Patents

Literature

139 results about "Tire shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

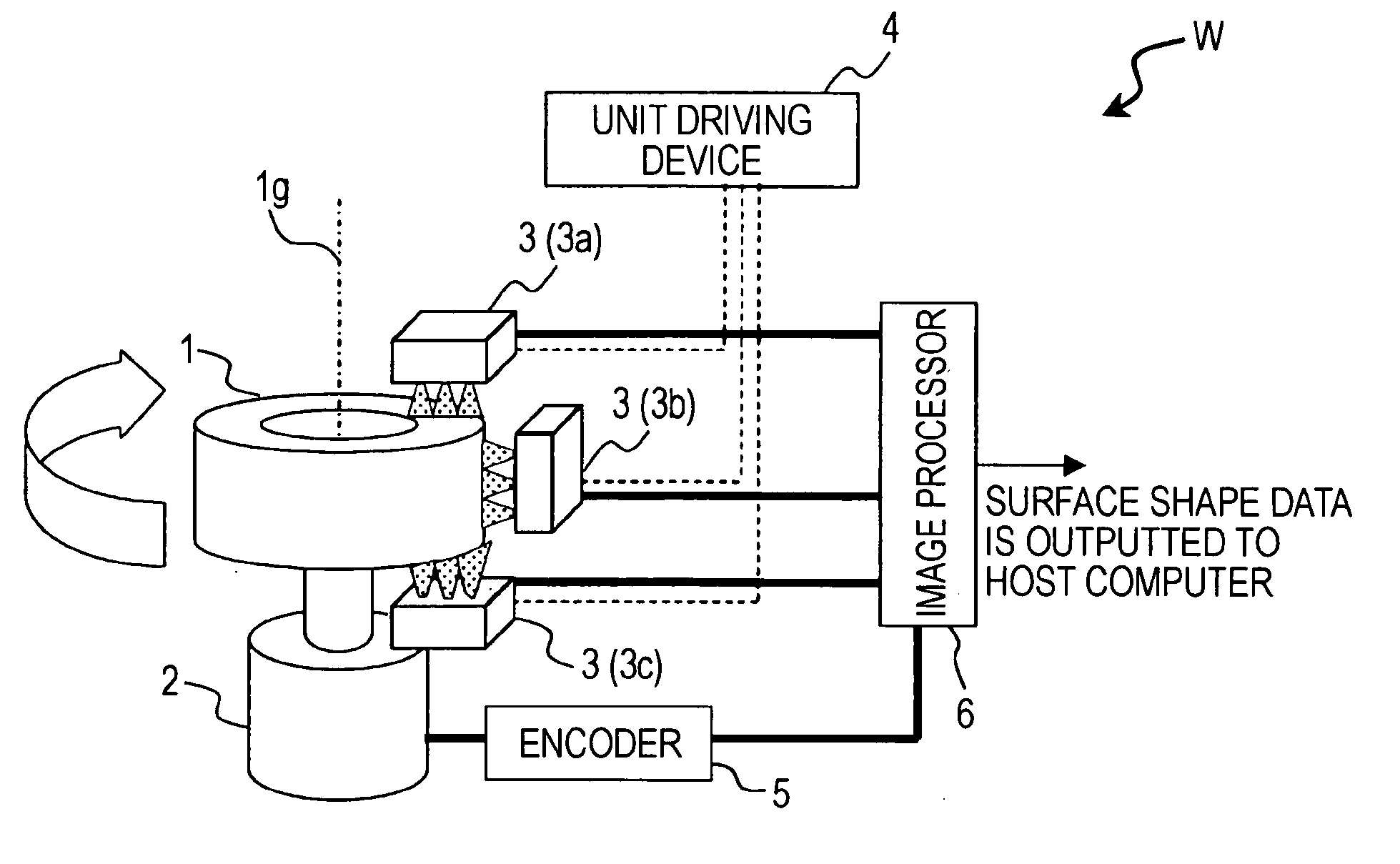

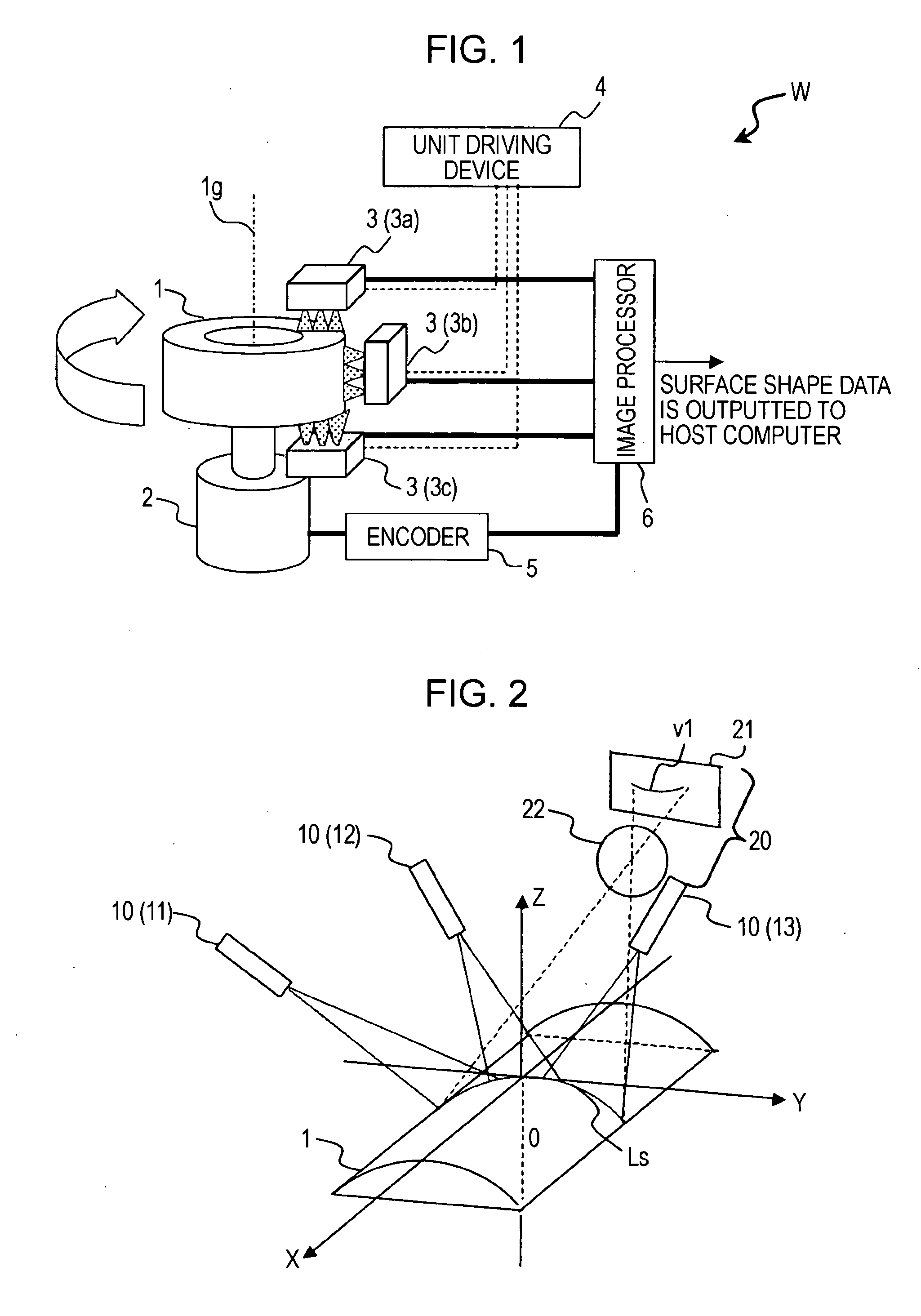

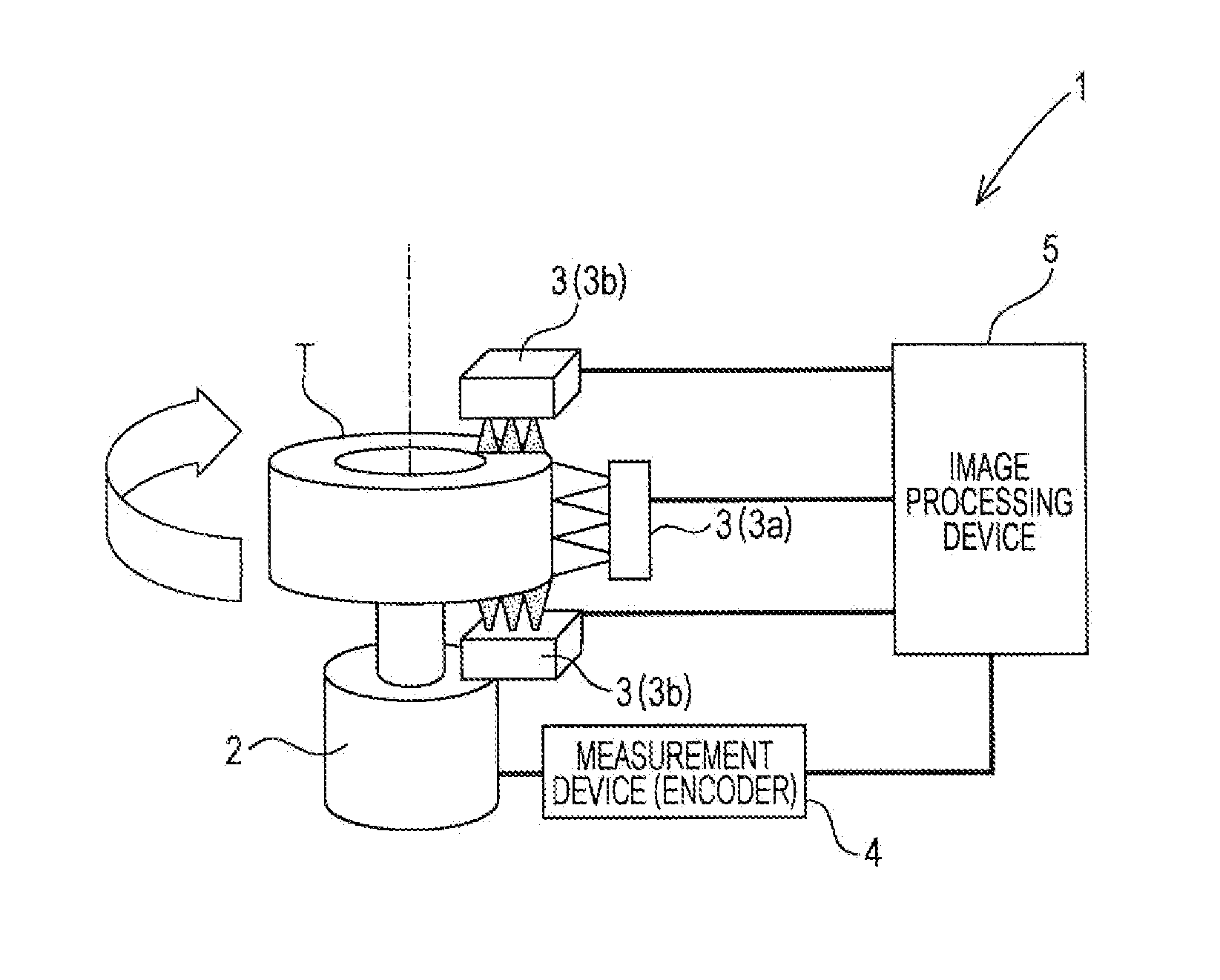

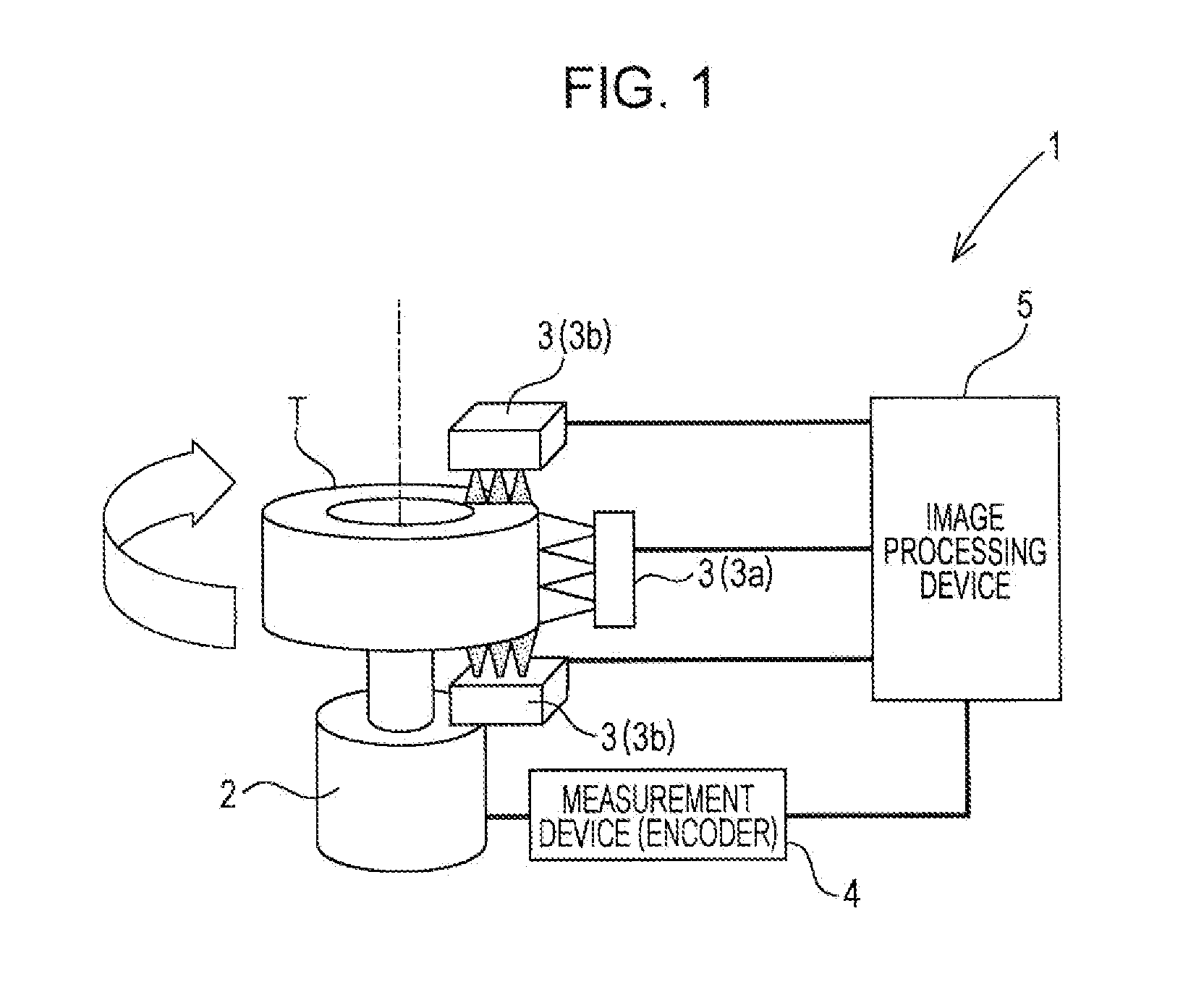

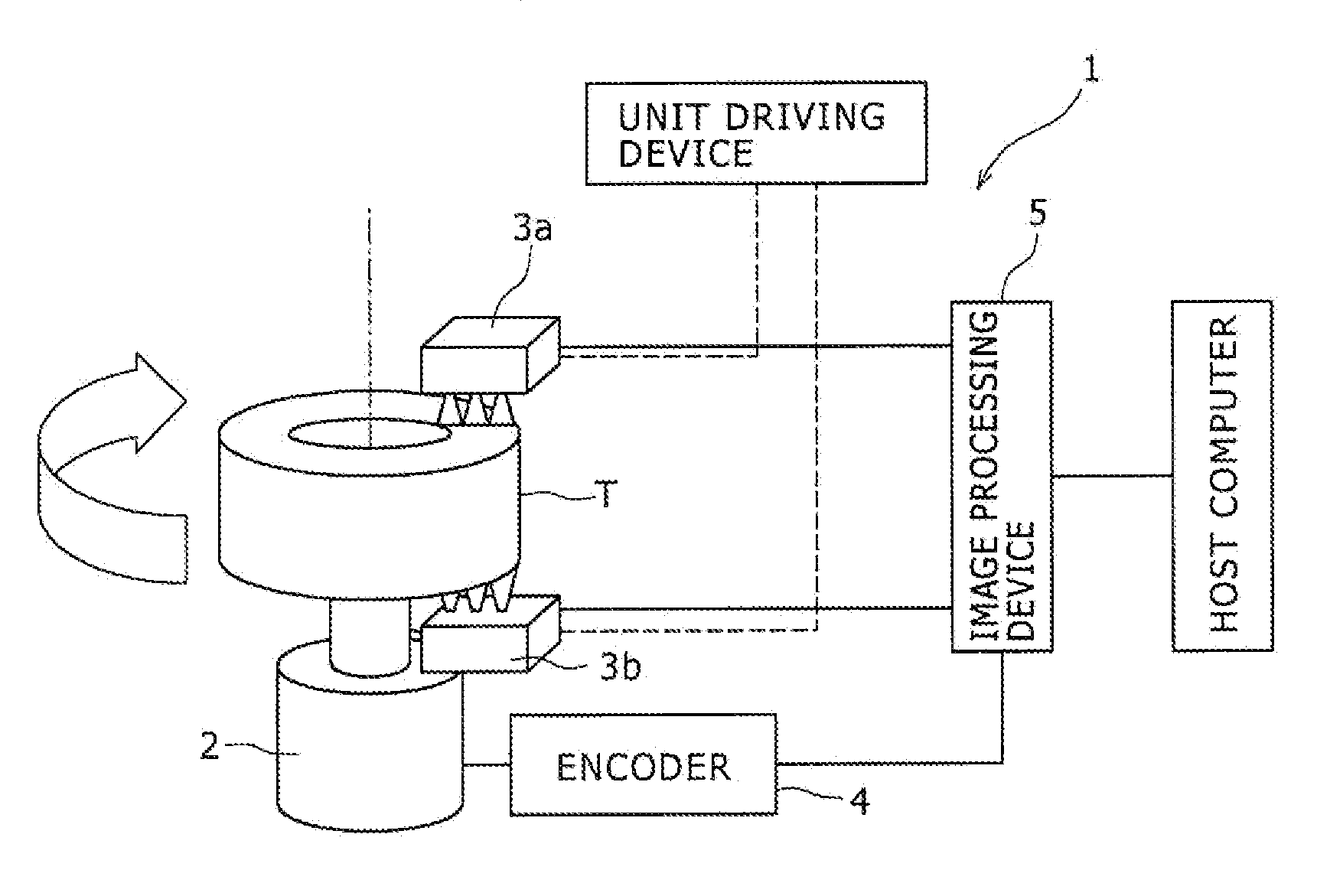

Tire shape measuring system

ActiveUS20090040533A1Reduce processing loadHigh image capture rateVehicle testingImage analysisImaging processingTire shape

