Patents

Literature

71results about How to "Improve vulcanization quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

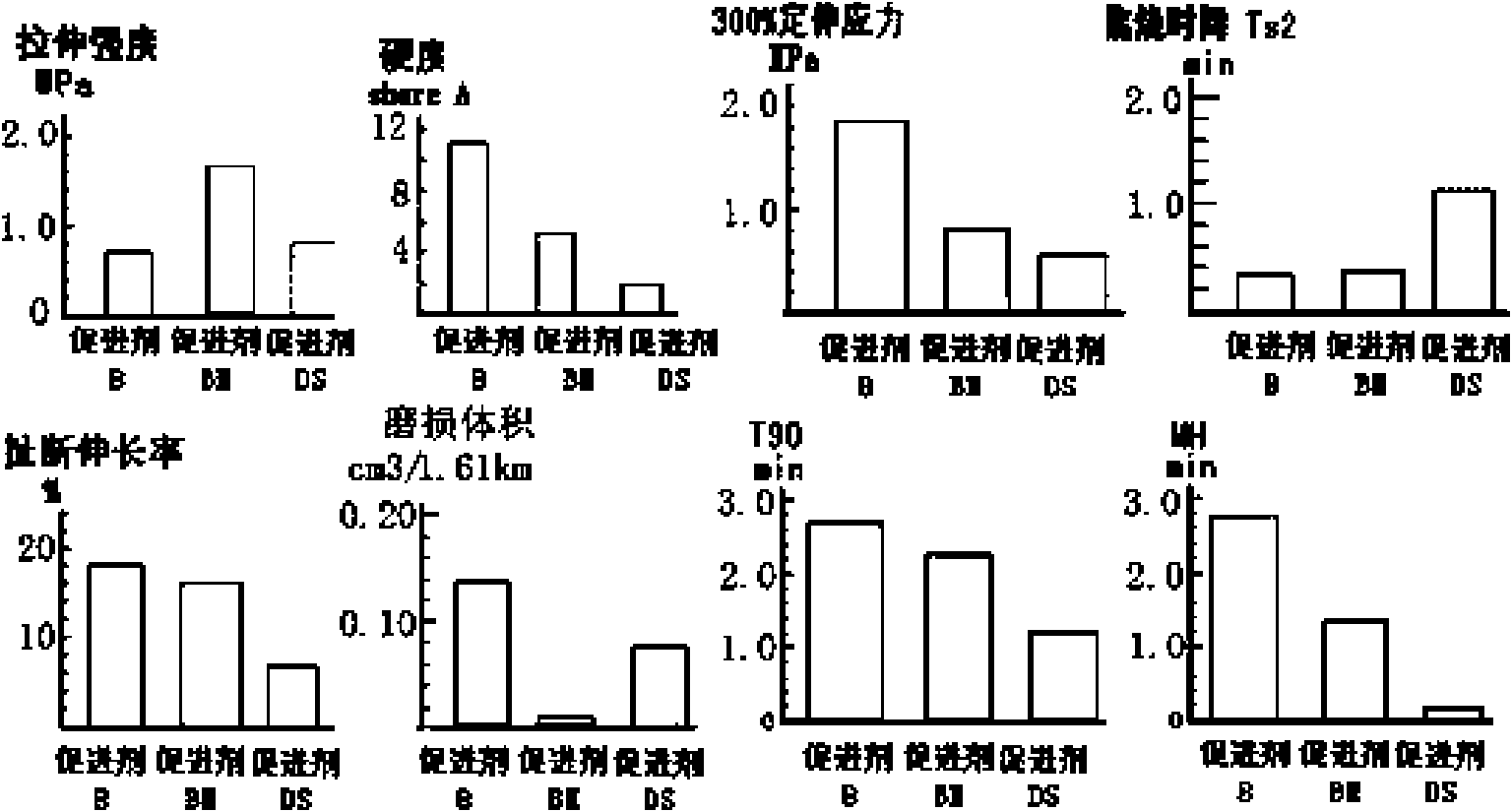

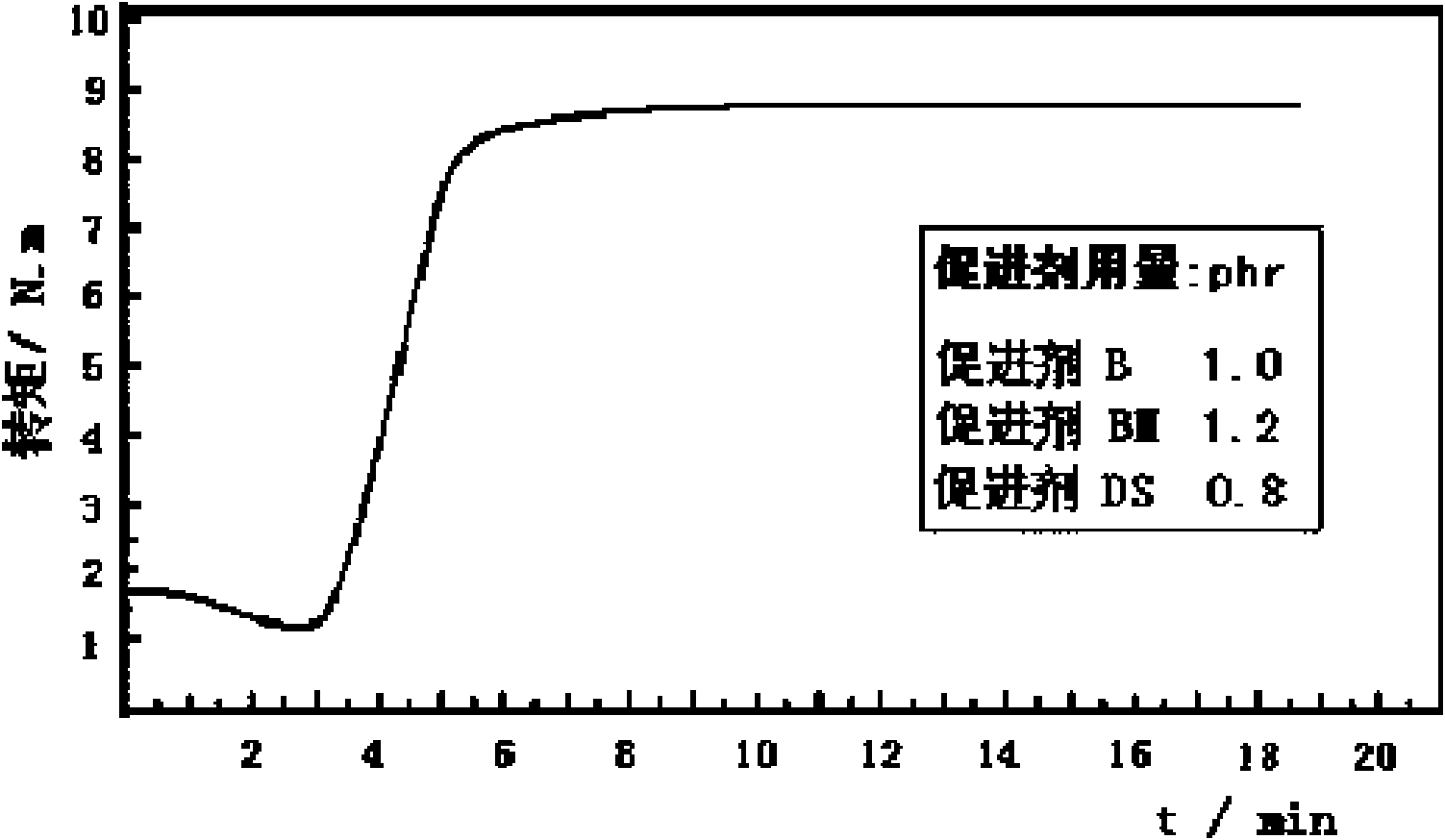

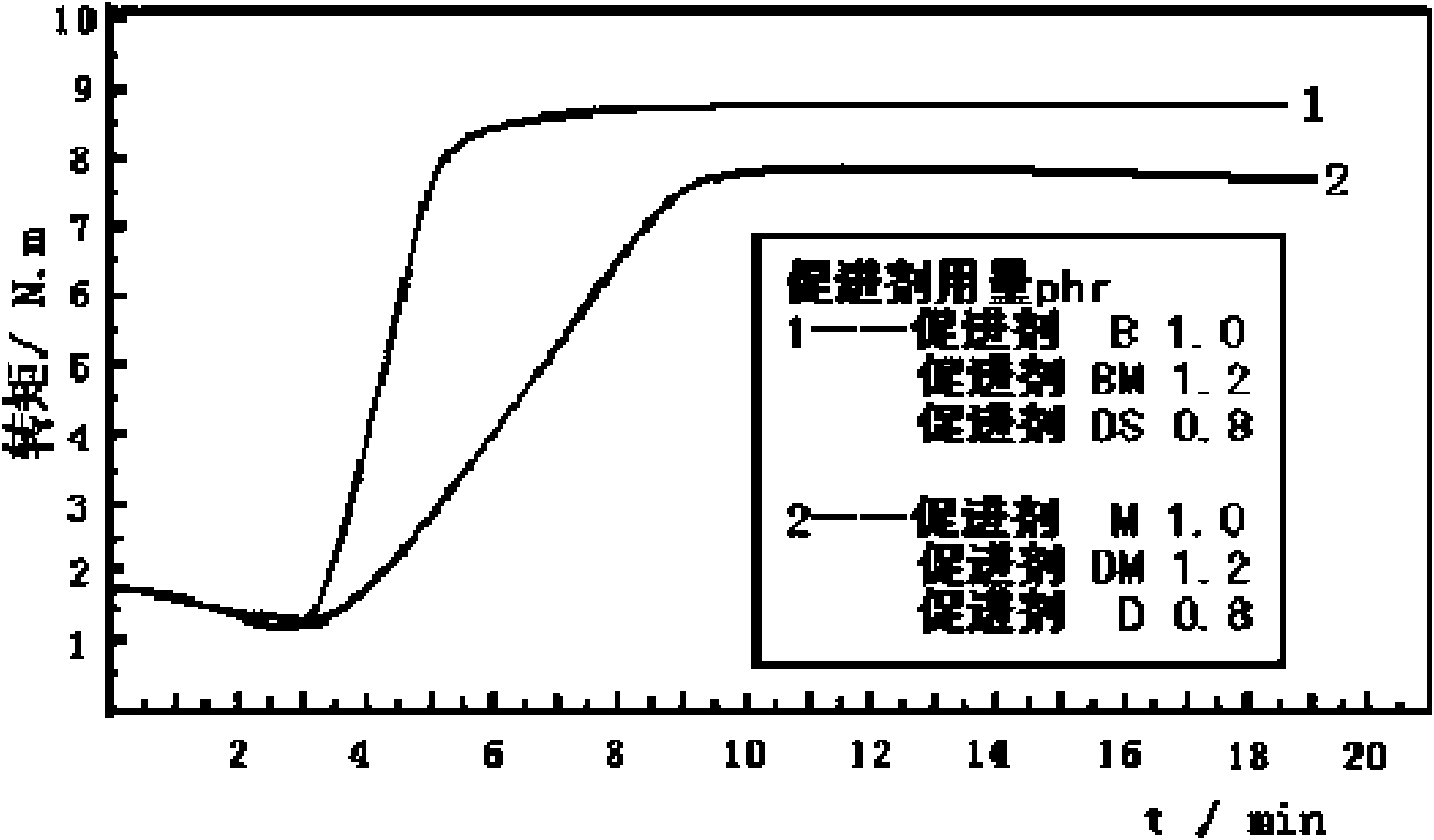

The invention discloses a vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and a preparation method and a vulcanization process thereof. The vulcanized rubber isprepared from natural rubber, styrene-butadiene rubber, butadiene rubber, accelerator B, accelerator BM, accelerator DS, nanometer zinc oxide, rubber softening oil, sulphur, stearic acid, aging resister CD, carbon black N330, pine tar oil, solid coumarone, reclaimed rubber and pot clay. Compared with the prior art, the vulcanized rubber of the invention has suitable starting time of vulcanization,faster velocity of vulcanization and higher thermal oxidative aging property, the vulcanization efficiency is increased, and the heat-conducting property, processing safety and storage property of the rubber are increased in the vulcanization process; the provided vulcanization process can effectively shorten the vulcanization time, improve the vulcanization quality and increase the vulcanizationefficiency to 2-3 times of the original one.

Owner:JIHUA 3537 SHOE MAKING

Green preparation technology and special vulcanization mold for V belt of washing machine

Owner:河北佰特橡胶有限公司

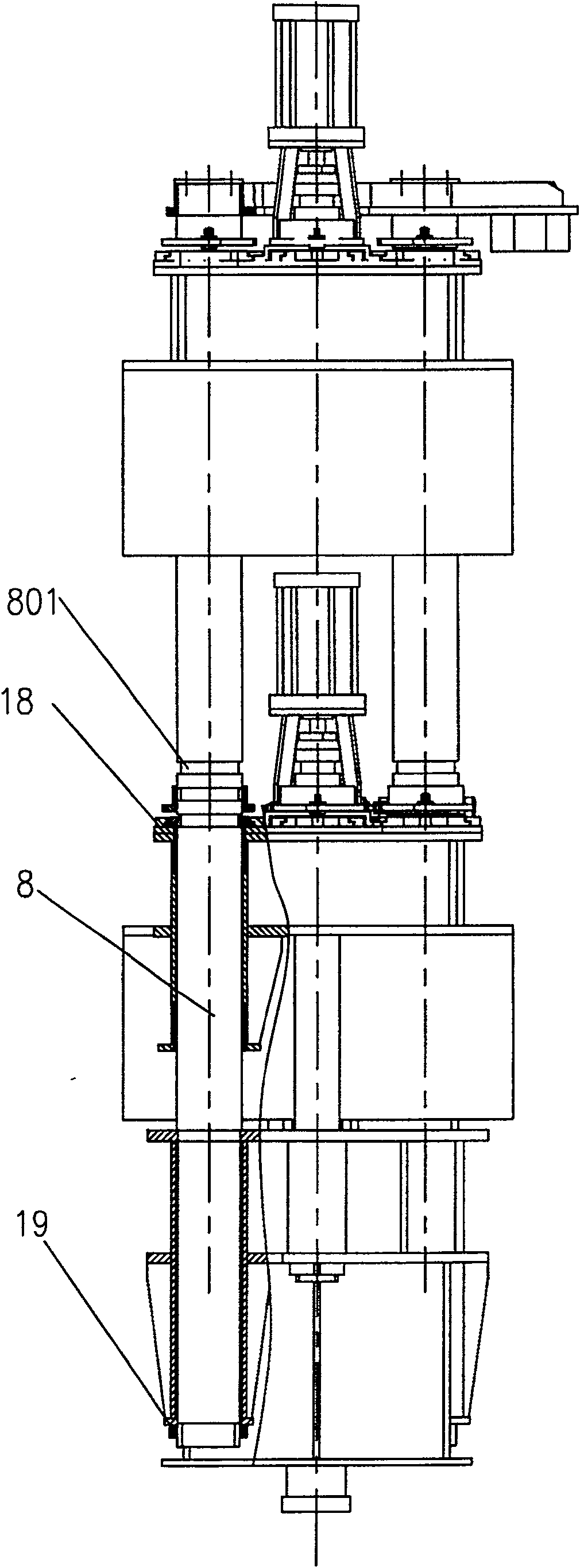

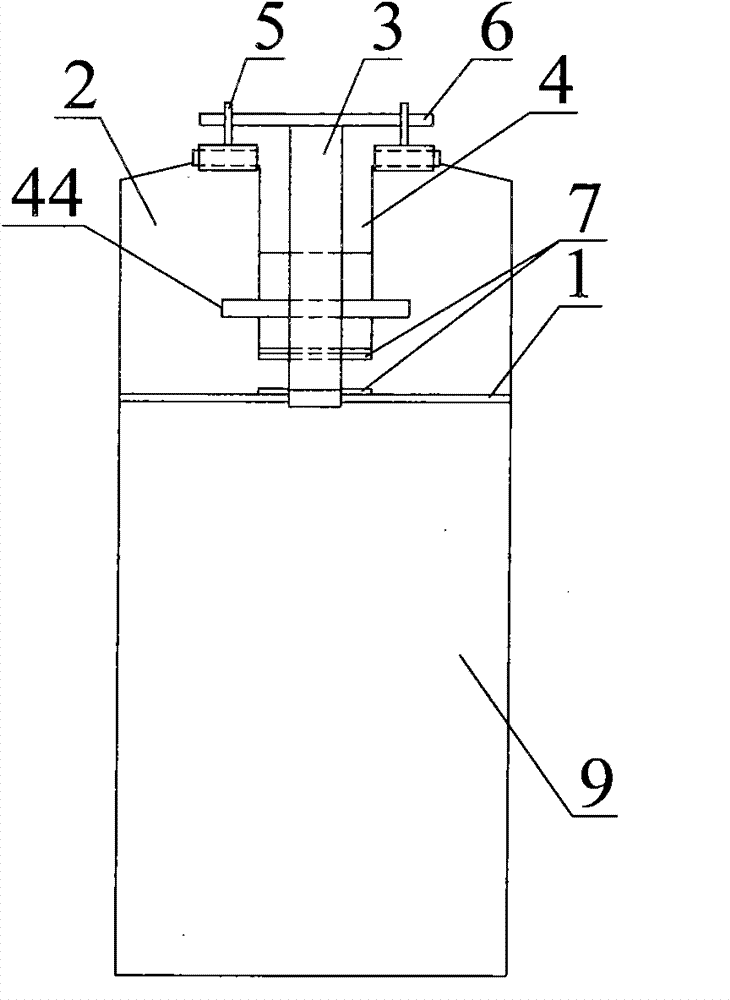

Locking ring pole type hydraulic tyre vulcanizing machine pressurize from inside

A hydraulic sulfurizing machine for tyre is composed of one or two barrel bodies consisting of upper and lower barrel bodies for closing the mould, base, top supporting plate, 4 or 5 or 8 vertical columns between said top supporting plate and base, multiple pressing cylinders fixed to the base plate of lower barrel bodies, transverse lift beam linking with said vertical column in sleeve joint mode, and two lift cylinders arranged at both ends of said transverse lift beam.

Owner:福建天华智能装备有限公司

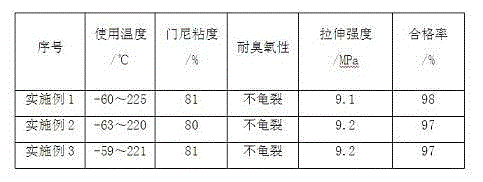

Production technology for chloroprene rubber

Relating to the rubber field, the invention discloses a production technology for chloroprene rubber. The technology comprises the processes of: rubber drying, plastication, mixing, semi-finished product cutting and vulcanization. According to the method, by strictly controlling the rubber drying temperature and time in the rubber drying process, the quality of the dried rubber material is improved. The mixing process adopts a two-stage mixing process, well controls the mixing time and discharge temperature, so that scorching phenomenon of chloroprene rubber is significantly reduced, and the rubber guiding, discharge and batch-out of an open mill are smooth, and no roll sticking phenomenon appears. The vulcanization process adopts N-tert-butyl-2-bisbenzothiazole sulfenamide as a vulcanization accelerator, which is safe and pollution-free and has no harm to the human body. The technological process adopts a drum type vulcanizing machine, the vulcanization efficiency and quality are greatly improved, and the produced product has high Mooney viscosity and good quality. The technological method has the advantages of good technology, simple operation, and good technological stability, thus being suitable for factory automation production.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

