Compression joint type squeezing bag penetrating umbrella composite insulator core bar jacket squeezing bag sulfuration process and device

A synthetic insulator, crimping technology, used in insulators, electrical components, circuits, etc., can solve the problems of poor vulcanization effect, difficult operation, inability to complete extrusion and vulcanization at one time, and achieve good operating conditions and ensure safe operation. , The effect of excellent vulcanization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

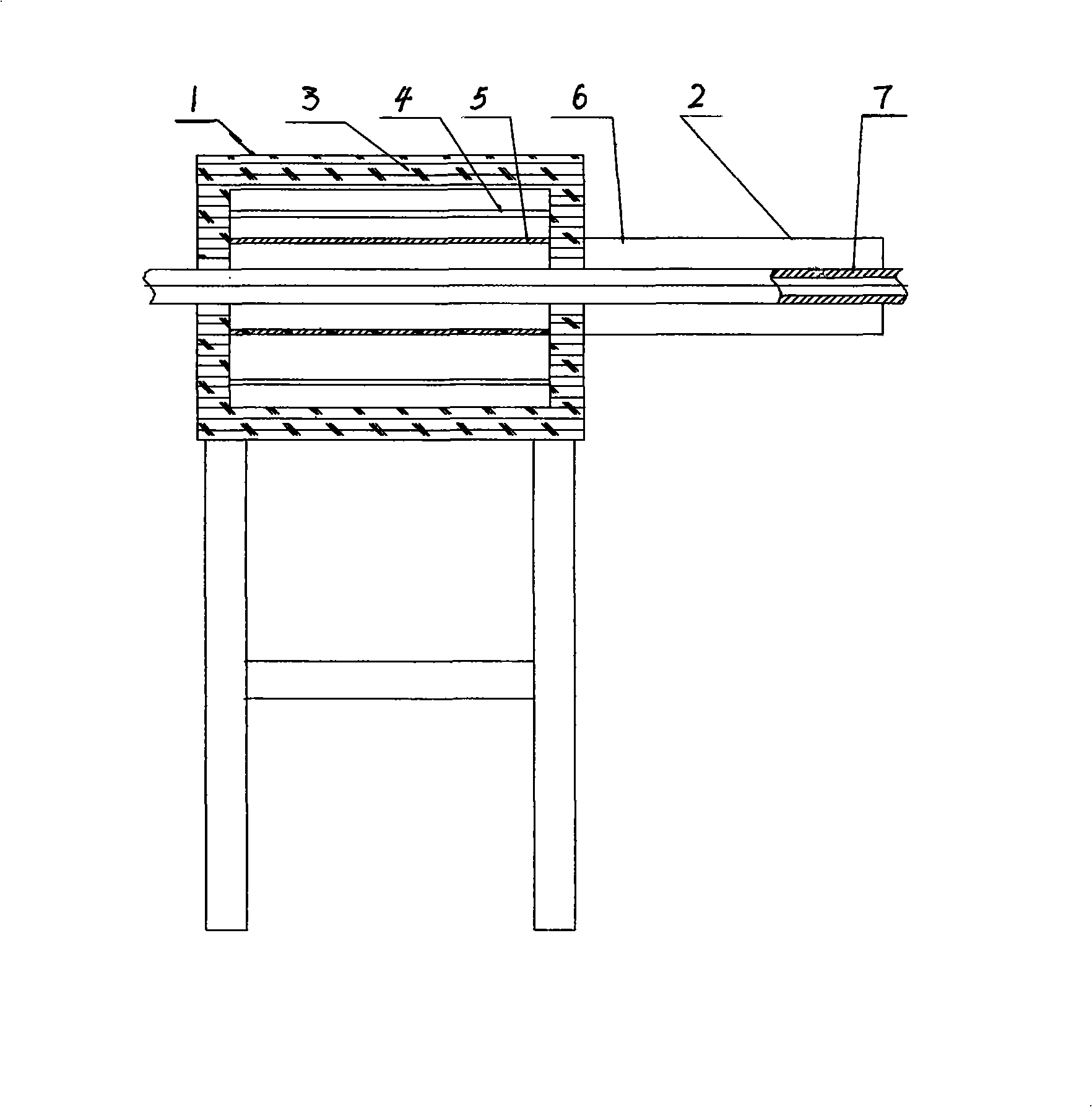

[0016] Embodiment: before use, the surface of the mandrel is cleaned with absolute ethanol and then coated with a layer of adhesive; silicone rubber, coupling agent and other extrusion encapsulation raw materials are added to the formula for extruding the mandrel to prepare the extrusion encapsulation. Lagging; add the extruded rubber into the cavity and directly extrude the mandrel through the extruder at a speed of 1m / min, and then enter the hot air vulcanization oven for vulcanization; the rubber mandrel is in the extrusion process In the middle, through the front drying tunnel 1, the working temperature of the front drying tunnel 1 is 620±50°C, and the surface temperature of the silica gel on the core rod of the drying tunnel: 140±20°C, due to the heat conduction of the quartz heating tube 4, the radiant tube 5 and the vulcanized strengthening tube 6 Due to the dual effects of thermal radiation and heat radiation, the surface of the rubber-coated mandrel quickly reaches the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com