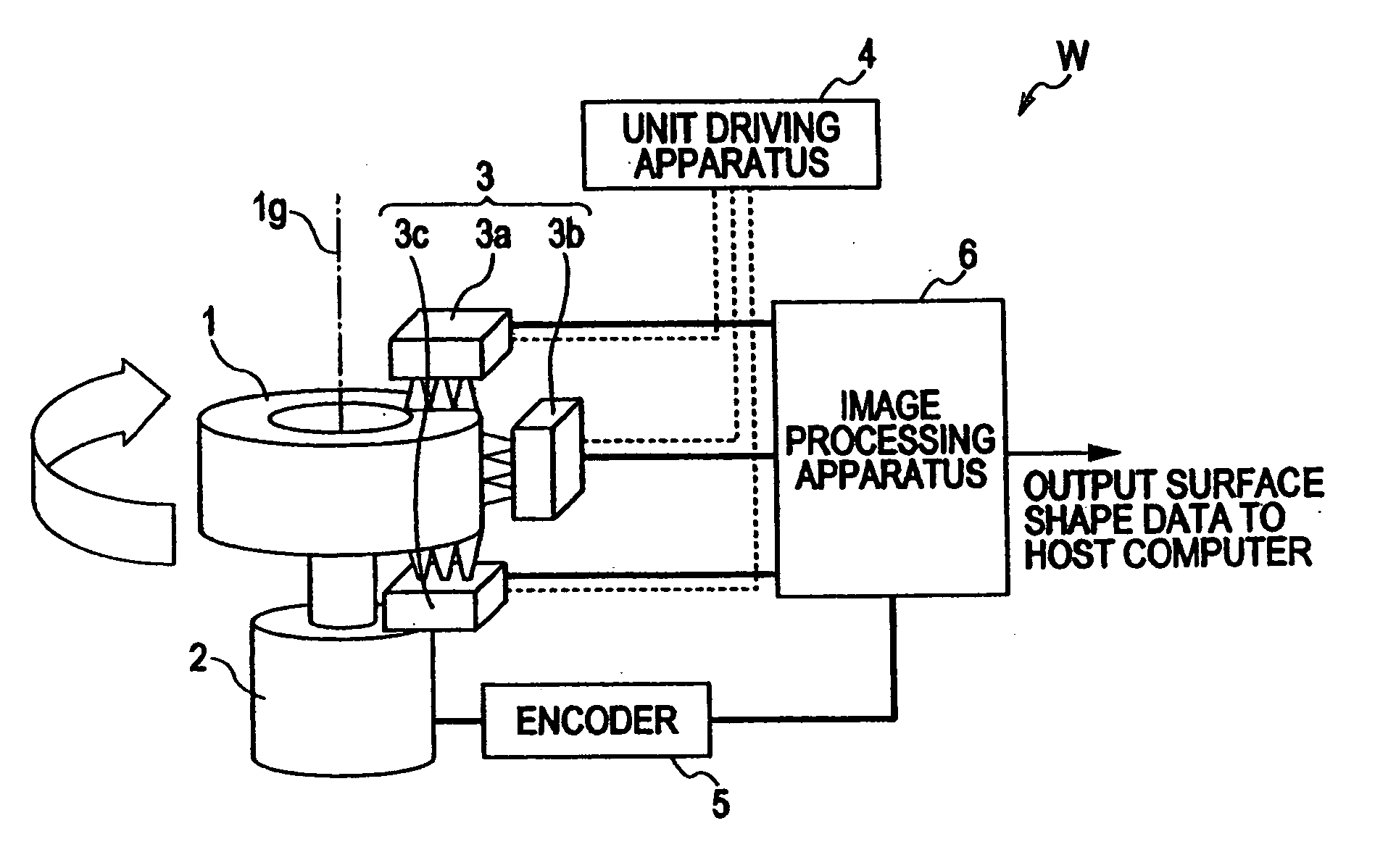

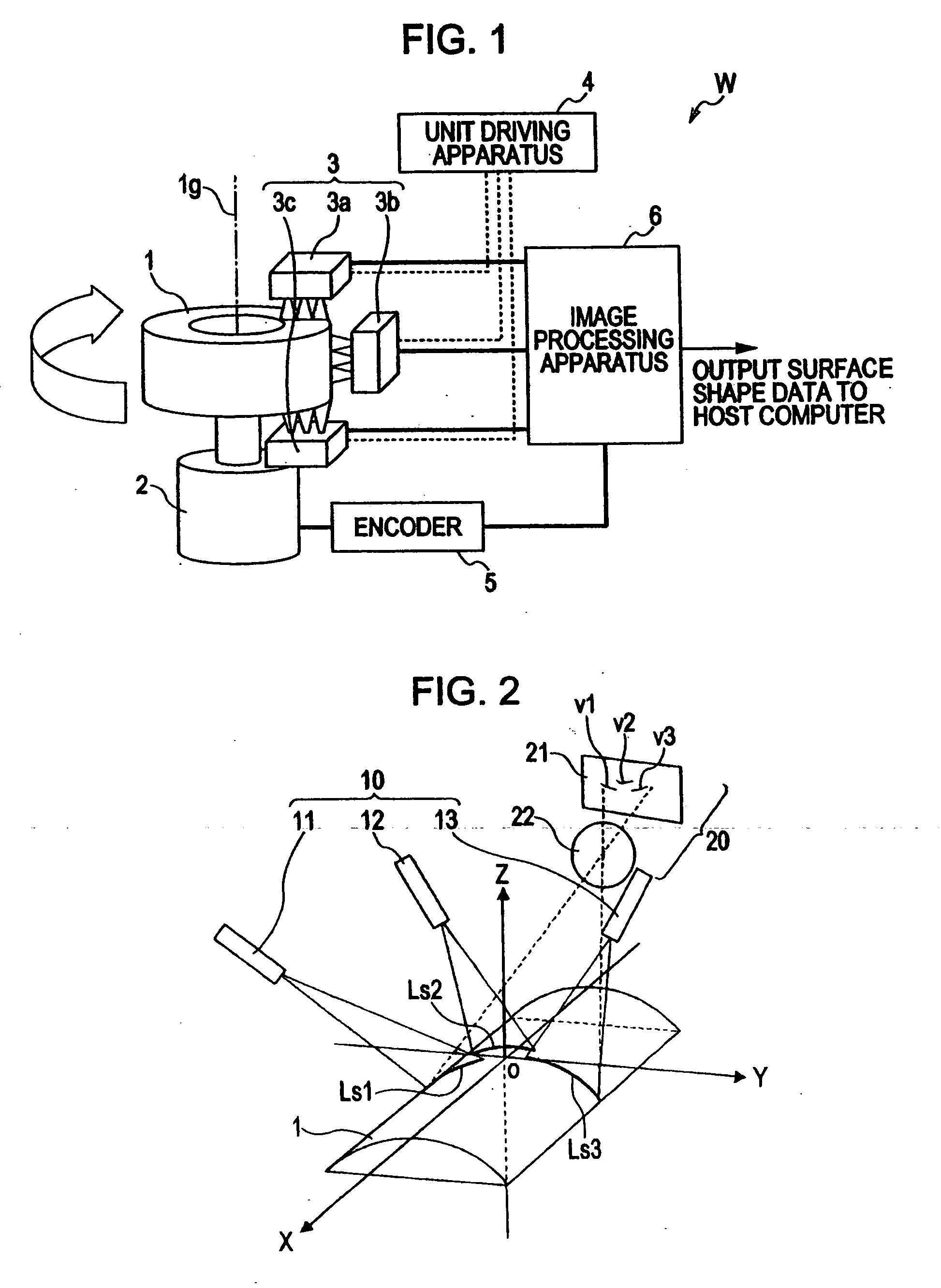

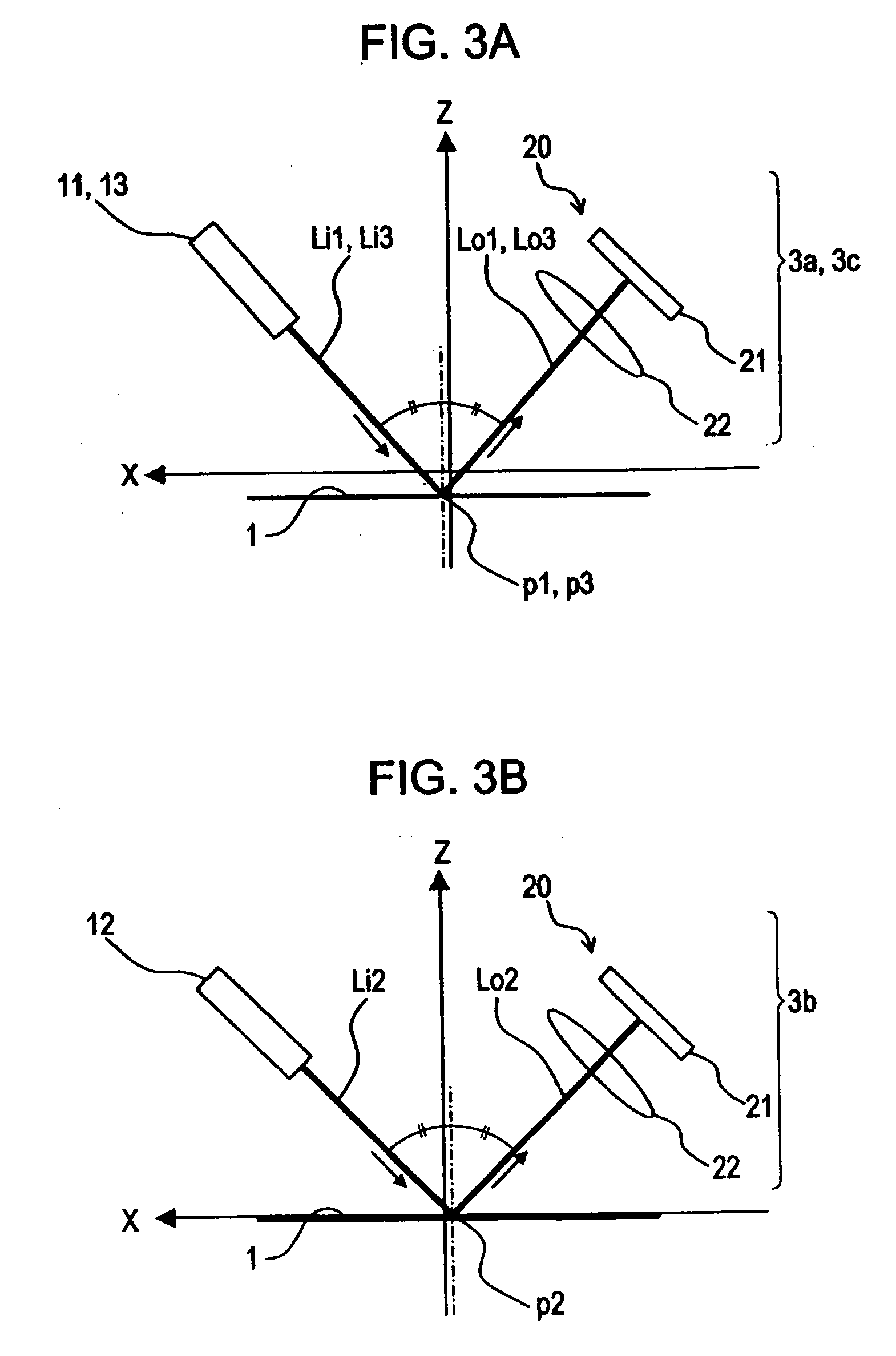

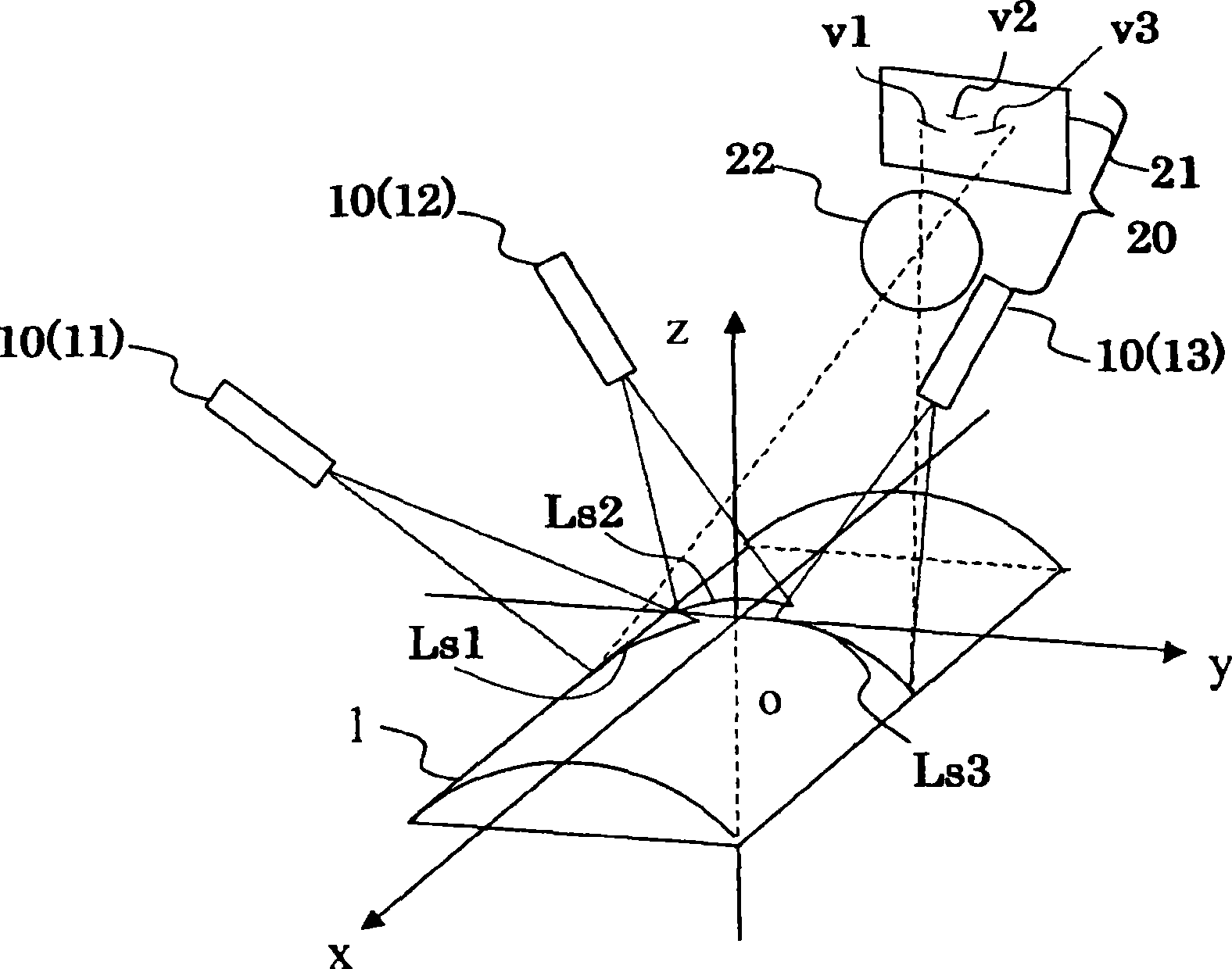

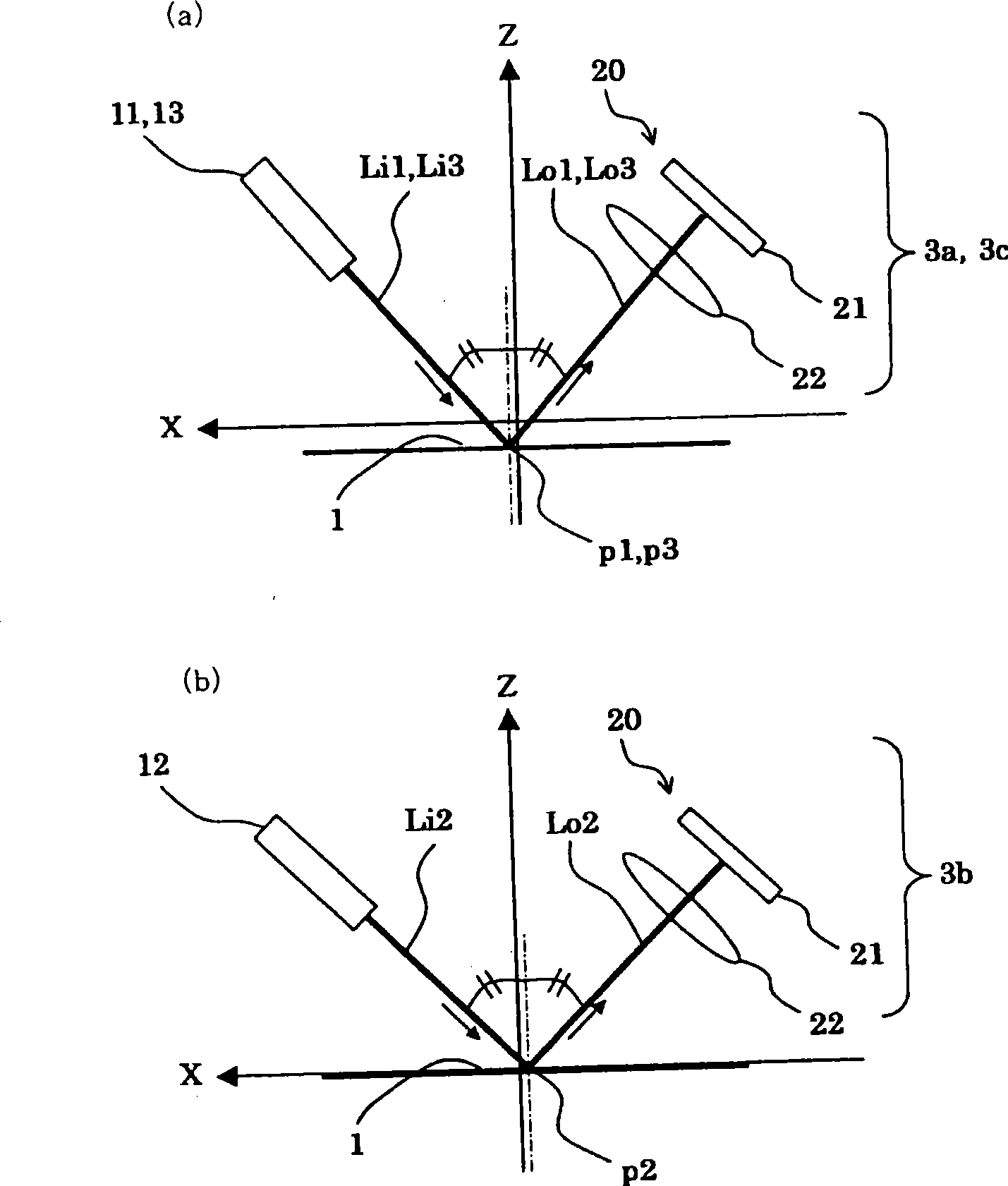

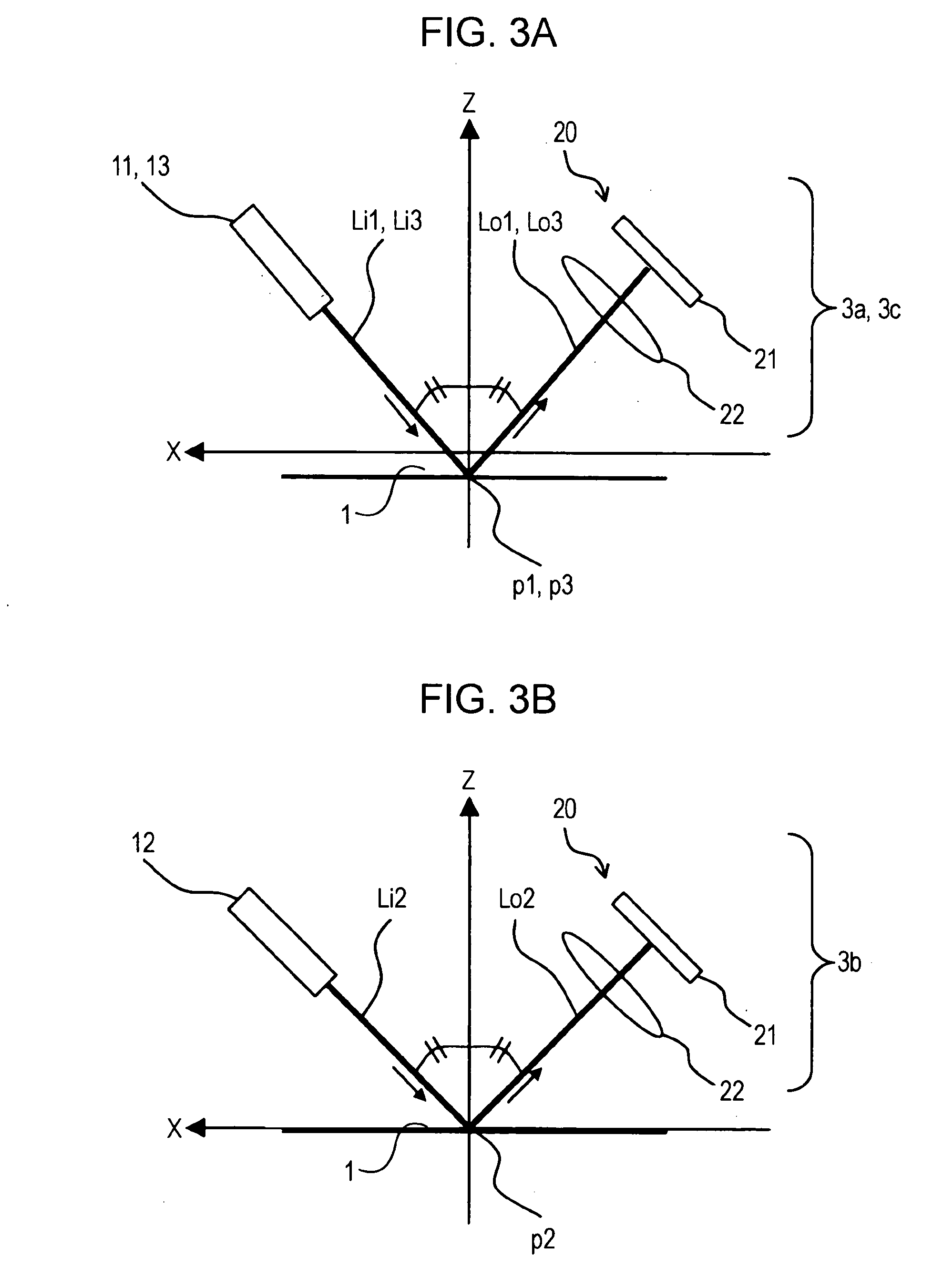

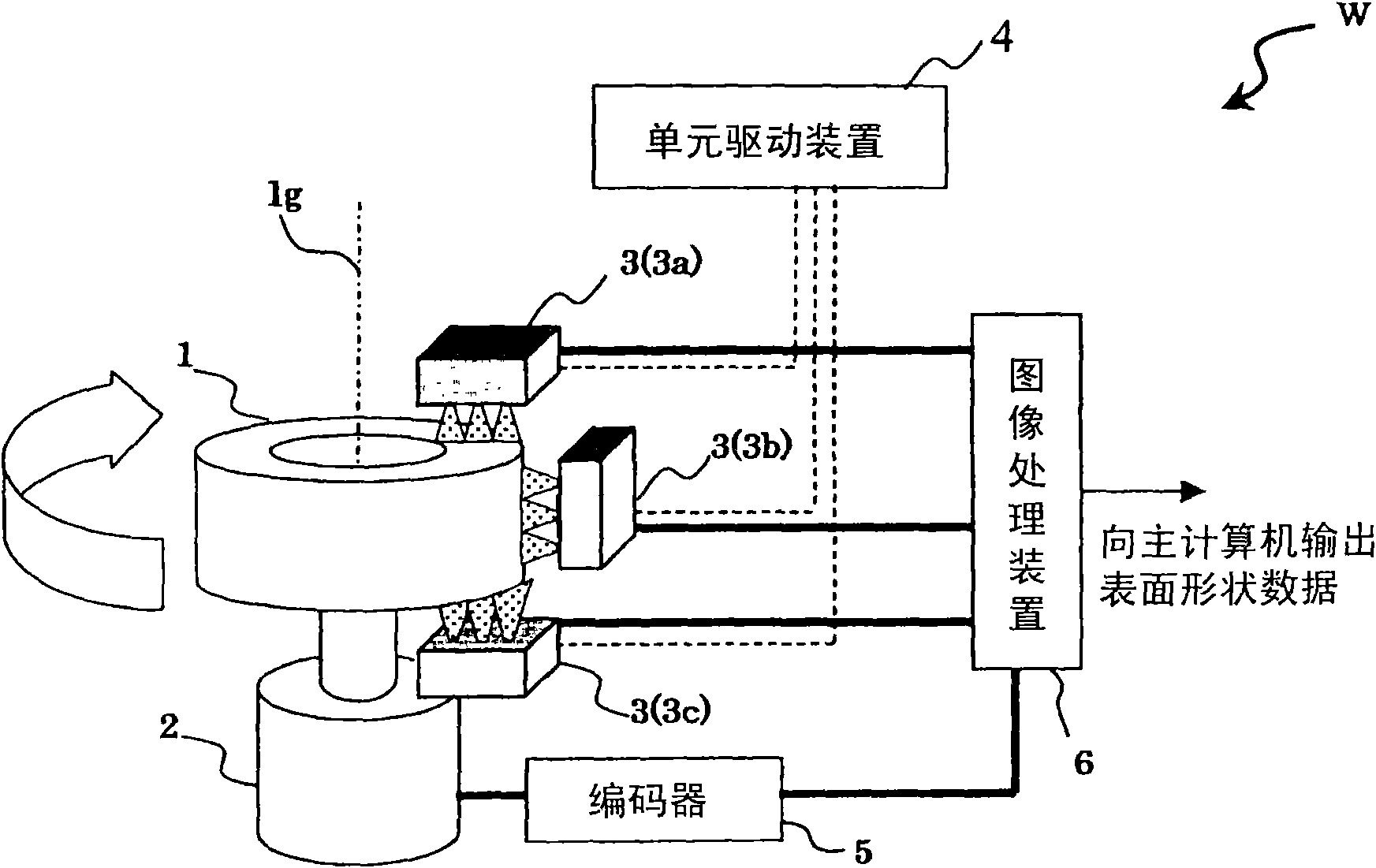

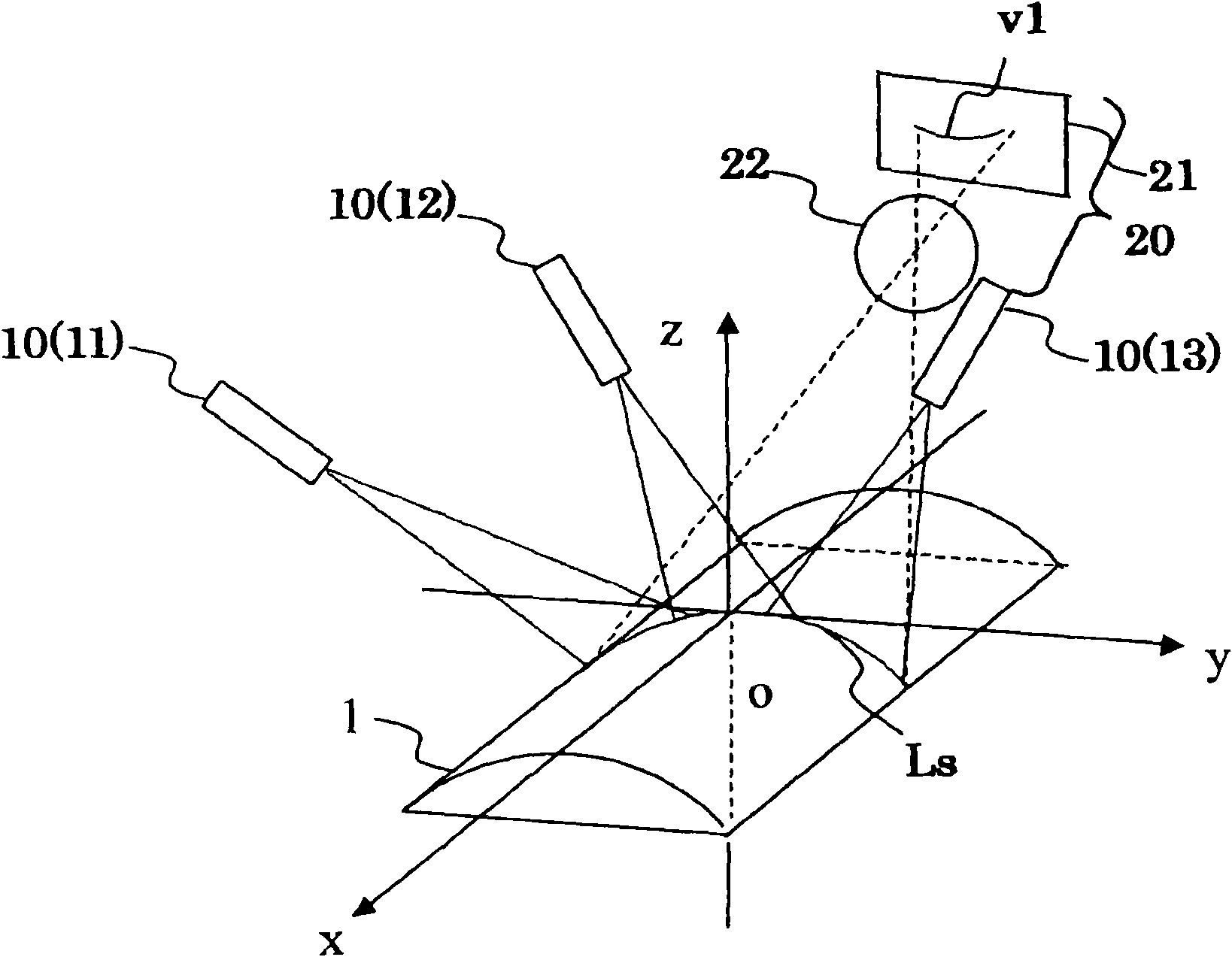

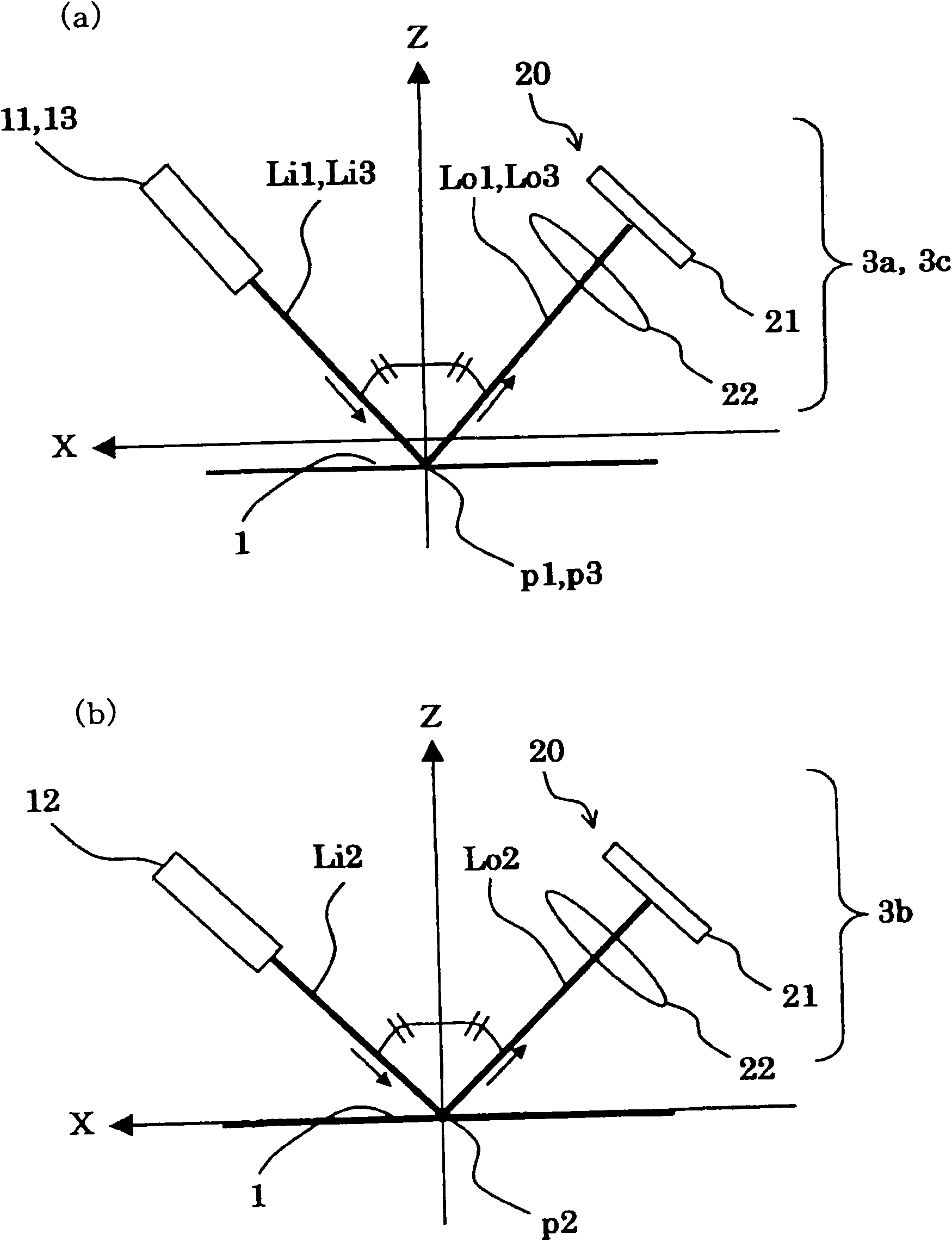

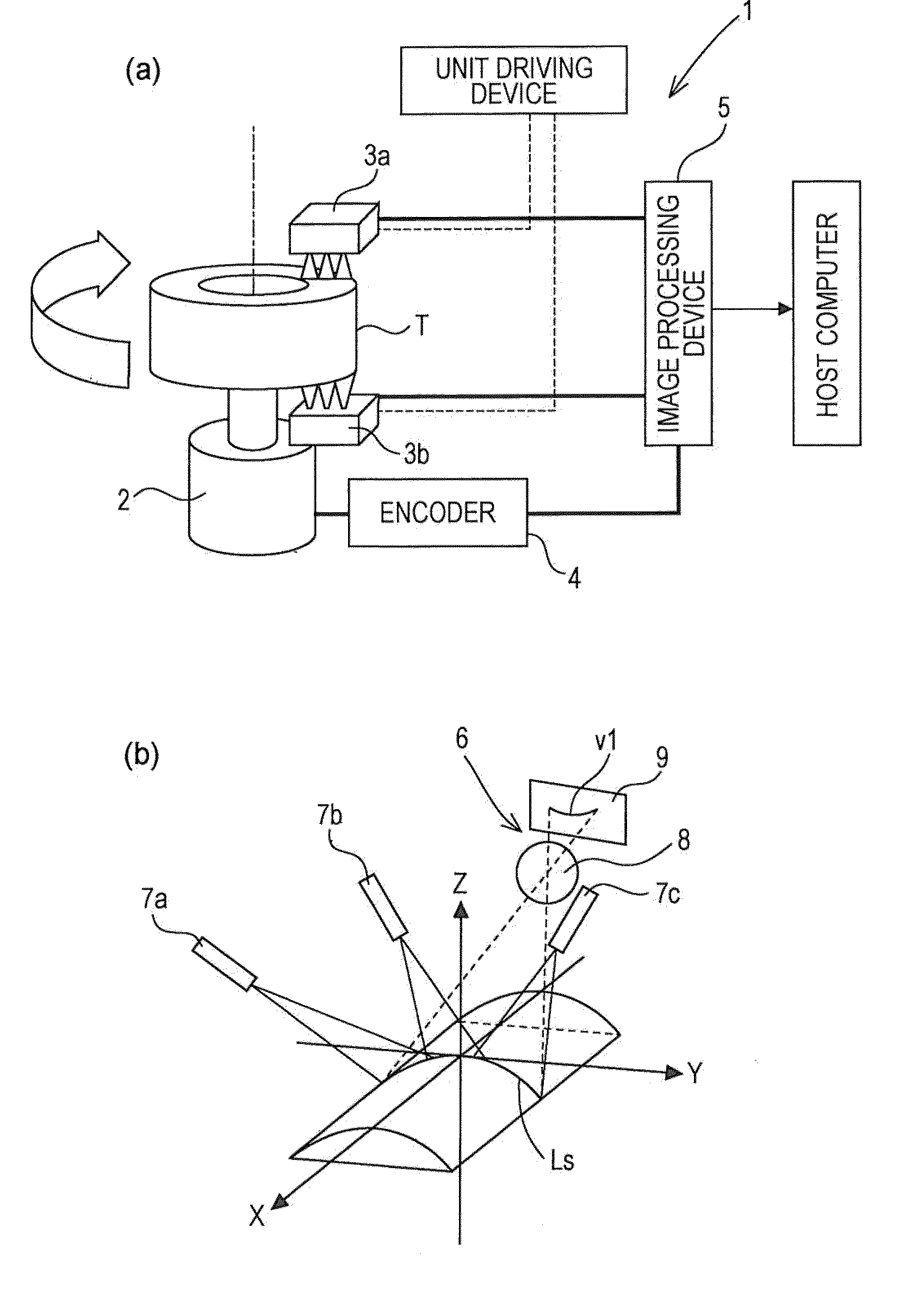

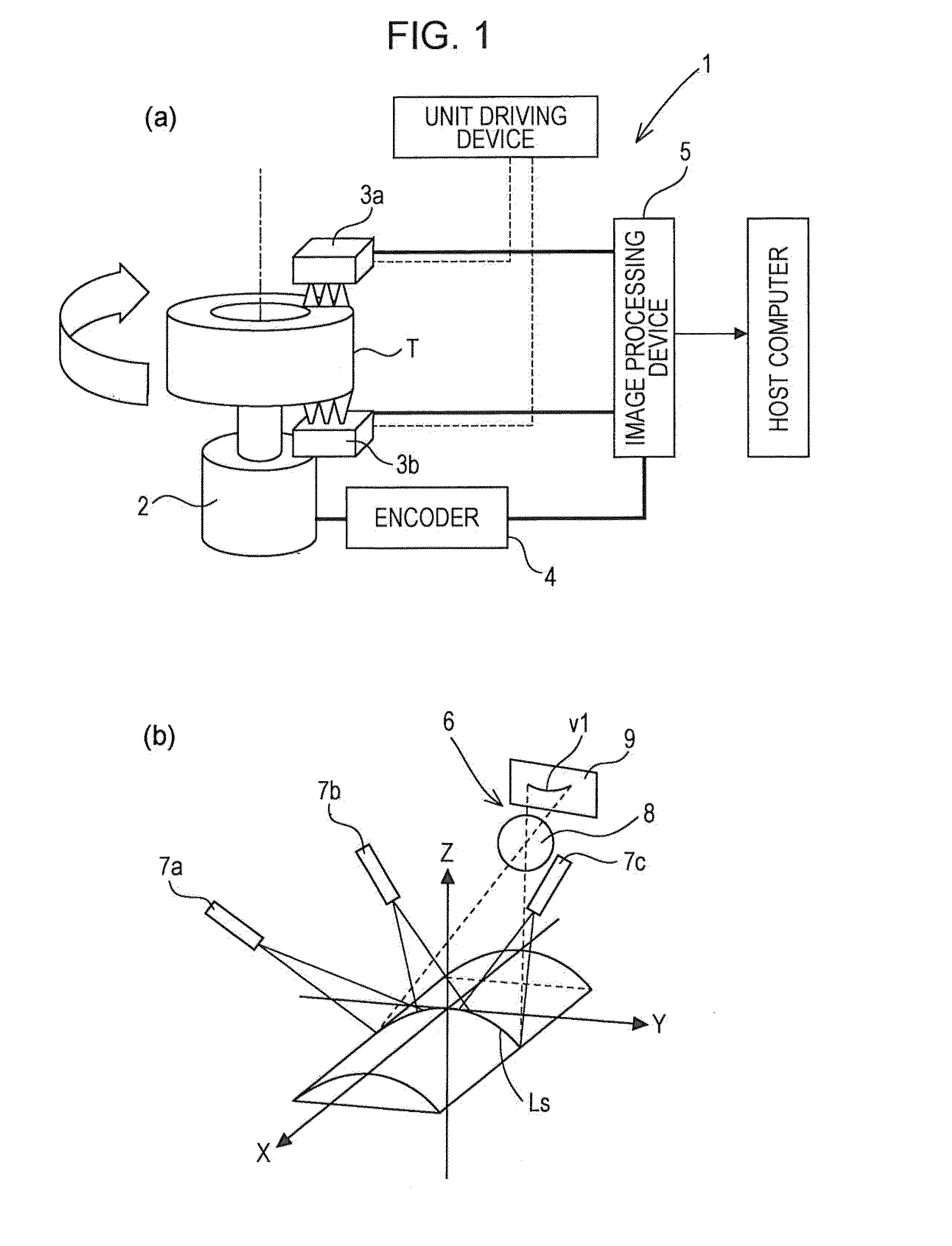

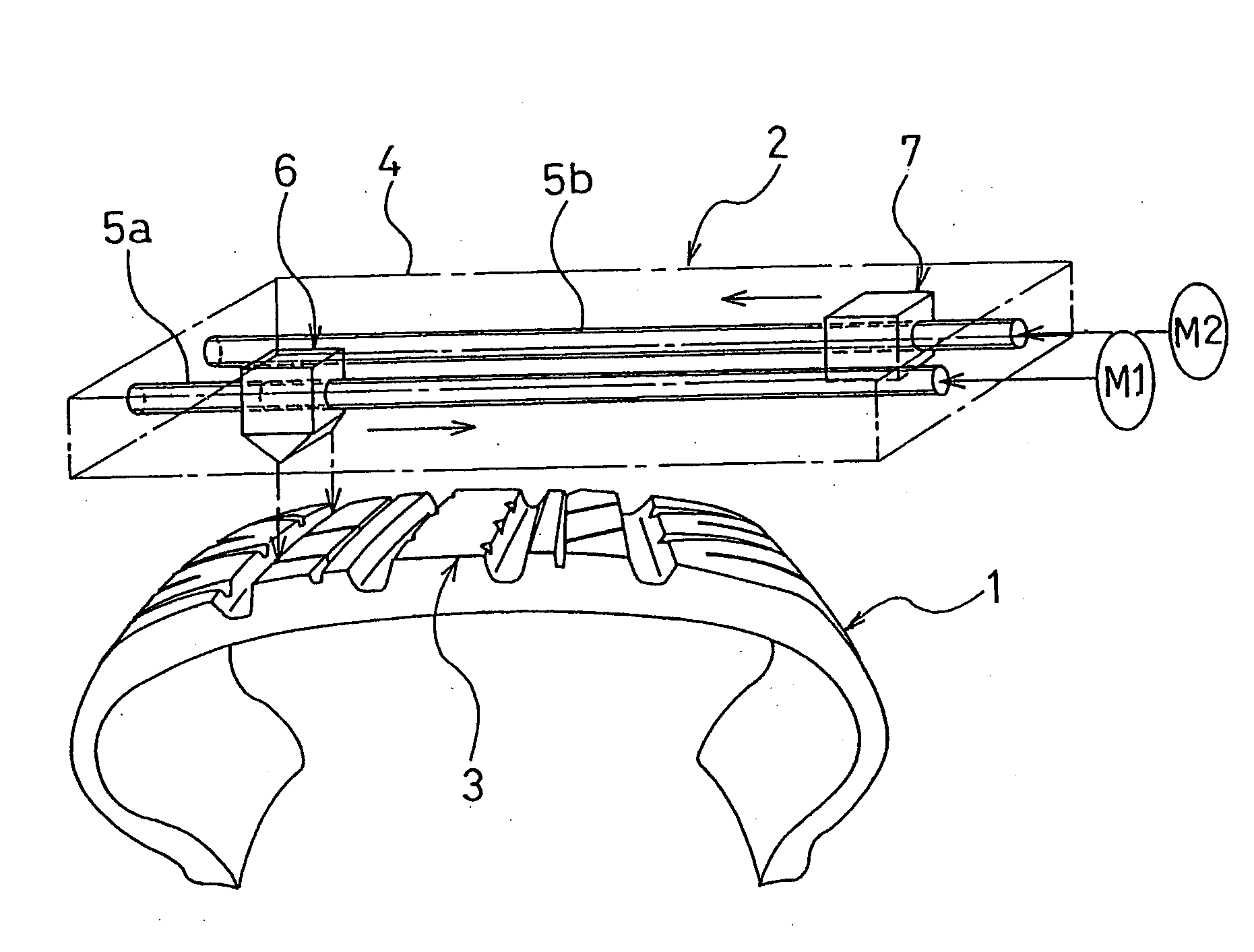

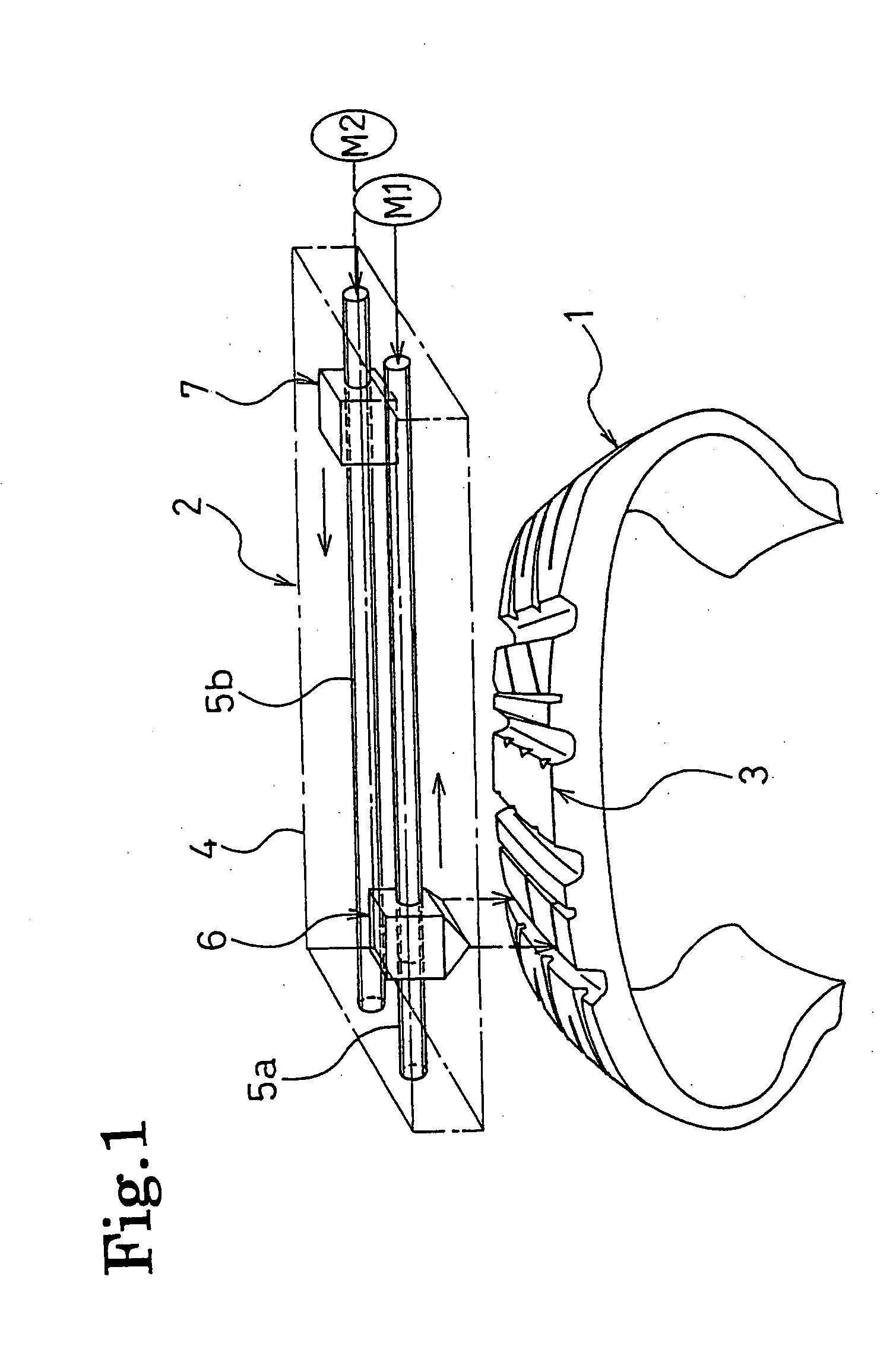

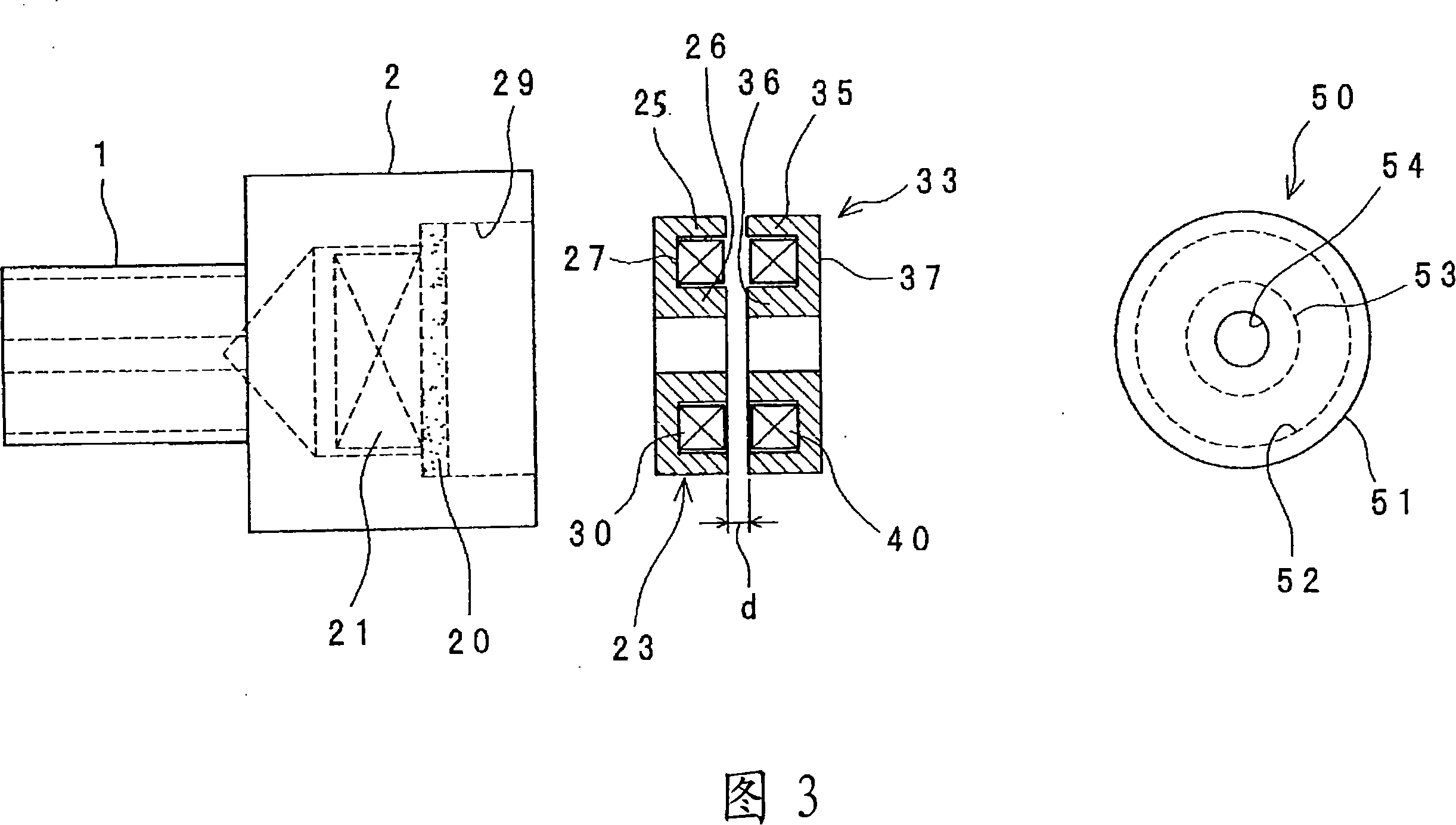

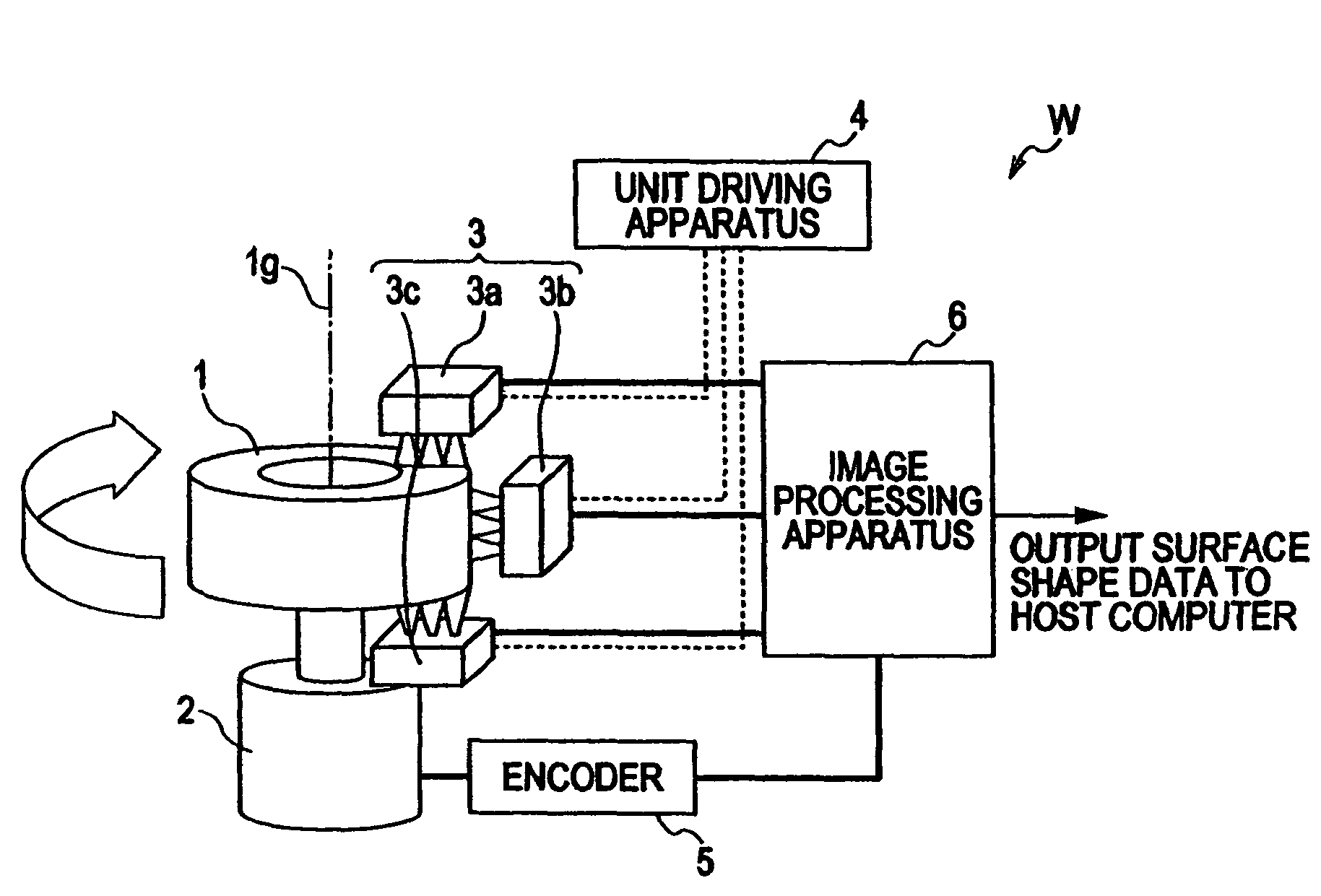

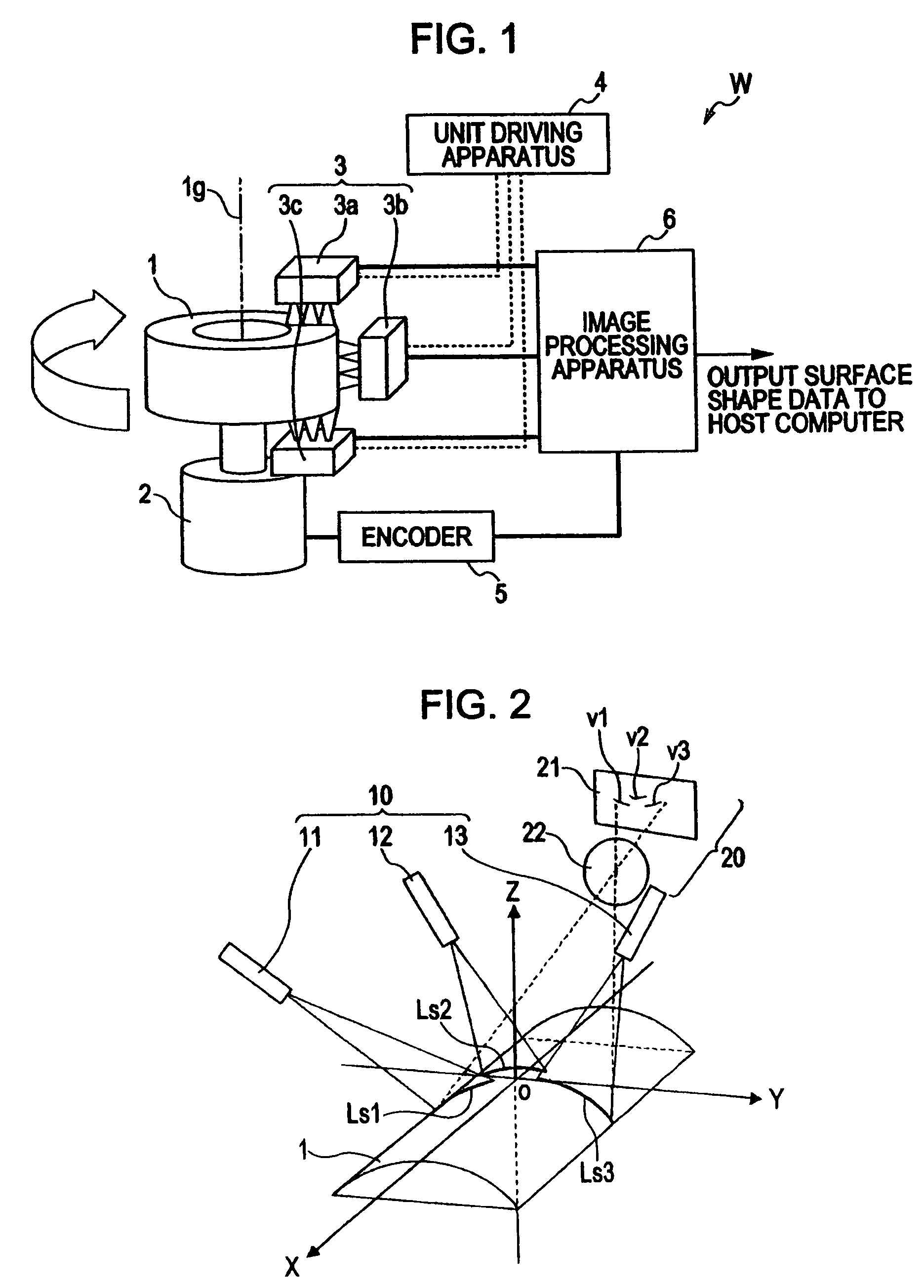

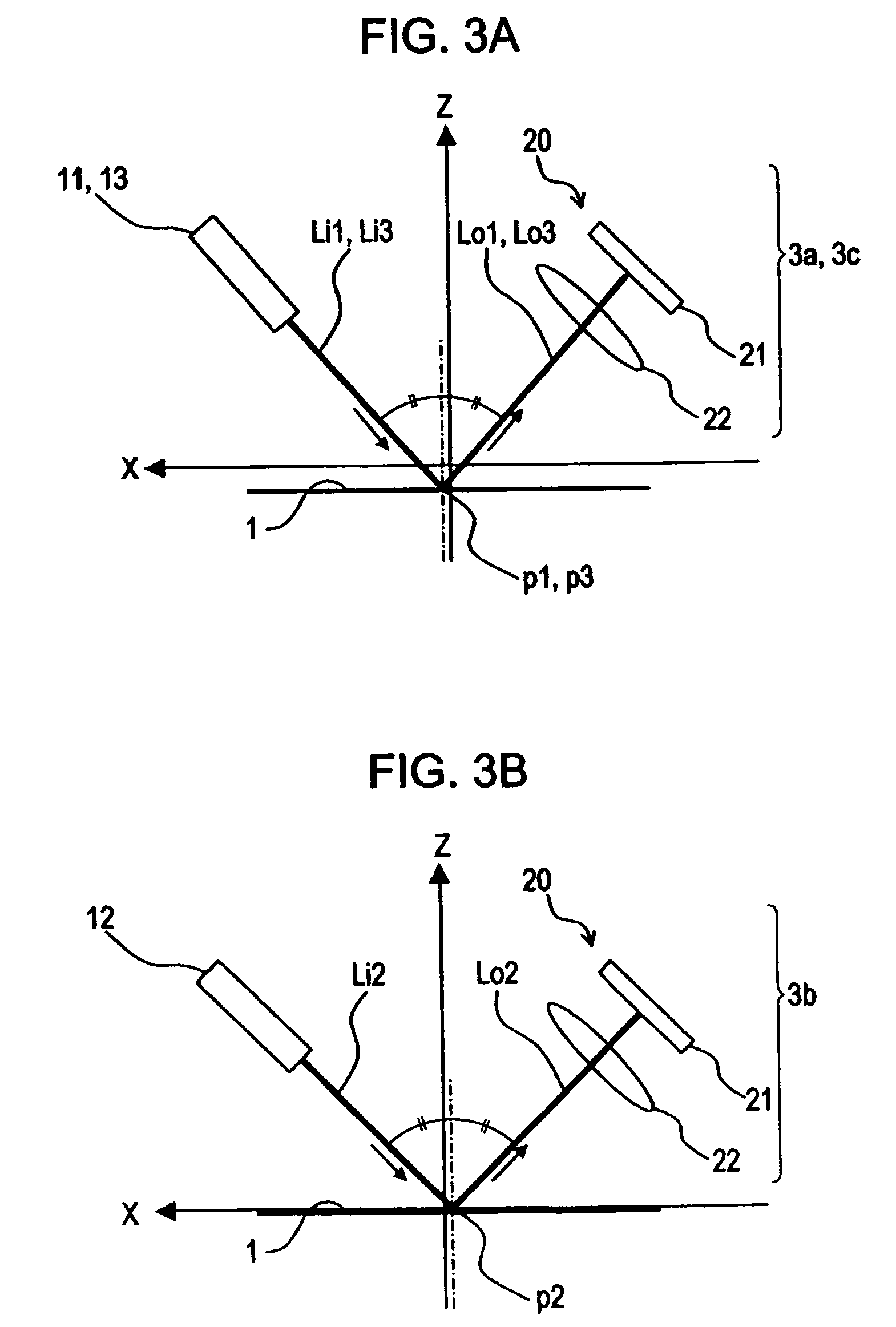

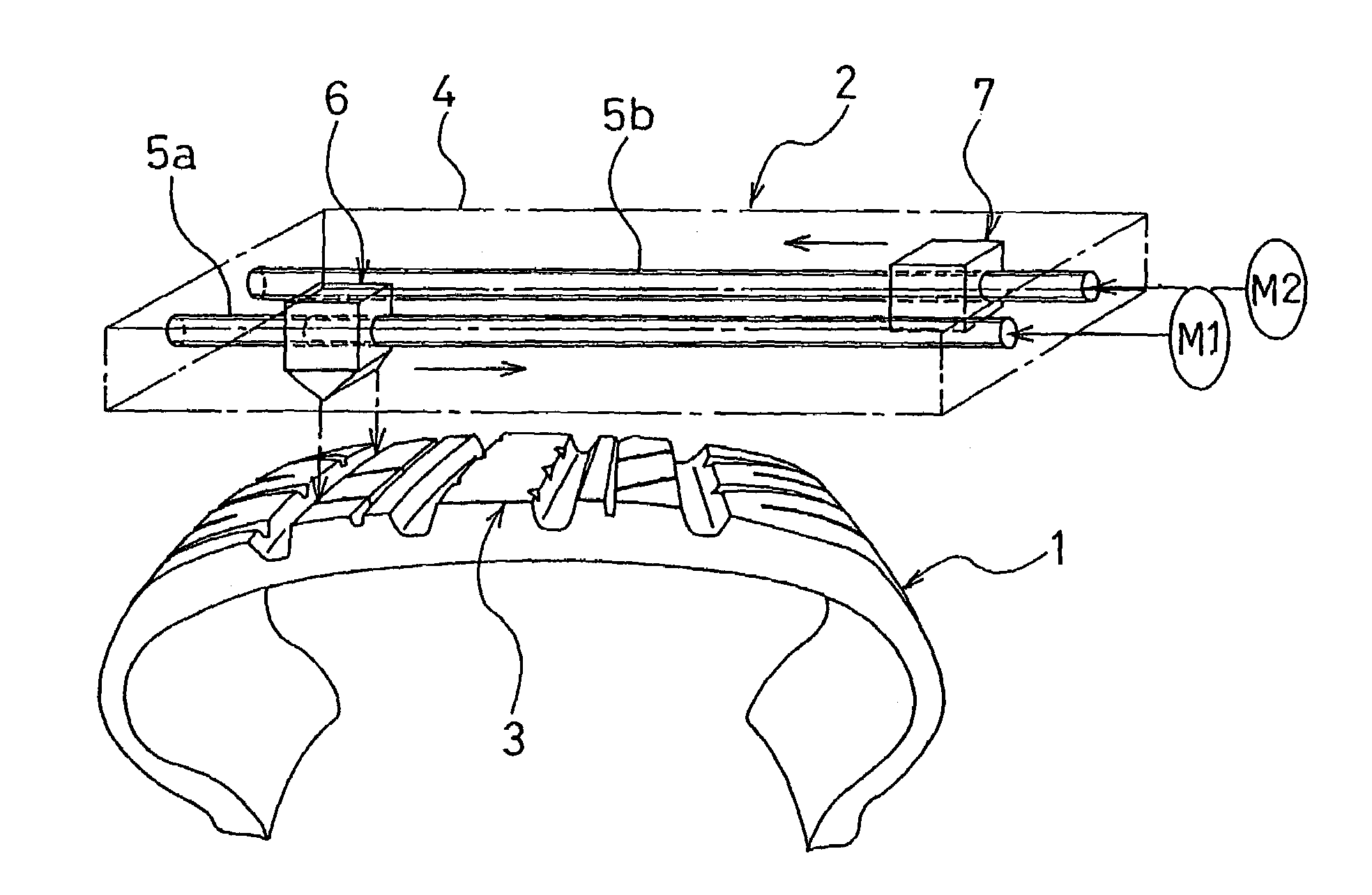

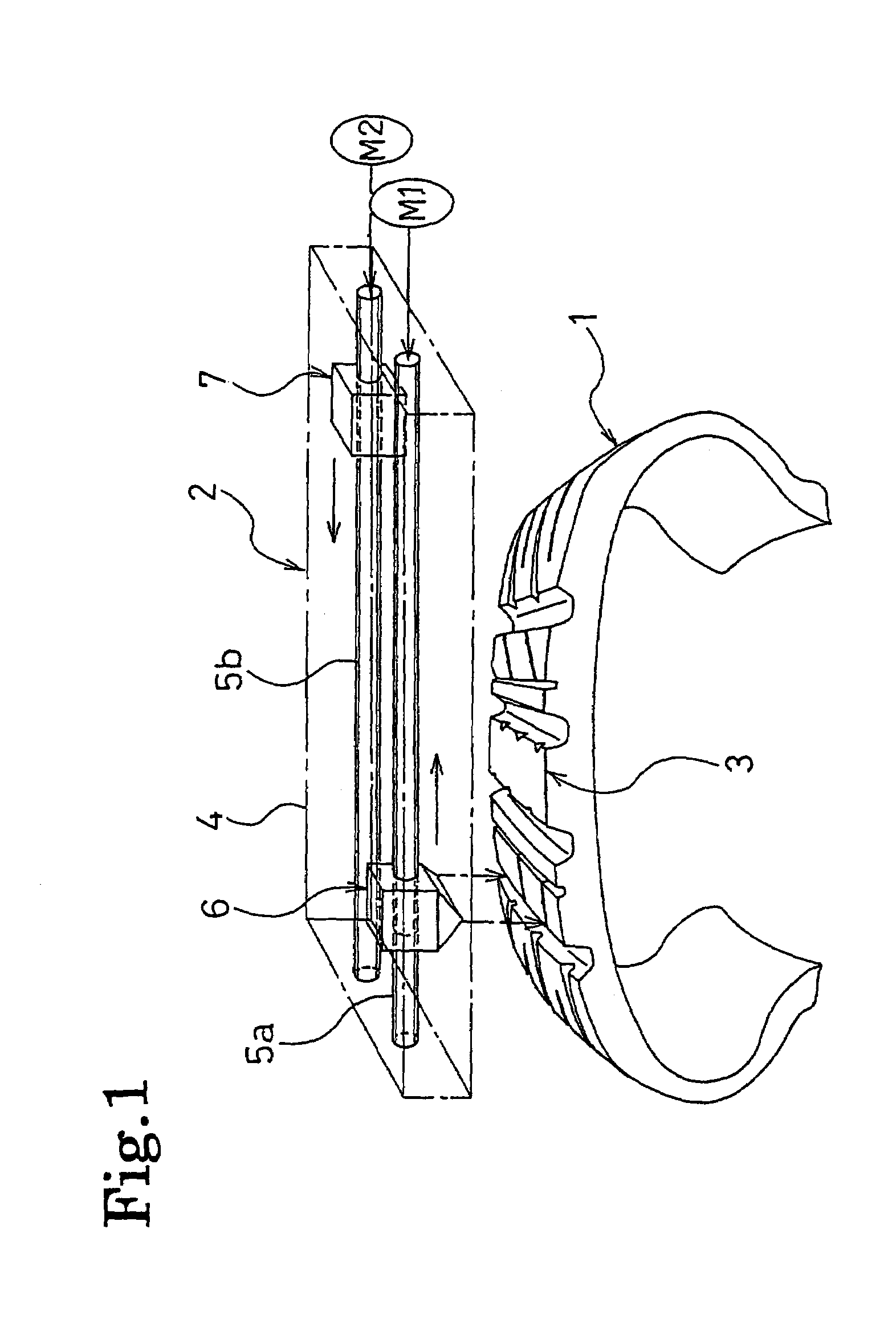

A tire shape measuring system measures a surface shape on the basis of an image of a line of light (a light section line) emitted to a surface of a relatively rotating tire using a light-section method. The shape measuring system includes a light projector for emitting a plurality of lines of light onto a tire surface in directions different from a direction in which the height of the surface is detected so as to form a plurality of separate light section lines and a camera for capturing images of the light section lines in directions in which chief rays of the lines of light are specularly reflected by the tire surface. The shape measuring system individually detects the coordinates of the light section lines from images of pre-defined independent image processing target areas for each captured image and calculates the distribution of the surface height using the detected coordinates.

Owner:KOBE STEEL LTD

Tire shape measuring system

A tire shape measuring system measures a surface shape on the basis of an image of a line of light (a light section line) emitted to a surface of a relatively rotating tire using a light-section method. The shape measuring system includes a light projector (10) for emitting a plurality of lines of light onto a tire surface in directions different from a direction in which the height of the surface is detected so as to form a plurality of separate light section lines and a camera (20) for capturing images of the light section lines in