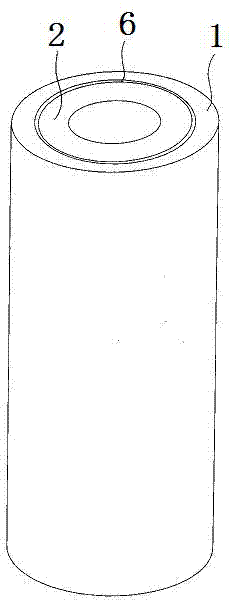

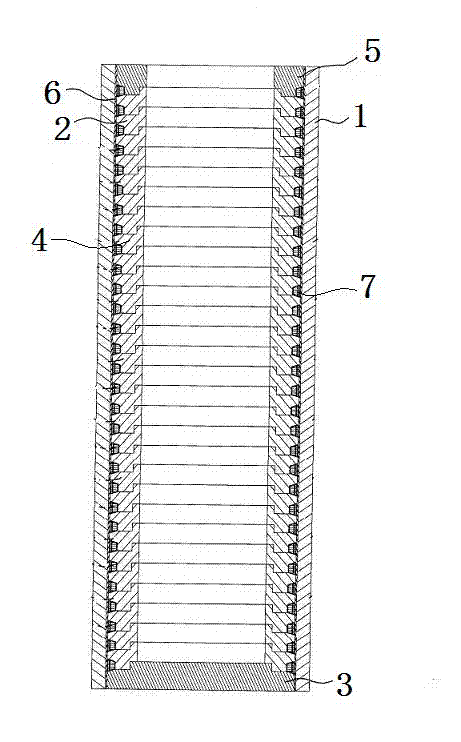

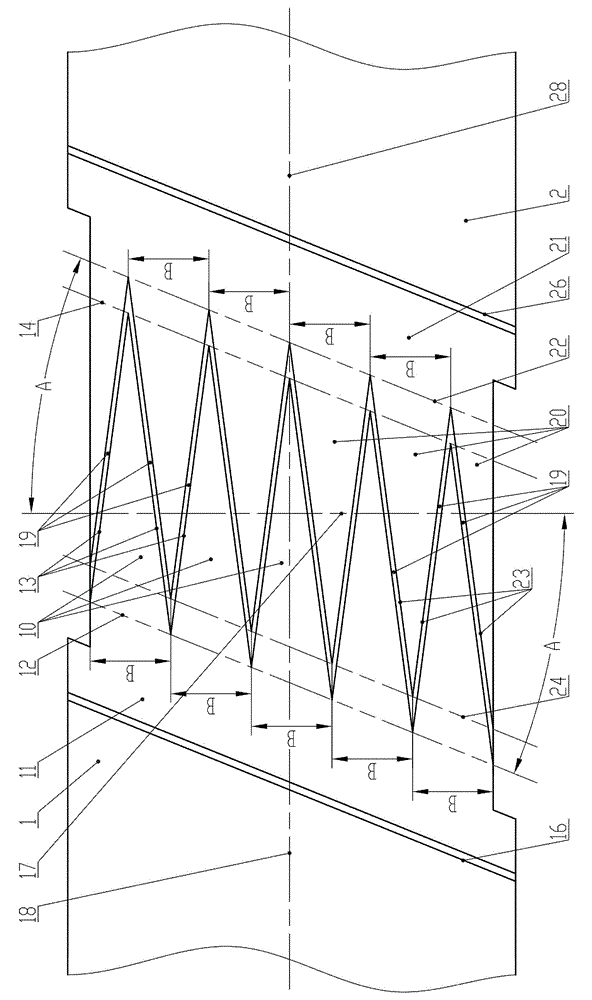

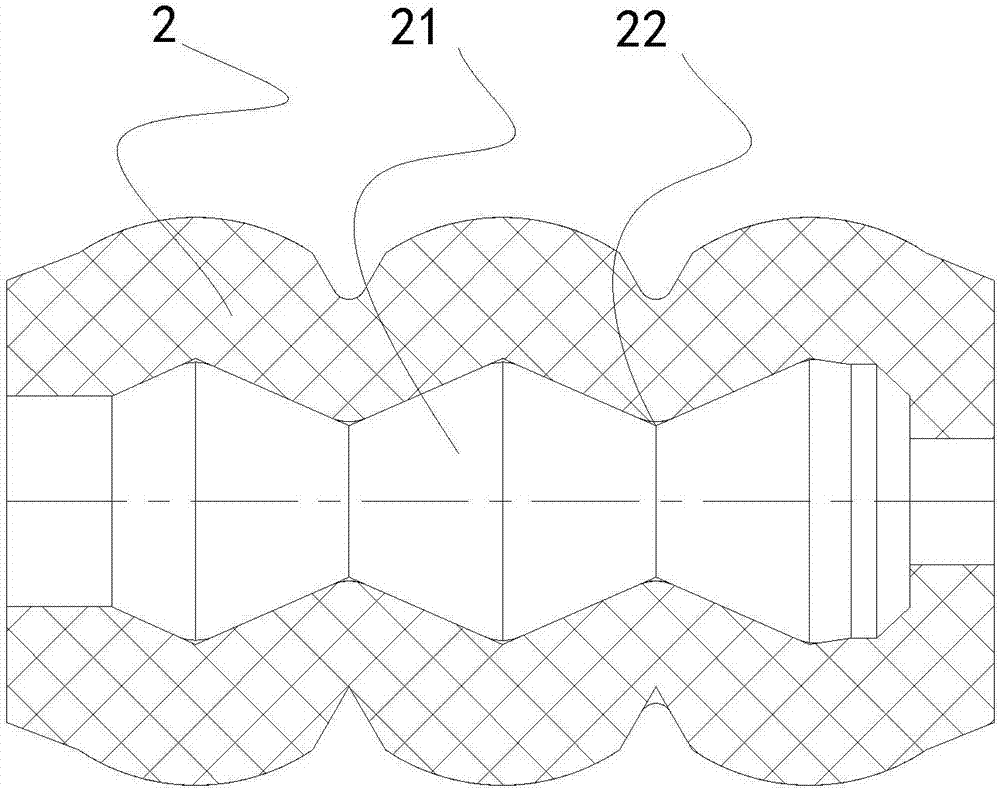

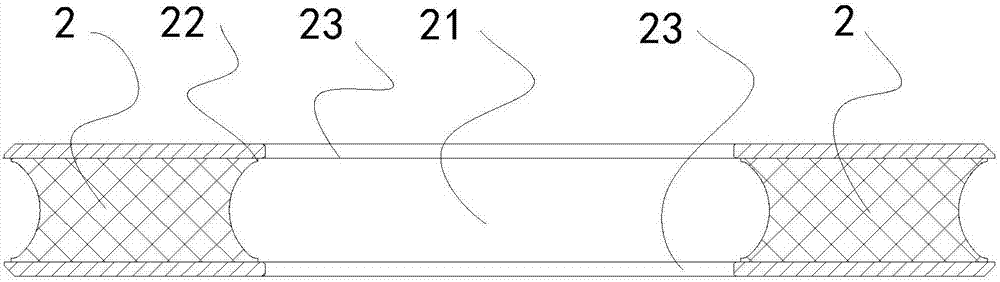

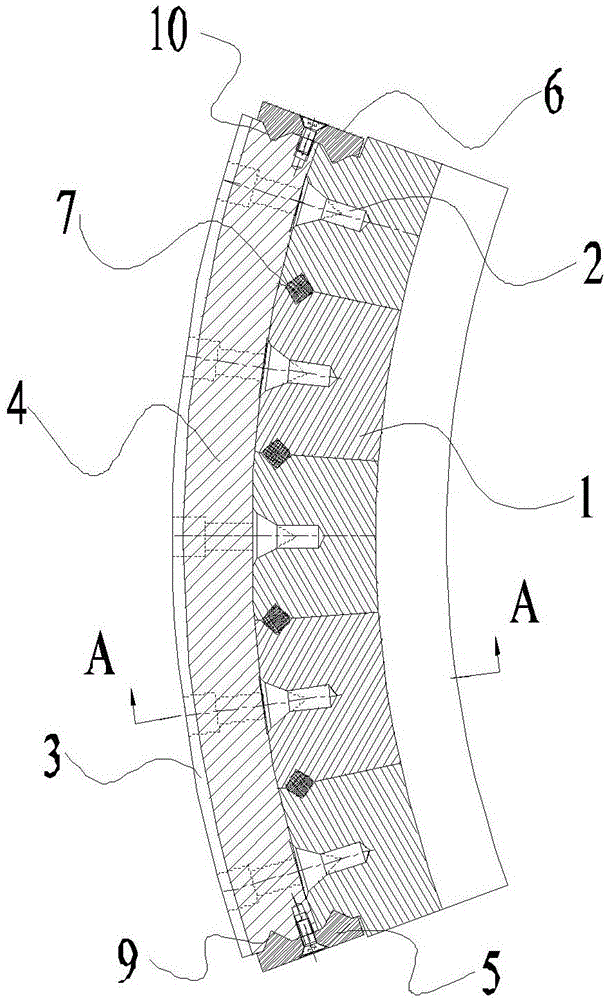

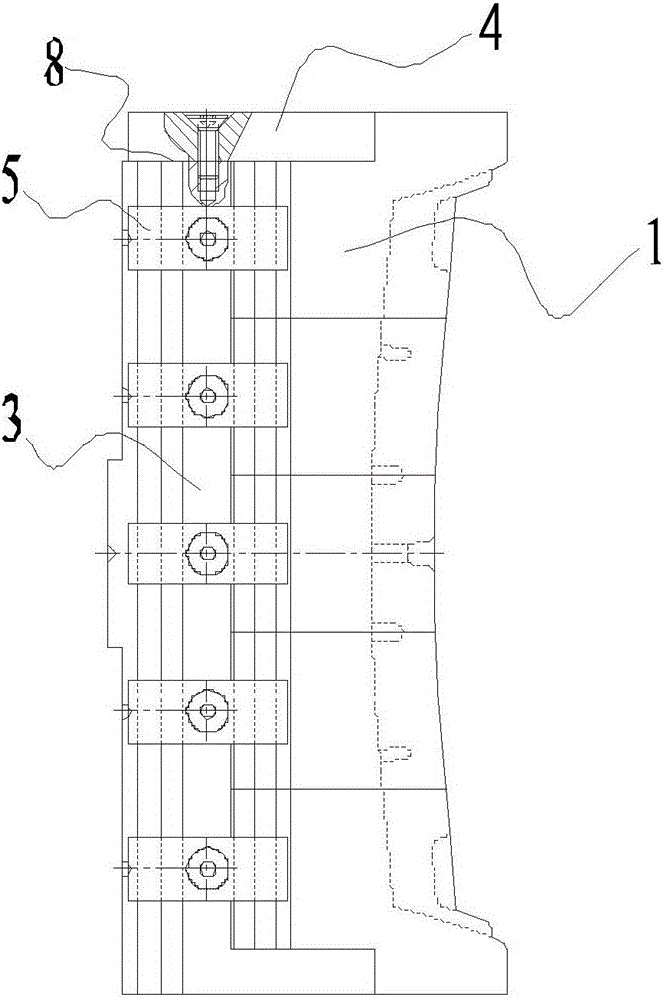

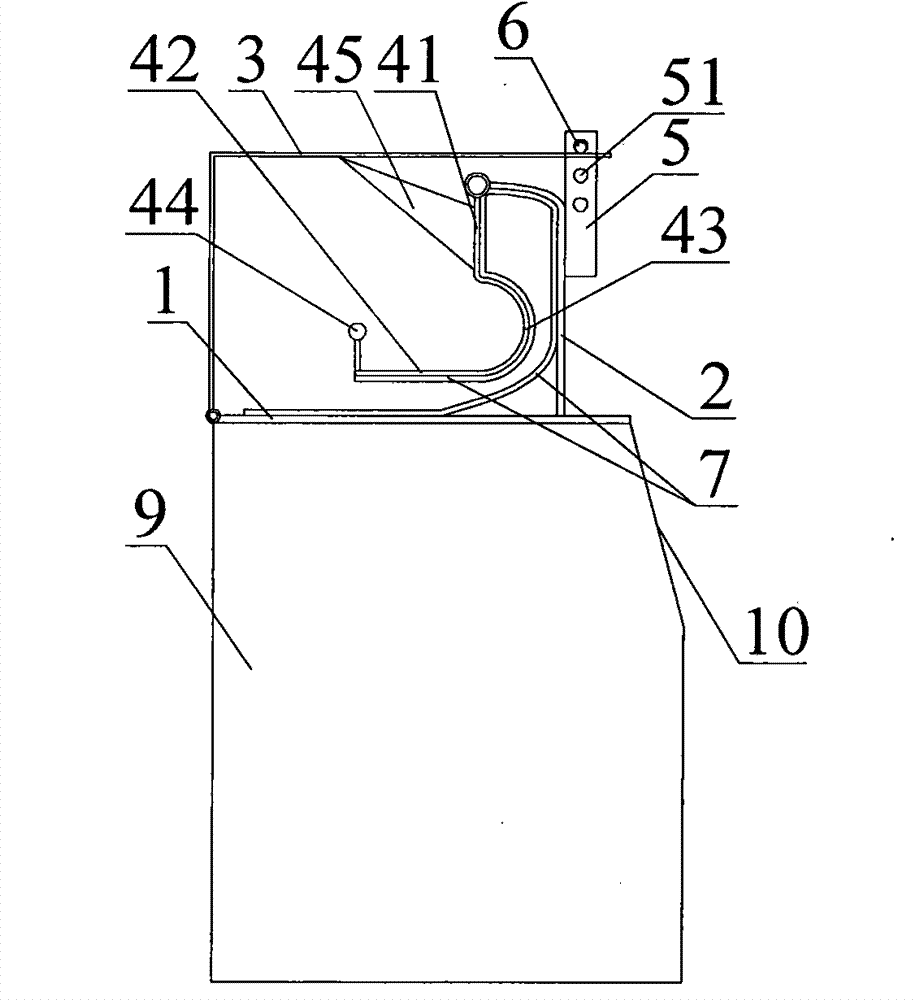

Green preparation technology and special vulcanization mold for V belt of washing machine

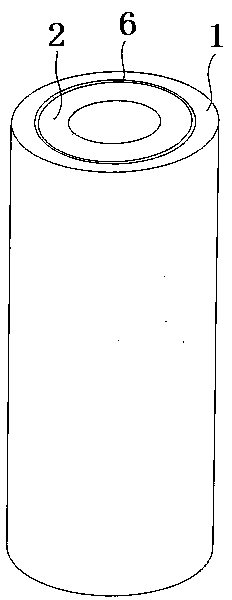

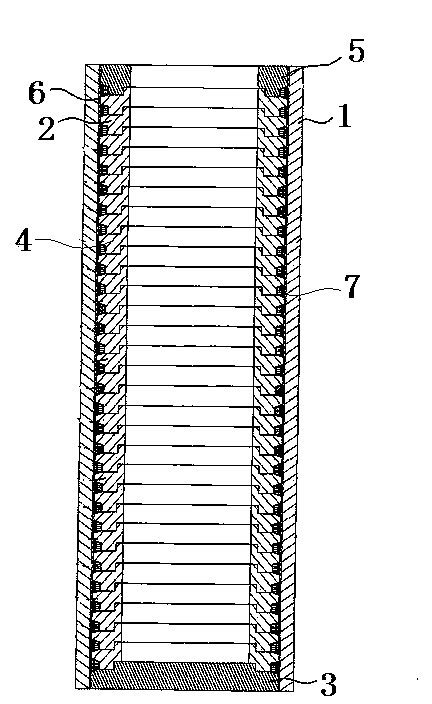

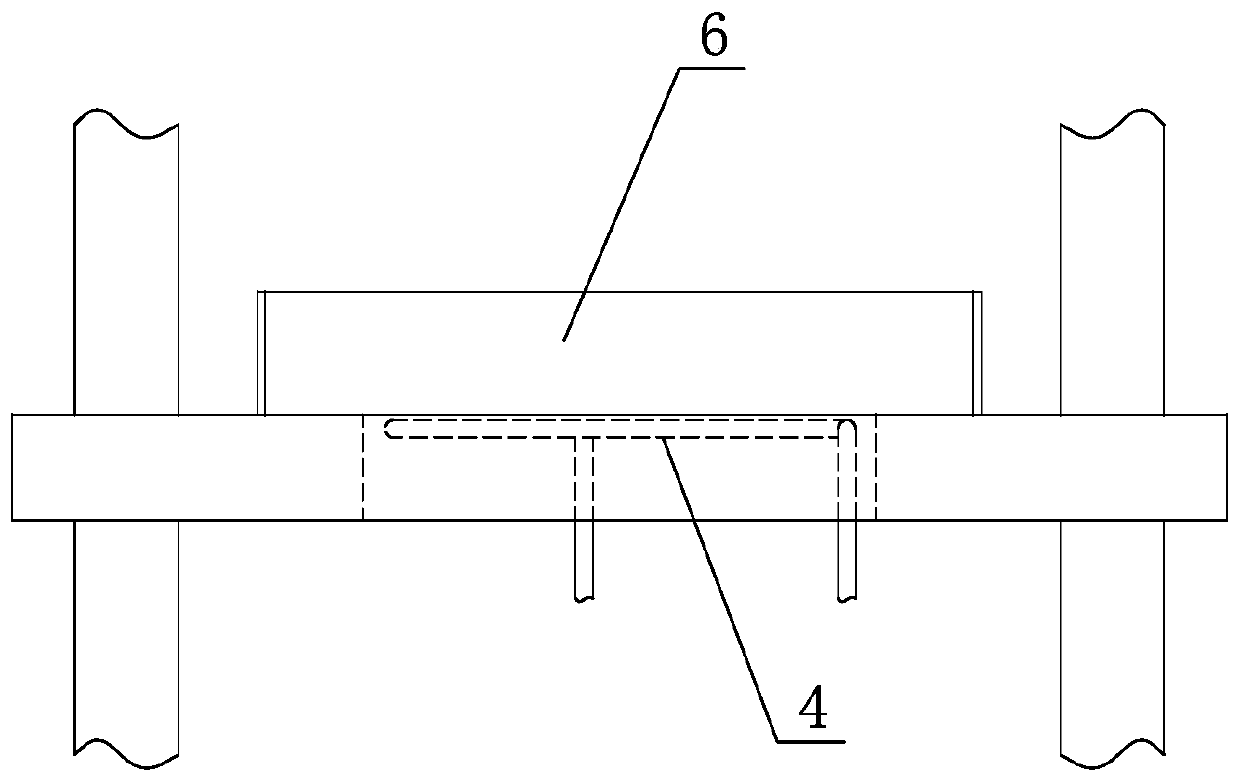

The invention belongs to the technical field of preparation technology and vulcanization mold for a V belt of a washing machine and discloses a green preparation technology and a special vulcanization mold for the V belt of the washing machine. The vulcanization mold is mainly and technically characterized by comprising an outer sealed rubber jacket, a bottom mold, inner mold units and a gland, wherein the bottom mold, the inner mold units and the gland form a cylindrical inner mold assembly and an isolation fabric layer is arranged between the inner mold assembly and the outer sealed rubber jacket. In vulcanization, due to the isolation fabric layer arranged between the inner mold assembly and the outer sealed rubber jacket, the defects such as environmental pollution, cooled water chemical pollution, personal injuries and low production efficiency caused by the adoption of a mold releasing agent are avoided, the skidding phenomenon of the V belt in early use is avoided, the quality of the V belt of the washing machine is improved and the service life of the outer sealed rubber jacket is prolonged greatly.

Owner:河北佰特橡胶有限公司

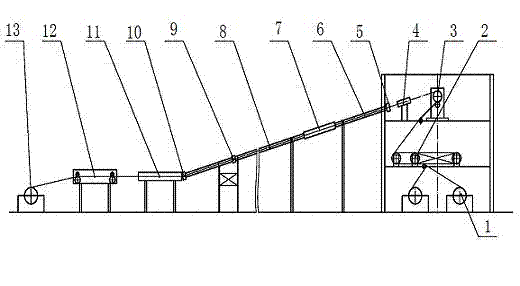

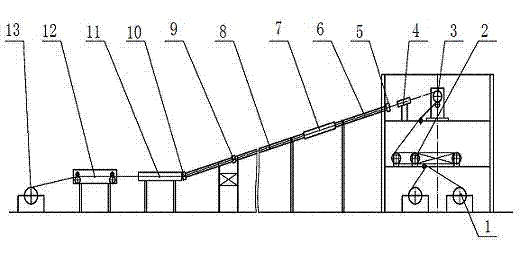

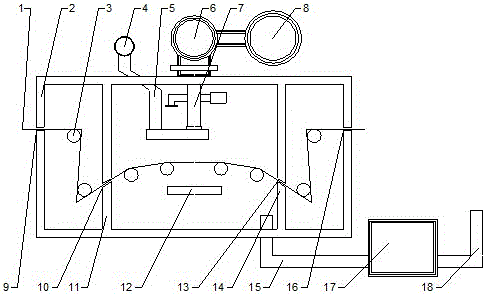

Continuous microwave curing production line for rubber cables

The invention discloses a continuous microwave curing production line for rubber cables, which comprises a drive paying out machine, a horizontal storage hub, an upper tractor, a co-extrusion die, an automatic upper sealer, a high-temperature setting device, a microwave curing section, a hot-air curing section, a midpoint controller, an automatic lower sealer, a cooling section, a tractor and a cable machine which are sequentially connected. The continuous microwave curing production line provided by the invention not only has a rational design and a unique structure, but also has no pollution with big social benefit, and saves energy since the plastic generates heat directly by absorbing the microwaves without being heated by using equipment, thus the continuous microwave curing production line has the advantages of high energy use ratio, fast temperature rise, short desulfuration time, capability of continuous automatic production, reduced labor load of workers, improved production environment, good product property, and allowed dosage of permeability which is 15% larger than that of the conventional method.

