Patents

Literature

121results about How to "No indentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

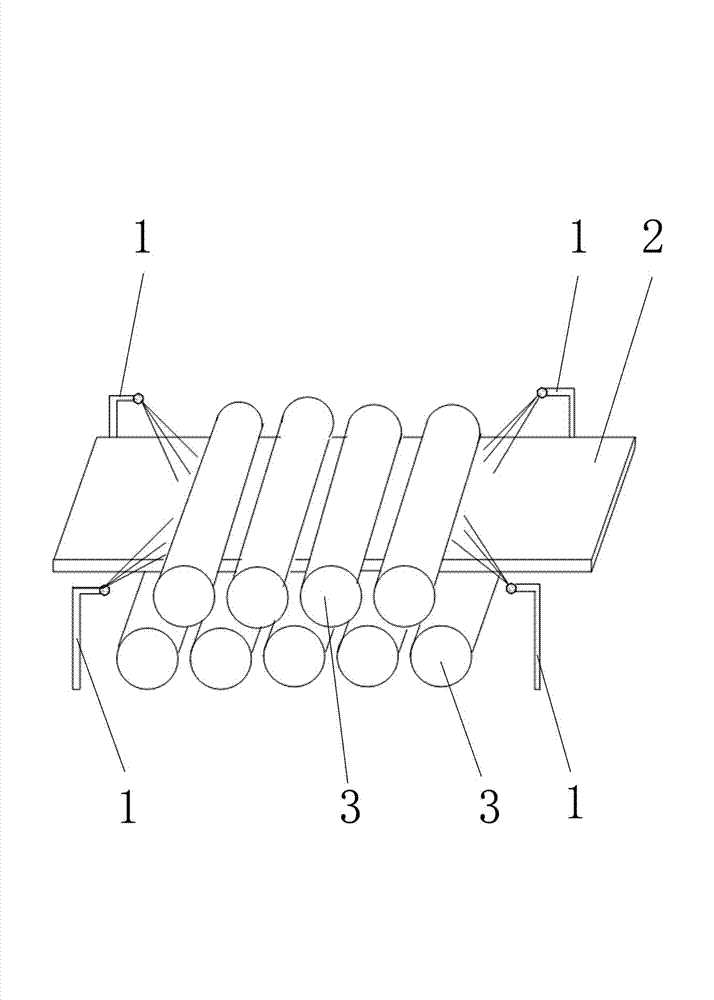

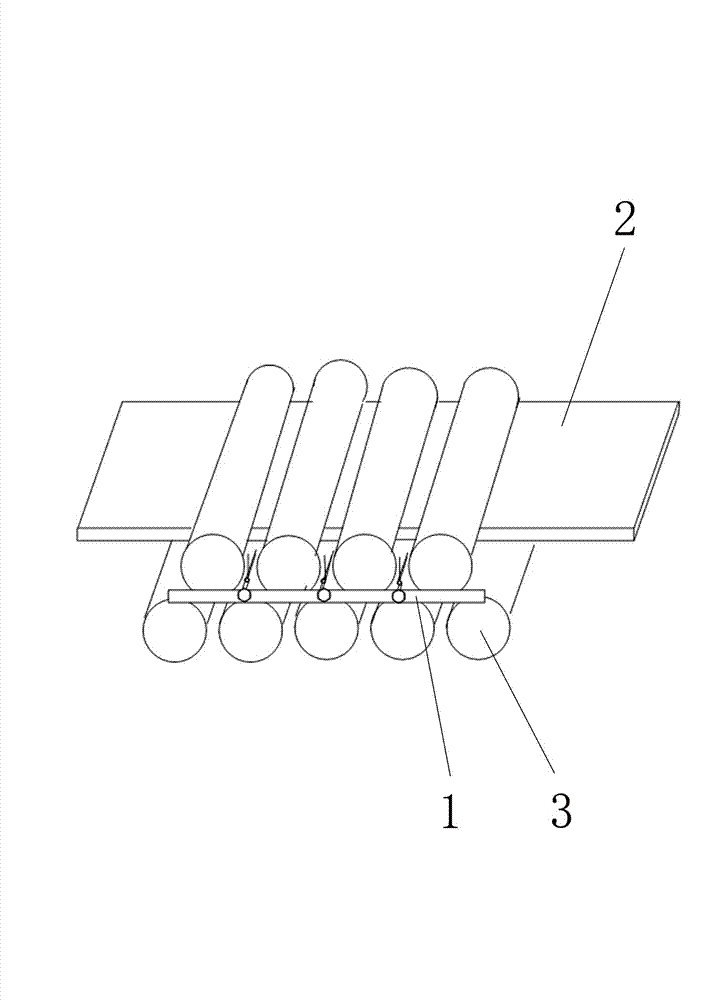

Eye massager

InactiveCN104739577AReduce use costIncrease heating massage effectVibration massageEye-masksOphthalmologyHuman eye

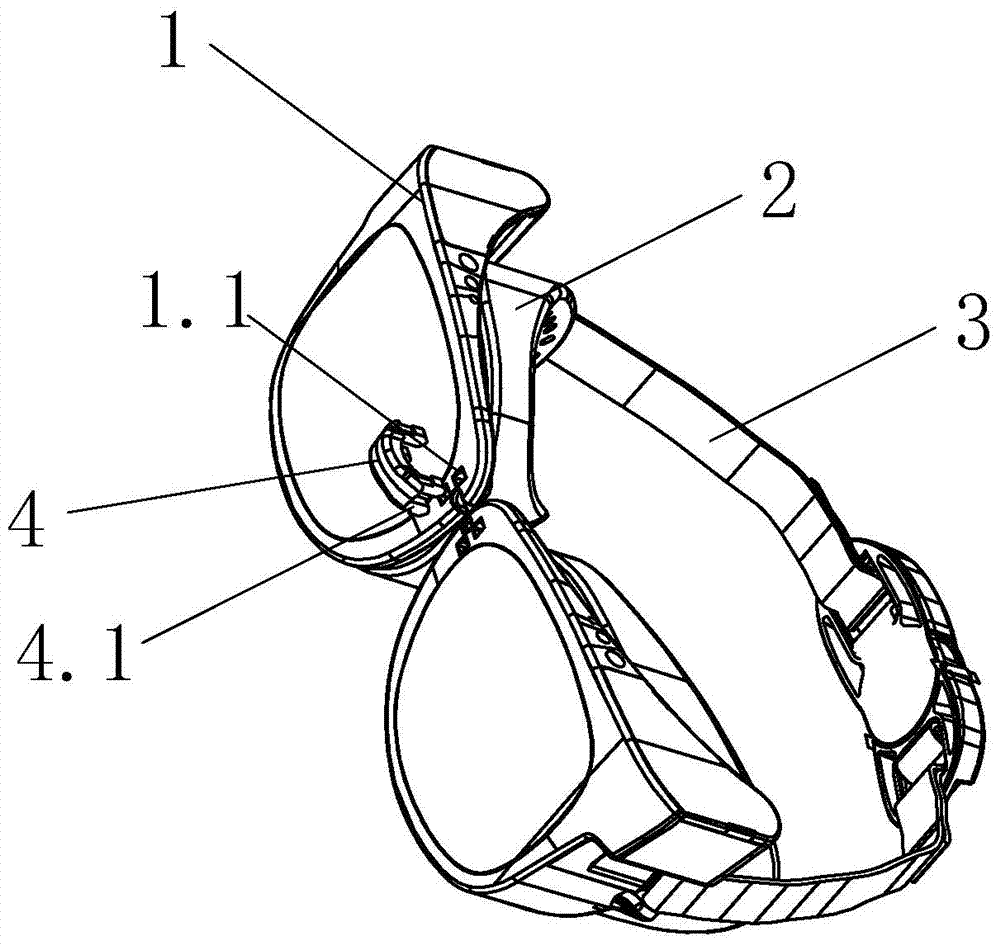

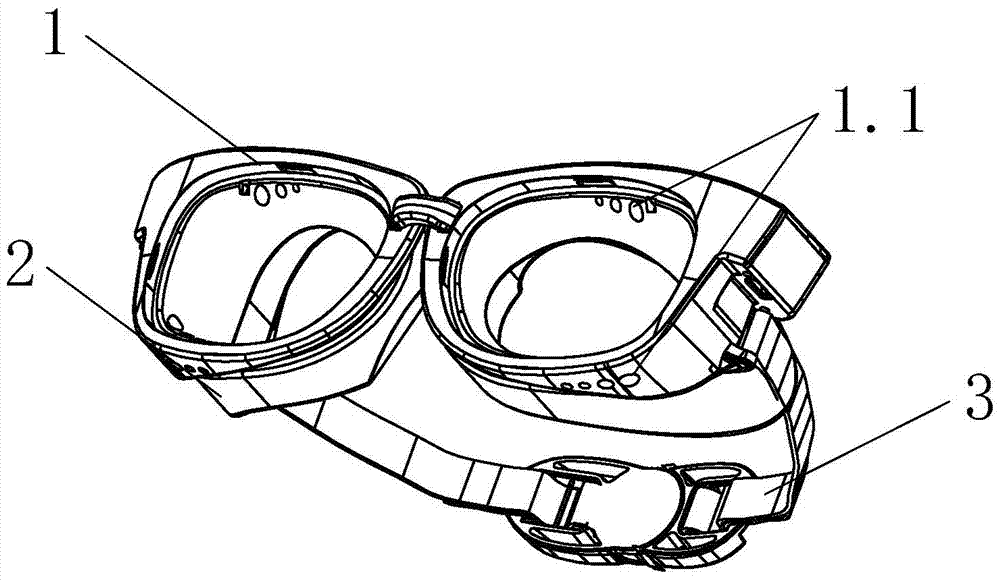

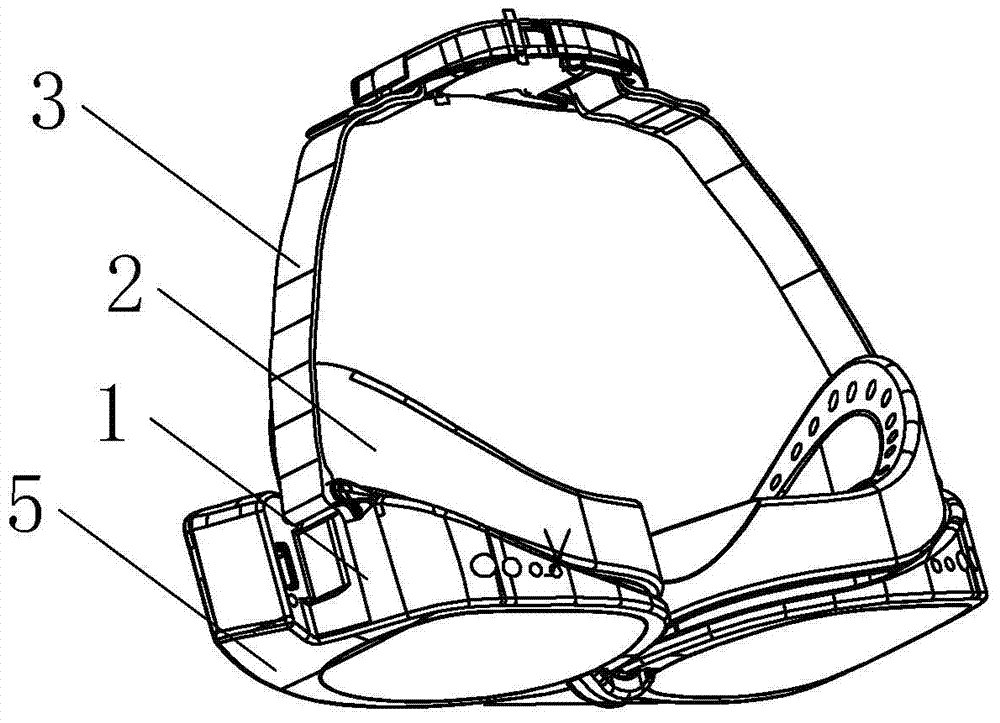

The invention discloses an eye massager. The eye massager comprises a pair of eye socket rings (1), a pair of eye patch bodies (2) and a head belt (3), wherein the eye patch bodies (2) fit the human eye sockets. Each eye patch body (2) is installed on the corresponding eye socket ring (1). A vibration assembly for massaging is arranged inside a cavity of each eye socket ring (1). The two ends of the head belt (3) are connected to the corresponding eye socket rings (1) respectively. The eye massager is characterized in that a pupillary distance adjusting buckle (4) is arranged between the two eye socket rings (1), the side wall of each eye socket ring (1) is provided with one or more vent holes (1.1) communicating the corresponding inner cavity with the external world, detachable connecting devices are arranged at the joints of the two ends of the head belt (3) and the two eye socket rings (1) respectively, and a plurality of radiating holes (2.1) are formed in the annular ring of each eye patch body (2). The eye massager can bring convenience to a user.