directions in which chief rays of the lines of light are specularly reflected by the tire surface. The shape measuring system individually detects the coordinates of the light section lines from images of pre-defined independent image processing target areas for each captured image and calculates the distribution of the surface height using the detected coordinates. Thereby, clear images of light section lines can be obtained at high image of the light section lines capturing speed without reinforcing the strength of lines of light, and calculating load of image processing needed by light section lines detection is reduced.

Owner:KOBE STEEL LTD

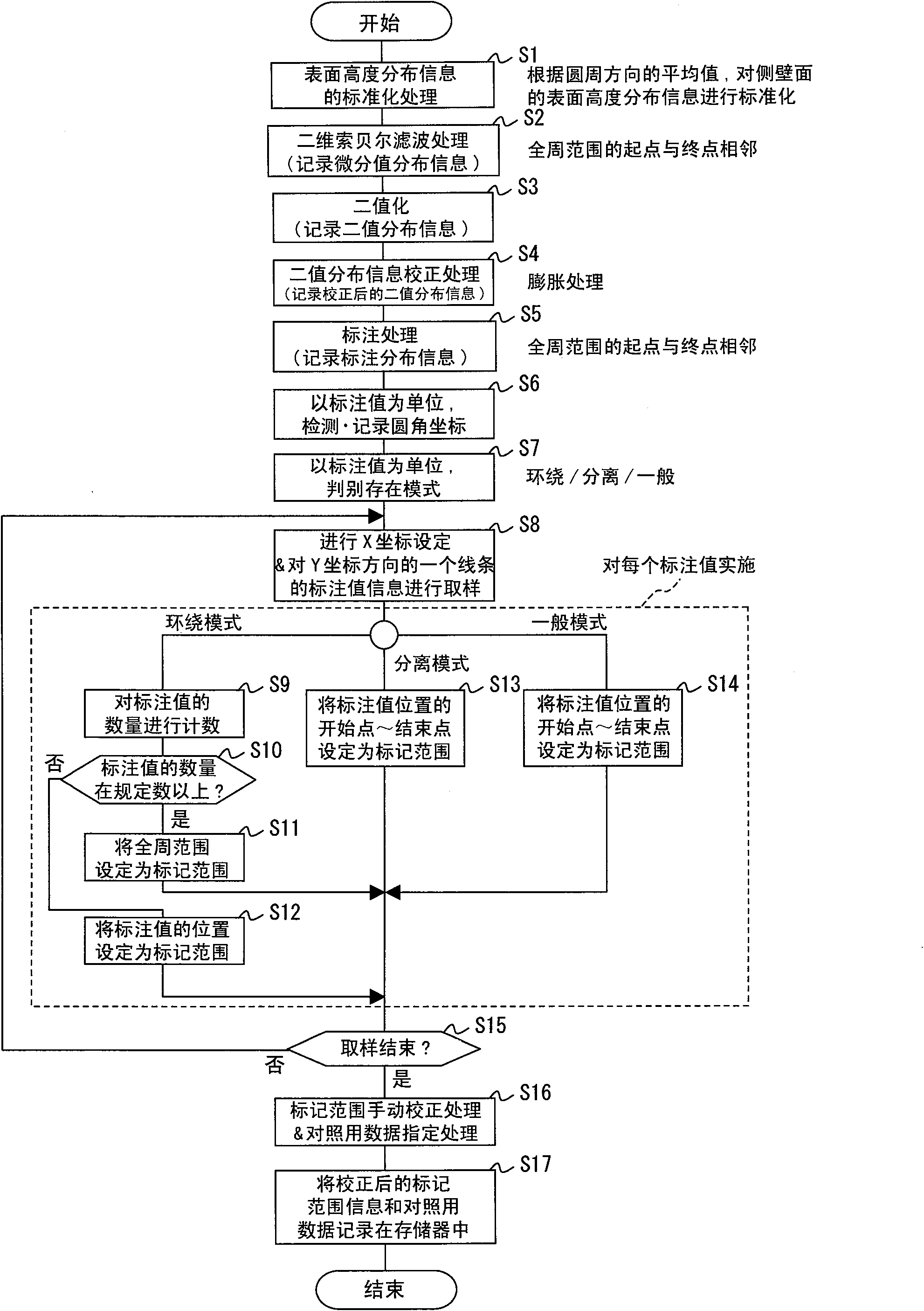

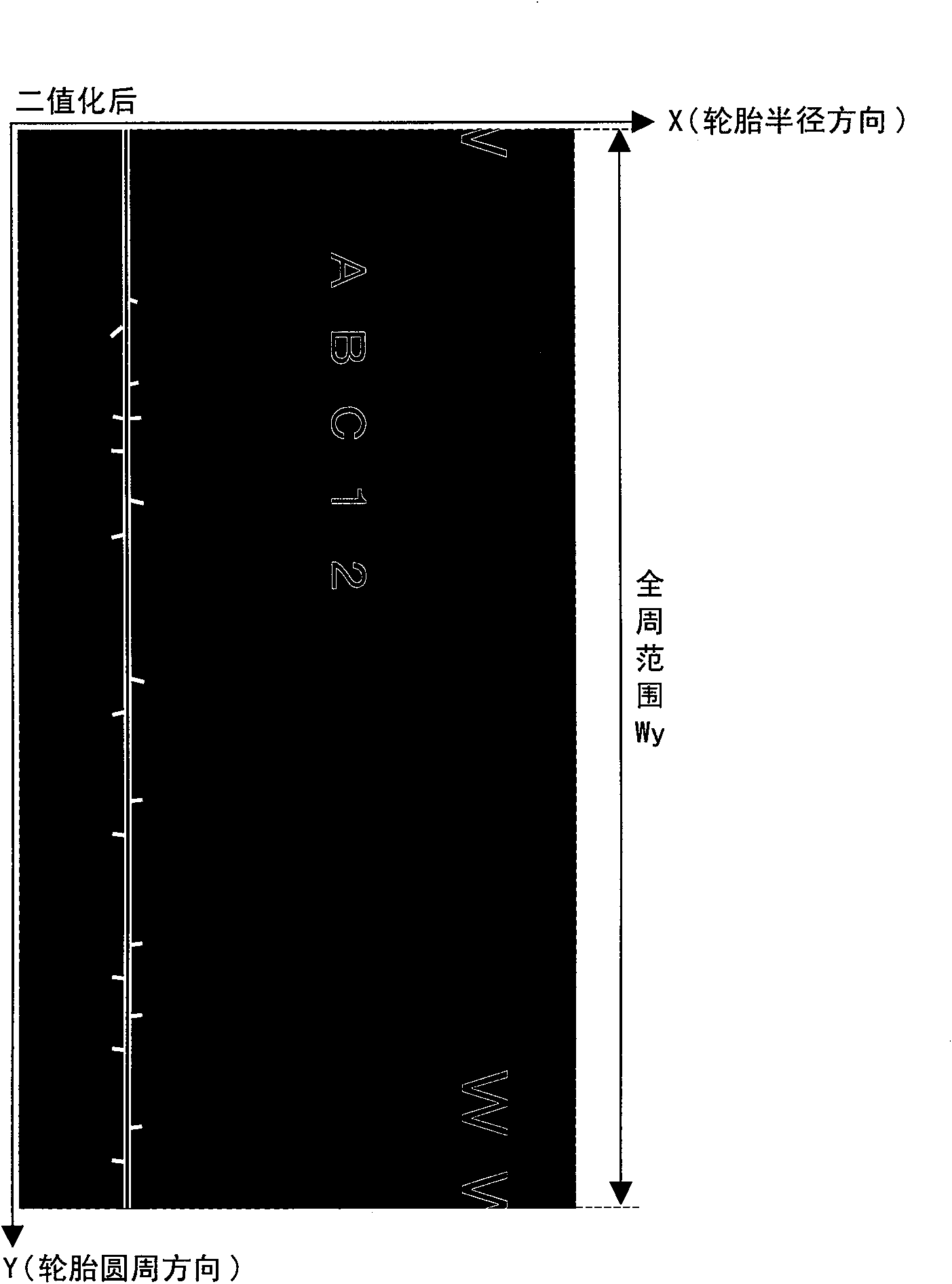

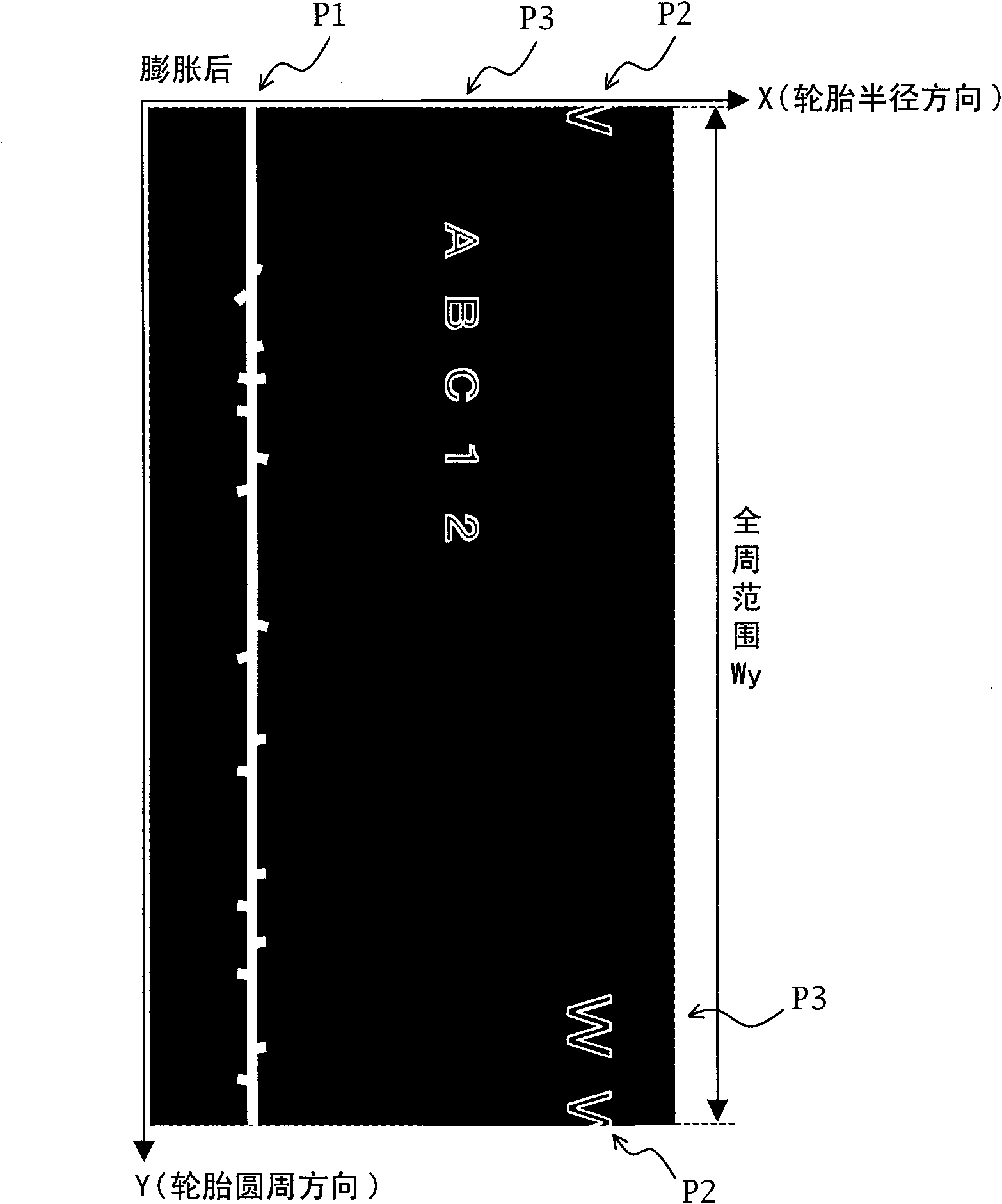

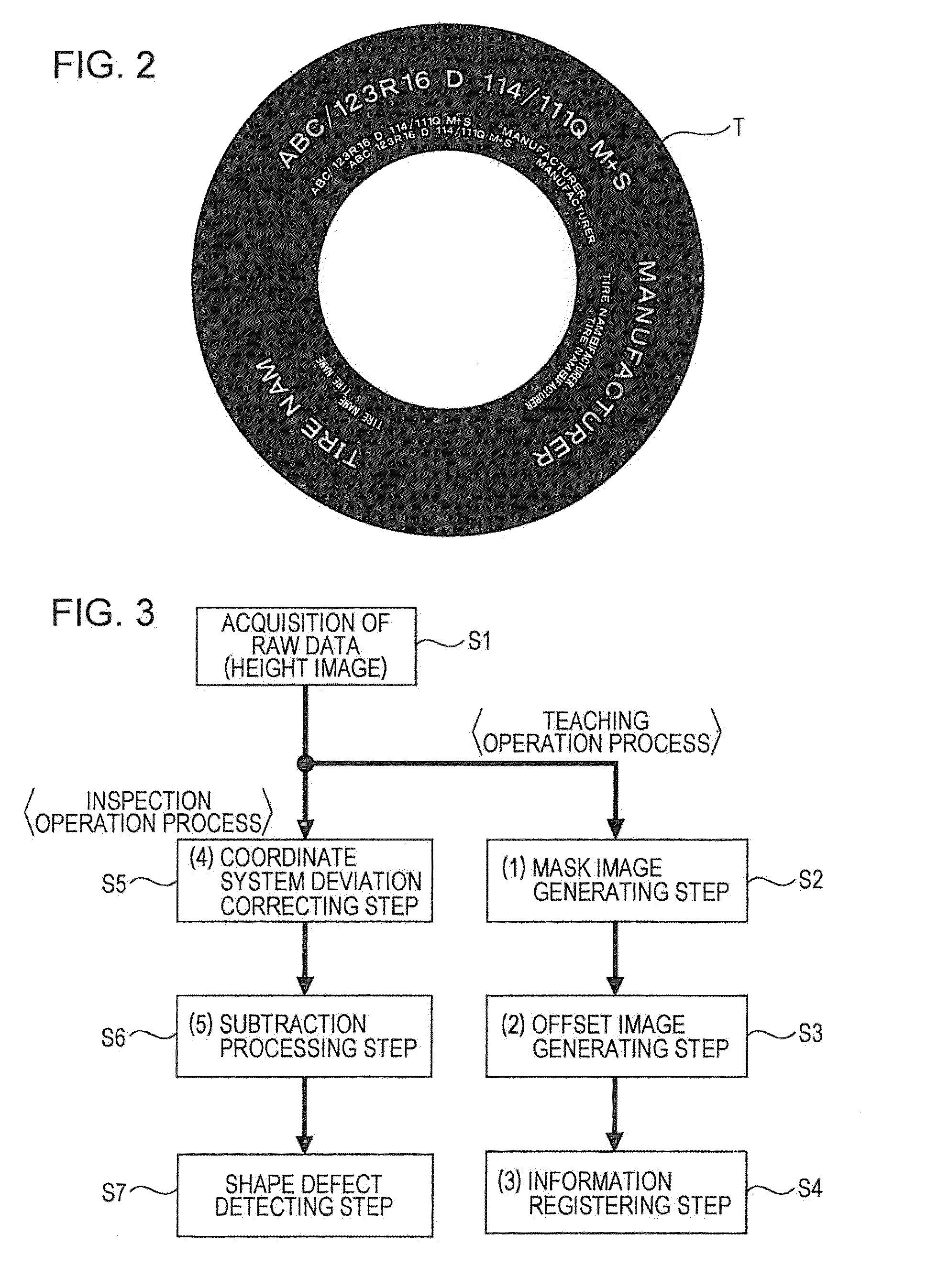

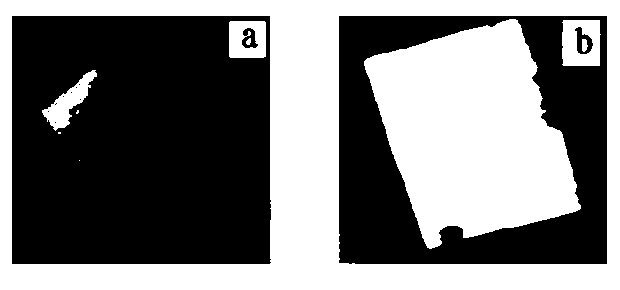

Tire shape inspection method and tire shape inspection device

ActiveCN102084213AIncrease computing loadShorten the timeImage enhancementTyre partsTire shapeEngineering

Disclosed is a tire shape inspection method that can reliably and without misidentification perform accurate shape defect inspection in a short period of time by excluding measurement values in a range in which embossed marks are formed from distribution information for surface height measurement values on the sidewall surface of a tire. In the method, a processor automatically detects the positions of the embossed marks based on sample surface shape information obtained from a sample of the tire, and automatically sets coordinate information for a mask range surrounding the area where said marks are present (S2-S15). The processor also causes a surface shape image based on the sample surface shape information and a mask range image based on the coordinate information for the mask range to be displayed superimposed on a display means, and changes the coordinate information for the mask range according to an operating input (S16). The processor also corrects deviation in the coordinatesystem between the surface height distribution information obtained from the tire undergoing inspection and the coordinate information for the mask range after changing, and excludes measurement values in the mask range from shape defect inspection processing.