Owner:大连云山机械有限公司

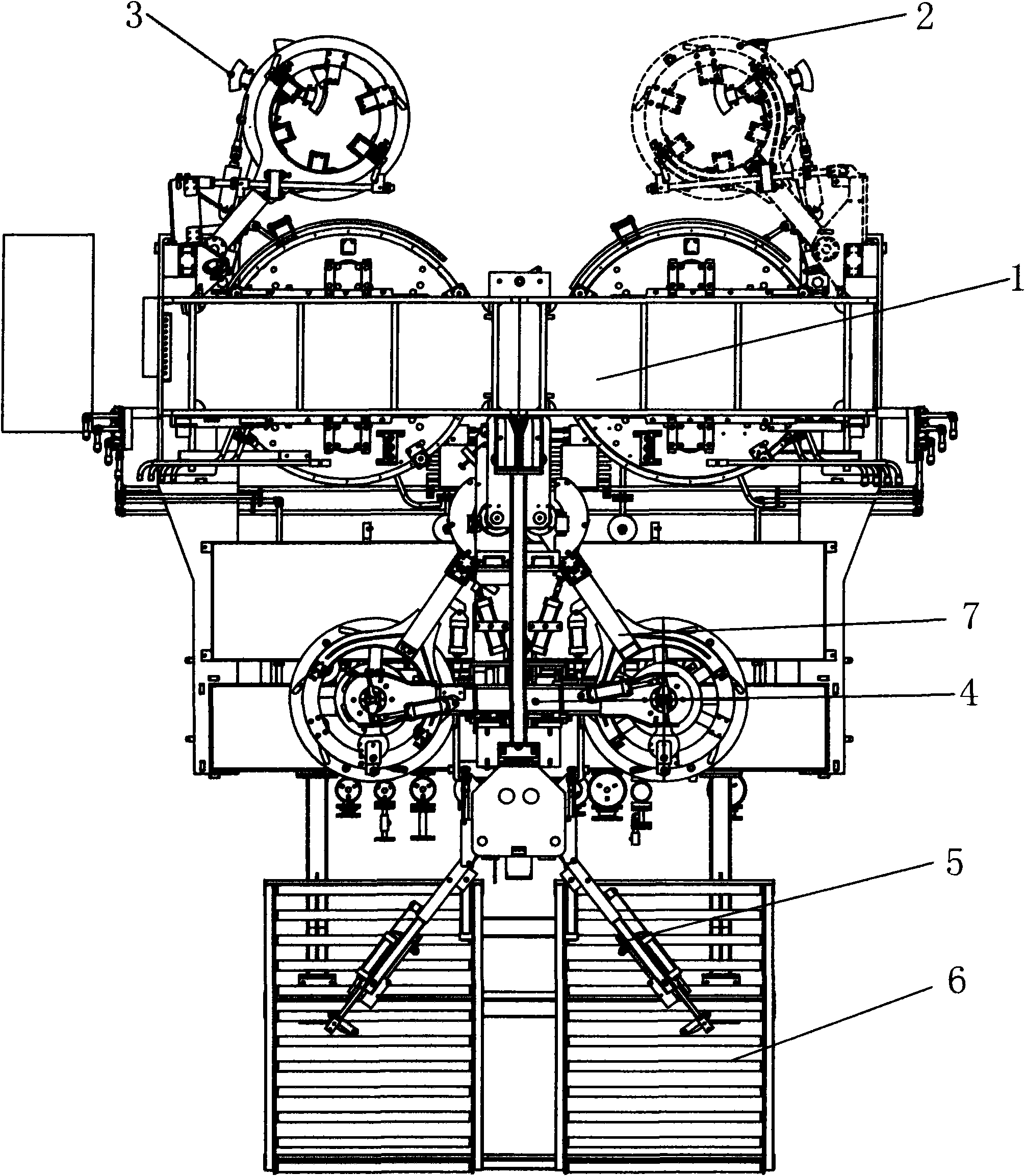

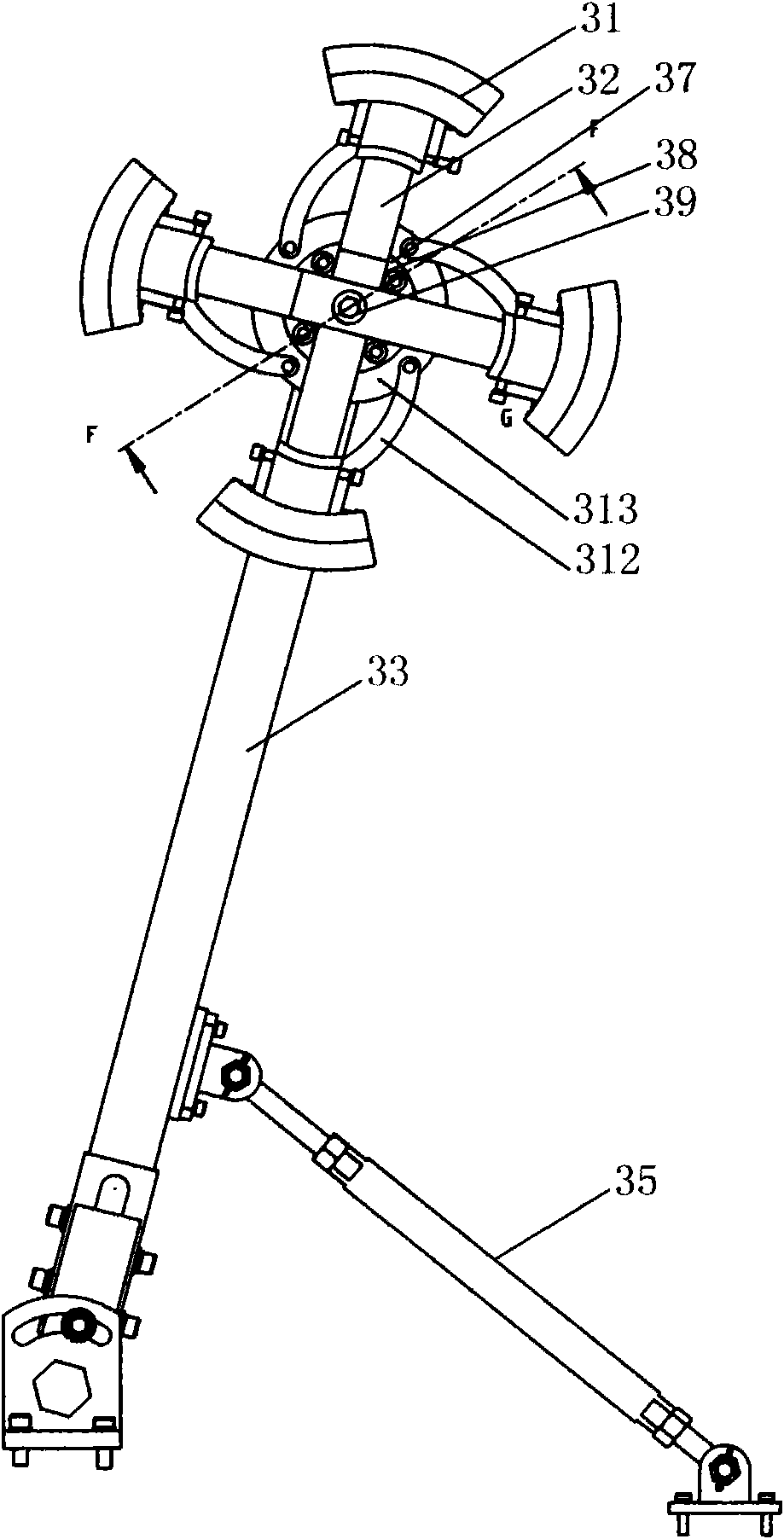

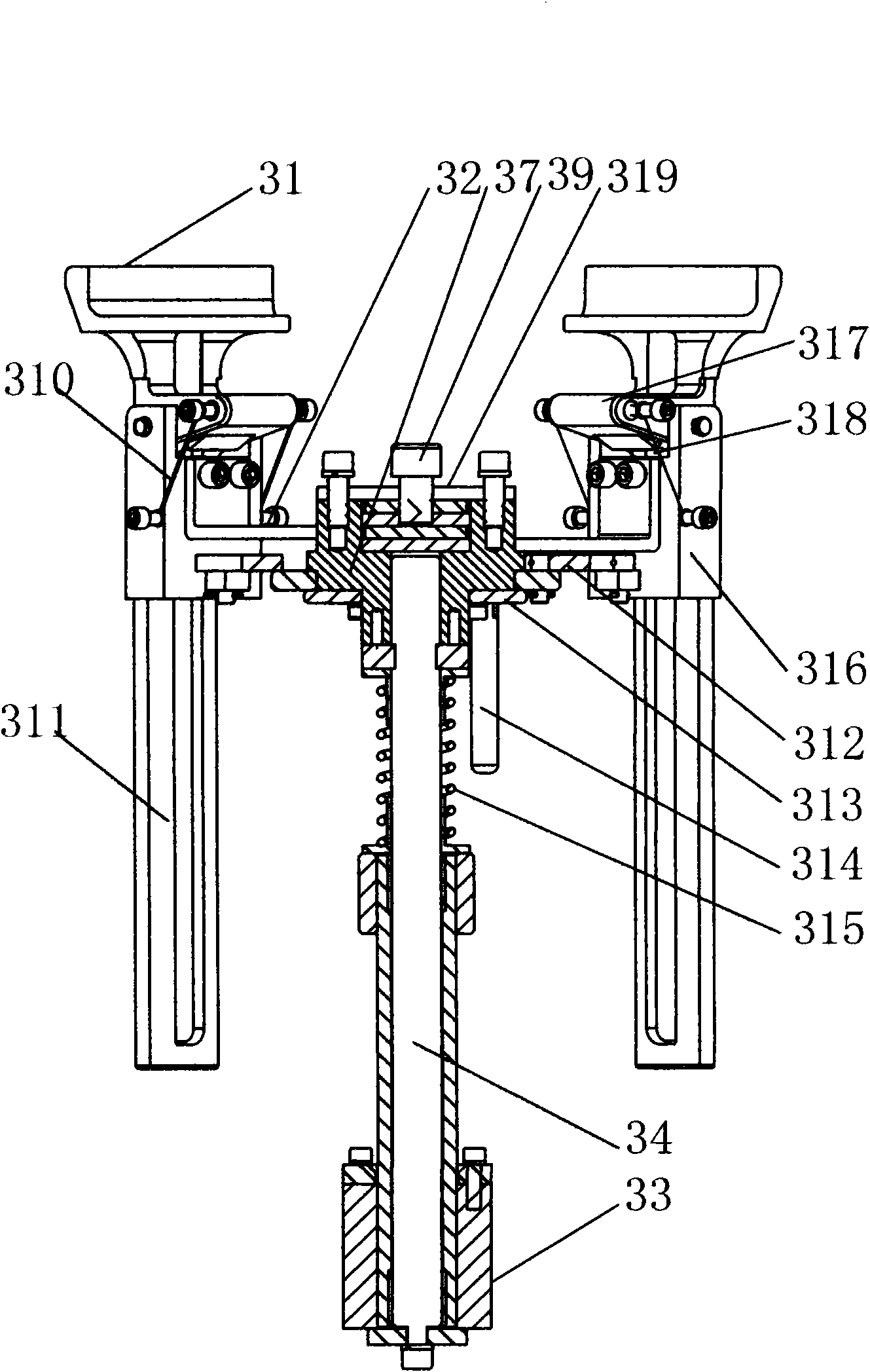

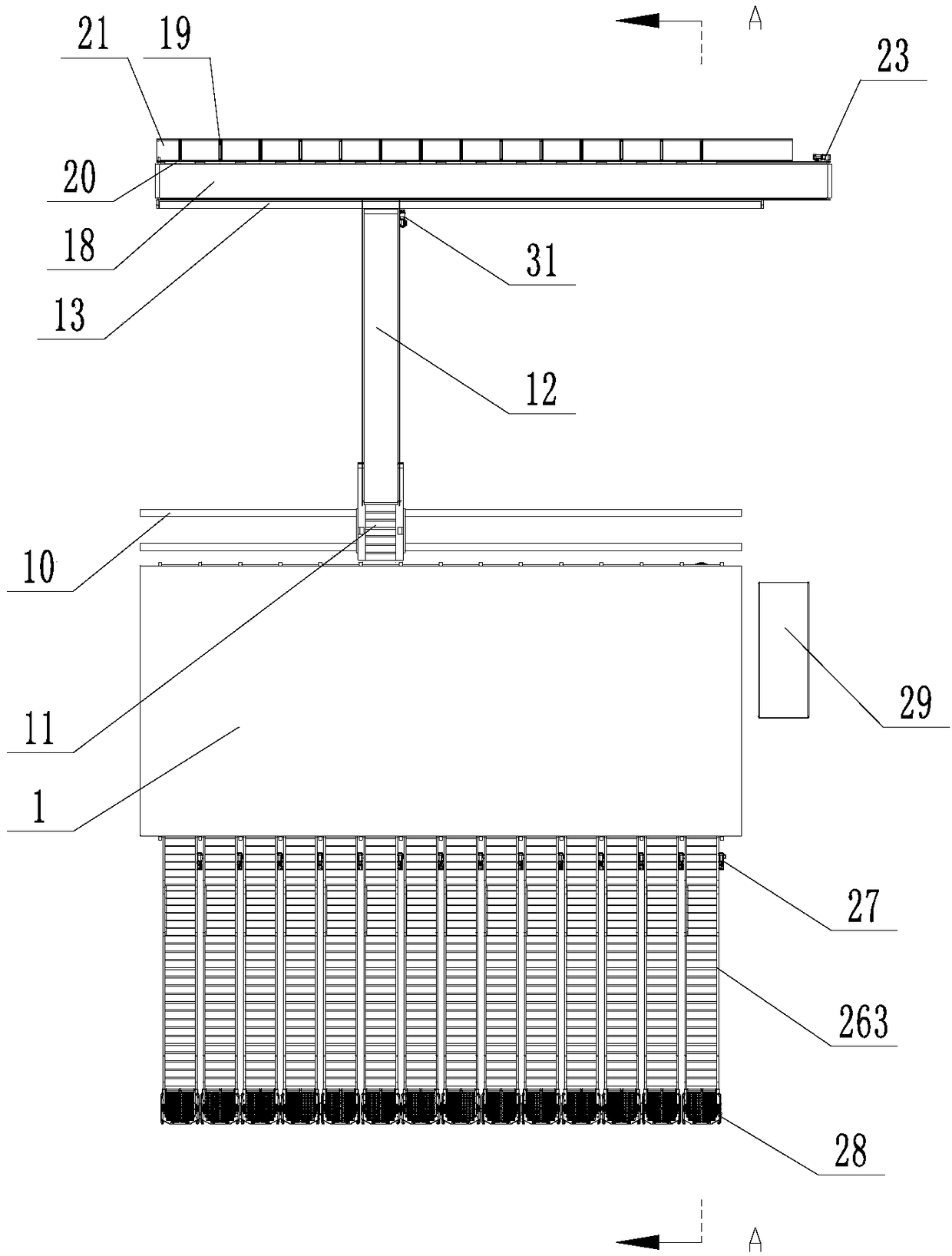

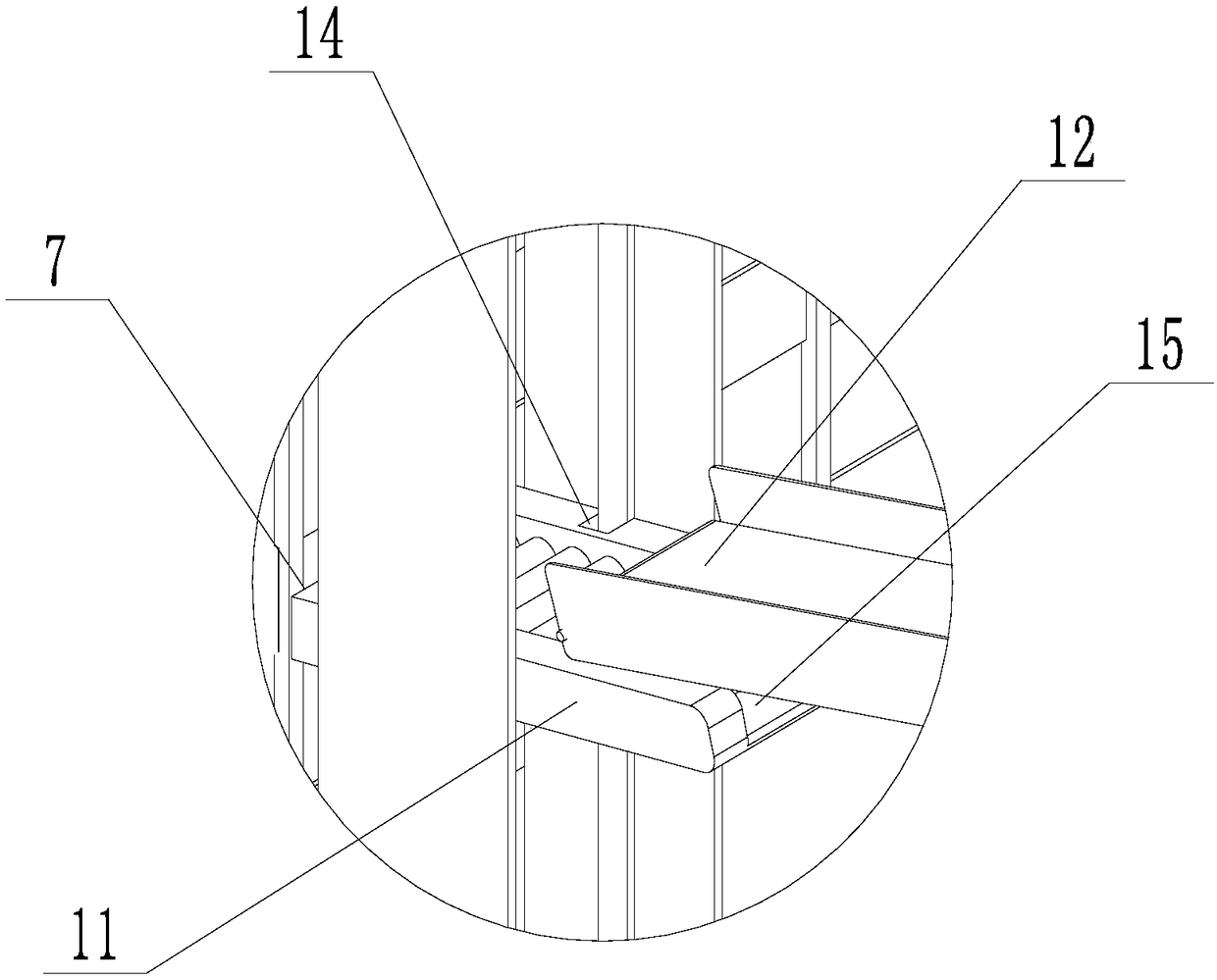

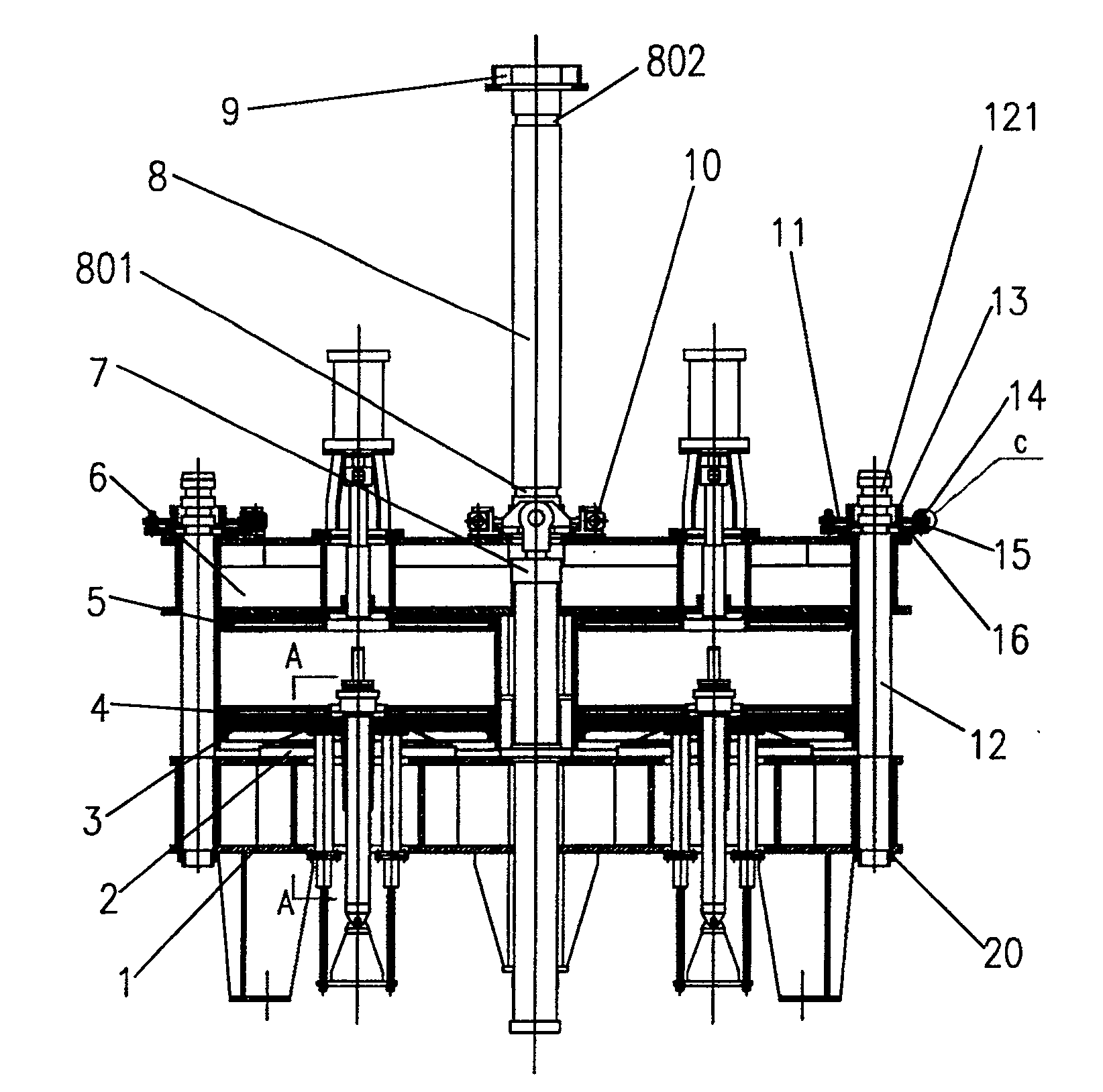

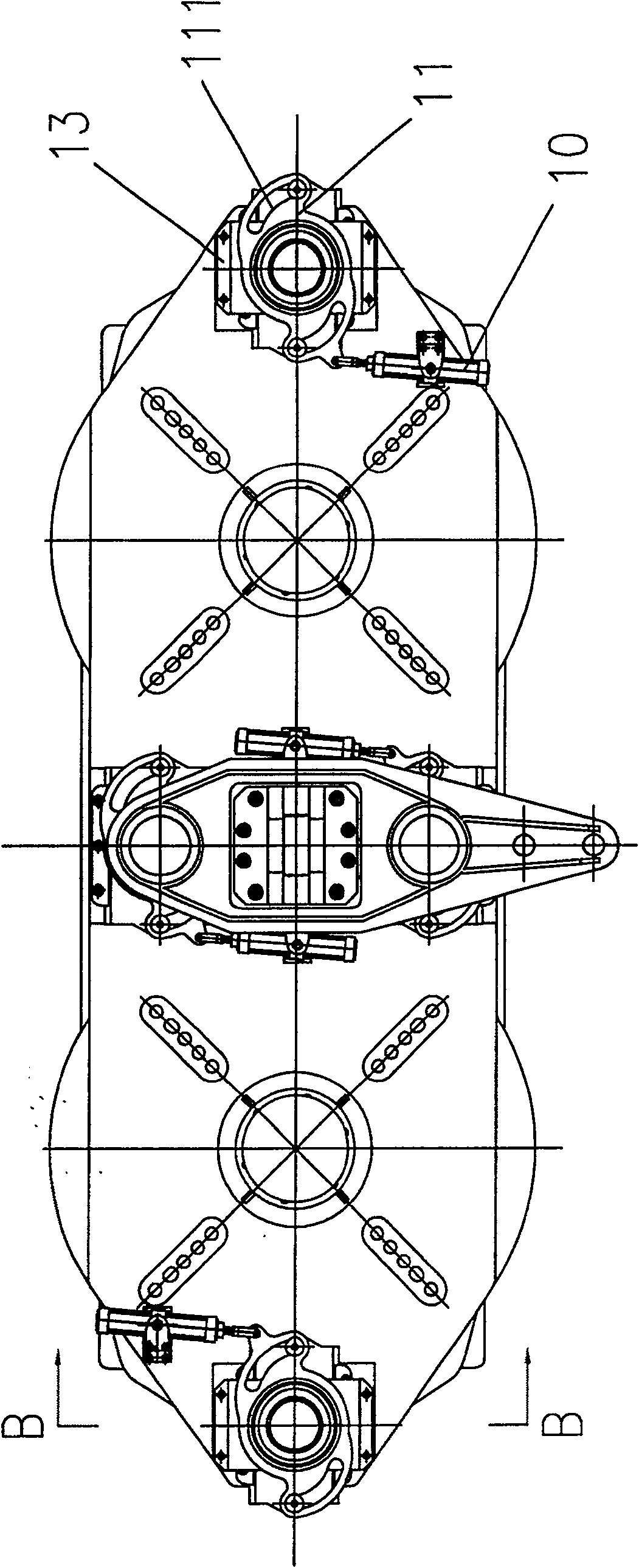

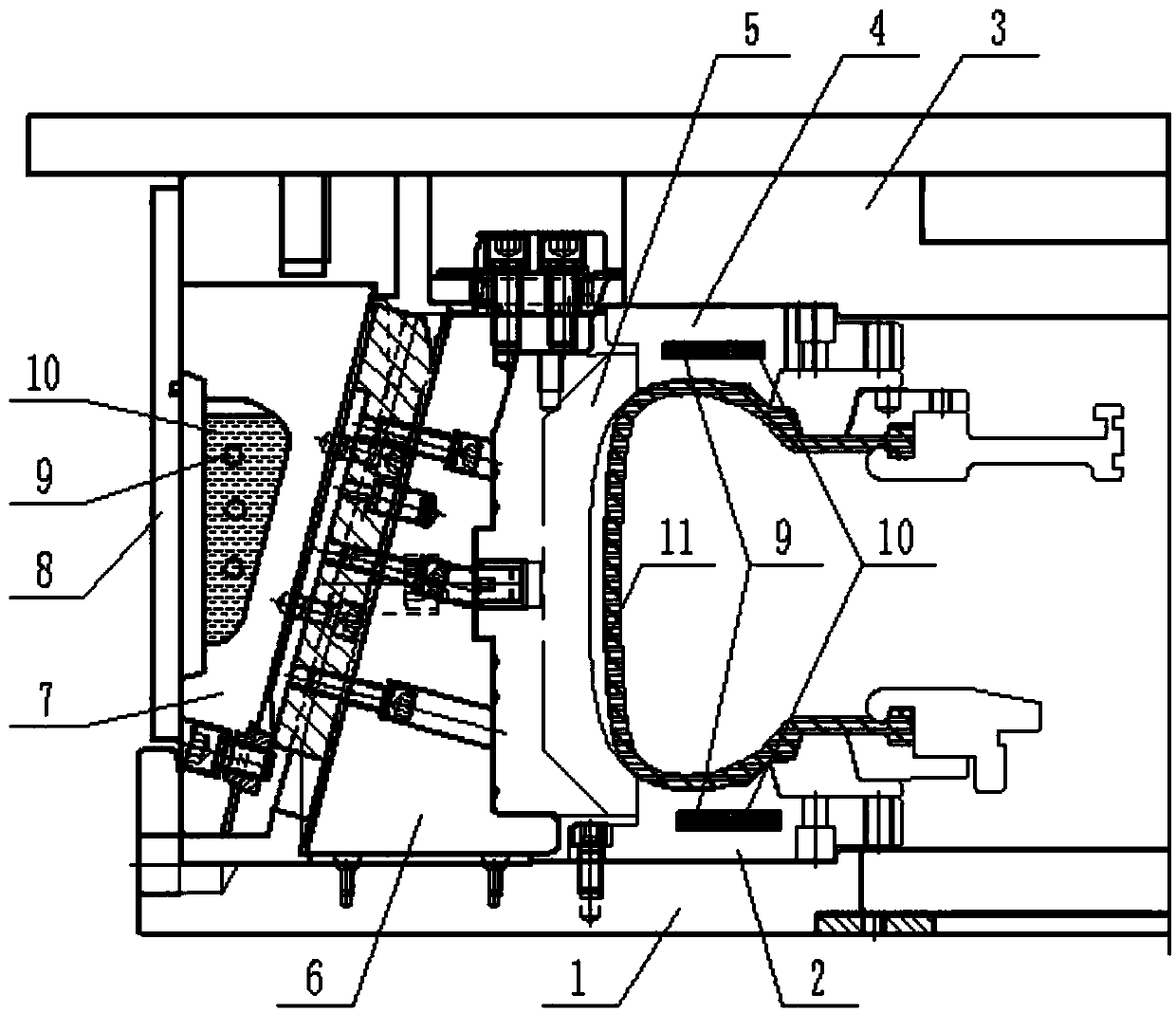

High-performance radial tire intelligent vulcanizing machine

ActiveCN102490296AImprove vulcanization efficiencyImprove vulcanization qualityAutomotive engineeringManipulator

