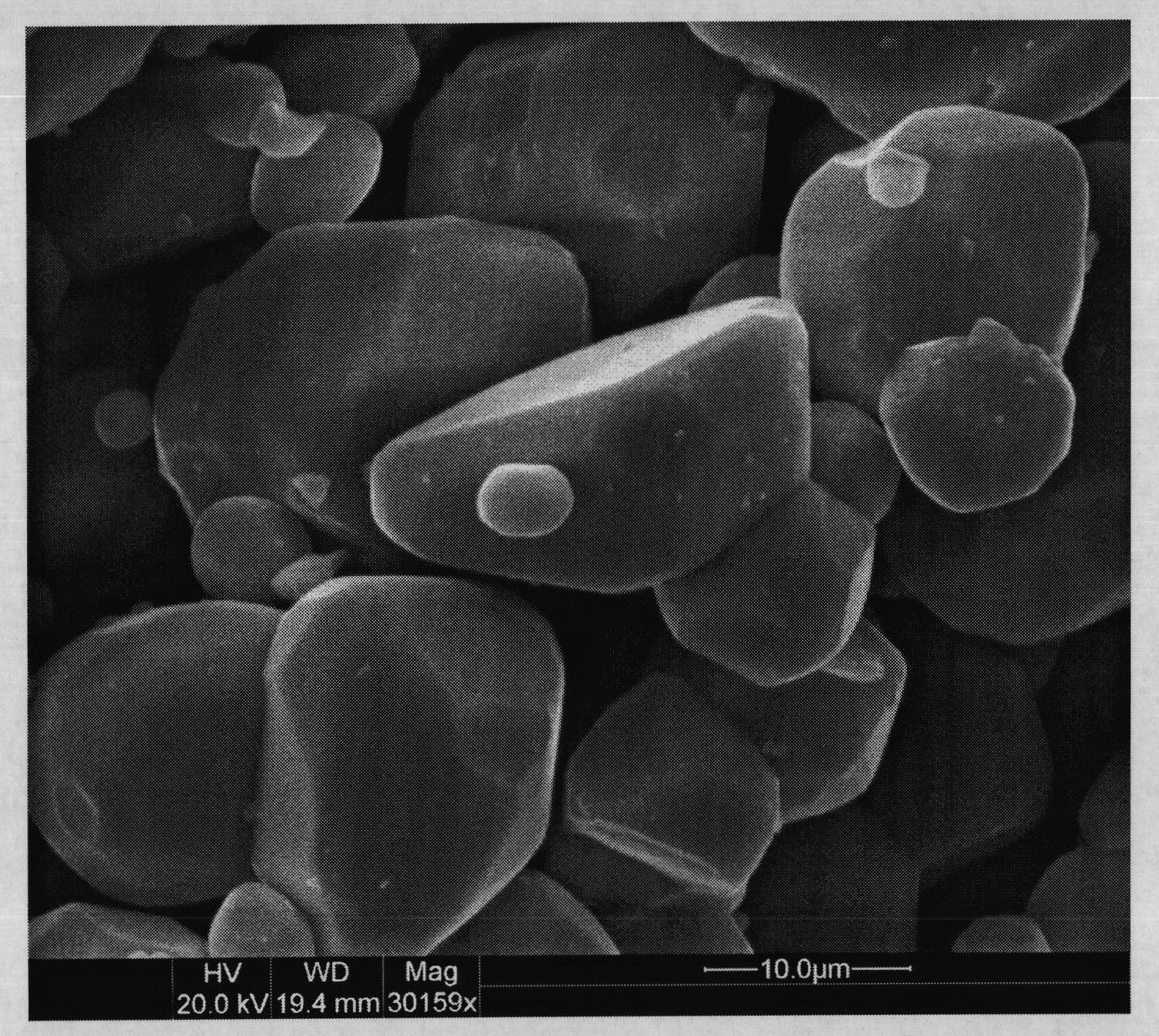

Preparation method of nano cobalt oxide

InactiveCN101982421AHigh densityHigh chemical purityNanostructure manufactureChemical industryForeign matterReaction temperature

The invention provides a preparation method of nano cobalt oxide, comprising the following steps: respectively preparing a cobalt raw material and precipitant into cobalt solution and precipitant solution by deionized water; adding the prepared cobalt solution with a certain concentration and the prepared precipitant solution with a certain concentration in accordance with a certain mole ratio toa reactor by using a parallel flow feed method; controlling the reaction temperature, the feed rate, the pH value and the stirring speed to prepare cobalt salt precursor; directly filling a water-containing filter cake into a bowl after washing and dehydrating; controlling the grain size and the crystal morphology through low-temperature dehydration, phase change calcination, mechanical pulverization and graded activation; and finally removing magnetic metallic foreign matters to obtain the nano cobalt oxide with high quality. The method is simple and easy to operate, has low cost, saves energy, is environmental friendly, and is applicable to industrial production; and the prepared cobalt oxide grains are fine and evenly distributed.

Owner:JIANGSU DONGXIN ENERGY TECH

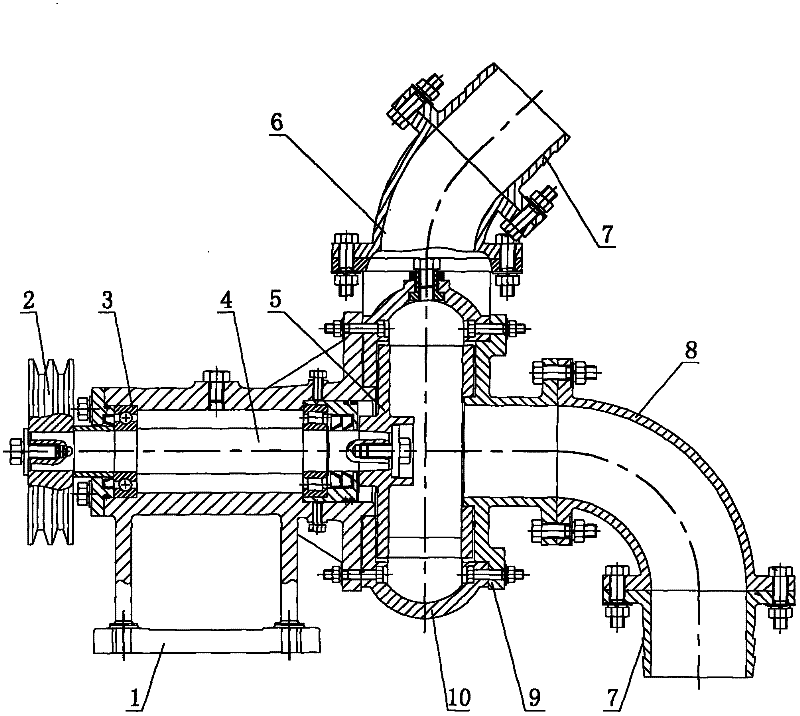

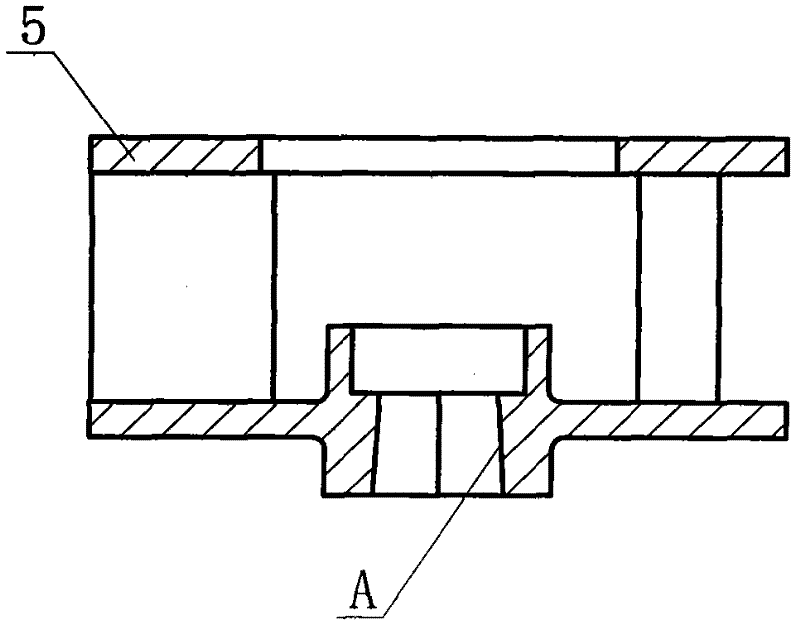

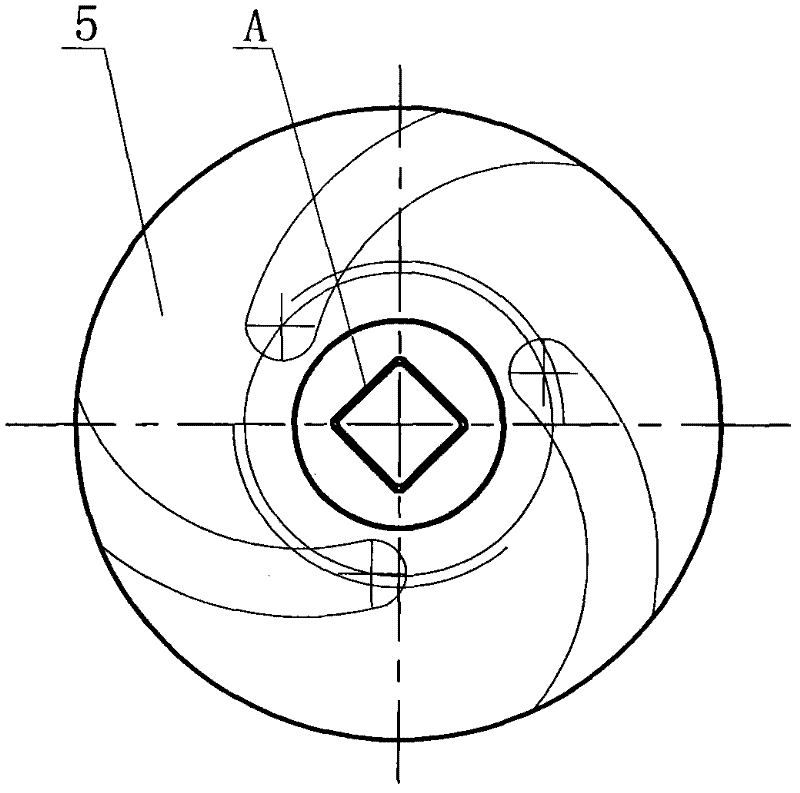

Wear-resisting sand pump and casting method thereof

InactiveCN102235365AQuality improvementGood surface accuracySpecific fluid pumpsFoundry mouldsImpellerDry sand

The invention discloses a method for casting a wear-resisting sand pump. In the wear-resisting sand pump, a pump impeller, a material inlet and a pump body are precisely cast by a vacuum lost mold; a shaft is connected with the pump impeller through an outer cone and an inner cone; and the outer cone and the inner cone are rectangular, prismatic or hexagonal and are fastened by screws. The precise casting method comprises the following process steps of: 1, partitioning a foam material to obtain main parts, and bonding by using an adhesion agent to obtain an integrated model of which the shape is consistent with the main shape of a casting; 2, coating a mica-based coating onto the outer surface of a foam model, and drying; 3, putting the dried foam model into a sand box, filling dry sand into the sand box, and performing three-dimensional oscillation compaction; 4, vacuumizing the sand box by using a vacuum system through negative pressure; 5, pouring molten metallic iron from the feeder head of the sand box to replace the position of a foam-molded model so as to obtain a corresponding main part of the sand pump; and 6, condensing. The wear-resisting sand pump has the characteristics of high casting quality, high surface precision, high rigidity, high wear-resisting property, environment friendliness and the like, and is sanitary, safe and reliable.