Owner:NINGBO YOUSHIJIA VISION CARE

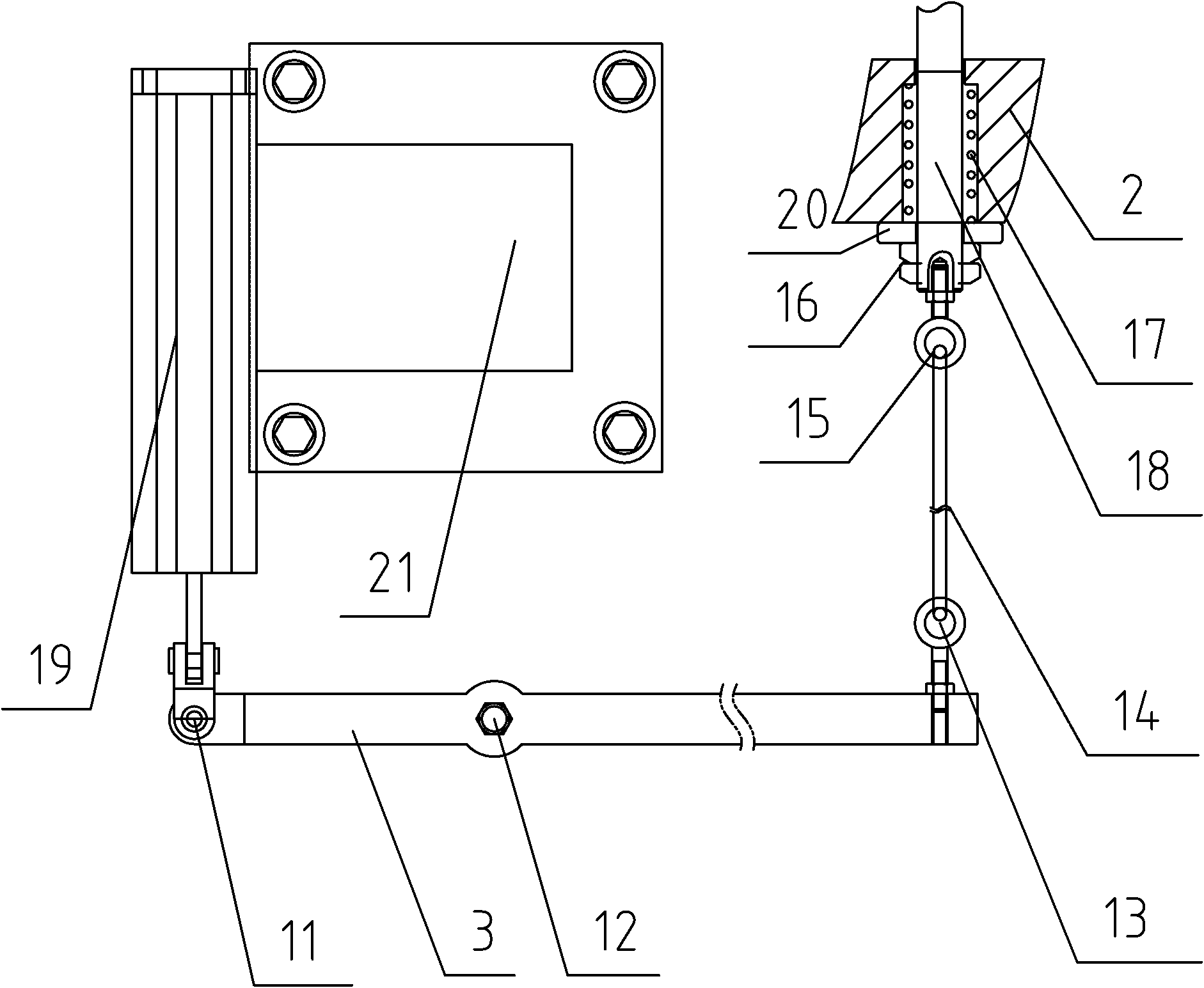

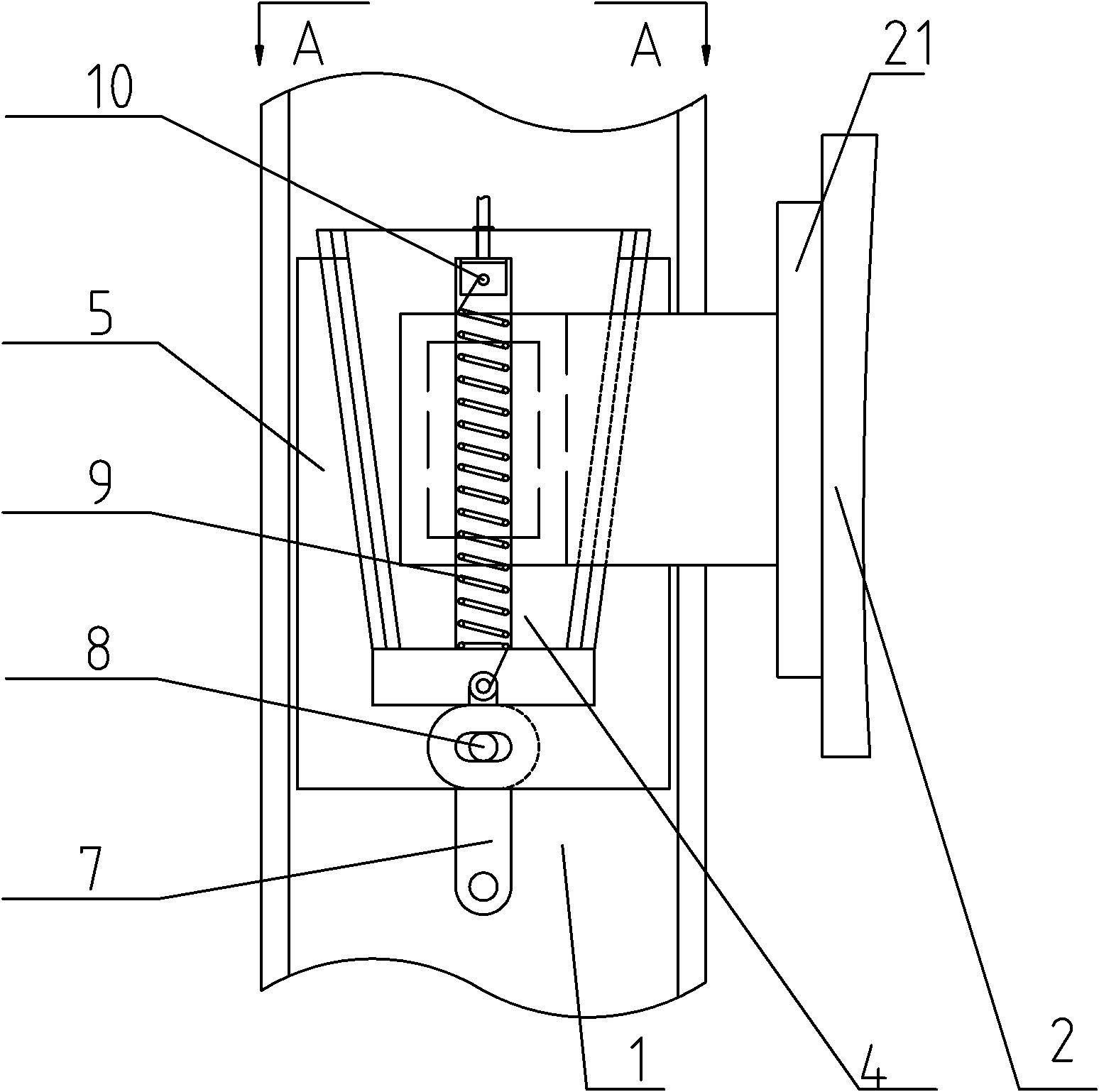

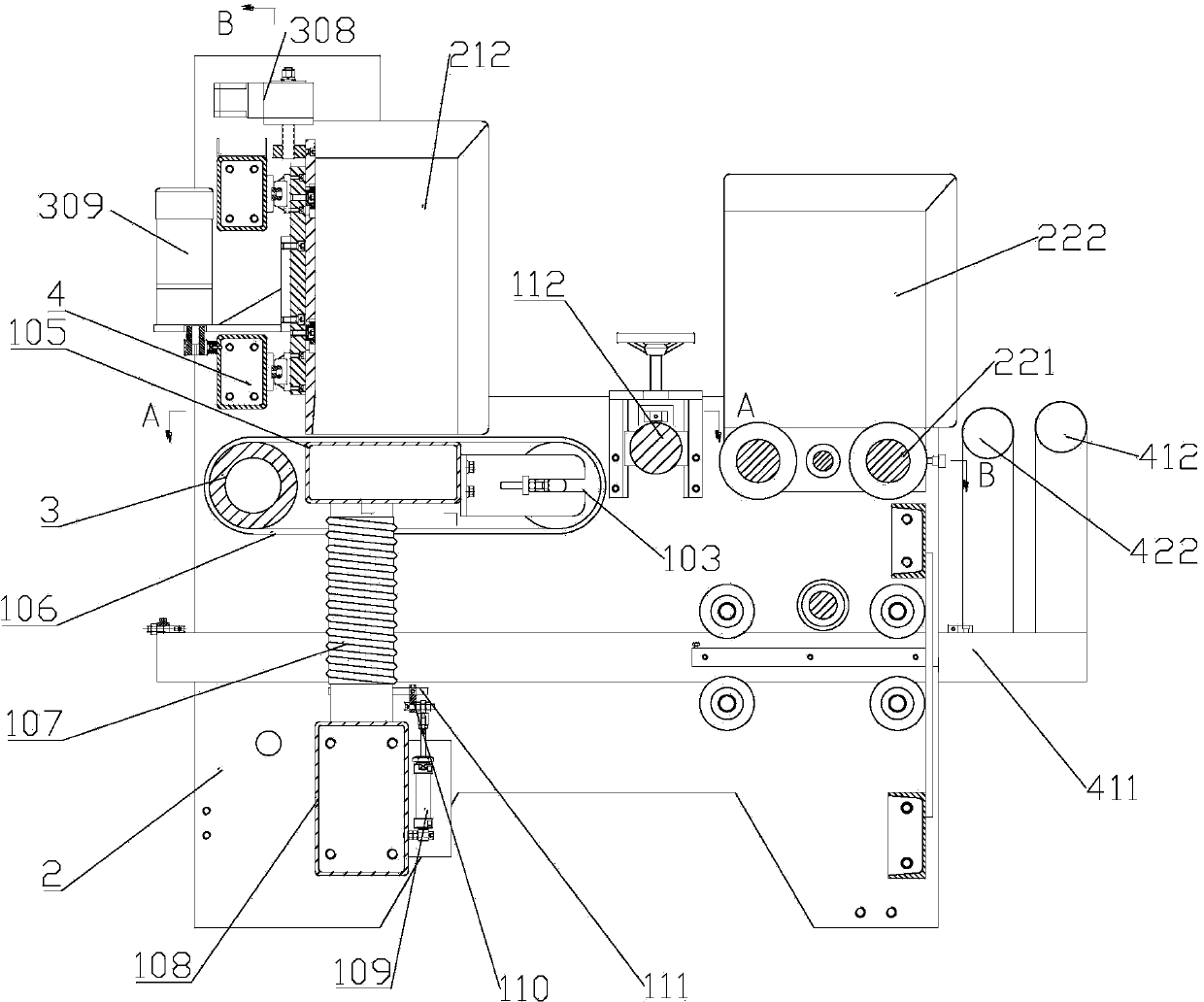

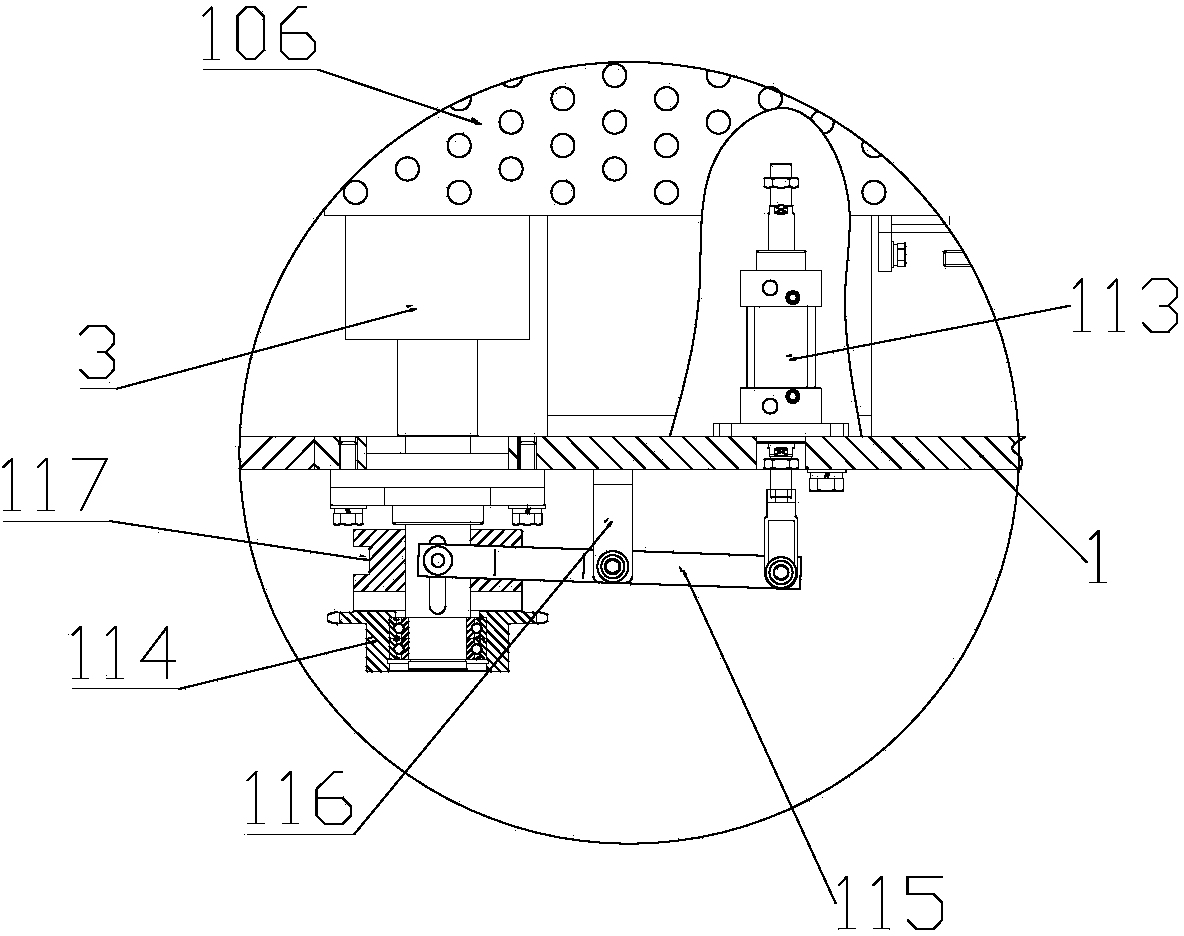

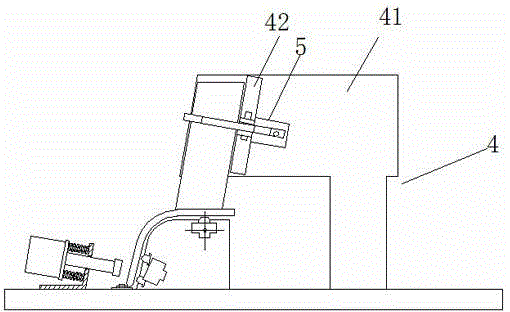

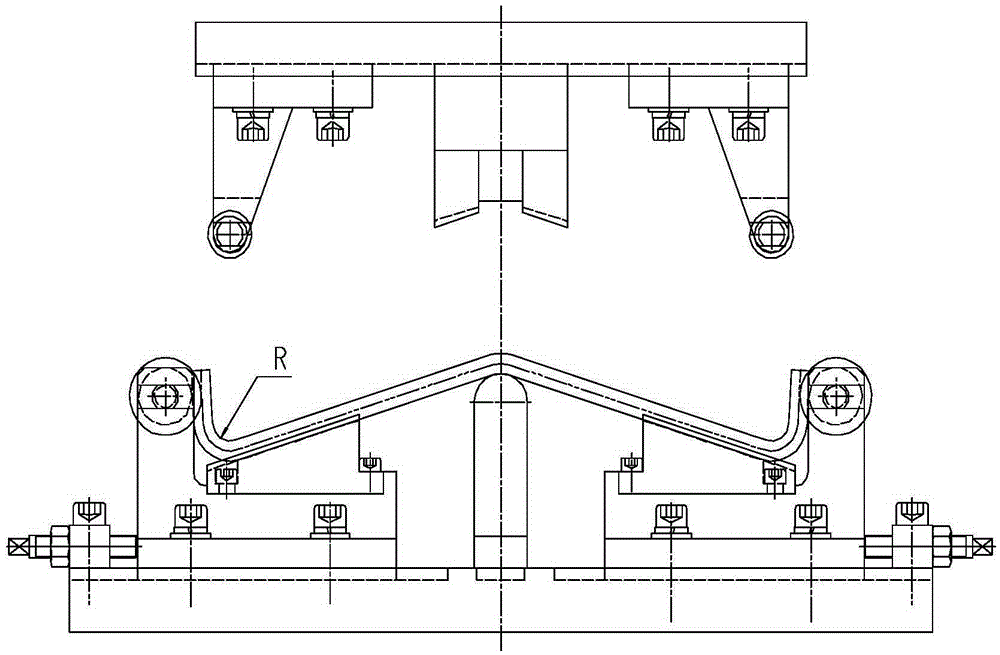

Welding clamp for automobile roof drip

InactiveCN104002074AImprove qualitySimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

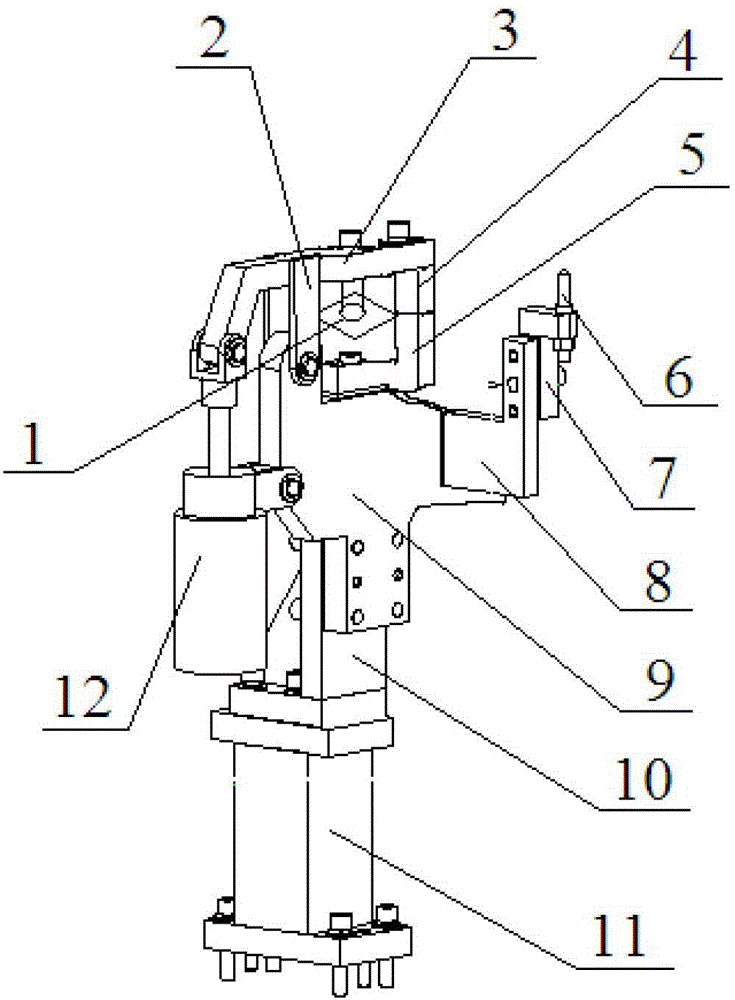

The invention relates to a welding clamp used for an automobile roof drip. The welding clamp comprises a mounting plate, a cylinder, a positioning block, a positioning pin, a pressing rotary arm and a pressing block, wherein the cylinder is fixed on the rear side of the mounting plate, the positioning block and the positioning pin are both fixed on the front side of the mounting plate, the pressing rotary arm is connected with a connecting rod of the cylinder, the pressing block is fixed on the pressing rotary arm and located right above the positioning block, the pressing rotary arm is provided with a copper plate which is located between the pressing block and the positioning block, the cylinder drives the pressing rotary arm to be lifted through the connecting rod so that the positioning pin penetrates through a positioning hole of the roof drip, a positioning face of the roof drip is located on the positioning block, the cylinder drives the pressing rotary arm to press downwards, the pressing block on the pressing rotary arm presses downwards to tightly press the roof drip, after pressing downwards along with the pressing rotary arm, the copper plate is located on a welding point to be welded, and when the roof drip is welded, one side of a welding gun makes contact with the copper plate while the other side of the welding gun makes contact with the roof drip. Compared with the prior art, the welding clamp is simple in structure and good in welding effect.