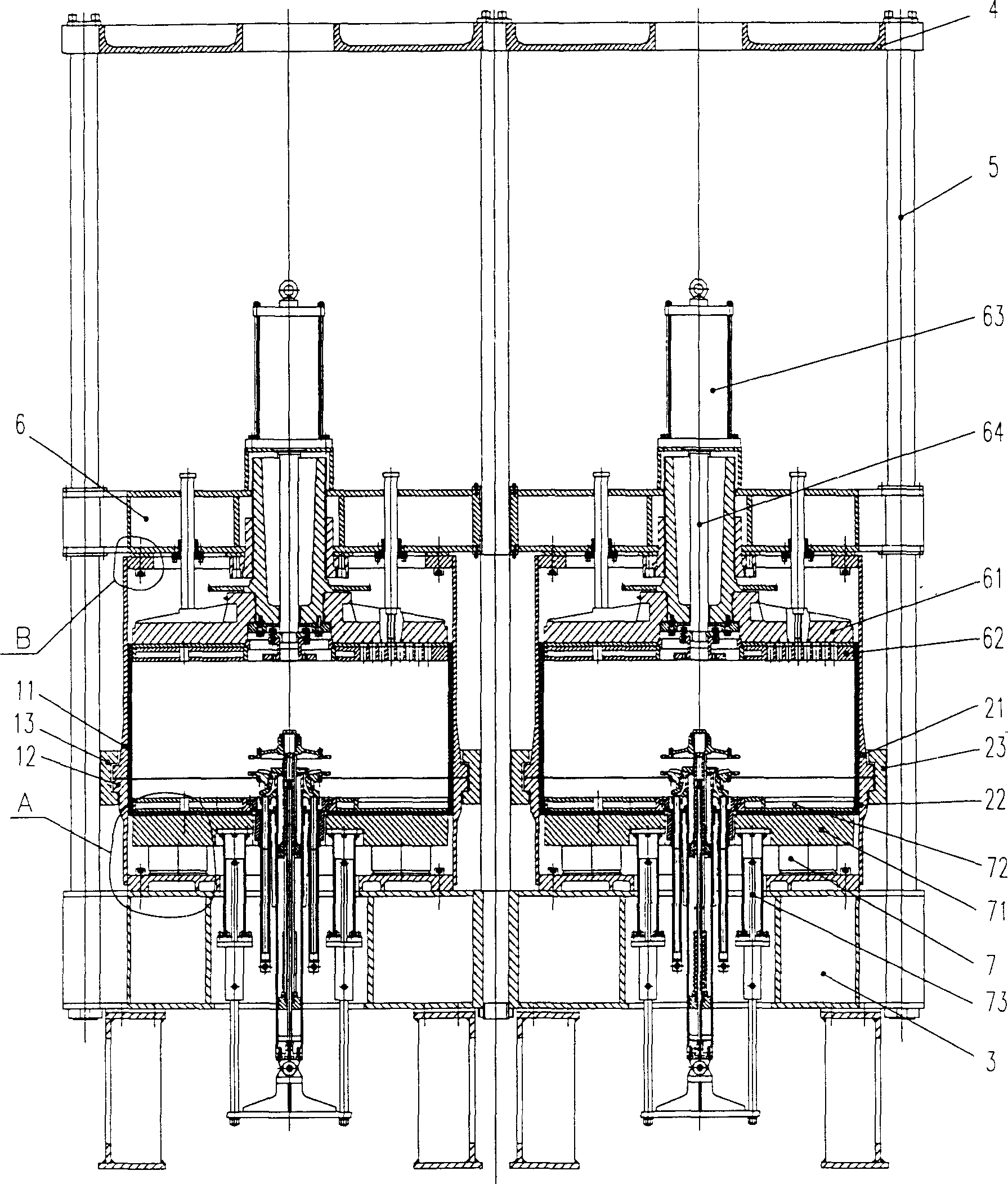

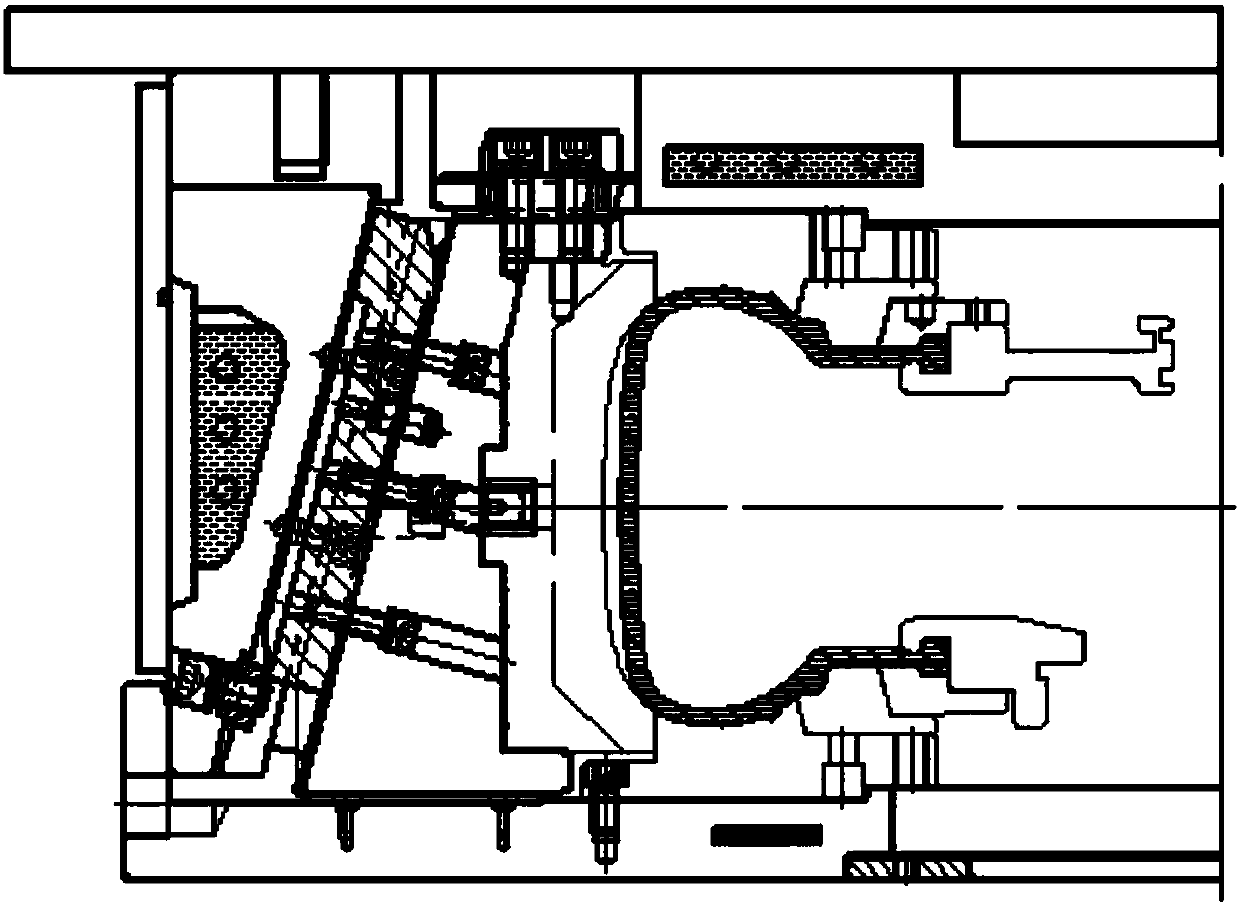

The invention relates to a high-performance radial tire intelligent vulcanizing machine. The machine comprises a frame, a tire assembly mechanical arm, a pressurization mechanism, a vulcanizing chamber and a mould opening and closing mechanism, a central mechanism, a segmented mold drive device, an intermediate mechanical arm, a two-station four-point type rear inflation device, a tire detachment mechanical arm and a connecting roller way, wherein the frame is of a frame type integrated structure; and a lifting mechanism of the mould opening and closing mechanism adopts roller locking guidance, and a tire storage mechanism is arranged at the front end of the frame. The high-performance radial tire intelligent vulcanizing machine is of the frame type integrated structure, and a cylindrical insulator can be used for realizing pressure transfer, hydraulic and pneumatic pressure transmission and electrical signal control, so that the high automatic dual-mould vulcanizing machine integrated with machine, electricity, hydraulic pressure and pneumatic pressure can be realized. Steam and nitrogen are adopted as vulcanizing media, so that the vulcanizing efficiency and vulcanizing quality of a tire are greatly improved.

Owner:双星东风轮胎有限公司

Removable gas hole type flat panel vulcanizing machine

The invention relates to a removable gas hole type flat panel vulcanizing machine, and belongs to the technical field of vulcanizing machines. According to the removable gas hole type flat panel vulcanizing machine disclosed by the invention, rubber materials needing vulcanization are placed in a mould, the mould is placed on a flat panel on the lower part of the vulcanizing machine in a vulcanizing window; after a temperature is set, a heating device controls the temperature, and a hydraulic ejection plate is moved upwards by a hydraulic device, flat panels arranged on the upper part and the lower part of the vulcanizing machine are laminated, and subjected to mould closing and hot pressing treatment; after hot pressing treatment, a circulating vibration device starts and sequentially vibrates from left to right; meanwhile, the flat panel arranged on the lower part of the vulcanizing machine descends and does reciprocation through a crawler belt from right to left; after bubbles are removed, the movement stops, the hydraulic ejection plate is moved upwards by the hydraulic device and laminated to a required temperature to complete rubber vulcanization. According to the removable gas hole type flat panel vulcanizing machine disclosed by the invention, bubbles are removed by vibration, so that the quantity of gas holes in the material can be effectively reduced.

Owner:董晓

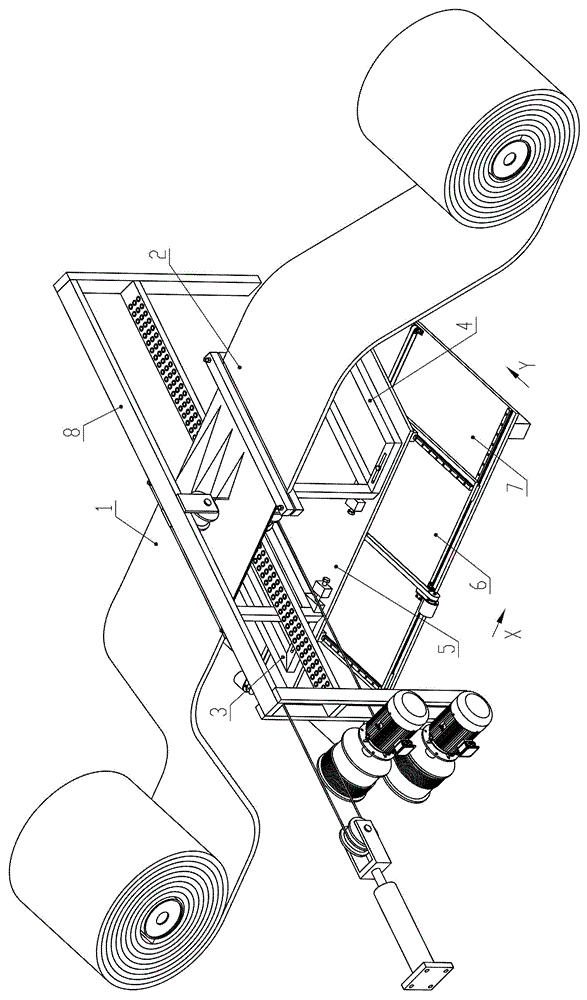

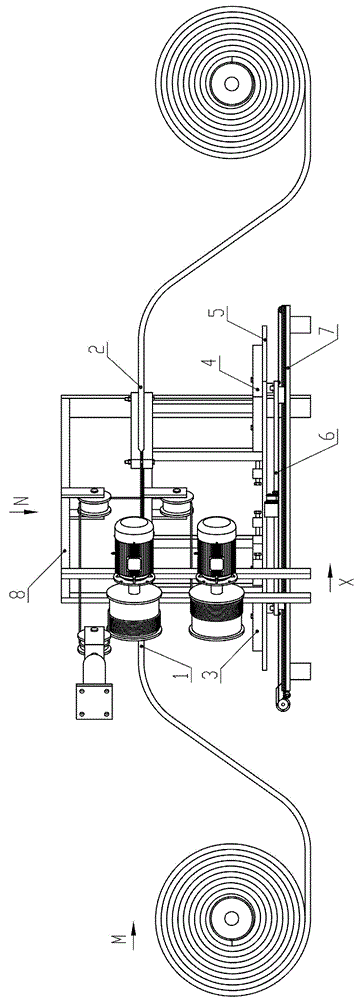

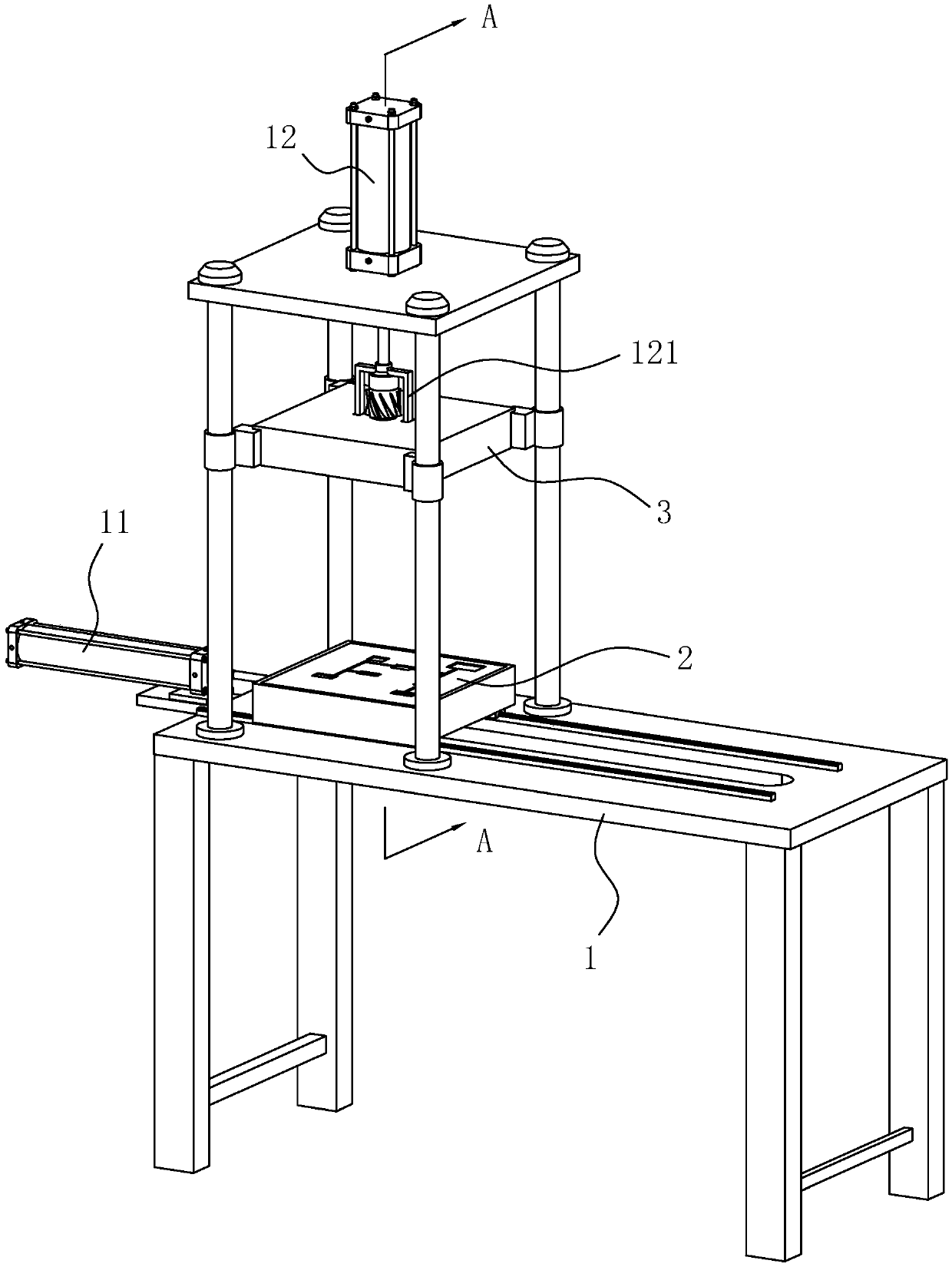

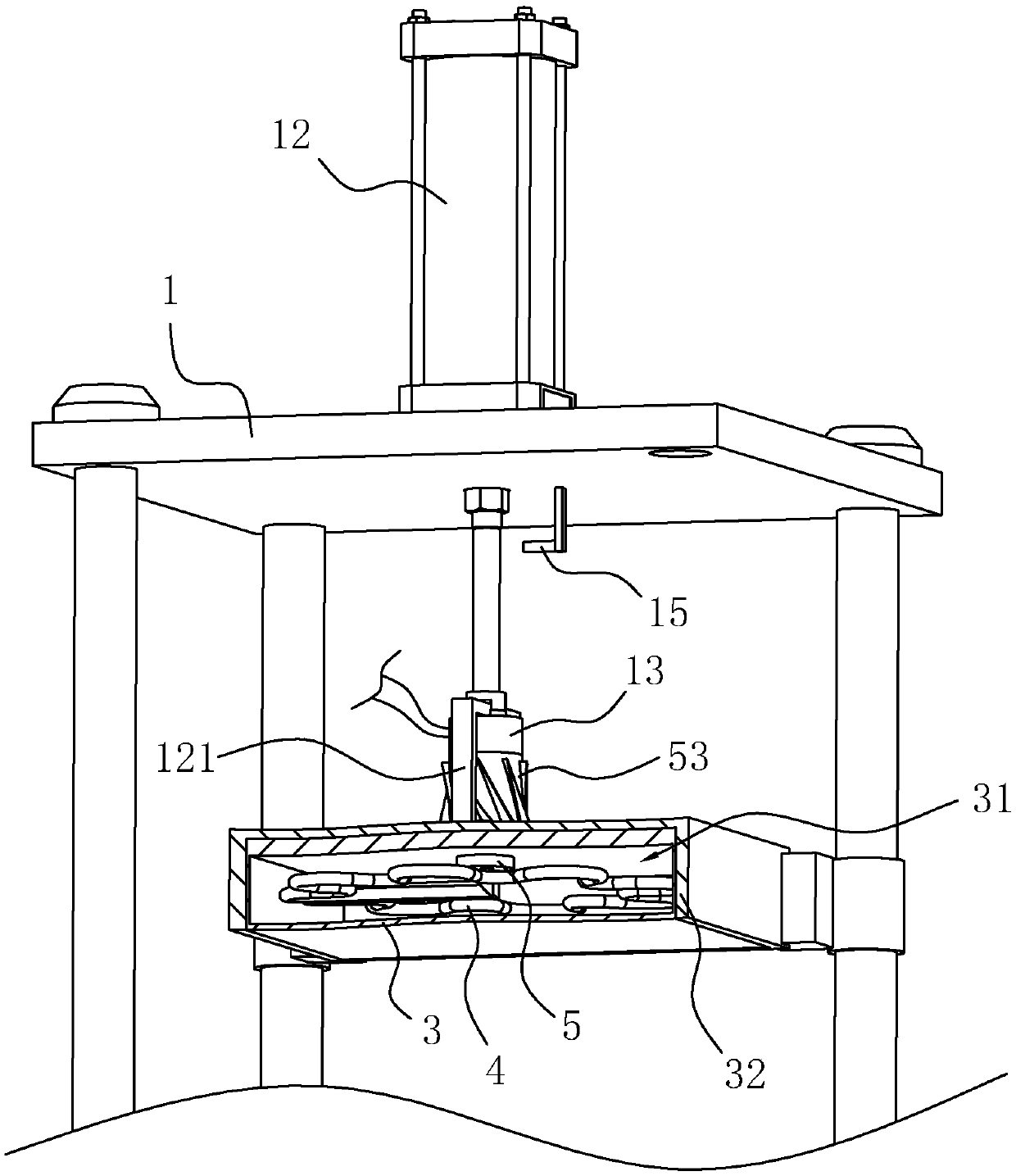

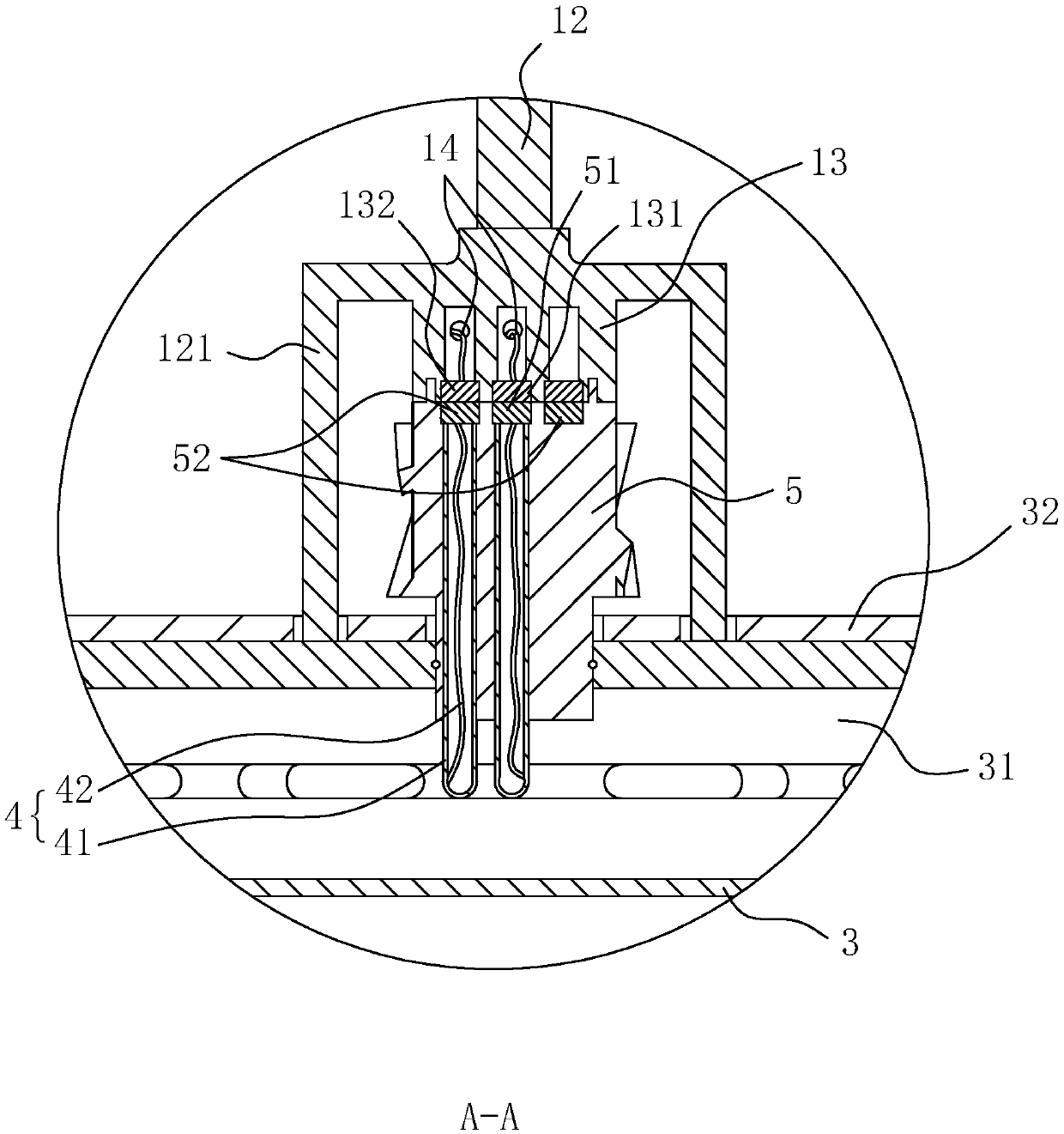

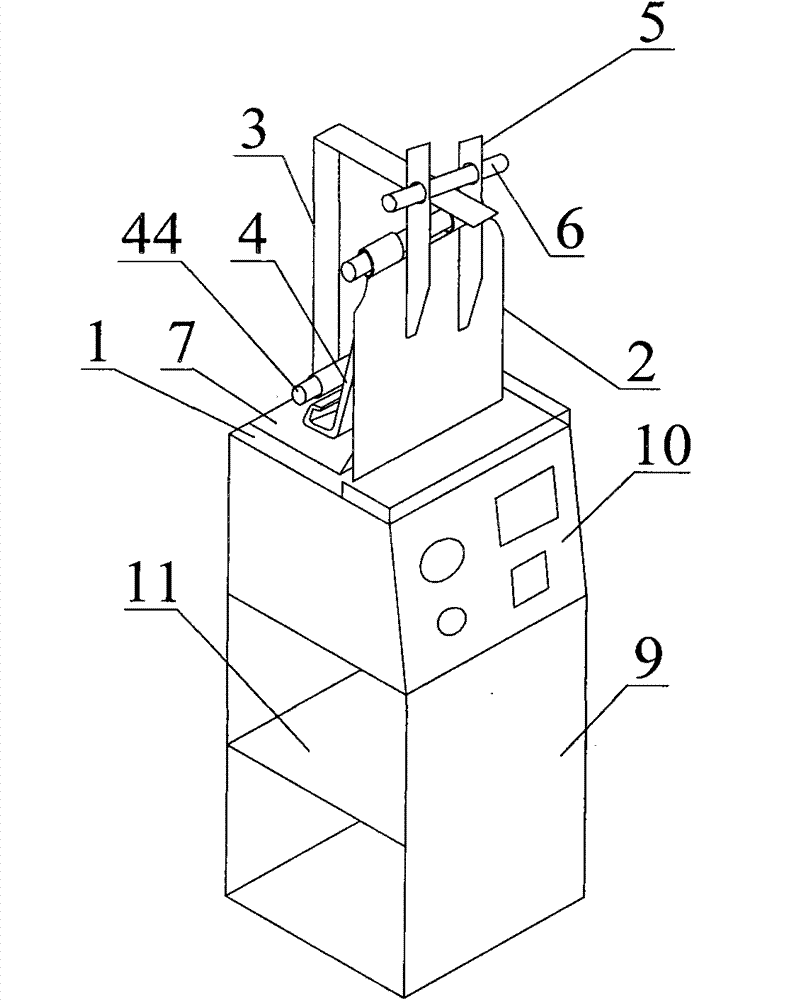

Finger-shaped cutting device

InactiveCN104552404AImprove continuitySave labor timeMetal working apparatusDiamond cuttingMotor drive

