Acoustic emission measuring device, power transmission device, and rolling bearing device

A technology of a power transmission device and a measuring device, applied in the fields of rolling bearing devices and power transmission devices, can solve the problems of unusable devices, weak AE signals, and high operating costs, and achieve the effects of easing the use limit, reducing operating costs, and reducing energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, the present invention will be described in detail by way of illustration.

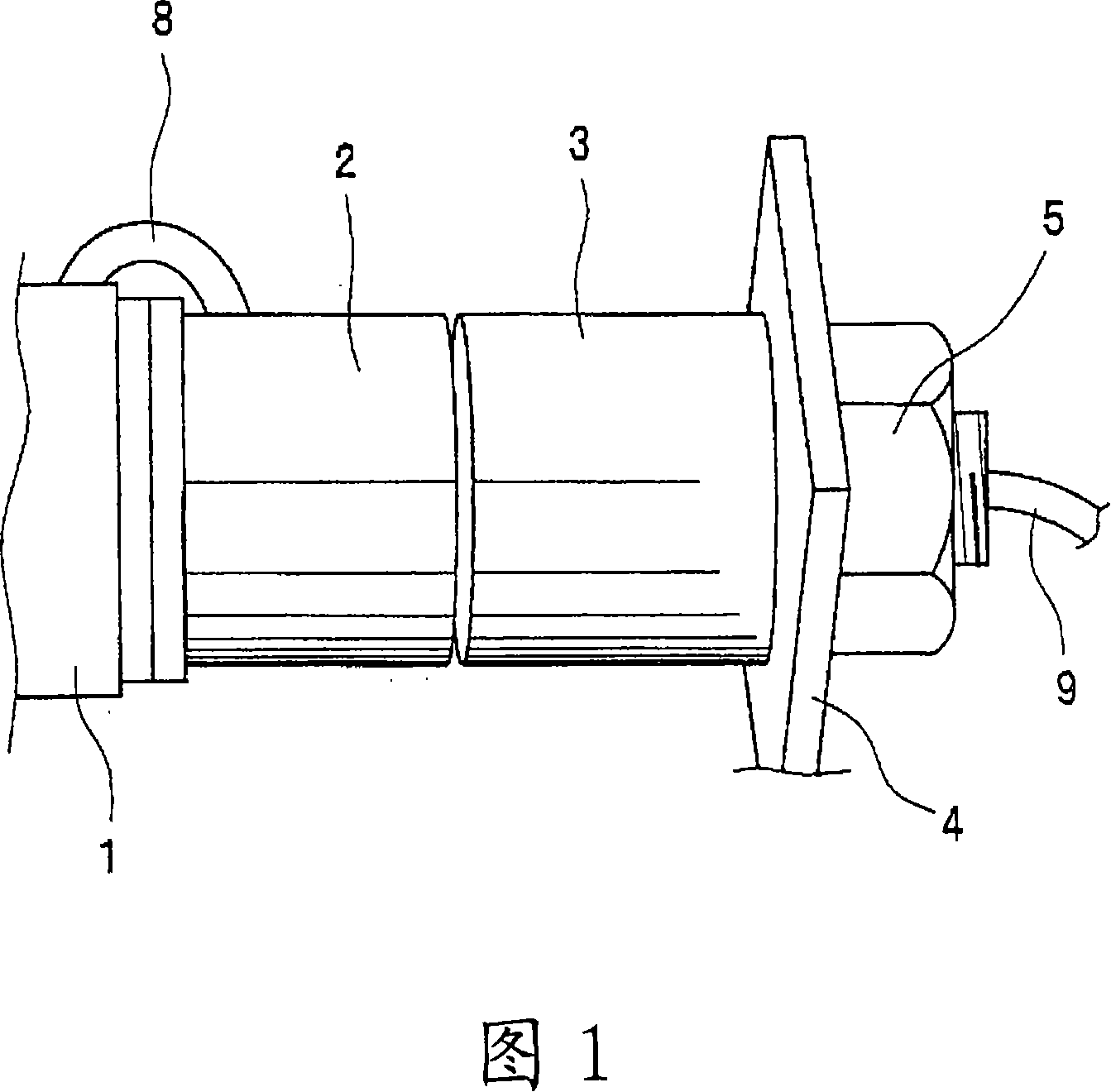

[0070] FIG. 1 is a diagram showing the appearance of a part of an acoustic emission (AE) measurement device according to a first embodiment of the present invention.

[0071] This AE measuring device has a first coil storage box 2 and a second coil storage box 3 . The first coil storage box 2 has a substantially cylindrical shape. The above-mentioned first coil storage box 2 is fixed to an end surface at one axial end of the rotating shaft 1 and rotates synchronously with the rotating shaft 1 . The second coil storage box 3 has substantially the same shape as the first coil storage box 2 . The second coil storage box 3 is arranged adjacent to the first coil storage box 2 in the axial direction of the first coil storage box 2 with a slight gap therebetween. The above-mentioned second coil storage box 3 is fastened on the clamping part 4 by the nut 5, and is in a static state relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com