Owner:梁汉民

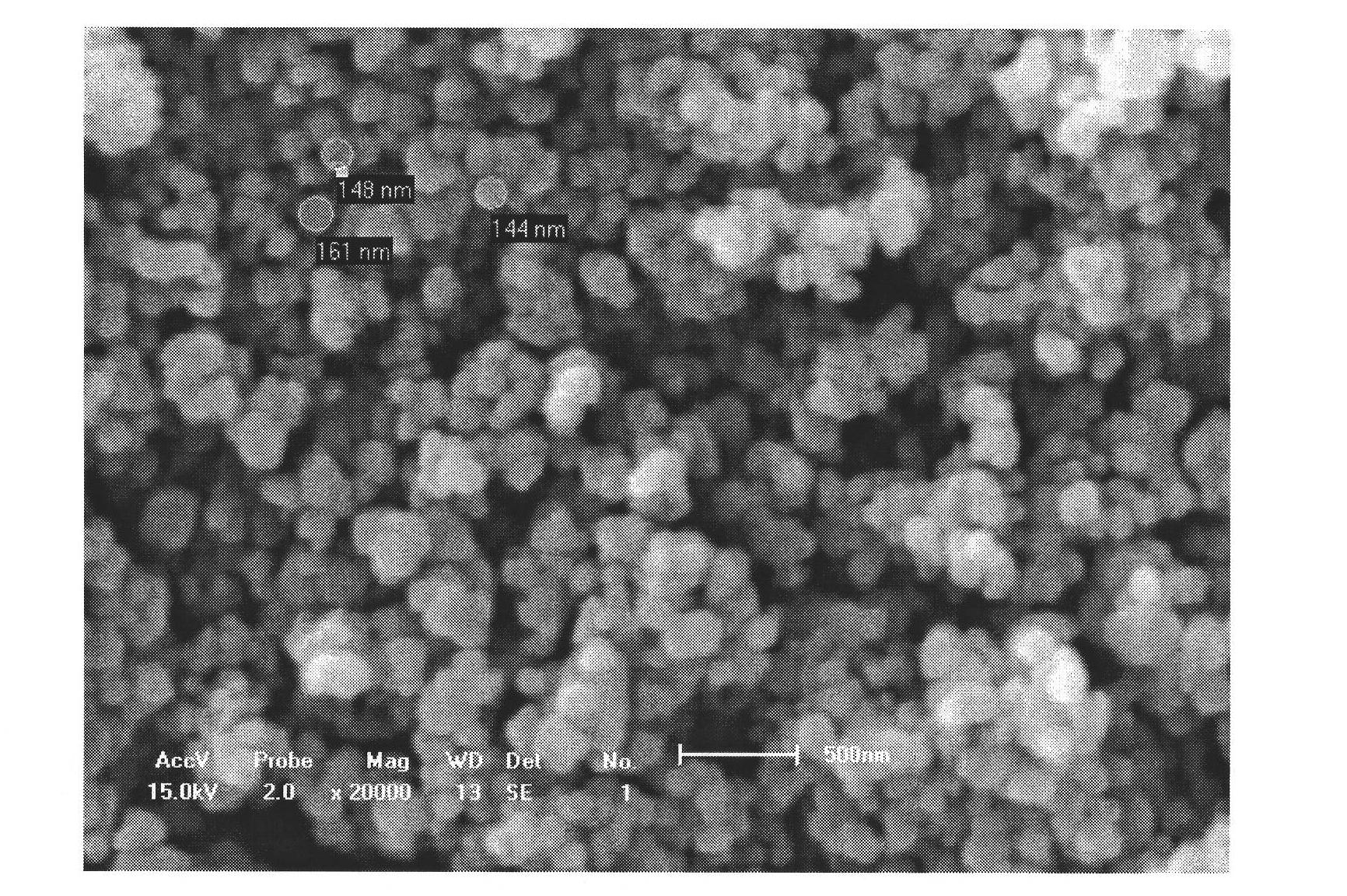

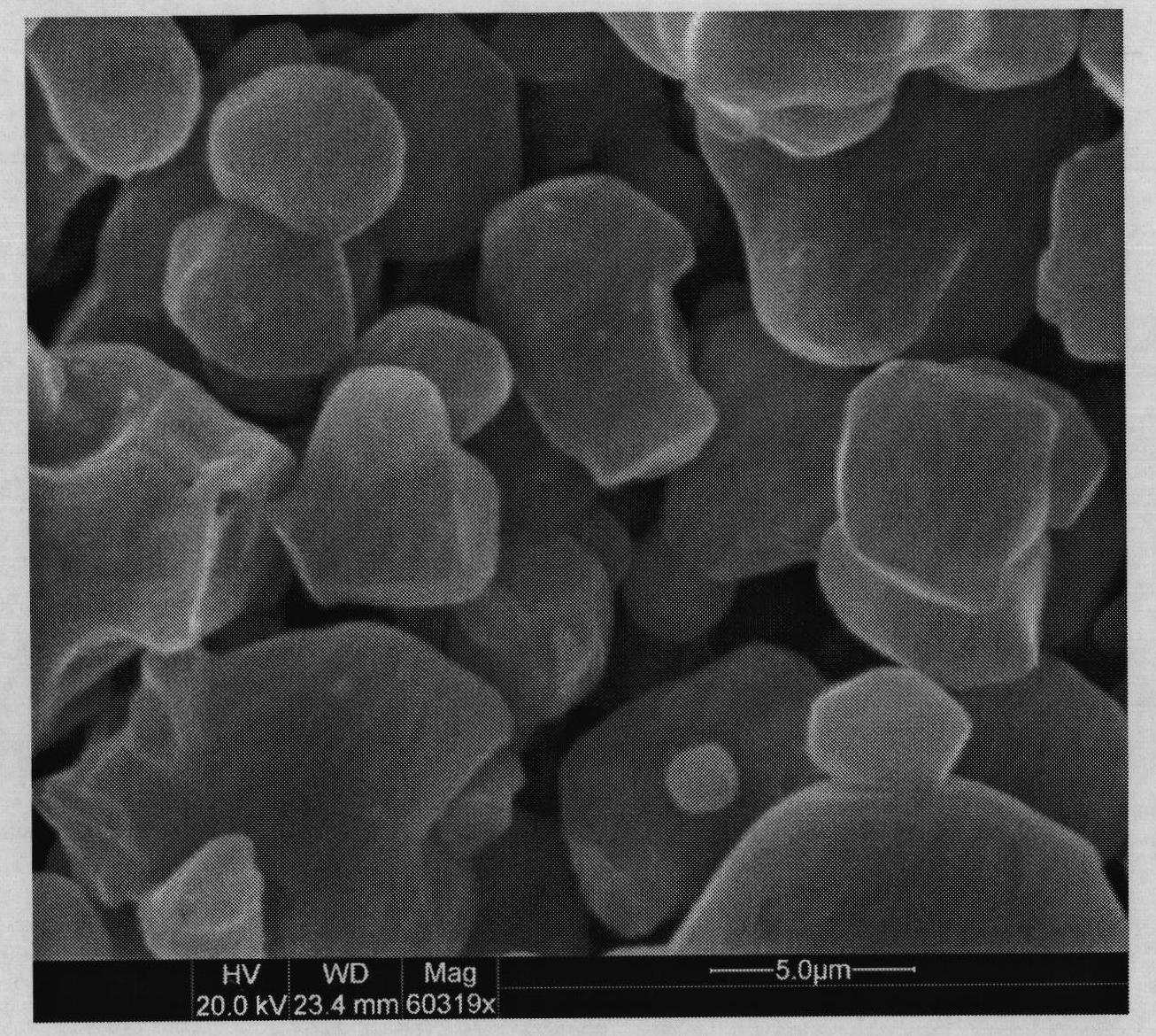

Method for preparing cobaltosic oxide with large grain size and high safety

InactiveCN101982422ARefined grain sizeGrain Size ControlCobalt oxides/hydroxidesCrystal morphologyForeign matter

The invention provides a method for preparing cobaltosic oxide with large grain size and high safety, comprising the following steps: preparing the raw material cobalt and a precipitant into cobalt solution and precipitant solution with deionized water, adding the cobalt solution and the precipitant solution which are prepared to certain concentration to a reaction vessel by the charging methods including cocurrent charging according to certain molar ratio, preparing the cobalt salt precursor by controlling the reaction temperature, charging speed, PH value and stirring speed, washing and dehydrating the precursor, directly putting the water-containing filter cake into a pot, spheroidizing and calcining the pot at high temperature, carrying out mechanical grinding, grading and activating, controlling the grain size and the crystal morphology and finally removing the magnetic metal foreign bodies, thus finally obtaining the high quality battery grade cobaltosic oxide. The method is simple in process, easy to operate, low in cost, energy-saving, environment-friendly and suitable for industrial production. The prepared cobaltosic oxide looks like spheroid and has large grain size, good powder flowability and uniform granularity.