Owner:SHANGHAI ANDELAI AUTO PARTS

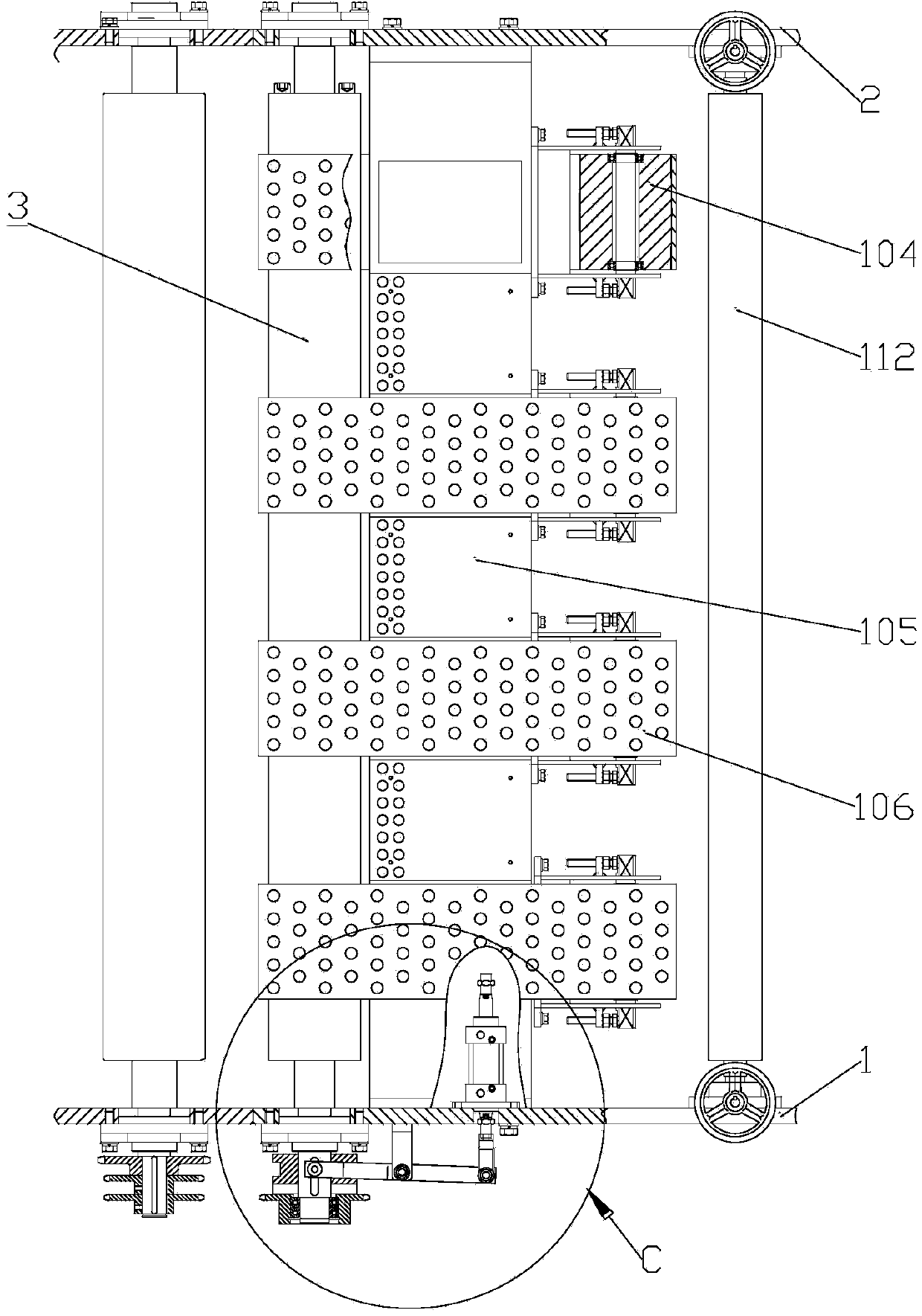

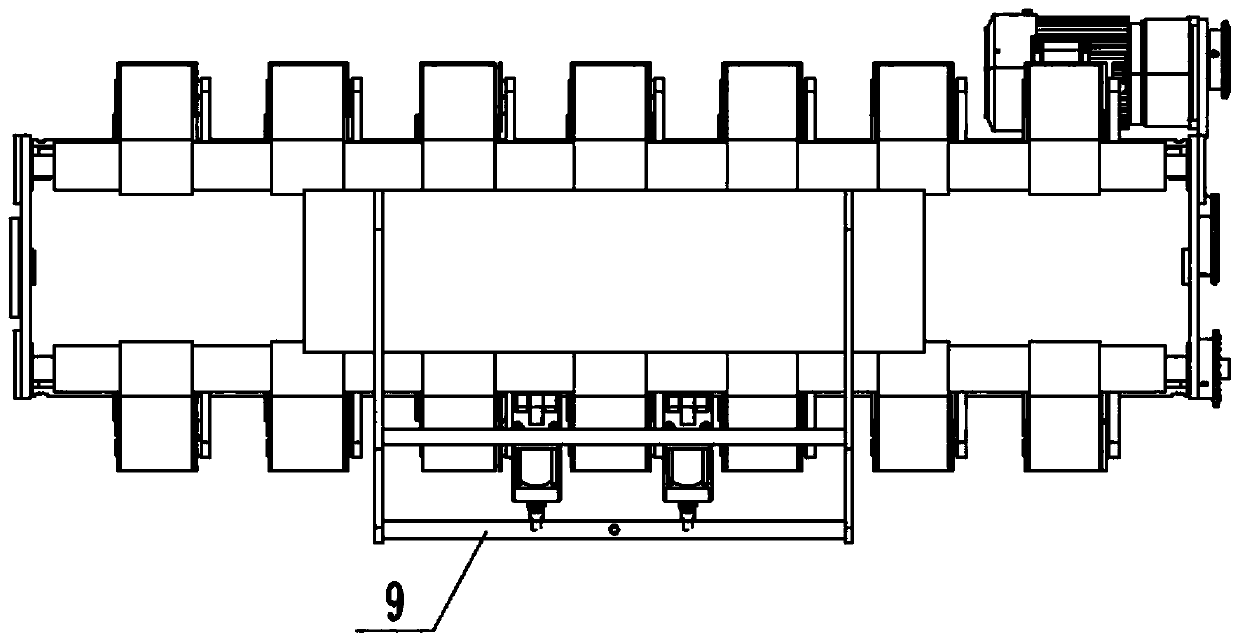

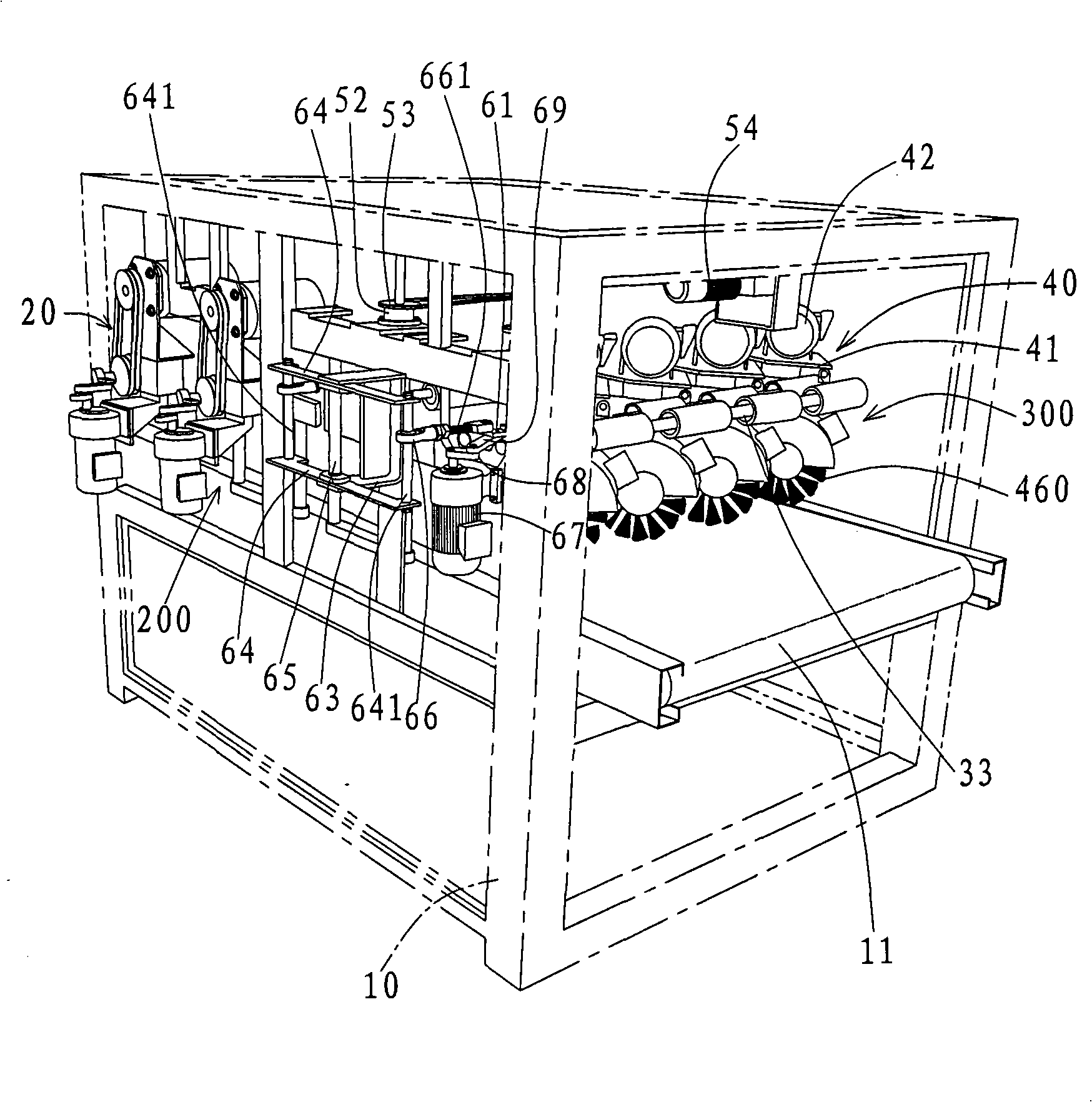

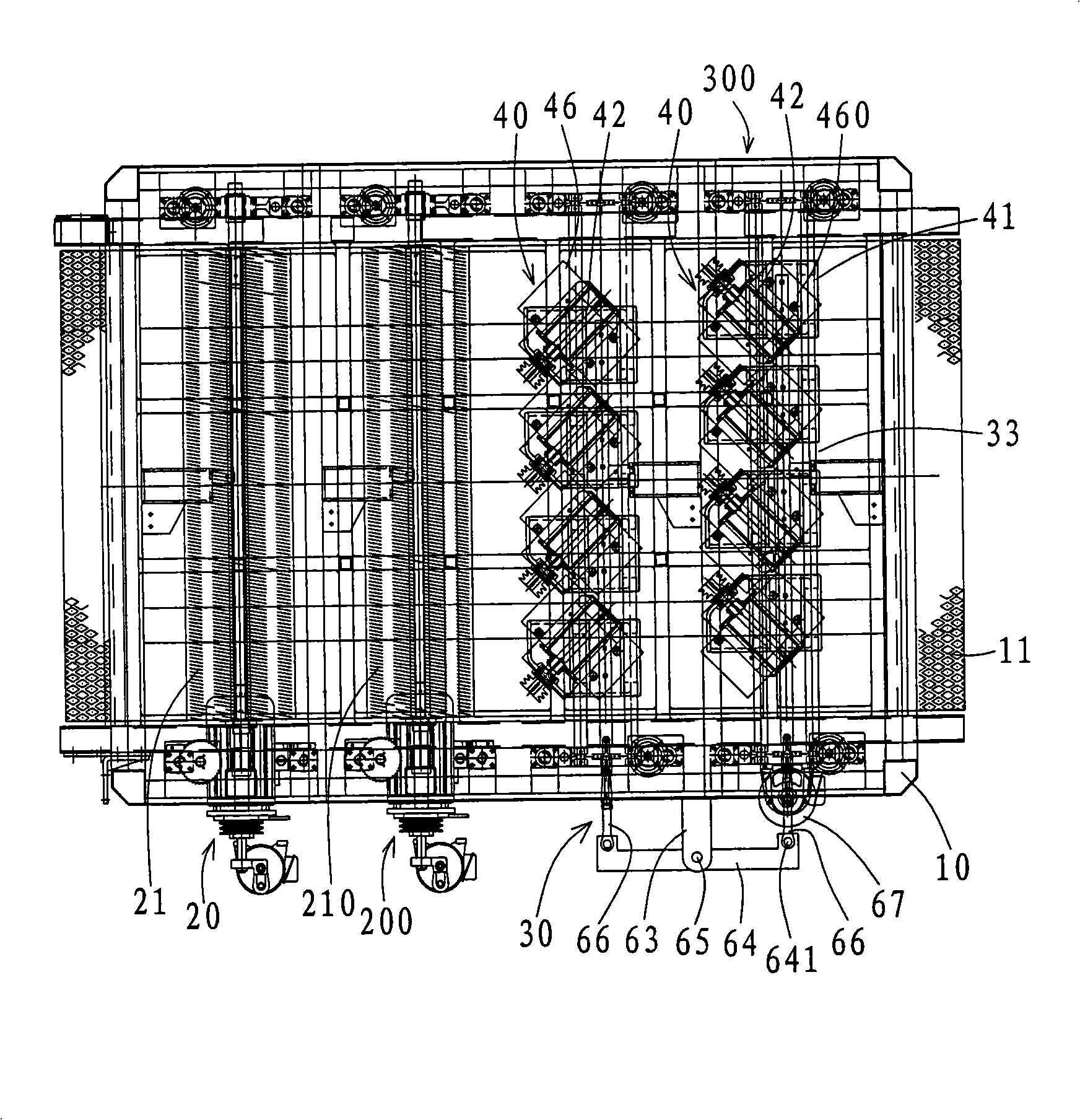

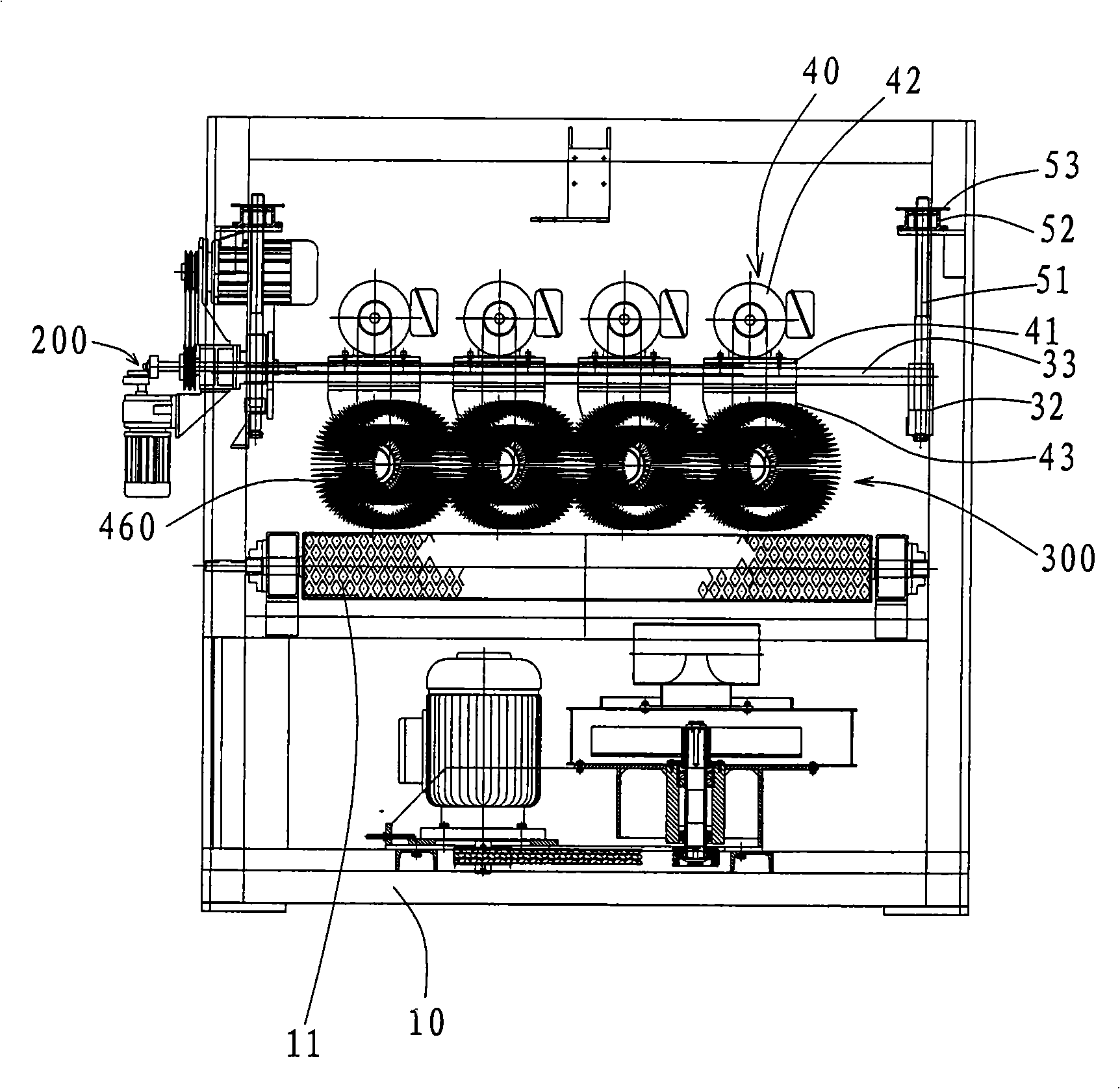

Book gluing system

The invention discloses a book gluing system, and aims to overcome the defects of low efficiency and unsatisfactory gluing effect in the existing book gluing system. In order to realize the above goals, the invention discloses a book gluing system. The system comprises a book conveying transmission mechanism, an automatic gluing mechanism, a drying mechanism and a compacting mechanism, wherein the book conveying transmission mechanism is connected with the compacting mechanism; the automatic gluing mechanism and the drying mechanism are arranged on the book conveying transmission mechanism; the automatic gluing mechanism comprises gluing rollers and brushes; and the gluing rollers are connected with the brushes in a synchronous rotation mode. The book gluing system ensures stable transmission, no press mark, even gluing, adjustable gluing thickness, favorable drying effect and flat and compact book core in the book gluing process.

Owner:东莞城市装钉器材有限公司

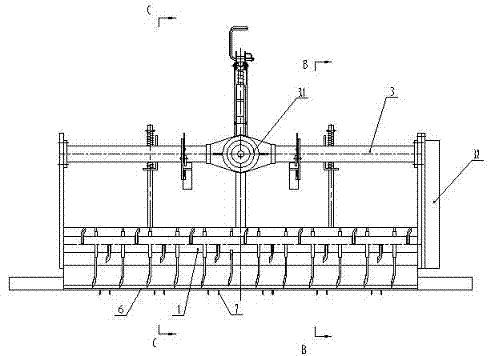

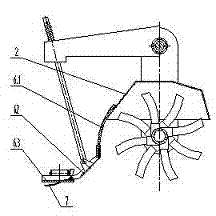

Paddy field stubble burying cultivator

ActiveCN103109600AEasy maintenanceEasy to adjustSpadesSoil-working equipmentsAgricultural engineeringPaddy field

The invention discloses a paddy field stubble burying cultivator. The paddy field stubble burying cultivator comprises a rotary tillage and beating mechanism, a casing, a transmission system, a suspension assembly, a rack assembly and a carriage assembly, wherein the transmission system comprises two stages of transmission mechanisms, namely a front bevel gear transmission mechanism and a rear chain transmission mechanism. The cultivator is characterized in that the chain transmission mechanism is arranged on one side of the cultivator; a carriage flexible buffer and compensation connection structure is arranged between a secondary carriage of the carriage assembly and the casing; a stubble burying structure is arranged on a primary carriage and comprises a compression bar overhung on the lower end face of the primary carriage; a left carriage and a right carriage are respectively arranged on the two sides of the primary carriage to form an assembled carriage structure; a primary carriage adjusting mechanism is arranged on the primary carriage and comprises a plane four-bar mechanism and a limiting structure; and the plane four-bar mechanism is formed by a support frame component, an oblique push bar, a supporting bar and a vertical bar. The paddy field stubble burying cultivator is reasonable in structure and convenient to adjust and maintain, works without dead zones, can complete rotary tillage, beating, stubble burying and harrowing in one step and has high ground flatness.

Owner:泰州樱田农机制造有限公司

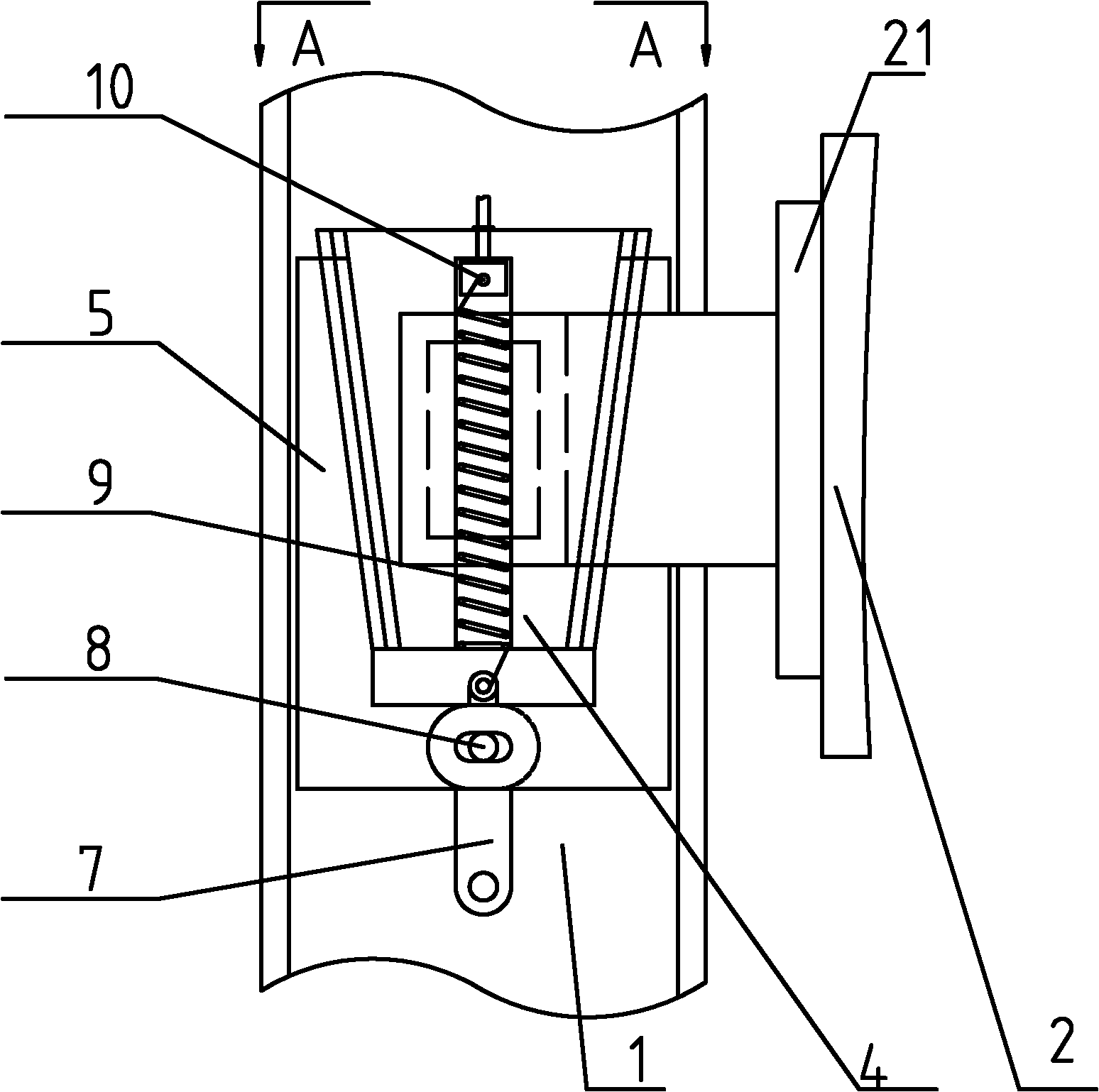

Anti-falling device of vertical elevating equipment

The invention discloses an anti-falling device of vertical elevating equipment, which comprises a brake control connecting lever and a brake locking mechanism which is arranged in a groove-shaped guide rail, wherein the brake locking mechanism comprises a wedge-shaped inner brake block which is fixedly connected with an elevating platform and two wedge-shaped outer brake blocks which are arranged on the two sides of the wedge-shaped inner brake block respectively; one side, which is close to the groove-shaped guide rail, on each wedge-shaped outer brake block is provided with a friction plate; the two wedge-shaped outer brake blocks are hinged with each other through a wedge-shaped outer brake block pin for a waist-shaped hole on the lower part of the two wedge-shaped outer brake blocks; a tension spring is connected on the wedge-shaped outer brake block pin; the upper end of the tension spring is connected on the wedge-shaped inner brake block; the brake locking mechanism is connected at one end of the brake control connecting lever; the other end of the brake control connecting lever is connected to an elevating pull rod; the elevating pull rod is inserted into the hole of the elevating platform; and pressure springs are arranged in the space between the elevating pull rod and the hole of the elevating platform. By the anti-falling device, the problem of insufficient safety of the elevating platform capable of vertically ascending and descending is solved; and the anti-falling device has a simple structure and low cost and can be flexibly braked.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