Owner:KOBE STEEL LTD

Inner Liner of Pneumatic Tire

InactiveUS20080047646A1Avoid stickingEasy to packWithout separate inflatable insertsWith separate inflatable insertsElastomerRoom temperature

The present invention provides an inner liner of pneumatic tires that is formed from a non-drawn film of a polymer composition including 60 to 90 wt. % of a thermoplastic resin and 10 to 40 wt. % of an elastomer to have an oxygen permeation rate of less than 15×10−3 ccm / m2 24 hratm, and a fracture elongation of more than 200% at the room temperature. The tire thus manufacture has no fracture under a severe deformation during the tire shaping process, facilitating the tire manufacture, and exhibits an air permeation preventive property as an excellent air permeation preventive layer.

Owner:KOLON IND INC

Apparatus and method for detecting tire shape

A tire shape detecting apparatus includes a projector that applies a plurality line light beams in a continuously joined manner, from a direction different from the detection height direction (Z-axis direction) in one light section line, or that applies one line light beam in a condensed manner in the line length direction thereof in order that the one light section line may be formed on the one line Ls on the surface of the tire; and a camera for picking up images of the plurality of line light beams applied to the tire surface in the direction in which the principal ray of each of the plurality of line light beams performs specular reflection with respect to the tire surface, or in the direction in which the principal ray of the condensed one line light beam performs specular reflection with respect to the tire surface.

Owner:KOBE STEEL LTD

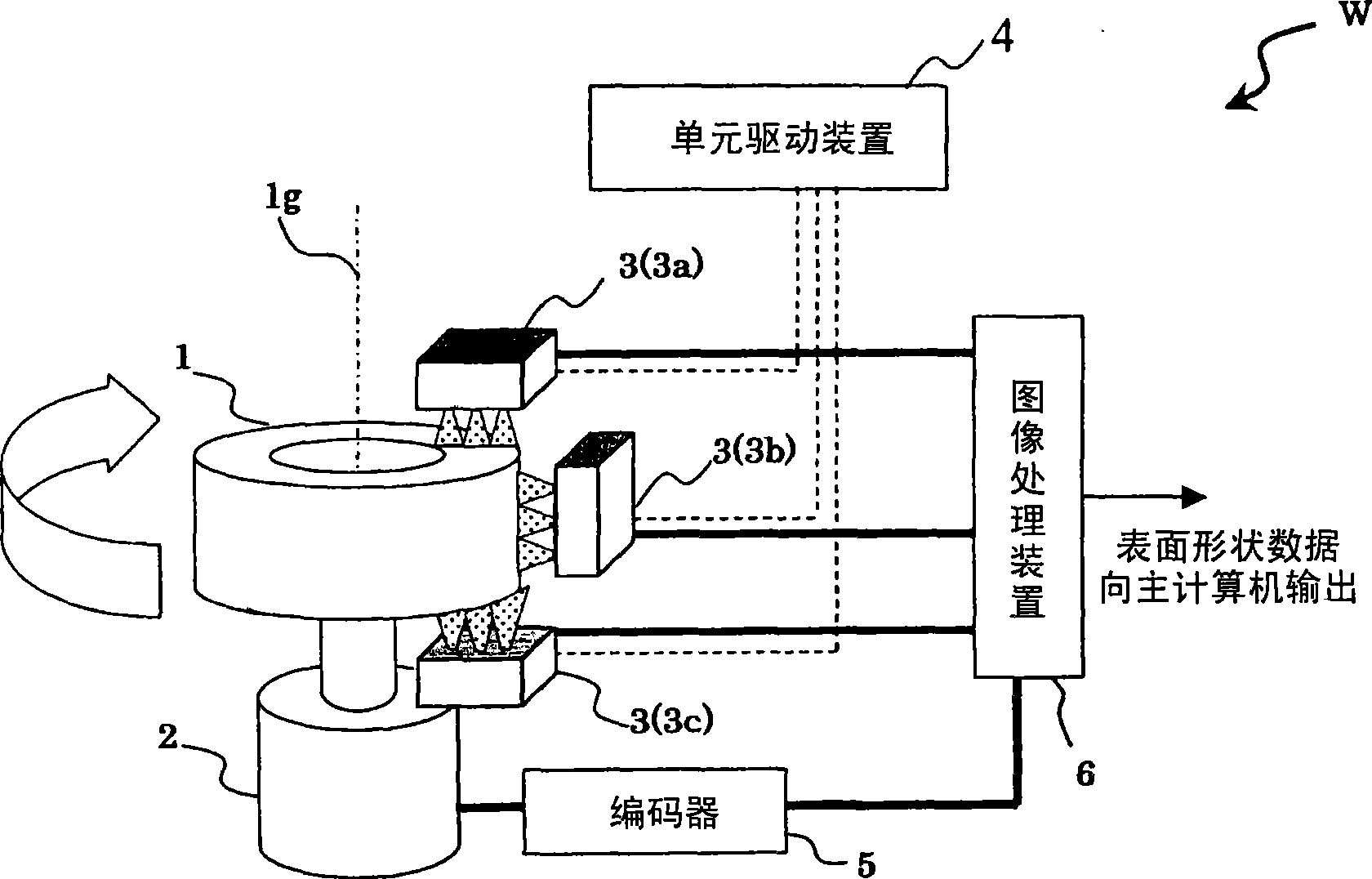

Tyre shape detecting device and tyre shape detecting method

The invention discloses a tyre shape detecting device, which can acquire a clear picture of linear light irradiated on the surface of a tyre by picking up the picture of the linear light with quite high pickup speed under the condition of not enhancing the intensity of the linear light during shape detection of a light-section method based on an image of the picture of the linear light irradiated on the surface of the tyre. The device is provided with a light projection device (10) and a camera (20), wherein in order to form light-section lines on a single beam line Ls on the surface of the tyre (1), the light projection device (10) connects a plurality of linear light rays into a row for irradiation in the direction different from the detection height direction (Z-axis direction) of the light-section lines, or condenses the light in the length direction of the linear light to irradiate one linear light ray; and the camera (20) picks up the image of the linear light connected into one row in a single beam line shape to be irradiated to the surface of the tyre (1) in the normal reflection direction of respective main rays of a plurality of sheet light rays relative to the surface of the tyre (1) or in the normal reflection direction of a main ray of one condensed linear light ray relative to the surface of the tyre (1).

Owner:KOBE STEEL LTD

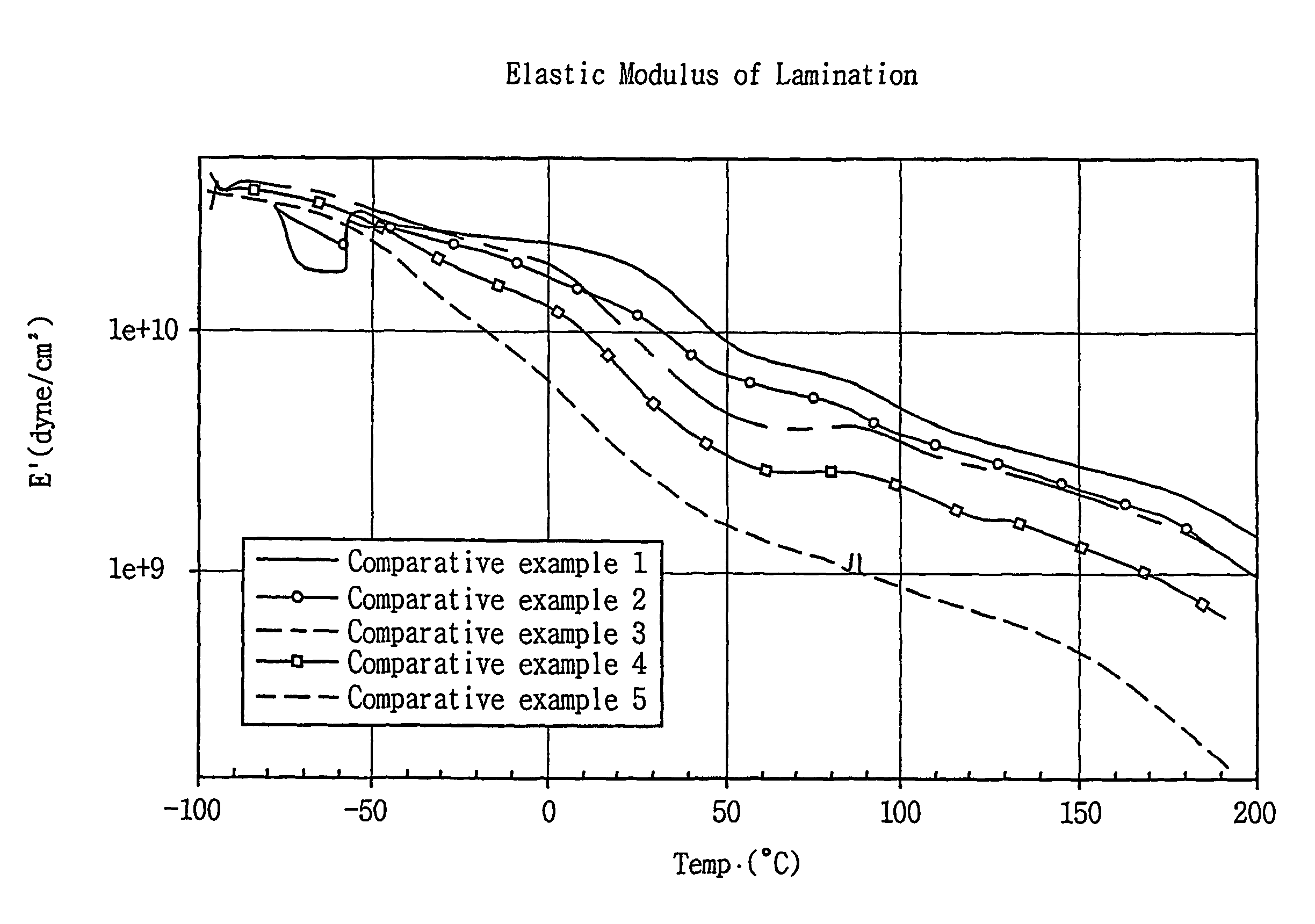

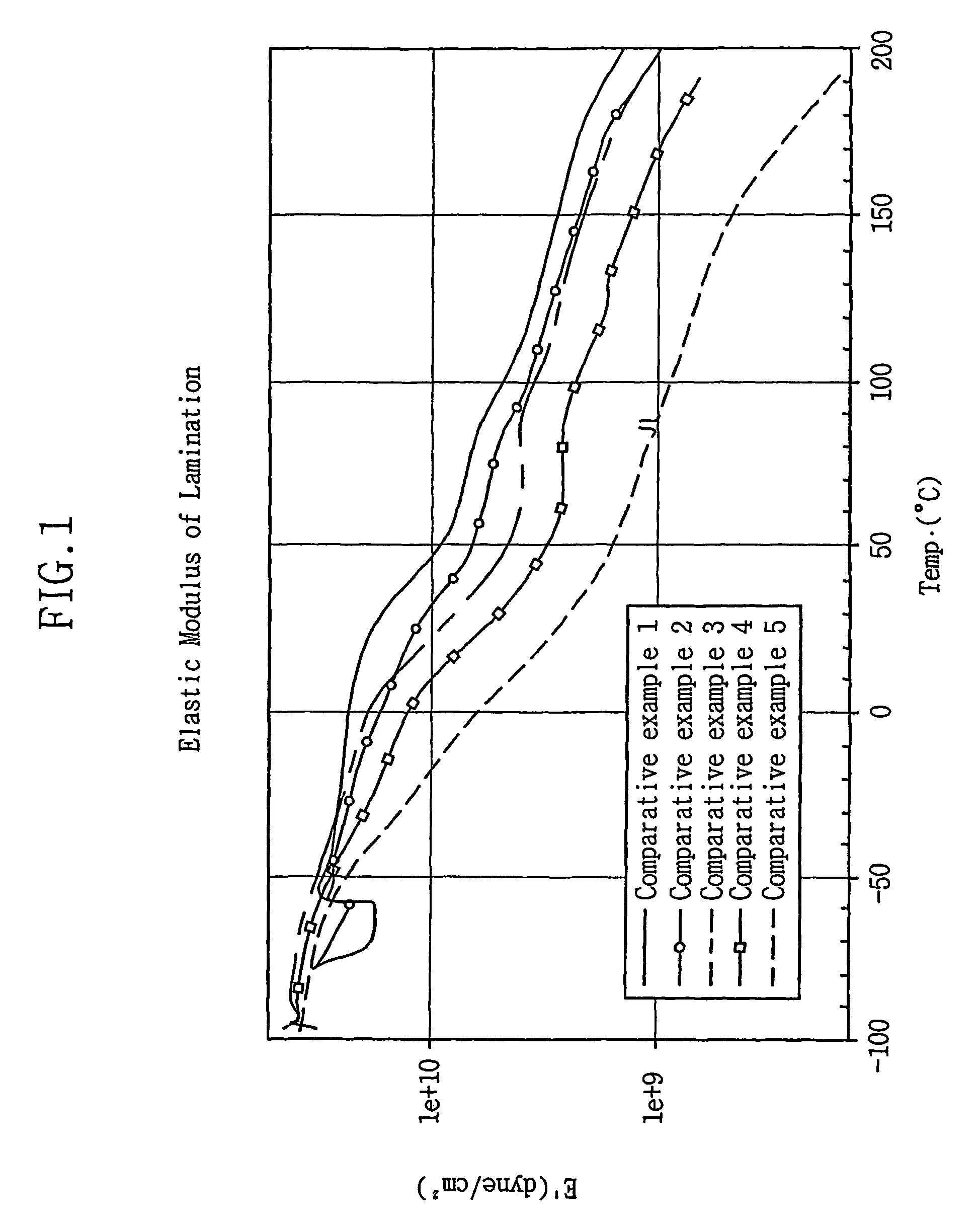

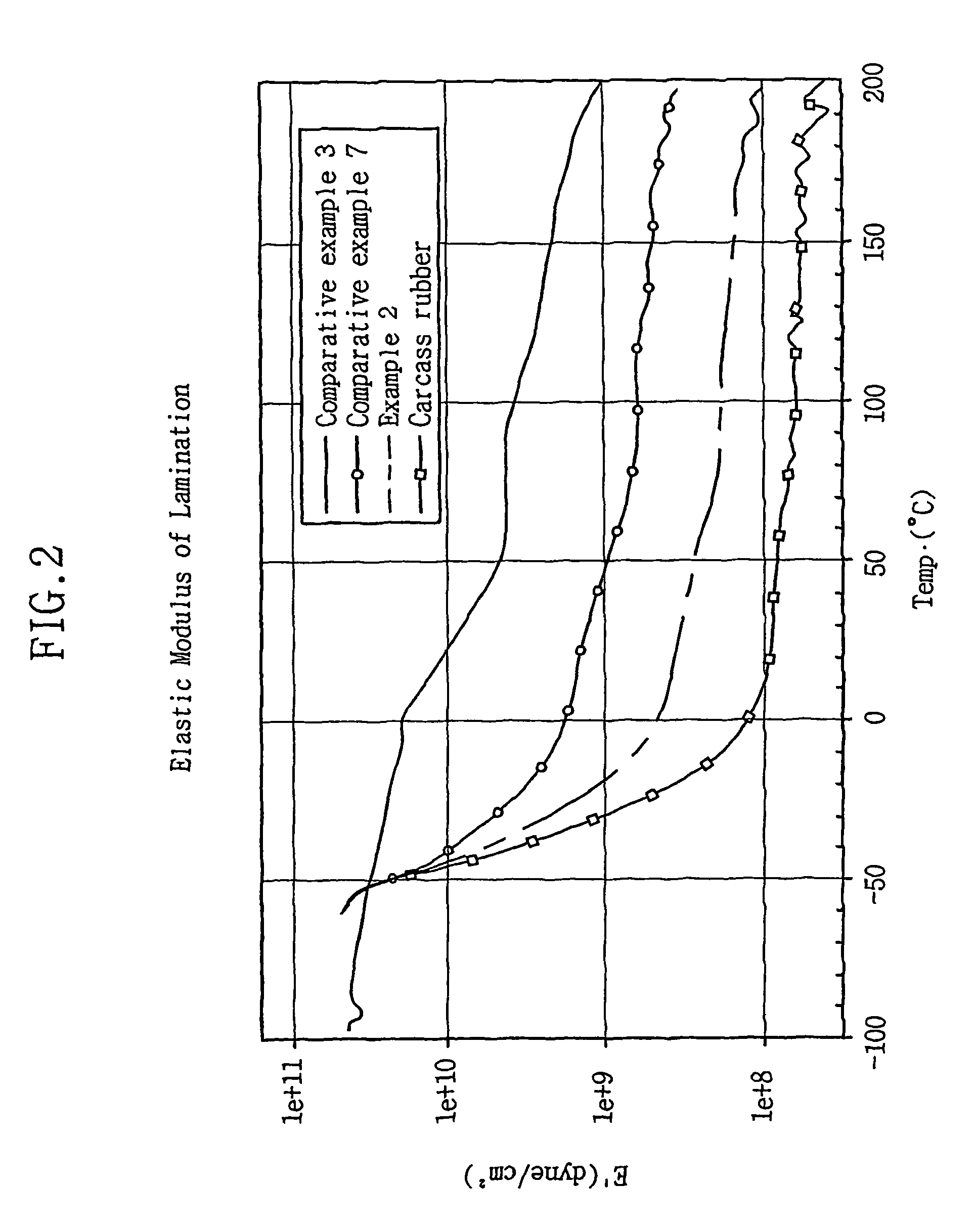

Multi-Layered Air Permeation Preventing Layer of pneumatic Tires

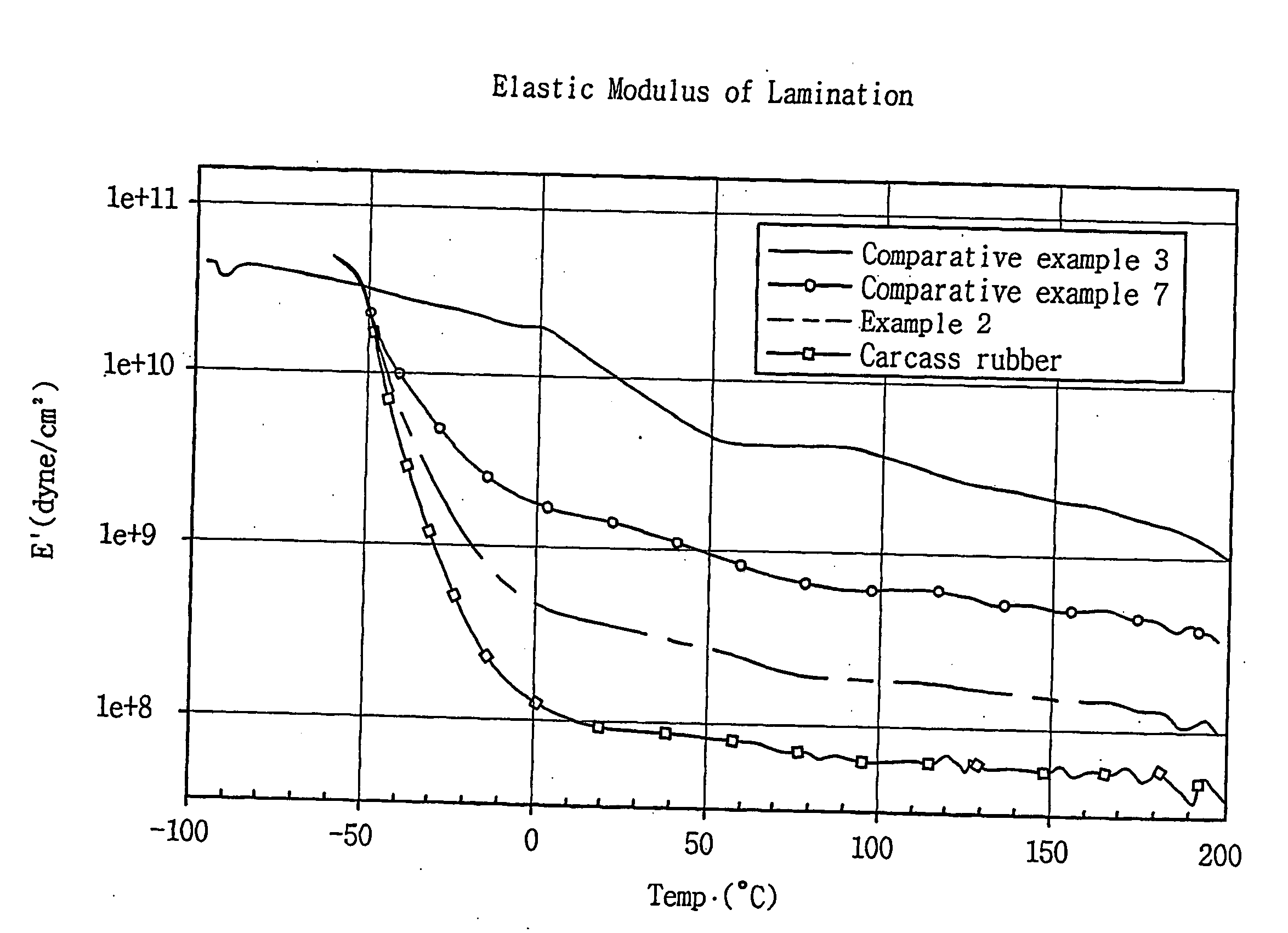

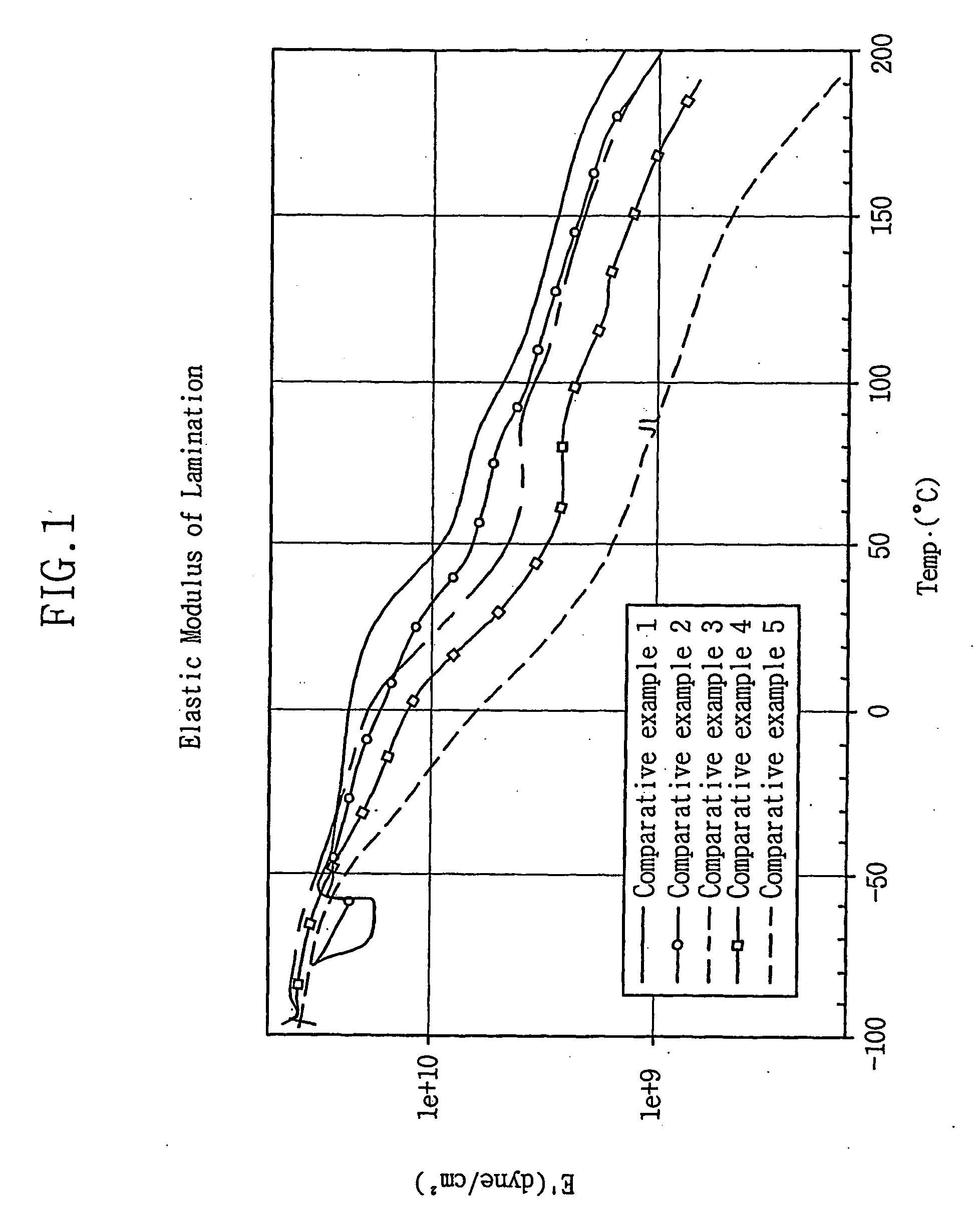

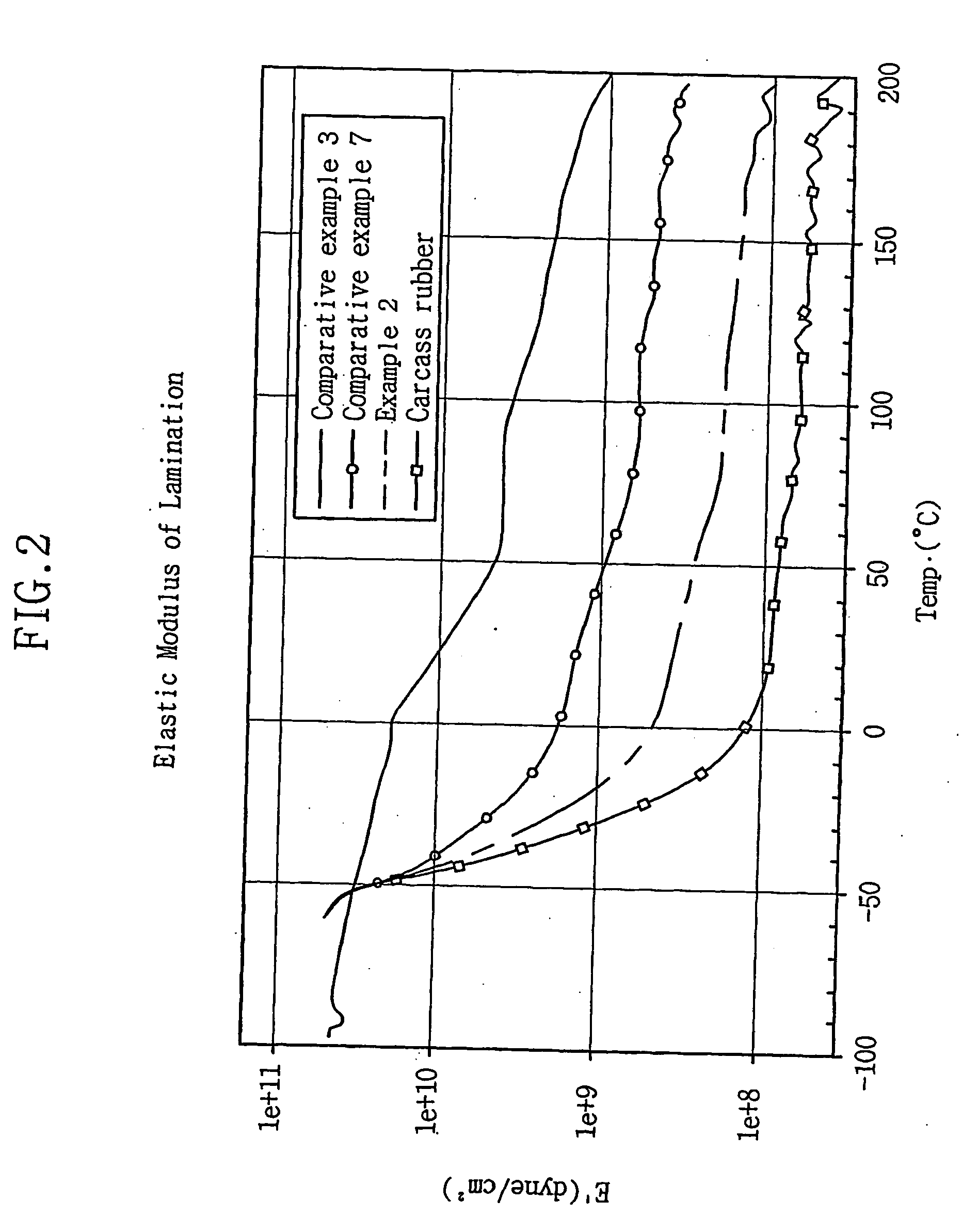

ActiveUS20090038727A1High deformationHinder propertyWithout separate inflatable insertsWith separate inflatable insertsElastomerTire shape

The present invention provides a multi layered air permeation preventive layer of pneumatic tires having −50 to −10i É of the steep decreasing range of the elastic modulus includes inner liner layer of a non-drawn film formed from a polymer composition including 60 to 90 wt. % of a thermoplastic resin and 10 to 40 wt. % of an elastomer, and carcass layer coated on the inside and outside of the inner liner layer, the tire thus manufacture has no fracture under a severe deformation during the tire shaping process, facilitating the tire manufacture, and exhibits an air permeation preventive property as an excellent air permeation preventive layer.

Owner:KOLON IND INC

Tire shape inspection method and tire shape inspection apparatus

A tire shape inspection method executes the following steps: first, as a teaching operation step, boundary lines of the bulge and dent marks are detected in a sample source image of a sample tire, a mask image is generated which denotes the boundary lines, regions are removed from the sample source image which correspond to the boundary lines which are denoted in the mask image, and a height offset image is generated which represents the heights of the remaining regions with one or more offset values. Next, as an inspection operation step, the height offset image is subtracted from an inspection image of the inspection tire, the boundary regions which the mask image represents are removed, and, on the basis of the obtained bulge / dent removal image, shape defects of the sidewall surfaces of the inspection tire are inspected.

Owner:KOBE STEEL LTD

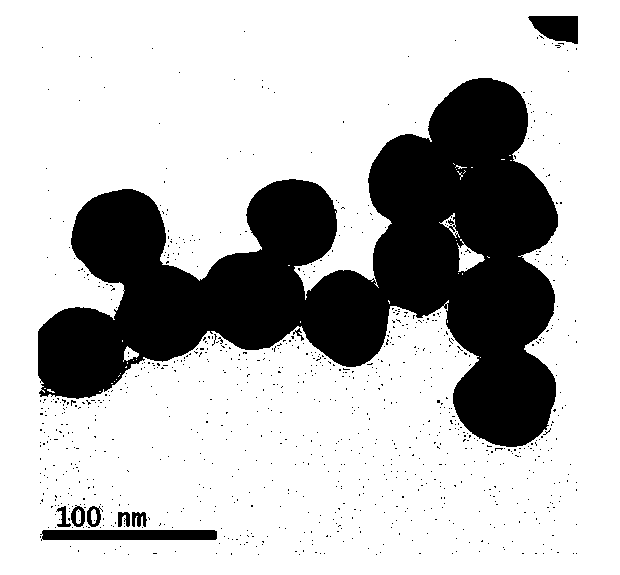

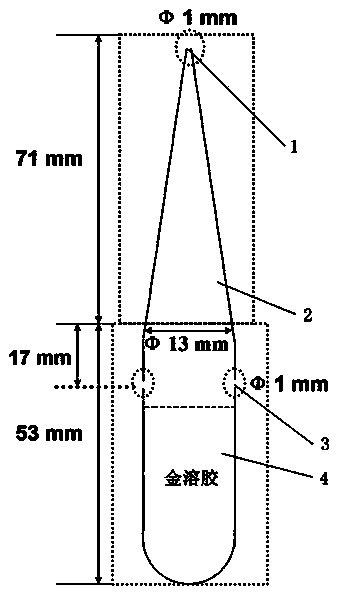

Gold nanoparticle monofilm preparation method and device thereof

InactiveCN103590037AMake sure to formControl densityVacuum evaporation coatingSputtering coatingNanoparticleTire shape

The invention discloses a gold nanoparticle monofilm preparation method and a device thereof. The gold nanoparticle monofilm preparation method comprises the steps of preparation of gold sol, formation, transfer and optimization of monofilm, and so on. A desired gold nanoparticle monofilm can be prepared by controlling monodispersity of the gold sol and solvent volatilization, and designing transfer of an interface monofilm. A special chimney device is designed in the solvent volatilization step, and comprises an upper part and a lower part communicated with each other, wherein the lower part is a columnar container chamber; the upper part is a tire-shaped exhaust pipe with an air hole on the top, and can effectively control volatilization of the gold nanosol. The method provided by the invention can prepare a large-area gold nanoparticle monofilm assembly structure at normal temperature and under normal pressure without adding any other extra agents; the monofilm is excellent in uniformity and high in SERS (surface enhanced raman scattering) activity, and can serve as an ideal SERS substrate and membrane electrode. The preparation method has the advantages of easy process, mild conditions, and no need for particular large-scale apparatus and equipment, and can be conducted in a laboratory.

Owner:SUZHOU UNIV

Method of and apparatus for determining tire shapes

InactiveUS20050057758A1Reduce weightHigh measurement accuracyTyre partsUsing optical meansAccuracy improvementTire shape

A method of and an apparatus for determining tire shapes are provided which enable both an apparatus weight reduction and a determination accuracy improvement. The apparatus of the present invention includes: a portable base member; a non-contact displacement gage held on the base member so as to be freely movable along a predetermined scanning direction; a weight supported on the base member so as to be movable along the scanning direction; and means for symmetrically driving the displacement gage and weight while synchronizing them with each other. Using this apparatus, the method includes: setting the base member in proximity to a tire tread portion so that the displacement gage will scan the tread portion; allowing the displacement gage and weight to symmetrically move along the scanning direction while synchronizing them with each other; and determining the shape of the tread portion, based on an output from the displacement gage.