Owner:JIANGSU DONGXIN ENERGY TECH

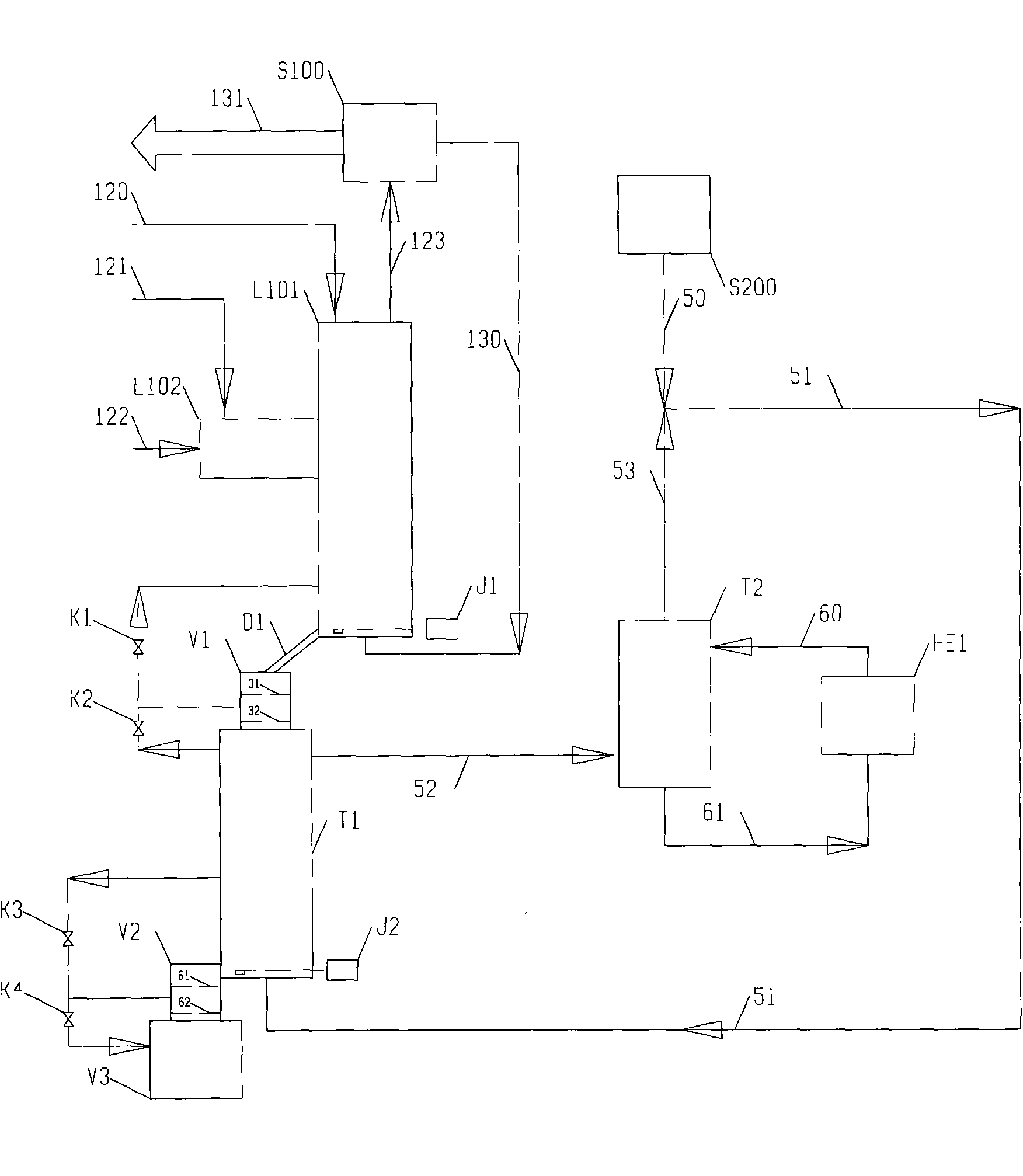

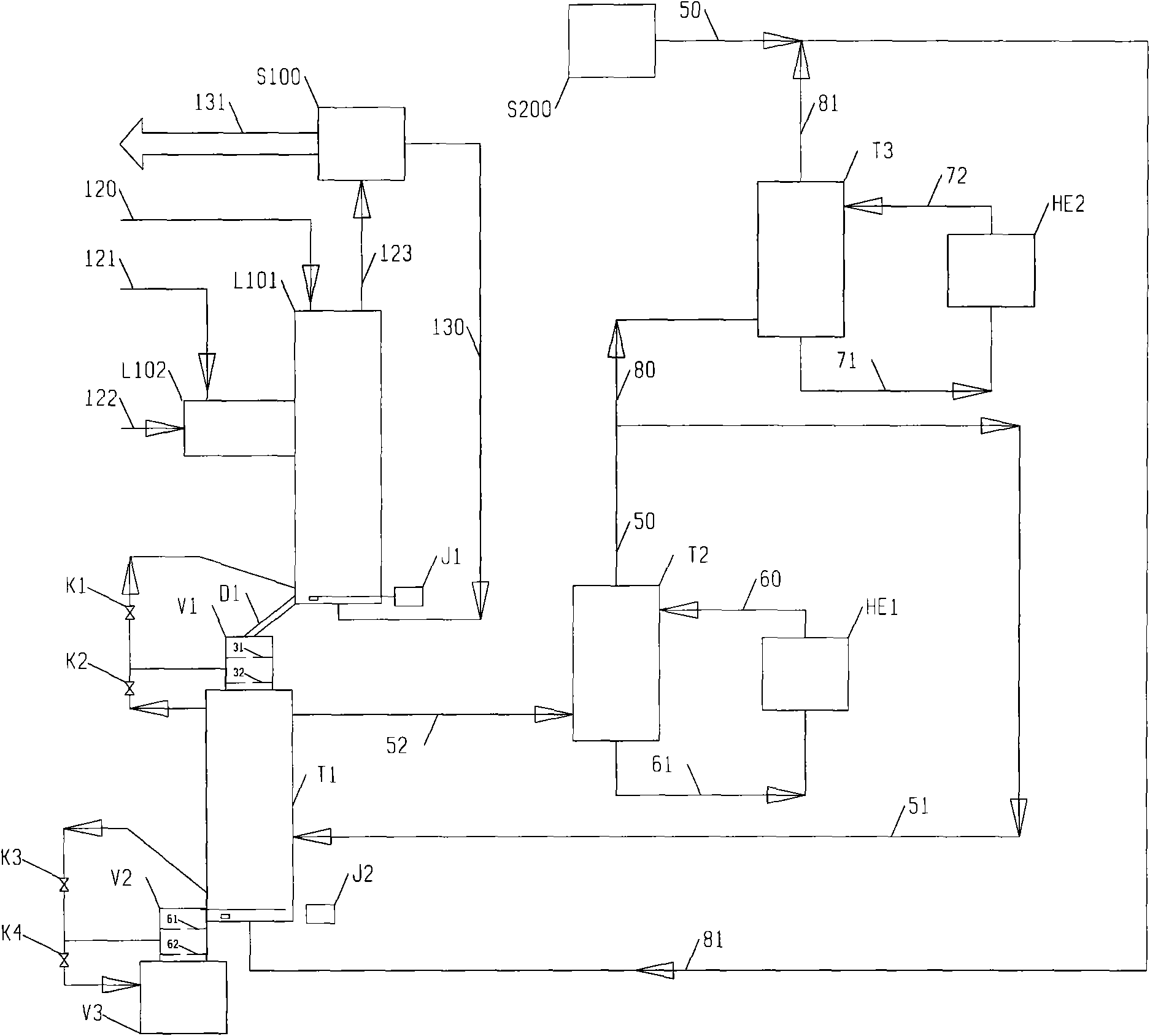

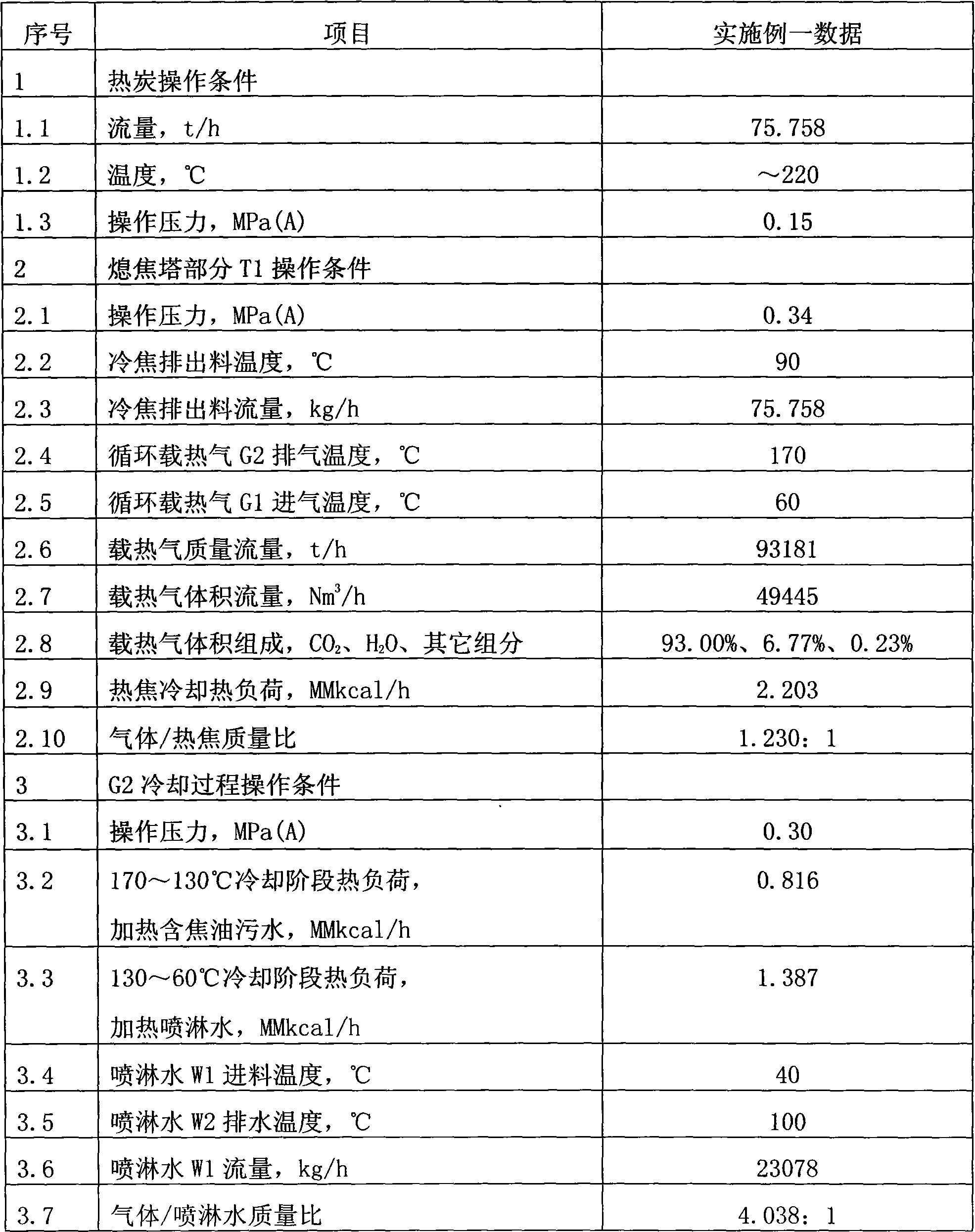

Coke dry quenching method for coal coking device

The invention discloses a coke dry quenching method for a coal coking device. The coke dry quenching method is suitable for a semi-coking device. Usually, multiple coking chambers share a coke quenching system. The coke dry quenching method comprises that 1, hot coke from the bottom of a coke cooling section of a coking chamber is pushed to a hot coke transferring warehouse V1 by a coke pusher J1; 2, the hot coke is regularly discharged into the hot coke transferring warehouse V1 by a V1 charging valve and then the V1 charging valve is closed; and after the hot coke transferring warehouse V1 is pressurized by gas from a coke quenching tower T1, the hot coke is regularly discharged into the coke quenching tower T1; 3, the coke quenching tower T1 is operated under pressurized conditions and the hot coke moves from bottom to top under the action of gravity and contacts with inert gas such as CO2 flowing from bottom to top so that a temperature of the hot coke is reduced; and the cold coke is pushed into a cold coke transferring warehouse V2 by a coke pusher J2; 4, the cold coke is regularly discharged into the cold coke transferring warehouse V2 by a V2 charging valve and then the V2 charging valve is closed; and after the cold coke transferring warehouse V2 is deflated so that a cold storage chamber V3 is depressurized, the cold coke is regularly discharged into the cold storage chamber V3 or is transmitted into the cold storage chamber V3 by a belt; and 5, hot heat-carrying gas G2 departing from the coke quenching tower T1 enters into a spray tower T2 and then carries out counter-current contact with recycled cold spray water W1 so that the hot heat-carrying gas G2 is cooled by heat transmission; and the cooled gas as G1 is fed back to the coke quenching tower T1 for recycle.