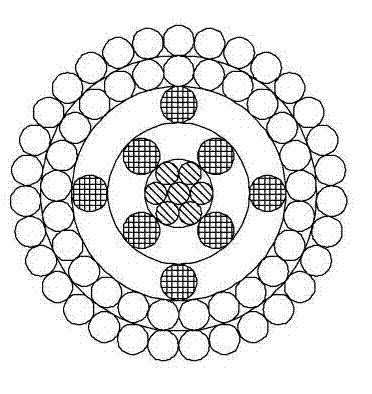

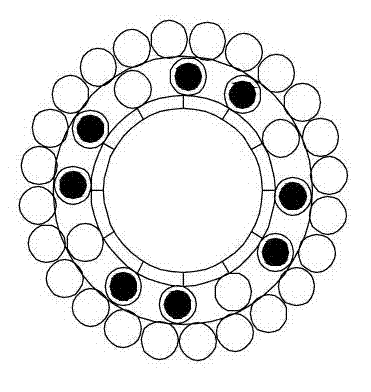

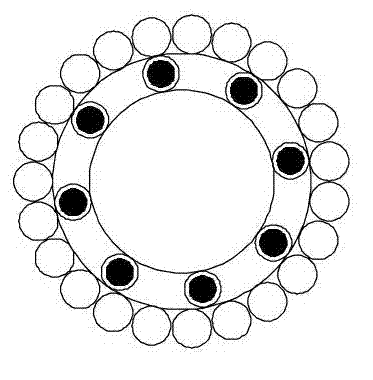

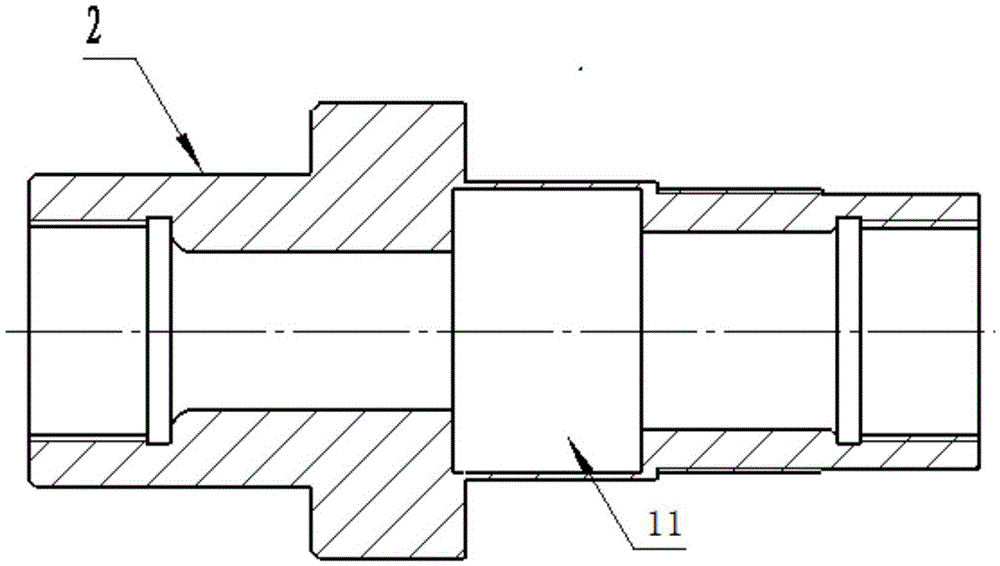

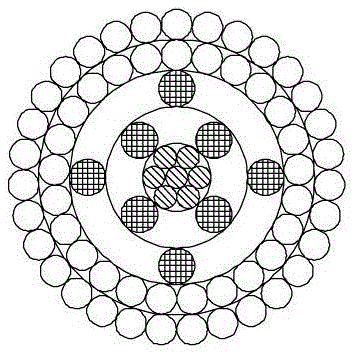

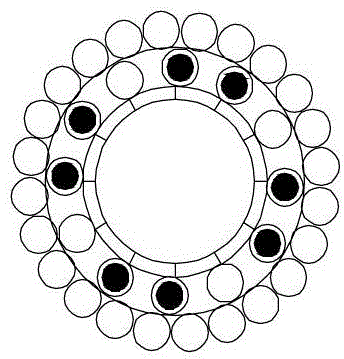

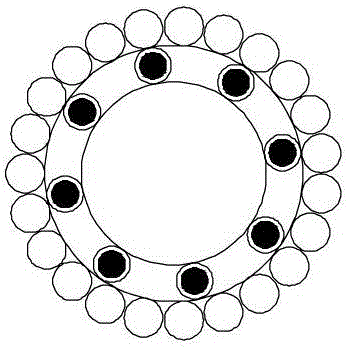

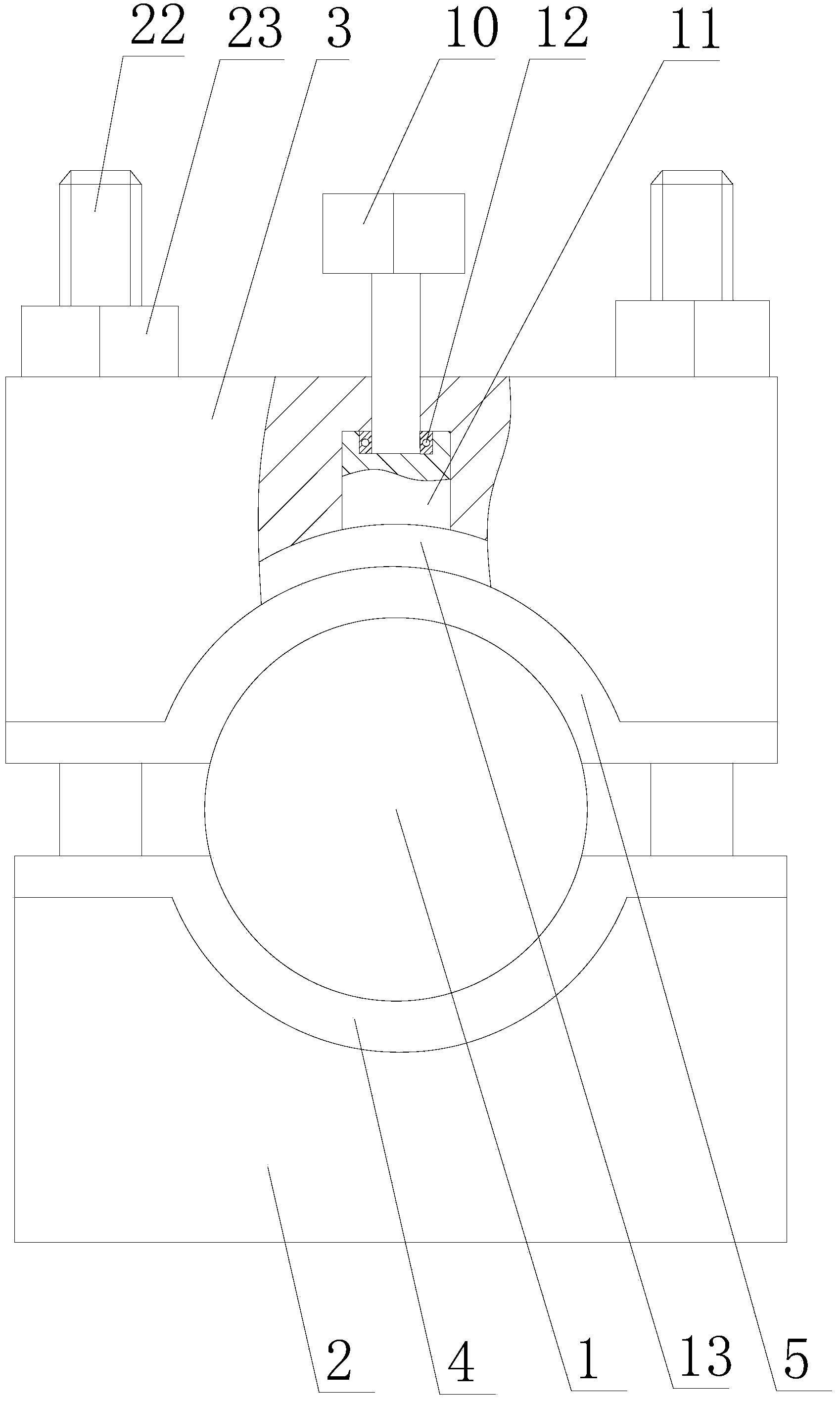

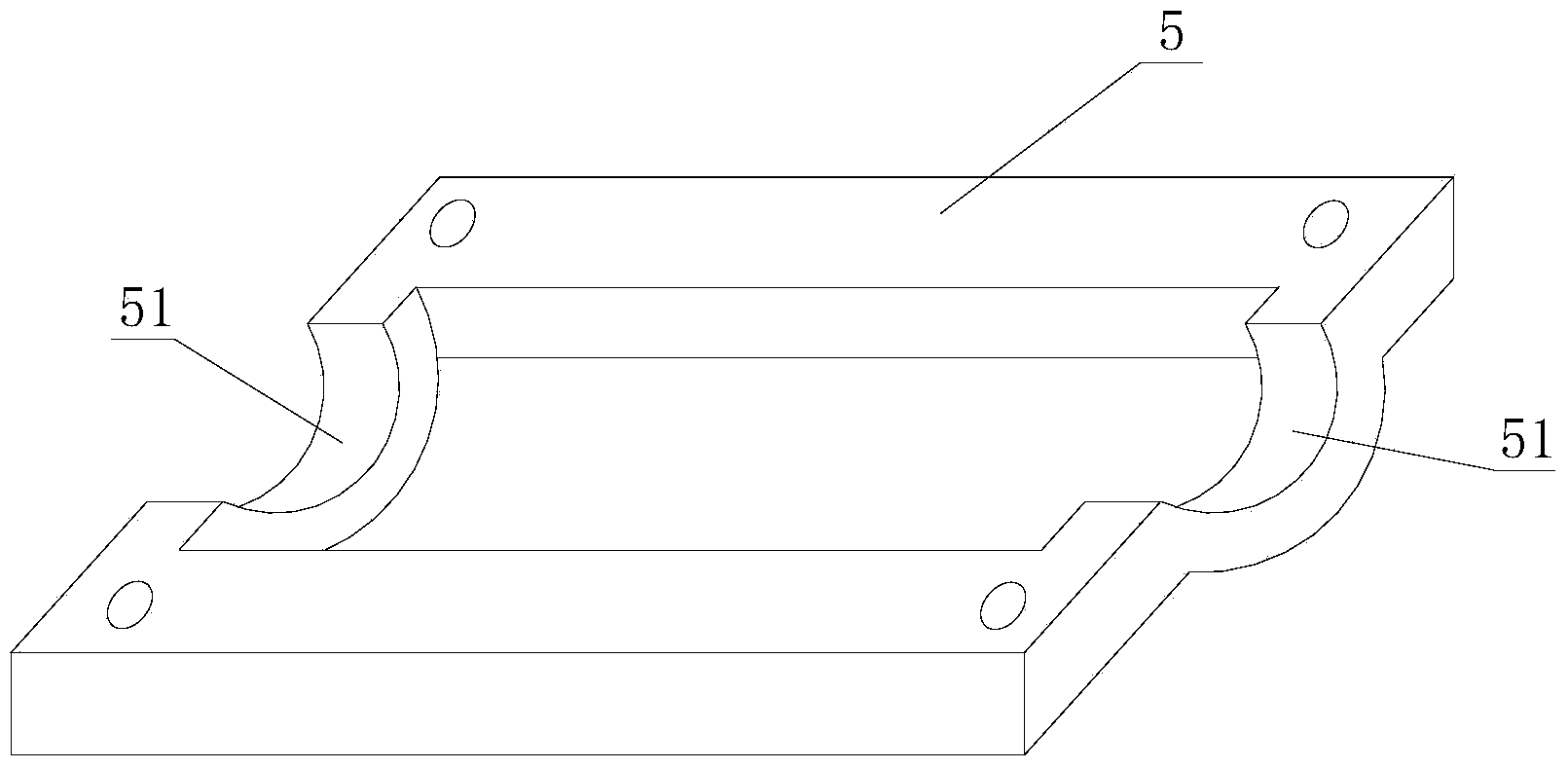

Clamping device for large-section expanded diameter conductors

ActiveCN102832570ATroubleshoot anchor connection issuesNo deformationApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention provides a clamping device for large-section expanded diameter conductors, and relates to the technical field of construction equipment and construction technology of transmission lines. The clamping device is particularly suitable for anchoring connection of large-section supporting-type high-density polyethylene expanded diameter conductors, sparse-coiled concentrically stranded circular aluminum conductors and the like in the tension stringing construction, and simultaneously, can be used for anchoring connection of larger-section four-layer concentrically stranded circular aluminum conductors. When the clamping device disclosed by the invention performs anchoring, the loading capacity is large and no slippage occurs, and the structures of the clamped parts of the conductors do not deform and have no indentation; the weight of the clamping device is lightened, therefore, the clamping device is convenient for working at heights; the good clamping performance provides safe and reliable guarantee for the anchoring connection of the large-section expanded diameter conductors; and the big problem that the clamping device for the expanded diameter conductors is lack in the tension stringing construction is solved.

Owner:CHINA ELECTRIC POWER RES INST +1

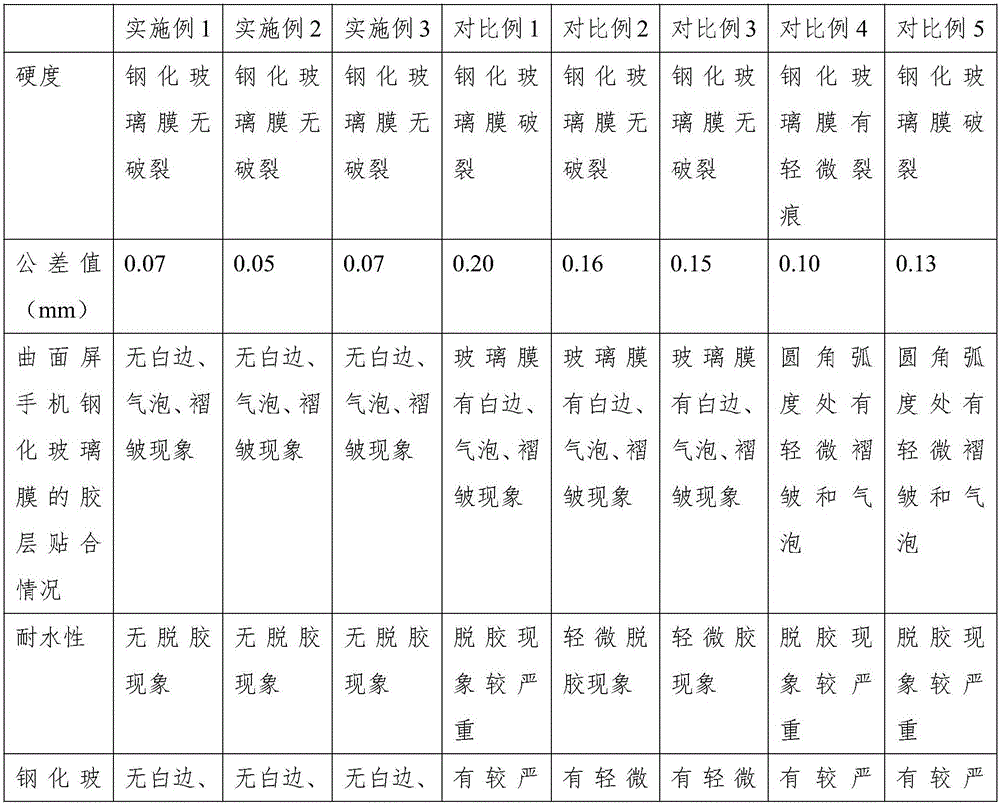

Preparation method of curved screen phone tempered glass film

ActiveCN106827776AAvoid the problem of not being able to fit the screen completelyGuarantee the effect of hot bendingLamination ancillary operationsLaminationAdhesiveThermoplastic polyurethane

The invention belongs to the technical field of phone protective films, and particularly relates to a preparation method of a curved screen phone tempered glass film. The preparation method comprises the following steps: attaching an OCA optical adhesive with a specific thickness to the upper surface of a TPU (thermoplastic polyurethane) substrate, attaching a silica gel with a specific thickness to the lower surface of the TPU substrate to obtain a TPU film, and attaching the TPU film to a glass film subjected to hot bending tempering treatment. The curved screen phone tempered glass film has the advantages of favorable hardness, favorable water resistance and favorable high-temperature resistance, and can achieve favorable effects of impact resistance, scratch resistance, wear resistance and drop prevention. The curved screen phone tempered glass film can be completely attached to the phone curved screen without the phenomena of bubbles, degumming, press marks and the like, can effectively enhance the aesthetic property of the phone, can not influence the sensitivity of the phone screen after being attached to the phone curved screen, and is an ideal curved screen phone tempered glass film.

Owner:GUANGZHOU EHANG ELECTRONICS CO LTD

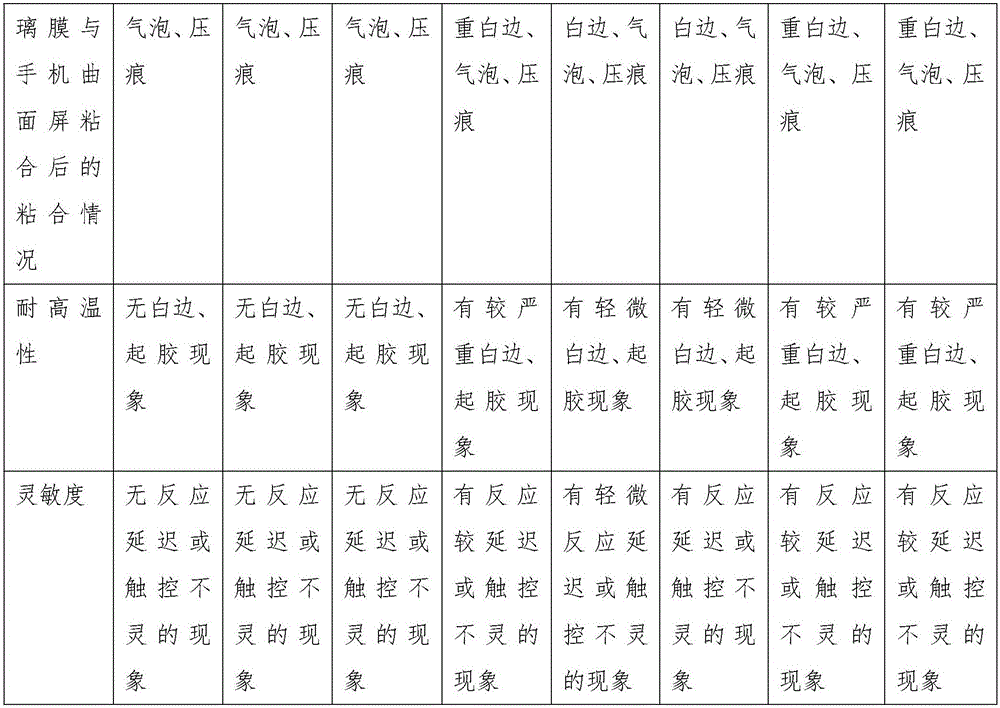

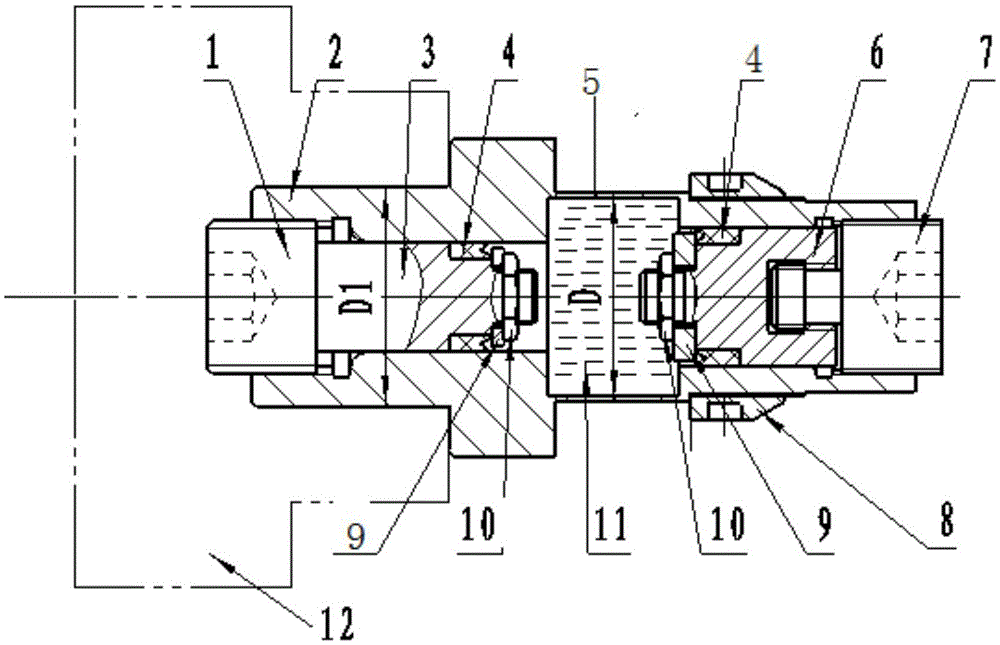

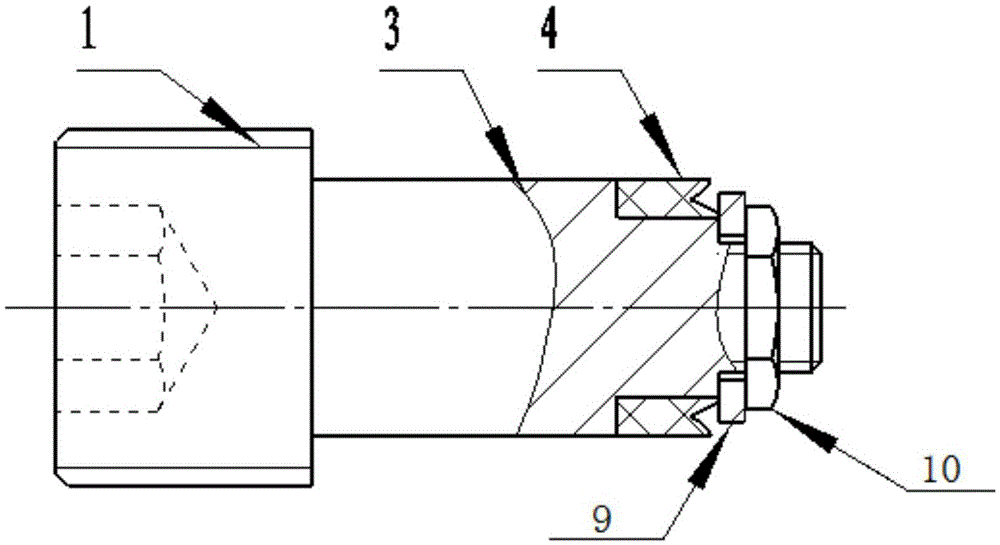

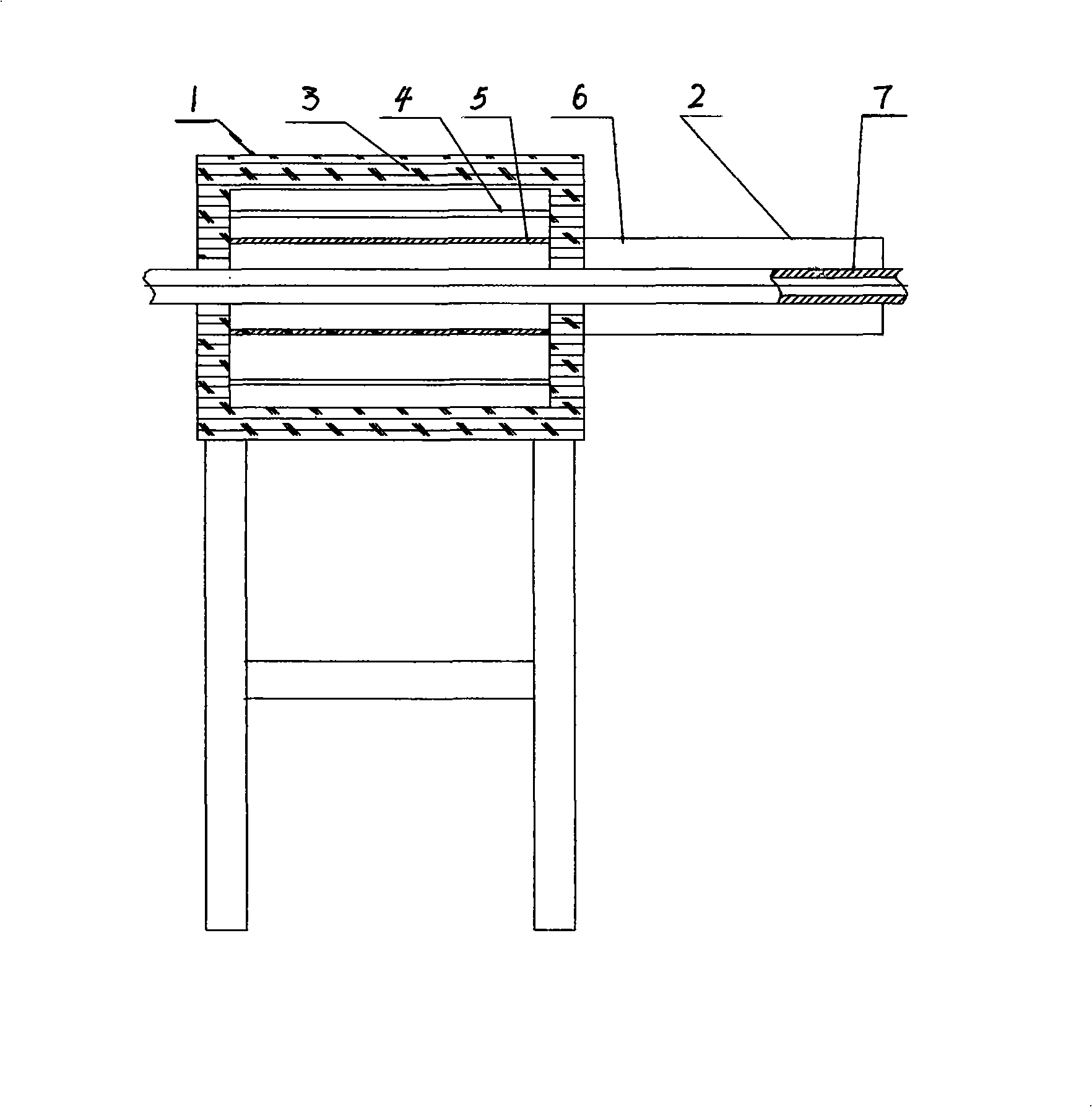

Hydraulic tensioning clamping mandrel for thin-wall shaft sleeve

InactiveCN105458317AReliable positioning and clampingSimple structureExpansion mandrelsEngineeringMachine tool

The invention discloses a hydraulic tensioning clamping mandrel for a thin-wall shaft sleeve. The hydraulic tensioning clamping mandrel is provided with a mandrel body located to the end face of a machine tool chuck or a spring sleeve. A step shaft table for locating the end face of a part to be machined is manufactured on the mandrel body, and step holes for assembling of plungers and a hydraulic oil cavity communicated with the step holes are formed in the two ends. The left pressure adjusting plunger (3) is sealed at the left end of the hydraulic oil cavity from the leftward step hole of the mandrel body (2), the right pressure adjusting plunger (6) is sealed at the right end of the hydraulic oil cavity from the rightward step hole of the mandrel body, and a closed container is formed. The to-be-machined part assembled on a rightward barrel of the mandrel body is clamped between the end face of the step shaft table of the mandrel body and a compressing nut (10) through the compressing nut (10). Sealing screws (7) are screwed down to drive the plungers to move and compress hydraulic oil in the hydraulic oil cavity, and the to-be-machined part clamped on the external circle tensioning mandrel body on the thin wall of the hydraulic oil cavity is expanded through pressure generated by the hydraulic oil cavity under the action of oil pressure. The hydraulic tensioning clamping mandrel is easy to manufacture and high in clamping precision, and a clamping area is stable and reliable in clamping.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

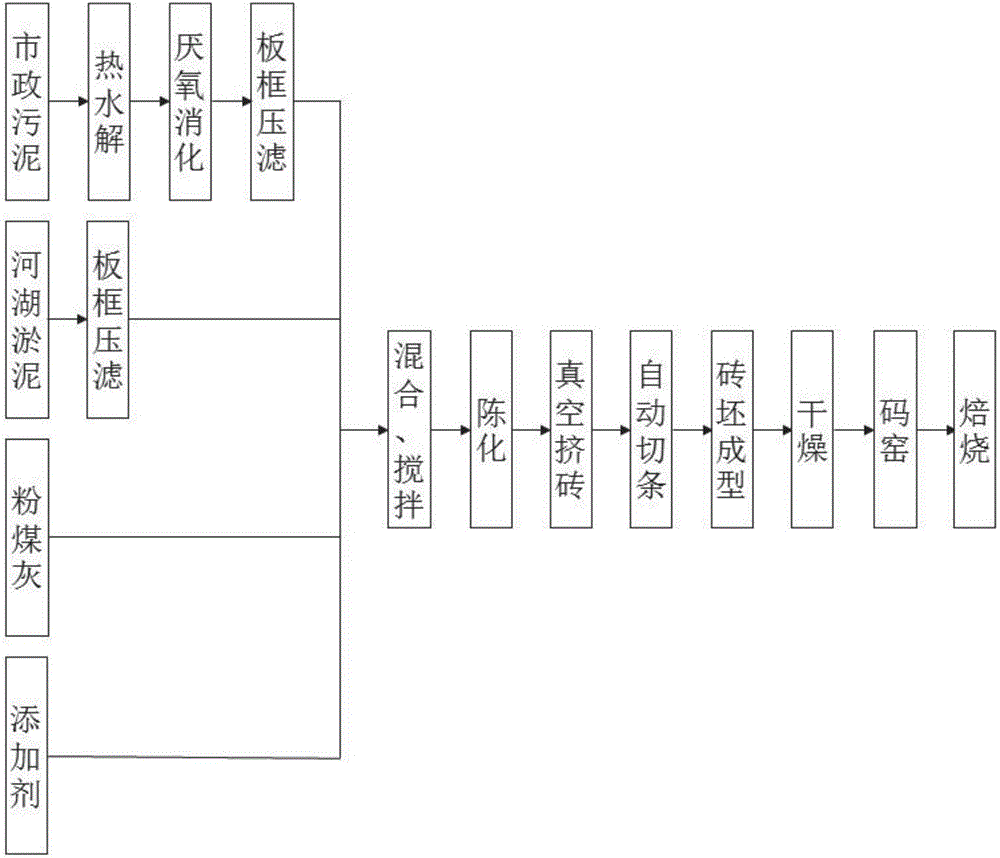

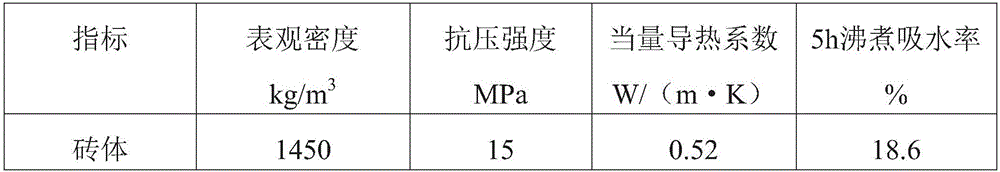

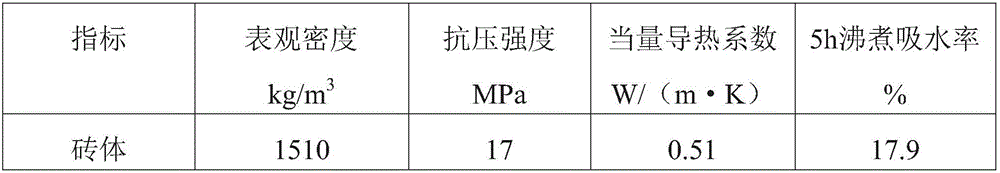

Mud and sludge sintered brick and preparation method thereof

InactiveCN106747314ASolve the way outRealize resource utilizationSludge treatment by pyrolysisWaste based fuelBrickResource utilization

The invention discloses a mud and sludge sintered brick, which is prepared from the following sintering raw materials in mass fraction according to the oven dry weight: 30 percent to 45 percent of municipal mud sequentially subjected to pyrohydrolysis pretreatment and anaerobic digestion treatment, 35 percent to 60 percent of river sludge with the solid content being 60 to 70 percent, 5 percent to 10 percent of pulverized fuel ash and 5 percent and 10 percent of additive. The invention also discloses a preparation method of the mud and sludge sintered brick. The preparation method comprises the steps of pretreating the municipal mud, pretreating the river sludge, preparing a mixture, forming a green brick, drying, roasting to obtain a finished product, and the like. According to the mud and sludge sintered brick and the preparation method thereof provided by the invention, the digested mud and the dried river sludge are mixed to prepare the sintered brick, so that not only are the problems of the two kinds of sludge solved, but also the secondary pollution problem produced by stacking of the two kinds of sludge is solved, and the resource utilization of the mud and the sludge is realized. The sintered brick prepared through the invention has no crack, no unfilled corner and no pressing marks on the appearance, and has better physical and mechanical properties.