Owner:THE YOKOHAMA RUBBER CO LTD

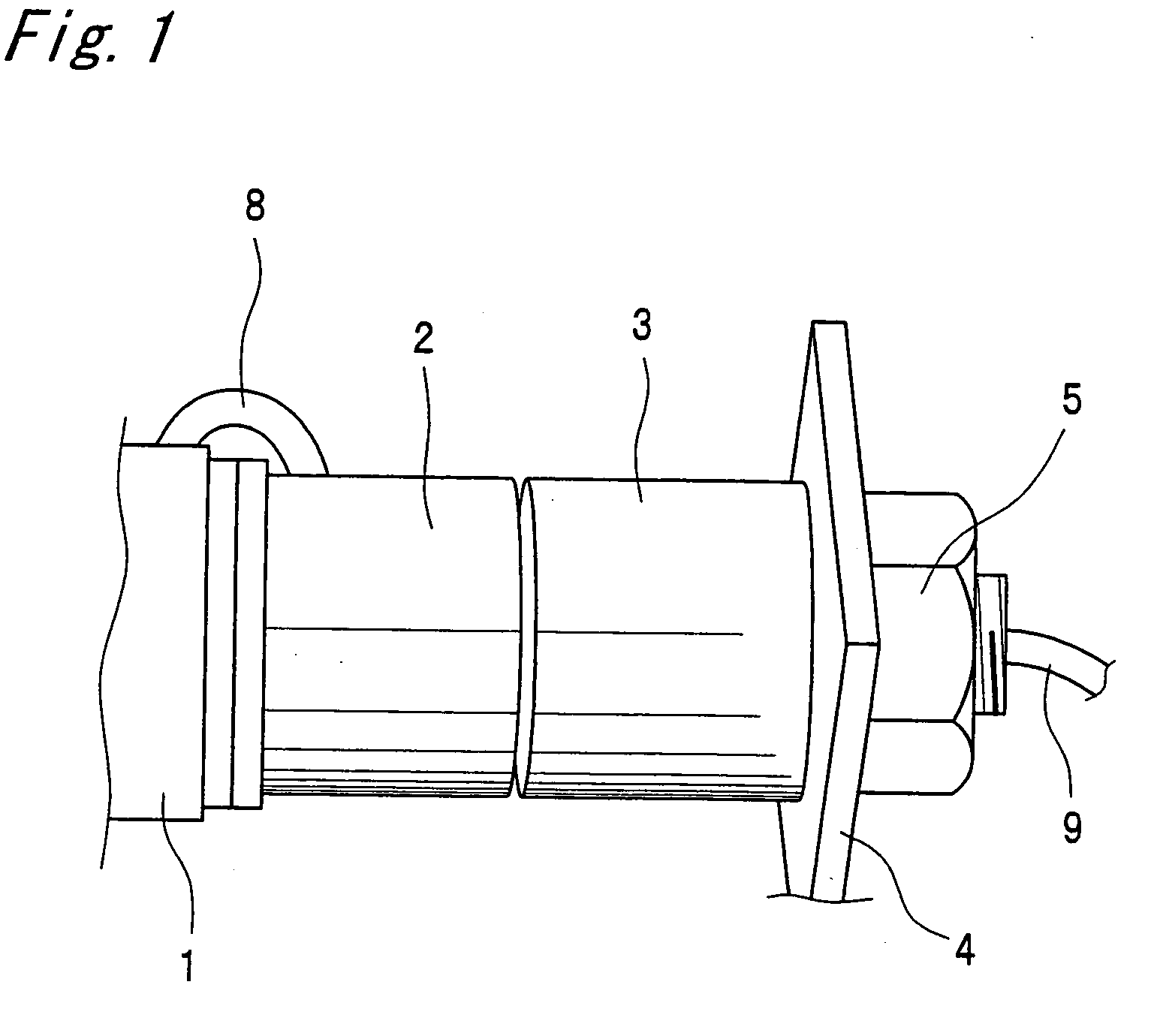

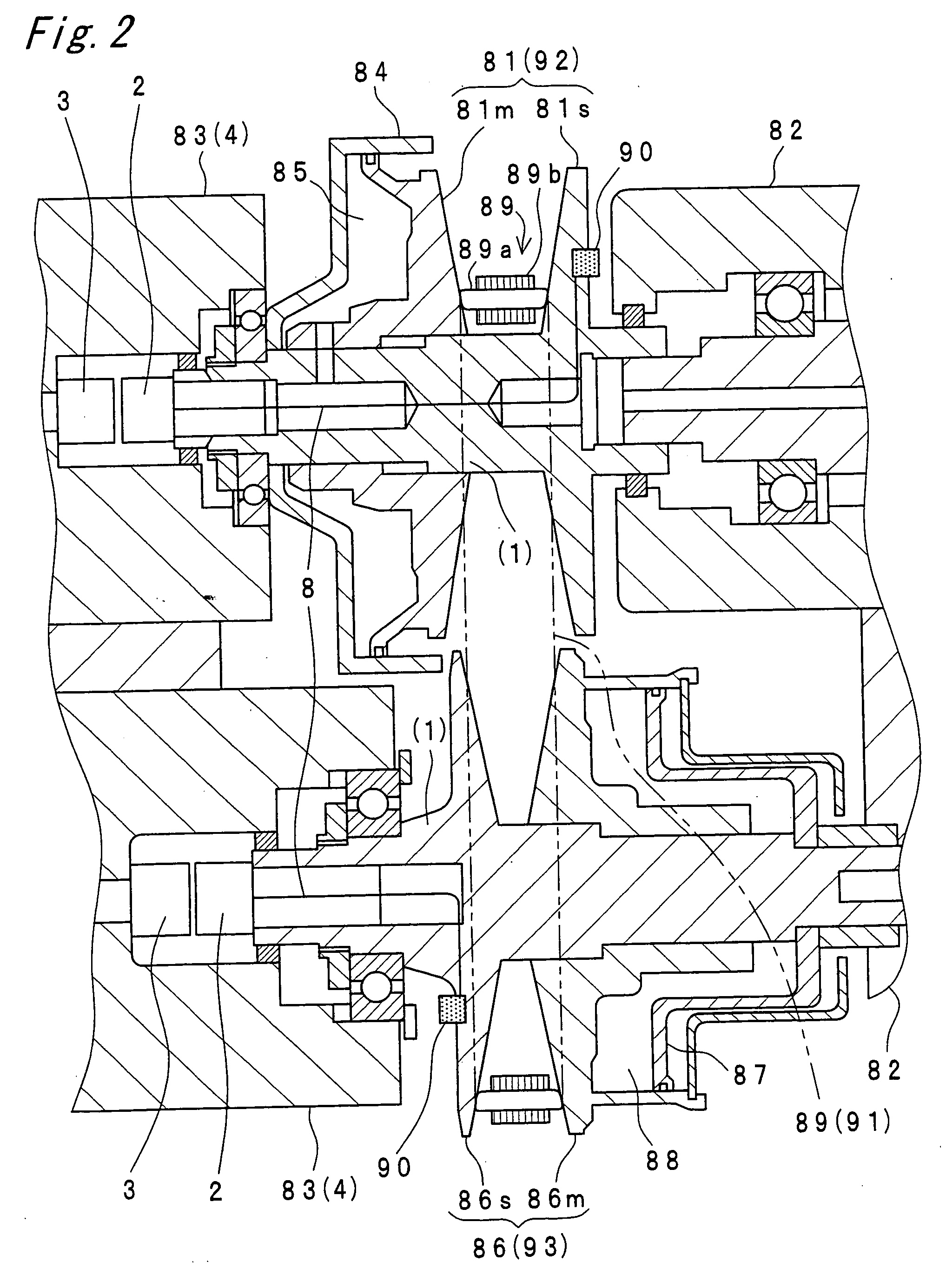

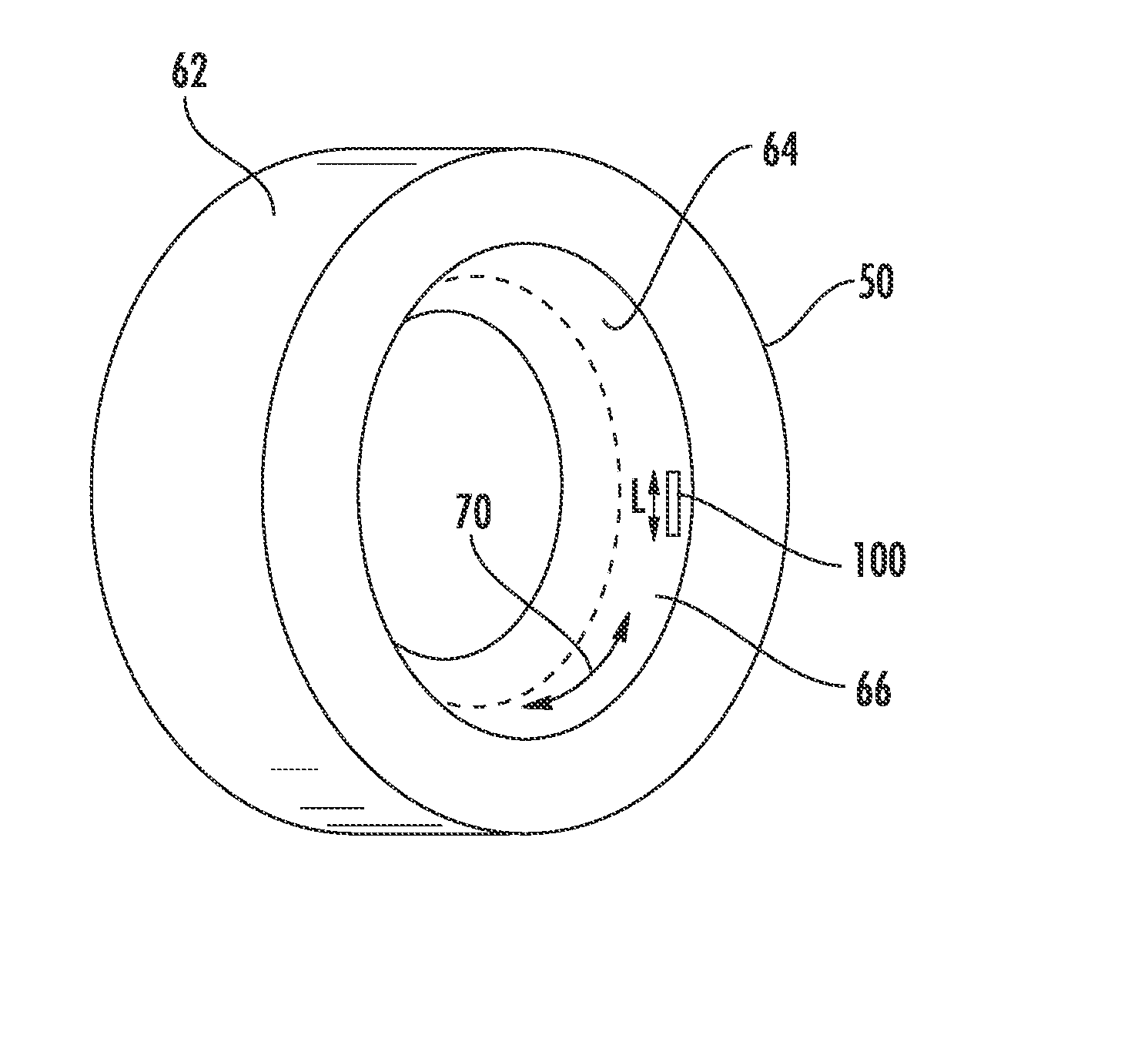

Acoustic emission measuring device, power transmission device, and rolling bearing device

InactiveCN101151528AHigh sensitivity detectionAccurate detectionRolling contact bearingsMaterial analysis using acoustic emission techniquesElectricityBall bearing

An acoustic emission measuring device in which a piezoelectric element (63) used as an AE sensor is secured to the inner ring (62) of a ball bearing (61) fixedly fitted onto a rotating shaft (60). The axial end face of a roughly tire-shaped case (65), which is capable of rotating in synchronism with the inner ring (62) and storing a firs coil in which a current flows from the piezoelectric element (63), is secured to the inner ring (62). The axial end face of a roughly tire-shaped case (66) for storing a second coil is secured to an outer ring (64). The first coil and the second coil are oppositely disposed on the radial outer side of the rotating shaft (60) so that the first coil and the second coil can face to each other in the radial direction.

Owner:JTEKT CORP +1

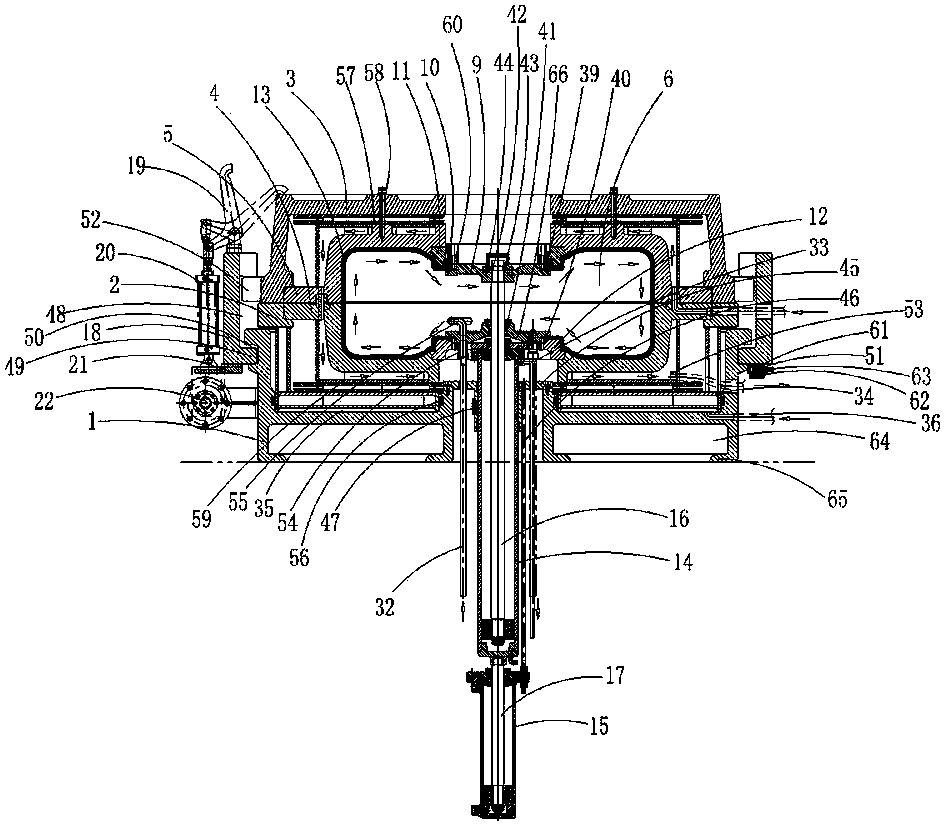

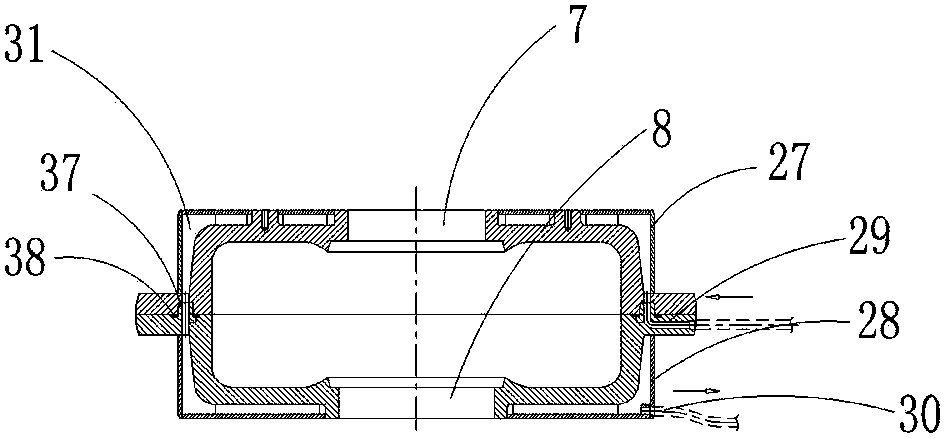

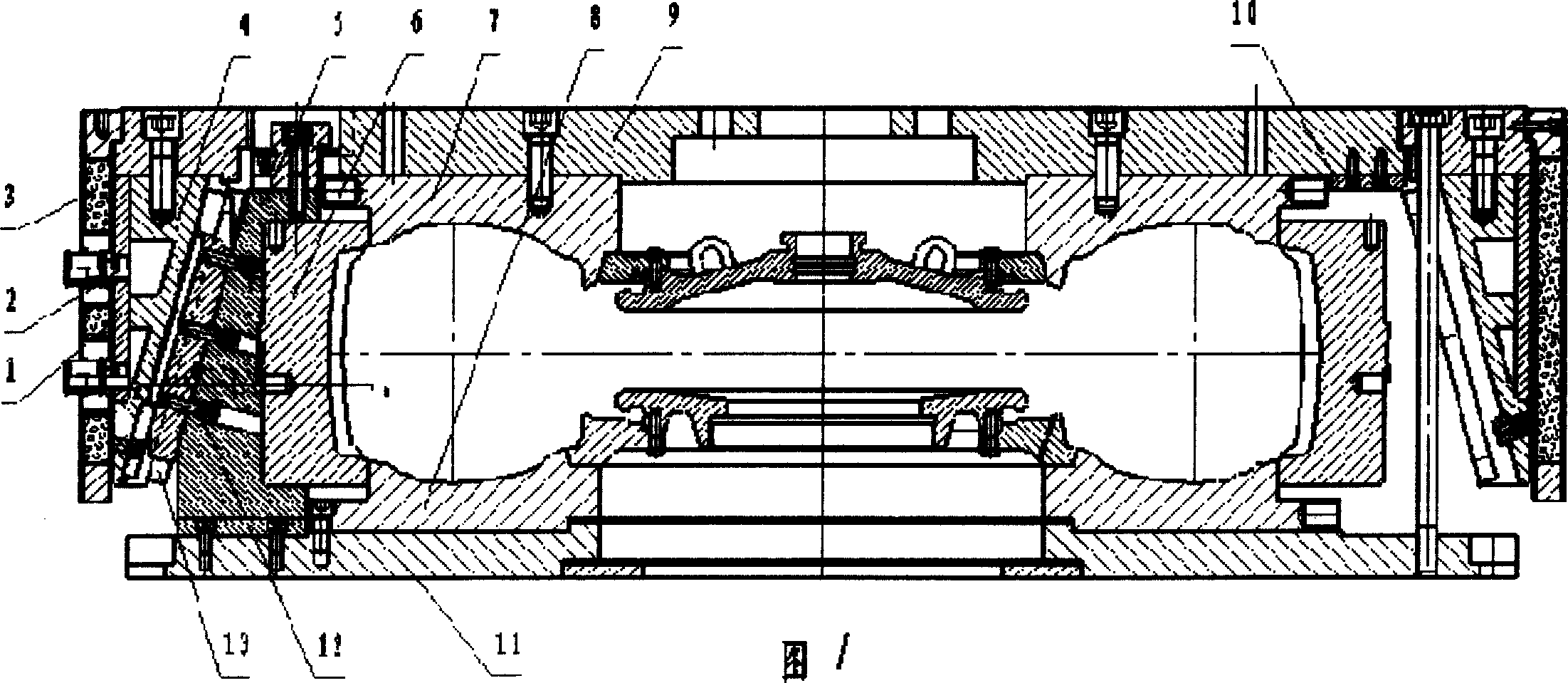

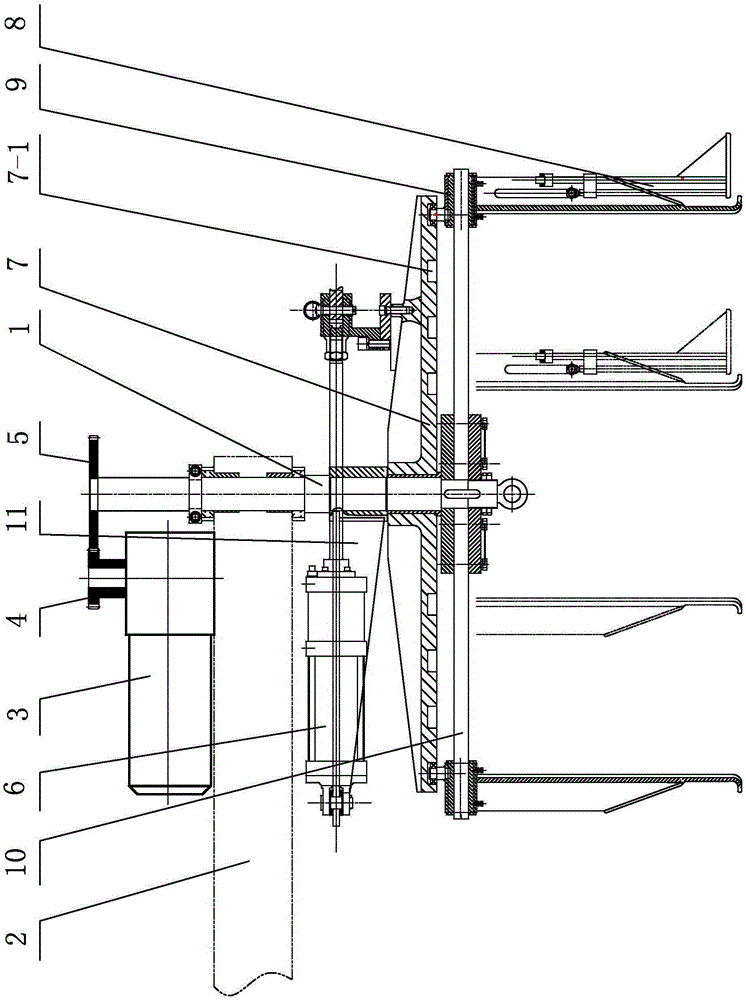

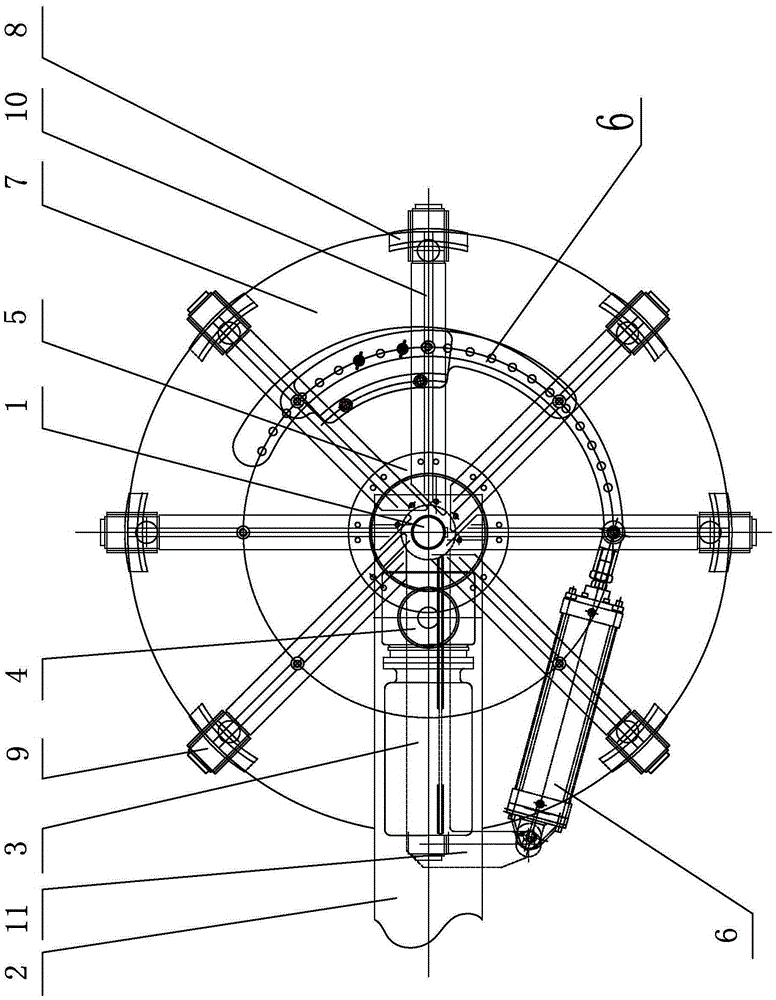

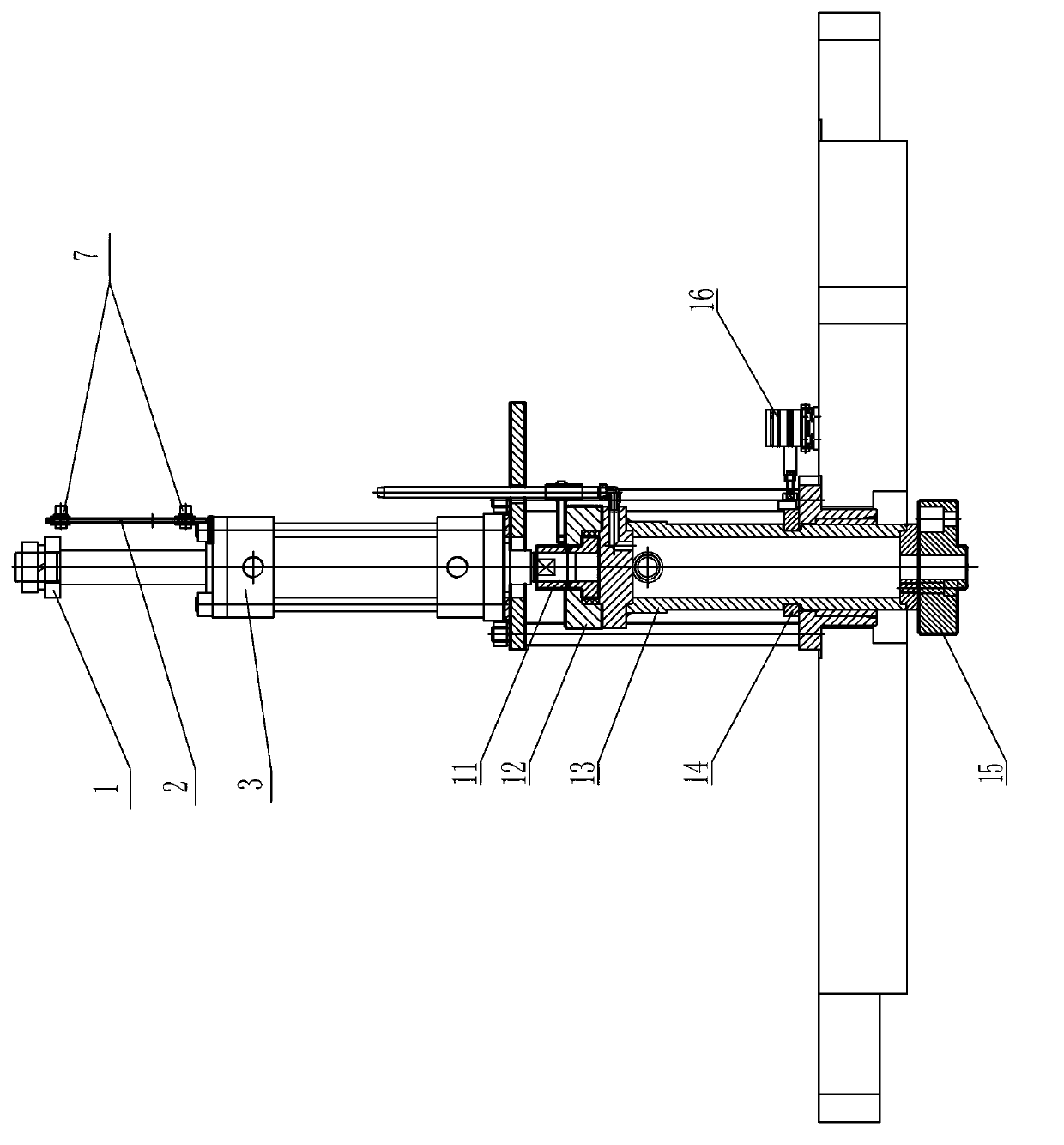

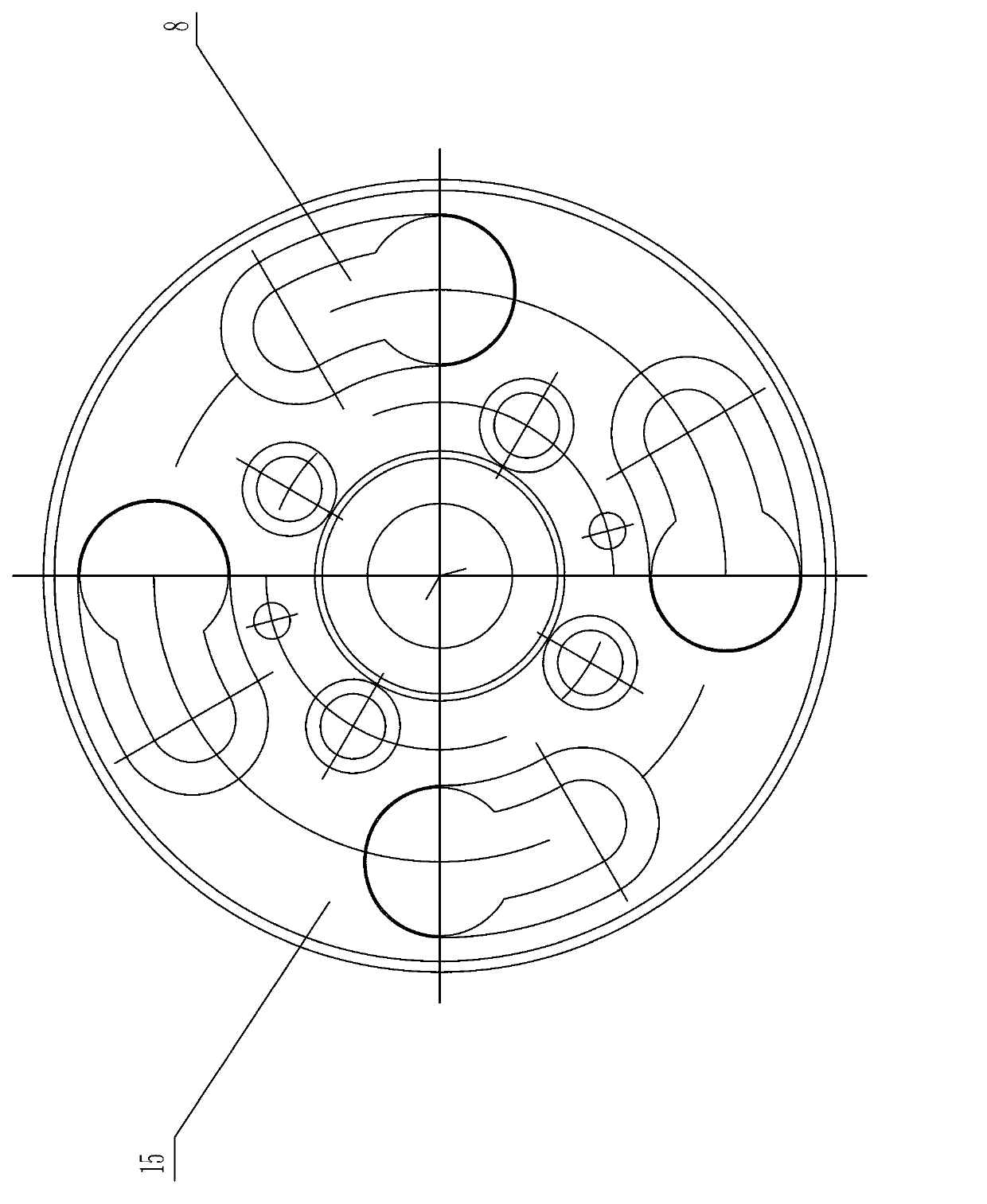

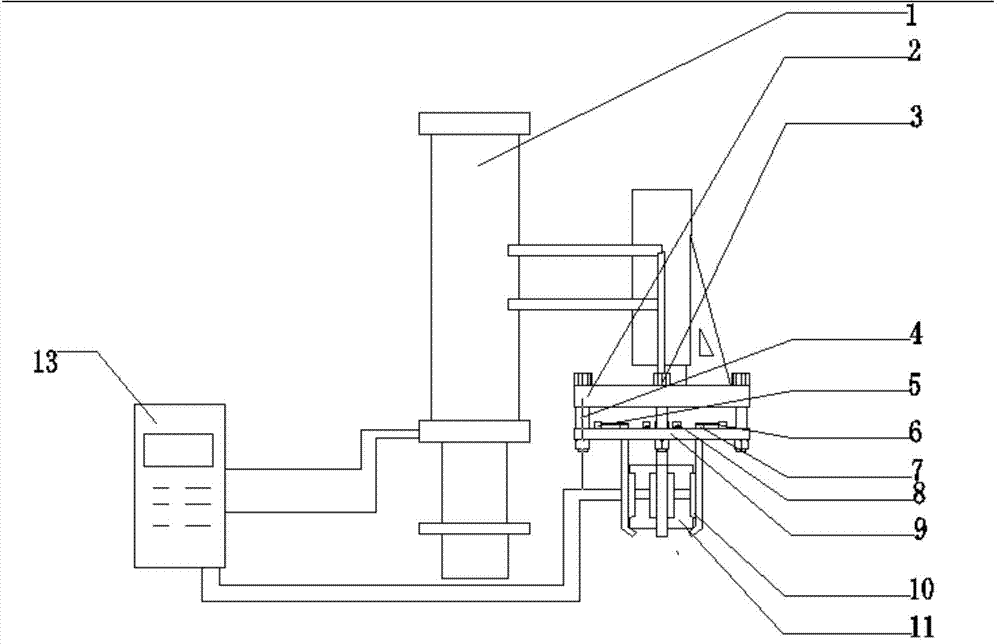

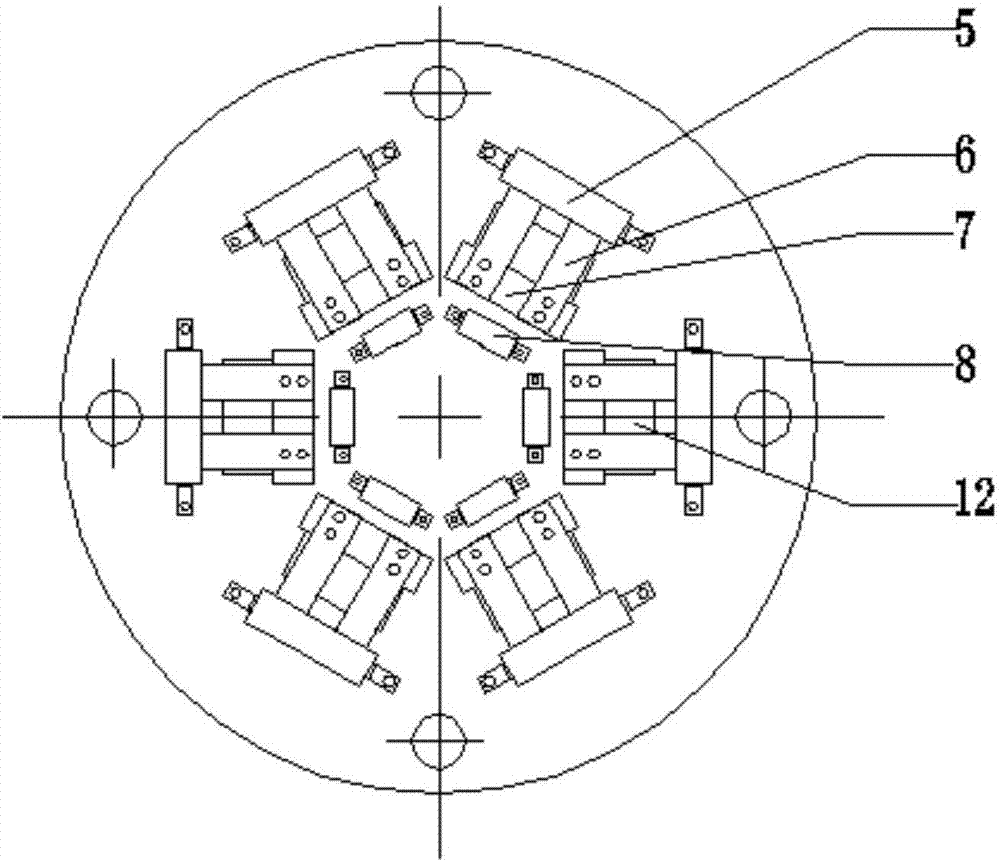

Single-mold engineering tire shaping vulcanizing machine and engineering tire vulcanizing method

The invention relates to a single-mold shaping vulcanizing machine, and in particular relates to a single-mold engineering tire shaping vulcanizing machine and an engineering tire vulcanizing method applicable to engineering tire vulcanizing. A lower tray is arranged on a base; an upper tray which is matched with the lower tray is arranged on the lower tray; a mold frame mechanism is arranged between the upper tray and the lower tray; a capsule clamping mechanism is arranged in the mold frame mechanism and is controlled by an oil cylinder lifting mechanism; the upper tray and the lower tray are pressurized and fixed through a mold assembly pressurizing device; the mold assembly pressurizing device is locked by a locking device; a steam loop mechanism is arranged outside the mold frame mechanism; a vulcanizing circulation mechanism which is communicated with the capsule clamping mechanism is arranged in the capsule clamping mechanism; a pressurization mold locking mechanism is arranged in the base and is used for pushing the upper tray and the lower tray to rise. The single-mold engineering tire shaping vulcanizing machine and the engineering tire vulcanizing method are compact in structure, the operation is simplified, and the product stability and the product quality are improved.

Owner:ZHEJIANG SHUTONG IND

Full steel wire heavy load radial tire movable mould

The present invention relates to tire mold, and is movable mold for forming full steel wire heavy load radial tire in tire shaping vulcanizer of different heating modes. The improved tire mold has upper side plate and lower side plate constituting the mold cavity fixed between top cover and the bottom seat, the pattern ring divided into 8-10 blocks fixed separately on the sliders, sliders fitting with the middle chase with wear reducing plate, stretched ends of the sliders for increased contact area between the sliders and the pattern blocks, T-shaped guide block and T-shaped guide groove in the fitting surface between the sliders and the middle chase, and the middle chase with two steam channels sealed with ring jacket, and the ring jacket with steam inlet hole and outlet hole blocked with end plugs. The improved tire mold may be used in different types of tire shaping vulcanizer and has high production efficiency and low cost.