Owner:何巨堂

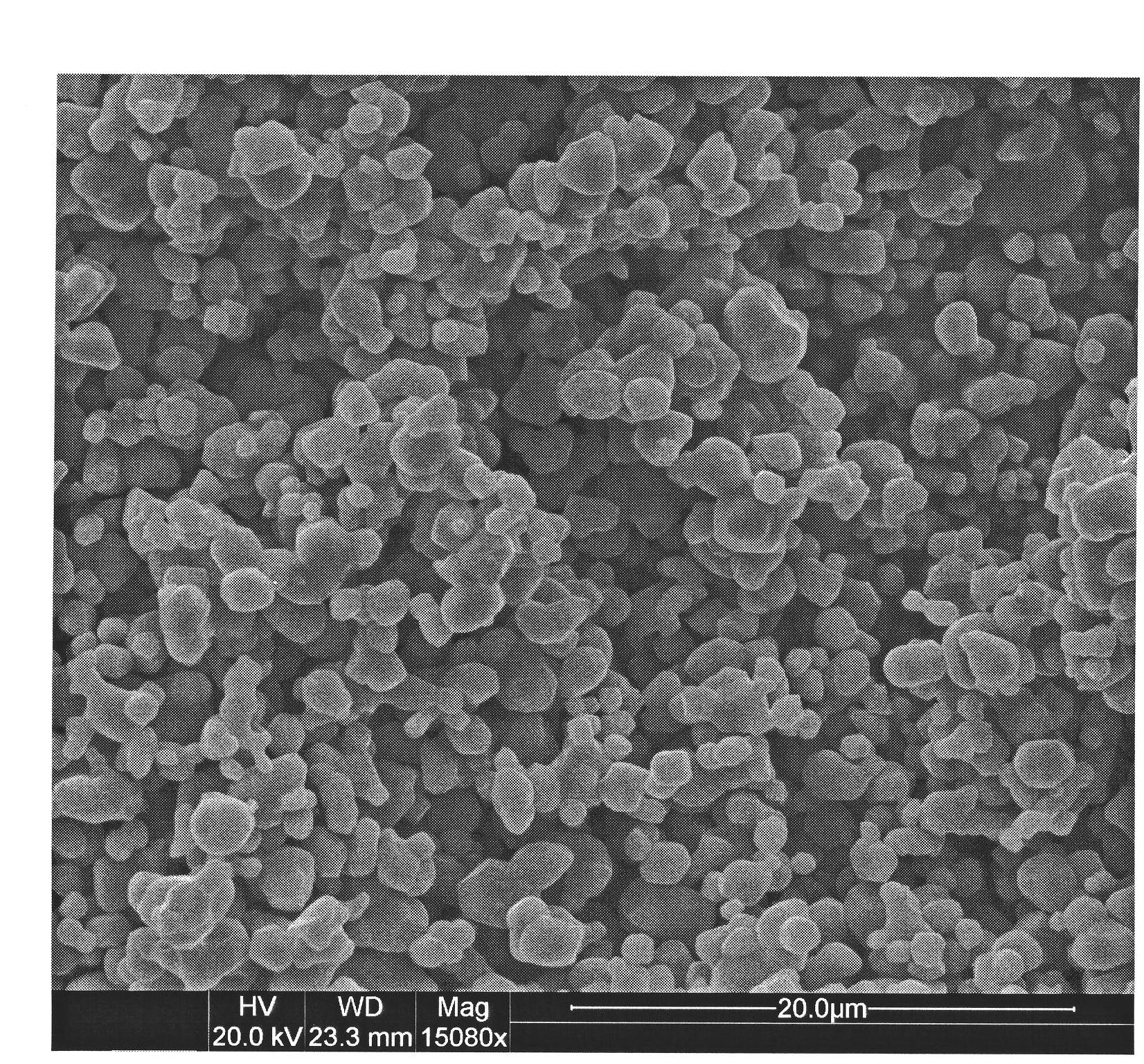

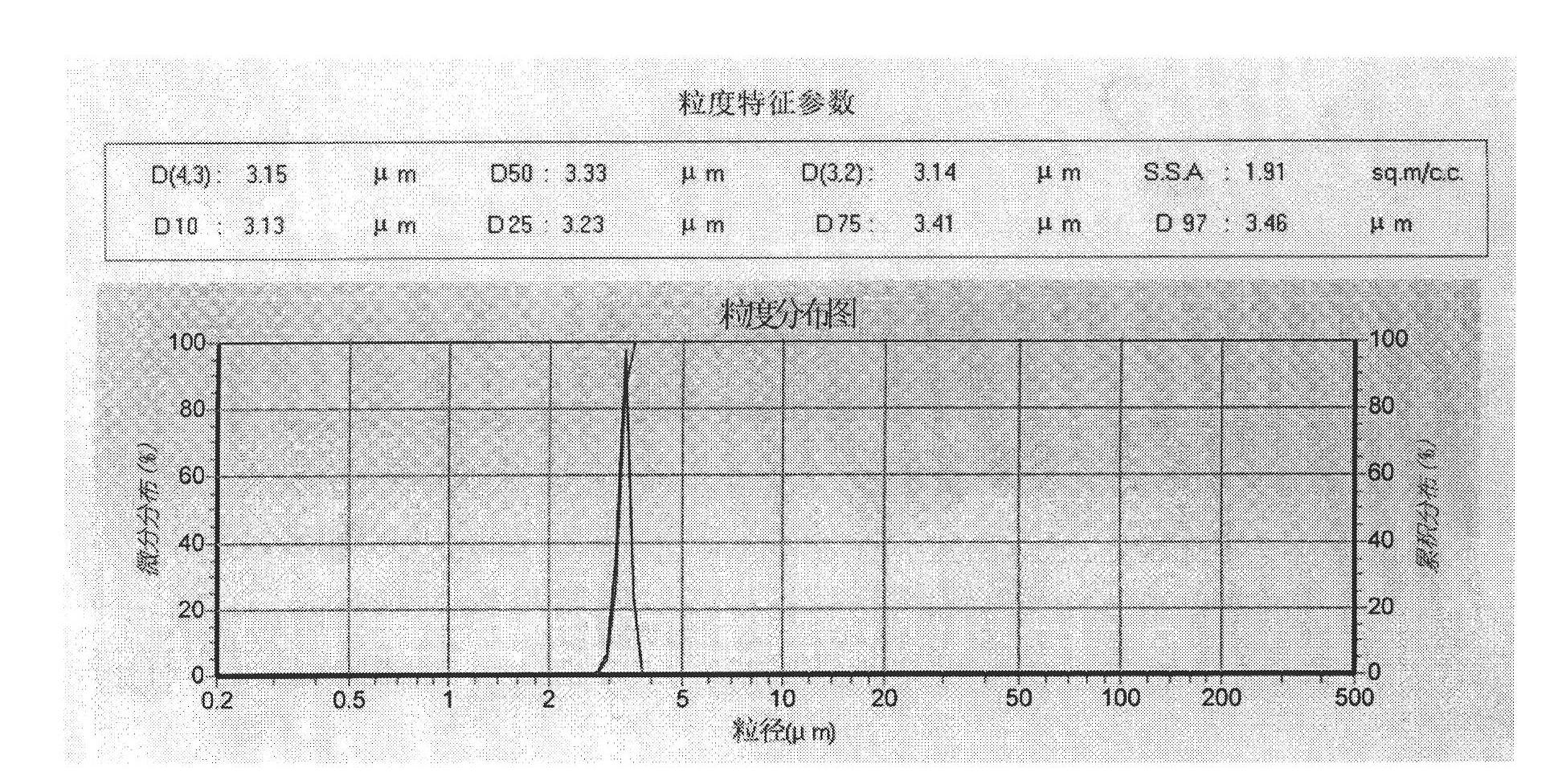

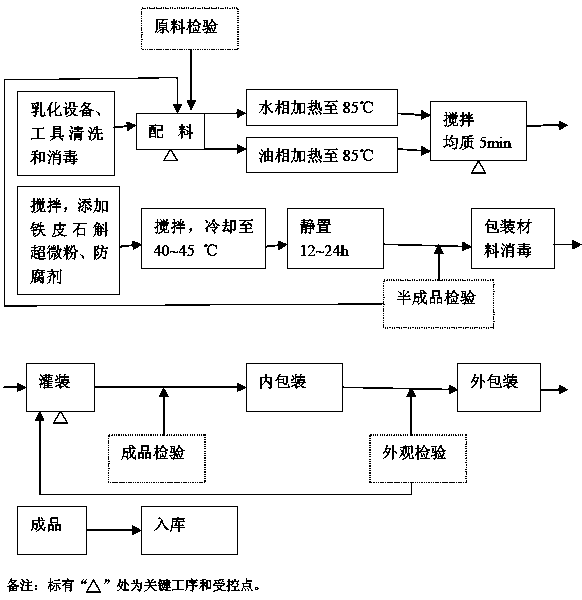

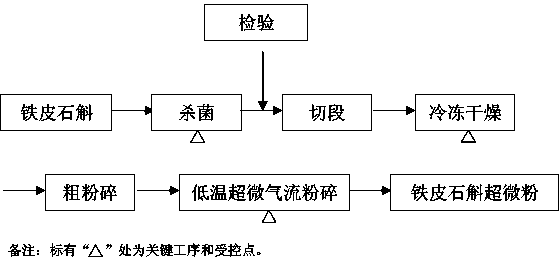

Dendrobium candidum paste mask and preparation method thereof

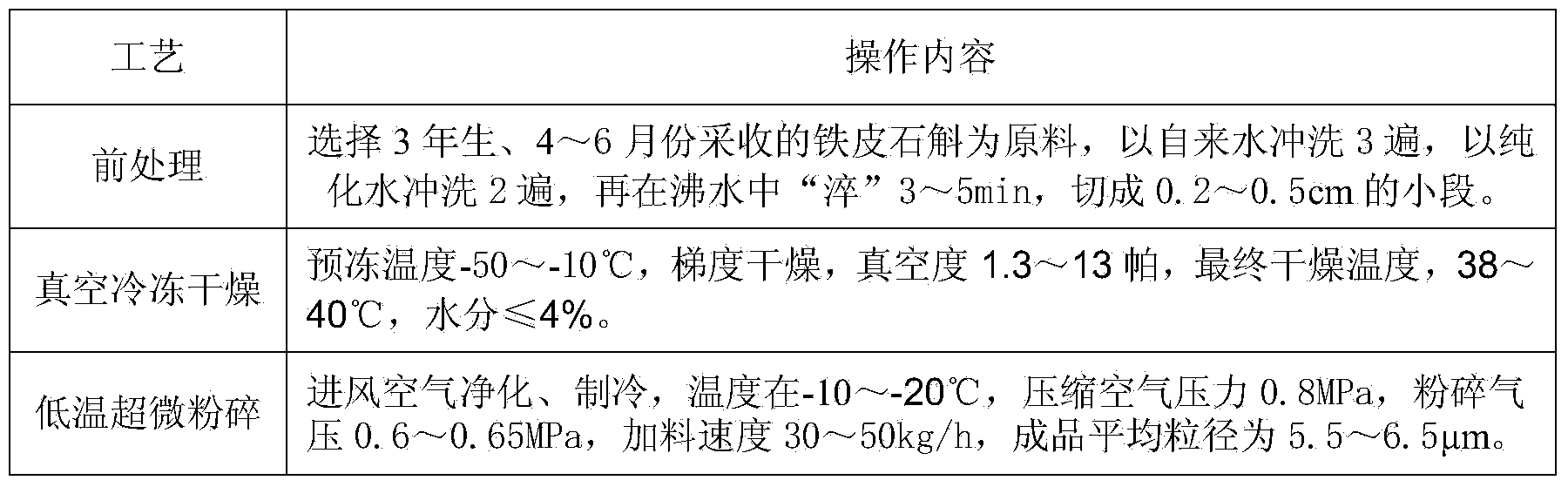

InactiveCN104107151AAvoid breakingReduced drying processCosmetic preparationsToilet preparationsFreeze-dryingRaw material

The invention relates to a dendrobium candidum paste mask and a preparation method of the dendrobium candidum paste mask, aiming at providing a dendrobium candidum paste mask which can be used for keeping effective components of dendrobium candidum and the preparation method of the dendrobium candidum paste mask. The dendrobium candidum paste mask comprises 4-6 parts by weight of dendrobium candidum ultra-micro powder, wherein the dendrobium candidum ultra-micro powder contains polysaccharide, chlorophyll, vitamins and proteins. The preparation method of the dendrobium candidum paste mask sequentially comprises the following processes: A, a pre-treatment process; B, a freeze-drying process; C, a low-temperature ultra-micro airflow crushing process: screening by using a 100-mesh sieve, and performing low-temperature ultra-micro airflow crushing to obtain dendrobium candidum ultra-micro powder of which the average particle size is 5.5-6.5 microns; D, an emulsification process; and E, a filling process. The dendrobium candidum paste mask disclosed by the invention performs freeze-drying and low-temperature ultra-micro crushing by adopting a dendrobium candidum fresh product as a raw material, and can be used for reserving the effective components of dendrobium candidum to the highest extent; and an obtained product is high in content of polysaccharide, vitamins, chlorophyll and free amino acids.

Owner:浙江森宇实业有限公司

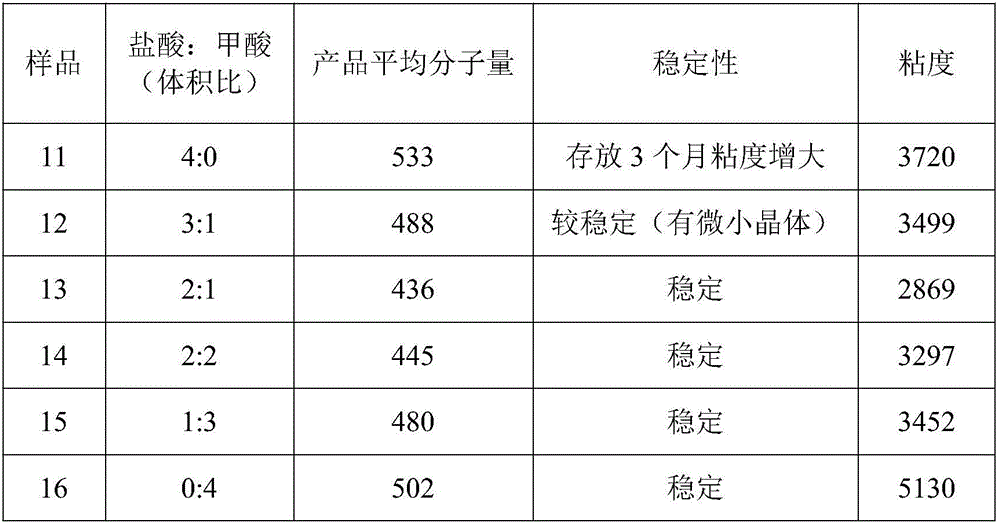

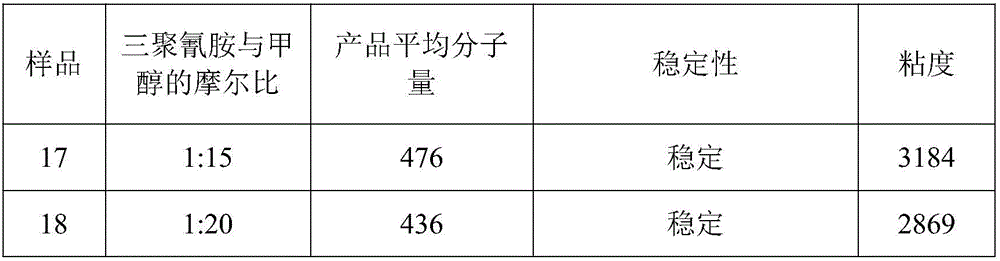

Preparation method of high-imido and high-methoxylation melamine resin capable of being cured at low temperature

The invention discloses a preparation method of a high-imido and high-methoxylation melamine resin capable of being cured at low temperature. According to the method, the high-imido and high-methoxylation melamine resin capable of being cured at low temperature is obtained by reacting melamine, a formaldehyde solution and methanol, paraformaldehyde is not required to be added, the step of synthesis of hydroxymethylation melamine as an intermediate product is omitted, preparation costs are reduced, links of crystallization, drying and the like of the intermediate product are omitted, energy consumption is low, a technological process is simple, the methanol only needs to be added at one step in reaction, and the preparation method is easy to control. In addition, a mixture of hydrochloric acid and formic acid is used as an etherification catalyst, and the effect of the obtained product is better than that of a single acid catalyst.

Owner:重庆建峰新材料有限责任公司

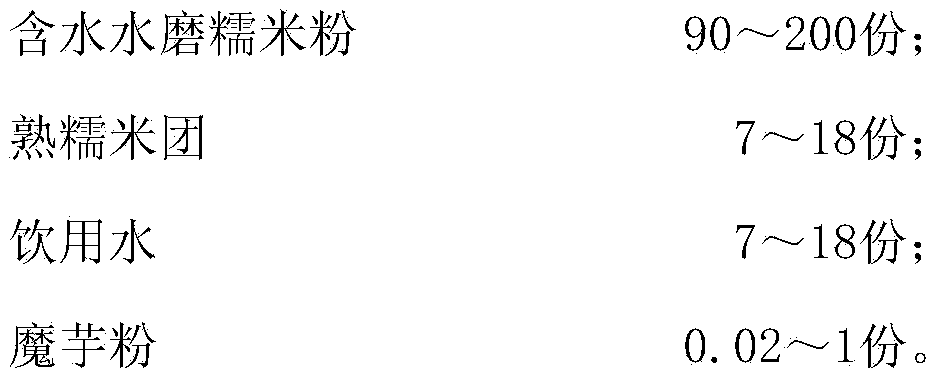

Common perilla and brown sugar stuffing sweet dumplings and production method thereof

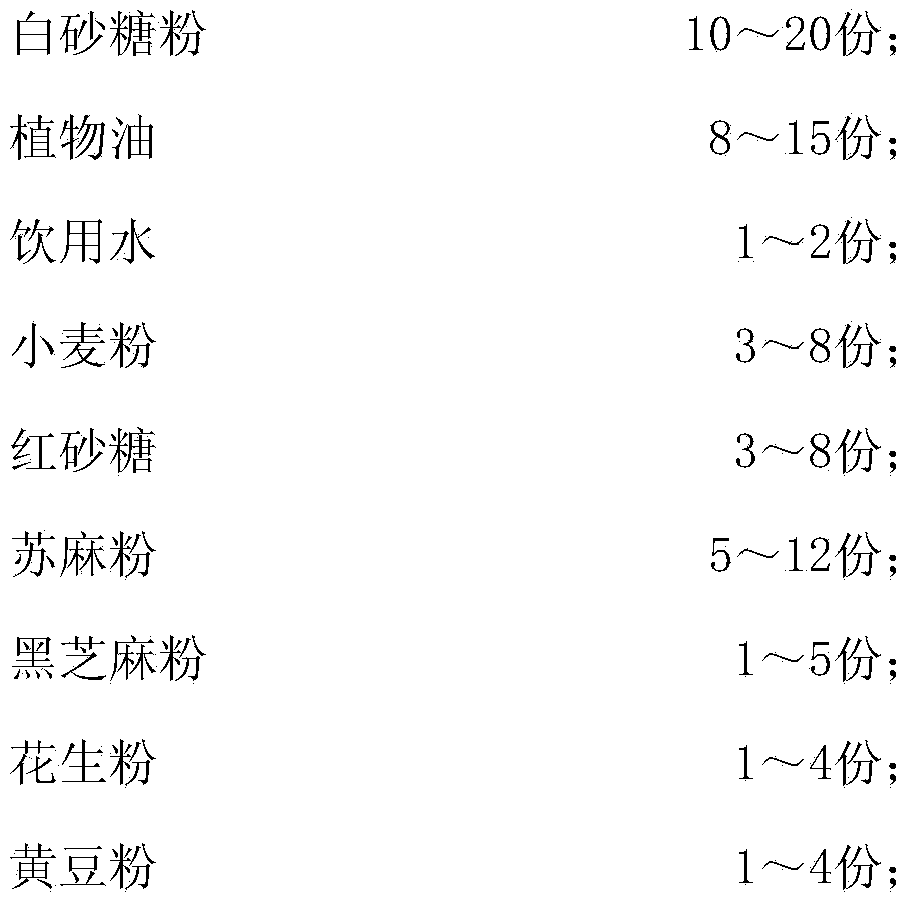

ActiveCN104207019AInhibition of reproductionGreat tasteFood coatingFood shapingMicroorganismTriticum turgidum

The invention discloses common perilla and brown sugar stuffing sweet dumplings and a production method thereof. The common perilla and brown sugar stuffing sweet dumplings consist of sweet dumpling stuffing and sweet dumpling wrappers, wherein the sweet dumpling stuffing comprises the components of white granulated sugar powder, plant oil, drinking water, wheat flour, brown sugar, common perilla powder, black sesame powder, peanut powder and soybean meal; and the sweet dumpling wrappers comprise the components of water-containing water-milled glutinous rice flour, cooked sticky rice roll, drinking water and konjaku flour. The production method of the common perilla and brown sugar stuffing sweet dumplings comprises the following steps: making the aqueous water-milled glutinous rice flour; preparing a sweet dumpling wrapper dough; preparing the stuffing; and making the sweet dumplings. If the prepared sweet dumplings are frozen quickly and preserved in a freezing manner, the preservation time of the sweet dumplings can be prolonged. Compared with the prior art, the common perilla and brown sugar stuffing sweet dumplings are rich and balanced in nutrition, have the effects of improving health, are good in color and mouthfeel, and are fine and smooth in taste. Moreover, the production method of the common perilla and brown sugar stuffing sweet dumplings is convenient and is easy in operation. The produced sweet dumplings are safer and more sanitary by means of inhibition of the breeding of microorganisms.

Owner:SICHUAN LONGWANG FOOD

Method using titanium gypsum and acetylene sludge to prepare high-calcium sulphoaluminate or high-sulfur clinkers

A method using titanium gypsum and acetylene sludge to prepare high-calcium sulphoaluminate or high-sulfur clinkers includes the steps: (1) compounding; (2) homogenizing; and (3) calcining. According to the method using the titanium gypsum and the acetylene sludge to prepare the high-calcium sulphoaluminate or the high-sulfur clinkers, drying and grinding of wet sludge titanium gypsum and the acetylene sludge are omitted, energy consumption in drying and grinding is reduced, the firing temperature is low, firing energy consumption is low, production cost of the clinkers is low, and waste recycling benefits are good.