Owner:上海同济普兰德生物质能股份有限公司

Thermoplastic polyimide (TPI) adhesive film, double-sided base material containing same and preparation method thereof

InactiveCN103232818AImprove adhesionIncrease freedomFilm/foil adhesivesMetal layered productsMetal foilThermal expansion

The invention provides a thermoplastic polyimide (TPI) adhesive film, a double-sided base material containing the same and a preparation method thereof. Through the combination of dianhydrides and diamines which are different in number of benzene rings and replacement position, the inlaid TPI adhesive film is prepared by inlaying a thermosetting material in a thermoplastic material; in the crystal imidization process, the glass transition temperature is 255 DEG C, the melting point is 380 DEG C, and the storage modulus is 2*10<6>Pa; the double-sided base material is synthesized by taking the TPI adhesive film as a medium carrier and coating the TPI adhesive film with a copper base, an aluminum base or other metal foils; the peel strength of the double-sided base material is ultra high (2.5KN / CM or above), the dielectric strength is more than 190KV / mm, and the thermal expansion coefficient is 21ppm DEG C; and the double-sided base material has a roughness of less than 2mu m, and does not warp or curl.

Owner:SHENZHEN DANBOND TECH

Casting method of hub

The invention discloses a casting method of a hub. The hub comprises the following components by pass percent: 10 to 50% of iron, 1 to 10% of manganese, 5 to 15% of magnesium, 1 to 10% of zinc, 1 to 5% of chromium, 1 to 5% of copper, 1 to 5% of nickel and 3 to 10% of tungsten, and the balance being aluminium. According to the casting method, the hub is high in strength, good in toughness, good in quality, free of impressions, and not liable to deform, the impact resistance is high, and the popularization of a product is facilitated.

Owner:KAIPING ZHONGLV IND

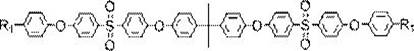

Preparation method of double-terminated polysulfone

The invention belongs to the technical field of high polymer materials, and particularly relates to a preparation method of double-terminated polysulfone, thepreparation method comprises the following steps: taking bisphenol A and 4, 4 '-dichlorodiphenyl sulfone as reaction monomers, adding an end-capping reagent A with activity lower than that of the bisphenol A, a salt-forming agent and a solvent for reaction until the molecular weight reaches the target molecular weight, adding an end-capping reagent B with activity higher than that of the bisphenol A for continuous reaction, and after the reaction is finished, carrying out post-treatment to obtain the double-terminated polysulfone. The end-capping reagent A with activity lower than that of bisphenol A is added in the early stage of the reaction to reduce the low molecular weight polymer part in the final product so that the mechanical property, heat resistance, thermal stability and other properties of the product are improved. When the reaction is about to be finished, the end-capping reagent B with higher activity than bisphenol A is added so that the molecular weight is controlled through rapid end capping, the performance of products in different batches can be more stable, and the method is more suitable for the field of preparation of hollow fiber membranes.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

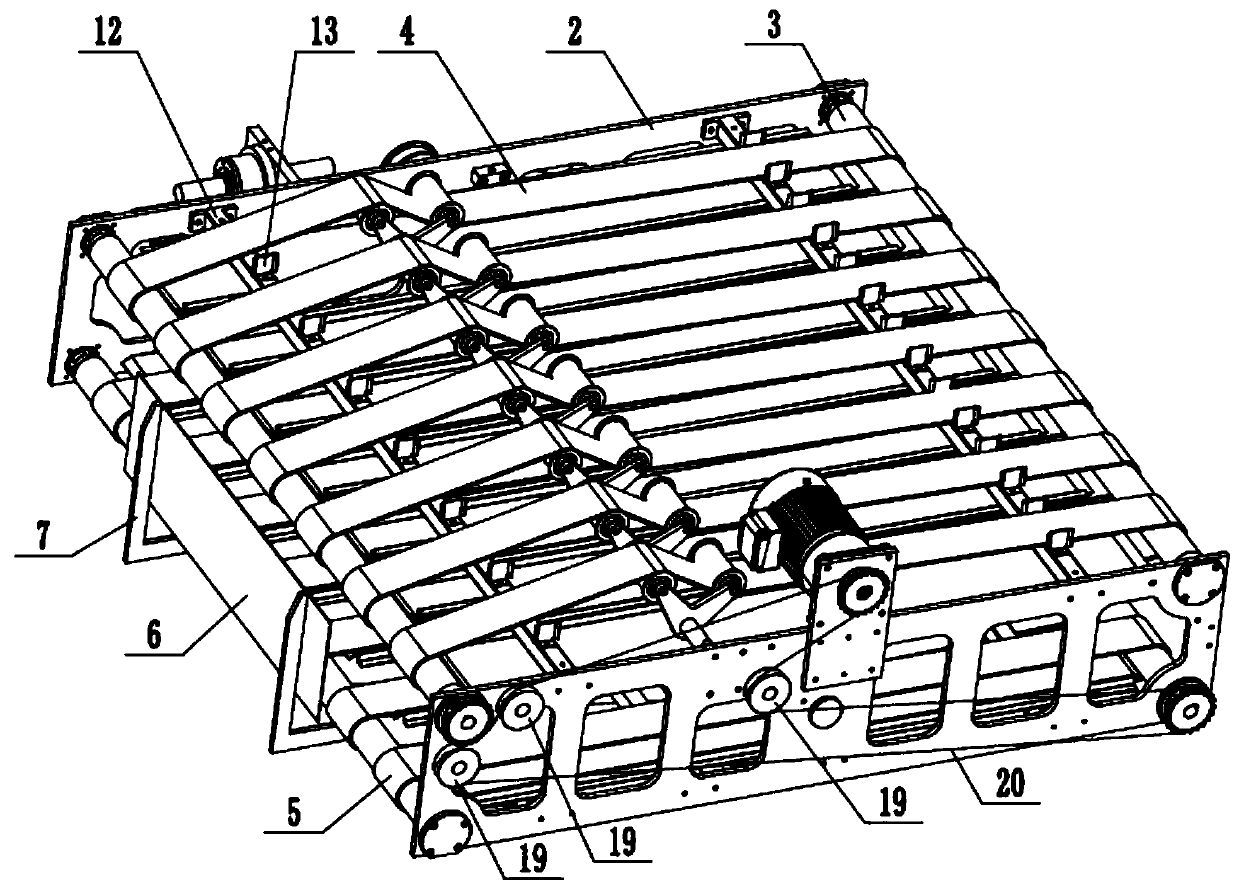

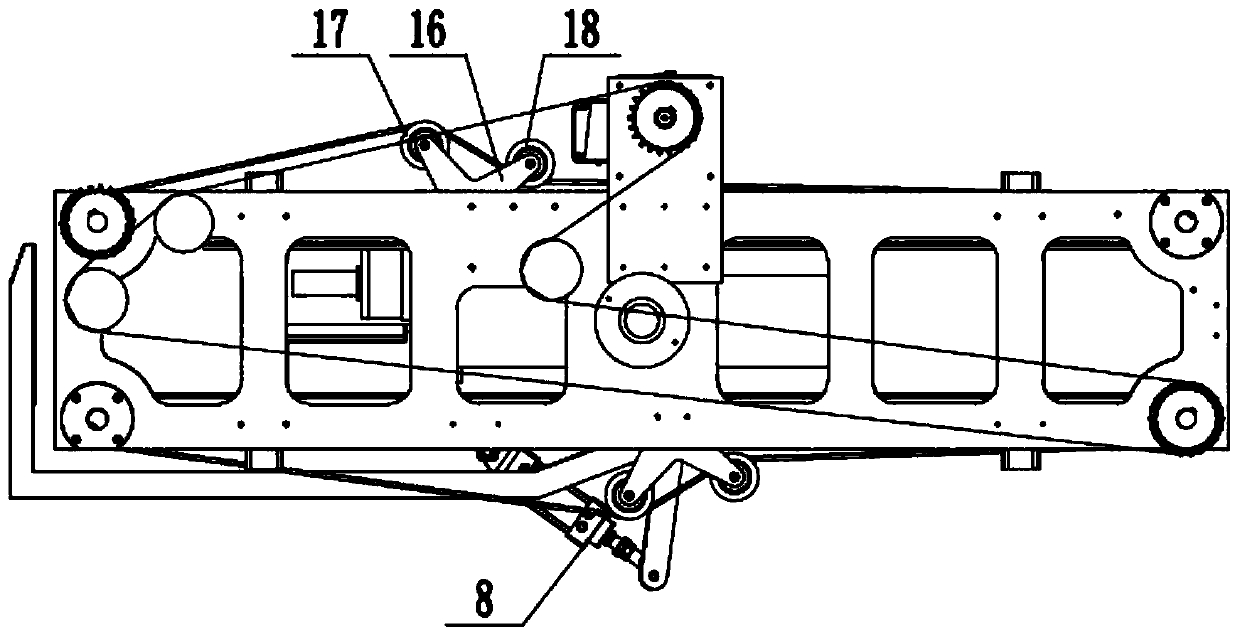

Paper automatically-feeding table

ActiveCN103738754AQuality assuranceGuaranteed aestheticsRegistering devicesArticle feedersNumerical controlPaperboard

The invention discloses a paper automatically-feeding table. The paper automatically-feeding table comprises a left wallboard, a right wallboard, a transmission roller, a driven wheel, a belt, a vacuum absorbing mechanism, guide rails, a width adjusting device, a height adjusting device and a length adjusting device, wherein the left wallboard and the right wallboard are oppositely arranged, the transmission roller is arranged between the left wallboard and the right wallboard and drivingly connected with a first power mechanism, the belt sleeves the transmission roller and the driven wheel and provided with an exhaust inlet, the vacuum absorbing mechanism is arranged inside the belt, the guide rails are arranged above the belt, the width adjusting device is used for adjusting the paper feeding width, the height adjusting device is used for adjusting the paper feeding height, and the length adjusting device is used for adjusting the paper feeding length. Therefore, by mounting the width adjusting device, the height adjusting device and the length adjusting device on an existing paper feeding table, conveyed paperboards can be limited and positioned; the position of baffles can be adjusted through numerical control, and the working efficiency can be greatly improved; a vacuum absorbing type conveying mode can avoid indentations on corrugated paperboards and further quality and attractiveness of the paperboards can be guaranteed.

Owner:江门市金钩包装机械有限公司

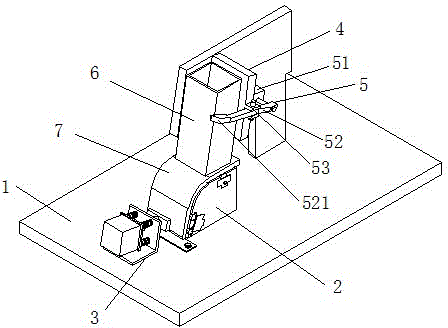

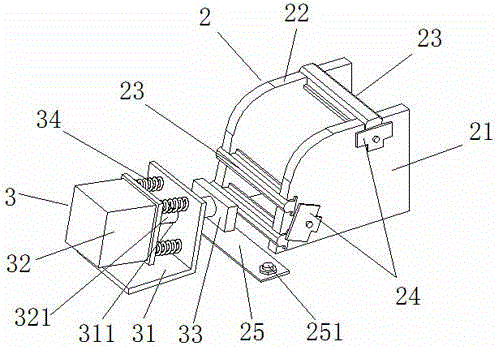

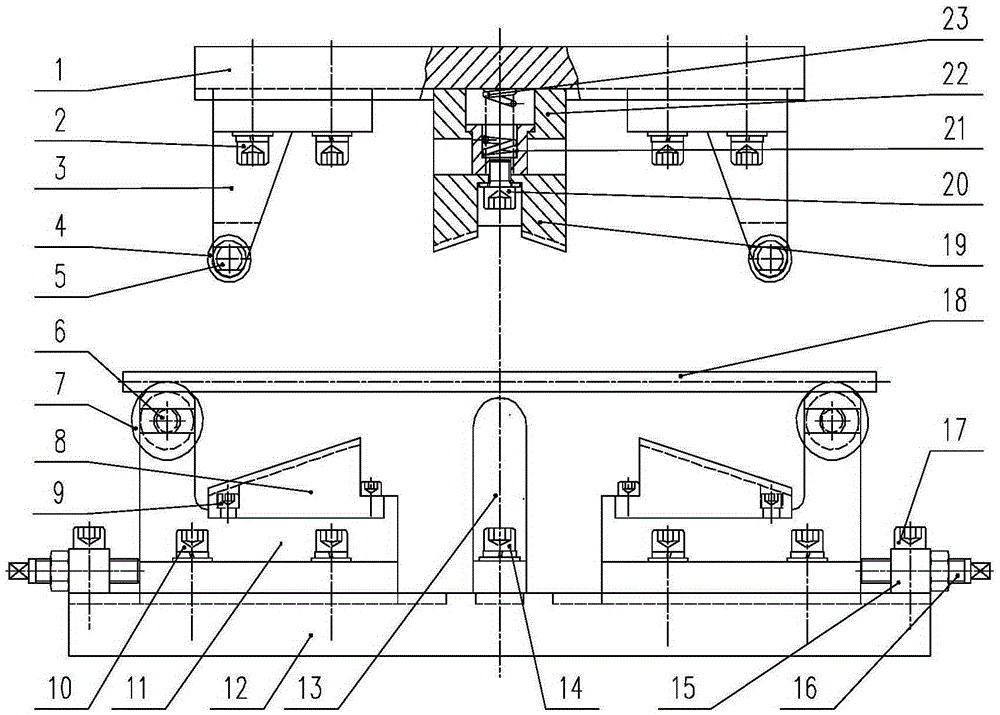

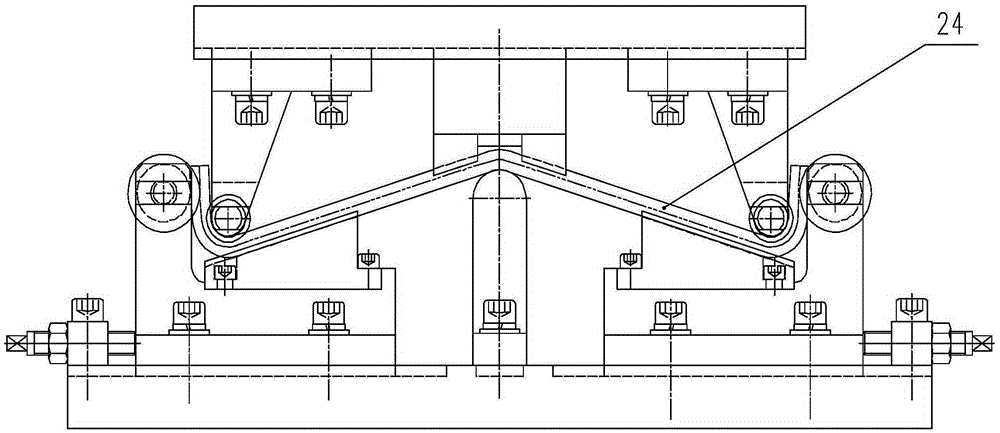

Aluminums strips position and compaction device of hollow glass molecular sieve filling machine

The invention relates to an aluminum strips position and compaction device of a hollow glass molecular sieve filling machine, in particular to an aluminum strips position and compaction device which has simple structure and adjustable compacting force, and can ensure even touch between the surface of the aluminum strips and the compaction device when compacting; the hollow glass molecular sieve filling machine aluminum strips position and compaction device comprises a compaction and position assembly, a square-tube bracket and a rear panel; the compaction and position assembly comprises a transverse compaction device and a vertical compaction device and is connected on the hollow glass molecular sieve filling machine through the square-tube bracket and the rear panel; a transverse compaction cylinder in work drives a transverse compaction block and pushes the aluminum strips to a transverse position plate to finish transverse position after arriving at the designated position; the vertical compaction cylinder uses a vertical cylinder mandril to push a V-shaped compaction block to compact the aluminum strips vertically, and stops vertical compaction after pushing the aluminum stripsto the position of the compaction block.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY +1

Positioning device for precisely manufacturing curve-shaped automobile accessory

ActiveCN104646901ASolve the positioning problemEffective positioningWelding/cutting auxillary devicesAuxillary welding devicesSingle supportCurve shape

The invention relates to a positioning device for precisely manufacturing a curve-shaped automobile accessory. The positioning device comprises a platform, a support seat, a position limiting device and a positioning component, wherein the support seat is arranged on the platform, the position limiting device is used for fixing one side of an accessory arranged on the support seat, the positioning component is used for carrying the other part of the accessory, a fixing component is arranged on the positioning component, the support seat comprises two support plates in mutually parallel arrangement, the support plates are used for carrying at least two support strips arranged on the arc-shaped carrying surface of the accessory, the single support strip penetrates through the two support plates at the same time and is projected out of the carrying surface, the positioning component is correspondingly arranged at the upper end of the carrying surface, and the position limiting device is correspondingly arranged at the lower end of the carrying surface. The positioning device has the advantages that through the arrangement of the support strips in the support seat, the positioning problem of automobile accessories in different curves is solved, the efficient and fast positioning is realized, and in addition, the accessory surface can be effectively protected from generating impressions.

Owner:HANQIAO HUZHOU HARDWARE PROD

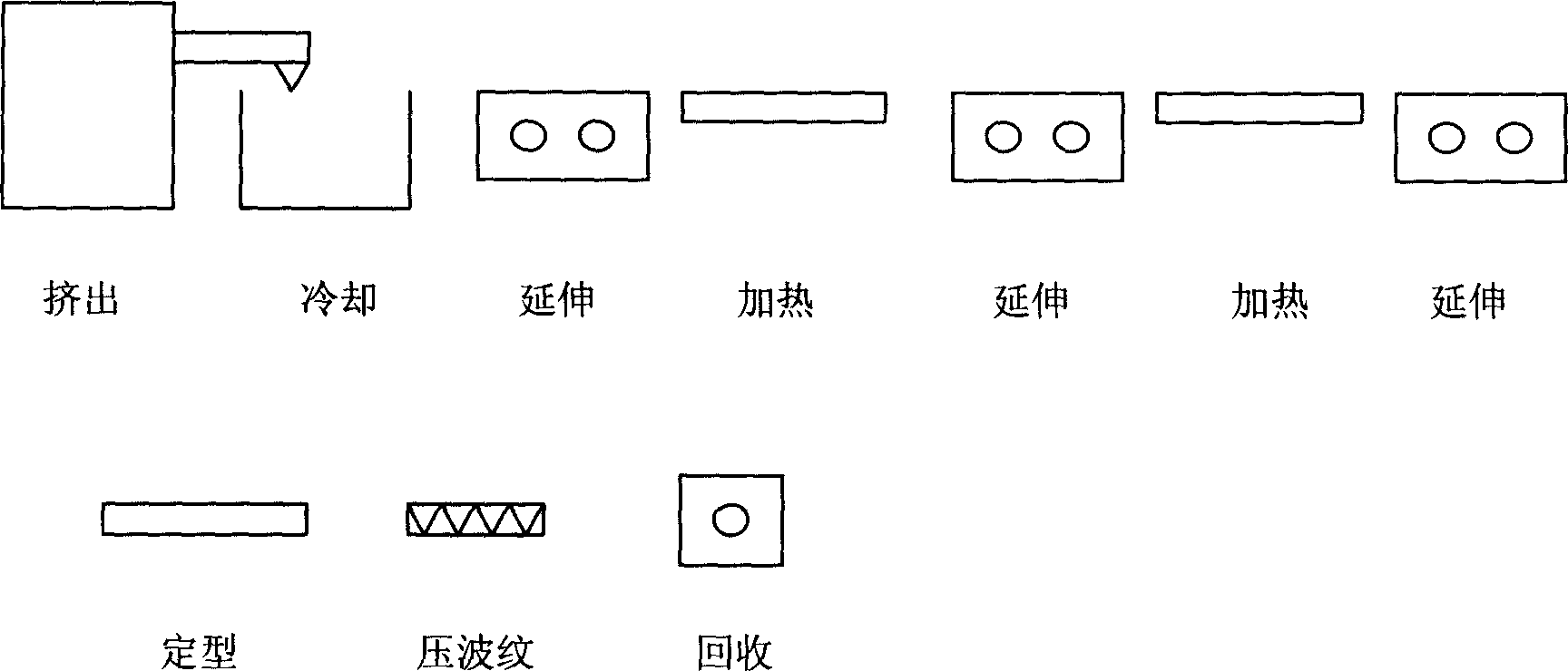

Nylon grinding moire and method for preparing same

The present invention is one kind of nylon brush product and its making process, and may be used widely in cleaning, polishing and finishing workpiece surface in different surface shapes. The present invention makes wavy abrasive nylon filament with nano modified nylon as basic material and SiC or Al2O3 of 80-800 mesh grain size as abrasive material, and through soaking in coupling agent, stoving, mixing, smelting, extruding, drawing and pressing to form waves.