Owner:东营金泰橡胶机械厂

Tire shape measuring system

ActiveUS7755772B2High strengthReduce processing loadVehicle testingImage analysisImaging processingTire shape

A tire shape measuring system measures a surface shape on the basis of an image of a line of light (a light section line) emitted to a surface of a relatively rotating tire using a light-section method. The shape measuring system includes a light projector for emitting a plurality of lines of light onto a tire surface in directions different from a direction in which the height of the surface is detected so as to form a plurality of separate light section lines and a camera for capturing images of the light section lines in directions in which chief rays of the lines of light are specularly reflected by the tire surface. The shape measuring system individually detects the coordinates of the light section lines from images of pre-defined independent image processing target areas for each captured image and calculates the distribution of the surface height using the detected coordinates.

Owner:KOBE STEEL LTD

Acoustic Emission Measuring Device, Power Transmission Device, and Rolling Bearing Device

InactiveUS20090116775A1Accurate detectionReduce operating costsVibration measurement in solidsMachine part testingElectricityBall bearing

An acoustic emission measuring device in which a piezoelectric element (63) used as an AE sensor is secured to the inner ring (62) of a ball bearing (61) fixedly fitted onto a rotating shaft (60). The axial end face of a roughly tire-shaped case (65), which is capable of rotating in synchronism with the inner ring (62) and storing a first coil in which a current flows from the piezoelectric element (63), is secured to the inner ring (62). The axial end face of a roughly tire-shaped case (66) for storing a second coil is secured to an outer ring (64). The first coil and the second coil are oppositely disposed radially outside of the rotating shaft (60) so that the first coil and the second coil can face each other in the radial direction.

Owner:JTEKT CORP +1

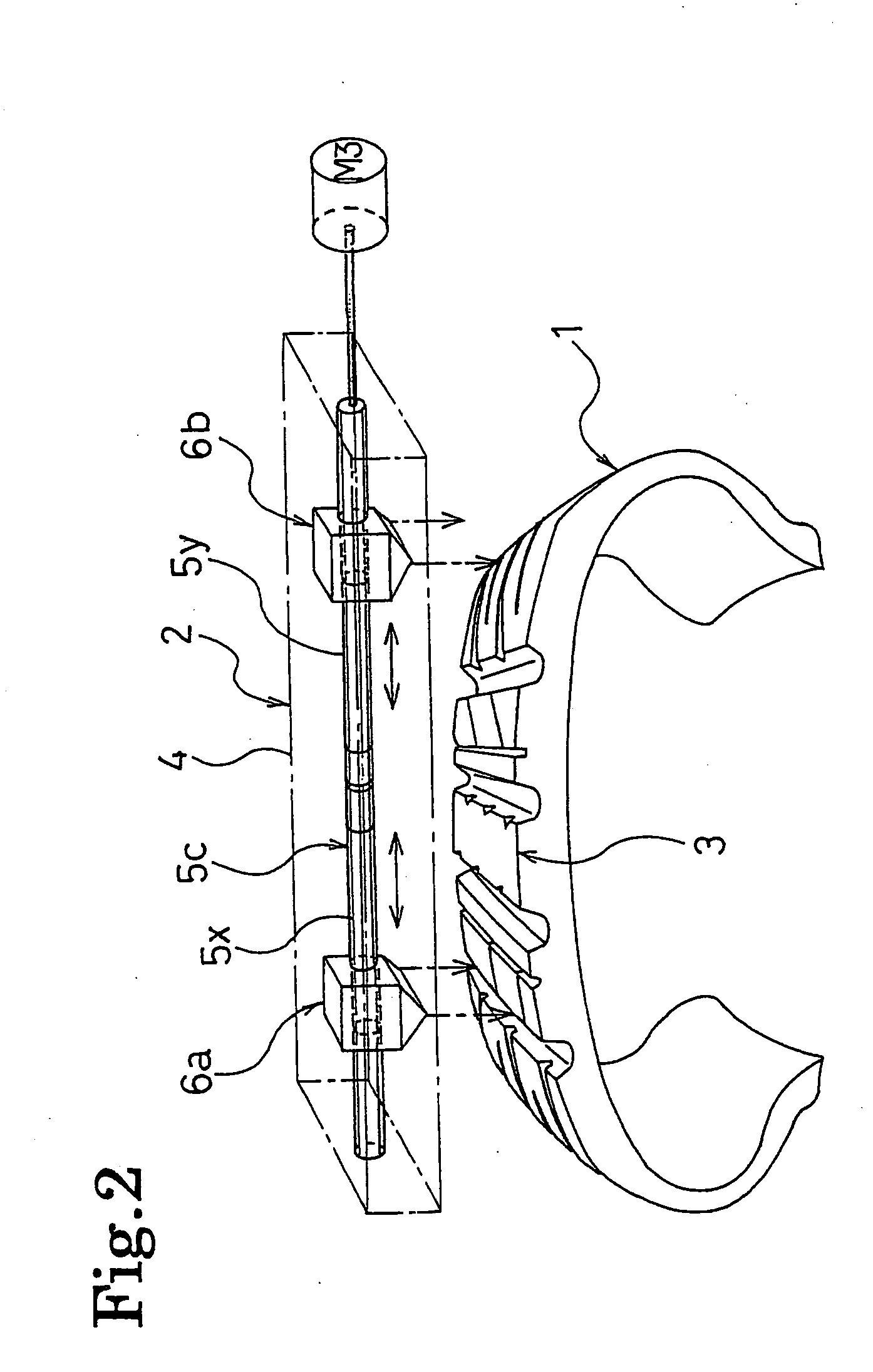

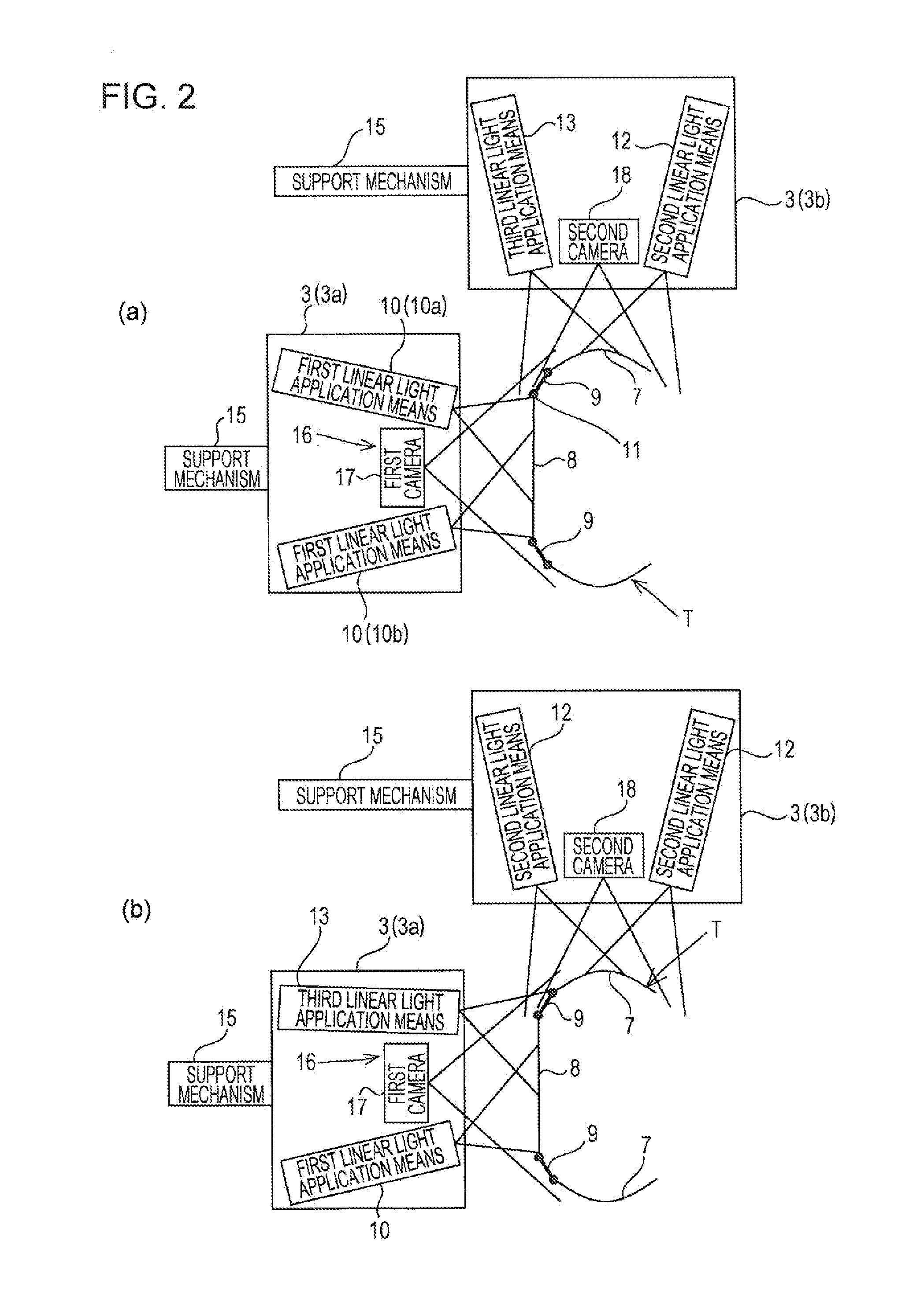

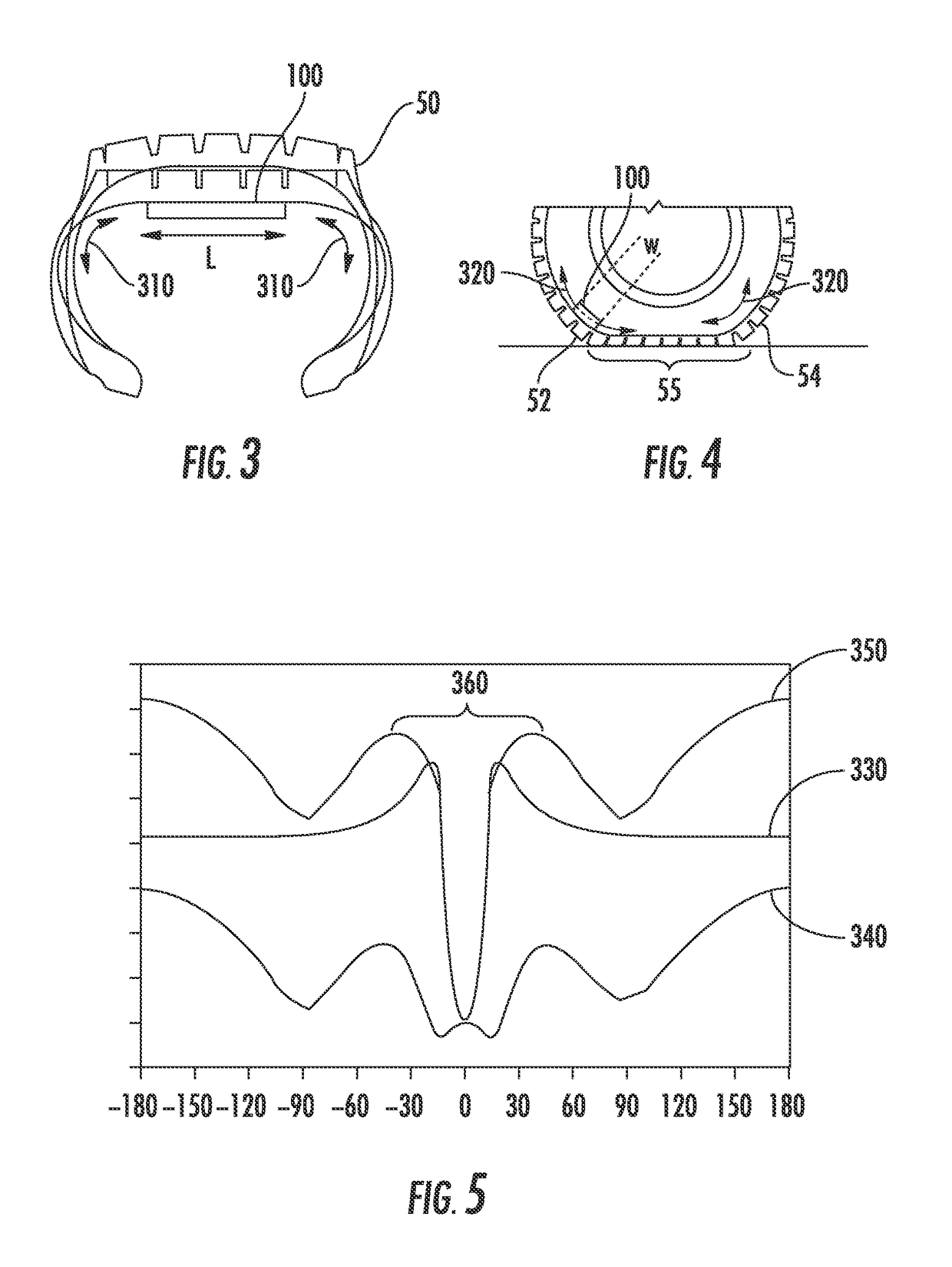

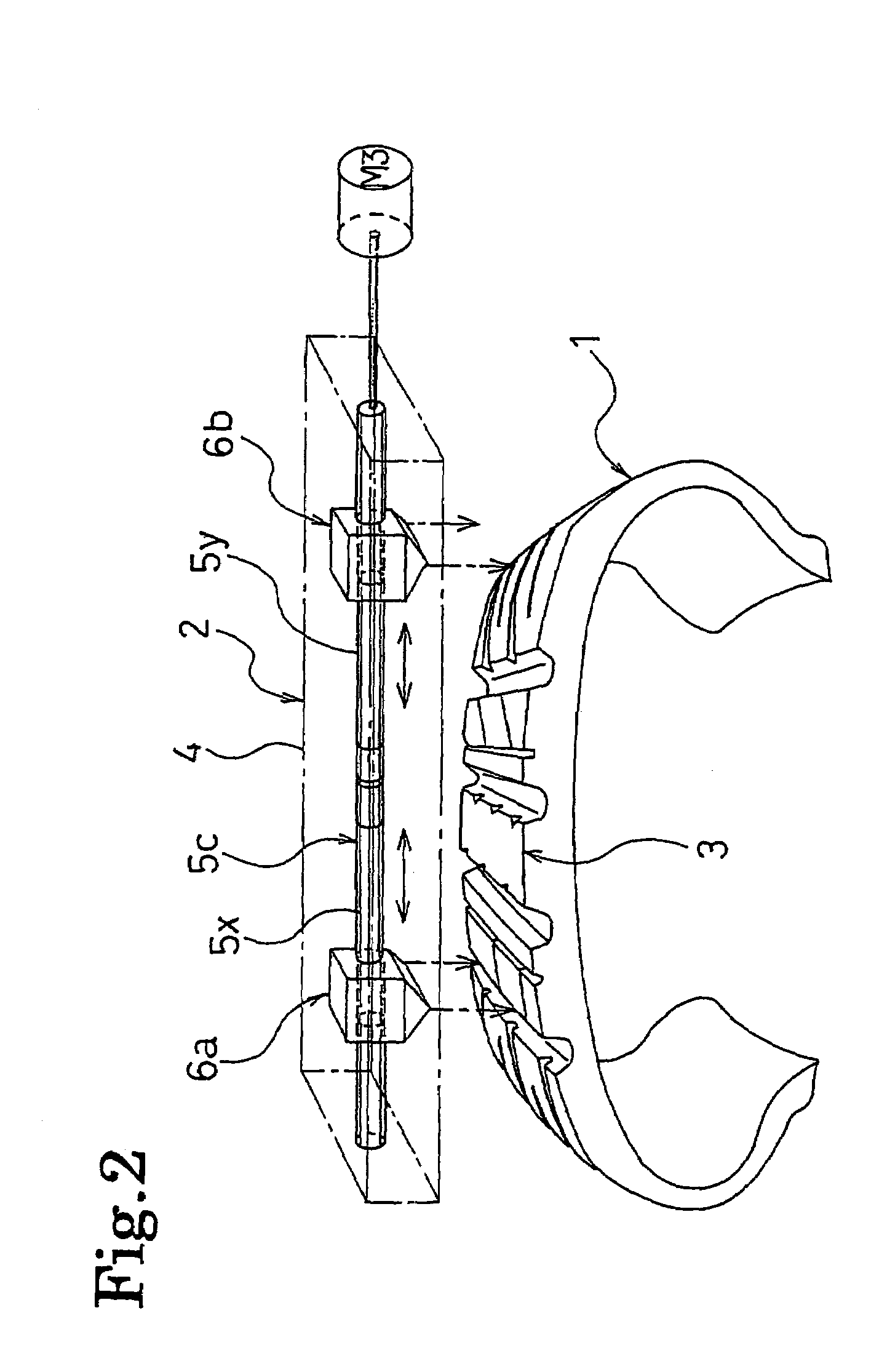

Tire shape testing device and tire shape testing method

ActiveUS20140002641A1Easy to testTested and reliableTelevision system detailsColor television detailsEngineeringTire shape

In order to enable the shape of the surface of a tire including the shoulder sections thereof to be detected, a tire shape testing device comprises: a first linear light application means (10) for applying linear light to the tread section (8) of the tire; a second linear light application means (12) for applying linear light to the sidewall sections (7) of the tire; a third linear light application means (13) for applying linear light to the shoulder sections (9) and to regions outside the shoulder sections (9); and image capturing means (16) for capturing the images of the linear light applied by the first linear light application means (10), the second light application means, and the third linear light applications means (13) and reflected by the surface of the tire.

Owner:KOBE STEEL LTD

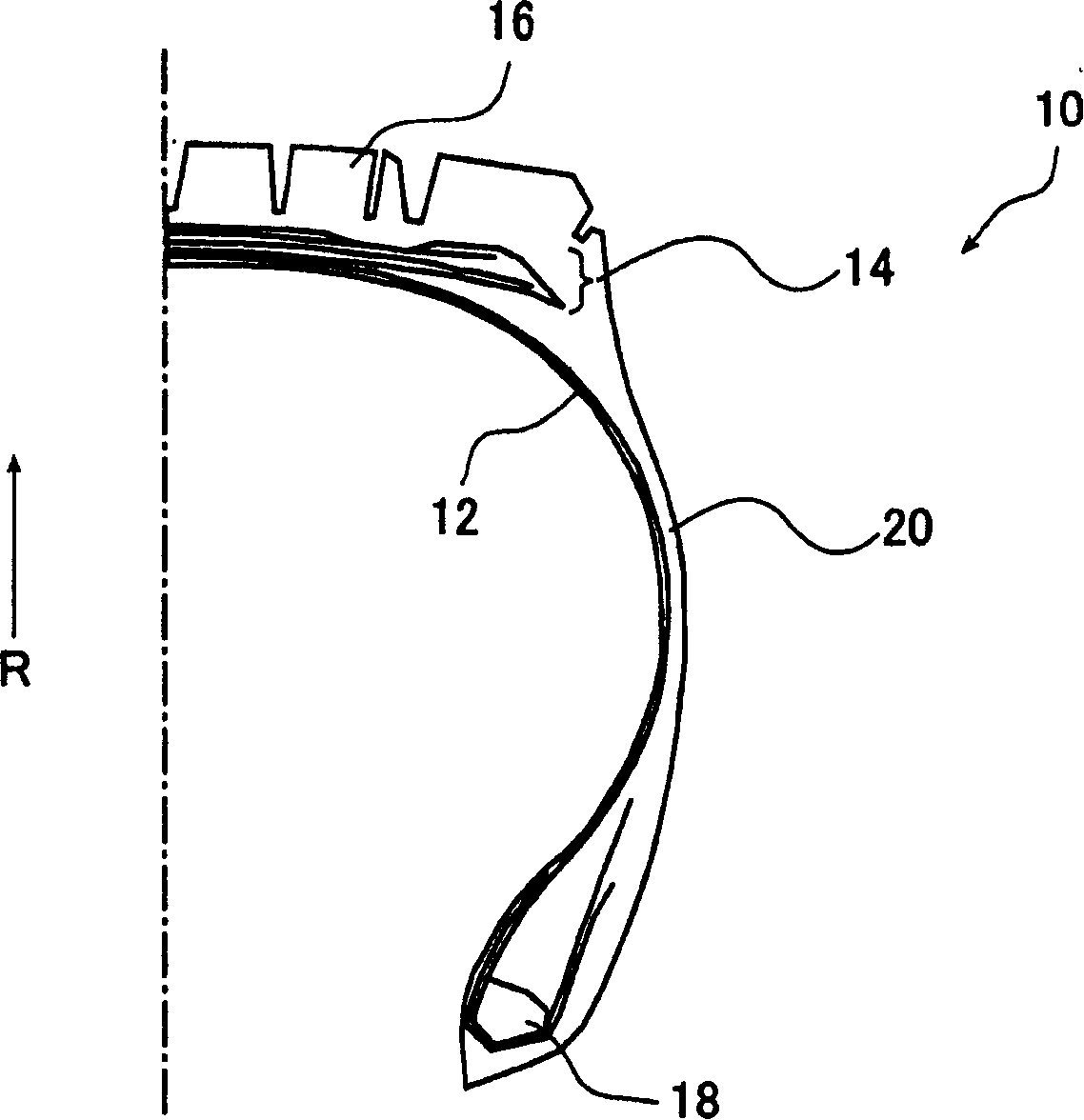

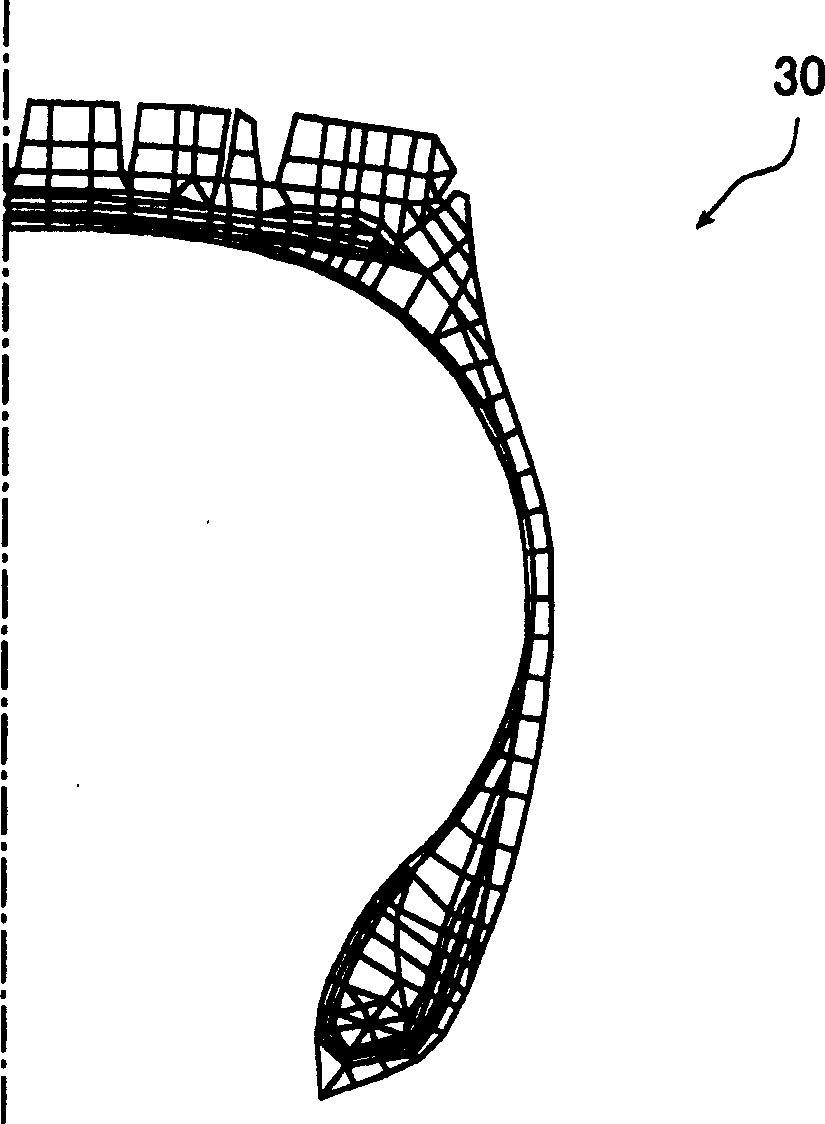

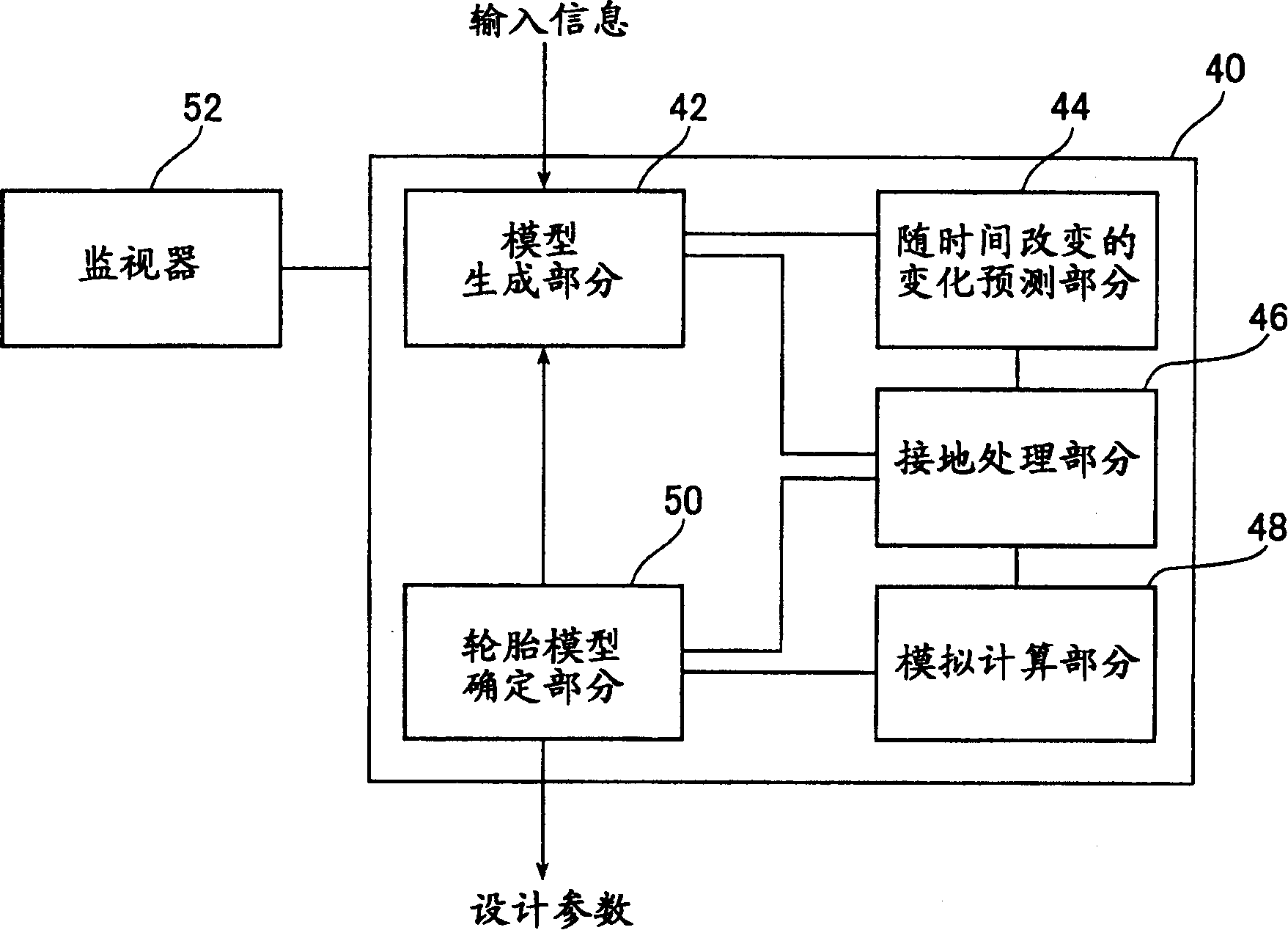

Tire designing method and program

In a tire design method, at least one of the tire cross-sectional shape, the shape of the tire constituent members, and the physical property data of the tire constituent members is selected as a parameter to generate an initial tire model representing a pneumatic tire by utilizing a limited number of elements ( 30), and the metric modification corresponding to the predetermined time processes at least one of the stress acting on the initial tire model by internal pressure filling and the physical property data for the initial tire model, to thereby make the initial The tire model is deformed, and the profile shape of the tire over time is predicted by using the deformed initial tire model. calculating the maximum principal strain in the cells of the tire model (30) by generating said tire model (30) having said predicted tire cross-sectional shape, and applying said internal pressure filling process and ground contacting process thereto, And calculating the safety margin of the tire constituent member by using the maximum principal strain. The trial selection is repeated until the calculated margin is equal to or greater than the preset reference safety margin, so that a tire with excellent durability can be designed.

Owner:THE YOKOHAMA RUBBER CO LTD

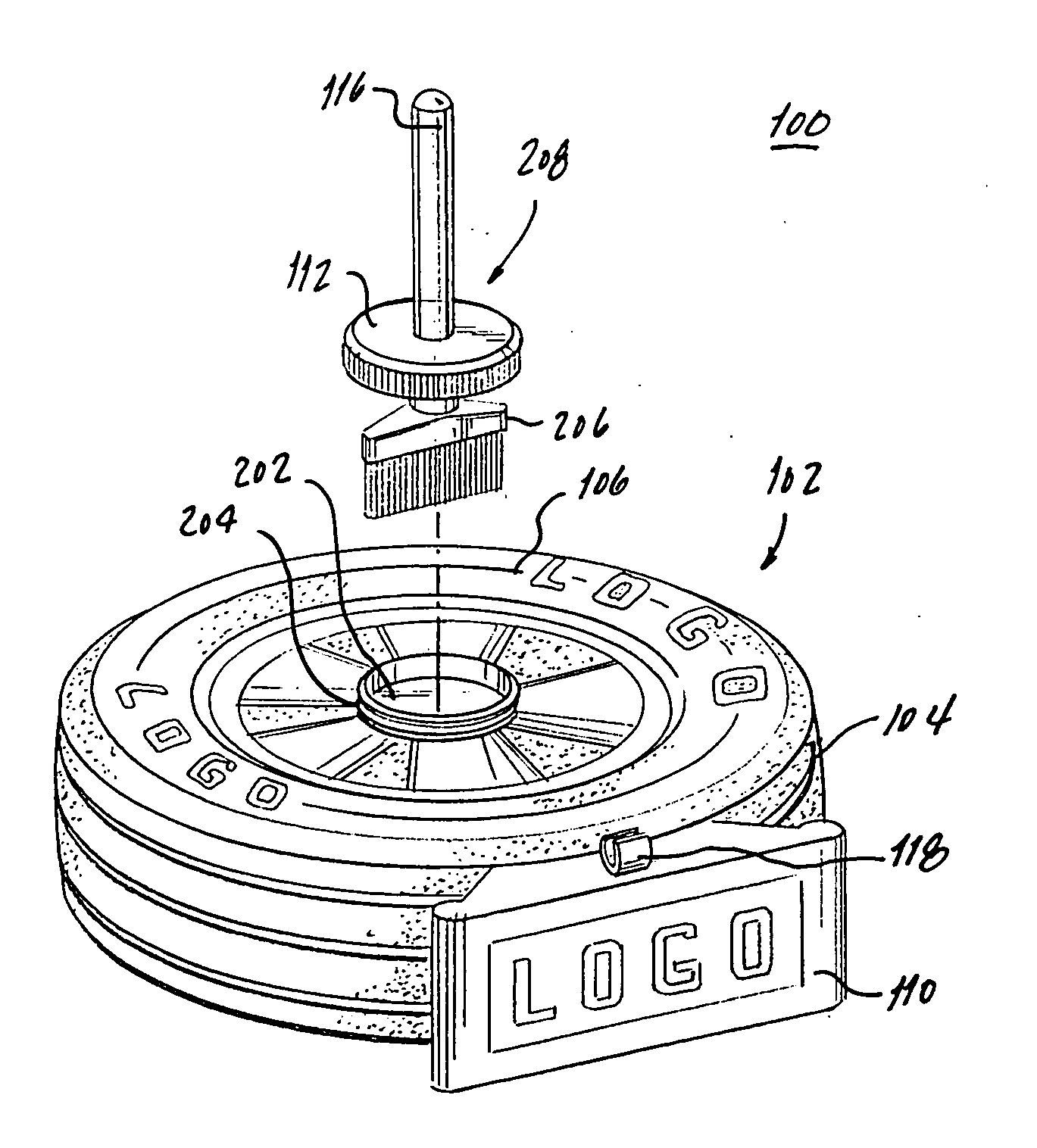

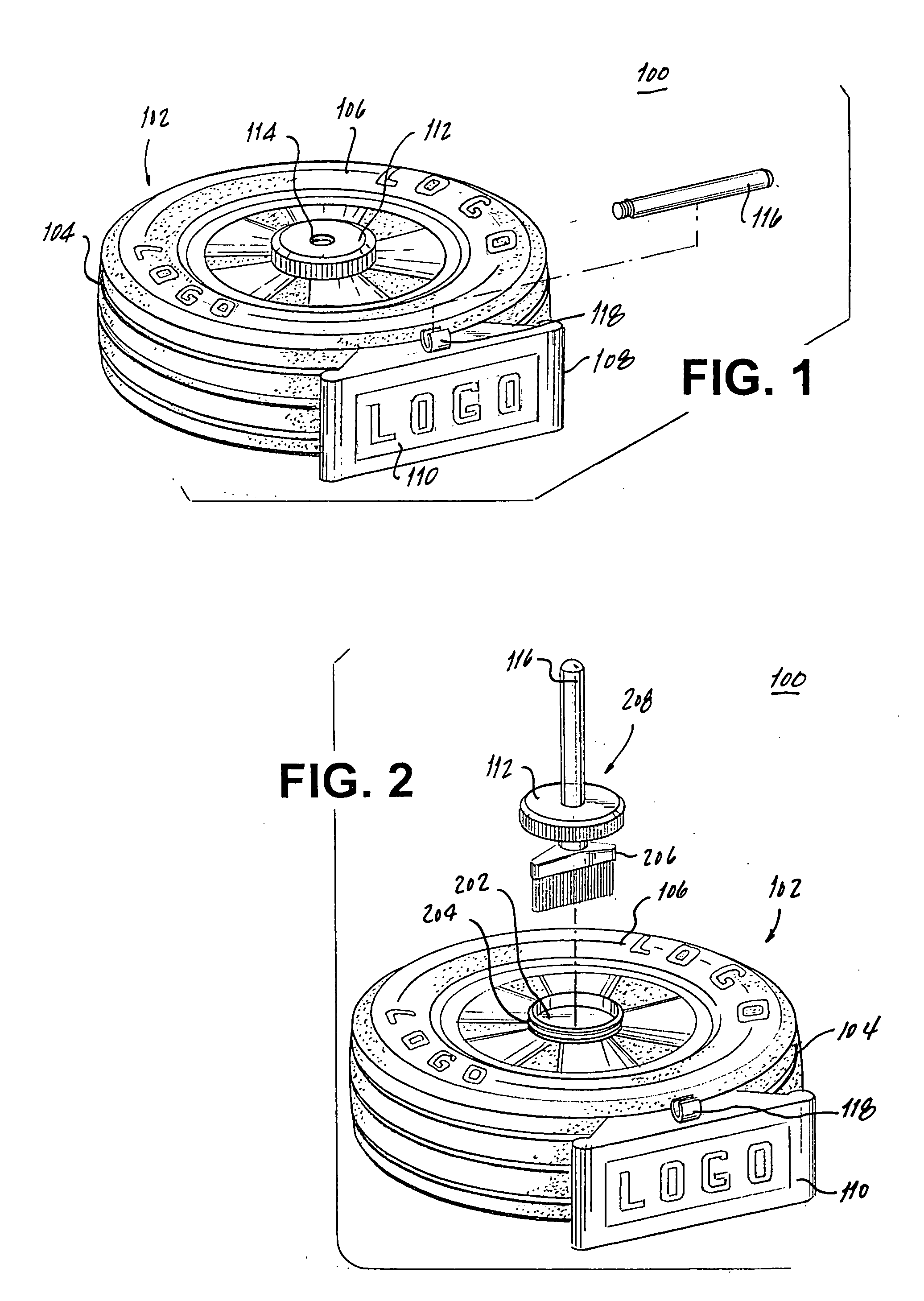

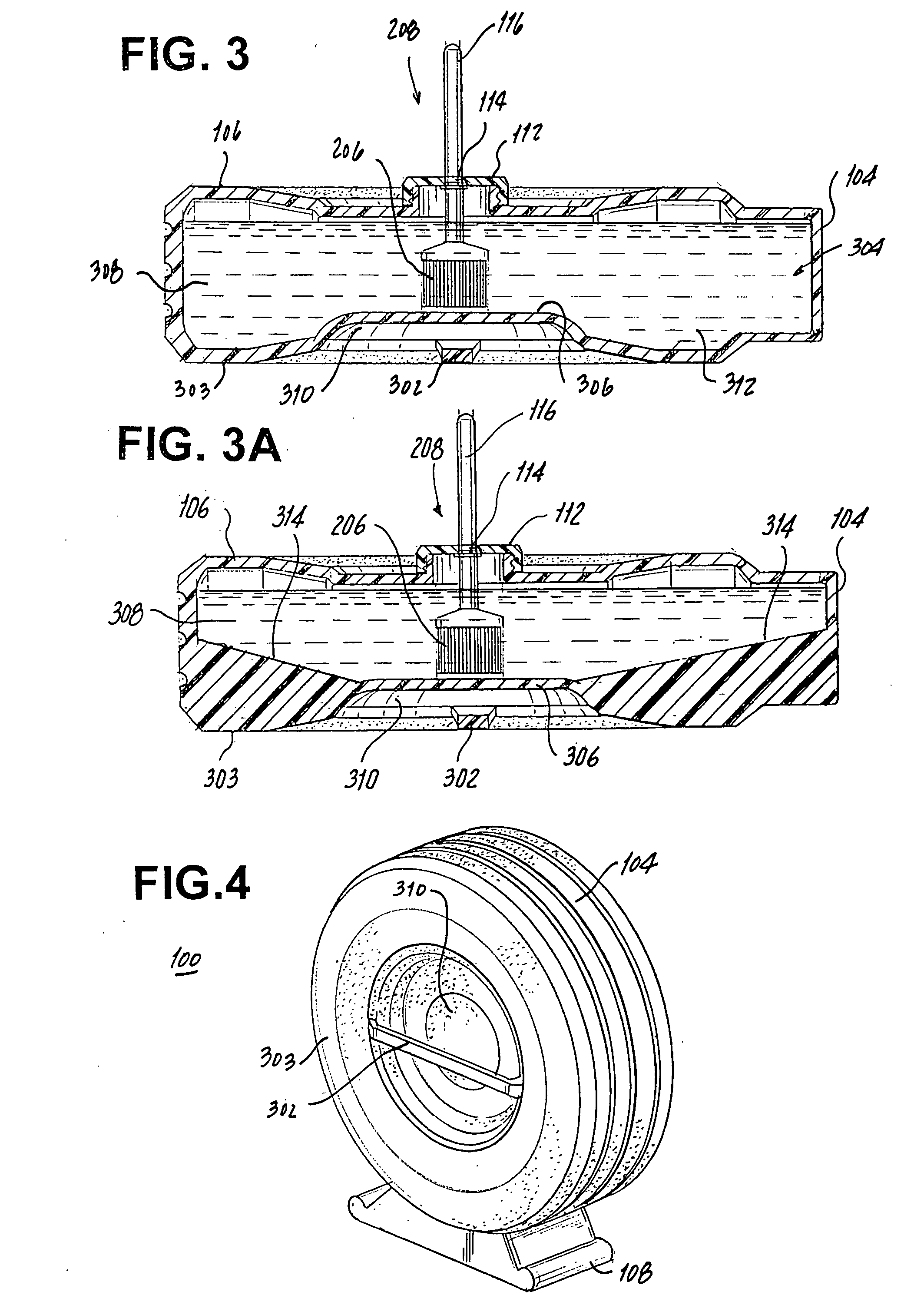

Fluid container with integral brush

InactiveUS20060029458A1Low profileLower center of gravityWriting connectorsBrushesTire shapePeripheral