Owner:长沙紫宸科技开发有限公司

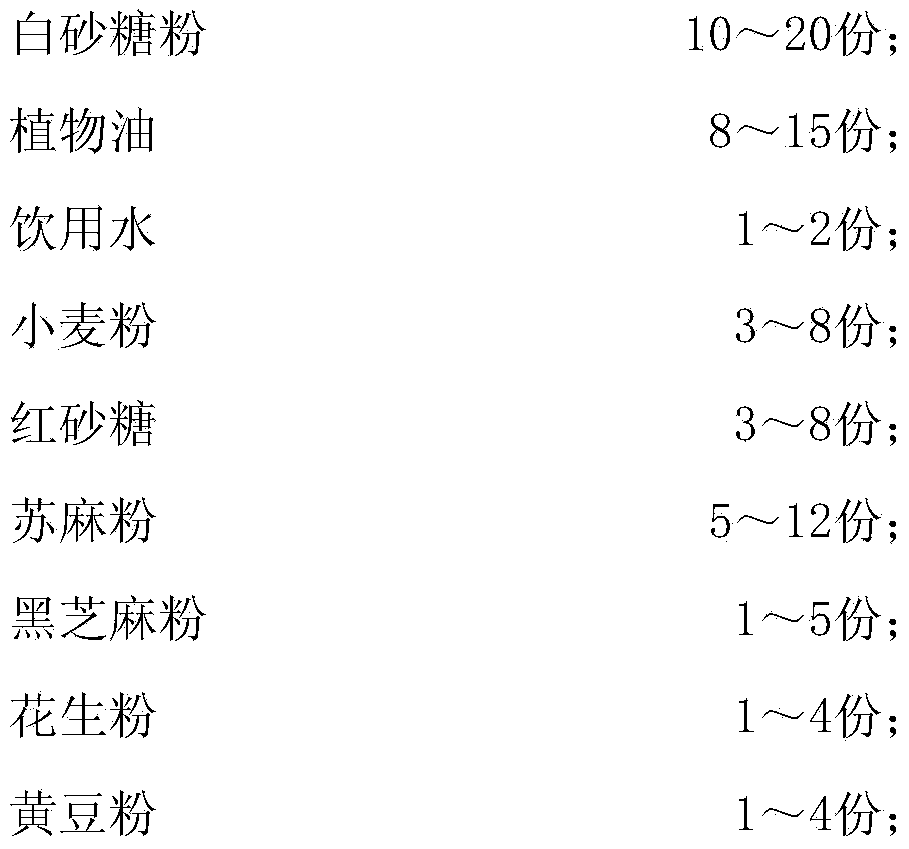

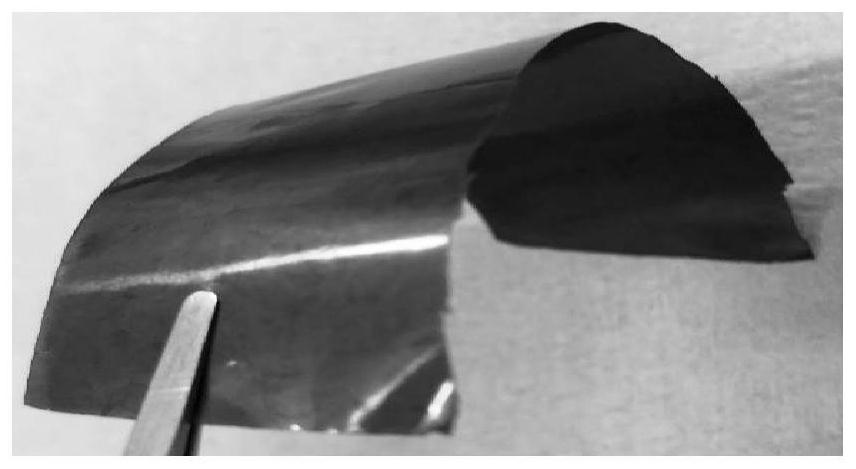

Positive electrode material layer, preparation method thereof, positive plate and battery

PendingCN112289976AImprove the lubrication effectImprove flexibilityElectrode rolling/calenderingFuel and secondary cellsFiberElectrical battery

The invention discloses a positive electrode material layer, a preparation method thereof, a positive plate and a battery. The method comprises the following steps: 1) mixing fibrosis polymer powder,a carbon-coated positive electrode active material and a conductive carbon material, and drawing the fibrosis polymer powder into fibers under the action of shearing force to obtain a mixture; and 2)carrying out hot pressing treatment on the mixture on a current collector to a preset thickness to obtain the positive electrode material layer. According to the method disclosed by the invention, thecarbon-coated positive electrode active substance is applied to the preparation of the dry-method positive electrode material layer, so that the lubrication degree of the positive electrode materialis improved, the mixing uniformity is improved, and the hardness of the positive electrode material is effectively reduced, thereby improving the softness of the electrode plate. The problems of non-uniform mixing of the positive electrode material and cracking of the pole piece caused by high positive electrode material ratio and high hardness when the positive electrode material layer is prepared by a dry method are solved, the requirement on the material of a roller shaft of a roller press in the preparation process of the dry method positive plate can be reduced, and the equipment cost isreduced.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

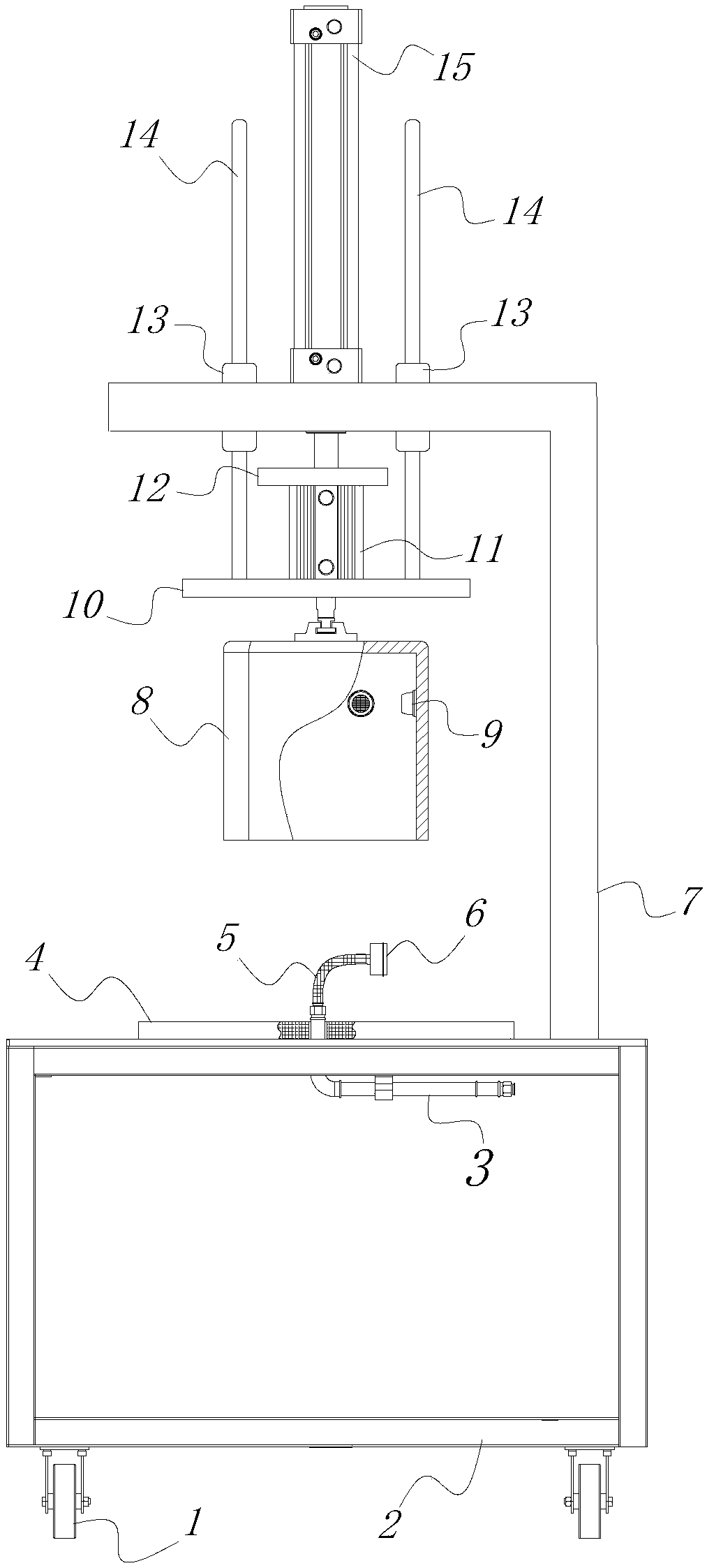

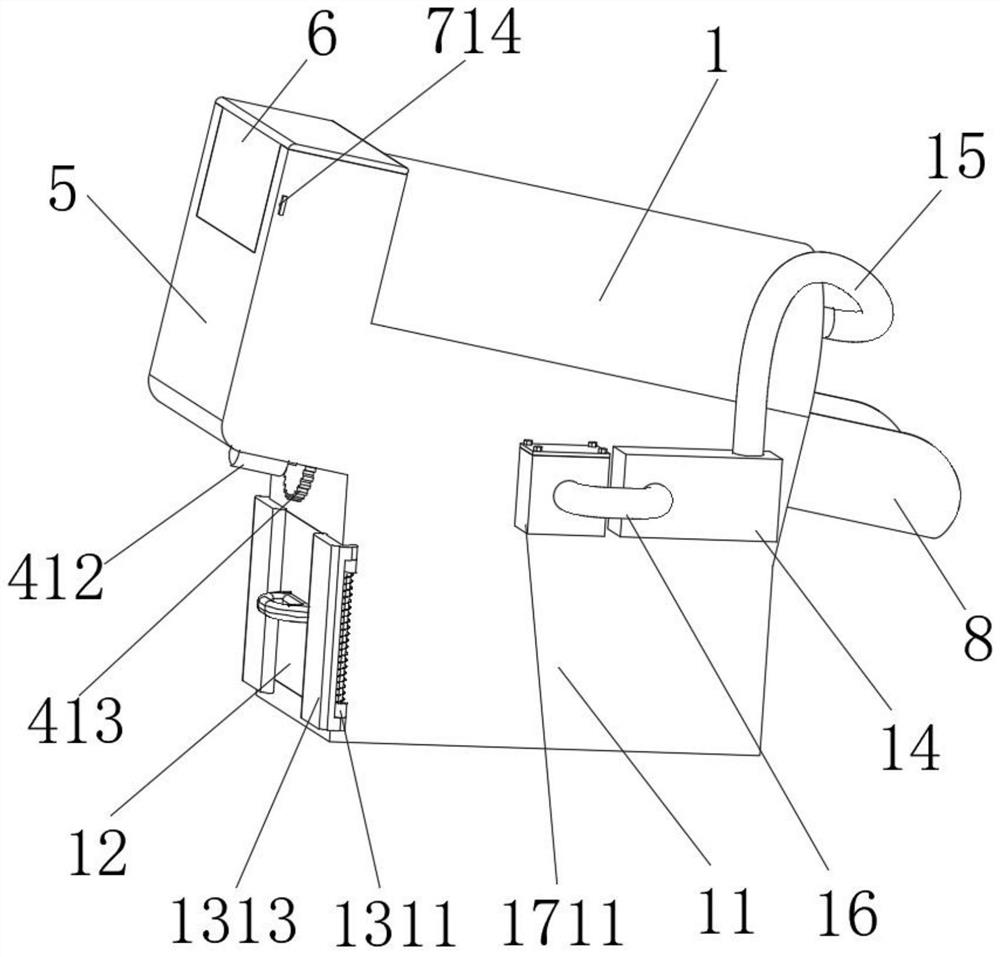

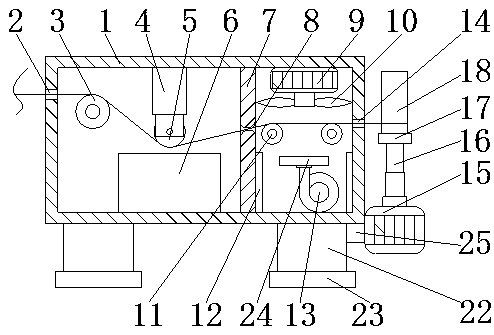

Helium mass spectrographic leak detector for leak detection of air filters

InactiveCN108254135AAvoid waterReduced drying processDetection of fluid at leakage pointAir filterEngineering

The invention relates to a helium mass spectrographic leak detector for leak detection of air filters. The helium mass spectrographic leak detector comprises an operating rack and a gas supply pipeline; a mounting frame is fixedly connected to a top plate of the operating rack, a lift cylinder with downward extending end is fixedly connected to the top of the mounting frame, a lift plate is arranged below the top of the mounting frame, and a guide rod in slide connection with the mounting frame is fixedly connected to the lift plate; a piston rod end of the lift cylinder is fixedly connected with a connecting plate, a fine-tuning cylinder with a downward extending end is fixedly connected between the connecting plate and the lift plate, a piston rod end of the fine-tuning cylinder is connected with a helium gas sealing hood with a downward opening and an internal sensor; a sealing pad which is in clearance fit with the helium gas sealing hood is arranged at the position, on the top plate of the operating rack and under the helium gas sealing hood; one end of the gas supply pipeline is communicated with a helium gas source while the other end thereof is communicated with a gas supply hose, and an inner cavity plug with a center through hole is arranged at the end of the gas supply hose. The helium mass spectrographic leak detector is used for detecting by a dry detection method,has high detection efficiency and is easy to operate.