The invention belongs to the technical field of rubber belt manufacturing equipment, and relates to a device for manufacturing a connector, in particular to a finger-shaped cutting device. The finger-shaped cutting device comprises a cutting device, a diamond cutting line and a mobile platform component, wherein the diamond cutting line performs cutting movement, a belt end 1 and a belt end 2 which are superimposed together are fixed on an upper tray component, a stepping motor drives the upper tray component to move horizontally along a finger-shaped line track, and finally the belt end 1 and the belt end 2 are simultaneously cut into finger shapes. The finger-shaped cutting device manufactures the finger shapes accurate in size, saves labor time, enables sizing material to achieve good continuity in a vulcanizing process, does not generate a fault in the middle of the sizing material, enables tensile strength of the belt connector to reach prospective strength, and is difficult to break during the use process, safe and reliable to use, high in production efficiency, and low in labor intensity.

Owner:STATE GRID CORP OF CHINA +1

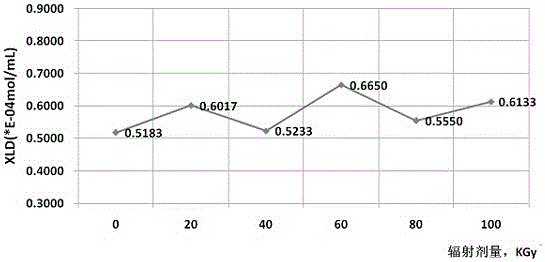

Method for carrying out radiation vulcanization on rubber material or preparing rubber material

InactiveCN104672475ASaving Ozonation ResistantSaving and crack resistanceRubber materialVulcanization

The invention relates to a vulcanization processing process of single radiation or mixed radiation rubber. The vulcanization processing process realizes a radiation vulcanization processing method of rubber and comprises the following steps of: firstly mixing a green glue stock, a compounding agent, a filler and a vulcanizing agent, and then mixing in a double-roller open mill or an internal mixer to primarily form an unvulcanized rubber profile; then carrying out one-time or multiple-time radiation vulcanization on the unvulcanized rubber profile to form single radiation vulcanized rubber, or firstly carrying out electron ray or gamma ray radiation prevulcanization and then carrying out heating type chemical vulcanization on the unvulcanized rubber profile to form radiation-chemical mixed vulcanized rubber, or firstly carrying out heating type chemical prevulcanization and then carrying out the electron ray or gamma ray radiation prevulcanization on the unvulcanized rubber profile to form chemical-radiation mixed vulcanized rubber. The vulcanization processing process disclosed by the invention can be used for enhancing the ozonization resistance, cracking resistance, heat resistance and mechanical property of a rubber product and has the advantages of energy conservation, material conservation, vulcanizing time shortening and vulcanizing quality enhancement.

Owner:于洪洲

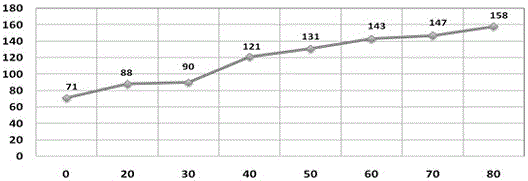

Machining method for pre-vulcanizing lining layer of all-steel tire by utilizing electron beams

The invention discloses a machining method for pre-vulcanizing a lining layer of an all-steel tire by utilizing electron beams. The machining method comprises the specific process that a lining layer rubber sheet production line is started, and lining layer rubber sheets are made to move to a pre-vulcanizing device; when the lining layer rubber sheets enter the pre-vulcanizing device, a device is started; when voltage starts to be boosted to reach 500 KV and keeps stable, the device emits electron beams to irradiate the lining layer rubber sheets, and components are marked; when the irradiation dose on a displayer of the pre-vulcanizing device reaches 40 KGy, the components are marked, and the lining layer rubber sheets begin to be compounded; the irradiated pre-vulcanized lining layer rubber sheets continue moving until leaving the pre-vulcanizing device, and then pre-vulcanization is ended. The machining method has the advantages that due to irradiation on the lining layer rubber sheets through the high-speed electron beams, the performance of rubber can be effectively improved, the mechanical strength of the rubber is remarkably improved, and the uniformity of the tire can be improved; in this way, the thickness of the components can be appropriately reduced, the material consumption can be reduced, and the manufacturing cost can be reduced.

Owner:DOUBLE COIN GRP JIANGSU TIRE

Vulcanization equipment and method for rubber products

PendingCN109109236AAchieve simultaneous vulcanizationImprove vulcanization qualityVulcanizationEngineering

The invention provides vulcanization equipment and method for rubber products. The vulcanization equipment comprises a constant temperature vulcanization chamber, wherein one side of the constant temperature vulcanization chamber is provided with a plurality of vulcanization inlets, and the other opposite side of the constant temperature vulcanization chamber is provided with a plurality of vulcanization outlets; a plurality of inclined vulcanization channels for holding and conveying rubber products are arranged in the constant temperature vulcanization chamber; one end of each vulcanizationchannel is communicated with the vulcanization inlets, and the other end of each vulcanization channel is communicated with the vulcanization outlets; the angles between the vulcanization channels andthe horizontal plane towards the vulcanization inlets are acute. According to the vulcanization equipment and method for rubber products provided by the invention, the plurality of vulcanization channels are arranged in the constant temperature vulcanization chamber, thereby simultaneously realizing synchronous vulcanization of a large number of rubber products, and greatly improving the vulcanization efficiency. The rubber products are transported and output through automatic operation and control, thereby effectively lowering the labor intensity of workers.

Owner:青岛海琅智能装备有限公司

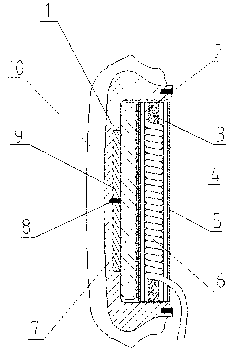

Compression joint type squeezing bag penetrating umbrella composite insulator core bar jacket squeezing bag sulfuration process and device

ActiveCN101577157APerformance impactImprove vulcanization qualityInsulatorsUltra high pressureComposite insulators

The invention relates to a compression joint type squeezing bag penetrating umbrella composite insulator core bar jacket squeezing bag sulfuration process which comprises: carrying out surface treatment on a core bar before use; adding squeezing bag glue to a die space and directly squeezing the core bar out of the bag glue core bar through a squeezing bag machine; fast forming the bag glue core bar in the squeezing process through a front drying tunnel, keeping the working temperature of the front drying tunnel to be 620+ / -50 DEG C, and the surface temperature of silicon glue of the core bar of the front drying tunnel to be 140+ / -20 DEG C; realizing sulfuration and semi-sulfuration to the outer layer of the surface of the bag glue core bar; and enabling the core bar to go into a rear drying tunnel to be completely sulfurized. The process is used for squeezing bag of long bars and can complete squeezing bag and sulfuration in one step, produced composite insulator has good sulfuration quality, high efficiency and no indentation. The process enhances ultraviolet resistance, hydrophobicity and age resistance of an umbrella skirt jacket, strengthens the entire external insulation life of products, solves the difficult problem of quality of traditional sulfuration production, prolongs the aging service life of the composite insulator, and ensures the quality of ultra-high pressure and extra-high pressure composite insulators.

Owner:STATE GRID CORP OF CHINA +2

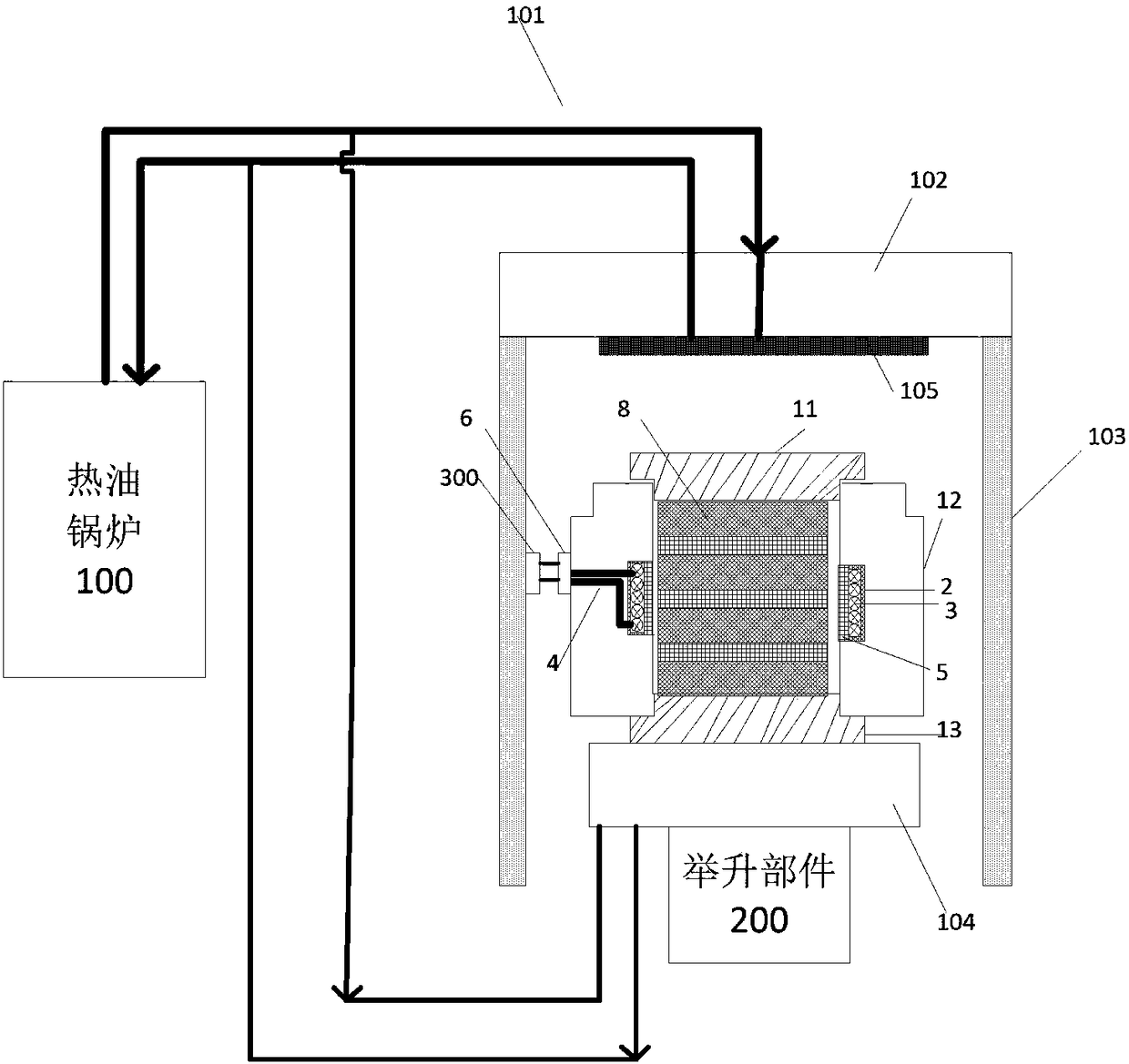

Electromagnetic sulfuration system

PendingCN108312398AImprove vulcanization efficiency and vulcanization qualityHeating fastSteel platesSheet steel

The invention provides an electromagnetic sulfuration system. A sulfuration mold is improved; a magnetic conduction tank made of magnetic conduction ceramic materials for accommodating an electrifyingcoil is arranged inside the sulfuration mold; the electrifying coil is electrically connected with an external medium-high frequency power supply, so that medium-high frequency current is obtained; afirst magnetic field is generated for heating a steel plate; the electrifying coil is directly arranged inside the sulfuration mold; the magnetic field generated by the electrifying coil is restrained inside the sulfuration mold through the magnetic conduction ceramic materials; the condition that an alternating magnetic field generated by the electrifying coil acts on the mold body can be avoided, so that the alternating magnetic field can be totally used for heating the steel plate. An upper heating plate and a lower heating plate of a sulfuration machine can be fast heated through heat conduction oil; further, heat is fast conducted to an upper mold and a lower mold of the sulfuration mold. Therefore the temperature of the upper mold, a middle mold and the lower mold of the sulfurationmold can be fast and uniformly raised; the temperature of the steel plate at inside is fast and uniformly heated, so that the sulfuration efficiency and the sulfuration quality of a rubber support seat are improved.

Owner:PEKING UNIV +1

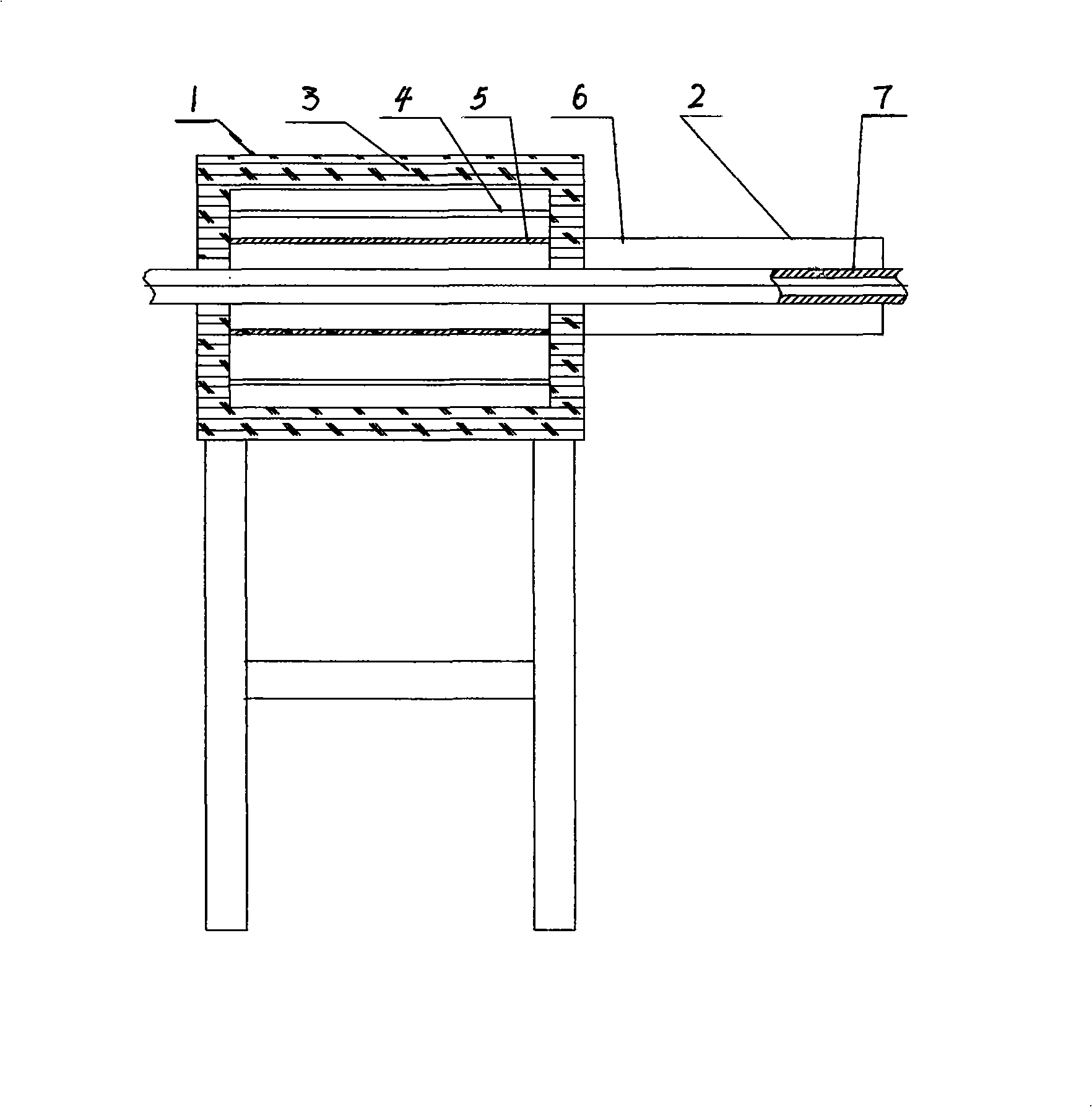

Hydraulic tyre vulcanizing machine in column type strap clamp locked mould mode, and method for adjusting mould

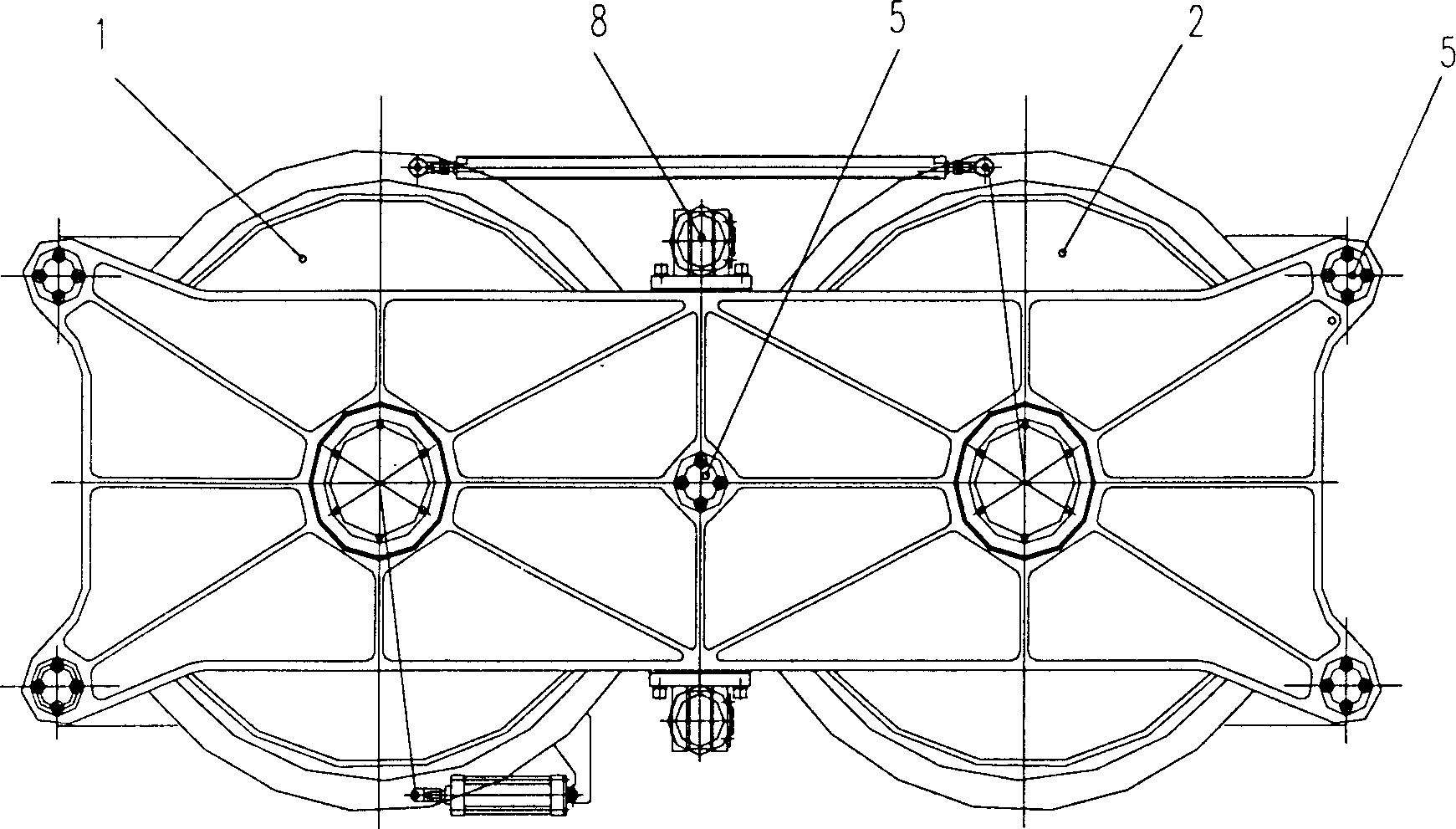

The invention discloses a hydraulic tire vulcanizing machine with column clamping plate lock mode and its mold adjustment method, which comprises a base, a liftable upper beam, a column for guiding mold opening and closing and bearing mold clamping force, an oil cylinder for opening and closing molds, Pressurized oil cylinder, lower supporting plate, upper and lower heating plates for mounting and connecting the upper and lower molds of the tire mold, and clamping mold clamping device. Through the loose / clip fit between the clamping plate and the annular groove of the column, a closed force system of the clamping force is formed, and the clamping force is applied, and components such as the frame, the upper and lower cylinders, and the locking ring can be omitted, so that the structure of the vulcanizing machine is simple. Reliable and easy to maintain. Due to the adoption of a unique mold clamping system, mold adjustment method, pressurized oil cylinder installation method, and multi-column guiding structure, the overall structure of the hydraulic tire curing machine can be greatly simplified, the height and weight of the whole machine are greatly reduced, and the amount of maintenance is greatly reduced. Reduced, thereby improving the precision of the hydraulic tire vulcanizing machine and greatly reducing the manufacturing cost.