Owner:马剑波

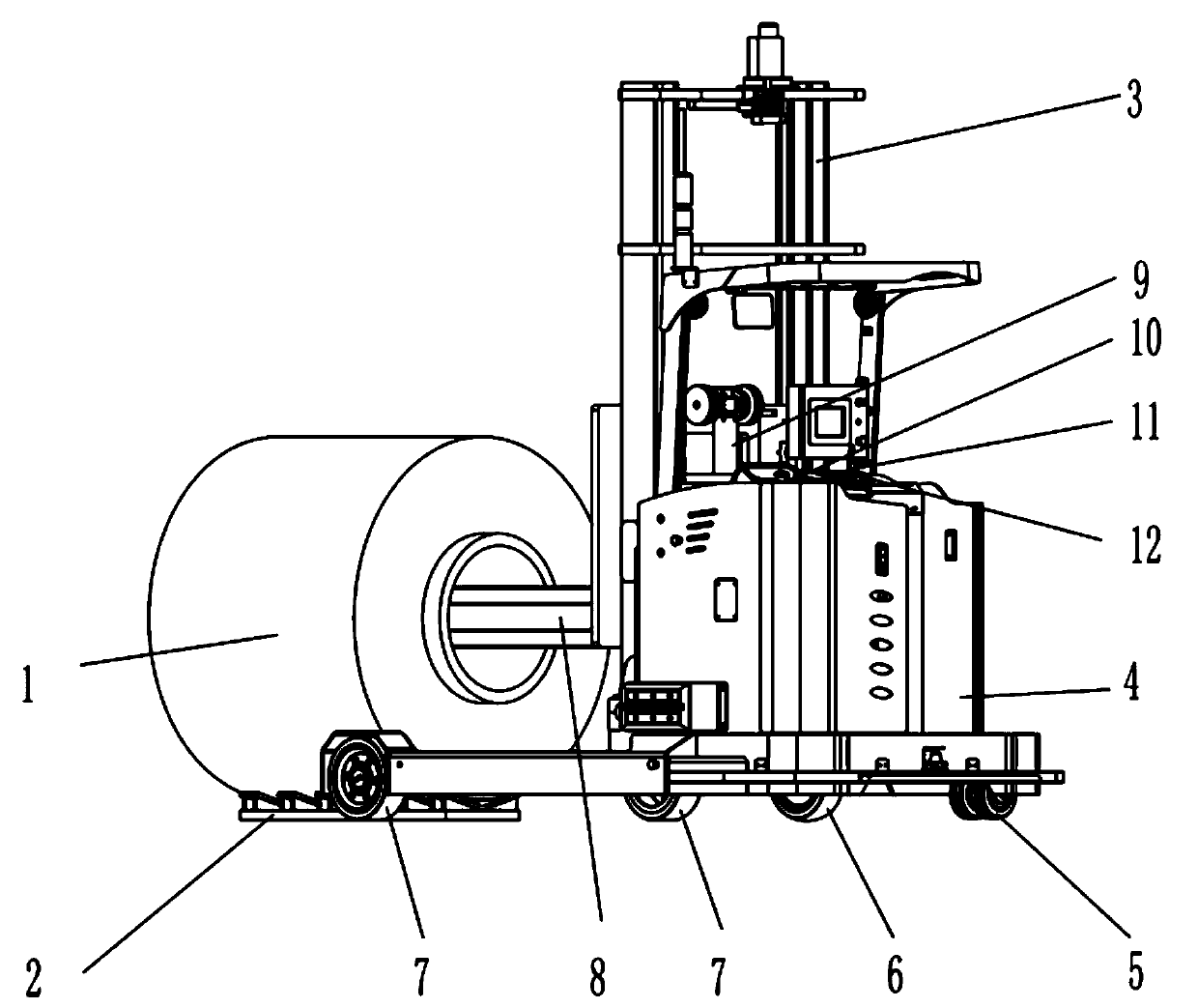

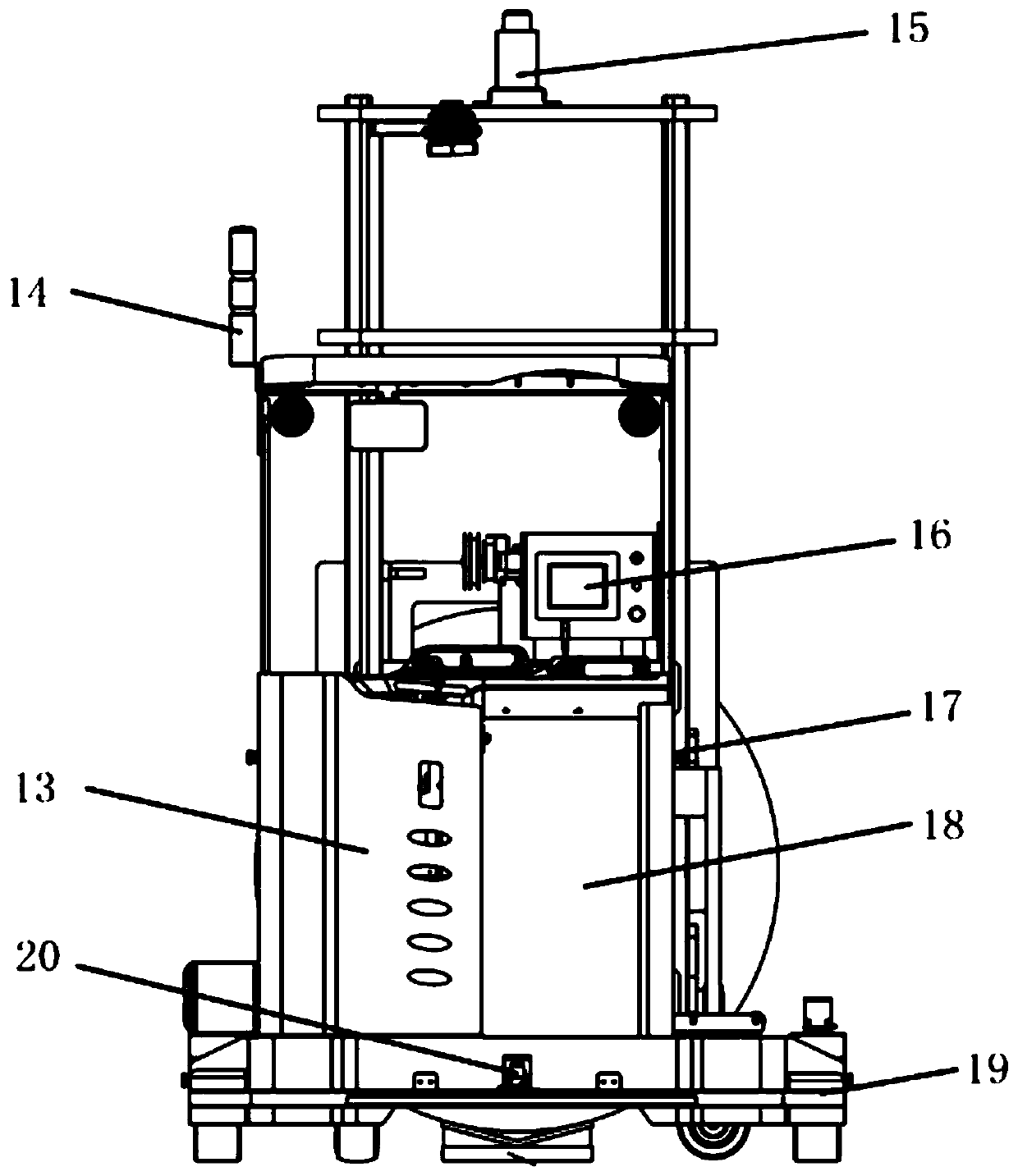

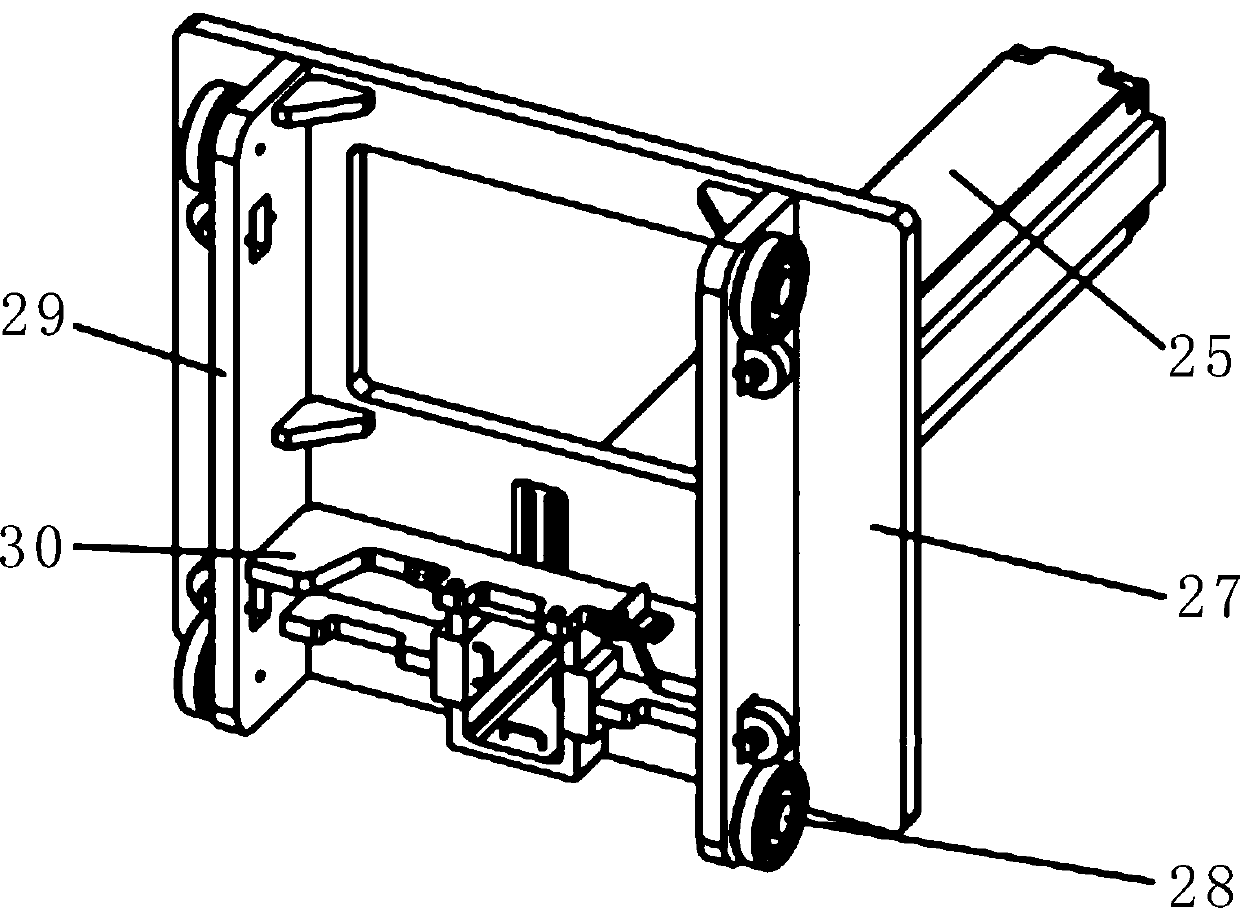

Heavy AGV suitable for carrying copper-aluminum coiled materials

PendingCN111268595AImprove securityLarge up and down range of motionSafety devices for lifting equipmentsIn vehicleElectric machinery

The invention relates to the technical field of nonferrous metals, in particular to a heavy AGV suitable for carrying copper-aluminum coiled materials. The heavy AGV comprises a vehicle body and a compartment, wherein a storage battery, a vehicle-mounted controller and a driving motor which are electrically connected are arranged in the compartment; the driving motor is used for driving the vehicle body to walk and turn; the heavy AGV also comprises an operation unit, a laser guidance unit and a sensor which are electrically connected with the vehicle-mounted controller; the vehicle body comprises a portal frame and a lifting mechanism; the lifting mechanism is movably connected with the portal frame and comprises a fork arm, a front plate and a chain hanging plate; the front plate is in sliding connection with a U-shaped groove rail arranged on the opposite side of the portal frame; the fork arm is arranged on the center line of the front side surface of the front plate; and the chainhanging plate is arranged on the rear side surface of the front plate. According to the heavy AGV suitable for carrying the copper-aluminum coiled materials, the chain hanging plate can move up and down relative to the portal frame under the action of a lifting system, the chain hanging plate moves to drive the fork arm to move up and down relative to the portal frame, the single fork arm conveniently carries the coiled goods, the lifting space of the lifting structure is large, and the manual operation mode and the automatic operation mode are freely switched, so that the coiled goods are carried efficiently and conveniently.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Automobile instrument board leather hot-pressing composite technology

InactiveCN105774186ASimple and fast operationEasy to implementLaminationLamination apparatusEngineeringCompositing

The invention discloses an automobile instrument board leather hot-pressing composite technology. The technology comprises the following steps of 1, skeleton glue spraying; 2, foam attaching; 3, skeleton glue spraying after foam attaching; 4, leather attaching; 5, prepositioning; 6, hot-pressing compositing; 7, edge covering. The automobile instrument board leather hot-pressing composite technology is easy and convenient to implement and easy to achieve, the obtained automobile instrument board is flat in surface and free of bubbles and pressing marks, the product consistency is ensured, manual covering uncertainty is eliminated, the requirement for surface attractiveness and comfortableness is met, the preparation time is effectively shortened, and the production working efficiency is greatly improved, so that the purpose of batch production is achieved, and the domestic industrial gap is filled.

Owner:常熟安通林汽车饰件有限公司

Straightening process with external cold water for working rolls of straightening machine

ActiveCN103028635AQuality assuranceNo indentationShaping toolsCleaning using liquidsForeign matterWork roll

The invention relates to a straightening process with external cold water for working rolls of a straightening machine. External cold water jets are respectively mounted on the two front ends and two rear ends of the hot straightening machine, and adopt laminar flow side jet nozzles, the jet state is radial, and front external cold water and rear external cold water are used for washing off oxide produced by the secondary oxidation of an unstraightened steel plate; or external cold water jets are mounted on the operating side of the hot straightening machine, and adopt laminar flow side jet nozzles, the jet state is radial, and the external cold water of the operating side is used for washing off foreign matters on the straightening rolls; or external cold water jets are mounted on the two front ends, two rear ends and operating side of the hot straightening machine, and adopt laminar flow side jet nozzles, and the jet state is radial. The surface of the straightened steel plate is bright and clean, and does not have impressions, meanwhile, overhigh temperature as the result of the long-time contact between the straightening rolls and the steel plate, which can cause the hardness decrease and consequent pileup of local parts of the roll surface leading to the roughness of the surface of the steel plate, is prevented, and thereby the surface quality of the steel plate is guaranteed.

Owner:SGIS SONGSHAN CO LTD

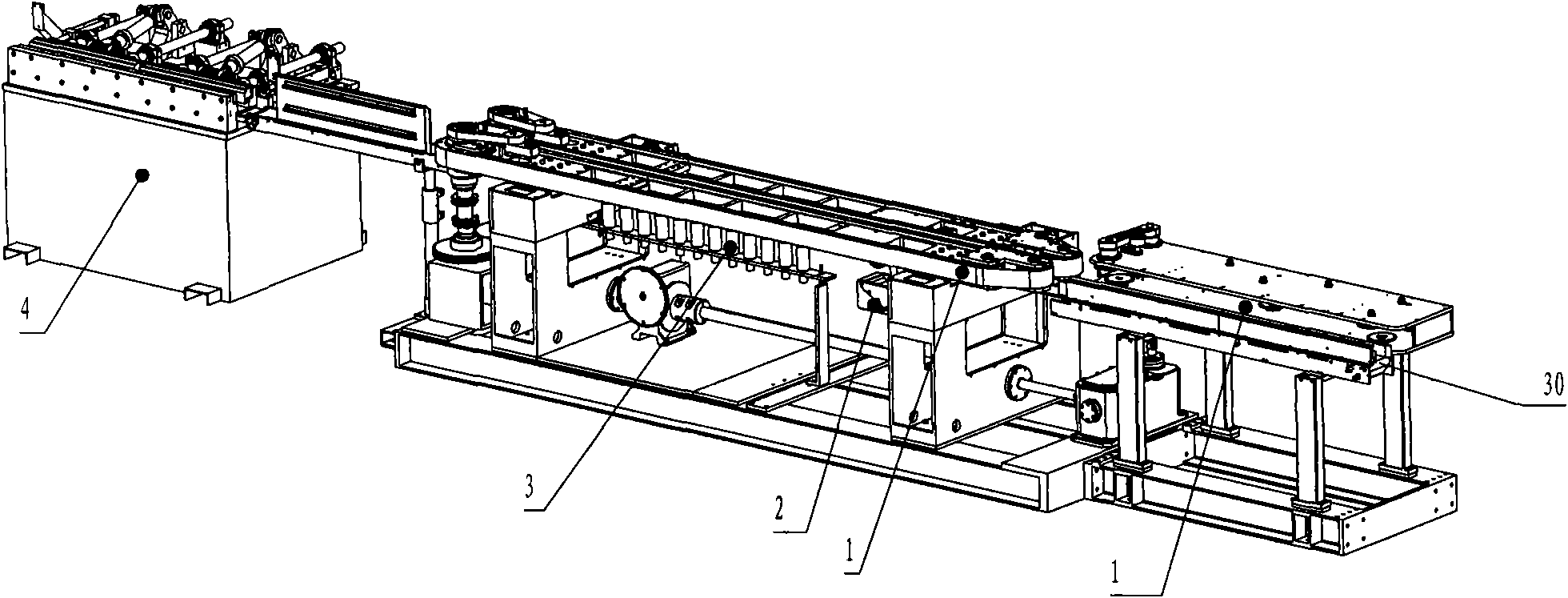

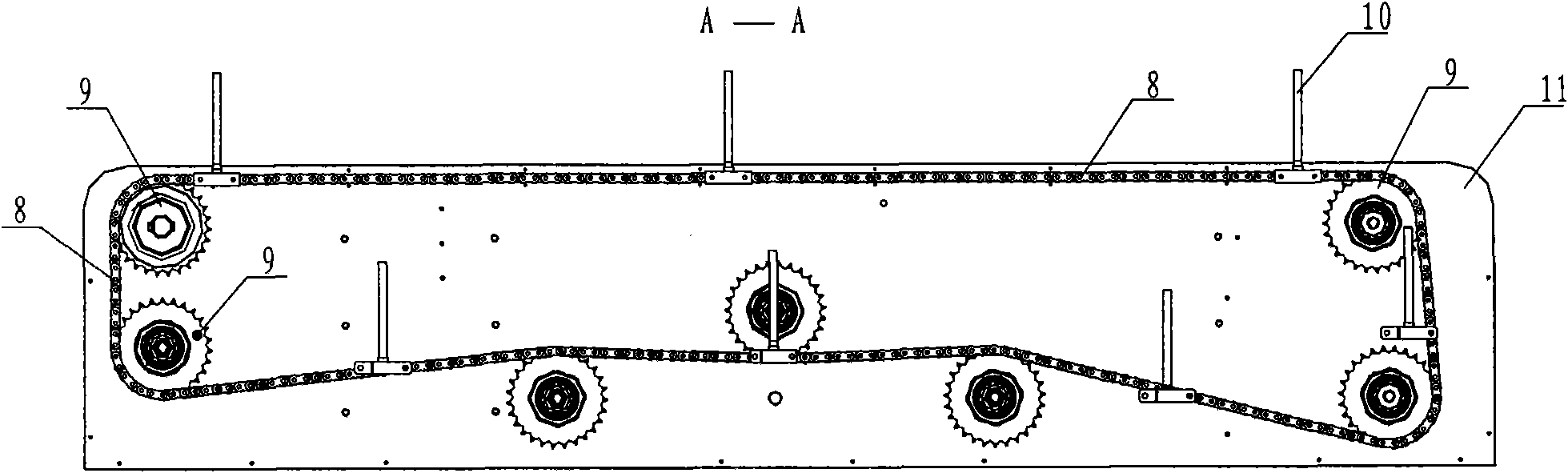

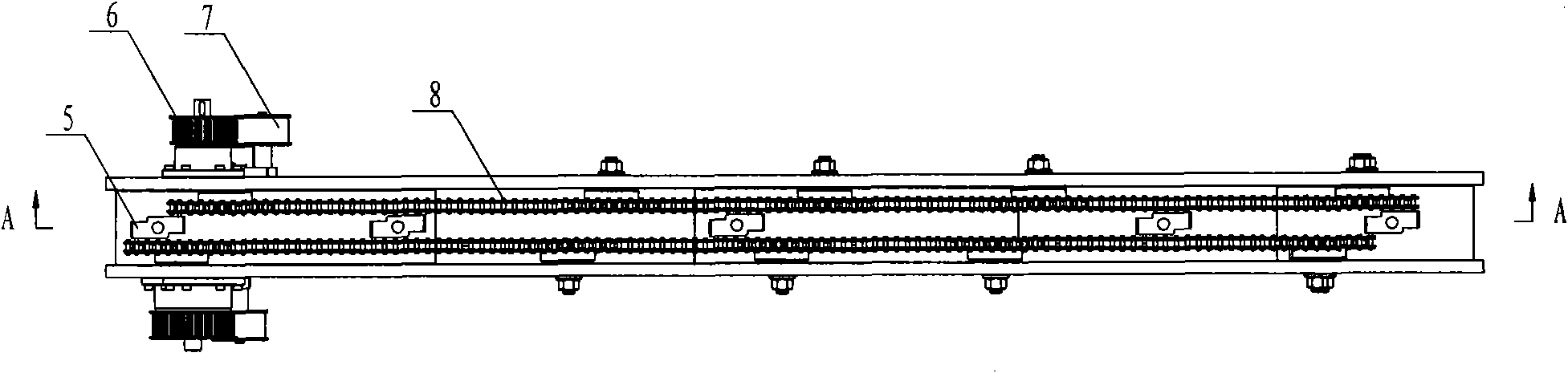

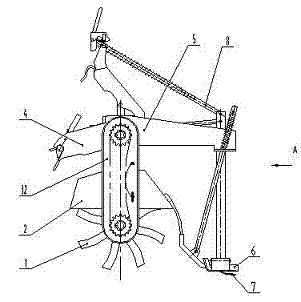

Overturning conveying structure of paper overturning machine

PendingCN110127278ANo indentationIndentationConveyorsOverturning articlesPulp and paper industryDrive motor

The invention discloses an overturning conveying structure of a paper overturning machine. The overturning conveying structure comprises a frame, conveyor belts, tensioning structures, at least one driving motor and a swinging mechanism. The frame comprises two oppositely-arranged mounting plates and rotating shafts with the two ends rotatably connected to the two mounting plates; the conveyor belts comprise a first conveyor belt and a second conveyor belt which are arranged on the outer sides of the rotating shafts on the upper row and the lower row correspondingly; the tensioning structuresare used for tensioning the conveyor belts; the driving motors drive the rotating shafts to drive the conveyor belts to rotate; the swinging mechanism comprises a shutter and a swinging structure, theshutter is fixed to the swinging end of the swinging structure, the shutter has a first extreme position and a second extreme position in the swing process, at the first extreme position, the shuttercan completely stop paper conveyed between the two conveyor belts, and at the second extreme position, the shutter cannot stop the paper conveyed between the two conveyor belts. The paper overturningcage can be used for overturning of the pasting paper and can be used for conveying of the pasting paper, and indentation of the pasting paper is avoided.