Owner:TIANJIN YULONG HAOTIAN AUTOMOBILE FILTER

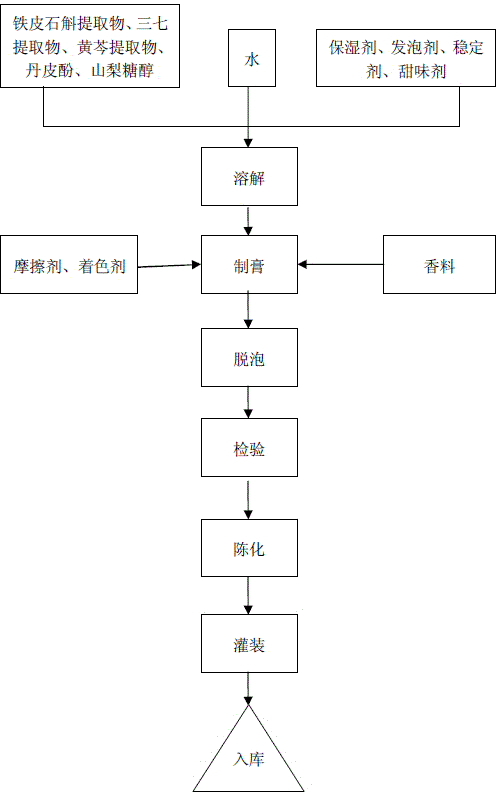

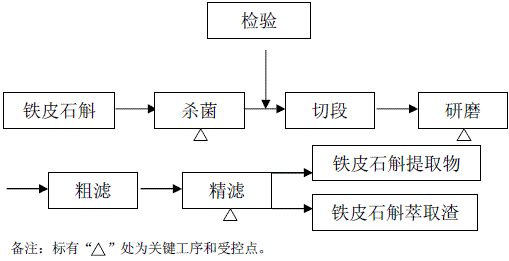

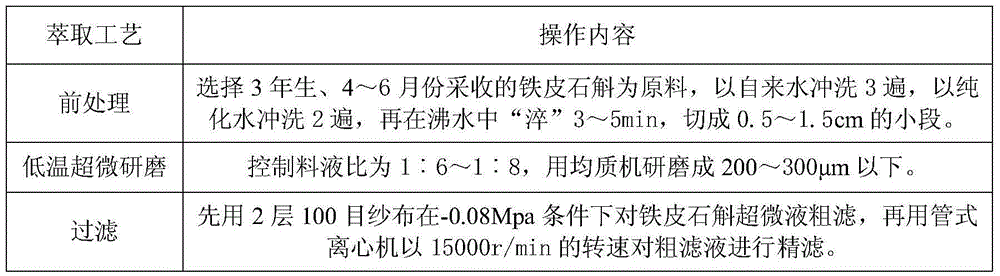

Dendrobium officinale toothpaste and preparation method

ActiveCN104127340AReduced drying processNot easily destroyedCosmetic preparationsToilet preparationsToothpasteDendrobium sanguinolentum

The invention relates to a Dendrobium officinale toothpaste and its preparation method. Nowadays, there is no Dendrobium officinale toothpaste, in which active ingredients in Dendrobium officinale can be retained, or a preparation method thereof. The Dendrobium officinale toothpaste provided by the invention comprises, by weight, 4.0-6.0 parts of a Dendrobium officinale extract which contains polysaccharide, chlorophyll, vitamin and protein. The preparation method of the Dendrobium officinale toothpaste successively comprises the following processes: A, pretreatment process; B, low-temperature ultramicro-grinding process: placing water of 2-10 DEG C and cut-off Dendrobium officinale into a homogenizer with the weight ratio of Dendrobium officinale to water being 1:6-1:8, starting the homogenizer and controlling discharging material fineness to below 200-300 microns so as to obtain a mother liquor of a Dendrobium officinale extract; C, filtering process; D, paste preparation process; and E, filling process. According to the invention, a Dendrobium officinale fresh product used as a raw material undergoes low-temperature extraction. The contents of polysaccharide, vitamin, chlorophyll, free amino acid and the like in the product obtained are high.

Owner:浙江森宇有限公司

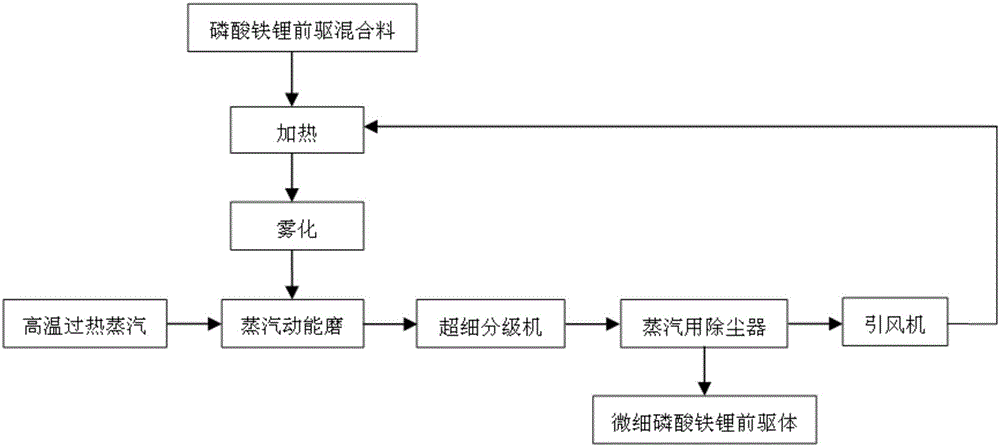

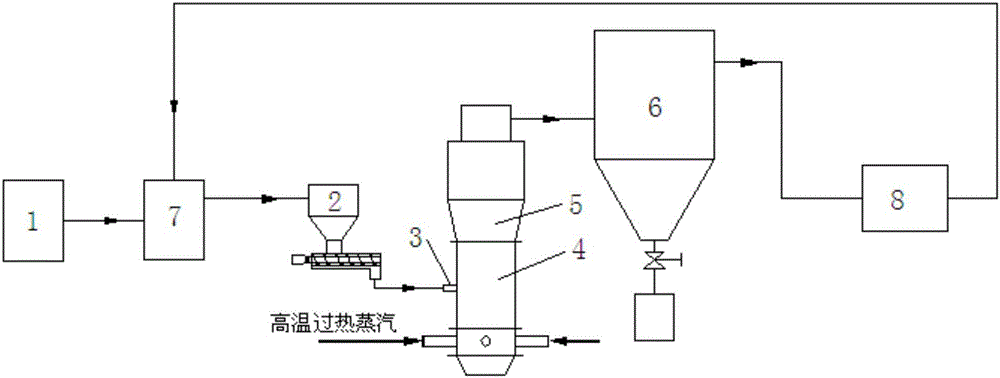

Method and device for preparing lithium iron phosphate precursor by high-temperature superheated steam dry method

ActiveCN105742576AReduce consumptionReduced drying processCell electrodesProcess engineeringWhole systems

The invention discloses a method and a device for preparing a lithium iron phosphate precursor by a high-temperature superheated steam dry method. A steam kinetic energy milling machine is arranged, high-temperature superheated steam is taken as a smashing power source, the lithium iron phosphate precursor mixture is first atomized and then is subjected to ultrafine grinding, and the method belongs to a dry smashing method to prepare ultrafine powder. Since the gas source of the whole system is high-temperature superheated steam, a water-containing material is rapidly dried during the smashing process, the drying process is reduced, the energy consumption is reduced, and the production cost is reduced. Compared with the prior art, the method has the advantages that the cost can be saved by 1190 yuan / ton.

Owner:LNPE POWDER EQUIMPENT CO LTD

Tencel facial mask containing dendrobium officinale ingredient and preparation method thereof

InactiveCN107126399AImprove bioavailabilityImprove utilizationCosmetic preparationsToilet preparationsBiotechnologyCentella asiatica extract

The invention discloses a tencel facial mask containing a dendrobium officinale ingredient. The tencel facial mask is prepared from four components A, B, C and D. Dendrobium officinale extract is used as a main active ingredient and combined with tremella fruit body extract, saccharomyces lysate extract and herba centallae extract, and the four components are synergistic to act deeply at the bottom layer of skin to supplement moisture and enhance moisturizing ability of the skin, so that moisture content in the skin can be maintained proper, cell metabolism of the skin can be improved, and microcirculation of the skin can be regulated; moisture locking is realized while moisture supplementing, so that the skin is promoted to restore a good shielding function, moisture loss is reduced effectively, moisture is locked, long-acting moisturizing is maintained for 24h, moisturizing performance, elasticity and flexibility of the skin are improved, the skin is refined and nourished, drying and itching of the skin are relieved, and natural regulating ability of the skin restores.

Owner:广东神石生物科技有限公司 +2

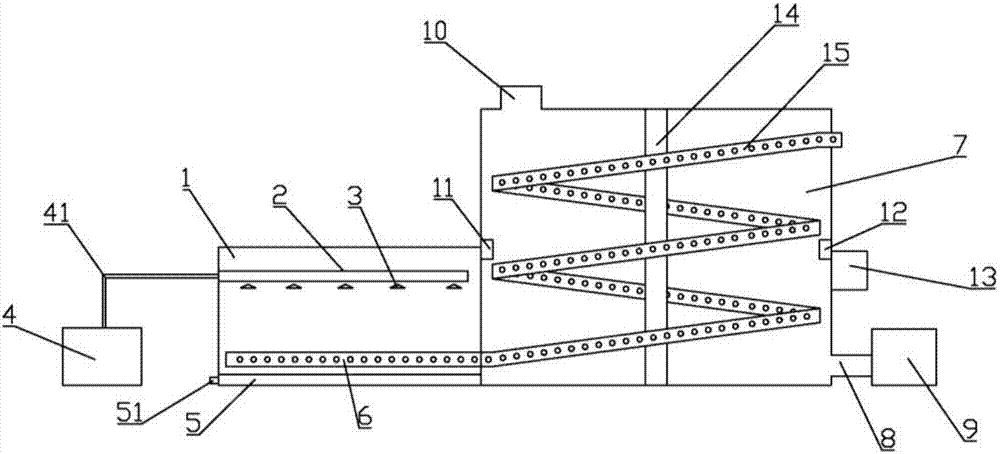

Cone yarn short-process energy-saving drying device and use method

InactiveCN106871611ALow costImprove drying efficiencyDrying gas arrangementsDrying chambers/containersYarnInlet valve

The invention discloses a cone yarn short-process energy-saving drying device and a use method. The drying device comprises a drying chamber, a yarn frame, a cart, a drying frame and a control device; fixing rods are evenly arranged at the upper end of the yarn frame at intervals, the fixing rods and the yarn frame are internally communicated with branched flow pipes; the yarn frame is arranged at the upper end of the cart, a main flow pipe is arranged in the cart, and he main flow pipe is communicated with the branched flow pipes; the cart is arranged on a guide rail, the main flow pipe is connected with an air inlet valve through a rapid connector, and seal doors are arranged on the two opposite side walls of the drying chamber. The use method comprises feeding, bin entering, drying and unloading. According to the cone yarn short-process energy-saving drying device and the use method, the tedious working procedure needed by drying can be reduced while the drying efficiency is improved, energy is saved, and the drying quality is improved.

Owner:罗湘春

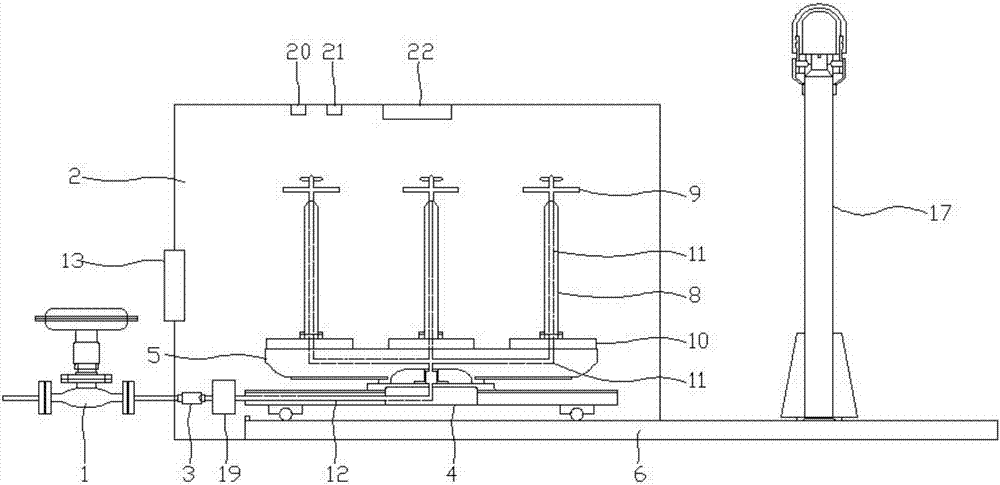

Device and process method for preparing polycrystalline silicon through coupling of electron beam smelting and crystal growing technology

InactiveCN103435043AEfficient removalStrengthen the surface volatilization effectSilicon compoundsFilling materialsCoupling

The invention belongs to the field of polycrystalline silicon ingot, and particularly relates to a device and a process method for preparing polycrystalline silicon through the coupling of electronic beam smelting and the crystal growing technology. The device for preparing the polycrystalline silicon through the coupling of the electron beam smelting and the crystal growing technology is characterized in that a graphite crucible is arranged inside a furnace body, the outer wall of the graphite crucible is sequentially provided with a graphite heating body and a graphite insulating sleeve from inside to outside, an upper graphite cover plate of the graphite insulating sleeve can be horizontally moved, and the position on one side of the furnace body, parallel to the upper graphite cover plate, is externally connected with a hollow plate groove; a water-cooling ingot pulling mechanism is installed on the center position of the bottom of the graphite crucible; a cooling circulating water pipe is arranged inside the water-cooling ingot pulling mechanism; the top of the furnace body is provided with an electron gun, the upper end of the side part of the furnace body is provided with an inflating valve, and the lower end is provided with a deflation valve. The process method for preparing the polycrystalline silicon through the coupling of the electron beam smelting and the crystal growing technology comprises the steps of filling materials, vacuumizing, charging argon to increase the pressure, heating to smelt the silicon material, smelting through an electron beam, growing the crystal, annealing the ingot, cooling and opening the furnace to take the ingot.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