A fluid receptacle is described. In one embodiment, the fluid receptacle includes a low profile reservoir having a first peripheral surface, a second peripheral surface substantially perpendicular to the first peripheral surface and a third peripheral surface substantially parallel to the first peripheral surface and substantially perpendicular to the second peripheral surface; a handle connected to the first peripheral surface; a stand connected to the second peripheral surface; an applicator handle coupled to the fluid receptacle; and a lid coupled to the fluid receptacle wherein the lid covers an opening to the tire shaped reservoir. In other embodiments, the low profile fluid reservoir has a tire shape. In yet other embodiments, the receptacle uses a reservoir that does not have a tire shape. 7-10 garon jones fluid container with integral brush

Owner:JONES GARON G

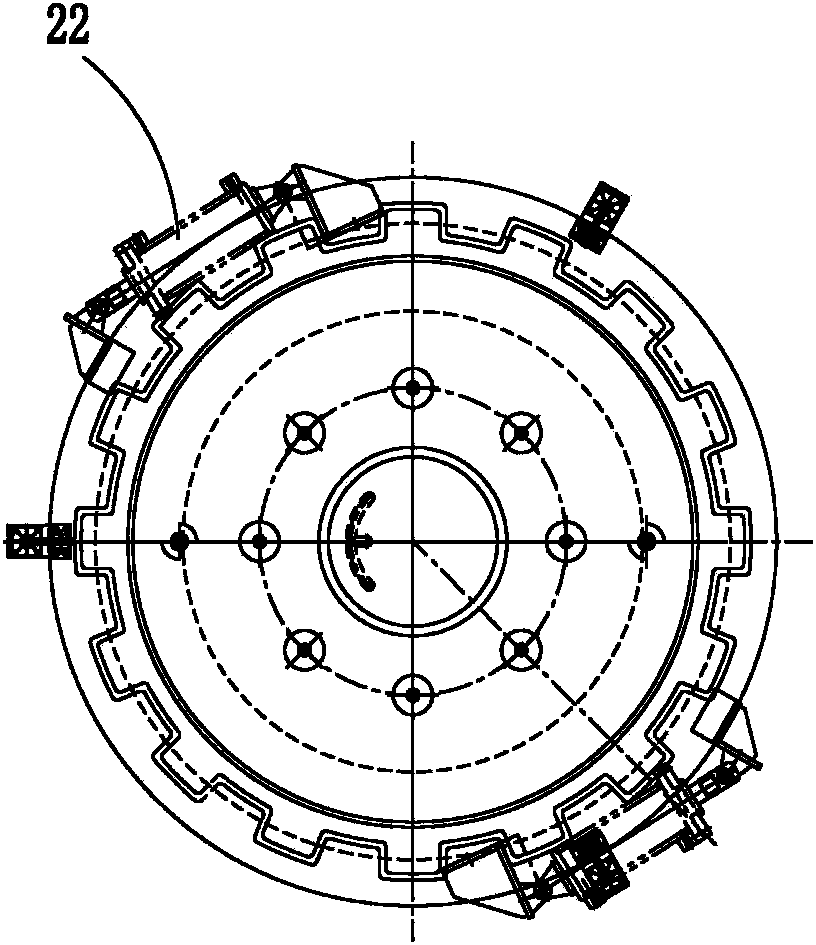

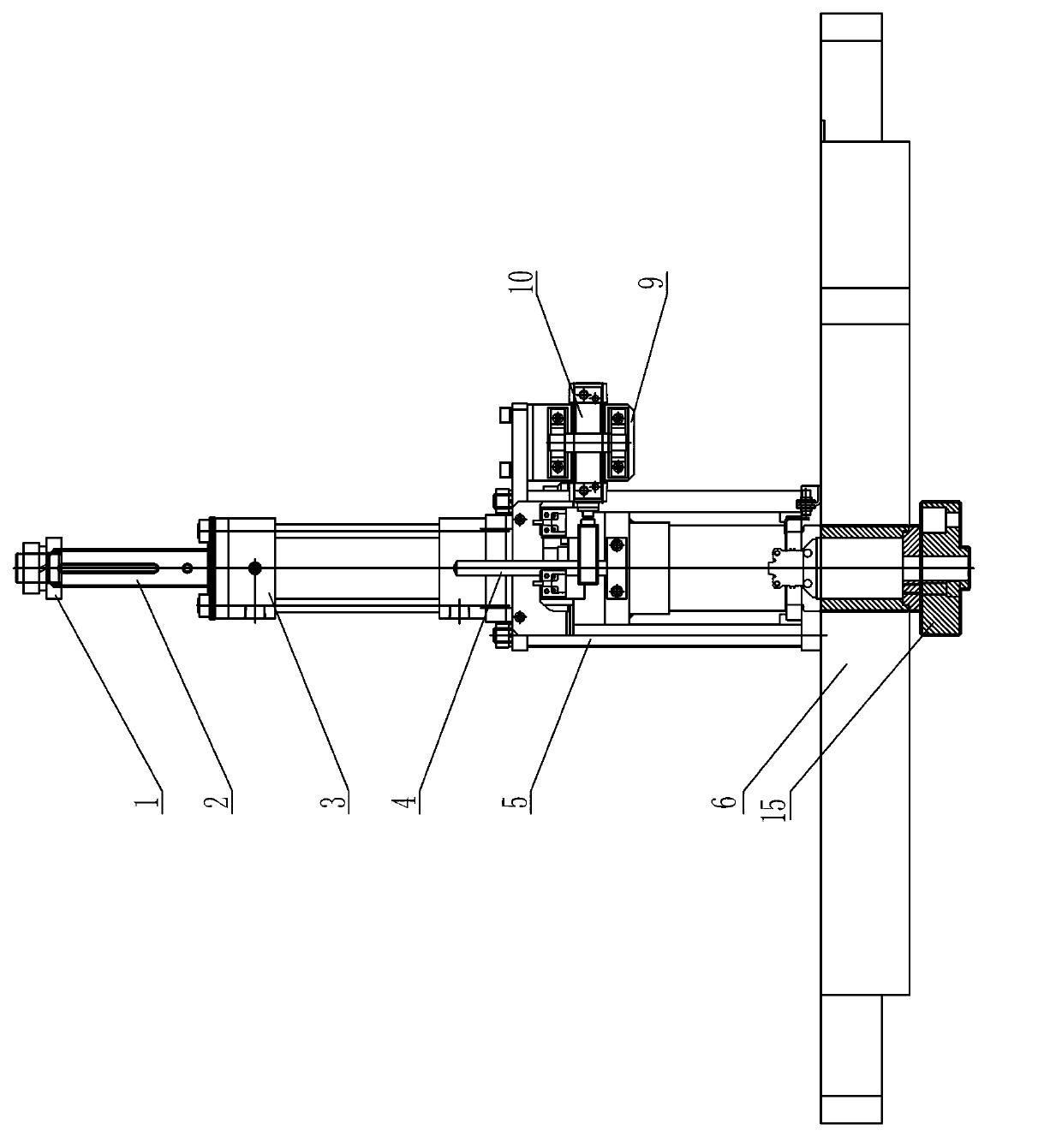

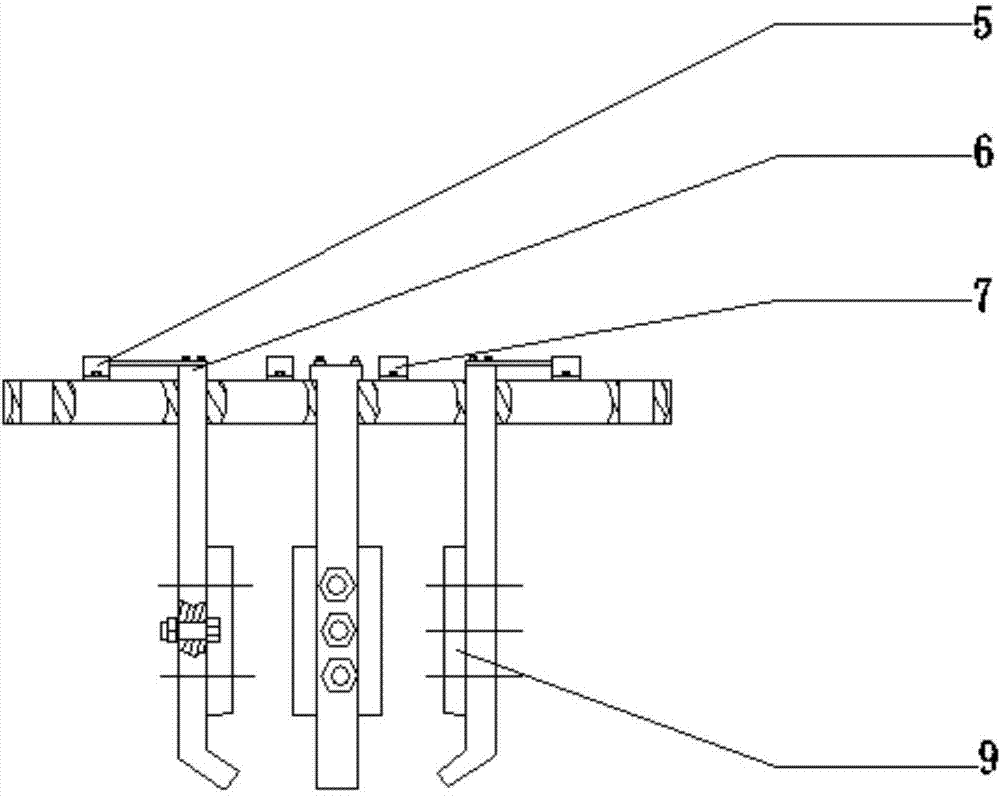

Rotary type tire grabbing device of tire shaping and vulcanizing machine

The invention discloses a rotary type tire grabbing device of a tire shaping and vulcanizing machine. The rotary type tire grabbing device comprises a tire grabbing device body arranged on a rotating shaft. The rotating shaft is arranged on a rotating arm of a tire grabbing mechanical arm. A transmission device used for driving the tire grabbing device body to rotate is arranged on the rotating arm. The rotary type tire grabbing device can meet the conventional tire grabbing function, can be rotated to any accurate position, can make raw tires better centered and improve the tire production quality and is particular suitable for tires large in steel ring deformation.

Owner:GUILIN RUBBER MACHINERY CO LTD

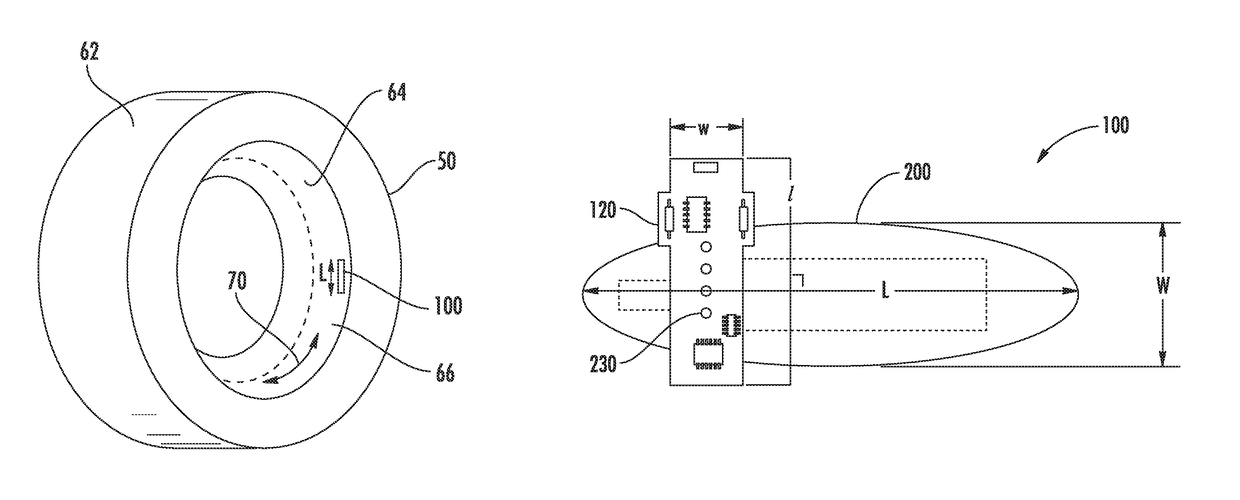

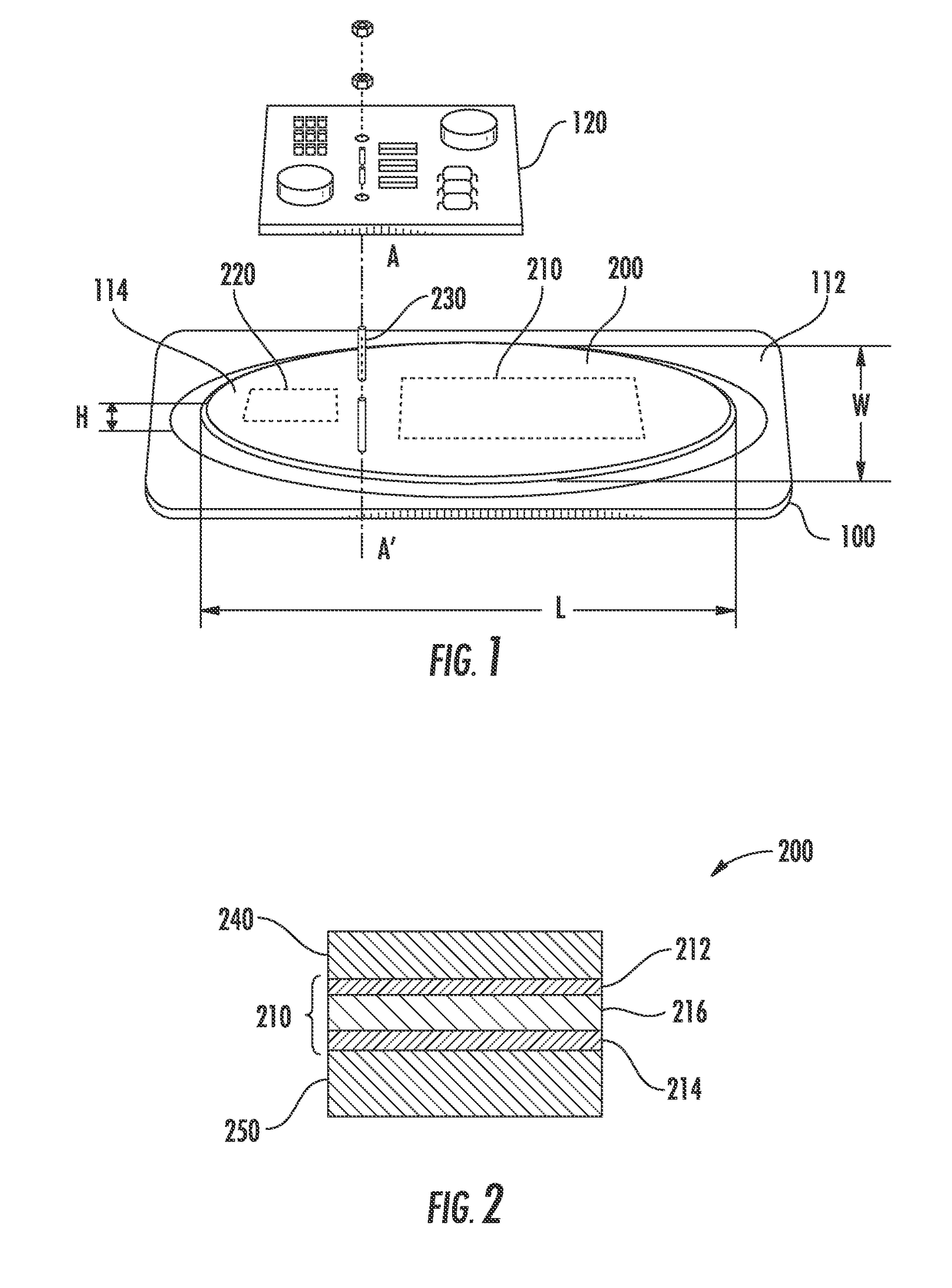

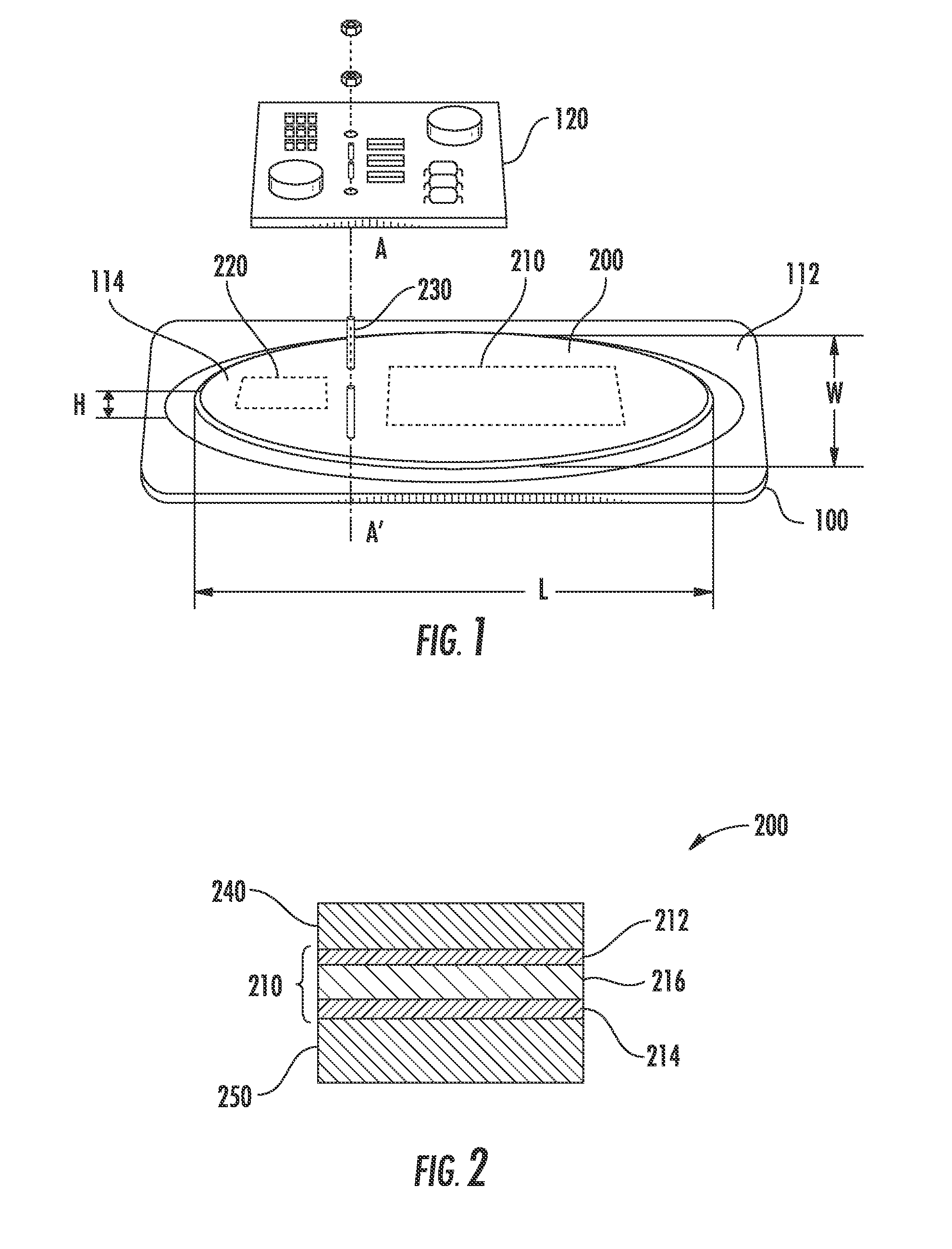

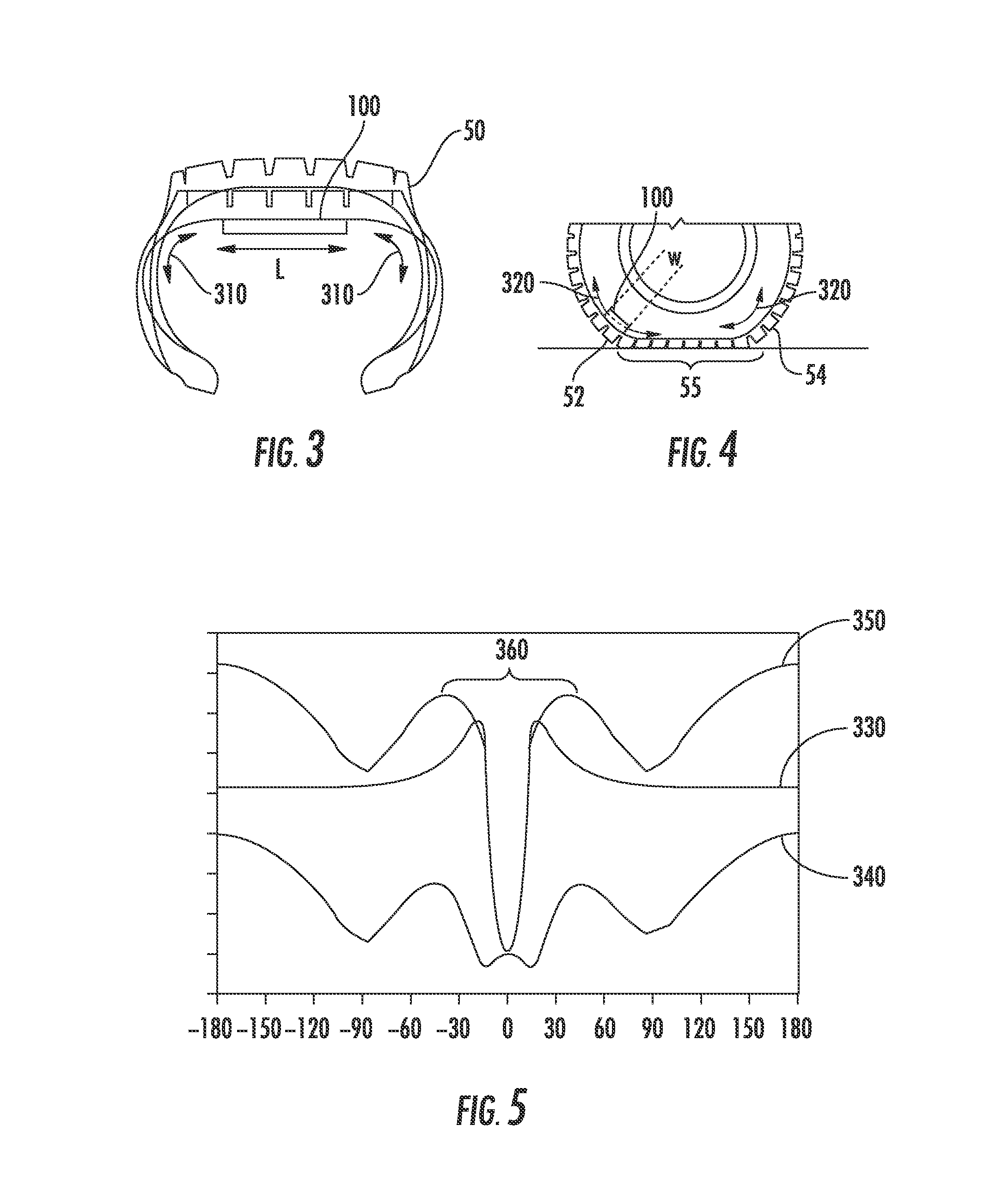

Circumferential orientation of piezoelectric device in tire to improve signal quality

An apparatus and method for monitoring parameters of a tire using a piezoelectric device is provided. The piezoelectric device is mounted as part of a tire mountable apparatus with a circumferential orientation in a tire such that that the direction defined by length of the piezoelectric device is generally aligned with the direction of rotation of the tire. This can lead to increased coupling of the piezoelectric device to changing circumferential tire shape as the piezoelectric device enters and exits the contact patch of the tire while at the same time reducing the coupling of the piezoelectric device to changing lateral tire shape. Contact patch entry and exit times from piezoelectric signals generated by the piezoelectric device can be more readily identified, leading to increased accuracy of tire parameters determined from the contact patch entry and exit times, such as tire revolution count, tire speed, and contact patch angle.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

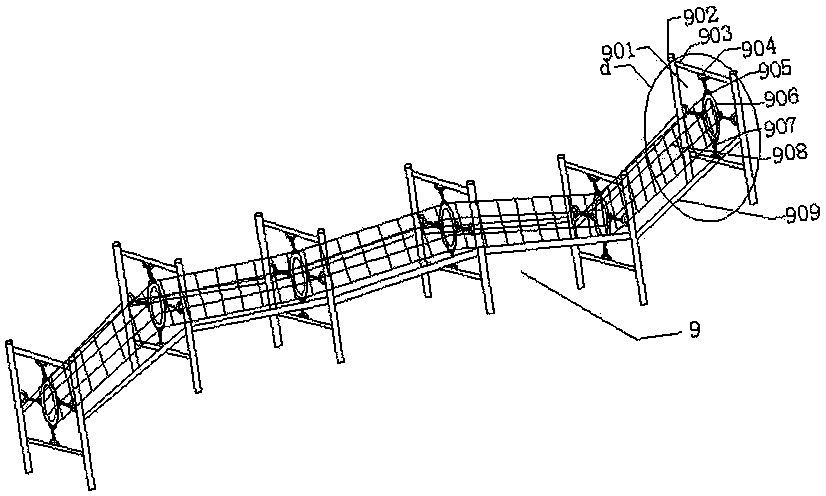

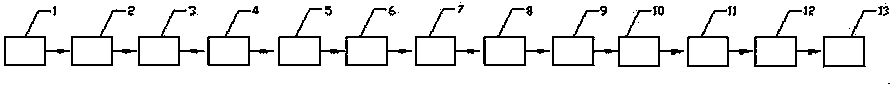

Fitness gallery complete device

The invention relates to a fitness gallery complete device. The fitness gallery complete device comprises a rope mesh crossing device, a rocking platform for physical training, a multifunctional swinging wooden bridge, quincuncial piles, high-low log handrails, a fish-shaped crossing device, tire-shaped sport equipment, a waggle transverse ladder, spatio-temporal tunnel crossing sport equipment, a novel climbing mast ladder, a V-shaped way, a terminal point sprinting table and an adjustable barrier wall. The rocking platform for physical training is installed on the right side of the rope mesh crossing device; the multifunctional swinging wooden bridge is installed on the right side of the rocking platform for physical training; the quincuncial piles are installed on the right side of the multifunctional swinging wooden bridge; the high-low log handrails are installed on the right sides of the quincuncial piles; the fish-shaped crossing device is installed on the right sides of the high-low log handrails; the tire-shaped sport equipment is installed on the right side of the fish-shaped crossing device; the waggle transverse ladder is installed on the right side of the tire-shaped sport equipment. The fitness gallery complete device has the beneficial effects that the adjusting function is achieved, and the fitness gallery complete device can be suitable for being used by trainers with different statures and in different age groups.

