Rubber powder modified asphalt macadam bridge surface waterproof layer and construction method

A technology of modified asphalt and rubber powder, which can be applied to cohesive pavement paved on site, bridges, bridge parts, etc., which can solve the problems of low shear strength and bonding performance, easy formation of pores in the waterproof layer of the bridge deck, and uniform construction It can reduce the cost of later maintenance and repair, facilitate mechanized operation, and the overall cost is beneficial to environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of raw materials: Finely grind waste rubber tires into powder, take rubber powder with a fineness of 30-40 mesh, add it to the base asphalt, and make modified asphalt by uniform stirring, shearing and swelling under high temperature. The weight ratio is 15%, the base asphalt is No. 90 grade A road petroleum asphalt; the particle size of the crushed stone is 5-10mm.

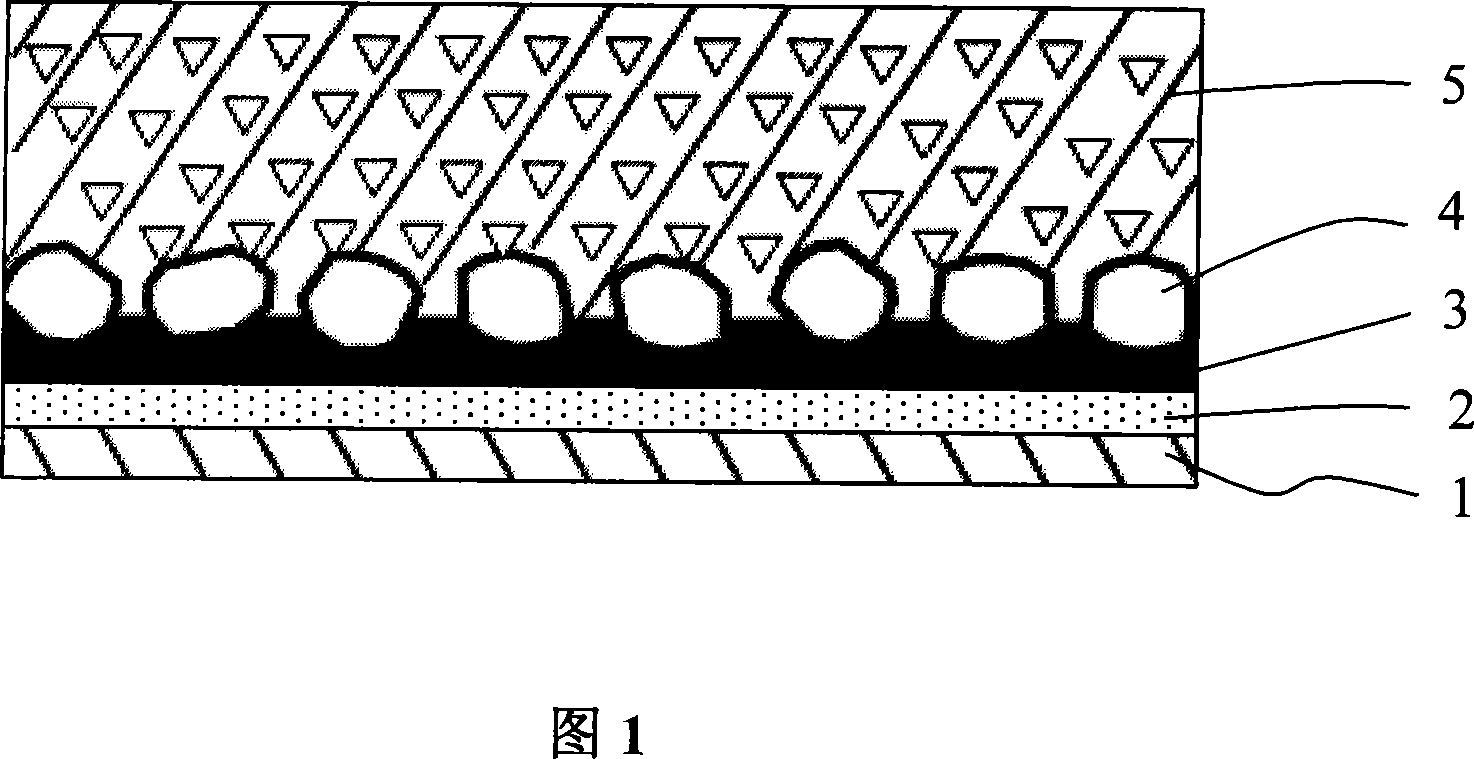

[0028] Referring to Figure 1, the construction steps of the bridge deck waterproof layer are as follows:

[0029] (1) Use a milling machine to mill and brush the bridge deck of the cement concrete pavement layer 1 to form a rough and uneven texture structure on the surface, and thoroughly clean and blow off the floating dust on the surface;

[0030] (2) The fully automatic asphalt distributor is used to distribute kerosene diluted asphalt to form the interlayer interface connection layer 2, and the distribution amount is 0.5 ~ 0.6kg / m 2 , the spraying temperature is not higher than 70 ℃;

[00...

Embodiment 2

[0036] The weight ratio of rubber powder in the rubber powder modified asphalt is 25%, the fineness is 40-50 mesh; the interlayer interface connection layer is SBR modified emulsified asphalt; the particle size of the crushed stone is 10-15mm.

[0037] The construction steps are basically the same as those in Example 1, except that: a synchronous gravel-sealing car is used to spread the rubber powder-modified asphalt and gravel at the same time, and the time interval is 3 to 6 seconds; 1.4~1.6kg / m 2 , the spreading temperature is 180~190℃; the spreading amount of SBR modified emulsified asphalt is 0.4~0.6kg / m 2 , the spraying temperature is not lower than 10 ℃.

Embodiment 3

[0039]The construction steps are basically the same as in Example 2, the difference is: the interlayer interface connection layer is high-performance emulsified asphalt, and the spraying amount is 0.4-0.6kg / m 2 , the spraying temperature is not lower than 20 ℃; the particle size of the crushed stone is 10 ~ 20mm.

[0040] After testing and testing, the performance of the bridge deck waterproof layer of the above embodiment is as follows:

[0041] project

[0042] As can be seen from the above, the bridge deck waterproof layer of the present invention has higher shear strength, better cohesion and interlayer bonding, and obvious waterproof effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com