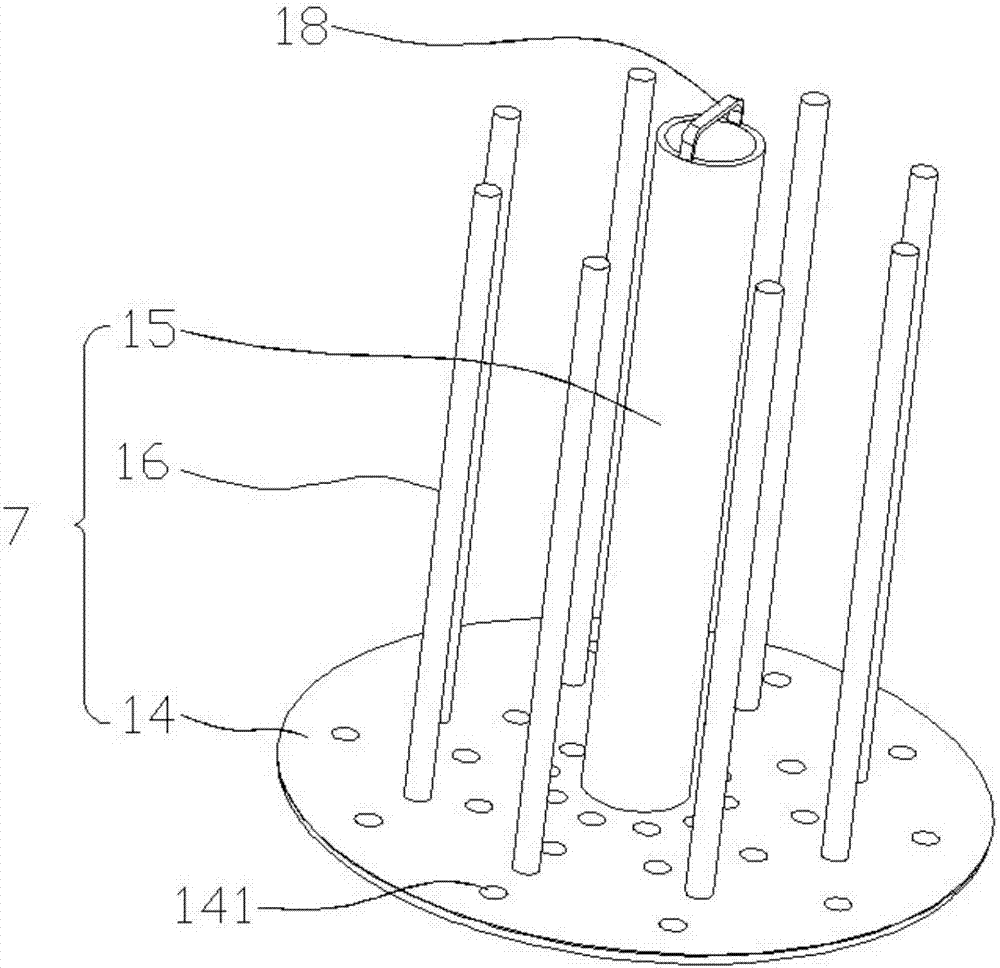

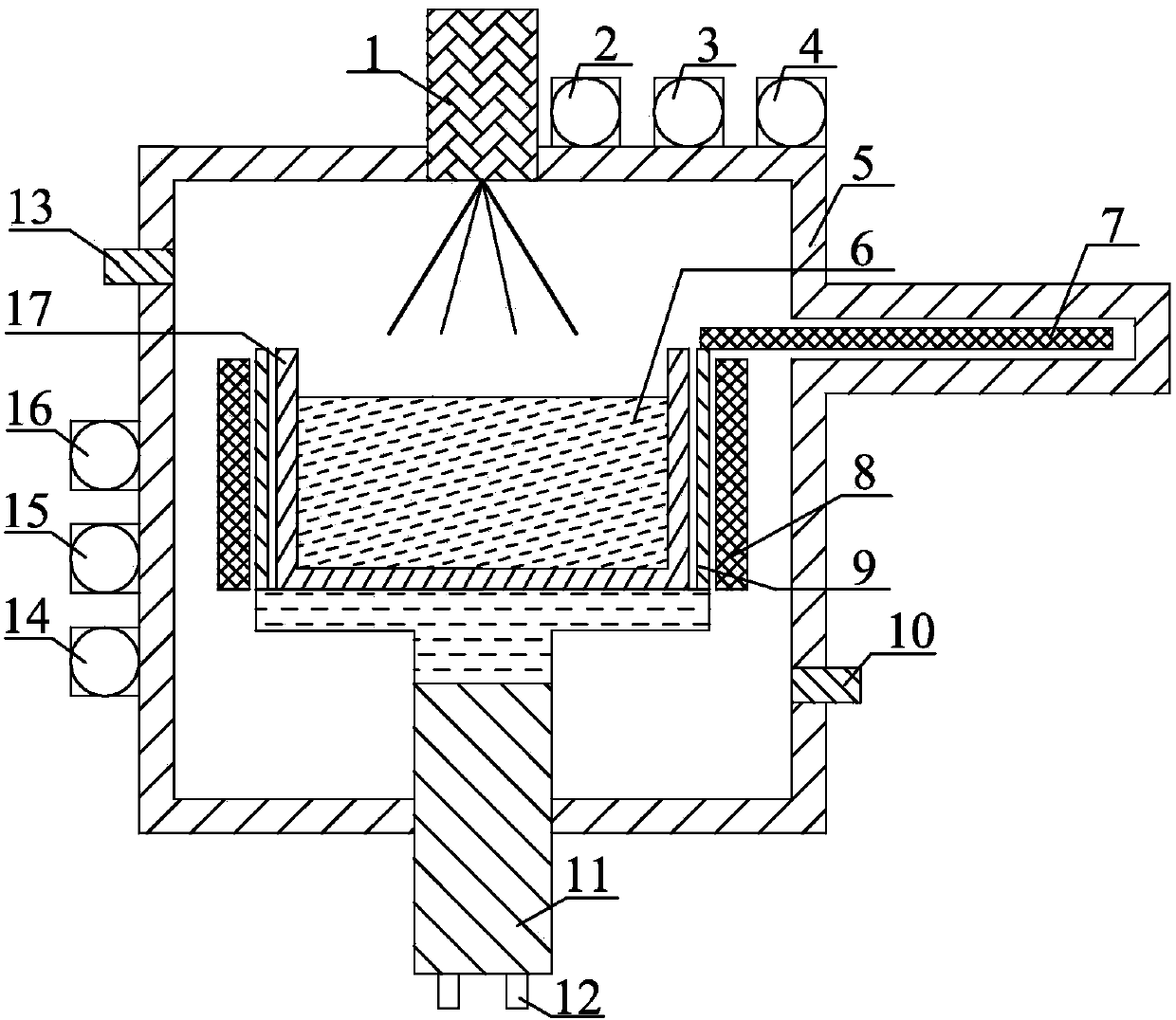

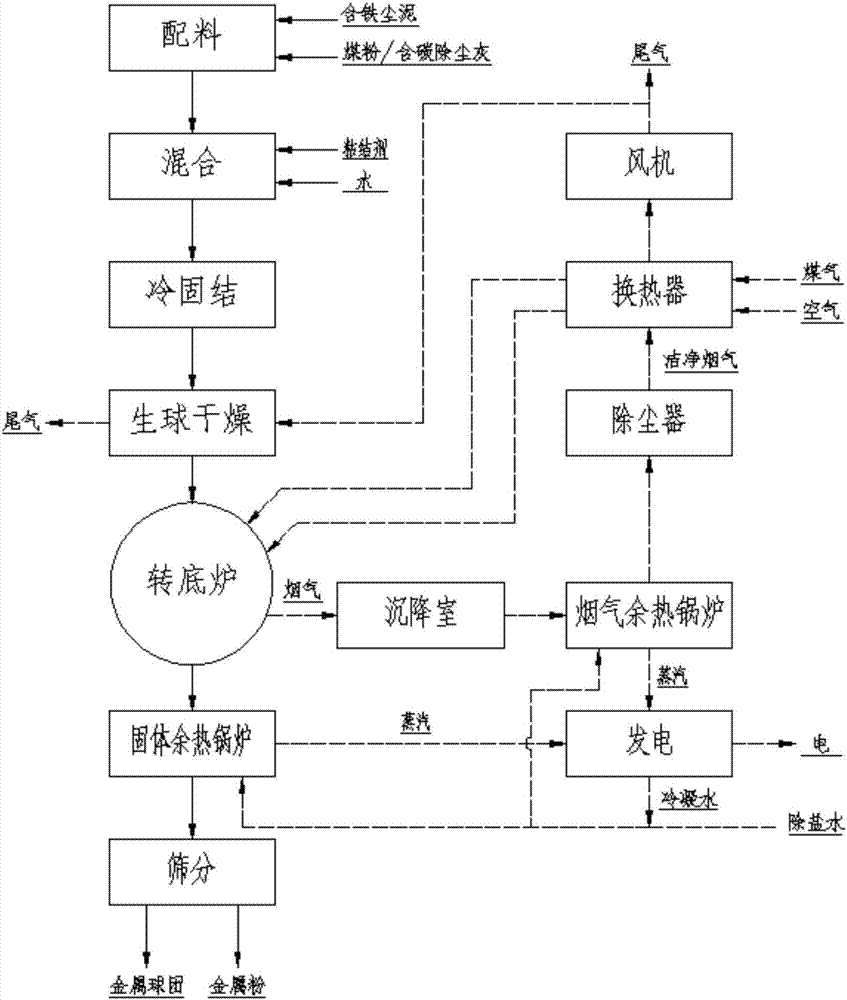

Rotary hearth furnace treatment process for iron-containing dust slime

InactiveCN107326128AReduced drying processReduce energy consumptionRecycling and recovery technologiesHearth type furnacesProduction lineSludge

The invention belongs to the field of metallurgy and particularly discloses a rotary hearth furnace treatment process for iron-containing dust slime. The rotary hearth furnace treatment process comprises the steps that the iron-containing dust slime, pulverized coal and / or carbon-containing dedusting ash are subjected to proportioning, a binding agent is added, and uniform mixing is conducted; after cold consolidation molding and drying are conducted, the mixture is fed into a rotary hearth furnace to be reduced; high-temperature pellets obtained after reduction are subjected to temperature reduction and heat recycling through a solid waste heat boiler; and flue gas of the rotary hearth furnace is subjected to step-by-step heat recycling through the waste heat boiler, a heat exchanger and fresh pellet drying equipment in sequence. According to the rotary hearth furnace treatment process for the iron-containing dust slime, the drying and energy consumption links of the raw material slime are omitted, the blocking problem of the flue gas system heat exchanger is solved, heat gradient utilization and recycling maximization are achieved, smooth operation and low energy consumption of a rotary hearth furnace production line are ensured, and the market competitiveness of the rotary hearth furnace process can be significantly improved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

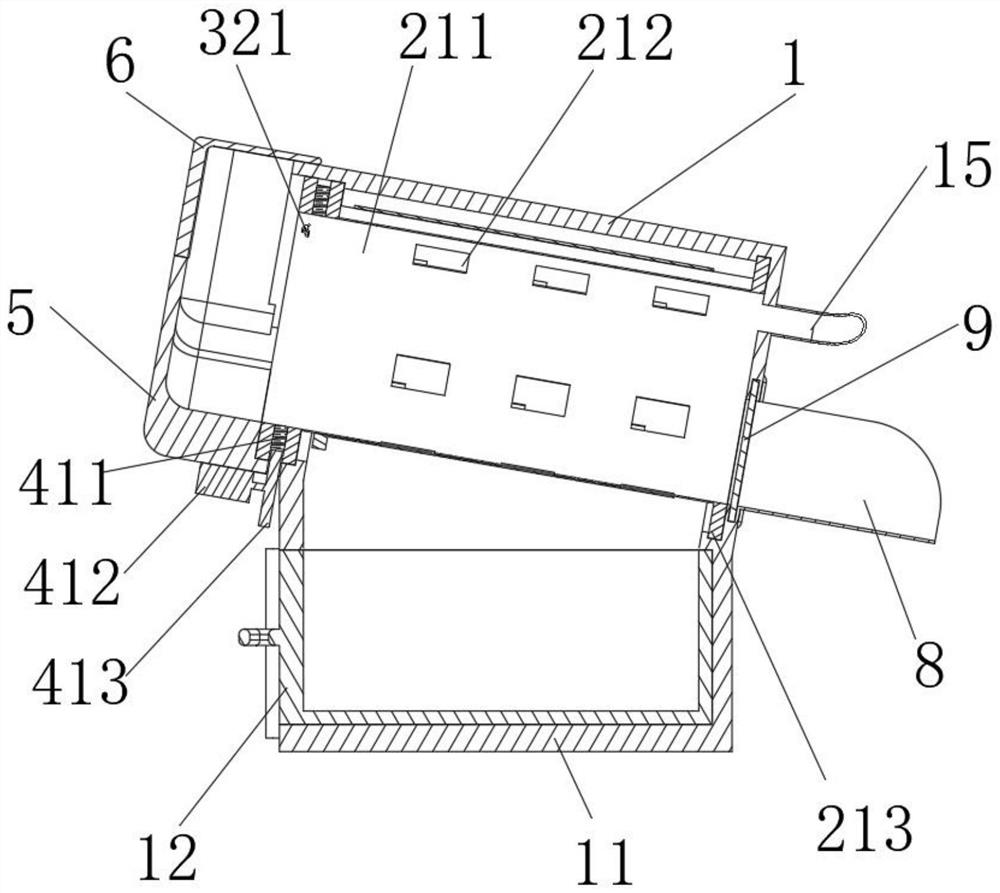

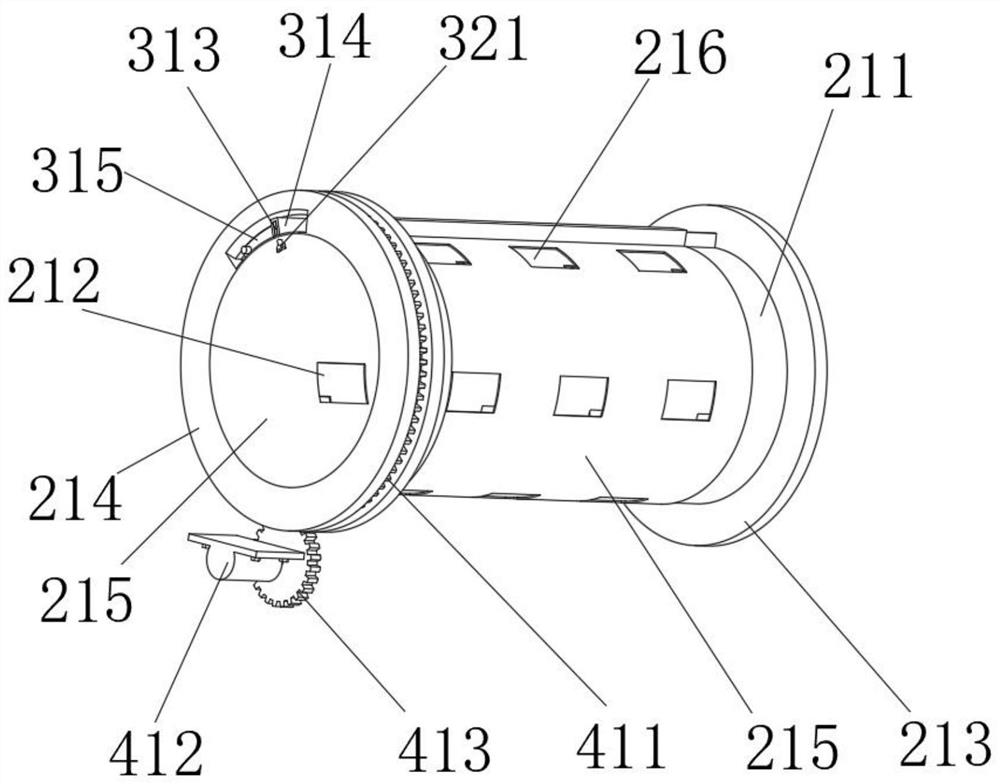

Traditional Chinese medicine decoction piece drying and impurity removing all-in-one machine

PendingCN112393554AShorten the timeReduced drying processSievingScreeningIndustrial engineeringAir heater

The invention relates to the technical field of traditional Chinese medicine decoction piece manufacturing, in particular to a traditional Chinese medicine decoction piece drying and impurity removingall-in-one machine. The machine comprises a device body, a motor and an air heater, wherein an impurity removing mechanism is arranged in the device body, and the impurity removing mechanism comprises a first screening barrel, first screening holes, a first rotating wheel, a second rotating wheel, a second screening barrel and second screening holes. The first screening holes are formed in the surface of the outer side of the first screening barrel, and the first rotating wheel is welded to the right end of the first screening barrel. The problems that traditionally, traditional Chinese medicine decoction pieces are generally dried and subjected to impurity removal separately, a large amount of time needs to be wasted when the traditional Chinese medicine decoction pieces are dried and subjected to impurity removal greatly, traditionally, the traditional Chinese medicine decoction pieces can only be dried on one sides generally, the complete drying time of the traditional Chinese medicine decoction pieces is long, time is wasted, and the labor cost is increased, so that the cost of the traditional Chinese medicine decoction pieces is increased, the drying and impurity removing time of the traditional Chinese medicine decoction pieces is effectively shortened, and the cost of the traditional Chinese medicine decoction pieces is reduced.