Owner:ANHUI INNOVO BEICHEN MACHINERY MFG CO LTD

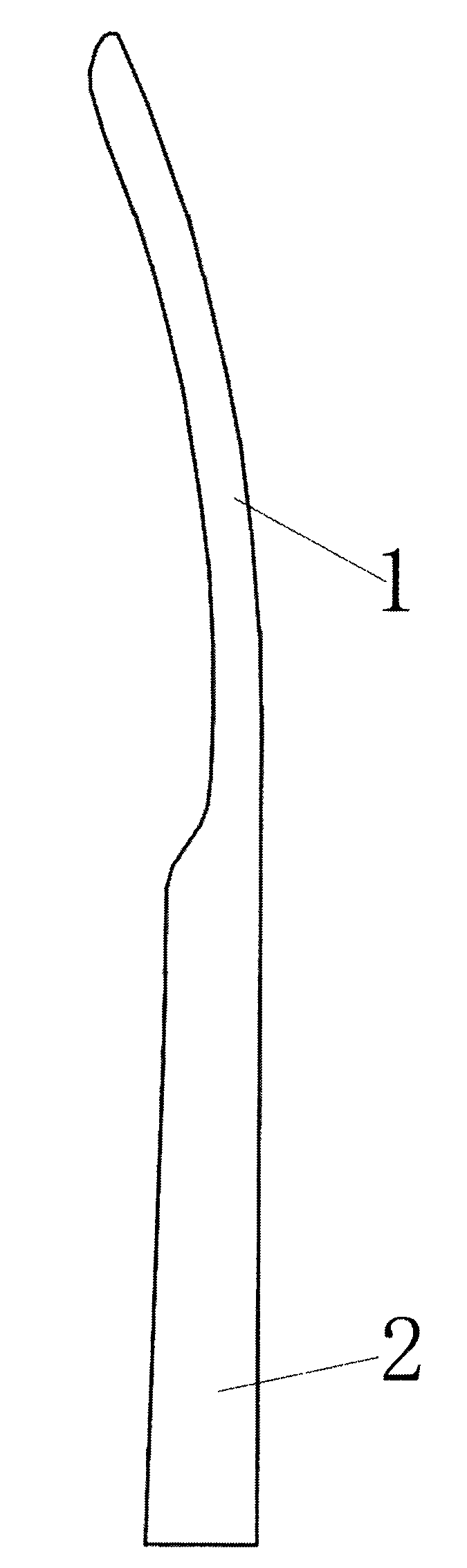

Spectacles leg manufacturing method

The present invention relates to the technical field of spectacles manufacturing, particularly to a manufacturing method for a spectacles leg with a characteristic of comfortable wearing, wherein the spectacles leg body is divided into a bending portion and a supporting portion, the bending portion and the supporting portion are subjected to integrated pressing molding, the internal of the spectacles leg body is the 2 / 3 silica gel layer, the external of the spectacles leg body is the 1 / 3 nylon rubber layer, and the silica gel layer and the nylon rubber layer are compounded into the integration, and are subjected to 200 DEG adhesion with an environmental protection glue, pressing, and polishing molding. The spectacles leg has the characteristic of beautiful and comfortable wearing.

Owner:ZHANGJIAGANG DANDAN GLASSES

Primary molding tool of omega-shaped elastic strips in automatic production

The invention discloses a primary molding tool of omega-shaped elastic strips in automatic production. The primary molding tool comprises an upper template and a lower template; an upper mold base and a material return base are arranged on the upper template; an upper mold roller is arranged on the upper mold base; a material return guide sleeve is arranged in the material return base; a pressure spring is arranged in the material return guide sleeve; a material return block is connected to the material return guide sleeve through an internal hexagonal bolt; a short lower mold and a middle bearing lower mold are arranged on the lower template; and a lower mold roller and a lower mold cushion block are arranged on the short lower mold. Compared with the prior art, the primary molding tool has the following beneficial effects: a material return mechanism is added on the molding tool, so that compressed workpieces are stably fixed on a lower mold, and workpiece stabilization positions are guaranteed. The lower mold cushion block is inlaid with R groove hard alloy, so that the service life is prolonged, and meanwhile, the workpiece cannot have indentations when the radius R of the molded workpiece is guaranteed.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

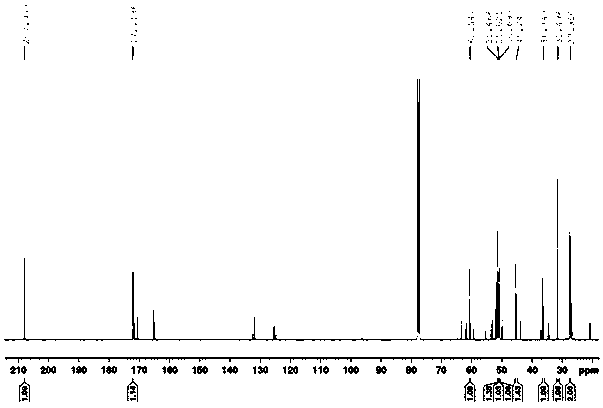

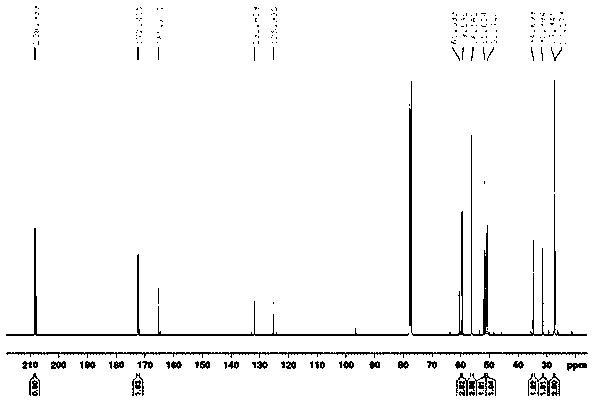

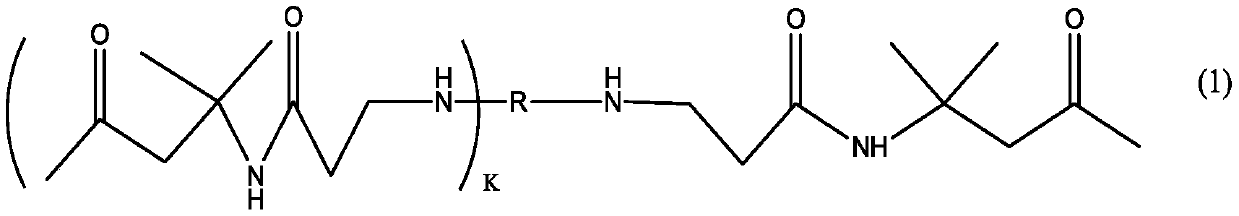

Self-crosslinking polyurethane-polyurea aqueous dispersion and preparation method and application thereof

PendingCN110294830AImproves toughness and chemical resistanceImprove water repellencyPolyurea/polyurethane coatingsHardnessHigh humidity

The invention provides a preparation method of a ketocarbonyl-containing chain extender for polyurethane-polyurea and a polyurethane-polyurea aqueous dispersion using the chain extender. The chain extender contains secondary amine active hydrogen connecting an amide group. The polyurethane polyurea aqueous dispersion adopting the ketocarbonyl-containing chain extender can be used in the fields ofwood coatings, industrial paints and the like, and a paint film of the polyurethane polyurea aqueous dispersion also has excellent indentation resistance, excellent chemical resistance and higher hardness under high humidity conditions.

Owner:WANHUA CHEM GUANGDONG

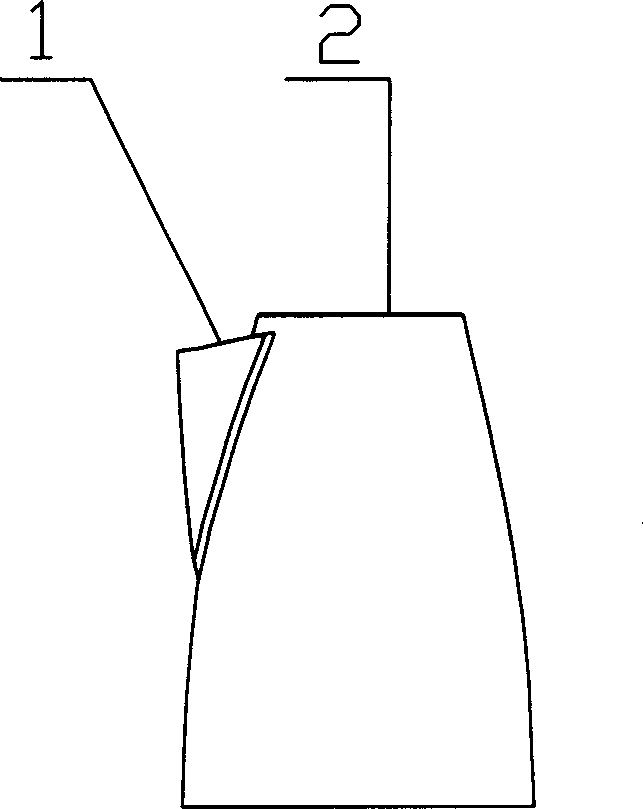

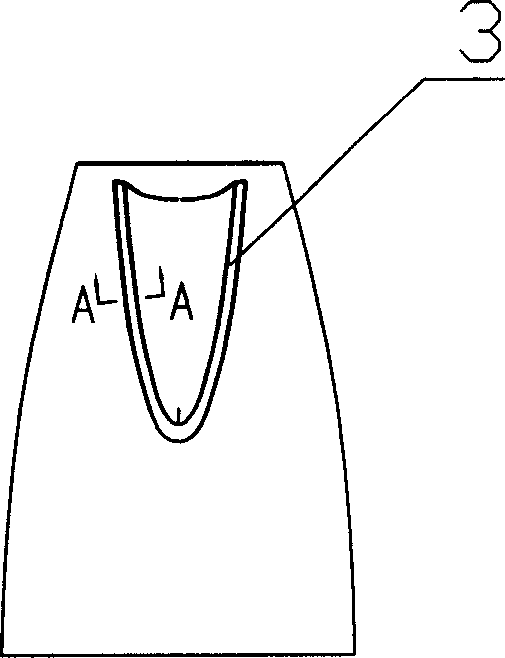

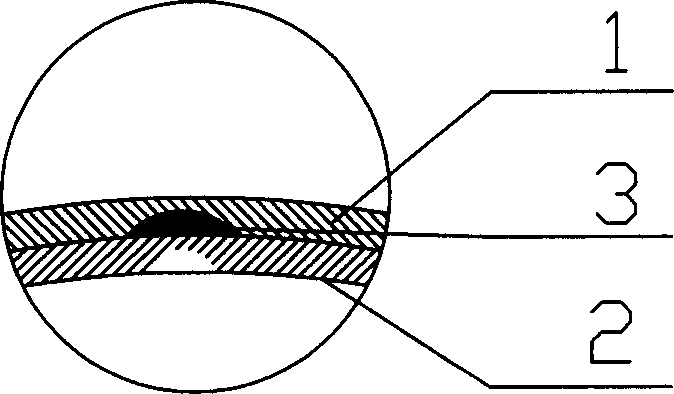

Disposable condenser discharge projection welding process for nozzle and body of stainless steel kettle

ActiveCN1762634AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesCurve shapeEngineering

The invention relates to a welding technology of mental pot spout and pot body in the field of welding. It is characterized in that it first integer punches the stainless steel welding side and processes the upper and lower electrode rod which is totally anatomists with the pot body, pot spout welding side by the punched pot body, pot spout curved shape.

Owner:HERON INTELLIGENT EQUIP CO LTD

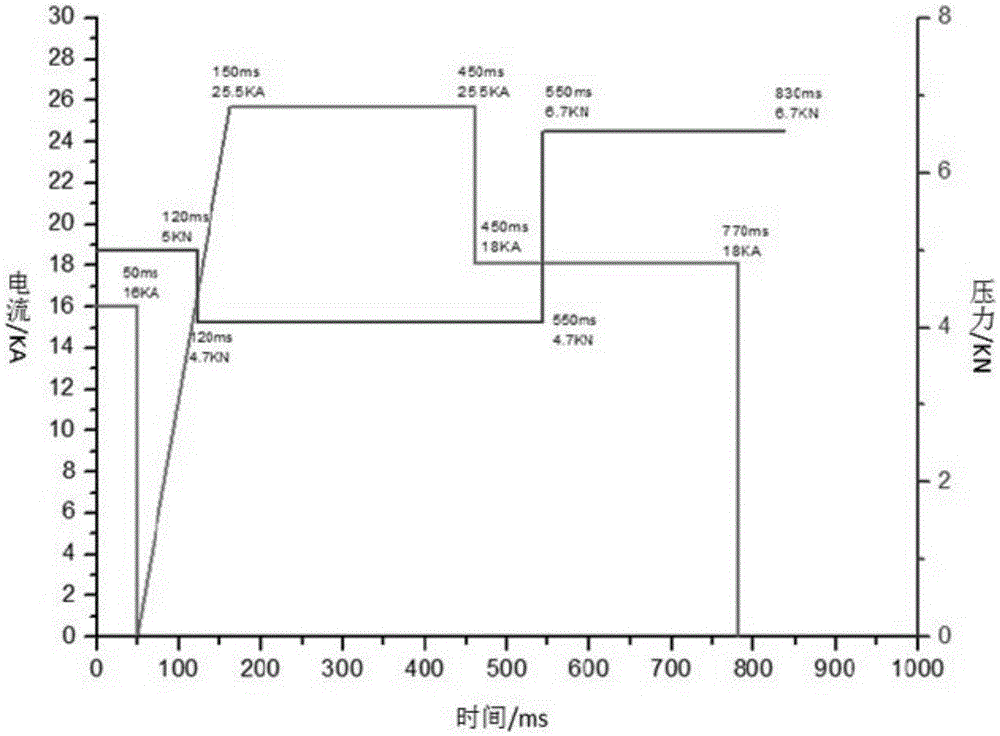

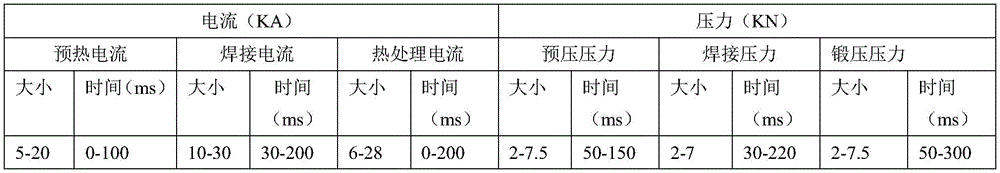

Spot welding technological method for aluminum alloy workpiece

ActiveCN105643077AReduce offsetNo indentationWelding/soldering/cutting articlesResistance welding apparatusHardnessSpot welding

The invention discloses a spot welding technological method for an aluminum alloy workpiece. The spot welding technological method comprises the following steps: pretreating the aluminum alloy workpiece to be subjected to spot welding; welding the pretreated aluminum alloy workpiece under the current of 15.2 KA and the pressure of 5.0 KN for 120 ms; then adjusting the welding current to 25.5 KA and the welding pressure to 4.2 KN, and welding the workpiece under the current and the pressure for 430 ms; further adjusting the welding current to 18 KA and the pressure to 6.7 KN, and welding the workpiece under the current and the pressure for 280 ms; naturally cooling the welded workpiece in air. According to the method disclosed by the invention, no splashing is generated in the welding process, and the diameter of a welded nugget can be greater than or equal to 6 mm, and the shear strength of the nugget is 0 to 5.4 KN; the surface hardness of the nugget is 0 to 50 HV; no obvious indentions are formed on the surface of the welded workpiece, and the offset of the nugget is extremely small (0 micron to 1 mm).

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

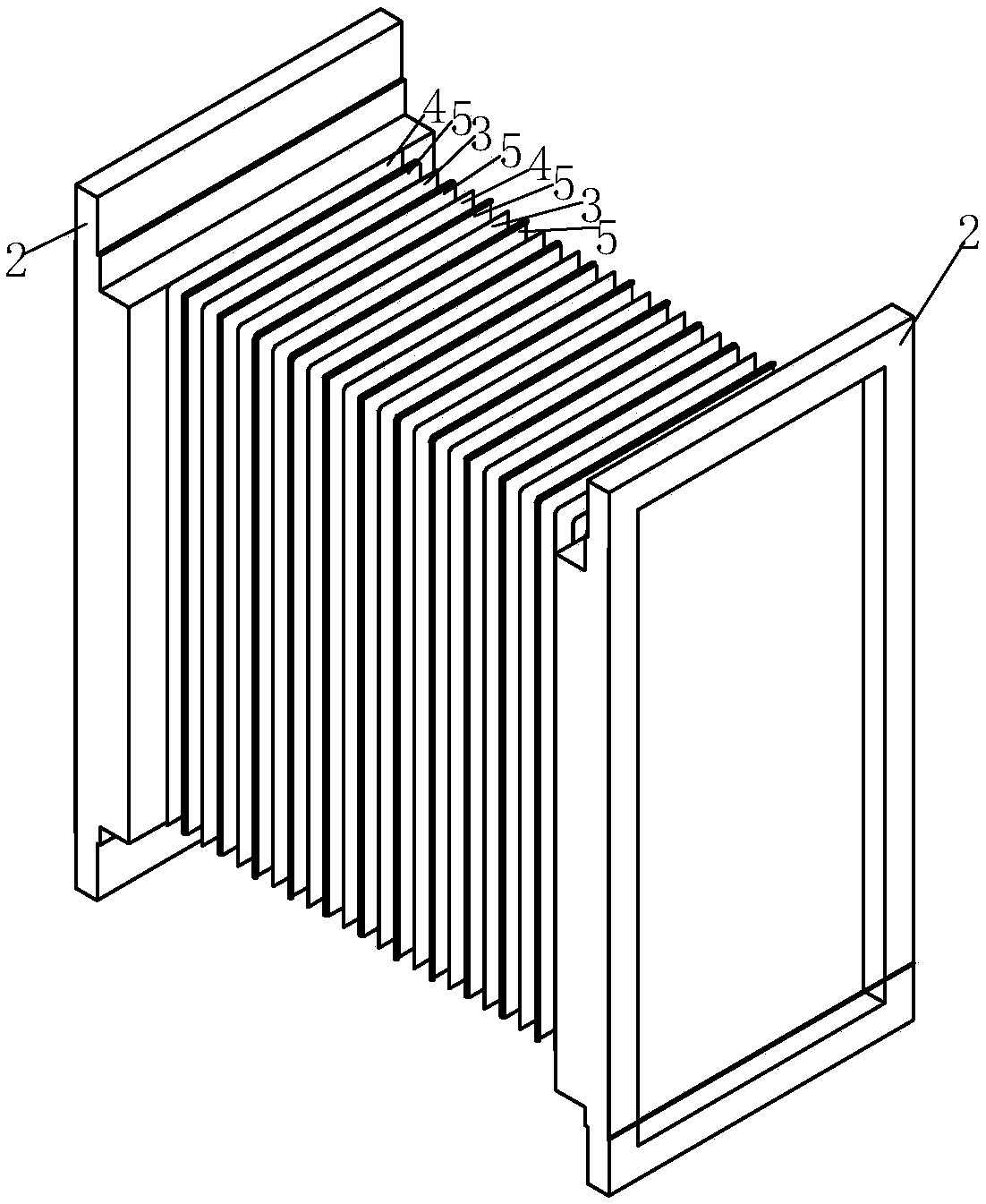

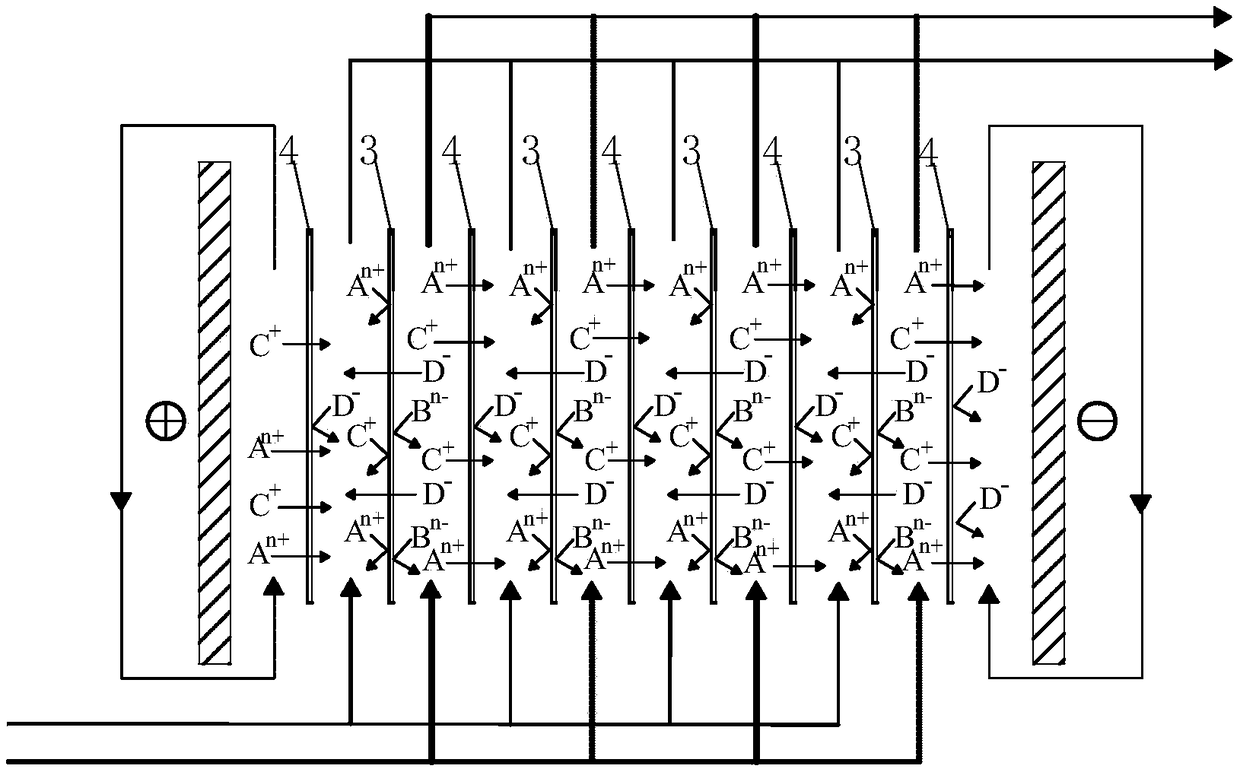

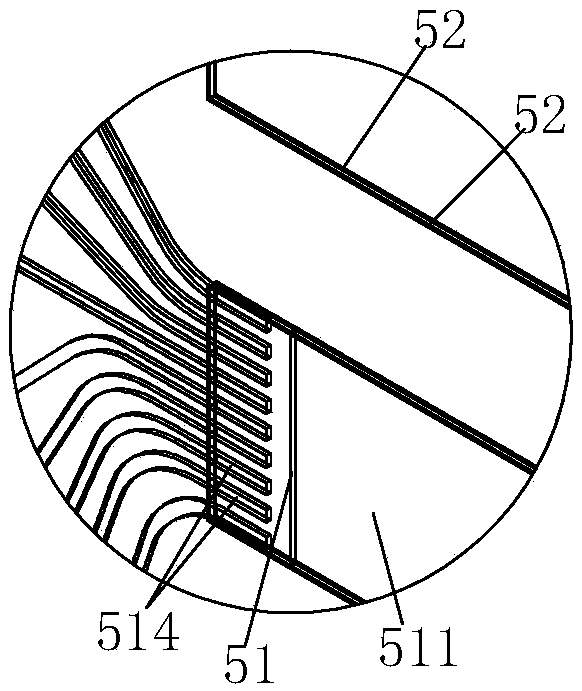

Electrodialyzer

PendingCN108911059AEasy to scaleAvoid blockingDispersed particle separationWater/sewage treatmentWater flowIon-exchange membranes