Owner:SINO ARP TIRES EQUIP TECH (SUZHOU) CO LTD

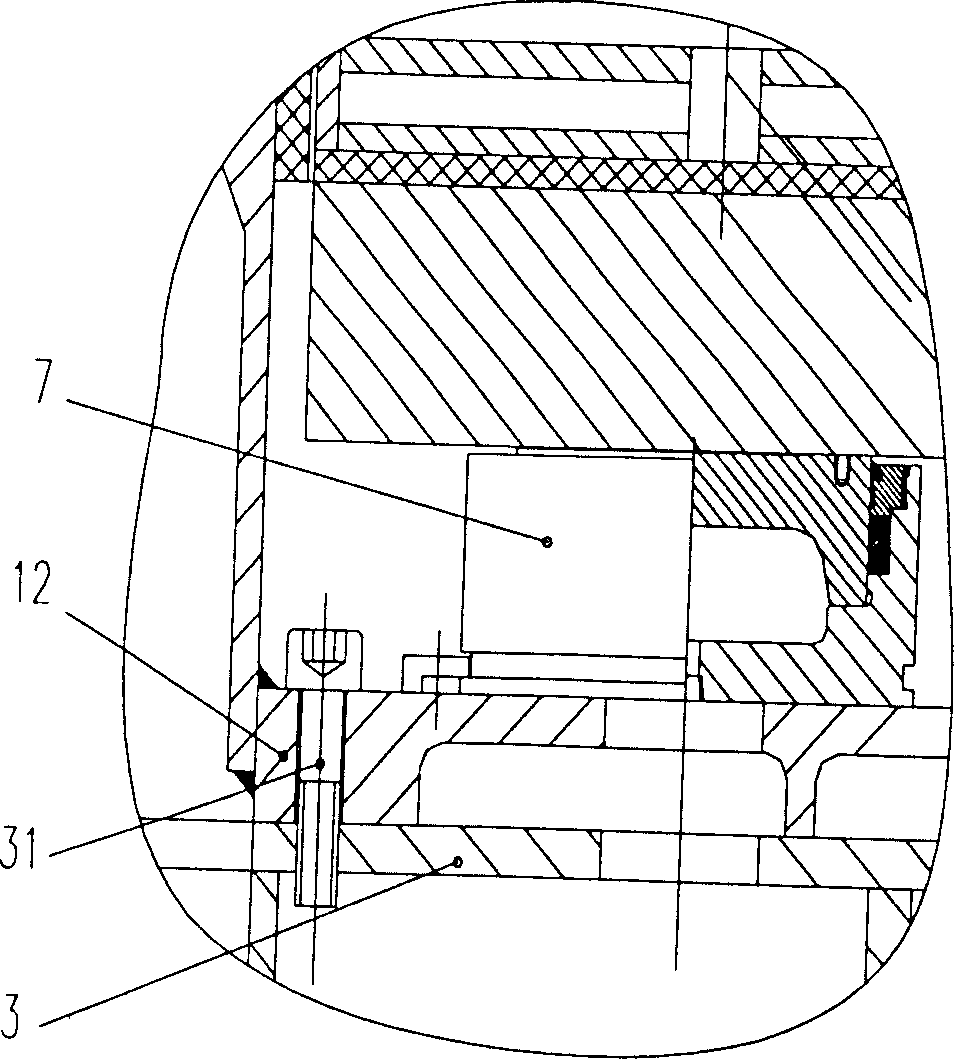

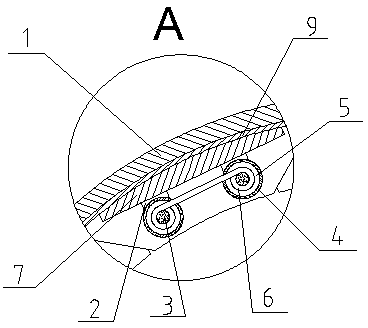

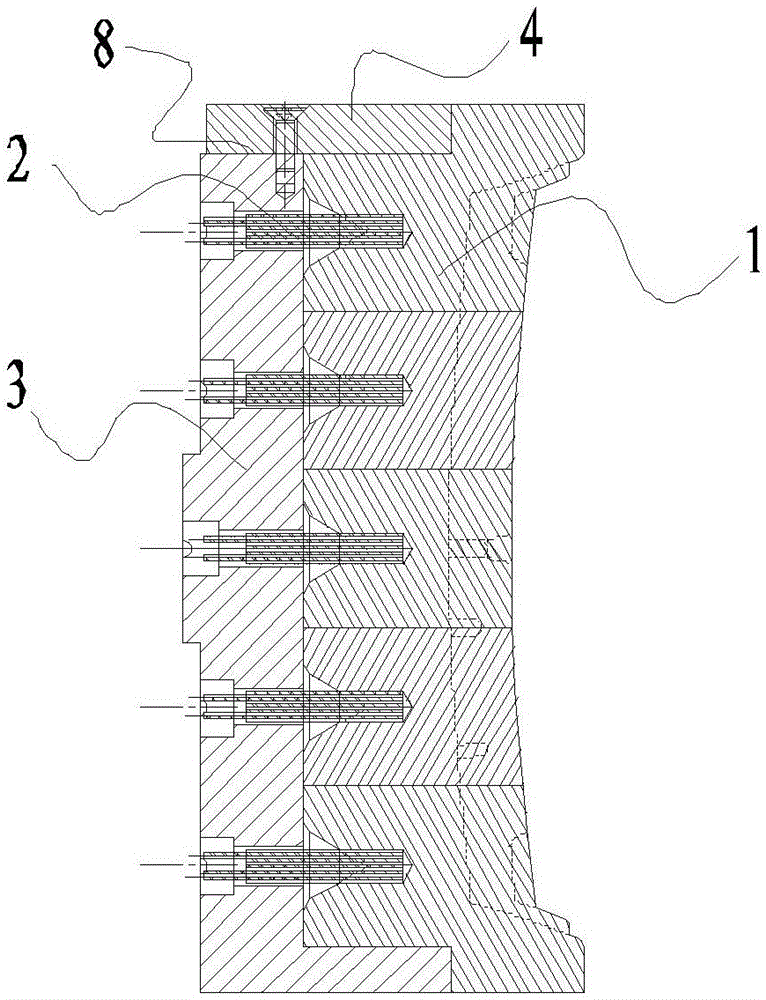

Externally-convex core and vulcanized mould

The invention provides an externally-convex core applicable to a vulcanized rubber product axially provided with a through hole. An internally-concave part extending to the direction deviating from the axial direction of the through hole is arranged in the through hole, the externally-convex core comprises a mandrel and a pellet assembly which is arranged on the surface facing to the rubber product, of the mandrel, the pellet assembly comprises a plurality of pellets arrayed in sequence, and the neighboring pellets are detachably connected; a plurality of fixing slots are axially arranged in the mandrel, each pellet is provided with fixing steps clamped with the fixing slots to fixedly connect the pellet assembly and the mandrel, and an externally-convex part matched with the internally-concave part is arranged in the surface facing to the rubber product, of the pellet assembly. The invention further provides a vulcanized mould provided with the above-mentioned externally-convex core. By the arrangement, separation of the core and the rubber product is facilitated, and vulcanization efficiency and product quality are improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

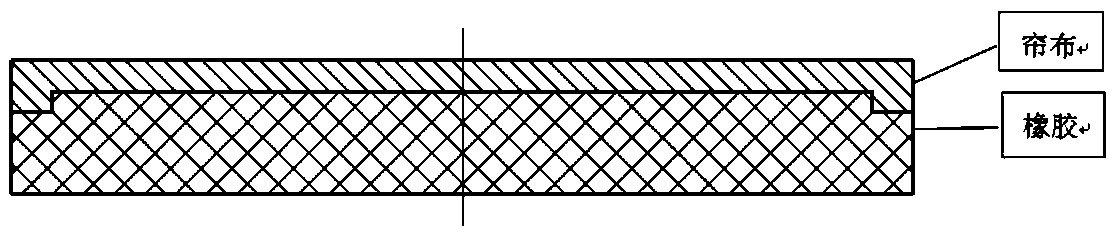

Composite rubber mat for pot bearing, and production method thereof

InactiveCN108749223AGood elasticity and abrasion resistanceGood wear resistanceRubber layered productsRubber matEngineering

The invention discloses a composite rubber mat for a pot bearing. The composite rubber mat comprises a rubber mat body and a cord fabric layer positioned on the upper layer of the rubber mat body, andthe cord fabric layer is formed by compounding a cord fabric with rubber. A production method of the composite rubber mat comprises the following steps: (1) preparing a rubber compound; (2) processing the rubber compound to form a preformed rubber block; (3) frictioning a cord fabric with the rubber compound to make the thickness of rubber adhered to the surface of the cord fabric be 1-2 mm in order to obtain a frictioned cord fabric; and (4) placing the frictioned cord fabric on the upper surface of the pre-formed rubber block, stitching the frictioned cord fabric and the pre-formed rubber block, and carrying out pre-heating and vulcanization molding to obtain the composite rubber mat for the pot bearing. The composite rubber mat for the pot bearing adopts NR and SBR as main rubbers, socomposite rubber mat has good elasticity and good wear resistance; and the surface of the composite rubber mat is compounded with the cord fabric, and the characteristics of good wear resistance and small deformation of amount of the fiber material of the cord fabric are used, so product damages caused by swinging and extruding in the use process are avoided, and the problems of wearing and extruding bloating of conventional rubber mats are solved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