Owner:安徽震和堂药业有限公司

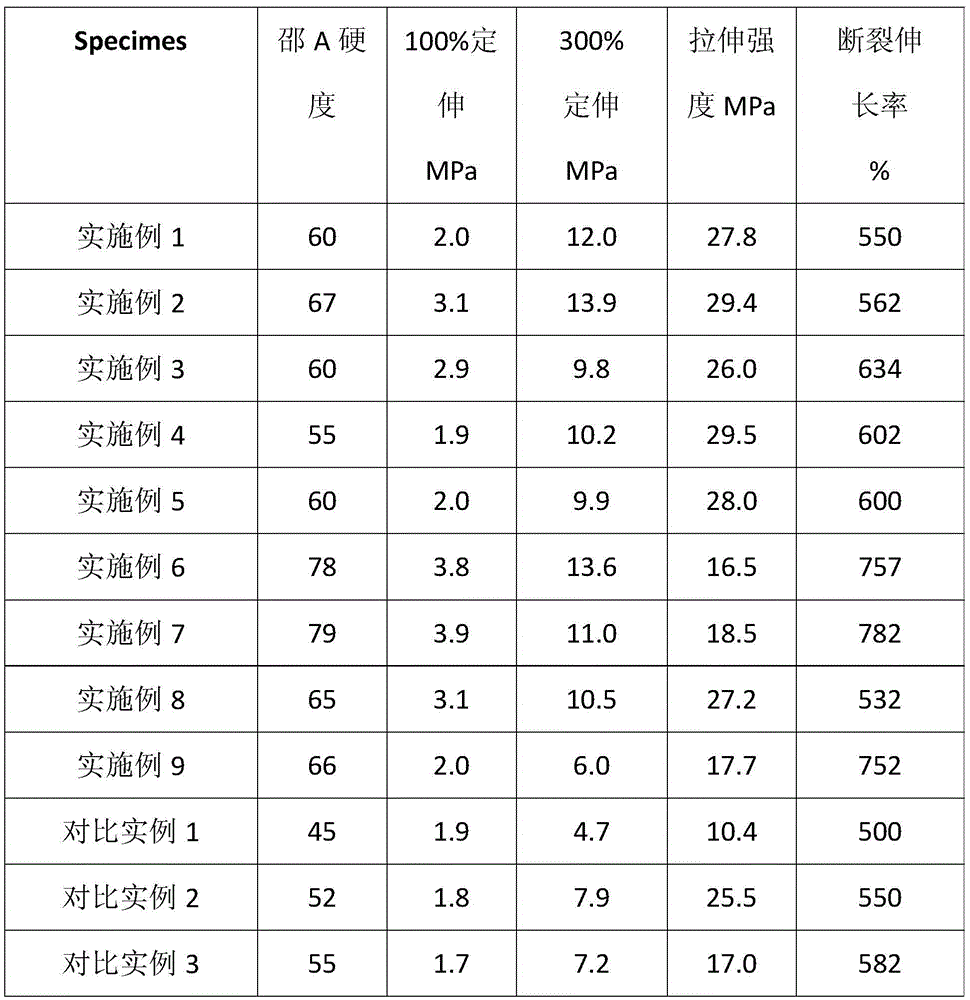

Method for preparing small-fraction filling composite masterbatch through semi-open type superheated steam spray-drying method

The invention provides a method for preparing small-fraction filling composite masterbatch through a semi-open type superheated steam spray-drying method. The technological method is used for preparing rubber nanocomposites through wet mixing and is less in energy consumption, safe and simple in technology. Rubber latex is selected and used for being mixed with filler slurry, a certain quantity of rubber auxiliary is added and stirred to be uniform, an obtained mixture is dried through a semi-open type superheated steam spray tower at a certain feed rate, the nano composite rubber masterbatch is prepared and collected and passes through a sieve plate, and blocks are formed after rolling is conducted. The method is simple in technology, complete in reaction, safe, free of hidden dangers, less in energy consumption and capable of reducing cost; human factors are few, continuous production can be achieved, the product quality is stable, industrial research is easy, and green and environmental protection is achieved. By means of the rubber masterbatch produced through the method, inorganic filler can be uniformly dispersed in a rubber matrix in a nano-scaled mode, and the rubber masterbatch can be applied to the fields such as saloon car tread rubber and engineering tread rubber.

Owner:BEIJING UNIV OF CHEM TECH

Blenching and drying device for textile yarn

InactiveCN107558052ABleach is quick and easyImprove work efficiencyLiquid/gas/vapor removalTextile treatment carriersBobbinTextile yarn

The invention discloses a textile yarn bleaching and drying device, which includes a working box, a wire inlet is opened on the left side of the working box, and a first roller is movably connected to the inner cavity of the working box and located on the right side of the wire inlet through a bearing. Shaft, the top of the inner cavity of the working box is fixedly connected with the first electric telescopic rod on the right side of the first roller shaft, the bottom of the first electric telescopic rod is movably connected with a pulley through the rotating shaft, the bottom of the inner cavity of the working box is located on the first The lower part of the electric telescopic rod is fixedly connected with a bleach box. The present invention uses the first roller shaft, the first electric telescopic rod, the pulley, the bleaching box, the partition, the through hole, the first motor, the fan blade, the second roller shaft, the heating block, the hot air blower, the wire outlet, the second motor, The combination of the second electric telescopic rod, threaded sleeve and take-up shaft can quickly and easily bleach the yarn, and directly dry and collect the yarn after bleaching, without manual drying, which greatly improves the work efficiency. .

Owner:SUZHOU BONUQI TEXTILE CO LTD

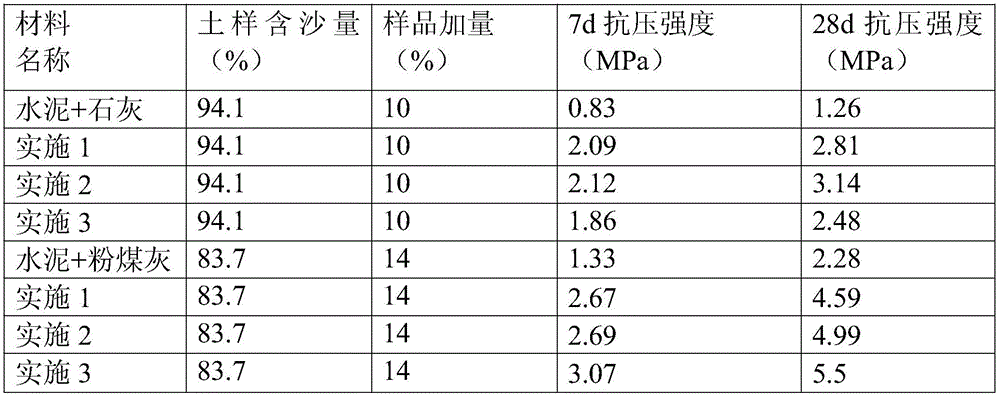

Soil stabilizer and preparation method thereof

InactiveCN105778923ASimple construction processReduce stepsBuilding constructionsOrganic fertilisersSoil propertiesEcological environment

The invention discloses a soil stabilizer.The soil stabilizer is characterized by comprising 30-50% of coal ash, 5-10% of slag, 5-10% of an activating agent, 0.5-1% of triethanolamine, 0.5-1% of a polycarboxylic acid compound, 0.5-1% of aliphatic series sulfonate, 2-4% of sodium sulfate, 28-50% of cement clinker and 0.5-2% of sodium fluosilicate.According to the soil stabilizer, a great amount of industrial waste is utilized, so that cost of raw materials is saved, and consumption of a traditional gluing material is reduced; the problems of industrial waste emission and environmental pollution are solved, and an active protection effect is achieved for the ecological environment.In the construction process of an overwet soil road foundation in a rainy and humid area, solidification of soil in a rainy season and overwet soil, the soil stabilizer is added easily, the process of tedding treatment is reduced under a certain circumstances, and the soil stabilizer is an ideal soil stabilizer.The soil stabilizer is simple in construction process and easy to operate, for soil in need of consolidation, according to the soil property, a certain amount of the soil stabilizer is added to soil and stirred to be uniform, compaction treatment is conducted under the optimum water content of the soil, and in other words, performance indexes such as the density degree and strength which are required by construction are reached.

Owner:吉林中路新材料有限责任公司

Negative electrode material layer suitable for all-solid-state battery, preparation method of negative electrode material layer, negative plate and all-solid-state battery

InactiveCN112133920AEvenly dispersedHigh ion conductivityElectrode rolling/calenderingNegative electrodesSolid state electrolyteElectrolytic agent

The invention discloses a negative electrode material layer suitable for an all-solid-state battery, a preparation method of the negative electrode material layer, a negative plate and the all-solid-state battery. The negative electrode material layer comprises a network-shaped structure formed by mutually overlapping polymer fibers, and a negative electrode active substance, a sulfide solid electrolyte and a conductive agent which are dispersed and bonded in the network-shaped structure. In the negative electrode material layer, the polymer fiber is used as a binder to construct the network-shaped structure, uniform dispersion of the negative electrode active substance, the sulfide solid electrolyte and the conductive agent is facilitated, and the sulfide solid electrolyte has good ion conductivity and is dispersed in the network-shaped structure to provide an ion transmission channel for charging and discharging of the battery, so that the addition of electrolyte is avoided, an all-solid-state battery is assembled, and the safety performance of the battery is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Earthworm drying device

PendingCN107449259AEvenly heatedLow ashDrying gas arrangementsDrying machines with progressive movementsEngineeringMoisture sensor

The invention relates to an earthworm drying device. The earthworm drying device comprises a cleaning section and a drying section, wherein the cleaning section comprises a cleaning box, a water pipe and a cleaning conveying belt, the water pipe is arranged on the upper portion of the cleaning box and connected with the water tank through a pipeline, the cleaning conveying belt is arranged on the lower portion of the water tank, and a water collecting tank is arranged below the cleaning conveying belt; the drying section comprises a drying box, a heating rod and a drying conveying belt, the heating rod is arranged at the center inside the drying box, and the drying conveying belt is spirally arranged around heating rod; one side of the top of the drying box is provided with an air outlet, and one side of the lower portion of the drying box is provided with an air inlet connected with a fan; the middle of the inner wall of the drying box is provided with a temperature sensor and a humidity sensor, and the outer side of the drying box is provided with a controller. The earthworm drying device is simple in design, good in drying performance, capable of reducing silt inside earthworm bodies, capable of reducing the ash content of earthworm finished products and capable of guaranteeing product quality.

Owner:JIANGSU BULONG BIOTECH

Integrally casting technology of tire mold patterned ring basic model, silica gel, gypsum and aluminum ring

The invention relates to an integral casting technology of a tire mold patterned ring basic model, silica gel, gypsum and an aluminum ring, which belongs to the semi-steel tire mold field. The technology comprises the following steps: 1.1 a basic model base is prepared to a basic tire shape , a whole circle is divided into eight equal parts, the external surface of the basic model base is milled a patterned surface; 1.2 the basic model is placed in a silica gel liner mold, then the regulated silica gel is injected between an inner wall of the silica gel liner mold and a cylindrical surface ofthe basic model; 1.3 the silica gel liner mold is opened after the silica gel in the silica gel liner mold is solidified, the formed silica gel is dismounted from the surface of the basic model; 1.4 the formed silica gel is placed in the silica gel liner mold, then secondary gypsum is injected in the silica gel; 1.5 a gypsum model is placed in a secondary drying furnace for heating and drying. The silica gel and gypsum model of the present invention are capable of realizing one-step forming, optimizing the technology step of the tire mold, reducing the production manufacture cost and decreasing workload and labor intensity of operators.

Owner:淄博昂达机电设备销售有限公司

Positive electrode material layer for semi-solid-state battery, preparation method of positive electrode material layer, positive electrode sheet and semi-solid-state battery

PendingCN112151745AHigh ion conductivityReduce hardnessElectrode rolling/calenderingPositive electrodesElectrolytic agentFiber

The invention discloses a positive electrode material layer for a semi-solid battery, a preparation method of the positive electrode material layer, a positive electrode sheet and the semi-solid battery. The method comprises the following steps: 1) mixing fibrosis polymer powder, a polymer electrolyte coated positive electrode active substance and a conductive agent, and drawing the fibrosis polymer powder under the action of shearing force to form fibers so as to obtain a mixture; and 2) carrying out hot-pressing treatment on the mixture on a current collector to a preset thickness so as to obtain the positive electrode material layer. According to the method disclosed by the invention, the problems of non-uniform mixing of the positive electrode material and cracking of the electrode sheet caused by high positive electrode material ratio and high hardness when the positive electrode material layer is prepared by a dry method are solved, the requirement on the material of the roller shaft of a roller press in the preparation process of the dry-method positive electrode plate is reduced, and the equipment cost is reduced; and the ionic conductivity of the electrode sheet is increased, the use amount of an electrolytic solution is reduced, and the safety performance of the battery is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com