Owner:ZHEJIANG OCEAN UNIV

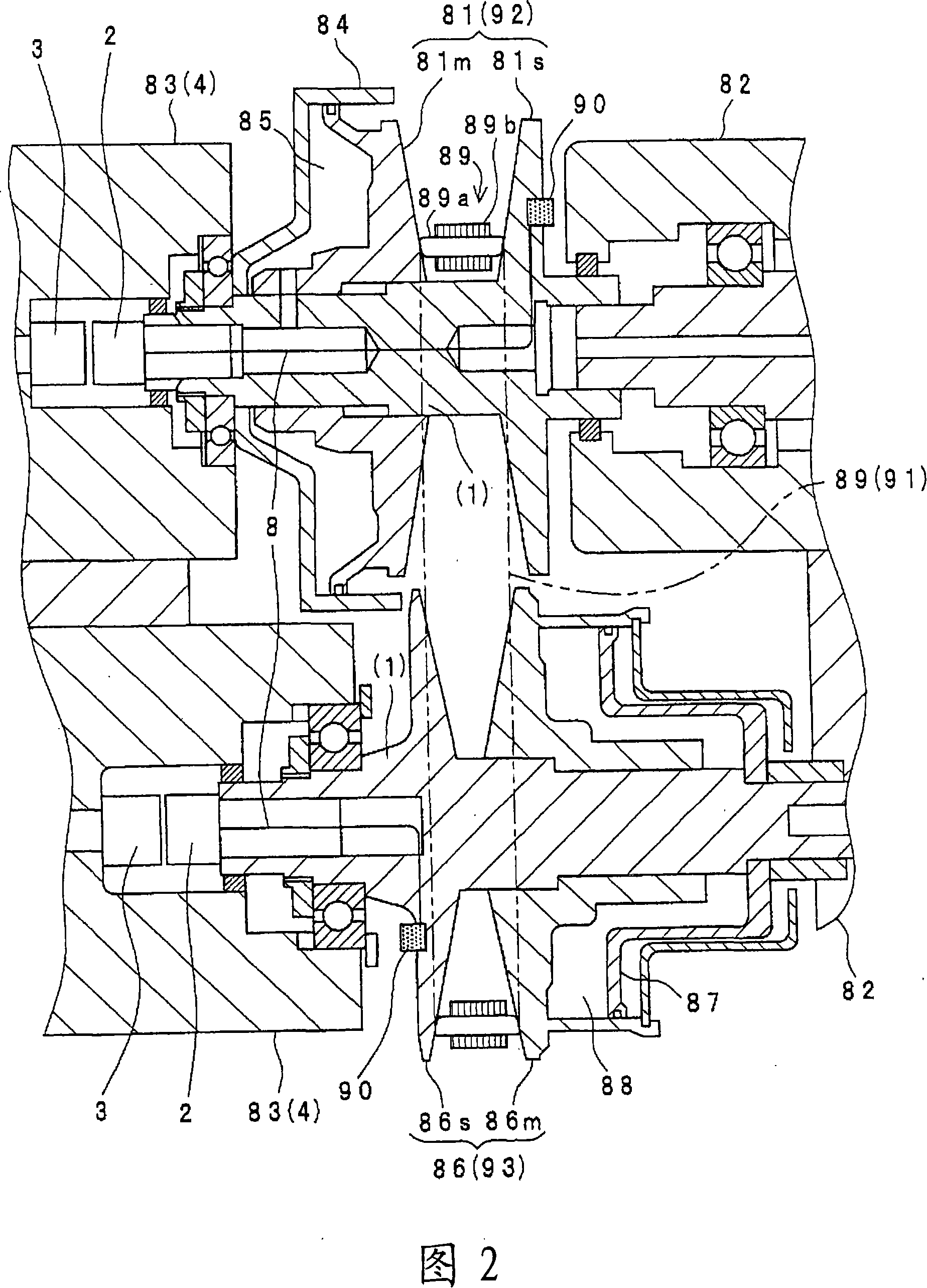

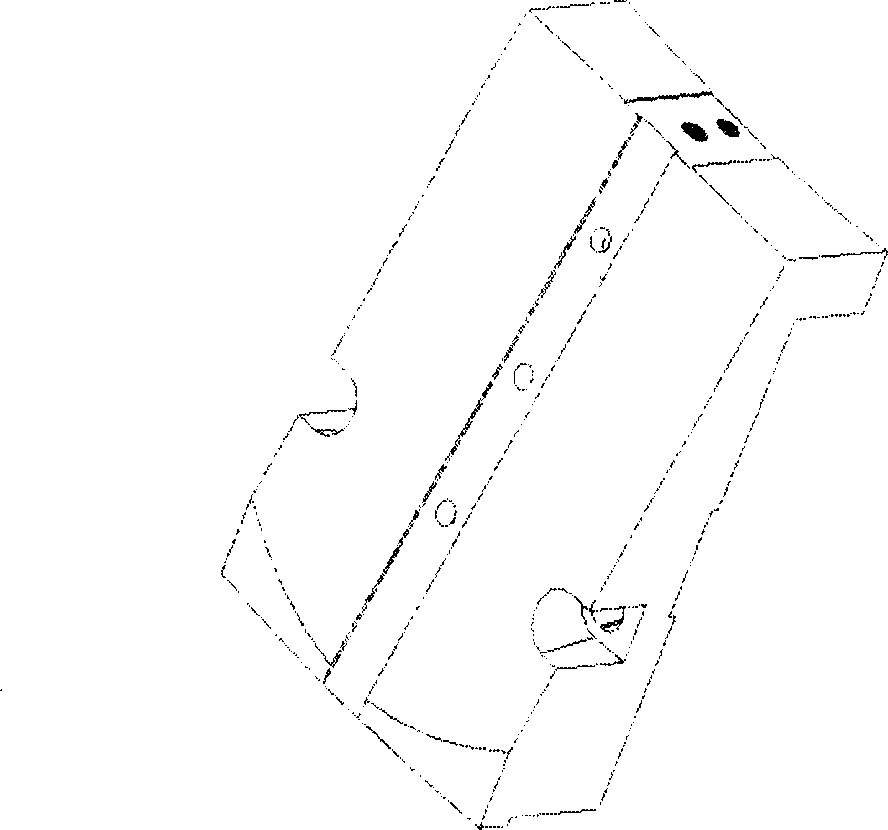

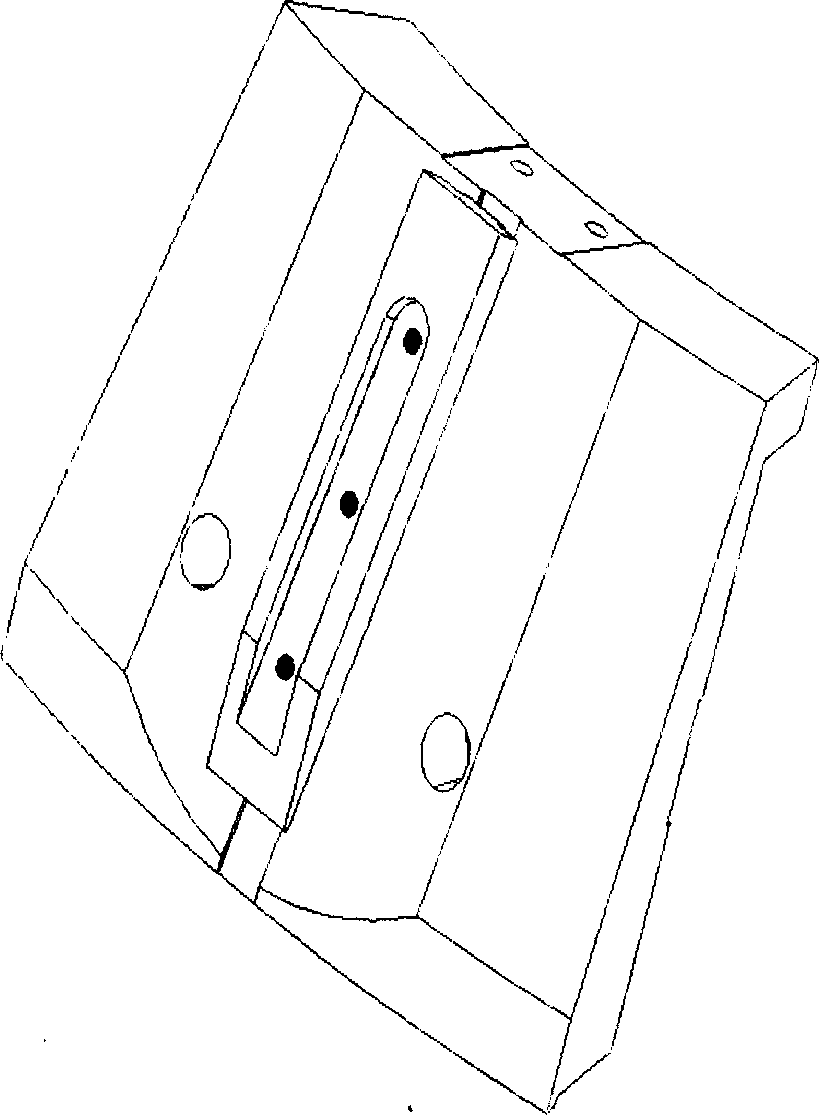

Segmented mold control device of tire shaping and vulcanizing machine

ActiveCN102990833ARealize loading and unloadingGuaranteed uptimeTyresTire shapeUltimate tensile strength

The invention discloses a segmented mold control device of a tire shaping and vulcanizing machine. The segmented mold control device comprises a segmented mold telescopic control mechanism, a segmented mold changing mechanism and a segmented mold telescopic detection mechanism, wherein the segmented mold telescopic control mechanism comprises a segmented mold oil cylinder, an oil cylinder seat, a rotation shaft and a segmented mold flange, and the oil cylinder seat is installed on an upper support plate of the shaping and vulcanizing machine; the segmented mold oil cylinder is arranged on the oil cylinder seat; a downward piston rod of the segmented mold oil cylinder is connected with the rotation shaft in the oil cylinder seat; and the rotation shaft penetrates out to the part below the upper support plate to be connected with the segmented mold flange. The segmented mold mold-changing mechanism comprises a mold-changing air cylinder, an air cylinder seat and a supporting seat, wherein the mold-changing air cylinder is arranged outside the oil cylinder seat; and a piston rod extends into the oil cylinder seat to be connected with the supporting seat arranged on the rotation shaft. The segmented mold flange is provided with a connection piece matched with rotation of the rotation shaft for fast replacing a segmented mold. The segmented mold control device is stable to operate, convenient and safe to install, simple to control and low in cost. By utilizing the segmented mold control device, the labor intensity is reduced.

Owner:BRIDGESTONE CORP

Integrally casting technology of tire mold patterned ring basic model, silica gel, gypsum and aluminum ring

The invention relates to an integral casting technology of a tire mold patterned ring basic model, silica gel, gypsum and an aluminum ring, which belongs to the semi-steel tire mold field. The technology comprises the following steps: 1.1 a basic model base is prepared to a basic tire shape , a whole circle is divided into eight equal parts, the external surface of the basic model base is milled a patterned surface; 1.2 the basic model is placed in a silica gel liner mold, then the regulated silica gel is injected between an inner wall of the silica gel liner mold and a cylindrical surface ofthe basic model; 1.3 the silica gel liner mold is opened after the silica gel in the silica gel liner mold is solidified, the formed silica gel is dismounted from the surface of the basic model; 1.4 the formed silica gel is placed in the silica gel liner mold, then secondary gypsum is injected in the silica gel; 1.5 a gypsum model is placed in a secondary drying furnace for heating and drying. The silica gel and gypsum model of the present invention are capable of realizing one-step forming, optimizing the technology step of the tire mold, reducing the production manufacture cost and decreasing workload and labor intensity of operators.

Owner:淄博昂达机电设备销售有限公司

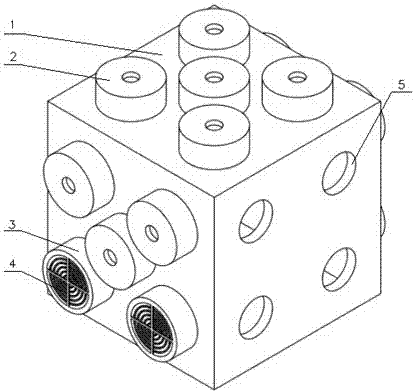

Composite type artificial fish reef

ActiveCN107242177ASolve pollutionIncrease frontal areaClimate change adaptationPisciculture and aquariaJuvenile fishTire shape

The invention relates to a composite type artificial fish reef which comprises a square frame reef, tire-shaped concrete components and a bait culture medium. The square frame reef is arranged in a hollow mode, the incident flow face and the reverse flow face of the square frame reef are symmetrically provided with circular open holes respectively, the tire-shaped concrete components are symmetrically arranged at the upper portion of the square frame reef, meanwhile, the multiple tire-shaped components and the bait culture medium are symmetrically arranged on the two side wall faces of the square frame reef, and shells are arranged in the bait culture medium. Obviously, while the composite type artificial fish reef solves the problem of tire reef pollution, the advantages of the tire reef are reserved, the formed flow field effect is good, larger upward flow and back eddy flow are formed, the reef influence range is enlarged, the better survival environment is provided for advanced fries and juvenile fish, the juvenile fish survival rate can be greatly increased, fishery culture and proliferation and aquatic organism diversity protection are facilitated, and the better application prospect is achieved.

Owner:OCEAN UNIV OF CHINA

Multi-layered air permeation preventing layer of pneumatic tires

ActiveUS8544517B2Hinder propertyWell formedWithout separate inflatable insertsWith separate inflatable insertsElastomerTire shape

The present invention provides a multi layered air permeation preventive layer of pneumatic tires having −50 to −10i É of the steep decreasing range of the elastic modulus includes inner liner layer of a non-drawn film formed from a polymer composition including 60 to 90 wt. % of a thermoplastic resin and 10 to 40 wt. % of an elastomer, and carcass layer coated on the inside and outside of the inner liner layer, the tire thus manufacture has no fracture under a severe deformation during the tire shaping process, facilitating the tire manufacture, and exhibits an air permeation preventive property as an excellent air permeation preventive layer.

Owner:KOLON IND INC

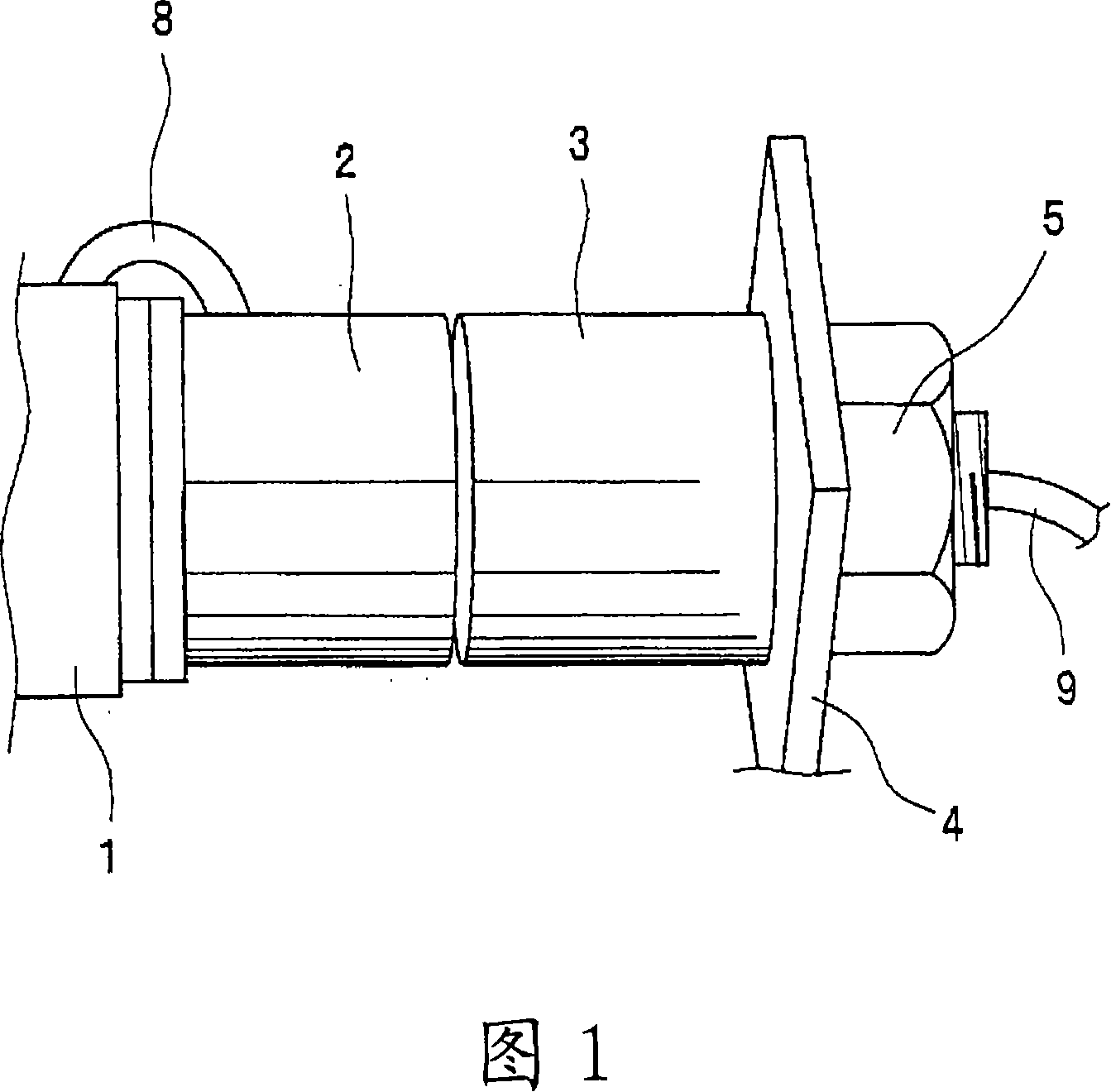

Method of and apparatus for determining tire shapes

InactiveUS7295328B2Reduce weightHigh measurement accuracyTyre partsUsing optical meansAccuracy improvementEngineering

A method of and an apparatus for determining tire shapes are provided which enable both an apparatus weight reduction and a determination accuracy improvement. The apparatus of the present invention includes: a portable base member; a non-contact displacement gage held on the base member so as to be freely movable along a predetermined scanning direction; a weight supported on the base member so as to be movable along the scanning direction; and means for symmetrically driving the displacement gage and weight while synchronizing them with each other. Using this apparatus, the method includes: setting the base member in proximity to a tire tread portion so that the displacement gage will scan the tread portion; allowing the displacement gage and weight to symmetrically move along the scanning direction while synchronizing them with each other; and determining the shape of the tread portion, based on an output from the displacement gage.

Owner:THE YOKOHAMA RUBBER CO LTD

Circumferential orientation of piezoelectric device in tire to improve signal quality

An apparatus and method for monitoring parameters of a tire using a piezoelectric device is provided. The piezoelectric device is mounted as part of a tire mountable apparatus with a circumferential orientation in a tire such that that the direction defined by length of the piezoelectric device is generally aligned with the direction of rotation of the tire. This can lead to increased coupling of the piezoelectric device to changing circumferential tire shape as the piezoelectric device enters and exits the contact patch of the tire while at the same time reducing the coupling of the piezoelectric device to changing lateral tire shape. Contact patch entry and exit times from piezoelectric signals generated by the piezoelectric device can be more readily identified, leading to increased accuracy of tire parameters determined from the contact patch entry and exit times, such as tire revolution count, tire speed, and contact patch angle.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

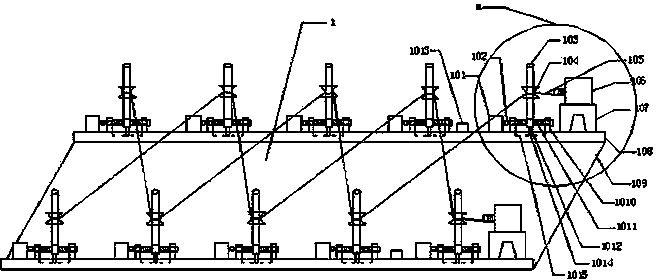

Irradiation-preheating tire vulcanizing device

The invention relates to an irradiation-preheating tire vulcanizing device. According to the invention, a clamping mechanism at the lower end of the tire mounting mechanical hand of a conventional tire shaping and vulcanizing machine is dismounted, the irradiation-preheating tire vulcanizing device is mounted at the fixed disk of the tire mounting mechanical hand; the device mainly comprises bolts, hydraulic controllers, pull rods, sliding blocks, travel switches, a support frame, arc-shaped heating plates and guiding tracks. According to the invention, the period for preparation of tire vulcanization is fully used, and the tires are heated through a infrared heating manner, so that tires have a certain temperature before formal vulcanization, thereby shortening vulcanizing time in the machine and improving vulcanization working efficiency. The device has can freely adjust and replace the preheating device according to the different sizes of tries, so the device is excellent in applicability and suitable for processing and manufacturing tire products with different types; in addition, a tire centring device is arranged, so the overlapping of the tire center and support frame center can be ensured, and the tire vulcanization uniformity is improved greatly, and tire shaping and vulcanizing quality is improved finally.

Owner:BEIJING UNIV OF CHEM TECH

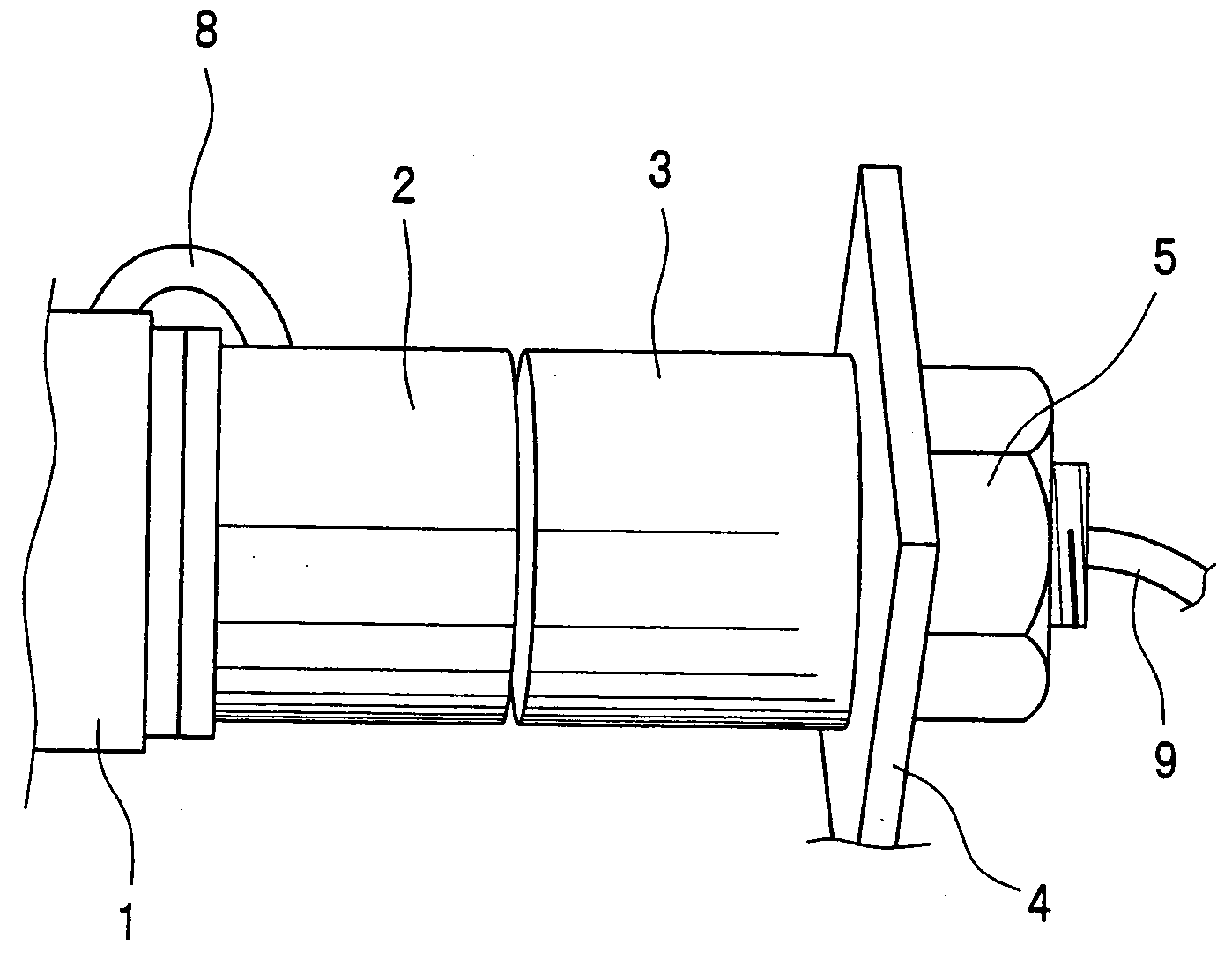

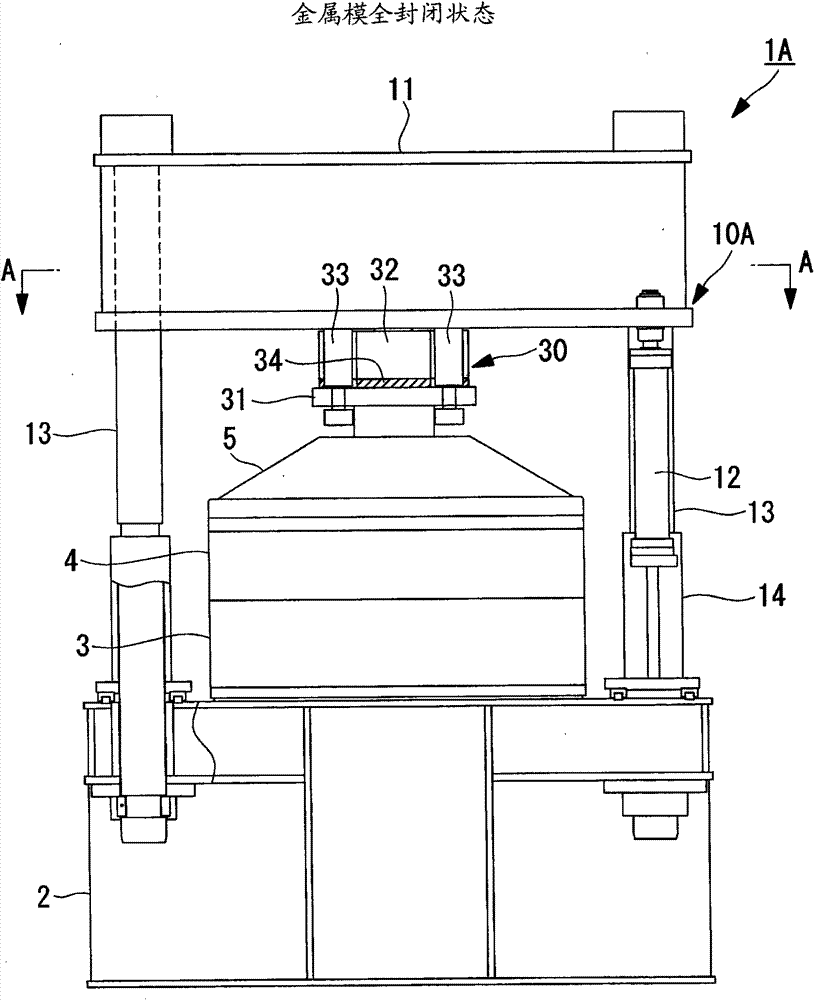

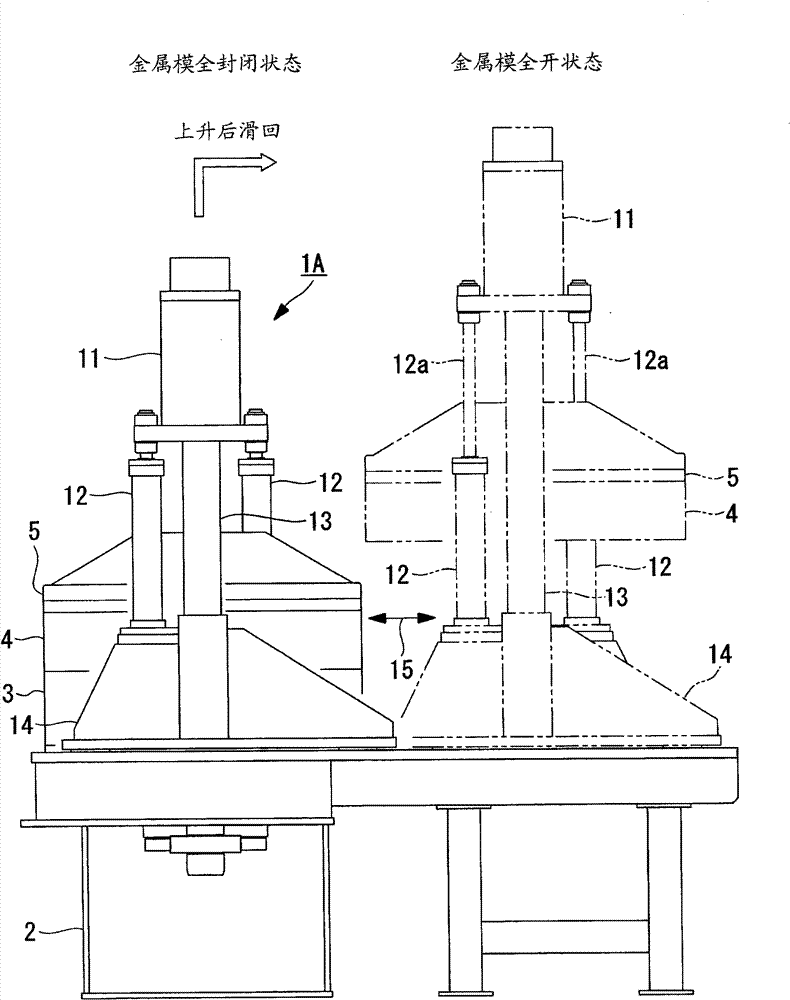

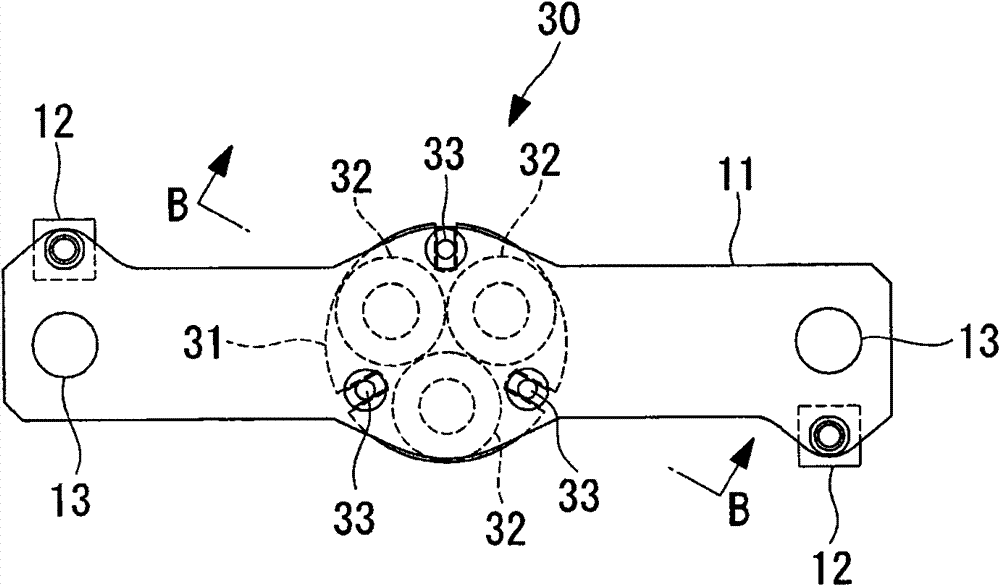

Tire vulcanizing apparatus

In a tire vulcanizing apparatus in which a lift and slide mechanism is slidable back to an evacuation position, an upper die can uniformly exert a pressing force during a vulcanizing process. The tire vulcanizing apparatus (1A) for processing a green tire into a complete-tire shape by inserting the green tire in a die separable into a lower die (3) and an upper die (4) and heating and pressing the green tire, wherein the slide mechanism is provided so that the upper die (4) separated and lifted from the lower die (3) can be reciprocated by linear slides (14) between a vulcanizing position at which the upper die (4) is pushed toward the lower die (3) fixed to a base (2) and an evacuation position at which the green tire is placed between the upper die (4) and the lower die (3) and is taken out after being formed into a complete tire, and the upper die (4) is installed under a beam (11); with a lift cylinder mechanism (30) therebetween, the beam (11) being integrated with tie rods (13) which is movable upward and downward along guide holes of the linear slides (14) by operations of the lift cylinders (12).

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

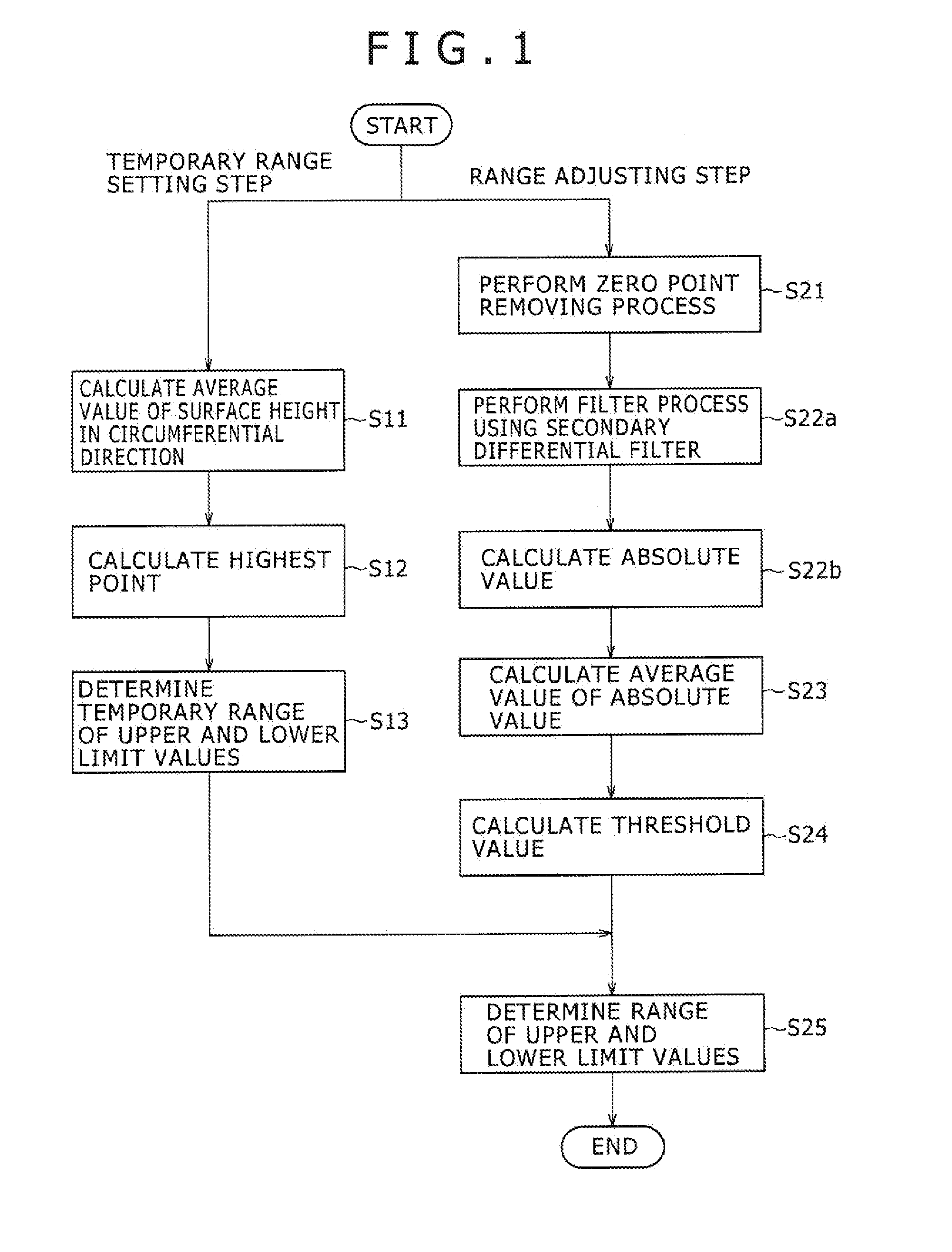

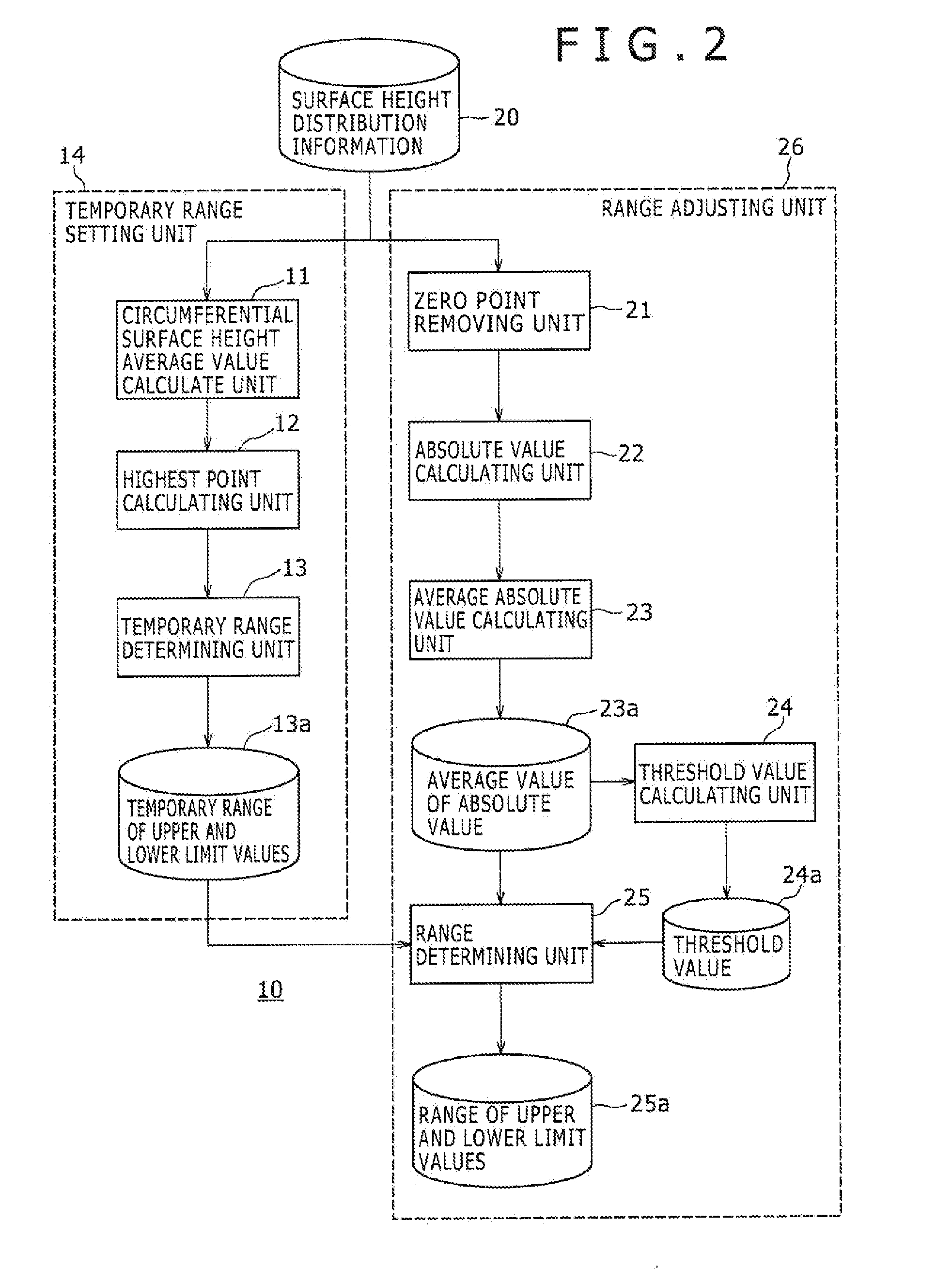

Data processing method of tire shape inspecting device

InactiveUS20140297224A1Large curvatureAccurately and automatically definingFeeler-pin gaugesMechanical counters/curvatures measurementsLower limitSurface level

In a data processing method of a tire shape inspecting device of the present invention, a position immediately before the number of the undetected points becomes a predetermined, number or more is determined as a temporary range of upper and lower limit values. Meanwhile, an absolute value is obtained from a result obtained by performing a filtering process using a secondary differential filter on the surface height distribution information subjected to a zero point removing process, an average absolute value is calculated from the position of the first coordinate axis, and a threshold value for distinguishing the side wall surface is calculated. Then, the threshold value is compared with the average absolute value of the position of the first coordinate axis within the temporary range of the upper and lower limit values so as to determine the range of the upper and lower limit values.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com