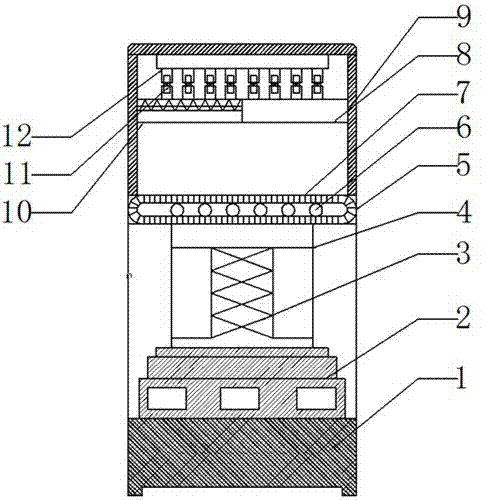

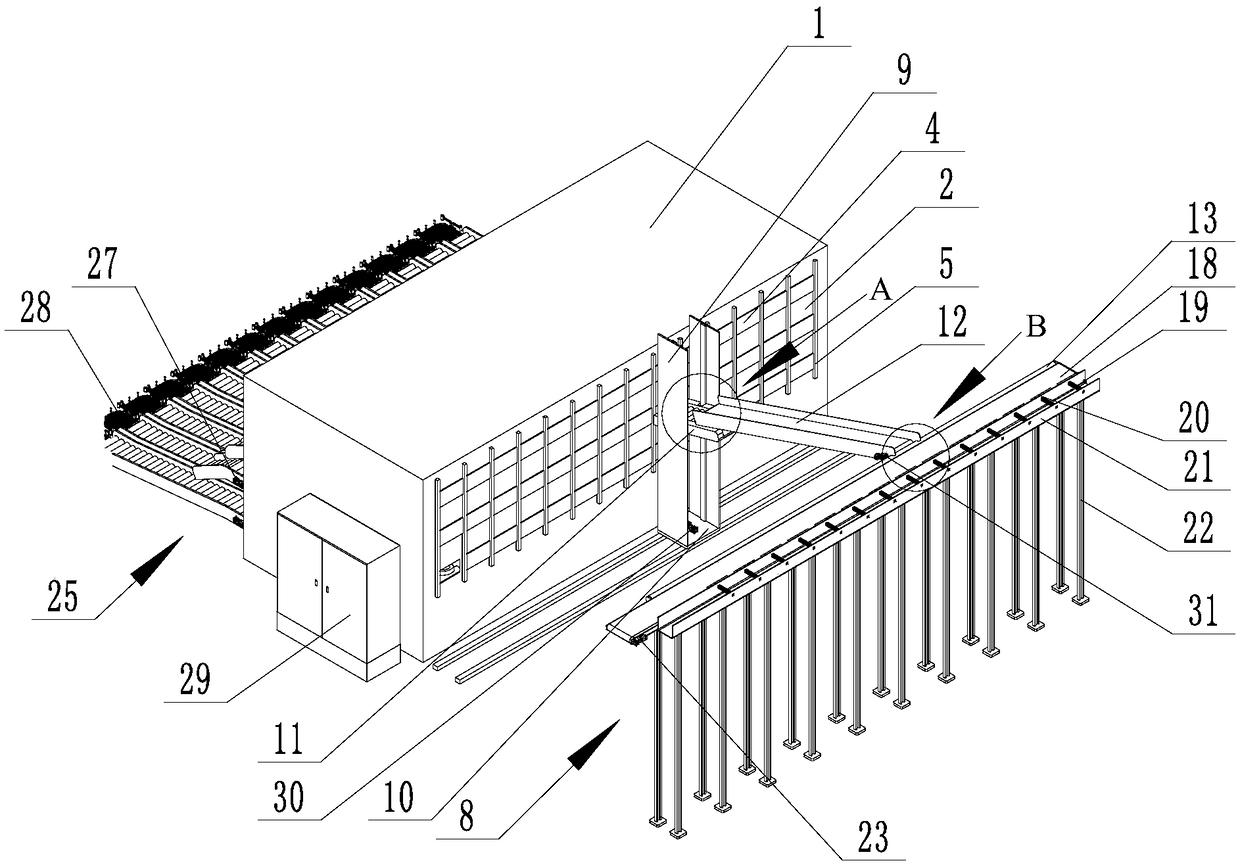

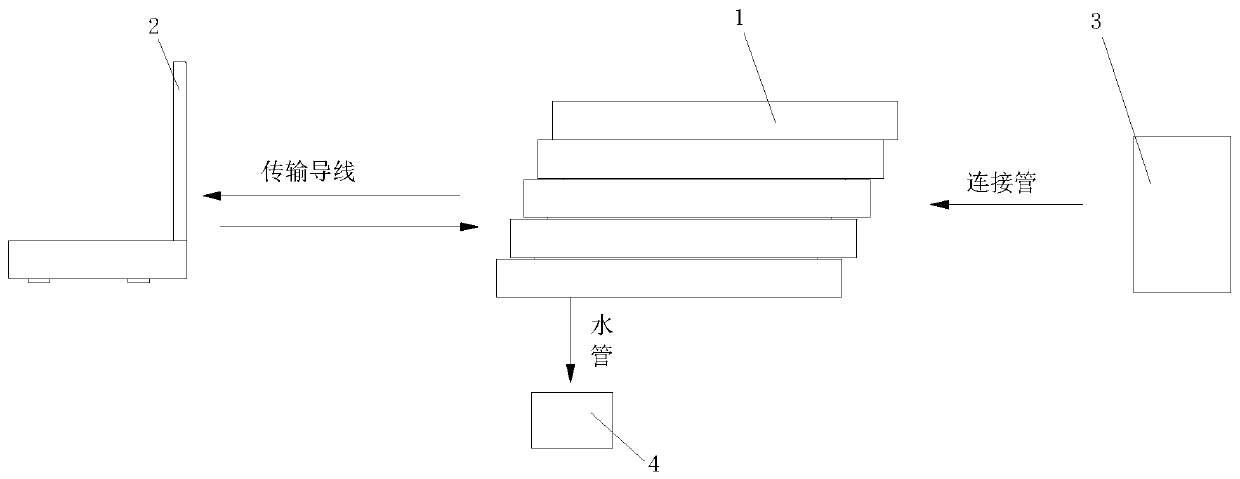

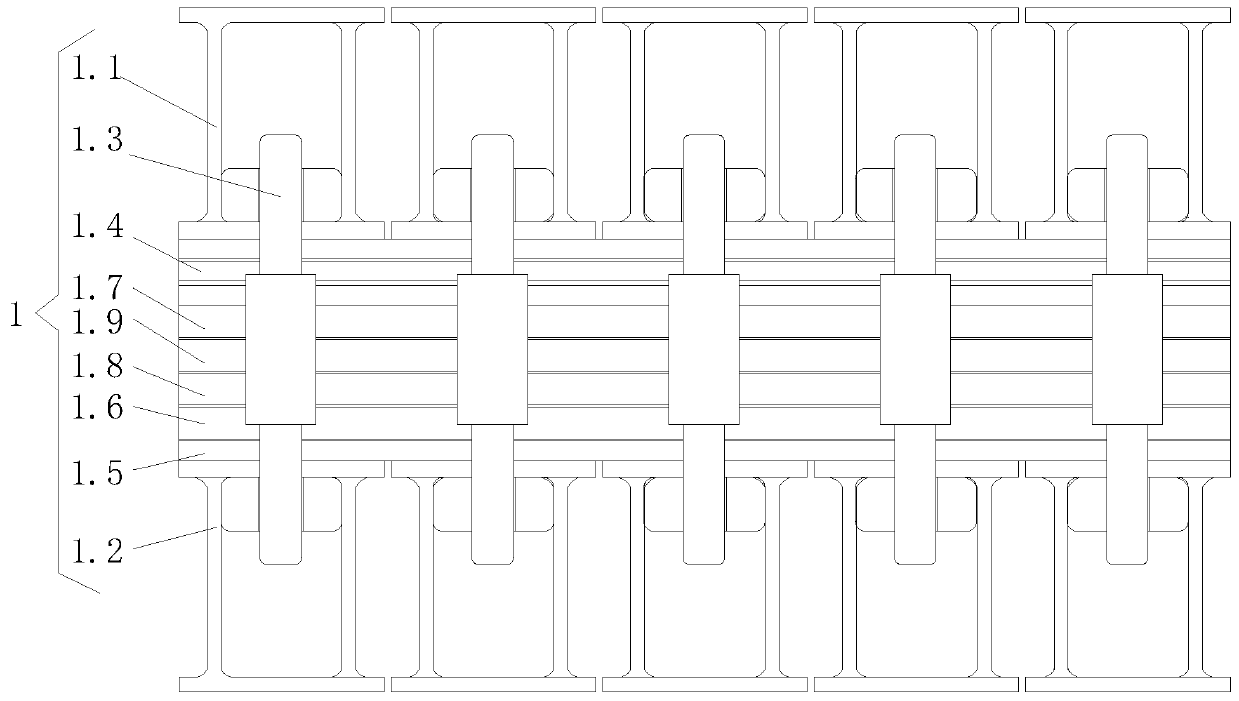

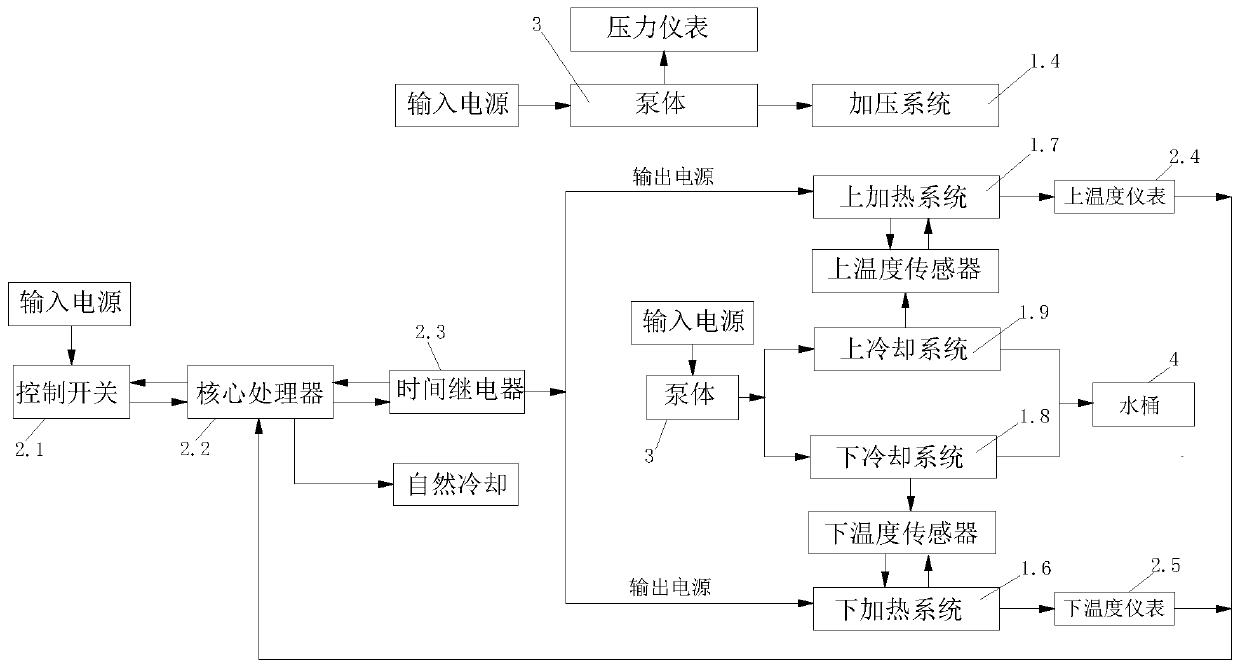

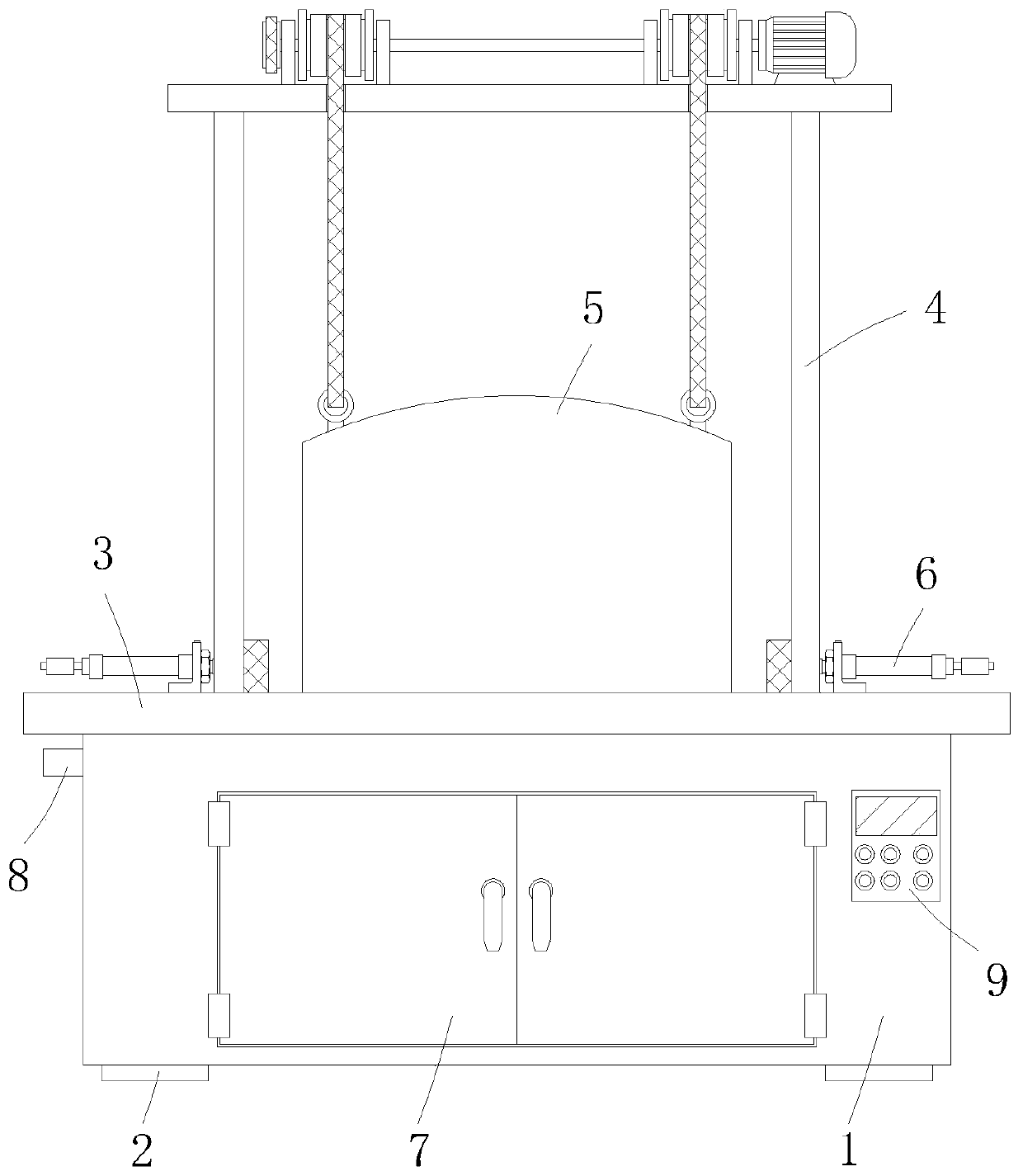

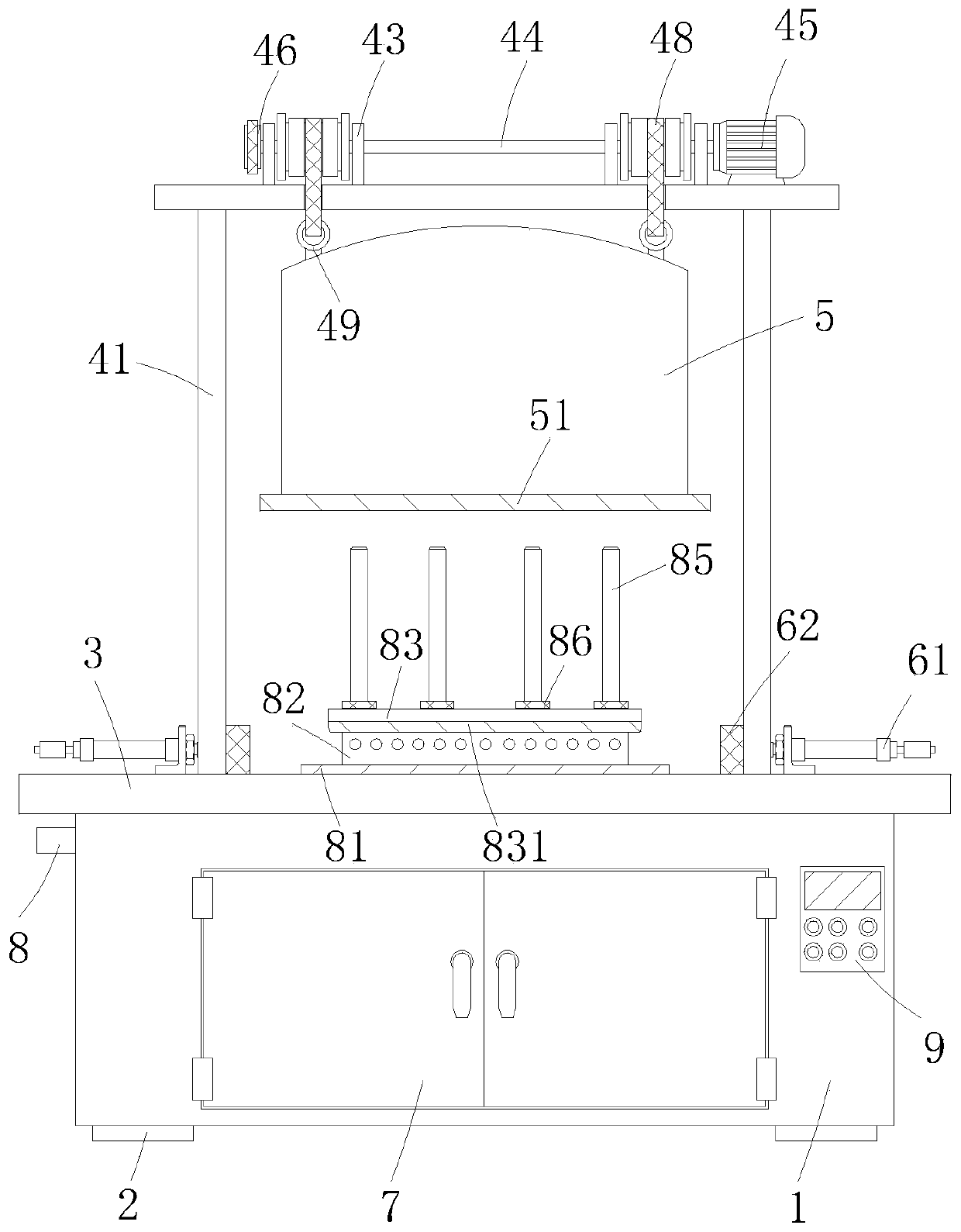

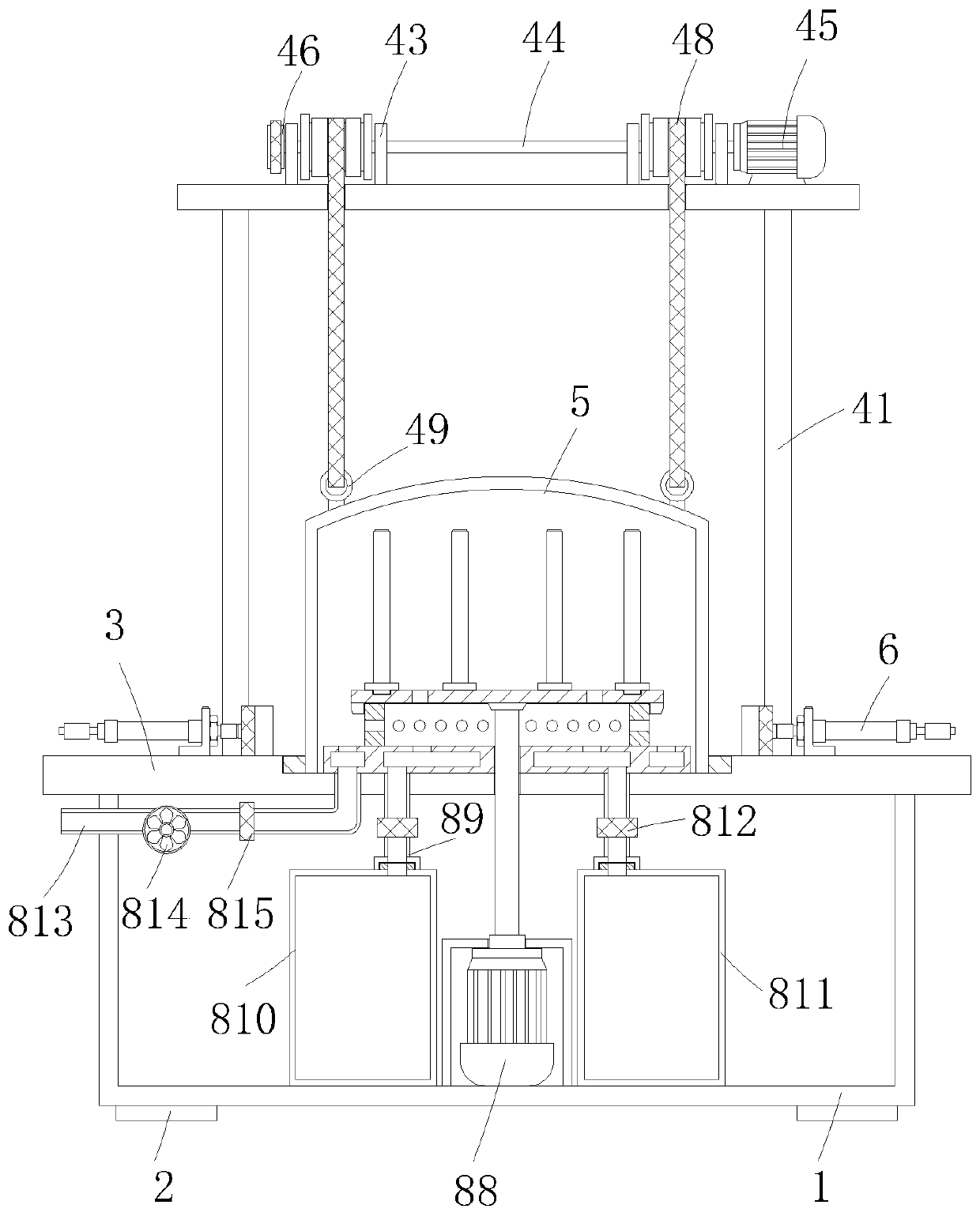

Ultra-light vulcanizing machine and control system assembly

PendingCN110900912AHigh degree of automationImprove vulcanization qualityBeltsVulcanizationControl system

The invention relates to the technical field of vulcanizing presses and control systems and discloses an ultra-light vulcanizing machine and control system assembly. The ultra-light vulcanizing machine and control system assembly comprises a vulcanizing machine, a control cabinet, a pump body and a water barrel. The vulcanizing machine comprises upper beams, lower beams, threaded rod mechanisms, apressurizing system, a heat insulation plate, a lower heating system, an upper heating system, a lower cooling system and an upper cooling system, wherein the upper beams are located over the lower beams, the upper beams and the lower beams are connected through the threaded rod mechanisms, the pressurizing system, the upper heating system, the upper cooling system, the lower cooling system, thelower heating system and the heat insulation plate are sequentially arranged between the upper beams and the lower beams in an sandwiched manner. According to the ultra-light vulcanizing machine and control system assembly, the overall vulcanizing process of the vulcanizing machine is controlled in real time through the control cabinet, so that the overall automation degree of the vulcanizing machine is improved; the pressurizing system conducts full-area omnibearing supporting pressing, the upper heating system and the lower heating system guarantee that the plane of a rubber vulcanized beltis evenly heated, and the lower cooling system and the upper cooling system enable the vulcanized belt cooling time of the vulcanizing machine to be greatly shortened.

Owner:康米克斯硫化科技无锡有限公司

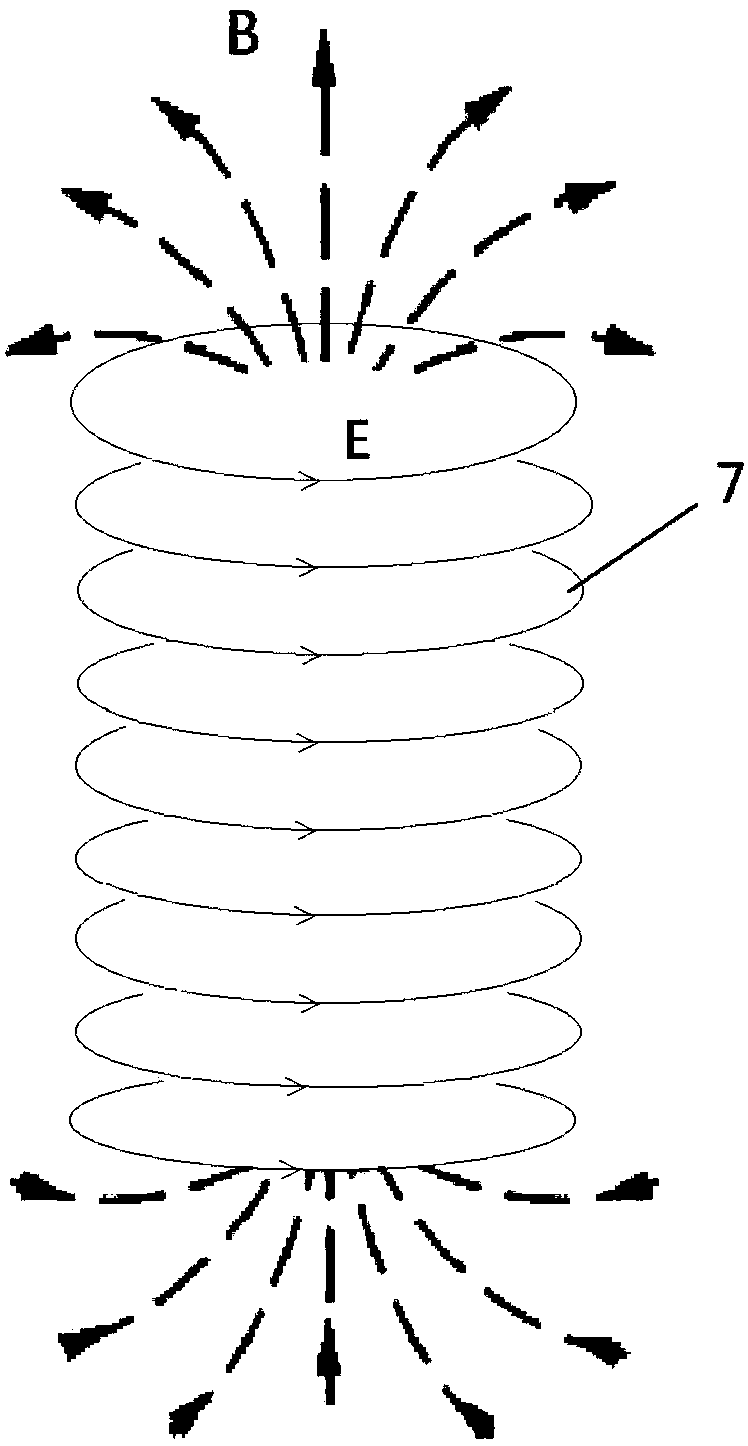

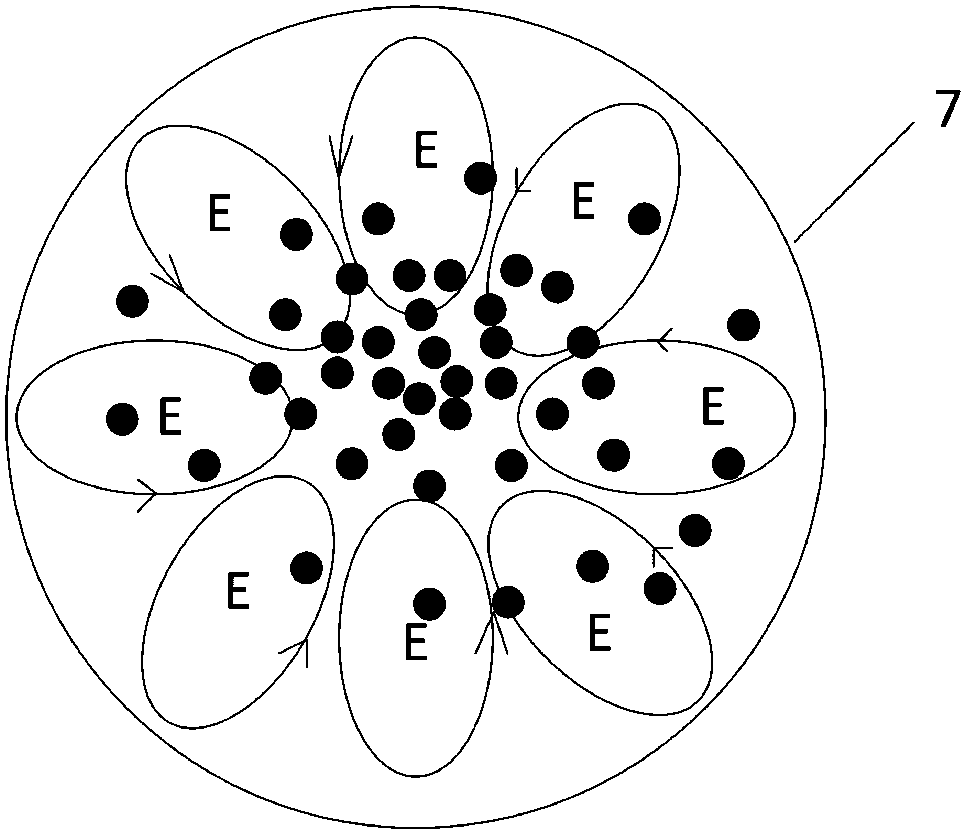

Electromagnetic-heating tire vulcanizing device capable of controlling heat source temperature segment by segment

The invention relates to an electromagnetic-heating tire vulcanizing device capable of controlling heat source temperature segment by segment and belongs to the field of tire production equipment. The device is provided with a telescopic metallic inner mold and is characterized in that the inner mold consists of wide drum tiles, narrow drum tiles, an expansion and contraction mechanism and rib plates which are fixedly connected with the wide and narrow drum tiles and play a role in supporting, the wide and narrow drum tiles are arranged alternately along the circumferential direction, the longitudinal outer contour curve of each part of all the wide and narrow drum tiles forming drum tiles is consistent with the inner contour curve of a finished product tire, the wide and narrow drum tiles are tightly clung to each other so as to form a complete circle in appearance when the inner mold is in an expansion state, molding cavities are formed in the middle parts of surfaces, in contact with the rib plates, of the wide and narrow drum tiles, phase-change materials are filled in the molding cavities, two electromagnetic coils with the same inductance are mounted on the back face of each of the wide and narrow drum tiles and are symmetrically distributed at the left and right sides of the longitudinal centerline of each drum tile, the winding direction of the electromagnetic coils is the longitudinal direction of the drum tiles, the electromagnetic coils are wound on l-shaped magnetic cores, the winding direction of the electromagnetic coils is the longitudinal direction of the drum tiles, heat insulating layers cover the surfaces of the electromagnetic coils, the outermost layers of the electromagnetic coils serve as shells, and two l-shaped magnetic cores are symmetrically distributed at the left and right sides of each rib plate.

Owner:TRIANGLE TIRE +1

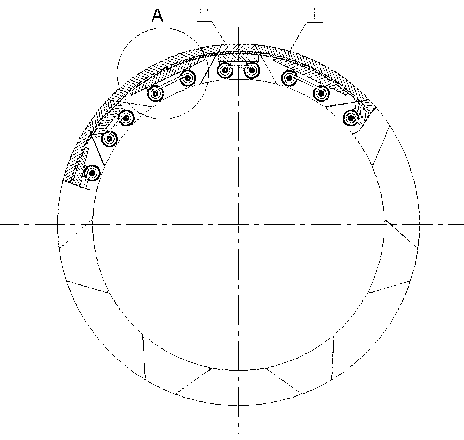

Tire segment mold

The invention discloses a tire segment mold, and belongs to the field of tire molds. The tire segment mold can be widely applied to riding-use tires, light truck tires, engineering tires and giant tires, and comprises a mold body and an inner side tire forming capsule. A sealed heating chamber is arranged on the mold body. An electric heating device and a heating medium are arranged in the sealedheating chamber. The electric heating device is electric heating coils. Water or other liquids with high specific heat capacity, or anti-corrosion liquids or solids which are heated to 100-200 DEG C and can generate phase change serve as the heating medium preferably. In addition, the electric heating device is preferably arranged in the position, away from the inner side tire forming capsule, ofthe cavity wall of the sealed heating chamber, and the electric heating device is prevented from directly heating the mold.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Vulcanizing machine hot plate based on electromagnetic heating

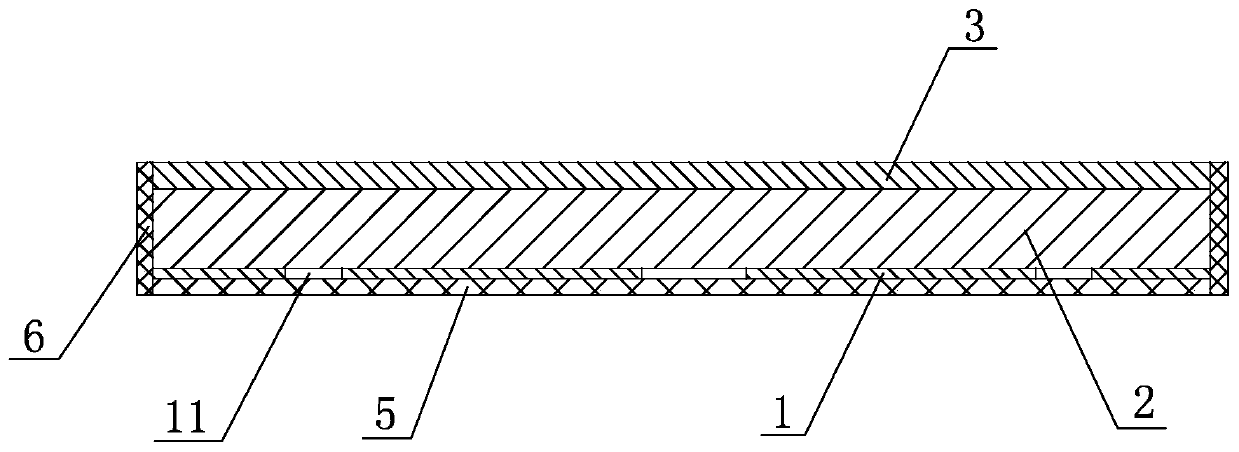

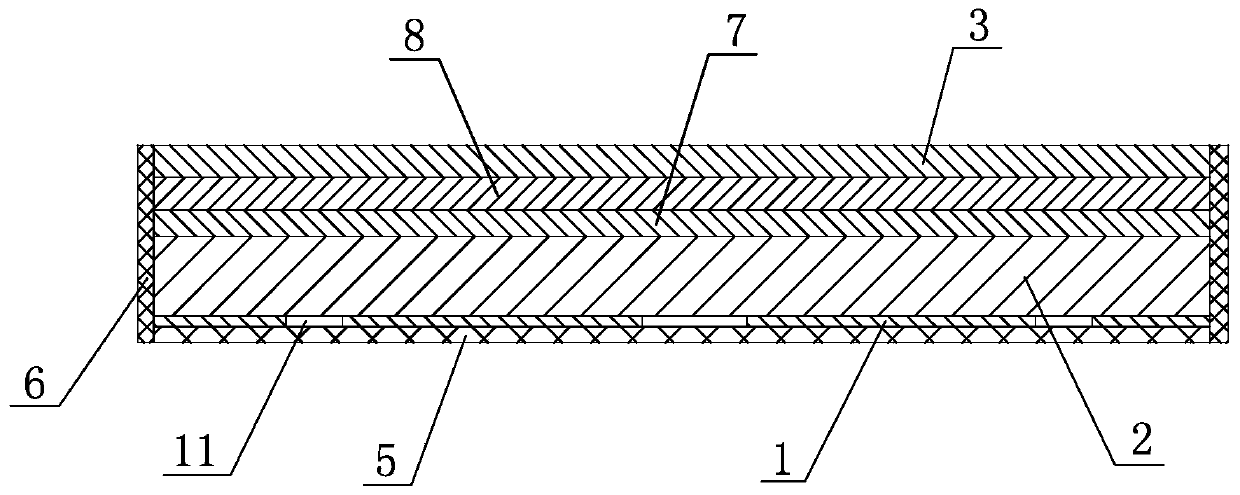

The invention discloses a vulcanizing machine hot plate based on electromagnetic heating. The vulcanizing machine hot plate is characterized by comprising a first metal plate, a first copper plate anda second metal plate, wherein the first metal plate, the first copper plate and the second metal plate are superimposed and fixed from bottom to top in sequence, an induction coil is positioned belowthe hot plate, the thickness of the first metal plate is larger than 0 mm and smaller than or equal to 2 mm, a magnetic induction vortex dense region on the first metal plate is removed to form a hole, a lower heat insulation layer is arranged between the induction coil and the first metal plate, the lower heat insulation layer is fixedly connected with the first metal plate, and side heat insulation layers are fixedly arranged on the periphery of the first metal plate, the first copper plate and the second metal plate. The hot plate has the advantages that the temperature difference is reduced through multiple layers and multiple times, so that the temperature of the surface of the hot plate is close to the uniform temperature, and the vulcanization quality of rubber is improved; and moreover, the hot plate realizes heat transfer through the copper plate, so that the heat conduction speed is high, and the heating speed of the vulcanizing machine hot plate is further improved.