The invention discloses an electrodialyzer. The electrodialyzer comprises an anode plate, a membrane stack, a cathode plate and compaction plates for fixing and sealing the membrane stack; the membrane stack comprises monovalent selective anion exchange membranes for monovalent anions to selectively permeate, cation exchange membranes for monovalent cation and polyvalent cations to permeate, and separator plates; the quantity of the monovalent selective anion exchange membranes is n, the quantity of the cation exchange membranes is n+1, and the cation exchange membranes and the monovalent selective anion exchange membranes are alternately arranged between the compaction plates; every separator plate comprises an intermediate plate and support plates, a compartment is arranged in the middlepart of the intermediate plate, and a channel communicates every water flow hole with the corresponding communication hole; and the support plates at two sides of the intermediate plate cover the remaining part of the channel. The electrodialyzer can selectively separate and concentrate the easily-deposited polyvalent anions and polyvalent cations to prevent electrodialyzer fouling.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

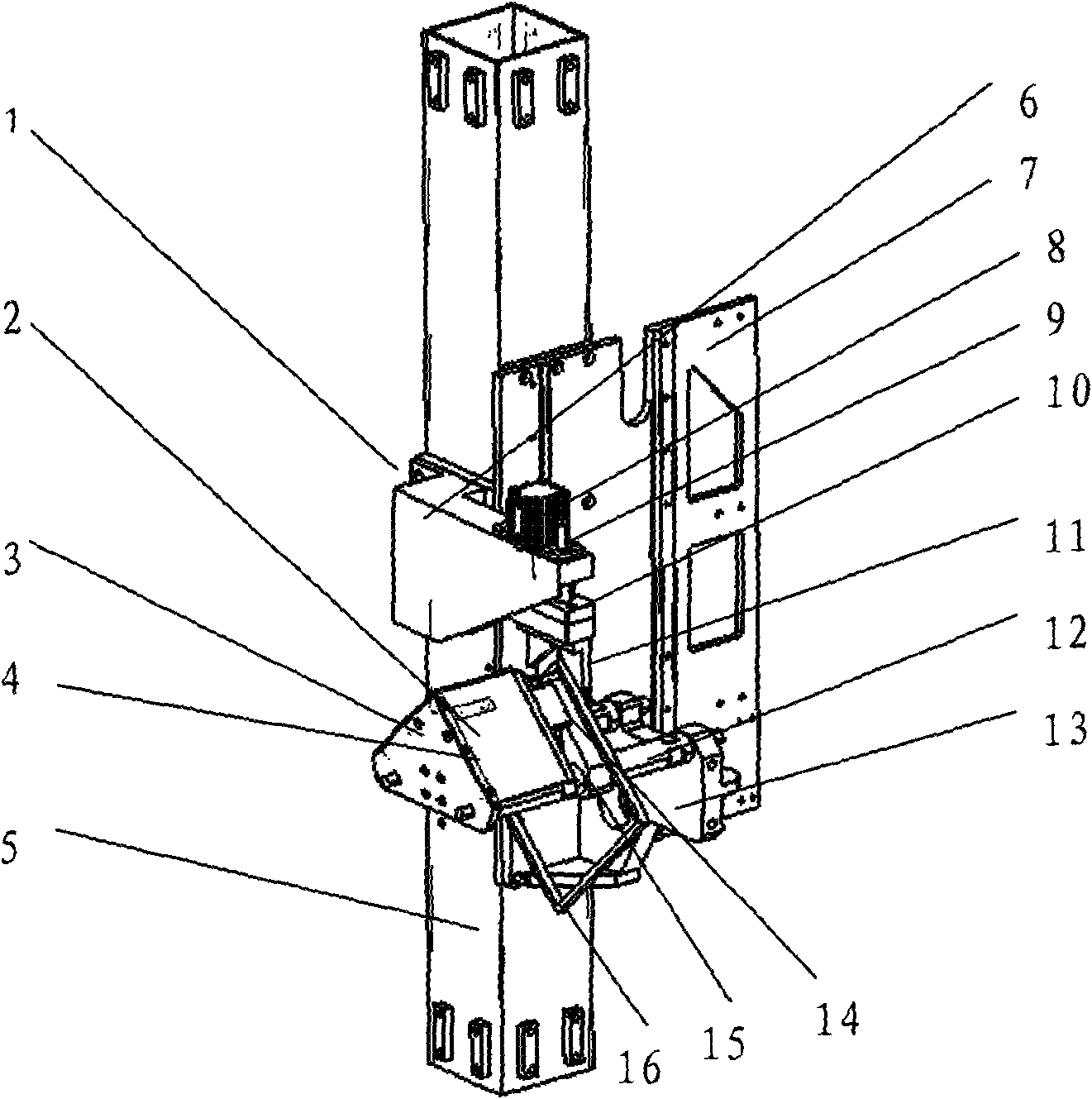

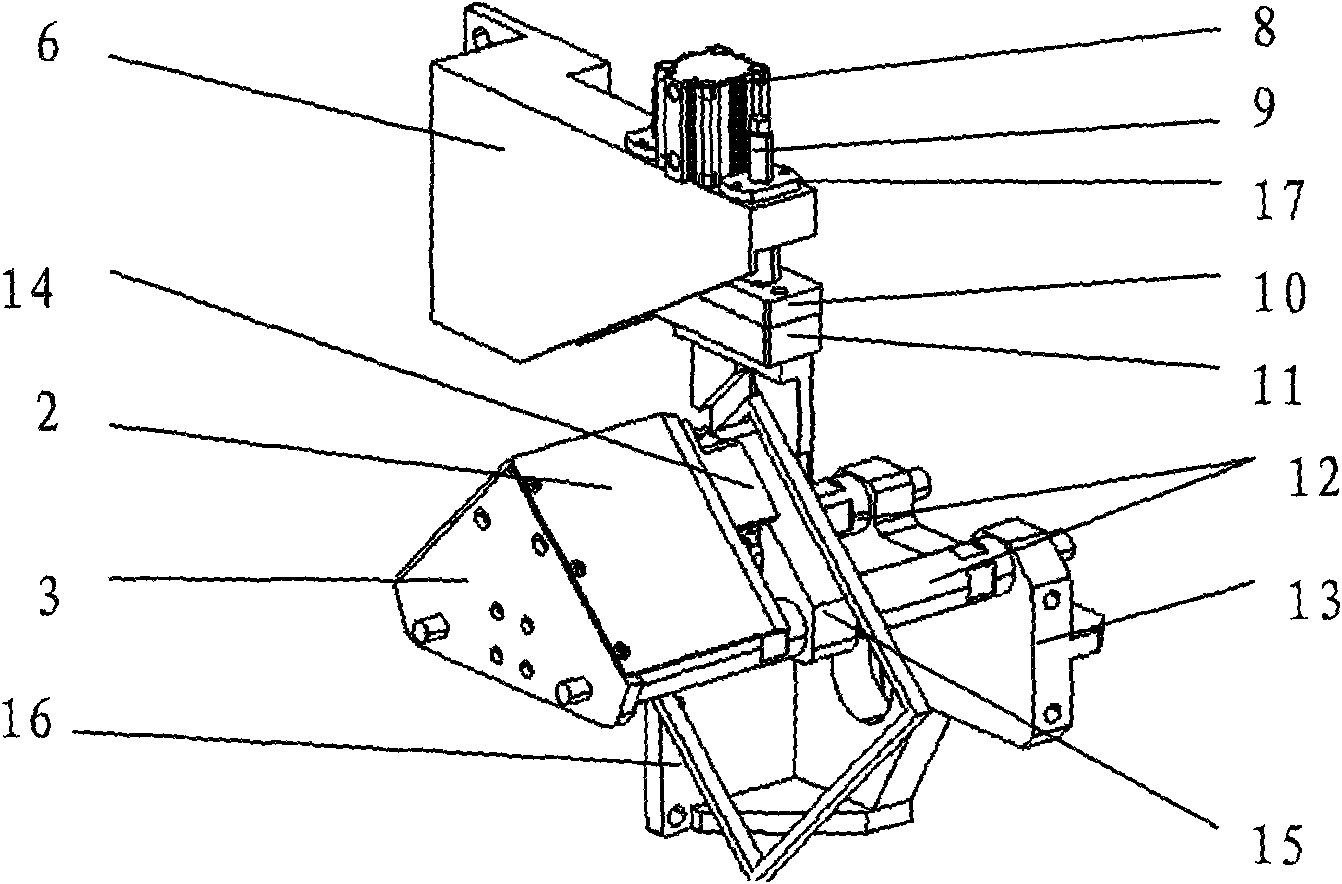

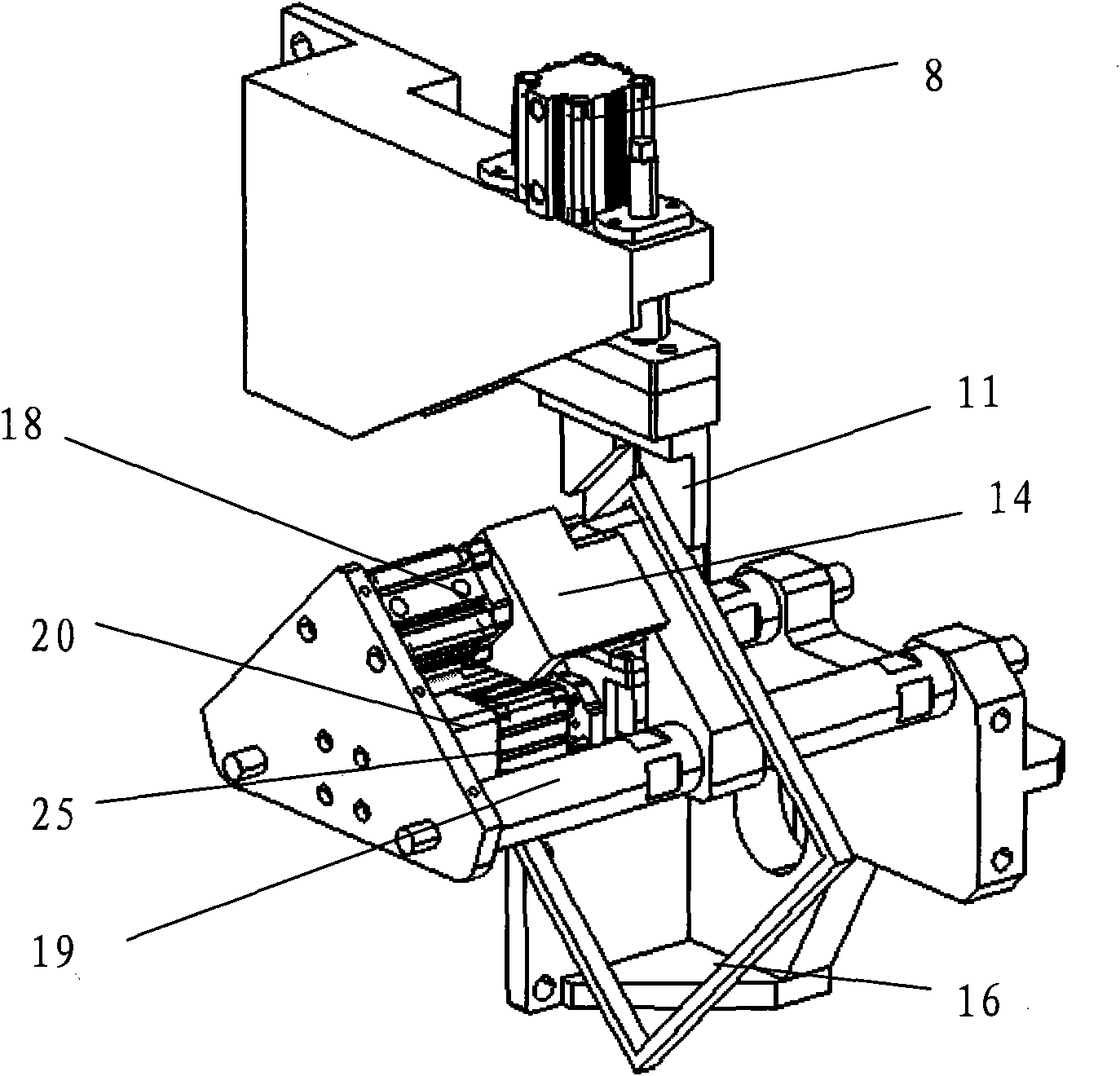

A Large-Section Expanding Diameter Wire Clamping Device

ActiveCN102832570BTroubleshoot anchor connection issuesNo deformationApparatus for overhead lines/cablesMechanical engineeringBuilding construction

The invention provides a clamping device for large-section expanded diameter conductors, and relates to the technical field of construction equipment and construction technology of transmission lines. The clamping device is particularly suitable for anchoring connection of large-section supporting-type high-density polyethylene expanded diameter conductors, sparse-coiled concentrically stranded circular aluminum conductors and the like in the tension stringing construction, and simultaneously, can be used for anchoring connection of larger-section four-layer concentrically stranded circular aluminum conductors. When the clamping device disclosed by the invention performs anchoring, the loading capacity is large and no slippage occurs, and the structures of the clamped parts of the conductors do not deform and have no indentation; the weight of the clamping device is lightened, therefore, the clamping device is convenient for working at heights; the good clamping performance provides safe and reliable guarantee for the anchoring connection of the large-section expanded diameter conductors; and the big problem that the clamping device for the expanded diameter conductors is lack in the tension stringing construction is solved.

Owner:CHINA ELECTRIC POWER RES INST +1

Sanding head straight reciprocating motion apparatus for sander

InactiveCN101407042AExpand the scope of processingMeet the requirements of economic efficiencyGrinding drivesLinear motionSander

The invention relates to a linear reciprocating device for a sanding head of a sander. A case is provided with two groups of sanding devices at intervals in front and back, the two groups of the sanding devices are provided with a sanding element capable of sanding respectively, a linkage device is arranged between the two groups of the sanding devices, the linkage device uses a shaft element to be pivoted with the center of a rocking lever to the case, one end of the rocking lever is linked with one group of the sanding devices, the other end of the rocking lever is linked with the other group of the sanding devices, and the linkage device uses a driving structure to apply a torque on the rocking lever, so that the rocking lever can do reciprocating circular motion within a limited angle by using the shaft element as a supporting point; and further the two groups of the sanding devices can do sanding work of mutually parallel and symmetrically cross reciprocating linear motion without interference.

Owner:张文奇

Compression joint type squeezing bag penetrating umbrella composite insulator core bar jacket squeezing bag sulfuration process and device

ActiveCN101577157APerformance impactImprove vulcanization qualityInsulatorsUltra high pressureComposite insulators

The invention relates to a compression joint type squeezing bag penetrating umbrella composite insulator core bar jacket squeezing bag sulfuration process which comprises: carrying out surface treatment on a core bar before use; adding squeezing bag glue to a die space and directly squeezing the core bar out of the bag glue core bar through a squeezing bag machine; fast forming the bag glue core bar in the squeezing process through a front drying tunnel, keeping the working temperature of the front drying tunnel to be 620+ / -50 DEG C, and the surface temperature of silicon glue of the core bar of the front drying tunnel to be 140+ / -20 DEG C; realizing sulfuration and semi-sulfuration to the outer layer of the surface of the bag glue core bar; and enabling the core bar to go into a rear drying tunnel to be completely sulfurized. The process is used for squeezing bag of long bars and can complete squeezing bag and sulfuration in one step, produced composite insulator has good sulfuration quality, high efficiency and no indentation. The process enhances ultraviolet resistance, hydrophobicity and age resistance of an umbrella skirt jacket, strengthens the entire external insulation life of products, solves the difficult problem of quality of traditional sulfuration production, prolongs the aging service life of the composite insulator, and ensures the quality of ultra-high pressure and extra-high pressure composite insulators.

Owner:STATE GRID CORP OF CHINA +2

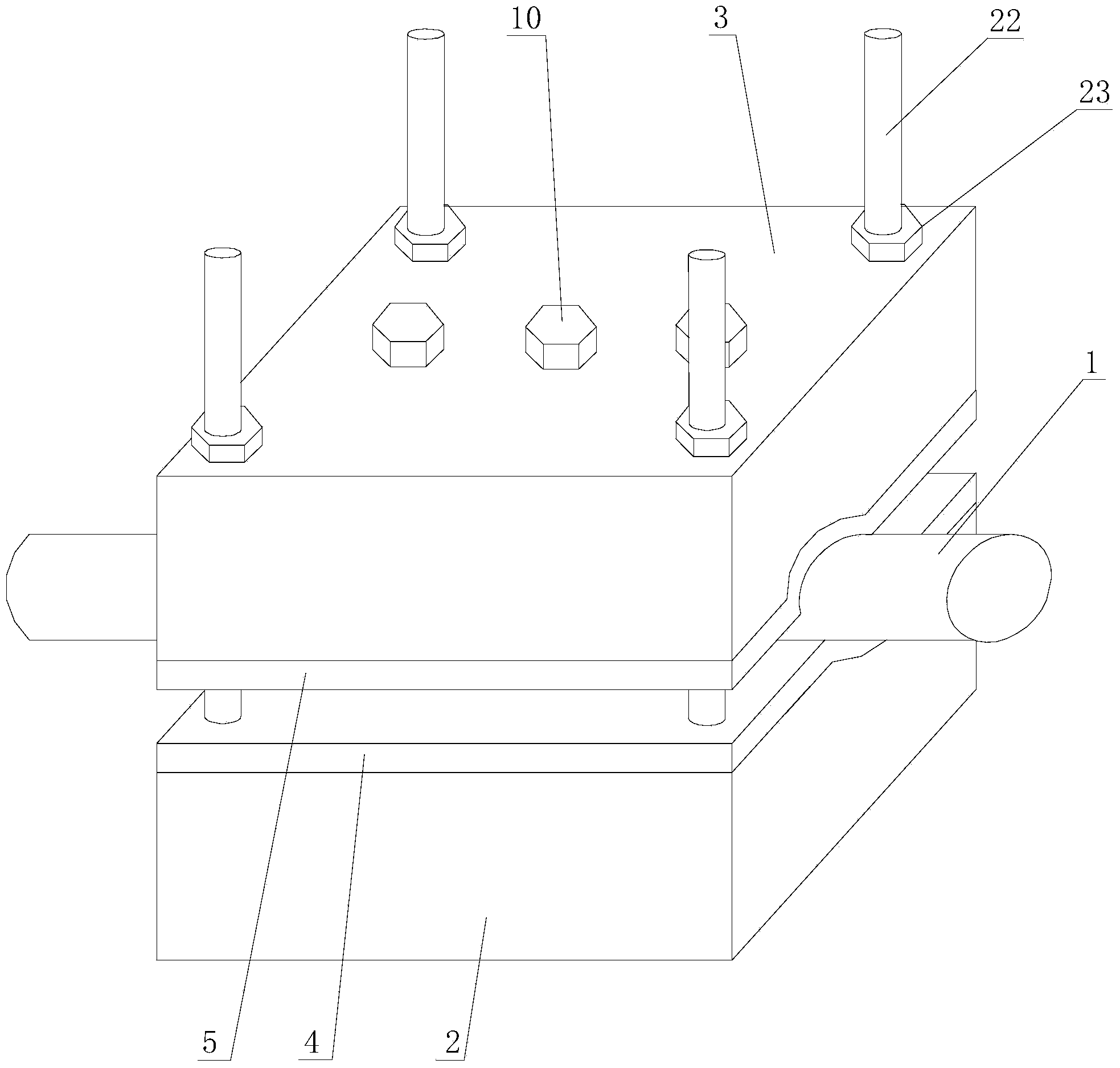

Fixing device for cylindrical silicon rod clamp

InactiveCN104227859AEasy to assemble and disassembleImprove general performanceWorking accessoriesEngineeringSilicon

The invention provides a fixing device for a cylindrical silicon rod clamp, aiming at solving the problems that indentations are easily formed on the surface of a silicon rod when a clamping claw of an existing cylindrical silicon rod clamp is used for clamping the silicon rod. The fixing device comprises four lower pressing blocks which are vertical to guiding columns of the upper surface are arranged at the four corners of the upper surface respectively; a thread is arranged at the upper part of each guiding column; the fixing device further comprises a lower module, an upper module, an upper pressing block and four pressing nuts; the lower module, the upper module and the upper pressing block sleeve the four guiding columns in sequence from top to bottom; the four pressing nuts are arranged on the four guiding columns respectively; upper arc-shaped grooves matched with the silicon rod are formed in the lower surface of the upper module; a lower arc-shaped groove matched with the silicon rod is formed in the upper surface of the lower module. According to the fixing device, the upper pressing block, the lower pressing blocks, the upper module and the lower module are arranged and are convenient to detach; cylinders with different diameters can be fixed through replacing the upper module and the lower module which have the different sizes and the commonality is strong; the indentations are not formed when the upper arc-shaped grooves of the upper module and the lower arc-shaped groove of the lower module are used for clamping the silicon rod.

Owner:ZHEJIANG HUIHONG SOLAR ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com