Owner:NINGBO UNIV

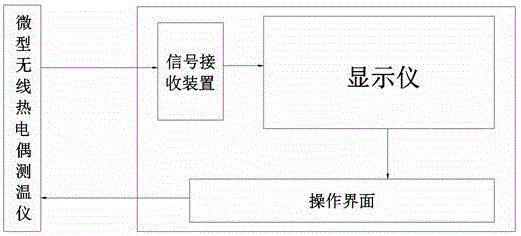

Tire vulcanizing temperature measuring method

The invention discloses a tire vulcanizing temperature measuring method. The method includes the following steps that a green tire to be subjected to vulcanizing temperature measuring is selected; secondly, a miniature wireless thermocouple thermodetector is embedded in the green tire selected in the first step and used for vulcanizing temperature measuring, and meanwhile a processing device is arranged; thirdly, the second step is finished, normal work of related equipment instrument is confirmed, needed data processing functional items are selected on the processing device, die assembly vulcanizing begins, the vulcanizing time and temperature changes of the green tire in the vulcanizing process are monitored in real time, and recording, summarizing and analyzing are conducted according to received signals; and fourthly, after vulcanizing is finished in the third step, a tire is cut apart, and the miniature wireless thermocouple thermodetector is taken out and secondarily used. Due to the fact that the miniature wireless thermocouple thermodetector is embedded in the tire blank, the time and temperature changing relations among all parts in the vulcanizing process of the tire can be accurately monitored in real time, and the vulcanizing temperature measuring success rate of the tire is increased.

Owner:SICHUAN YUANXING RUBBER

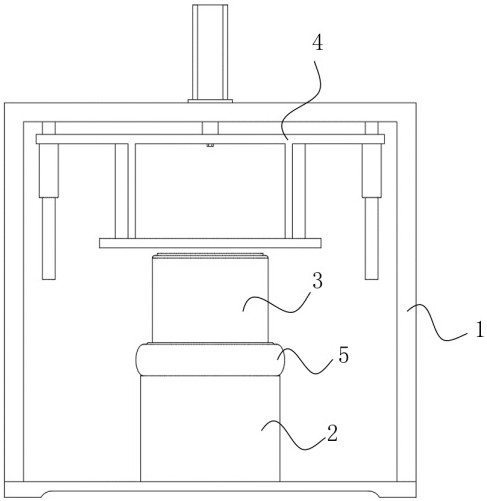

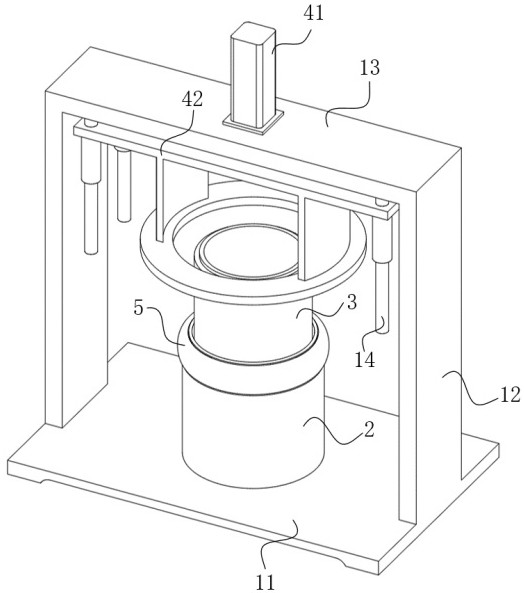

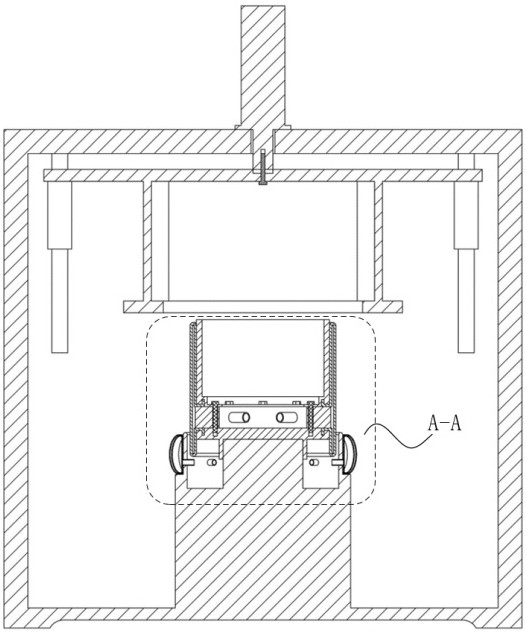

Turn-up capsule pressure uniformity detection device and method

ActiveCN112326272AQuick checkImprove molding qualityUsing mechanical meansVehicle tyre testingEngineeringStress sensors

The invention relates to the technical field of tire forming, in particular to a turn-up capsule pressure uniformity detection device and method. The turn-up capsule pressure uniformity detection device comprises a frame, a support cylinder, a turn-up capsule fixing assembly, a pressing plate assembly, a pressure detection assembly and a control part. The pressure detection assembly further comprises a large air bag on the outer layer and a plurality of small air bags arranged in the large air bag, and the small air bags are connected with valves and pressure sensors through external pipelines. By means of the device, whether a turn-up capsule is qualified or not can be detected, a defect area on an unqualified turn-up capsule can be found out, therefore, process personnel can be helped todiscover defects on a production process or equipment, an effect of defect early warning is achieved, and greater loss is avoided.

Owner:YONGYI RUBBER CO LTD

Vulcanizing machine

The invention discloses a vulcanizing machine and relates to the technical field of rubber production. According to the technical scheme, the vulcanizing machine is characterized by comprising a machine frame, a mold platform used for holding rubber is arranged on the machine frame, a hydraulic cylinder and pressurizing block are arranged on the upper side of the mold platform, heating devices arearranged both in the pressurizing block and the mold platform, an upper heating cavity is arranged in the pressurizing block, a lower heating cavity is arranged in the mold platform, the upper heating cavity and the lower heating cavity are both filled with heat conducting oil, the heating devices comprise an upper electric heating piece located in the upper heating cavity and a lower electric heating piece located in the lower heating cavity. When the vulcanizing machine is used for vulcanizing rubber, a rubber workpiece is heated evenly, the vulcanization quality of the rubber is good, andthe overall quality of a rubber product is good; the upper electric heating piece and the lower electric heating piece can automatically rotate, so that the temperature evenness degree of the heat conducting oil is further improved; through arrangement of an upper heat preservation board and a lower heat preservation board, heat waste of the heat conducting oil is reduced, and energy is saved.

Owner:浙江菲夫自控设备有限公司

Rubber band vulcanization device with rapid cooling function

The invention relates to the technical field of rubber band processing equipment, and provides a rubber band vulcanization device with a rapid cooling function. The device aims to solve the problem that a rubber band stacking effect is difficult to guarantee after existing vulcanization equipment is transformed and put into production, vulcanization is incomplete, and the vulcanization effect of rubber bands and cooling after vulcanization is completed cannot be guaranteed. The device comprises a base box and a plurality of supporting legs installed at the lower end of the base box, a machining table board is horizontally installed at the upper end of the base box, a vulcanization bottom groove is formed in the upper end of the machining table board, a vulcanizing mechanism is arranged inthe vulcanization bottom groove, a inverted bowl-shaped vulcanizing shell upper cover is arranged above the vulcanization bottom groove in a matched mode, the vulcanizing mechanism comprises a gas conveying disc installed in the vulcanization bottom groove, the gas conveying disc is of an internal hollow structure, and two communicating pipes are arranged at the lower end of the gas conveying discin a penetrating mode. The device is particularly suitable for high-quality vulcanization of the rubber bands, and has high social usage value and application prospect.

Owner:安徽省潜山市创先实业有限公司

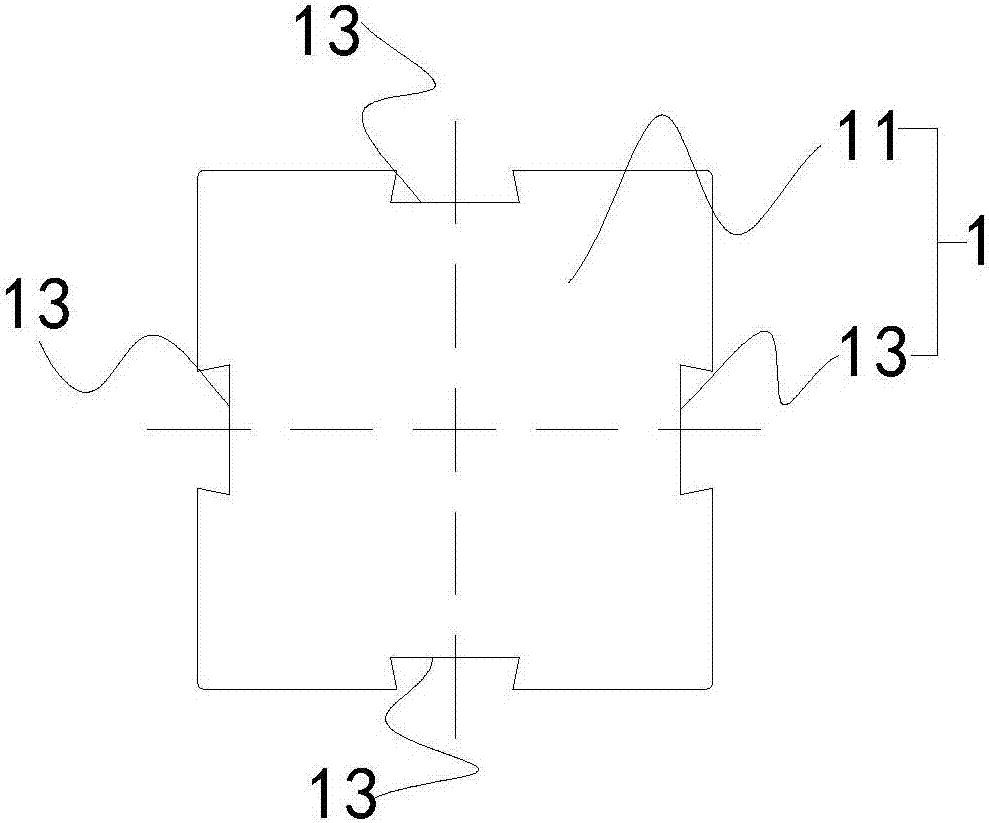

Pattern block and tire mold

ActiveCN106696318ABest vulcanization temperatureAchieve independent controlTyresEngineeringWater block

The invention relates to a pattern block. The pattern block comprises a pattern block body. The pattern block body comprises a plurality of unit blocks (1). The pattern block further comprises heat source units capable of heating the pattern block body, and a control unit electrically connected with the heat source units. The heat source units are arranged inside the multiple unit blocks (1) so as to provide heat sources for the multiple unit blocks (1). The control unit comprises an operation module and an adjusting module. The operation module is electrically connected with the heat source units so as to operate startup of the heat source units. The adjusting module is electrically connected with the heat source units so as to adjust the heat values provided by the heat source units. The pattern block has high heat transfer efficiency. In addition, temperatures of different portions of the pattern block are independently controlled, so that it is guaranteed that different portions of the pattern block are at the optimal vulcanizing temperatures, the phenomena of excessive vulcanizing and insufficient vulcanizing are prevented, and the vulcanizing quality of tires is further improved.

Owner:青岛海琅精密工业有限公司

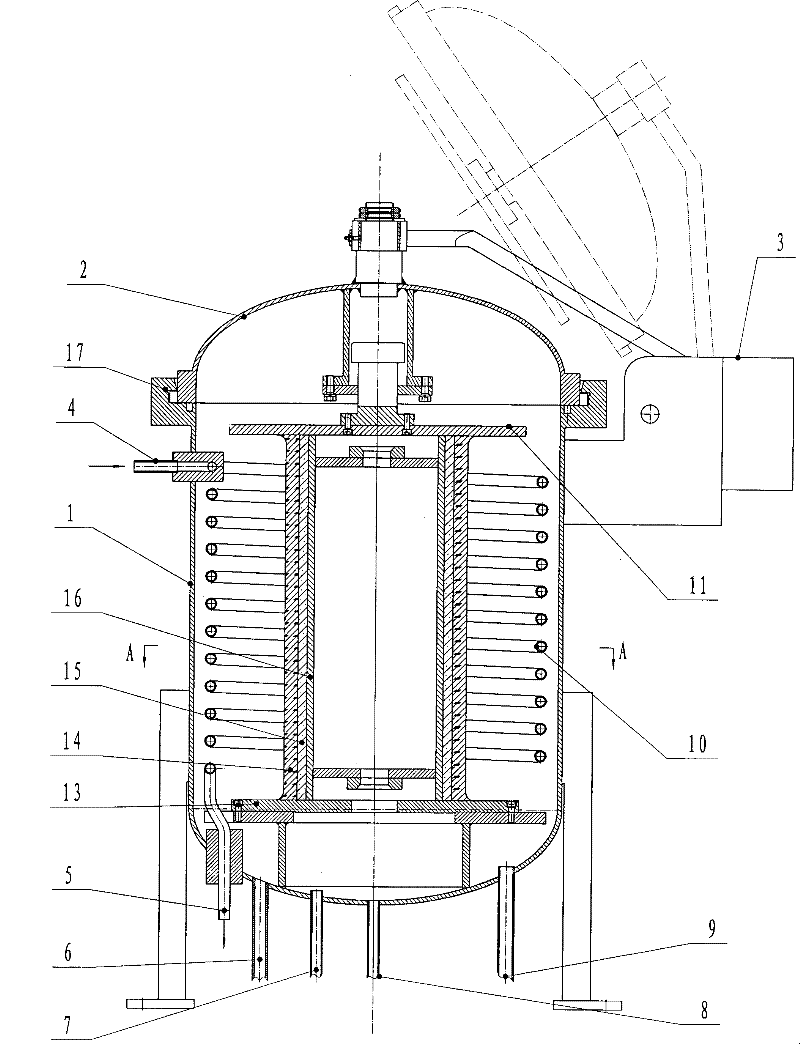

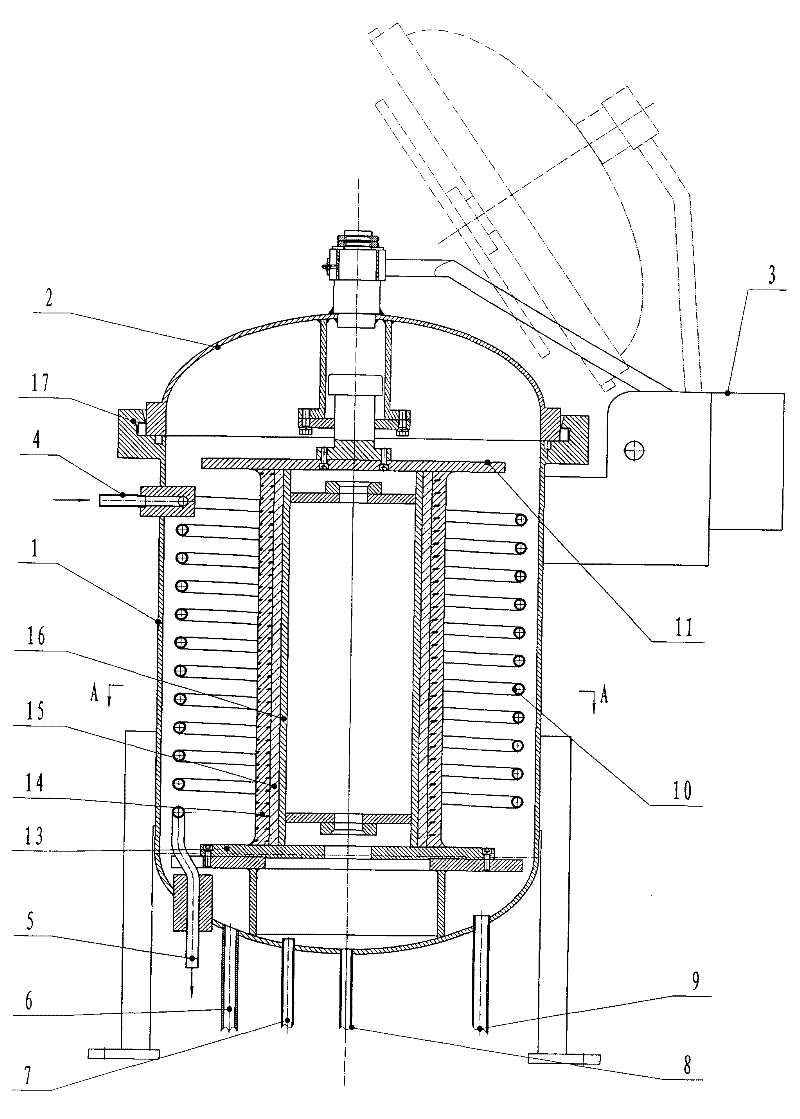

Drive belt vulcanization tank

A transmission belt vulcanization tank, including an inner cavity between the rubber sleeve and a cover plate and a supporting plate, an outer cavity between the rubber sleeve and the tank body of the transmission belt vulcanization tank, a steam inlet and a steam outlet in the inner cavity, and a pressure air inlet in the outer cavity And the pressure air outlet of the outer chamber, the outer chamber is provided with a high-temperature steam heating pipe, the high-temperature steam heating pipe has a high-temperature steam inlet and a high-temperature steam outlet. The high-temperature steam heating tube heats the pressure air in the outer cavity, which ensures the temperature requirements of the outer cavity and has a high utilization rate of heat energy; the high-temperature steam heating tube independently regulates the temperature of the outer cavity, and the temperature and pressure of the outer cavity are easy to control; the high-temperature steam heating tube is used to avoid steam Dissipation; the inner and outer chambers share a set of steam heating system, which saves energy consumption; the steam inlet of the inner chamber is also connected with the exhaust pipeline, which is beneficial to the full combination of the belt cylinder and the mold; the invention improves the vulcanization quality of the product and reduces the vulcanization time. Save steam consumption.

Owner:青岛信森机电技术有限公司

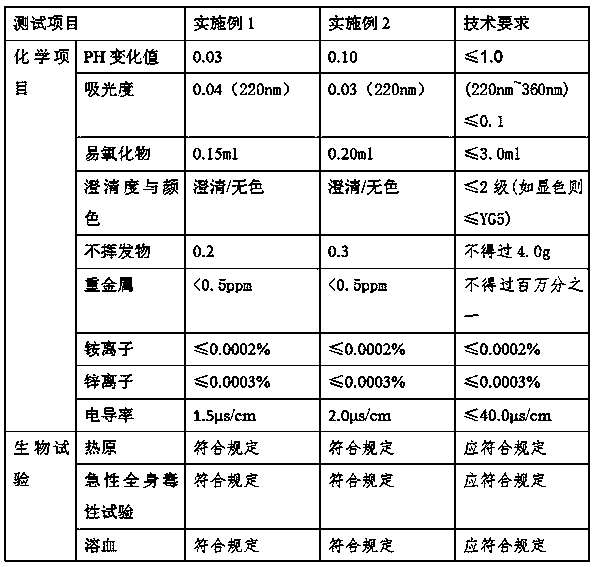

A kind of production method of rubber piston for prefilled syringe

The invention discloses a production method for a rubber piston for a pre-potting injector. The method comprises the first step of burdening, the second step of rubber mixing, the third step of precise pre-forming, the fourth step of die pressing vulcanization forming, the fifth step of freezing, punching and edge removing, and the sixth step of cleaning packaging, wherein in the third step, a precise pre-forming machine is adopted for placing a rubber compound in the second step into the precise pre-forming machine, then, small columnar rubber particles are obtained through accurate cutting according to the specification and weight of the rubber piston needing to be produced and used for the pre-potting injector, and treatment is conducted through a cooling vibration screen. The professional precise pre-forming machine is adopted in the production method, automatic and precise weighing is conducted, few procedures are adopted, the production efficiency is high, the size is precise, the yield of vulcanized products is higher, few waste edges are generated, and waste is greatly reduced. Through the vulcanization die optimization design, a freezing edge trimming machine can be adopted for conducting edge trimming on the rubber piston. Operation is simple, the automation degree is high, the situation that due to thick flanges of a traditional rubber piston, a method for punching through a mechanical punching machine must be adopted is avoided, little pollution is generated, and the edge trimming safety coefficient is high.

Owner:郑州翱翔医药科技股份有限公司

Method for vulcanizing solid tires in tank-type variable-pressure variable-temperature manner

InactiveCN103612356ASolve vulcanization quality problemsImprove securityTyresEngineeringHigh pressure

The invention discloses a method for vulcanizing solid tires in a tank-type variable-pressure variable-temperature manner. The method comprises the following steps: a high-pressure flashing stage, that is, evacuating air between a tire blank and a mold; a high-pressure low-temperature vulcanizing stage, that is, closing the mold under the pressure of 1082 plus or minus 2T and vulcanizing in a gradually heating mode; a high-pressure high-temperature vulcanizing stage, that is, keeping the mold closing pressure of a vulcanizing tank to be 1082 plus or minus 2T and vulcanizing for 180min by adopting steam at 135 plus or minus 2 DEG C; a low-pressure high-temperature vulcanizing stage, that is, relieving the mold closing pressure of the vulcanizing tank until 260 plus or minus 2T, and vulcanizing with steam at 135 plus or minus 2 DEG C until the optimum vulcanizing is finished; a low-pressure low-temperature tank-sealing stage, that is, keeping the mold closing pressure of the vulcanizing tank to be 260 plus or minus 2T without steam introduction, and sealing the tank for 60min and finishing the vulcanizing operation; taking out the tire after the pressure in the tank is zero. The method can effectively solve the quality problem of cracks of the vulcanized tire and has significances in improving safety and service life of the vulcanizing equipment and saving energy.

Owner:青岛国盛达科技股份有限公司

Small tyre repairing vulcanizing machine

The invention discloses a small tyre repairing vulcanizing machine which comprises a worktable, a fixed vertical plate and an external pressure plate, wherein the fixed vertical plate is arranged at one side of the worktable, the external pressure plate is articulated at the other side of the worktable, the upper part of the external pressure plate is connected with the fixed vertical plate through a connecting piece, an internal pressure plate is articulated at the upper end of the fixed vertical plate, and the upper part of the external pressure plate is higher than the upper part of the internal pressure plate; and a pressing gasbag and a heating vulcanizing plate are arranged along the plane of the worktable and the lower surface of the internal pressure plate. The small tyre repairing vulcanizing machine has simple structure, convenient operation, lower cost and wide application range, can repair small openings and large openings on all car tyres and has low repairing cost and good repairing quality.

Owner:洪林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com